Winpower POWR-PAK Instruction Manual

Generating Quality

Since

7925

POWR-PAK"

/

EGSA

ELEC-

WINPOWER CORPORATION

NEWTQN,

IOWA

50208

U.S.A.

PHONE:

(515) 792-1301

/CABLE: WINPOWER / TELEX

11:

910-520-1557

Printed

in

U.S.A.

INTRODUCTION

This manual covers the safety, operating and maintenance instructions for the

WINPOWER line of air-cooled generator

sets.

Included as a part of the package

is

a parts

list

and wiring diagram covering the particular model you have pur-

chased. The engine manufacturer's manual

is

also furnished with the set and

gives the necessary operating and maintenance information for the engine.

GENERAL

The engine generator

sets

covered by this manual are of the single bearing

type. The rotating member of the generator

is

mounted on a tapered extension

of the engine crankshaft.

All

sets

have been thoroughly tested at the factory. The normal carburetor

and engine

speed,adjustments have been made.

The

set

should

be

carefully inspected on delivery for evidence of possible

shipping damage.

If damage has occurred, a notation should

be

made on the

freight bill and you should file a claim, if necessary. If the damage appears

to

be of a major nature, the

set

should not be operated until the fault has

been corrected.

The model number and the serial number of the

set

must be given when contacting

the

dealer

or the factory.

ELECTRICAL DESCRIPTION

\

The generators used

in the

WINPOWER line of air-cooled engine generator

sets

are

revolving armature type.

The

static,

or

electronic excitation system,

uses rectifiers to change part of

the output of the

AC

generator

to

DC

for excitation of the field. On

most

models using

static

excitation, this system

is

extended

still

further by using

current feedback through rectifiers in order to obtain increasing field strength

with load increase

to

give

better

voltage regulation.

ENGINE

STARTING

The engine manual should be followed in regards to operation. The engine

crankcase must be filled with an oil

recommended by the engine manufacturer.

The fuel should

be

regular grade automotive gasoline. When filling the tank,

allow for fuel expansion. Never fill tank when engine is running.

The carburetor choke should

be

adjusted as required by temperature conditions.

When starting the generator, the operator should assume a stable stance to

prevent injury in the event of engine kickback.

Pull the start rope with a

quick, smooth pull to crank the engine.

Be

sure to pull the rope completely

through until it clears the starting pulley.

After the engine starts, return

choke to its normal position.

In cold temperatures it may

be

necessary to

keep the choke in the choke position longer;

HIGH MOISTLIRE CONDITIONS

The use of electrical equipent under extremely wet conditions should

be

avoided

.

EXHAUST

Generator units must

be

operated

in

a

well ventilated area

to

provide adequate

cooling air for the engine and proper discharge

of

exhaust fumes.

STABILITY

Generator units should

be

placed on a solid level surfhce for proper engine

operation.

If there is

any

indication that the unit may shift during opera-

tion, the use of tie downs is reconawnded.

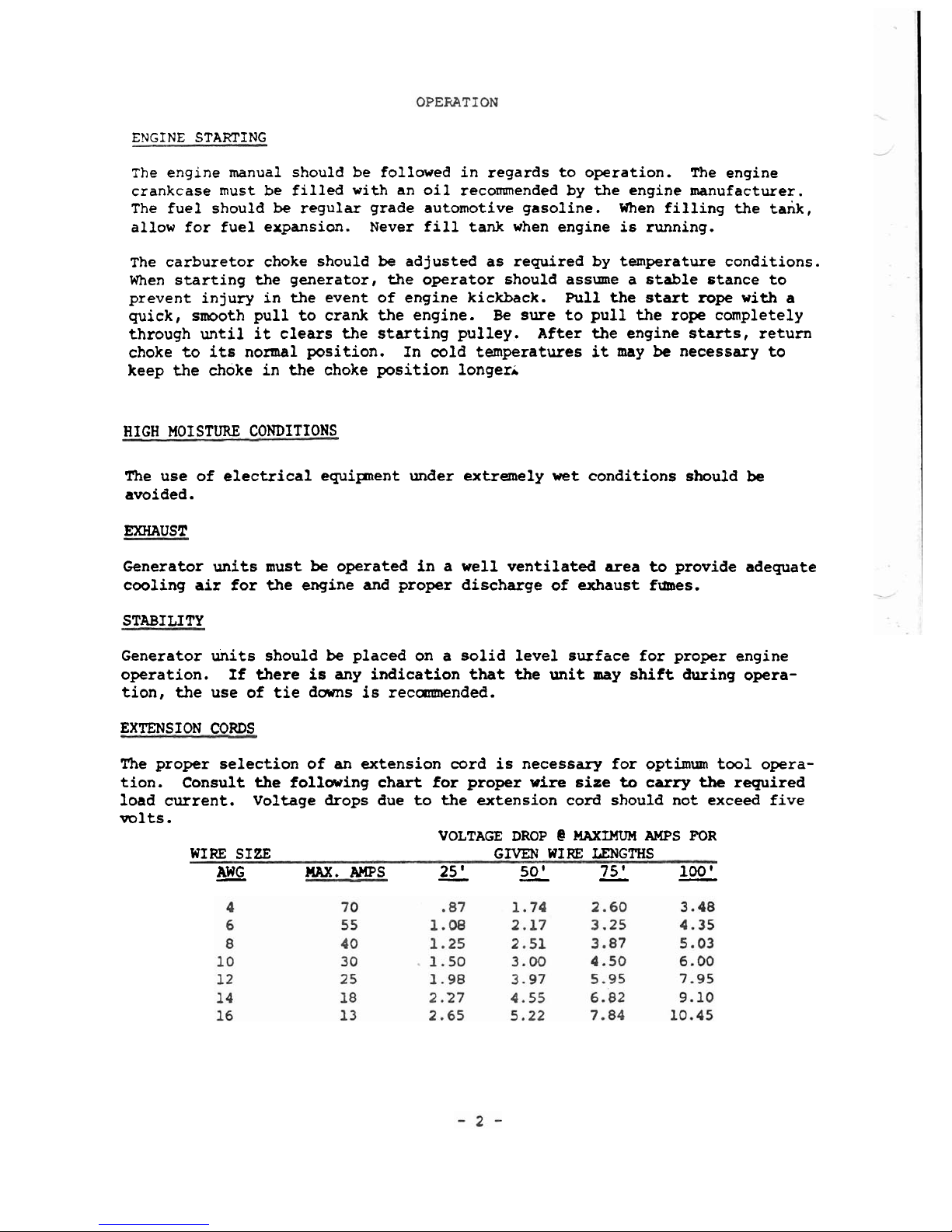

EXTENSION CORDS

The proper selection of

an

extension cord is necessary for optimum tool opera-

tion.

Consult the following chart for proper wire size to carry the required

load current. Voltage drops due to the extension cord should not exceed five

pol ts

.

VOLTAGE

DROP

@

MAXIMUM

AMPS

FOR

WIRe SIZE GIVEN WIRE

1;ENGTHS

AWG

-

MAX.

AMPS

25

'

-

50

'

-

75

'

-

100'

-

MAINTENANCE

ENGINE

Refer

to

engine manual.

GENERATOR

Check brush lengths after 500 hours of running and every 100 hours thereafter.

If brush length

is

less

than 1/2", the brush should be replaced with a new one.

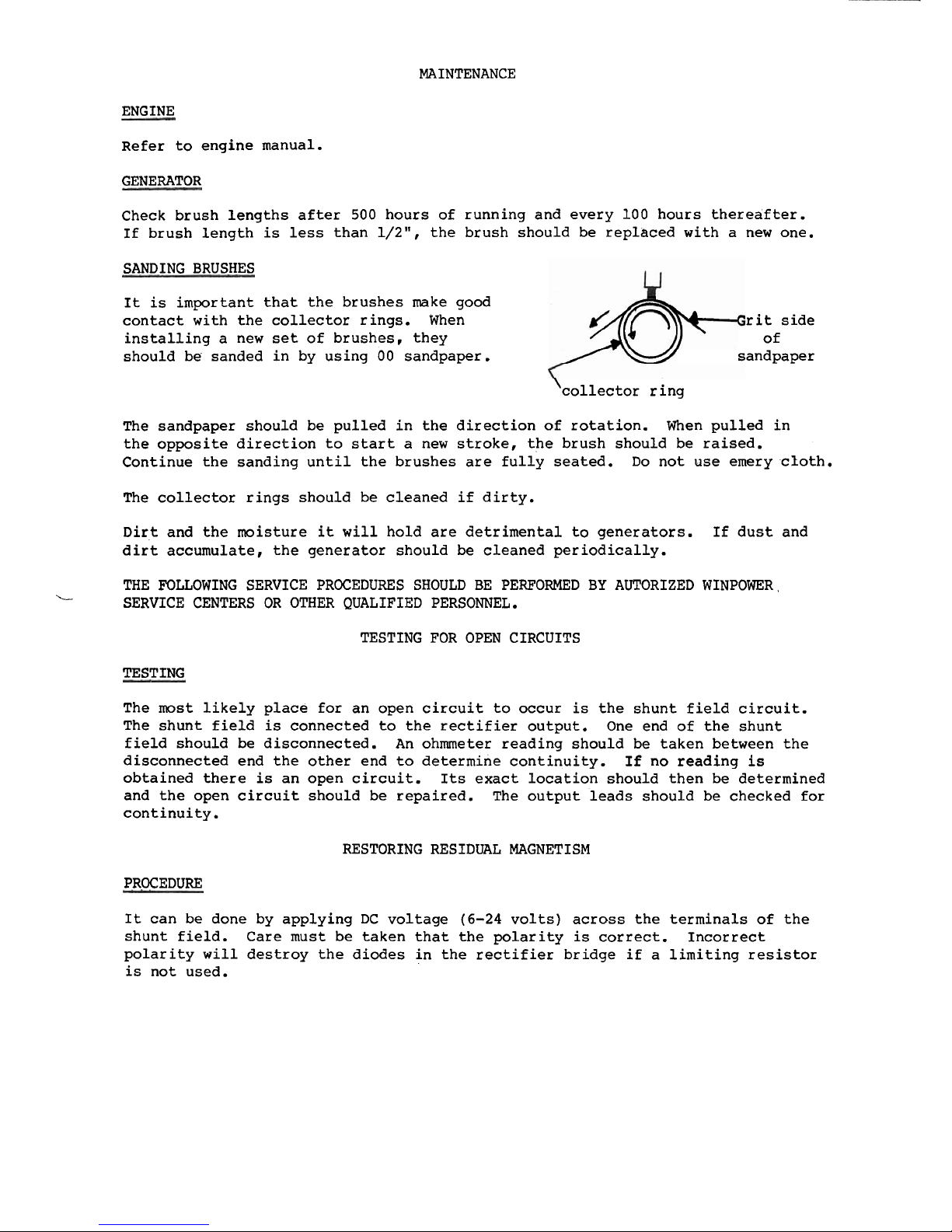

SANDING BRUSHES

It

is

important that the brushes make good

contact with the

collector

rings. When

rit

side

installing

a

new

set

of brushes, they of

should be sanded in by using 00 sandpaper. sandpaper

'collector

ring

The sandpaper should be pulled in the direction of rotation. When pulled in

the opposite direction

to

start

a new stroke, the brush should be raised.

Continue the sanding until the brushes are fully seated.

Do

not use emery -cloth.

The

collector

rings should be cleaned if dirty.

Dirt

and the moisture

it

will

hold are detrimental

to

generators. If dust and

dirt accumulate, the generator should be cleaned periodically.

THE FOLLOWING SERVICE PROCEDURES SHOULD BE PERFORMED

BY

AUTORIZED WINPOWER.

L

SERVICE CENTERS OR OTHER QUALIFIED PERSONNEL.

TESTING FOR OPEN CIRCUITS

TESTING

The most likely place for an open circuit

to

occur

is

the shunt field circuit.

The shunt field

is

connected

to

the rectifier output. One end of the shunt

field should be disconnected. An ohmmeter reading should be taken between the

disconnected end the other end

to

determine continuity.

If no reading

is

obtained there

is

an open circuit,

Its

exact location should then be determined

and the open circuit should be repaired. The output leads should be checked for

continuity.

RESTORING RESIDUAL MAGNETISM

PROCEDURE:

It

can be done by applying DC voltage

(6-24

volts)

across

the terminals of the

shunt field. Care must be taken that the polarity

is

correct. Incorrect

polarity

will

destroy the diodes in the rectifier bridge if a limiting resistor

is

not used.

Loading...

Loading...