Winpower G1536B Installation And Operation Manual

ENGINE

DIFFICULTIES

"In order to eliminate a needless waste of time to you, our customer, it is best in case

of engine trouble to contact the local dealer or distributor of that particular engine

within your area. He can often diagnose

a

problem and correct the trouble without

any difficulty. He also will have a stock of spare parts in case something has to be

replaced. All of our engines have National and International distributors or dealers.

There should be no trouble with getting our engine serviced within your area.

We

are always glad to assist you in obtaining full satisfaction from any engine assembled to a Generator of our manufacture but we know that by contacting the

local engine distributor or dealer, a more prompt correction of the engine malady

can

be achieved."

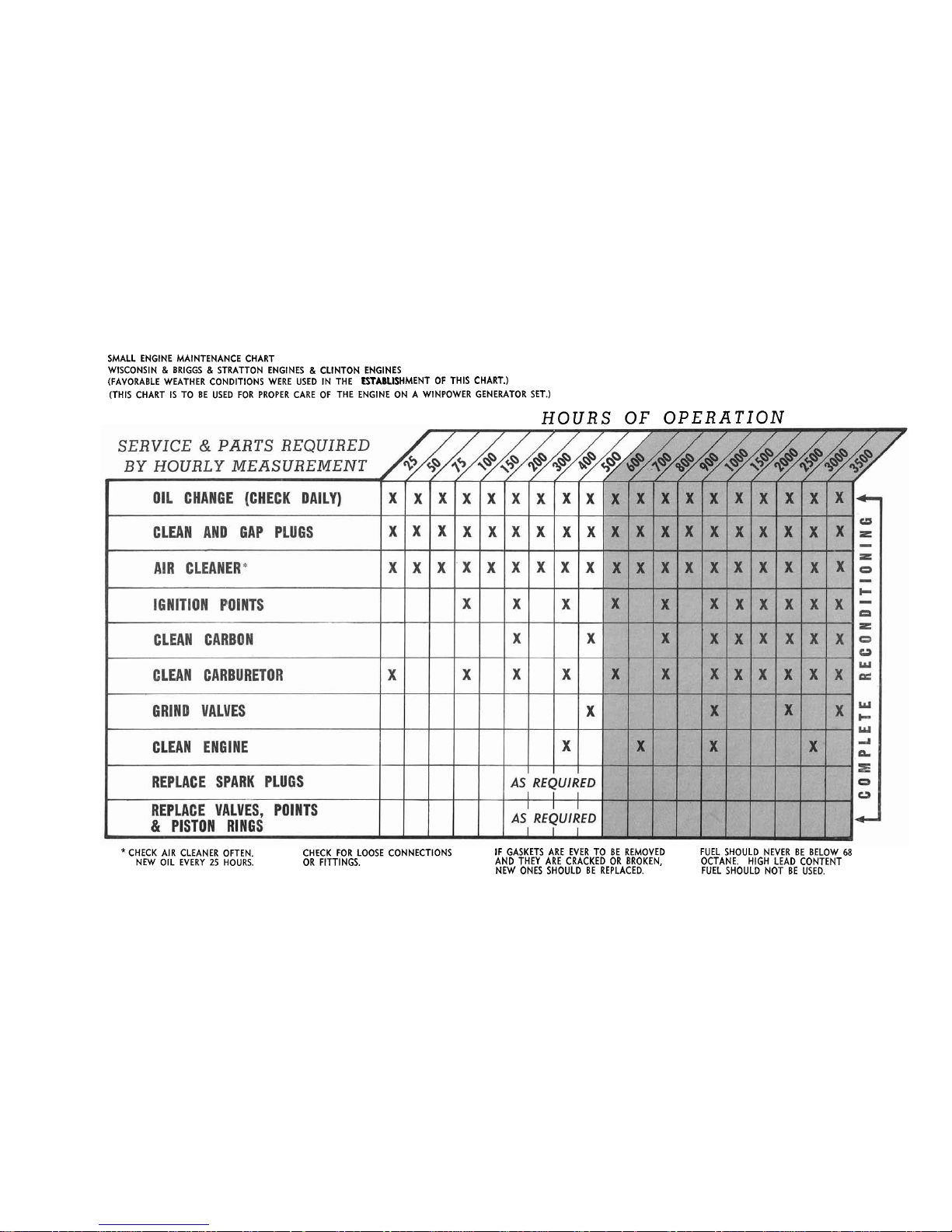

SMALL ENGINE MAINTENANCE CHART

WISCONSIN

&

BRIGGS & STRATTON ENGINES & CLINTON ENGINES

(FAVORABLE WEATHER CONDITIONS WERE USED

IN THE

ESTABLISHMENT OF THIS CHART.)

(THIS CHART

IS

TO BE USED FOR PROPER CARE OF THE ENGINE ON A WINPOWER GENERATOR SET.)

HOURS OF OPERATION

*

CHECK AIR CLEANER OFTEN.

NEW OIL EVERY

25

HOURS.

CHECK FOR LOOSE CONNECTIONS

IF GASKETS ARE EVER TO BE REMOVED FUEL SHOULD NEVER BE BELOW

68

OR FITTINGS. AND THEY ARE CRACKED OR BROKEN, OCTANE. HIGH LEAD CONTENT

NEW ONES SHOULD BE REPLACED. FUEL SHOULD NOT BE USED.

Each Generator

is

carefully inspected at the Factory and run until the brushes are

satisfactorily seated.

Then

it

is

checked for correct output under average operating

conditions.

When unpacking the machine, be sure to inspsct

it

carefully to see that no damage

occurred in transit.

If damage

is

noted, notify the transportation company ime-

diately and have them

write

the nature of the damage on the freight bill, so that

a claim can be filed

if

necessary.

If

upon installation a new Generator does not work properly,

check all of the elec-

trical connections and the Generator speed before assuming that the Generator

is

not

performing satisfactorily,

LOCATION

For best service from a ~ermanently installed unit,

it

should be installed in

a

reasonably clean and dry location.

Excessive moisture has a tendency to deterio-

rate

the electric insulation and damp surfaces always greatly increase the possi-

bility of shorts and grounds,

The surroundings should be relatively free from dirt

and dust because these or other foreign articles have a tendency to clog the venti-

lation slots, and thus cause excessive heating, This dust and dirt

is

also another

cause of rapid brush wear,

During the operation of the Generator Set, considerable heat

is

given off

by

the

engine, this thus

merits

a

good and adequate ventilation system to prevent temperature from becoming excessive. Without proper ventilation both the Engine and Generator can suffer severe damage. Under no circumstances should the temperature in

the room

be

allowed to reach 1200F.

Rxha~ist gases from Gasaline Engines are extremely poisonous!

Whenever an engine

is

installed indoors, exhaust fumes

must

be vented to the outside.

The engine should

be installed about two feet from the outside wall so the exhaust pipe

will

be

kept

short and

yet the engine

will

be a safe distance from the

wall.

Using an exhaust

pipe that

is

too small or too long

will

cause excessive back-pressure which

will

cause the engine to heat up excessively and eventlially cause serious damage to the

engine.

Pine the same

size as the exhaust hole in the engine

is

satisfactory for distances

not exceeding five feet.

For each additional ten feet use pipe

one

size larger.

Keep the number of elbows to a minimum and make sure that the

outward end of the

pipe

is

tilted slightly downward, so rain and snow do not run into the exhaust

pipe and down into the cylinders of the engine.

Where exhaust noises are to be kept to a minimum in urban areas, an underground

tank made from an old oil drum can be used successfully

if

installed above the

ground water level.

A

fifty gallon oil drum, vented above the ground and with

the bottom knocked out or pierced with holes

is

satisfactory for this purpose.

If

the exhaust pipe slants downward towards

the engine,

a

condensation trap should

be installed near the cylinder head to prevent the

water

which condenses from the

exhaust from flowing back into the cylinders

after

the engine has stopped.

This

condensation trap consists of

a

T

connection, a short piece of pipe and

a

pipe

cap.

A

petcock 3hould also

be

provided

at

the end of the cap so the

water

can

be drained

if

necessary.

The exhaust pipe should be supported so the weight

is

not applied to the engine.

In order to keep vibration of the exhaust pipe to a minimum,

a

24

inch piece of

flexible exhaust tubing should

be

installed between the engine and exhaust pipe.

Generators, which are installed to operate automatically, should preferably be

located where the temperature does not fall much below freezing.

Engines atart

and perform better

if

not subjected to excessively cold temperatures.

Batteries,

if

not fully charged

"my

also be damaged

by

low temperatures.

BASE

-

For best results from a permanently installed Generating Plant, a concrete base

should be used.

Although being mounted on concrete the Generator Set should

be

rubber shock mounted to absorb some of the vibration from the set

as

it

is

run-

ning.

Many owners, who have

small

Generator Sets use a rubber pad instead of

individual shock mounts.

This

is

a

very good application but for every day use

your rubber shock mounts are much better d-ue to the fact that dirt collects

underneath the Generator around the pad.

BA

TTE

RY

1

or 512 Volt batteries rated

at

72

ampere-hours or more

is

recommended for

starting Remote Start or

Elect,ric Start Plants of over 1500 Watts capacity.

Two

6-Volt car batteries connected in series

can

do the same job.

This can be done

by connecting the positjive terminal of one batteqr to the negative terminal of

the other. The remaining positive battery

terminal

is

joined to the positive

terminal on the side of the Generator panel and the remaining negative battery

terminal to the negative terminal on the side of the Generator also.

Speaking

of the Generator as we have above, we are referring directly to the-

ene era tor

panel.

All

connections must be clean and tight.

Check the electrolyte (fluid)

in the battery periodially to

be

sure

it

is

above the plates.

Never allow the

battery

to

remain in a discharged condition.

The charge rate on battery charging for the Generator remains constant. There

is

no worry to switch from high to low as on several other

type

Generators.

To

check the battery charger

to

find out

if

it

is

functioning,

start

the unit and

after

it

is

running smoothky, comsct, an ammeter in series to one of the battery

leads.

It

should read between 3 and 5 amps.

CAUTION:

Do not hook ammeter to

battery while cranking engine.

If

this

is

done most generally you

will

burn out

the ammeter. This

is

caused

by

the surge load in cranking.

ENGINE

FUELS

The Remote-Start Generators are equipped with fuel pumps and are designed for

use with small portable tanks or underground tanks.

Manual and Electric Start

Plants are equipped with engine mounted tanks.

The installation included in this manual shows a typical installation

of

an

Auto-

matic Stand-by Generator.

Many states and cities codes require an underground

tank

i.f

gasoline

is

to be used as fuel. In Stand-by service, the Generator may

remain idle for

a

considerable period of time.

If the gasoline has evaporated

fromthe carburetor,

it

becomes necessary to crank the engine until fuel has been

pumped up from the storage tank.

In

some locations a one quart reserve tank or

day tank may be located close to the plant to feed gasoline to the carburetor

by gravity so that

much of the prolonged cranking

is

eliminated.

GASEOUS

FDEL

Gaseous fuels can be used as a fuel for ensnes equipped with special gas-gasoline

carbu-

retion

kits

which are installed at the Factory.

These gaseous fuels may

be

natural or

manufactured gas, or a mixture

of the two, supplied to the customer through regular

gas

mains or liquified petroluem gas

(LP

or LPG) such as butane or propane - these

are

also

referred to as bottle gas since they are delivered in steel tanks under considerable

pressure.

Gaseous fuels are often preferred for permanent installations because of

convenience, safety, cost and cleaner operation.

Engines adapted for burning gaseous fuels are equipped with Model F Ensign Gas Fuel Regulators,

This regulator

is

designed to regulate the proper flow of gas over the entire

load range, from no load to full load on the Generator, and to stop the flow of gas when

the engine

is

stopped,

This

regulator

is

often referred to as the Secondary regulator

because the pressure of the gas from a storage tank or from the high pressure

gas

mains

has already been reduced by a primary regulator.

Gas reaching the secondary regulator

is

usually

at a pressure of four to

six

ounces

per

square inch, (seven to ten inches of water), When the engine

is

not running, that

is

when the pressure at the inlet to the regulator

is

highest, the pressure should not

ex-

ceed six ounces, (with greater pressure the regulator may be unable to stop the flow of

gas

)

,

When the enane Generator

is

running at

full load,

that

is

when the pressure

is

lowest,

it

should not fall below four ounces

-

less pressure may cause the engine to

be

starved for fuel. The engine

will

then lack power and be damaged internally.

Bottled gas, such as propane

is

usually stored in a liquid state in steel

tanks

under

a

pressure in excess of

70

pounds per square inch, Normally, from one-tenth to fifteen-

hundreths gallons of propane fuel

is

required per hour of operation for each horsepower

rating of the engine,

A

primary regulator must be used to reduce the pressure to about

six ounces per square inch,

Natural gas, manufactured gas or a mixture of the two

is

usually delivered at a pressure not exceeding six ounces per square inch, so that no

primary regulator

is

required.

When burning

LP

gas or natural gas having a BTU

content of

1100

or over, the Engine

Generator Plant

will

deliver

its

full rated output,

When burning mixed

gas

(natural

and manufactured) with the rating of

825

BTU,

it

will

deliver up to

80%

of

its

rated

capacity.

When burning manufactured gas of approximately

550

BTU,

it

will

produce up

to of

its

rated capacity.

Natural gas, manufactured gas and bottle gas do not usually ignite

as

readily as gaso-

line. However, since the Generators on remote starting Electric Start Generators crank

the engines at

a

high

rate of speed, no difficulty in starting

is

usually experienced

at normal temperatures.

The use of

LP

bottle gas, however

is

not recommended in freezing

temperatures,

OPERATING

ENGINES

ON

GAS

FUEL

Engines equipped with combination gas-gasoline carburetors

are properly adjusted before

they leave the Factory,

A

tag attached to the

unit

specifies whether the adjustments

were made for gasoline, propane gas

(LPG)

or natural gas.

On

this

tag also will be the

correct pressures for proper operation of

this

unit

with the new type gaseous fuels.

To operate on gasoline:

If the engine

is

equipped with a gasoline tank

it

can be used

in the regular manner,

If the engine does not have a gasolilre

tank

but

is

equipped with

Loading...

Loading...