Winpower DR20, DR600 Installation And Operation Manual

DR20 - DR600

With DGC-2020

Engine Control

DIESEL

GENERATOR

SYSTEMS

INSTALLATION AND

OPERATIONS MANUAL

DR45I4 Shown for Comparison

SAVE THESE INSTRUCTIONS

This manual contains important instructions that

should be followed during installation and maintenance

of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

USING THIS MANUAL

Congratulations on your choice of a Winpower generator set. You have selected a high-quality, precision-engineered generator set designed and tested to give you years

of satisfactory standby service.

To get the best performance from your new engine

generator set, it is important that you carefully read and

follow the operating instructions in this manual.

Should you experience a problem please follow the

“Things To Check” near the end of this manual. The

warranty listed in this manual describes what you can

expect from WINPOWER should you need service assistance in the future.

COPY YOUR MODEL AND SERIAL NUMBER HERE

No other WINPOWER generator has the same serial

number as yours. It is important that you record the number and other vital information here. If you should ever need

to contact us on this unit it will help us to respond to your

needs faster.

TABLE OF CONTENTS

INTRODUCTION i

GUIDE TO PRODUCT SAFETY 1

BASIC INFORMATION 2

Description 2

DGC-2020 Engine Control Layout 3

DGC-2020 Display Operations 5

RECEIVING THE GENERATOR 6

Unpacking the unit 6

Lifting the unit 7

ENGINE GENERATOR INSTALLATION 7

Installation 6

Engine Generator Set Mounting 8

Fuel Installation 8

Lubrication 8

Coolant 8

Battery Installation 9

Battery Charger/Block Heater Wiring 9

Mounting The Transfer Switch 10

AC ELECTRICAL CONNECTIONS 10

DC ELECTRICAL CONNECTIONS 12

INITIAL START-UP 13

EXERCISER CLOCK 14

TROUBLESHOOTING INFORMATION 14

APPENDIX DIRECTORY 15

Appendixes 16-29

12 MONTH WARRANTY 30

PROPER USE AND INSTALLATION

MODEL_____________________________________

SERIAL NUMBER____________________________

'M" Spec. __________________________________

PURCHASE DATE____________________________

DEALER____________________________________

You must be sure your new engine generator set is:

* Properly serviced before starting

* Operated in a well ventilated area

* Properly exhausted and gases safely dispersed

* Wired by a qualified electrician

* Operated only for its designed purposes

* Used only by operators who understand its operation

* Properly maintained

Page i

IMPORTANT SAFETY

2. FIRE HAZARD - Deisel fuel presents a hazard of possible

explosion and/or fire.

INSTRUCTIONS

SAVE THESE INSTRUCTION

This manual contains important instructions that

should be followed during installation and maintenance

of the generator and batteries.

Read and understand all instructions in the manual

before starting and operating the generator set.

This engine generator set has been designed and manufactured to allow safe, reliable performance. Poor maintenance,

improper or careless use can result in potential deadly hazards;

from electrical shock, exhaust gas asphyxiation, or fire. Please

read all safety instructions carefully before installation or use.

Keep these instructions handy for future reference. Take special

note and follow all warnings on the unit labels and in the manuals.

ANSI SAFETY DEFINITIONS

************************************************************

DANGER:

DANGER indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This signal word

is to be limited to the most extreme situations.

***********************************************************

************************************************************

WARNING:

WARNING indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

***********************************************************

a. Do not smoke or use open flame near the generator

set.

b. Keep a fire extinguisher nearby and know its proper use.

Fire extinguishers rated ABC by NFPA are appropriate.

3. DEADLY EXHAUST GAS - Exhaust fumes from any diesel

engine contain carbon monoxide, an invisible, odorless

and deadly gas that must be mixed with fresh air.

a. Operate only in well ventilated areas.

b. Never operate indoors.

c. Never operate the unit in such a way as to allow exhaust

gases to seep back into closed rooms (i.e. through

windows, walls or floors).

4. NOISE HAZARD - Excessive noise is not only tiring, but

continual exposure can lead to loss of hearing.

a. Use hearing protection equipment when working

around this equipment for long periods of time.

b. Keep your neighbors in mind when permanently install-

ing this equipment.

5. CLEANLINESS - Keep the generator and surrounding area

clean.

a. Remove all grease, ice, snow or materials that create

slippery conditions around the unit.

b. Remove any rags or other material that could create

potential fire hazards.

c. Carefully wipe up any fuel or oil spills before starting the

unit.

d. Never allow leaves or other flammable material to build

up around the engine exhaust area.

***********************************************************

CAUTION:

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be

used to alert against unsafe practices.

************************************************************

NOTE:

CAUTION is also used on the unit labels and in this manual to

indicate a situation that could result in serious damage or

destruction of the equipment and possible personal injury.

1. ELECTRIC SHOCK - The output voltage present in this

equipment can cause a fatal electric shock. This equipment

must be operated by a responsible person.

a. Do not allow anyone to operate the generator without

proper instruction.

b. Guard against electric shock.

c. Avoid contact with live terminals or receptacles.

d. Use extreme care if operating this unit in rain or snow.

e. Use only three-prong grounded receptacles and

extension cords.

f. Be sure the unit is properly grounded to an external

ground rod driven into the earth.

6. SERVICING EQUIPMENT - All service, including the

installation or replacement of service parts, should be

performed only by a qualified technician.

a. Use only factory approved repair parts.

b. Do not work on this equipment when fatigued.

c. Never remove the protective guards, cover, or recep-

tacle panels while the engine is running.

d. Use extreme caution when working on electrical compo-

nents. High output voltages from this equipment can

cause serious injury or death.

e. Always avoid hot mufflers, exhaust manifolds, and

engine parts. They all can cause severe burns instantly.

f. Installing a generator set is not a “do-it-yourself” project.

Consult a qualified, licensed electrician or contractor.

The installation must comply with all national, state, and

local codes.

g. Always make sure unit is disabled before placing your

hands anywhere near the fan, belts, alternator or water

hoses.

60708-142

Page 1

8122-00

TESTING POLICY:

Before any generator is shipped from the factory, it is fully

checked for performance. The generator is loaded to its full

capacity, and the voltage, current, and frequency are carefully

checked.

Rated output of generators is based on engineering tests of

typical units, and is subject to, and limited by, the temperature,

altitude, fuel, and other conditions specified by the manufacturer

of the applicable engines.

INTRODUCTION AND

DESCRIPTION

** NOTICE **

These units will automatically transfer if a power outage occurs

while running in an exercise mode.

MODEL NUMBER STRUCTURE:

The WINPOWER alpha-numerical numbering system consists of a

base model designation, followed by an options section, separated

by a dash mark. The base component of the model numbering

system identifies an engine type, engine starting method, fuel type,

kilowatt rating, engine manufacturer , and number of generator poles.

Following the separation dash mark is the voltage connection and

optional installed equipment. Options include features like weather

enclosures (housing), base mounted fuel tank sizes, and trailer

options.

PRODUCT DESCRIPTION:

This engine-generator set is designed for unattended remote start

operation. It can be operated as part of a fully automatic standby

power system or independently as a local start unit in a prime power

system. The engine-generator set is fully tested at the factory prior

to shipment to insure proper operation of each individual component

as well as the total system's performance and reliability.

The engine generator set consists of a multi-cylinder, liquid cooled

engine nominally operating at 1800 rpm. The generator frequency

regulation is maintained by the engine governor to within +/- 1.5 hertz

(cps), from no load to rated load for standard mechanical governors

and to within +/- .5 hertz or better for units equipped with an electronic

governor. The generator is a single bearing, direct drive, rotating

field design. The generator is connected to the engine flywheel via

flexible drive disks. The Generator Set is skid mounted with isolation

mounts between the engine and base on all units.

Unit Orientation Note: All references used in this manual for unit

familiarization, access and component locations on the Generator

Set are oriented from a TOP (plan) VIEW with engine at the FRONT

and generator to the REAR.

WINPOWER uses a common junction box for all customer control

and power connections (both AC output and DC control). The

common electrical junction box is always on the left side at the

generator end of the machine.

A customer supplied 12 (or 24) Volt battery is required to complete

the installation. See appendix 1, to identify the voltage, size and CCA

(Cold Cranking Amp) requirements for your specific unit.

The engine is controlled and Generator Set operation is monitored

for safe operation by a programmable microprocessor based Electronic Engine Control Module (ECM) with an LCD digital display. The

Generator Set ECM control is mounted on a vertical pedestal on the

right side of the generator. (Except for the DR10 & DR20 which are

mounted on top the generator housing) The ECM is programmed

with a cycle cranking sequence - 3 cycles of 15 seconds on / 15

seconds off, and a 5 minute cool down delay. The cool down delay

can be changed in the field from 0 to 30 minutes by your dealer. Other

features, timing cycles, set points and signal output capabilities are

possible. Consult factory for procedure and passwords.

Please note that some features or packages, such as NFPA level

I & II, do not have an indication place in this numbering system.

They are issued and built with an M-Spec (i.e. M-10372) number

which can be found on the WINPOWER data tag. When the MSpec is present, supplemental inserts will accompany this

standard manual providing information about the special equipment and features installed. The standard model numbering key

that can be used along with the data tag information and/or Mspec supplements to determine the generator sets ratings and

specifications

MODEL NUMBERING SYSTEM

BUILD YOUR GENSET REQUIREMENT FROM

THE BOTTOM OF THE PAGE TO THE TOP

TRAILER OPTION IF PRESENT UNIT IS MOUNTED ON A

TRAILER WITH FUEL TANK FUEL. TANK SIZES SHOWN BY

PREVOUIS LETTER (SMALL AND MEDUIM FUEL TANKS ONLY)

FUEL TANK SIZE

M = MEDUIM

HOUSING TYPE

H = WEATHER HOUSING (WEATHER-PAK)

S = SOUND ATTENUATED/WEATHER PROTECTIVE (SOUND-PAK)

VOLTAGE

A = SINGLE PHASE 120/240

D = THREE PHASE 120/208

BASE UNIT - OPTIONS SEPARATOR

NUMBER OF POLES ON THE GENERATOR

ENGINE MANUFACTURE

V = VOLVO I = ISUZU (10 & 20 kW)

D = DEUTZ N = NG ENGINES

KILOWATTS

GENERATOR OUTPUT IN KILOWATTS WITH STANDBY

GASEOUS FUEL TYPE

N = NATURAL GAS

P = LIQUID PROPANE VAPOR

STARTING METHOD

FUEL TYPE

G R N 20 I 4 - A H M T

L = LARGES = SMALL

* = NONE

J = THREE PHASE 120/240

L = THREE PHASE 277/480

4 POLES STANDARD

I = IVECO (ALL OTHERS)

L = L/P LIQUID WITHDRAWL

NOT USED WITH DIESEL FUEL

R - REMOTE STARTING

D = DIESEL

G = GASEOUS

SEE CURRENT PRICE SHEET

TO DETERMINE CAPACITY

* = NO HOUSING

G = GM

8122-00

Page 2

60708-142

SPECIFICATIONS

GENERATOR SET:

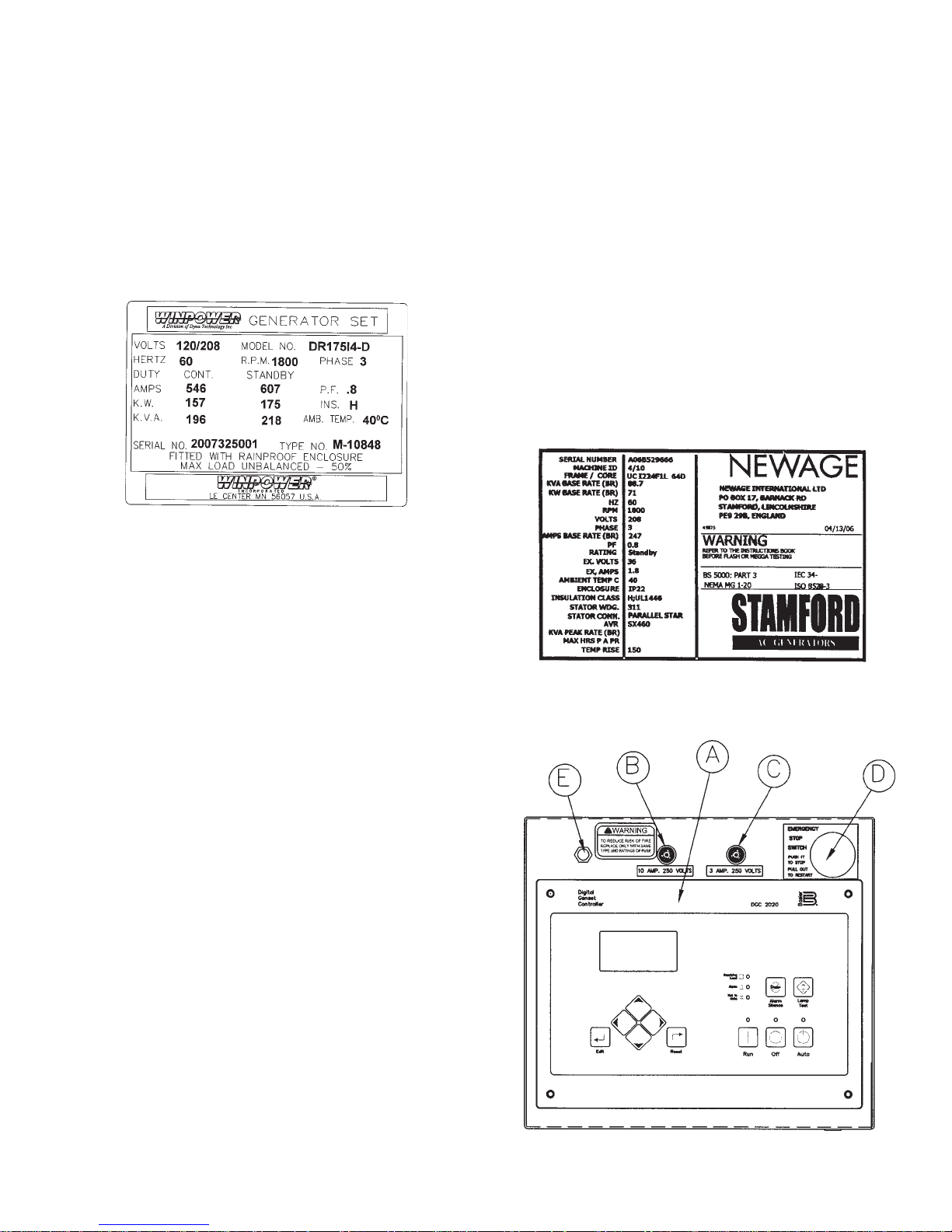

Every WINPOWER Generator Set has its own unique identity data

plate. This data plate identifies the complete unit model number,

the system serial number and has links to the individual components that form the generator set in our factory records. Several of

the major components also have their own individual identity plates

providing additional information to document build data for warranty

and replacement parts.

Typical Winpower Nameplate

Be sure to have the main WINPOWER unit data plate information

recorded inside the front cover of this manual for future reference

and for identification whenever requesting field or factory technical

assistance. Sample data plate is shown for reference. Primary fields

needed for assistance are complete model number, serial number

and especially the M-Spec number. The M-Spec number (if provided) is recorded in the ‘TYPE NO.’ block on the Lower Right of the

plate. See the appendixs in the back of this manual for individual

units specifications and wiring diagram references.

ENGINE:

The rated power of each engine-generator is limited by the

temperature, altitude and all other ambient conditions specified

by the engine manufacturer. Engine power will decrease 3-1/2%

for each 1000 ft. above sea level, and will decrease an additional

1% for each 10 degrees Fahrenheit above 60 degrees Fahrenheit. Units should not be operated in ambient temperature greater

than 125 degrees Fahrenheit.

GENERATOR:

WINPOWER Generators Sets use totally brushless, AVR (AutoVoltage Regulator) controlled broad-range generator ends. The

generator converts rotational mechanical energy into electrical

energy. Standard WINPOWER units are equipped with generators manufactured by Stamford/Newage. Each generator ‘end’

has its own data tag. The unique serial number is stamped on the

data plate and into the upper section of the mounting adapter of

the generator frame. The data label is affixed to the main frame

of the generator on the lower left side, similar to the sample

shown.

ENGINE CONTROL PANEL LAYOUT

Each engine has a nameplate on it that gives the specific engine

model number, build specification and the serial number for the

engine. See the technical data pages in the back of this manual

for individual engine specifications, fuel consumptions and wiring

diagram references.

This manual covers specific operation of the combined engine

generator set. Refer to engine operating and maintenance

instructions for specific instruction on the care and maintenance

of the engine. Oil and fuel requirements along with maintenance

schedules and engine warranty information are provided by the

individual engine manufactures.

** CAUTION **

EQUIPMENT DAMAGE - Be sure to check the engine oil level

frequently as specified in the engine manual.

The engine manufacturer has established an excellent worldwide

engine service organization; engine service is available from a

nearby authorized dealer or distributor; check the Yellow Pages

of the telephone directory under “engines,” or ask the dealer from

whom you purchased the power plant.

60708-142

Page 3

8122-00

A - DGC-2020 Digital Gen-Set Control. See Explanation

below.

B - DC Control Circuit Fuse. The 10 amp DC Circuit Fuse

protects the 12 volt circuits and engine wiring harness against

faults in wiring or control equipment. The fuse also prevents a

discharge of the battery due to a circuit fault. (Replacement

AGC-10A-250V)

C - DGC-2020 Fuse. This 3 amp DC fuse protects the DGC2020 printed circuit board. (Replacement AGC-3A-250V)

D - Emergency Stop Switch - When depressed this switch will

disconnect all the 12 volt power to the DGC-2020 shutting the

engine down. The lamp in the emergency stop switch will light

up when the switch is depressed showing that the power to the

panel has been disconnected.

E - Voltage Adjustment Rheostat. This 2 watt 1k ohm

rheostat is used to fine tune your output voltage from the

generator. If for some reason the voltage should get way out of

range and you can not get it back with the adjustment range on

the rheostat, there is a course voltage adjustment pot on the

voltage regulator

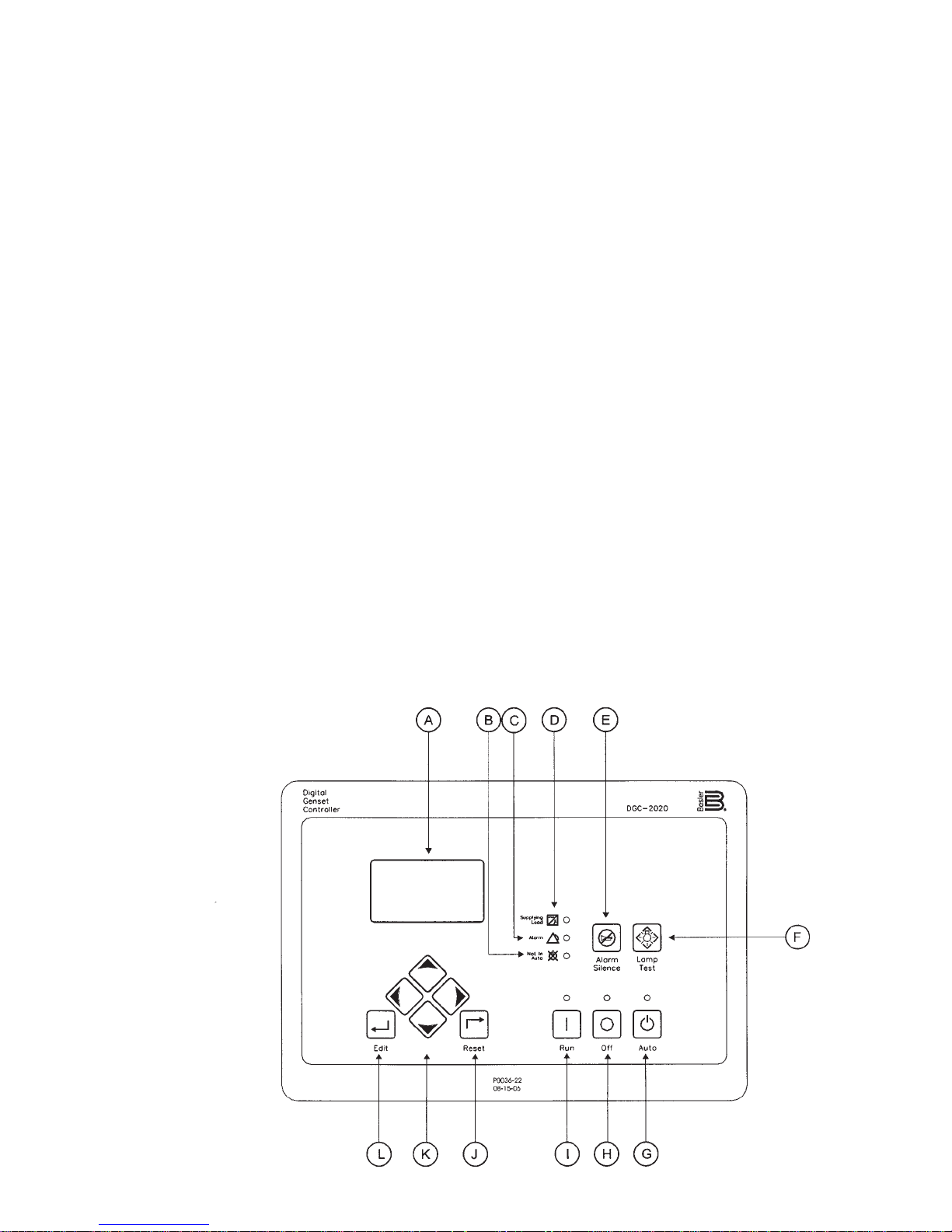

ENGINE CONTROL MODULE (DGC-2020)

Note: A CD was shipped with this unit to support the DGC-

2020. The CD contains the complete operators manual and

the software to reprogram the DGC-2020 if the need should

ever arise. Please store it in a safe place.

The DGC-2020 Digital Generator Set Controller provides

integrated engine-generator set control, protection, and

metering in a single package. Microprocessor based technology allows for exact measurement, set point adjustment, and

timing functions. Front panel controls and indicators enable

quick and simple DGC-2020 operation. Basler Electric communication software (BESTCOMSPlus) allows units to be easily customized for each application. A wide temperature-range liquid crystal

display (LCD) with backlighting can be viewed under a variety of

ambient light and temperature conditions.

FEATURES

DGC-2020 Digital Generator Set Controllers have the following

features:

• Local and Remote Generator Control

• Engine and Generator Protection

• Programmable Analog Engine Senders

• Programmable Logic

• Automatic Transfer Switch Control (Mains Failure)

• Integrated RS485 interface

• Auto Synchronizing

FUNCTIONS

DGC-2020 Digital Generator Set Controllers perform the following

functions:

Generator Protection and Metering

Generator protection guards against over voltage, under voltage,

under frequency, and over frequency. Over current and phase

imbalance protection is available as an option at the time of

manufacture. Each generator protection function has an adjustable

pickup and time delay setting. Metered generator parameters

include voltage, current, real power (watts), apparent power (VA),

and power factor (PF).

Engine Protection and Metering

Engine protection features include oil pressure and coolant temperature monitoring, over crank protection, ECU specific protection

elements, and diagnostic reporting.

ENGINE

CONTROL

MODULE

DGC-2020

8122-00

Page 4

60708-142

Metered engine parameters include oil pressure, coolant

temperature, battery voltage, speed, engine load, coolant level

(from ECU), ECU specific parameters, and run-time statistics.

All metering functions are displayed on the liquid crystal display.

The front panel display begins with the SUMMARY SCREEN.

Pressing the Right arrow key will open the MAIN MENU screen.

The MAIN MENU screen consists of METERING and SETTINGS

move downward through the menu levels and the left-arrow

button is pressed to move upward. Within a level, the up-arrow

and down-arrow buttons are used to move among items within

the menu level. Pressing the down-arrow button moves to items

lower in the list. Pressing the up-arrow button moves to items

higher in the list. During a settings editing session, the up- and

down-arrow buttons are used to raise and lower the value of the

selected setting.

Summary Screen

Summary screen can be set to standard or scrolling. When set to

standard, only the following are displayed:

• Generator Voltage

• Generator Amperage

• Generator Phase

• Generator Frequency

• Engine Oil Pressure

• Engine Coolant Temperature

• Engine Battery Voltage

A - Liquid Crystal Display. The backlit, 64 by 128 pixel LCD

serves as the local information source for metering, alarms, prealarms and protective functions. Display operation is maintained

at -20°C. An optional LCD heater would maintain display operation at -40°C.

B - Not in Auto Indicator. This red LED lights when the DGC2020 is not operating in Auto mode.

C - Alarm Indicator. This red LED lights continuously during

alarm conditions and flashes during pre-alarm conditions.

D - Supplying Load Indicator. This green LED lights when the

generator current is greater than EPS threshold current.

E - Alarm Silence Push-button. Pressing this button opens the

relay output programmed as the horn output.

F - Lamp Test Push-button. Pressing this button tests the DGC2020 indicators by exercising all LCD pixels and lighting all LEDs.

G - Auto Push-button and Mode Indicator. Pressing the Auto

button places the DGC-2020 in Auto mode. The green Auto mode

LED lights when Auto mode is active.

H - Off Push-button and Mode Indicator. Pressing this button

places the DGC-2020 in Off mode. The red Off mode LED lights

when the DGC-2020 is in Off mode.

I - Run Push-button and Mode Indicator. Pressing this button

places the DGC-2020 in Run mode. The green Run mode LED

lights when Run mode is active.

J - Reset Push-button. This button is pressed to cancel a

settings editing session and discard any settings changes. When

pressed, this button also resets the Breaker Management PreAlarms

L - Edit Push-button. Pressing this button starts an editing

session and enables changes to the DGC-2020 settings. At the

conclusion of an editing session, the Edit push-button is pressed

again to save the setting changes.

DISPLAY OPERATION

The front panel display is used to make settings changes and

display metering values. Refer to call-outs J, K, and L in text and

illustration for information on changing settings through the front

panel and navigating through the Metering screens. When the

unit is first powered up, the clock may need to be reset. Editing

the clock provides familiarity with the edit process. All programming changes from the front panel are accessed through the edit

key to begin and exit the internal microprocessor program.

Log-in and Permissions

To Log-in, navigate to the SETTINGS, ENTER PASSWORD

screen and press the Edit key. Use the Up/Down arrow keys to

scroll through the characters. Use the Left/Right arrow keys to

enter more characters. The Owner operator password is OP.

Once the password has been entered, press the Edit key to Login. See the key stroke sequence listed below to access the

control and enter the edit mode. A LOGOUT selection now

appears in the list of SETTINGS. To logout, navigate to SETTINGS, LOGOUT and press the Edit key. The LOGOUT selection

is removed from the SETTINGS list.

Sequence for setting (or resetting) the system clock -

1) Press ‘K’ (right key) for initial set or ‘K’ (left to back up, up /

down) to choose menu item and time/date element to be

changed.

2) Press ‘L’ (Edit) to access change mode to enter Password OP as follows:

2a -Press K (up) to select O

2b -Press K (right) to move cursor

2c -Press K (up) to select P

2d -Press L (Edit) to begin change mode

3) Press ‘K’ (up or down) to choose year

4) Press ‘L’ (Edit) to enter year

5) Press ‘K’ (down) to select month mode

6) Press ‘L’ (Edit) to access month change

7) Press ‘K’ (up or down) to choose month

8) Press ‘L’ (Edit) to enter month

9) Repeat sequence 5 through 8 for day, minute, second and

DST (Daylight Saving Time).

To finish clock setting, process - Press ‘K’ (left).

K - Arrow Push-buttons. These four buttons are used to

navigate through the front panel display menus and modify

settings. The left- and right-arrow buttons are used to navigate

through the menu levels. The right arrow button is pressed to

60708-142

Page 5

8122-00

The microprocessor is still in the General Settings Edit mode.

Pressing ‘K’ (left) a second time exits the Edit mode and allows

full access to the View Only mode for all control settings and

current status. Any items to be changed are accessed by

pressing ‘K’ (up/down/right or left) to select, ‘L’ (Edit) to change

and ‘K’ (left) to exit.

Communication

Standard DGC-2020 communication features include a standard

USB port and SAE J1939 interface. Optional communication

features include a dial-out modem and RS-485 communication port.

The USB communication port can be used with BESTCOMSPlus

software to quickly configure a DGC-2020 with the desired settings

or retrieve metering values and event log records. The CANBus

interface provides high-speed communication between the DGC2020 and the engine control unit (ECU) on an electronically controlled engine. This interface provides access to oil pressure, coolant temperature, and engine speed data by reading these parameters directly from the ECU. When available, engine diagnostic data

can also be accessed. The CANBus interface supports the following protocols:

• SAE J1939 Protocol - Oil pressure, coolant temperature, and

engine speed data are received from the ECU. In addition, DTCs

(Diagnostic Trouble Codes) help diagnose any engine or related

failures. The engine DTCs are displayed on the front panel of the

DGC-2020 and may be obtained using BESTCOMSPlus software.

• MTU/MDEC Protocol - A DGC-2020 connected to a generator

Set equipped with an MTU MDEC receives Oil pressure, coolant

temperature, and engine speed data from the engine controller , along

with various alarms and pre-alarms that are MDEC specific. In addition, the DGC-2020 tracks and displays the active fault codes issued by the MDEC ECU.

Optional - Dial-Out Modem One of two optional, dial-out modems

(a US version or international version) enables remote control,

monitoring, and setting of the DGC-2020. When an alarm or prealarm condition occurs, the DGC-2020 can dial up to four telephone

numbers, in sequence, until an answer is received and the condition is annunciated.

ining the unit for damage during shipment. Avoid signing for the

equipment until a full visual assessment and inventory have been

made. Verify that you have received the right equipment and the

proper amount by matching up the equipment to the packing list.

Larger units may ship with the fuel tank and muffler removed. V erify

that those components are undamaged and removed from the truck

prior to their release.

The keys for doors of the enclosed generators sets are typically

attached to lifting eye on the base of the machine. These keys are

matched to all the doors on the generator set housing.

UNPACKING INSTRUCTIONS:

When unpacking the generator set, be sure to inspect it carefully for

freight loss or damage. If loss or damage is noted at the time of

delivery, require that the person making the delivery make note of

the loss or damage on the freight bill, or affix his signature under the

consignee’s memo of the loss or damage. Contact the carrier for

claim procedures.

When loss or damage is noted after delivery, segregate the damaged material, and contact the carrier for claim procedures.

“Concealed Damage” is understood to mean damage to the contents of a package which is not in evidence at the time of delivery by

the carrier, but which is discovered later. The carrier or carriers are

responsible for merchandise lost or damaged in transit. The title to

goods rests with the consignee when generators are shipped fob

factory, and only the consignee can legally file a claim.

***** CAUTION ****

EQUIPMENT DAMAGE - These units are shipped with oil,

and a 50/50 mix of coolant. Be sure to check all fluid

levels before operating. See engine manufacturer’s

instruction manual for recommended oil requirements

before initial starting.

UNPACKING:

(Not recommended until the unit is on-site)

Optional - RS-485 Port The RS-485 communication port uses the

Modbus communication protocol and enables remote control and

monitoring of the DGC-2020 over a polled network

.

RECEIVING THE GENERATOR

The generator set will generally be shipped by a commercial ‘common freight carrier’. Large and bulky units are often shipped on a

dedicated or specially contracted ‘Flat-Bed’ truck. The means of

shipment is determined in consultation between the WINPOWER

Sales and Shipping staff and the customer. Routing is determined

by the bulk, size, and a means available to unload the generator at

the receiving end. WINPOWER recommends units that are shipped

by common carrier be delivered to a commercial dock to allow the

Generator Set to be unloaded in a safe, efficient manner and to

minimize handling damage to the unit.

Locate the packing slip on the side of the crate or request it from

the truck driver. When receiving the unit take special care in exam-

8122-00

1. Carefully remove the crate.

2. After inspecting the engine-generator for external physical

damage, locate and check the following items packed with

the unit.

a. Owner’s operators manual.

b. Engine manufacturer’s instruction manual.

c. Battery hold-down brackets & hardware.

d. Unit components or accessory items shipped loose

for on-site installation.

e. Optional accessories (i.e. remote annunciator)

3. Remove main frame hold down bolts.

4. Unit can now be lifted from shipping rails.

Page 6

60708-142

LIFTING THE GENERATOR SET

NOTICE - Personal Injury

To prevent injury to persons or equipment, observe the following guidelines when lifting the generator:

Due to the different designs, configurations, options, weights, site

conditions, and available material handling equipment, specific lifting instructions are not provided for each individual generator set

model. General guidelines provided are applicable to the entire

standby generator line. It is the responsibility of the installing party

to follow the lifting equipment’s operators manual to prevent injury

to personnel and damage to the generator. Smaller Generator Sets

may not require use of overhead lifting equipment and may be placed

on the pad with basic material handling equipment, i.e. a forklift.

CAUTION: - Do not attempt to lift the generator set by the means

of the lifting eyes on the engine or generator end.

These lifting points are only for use during the manufacturing process and are designed for lifting of the individual Generator Set

component.

WINPOWER has designed all of its Generators Sets to be lifted at

the corners with an appropriate lifting rig. The lifting points are

located on the side rails of the generator base or on the optional

base mounted fuel tank of a Diesel Generator Set.

The generator set can be lifted with properly rated chains or cables

along with the use of spreader bars. The spreader bars should be

long enough so that the lift cables or chains do not come into contact with the generator set. Use of commercially available lifting

fixtures may also be used. Always be sure that the equipment is

properly rated for the weight of the generator. Failure to do so can

cause damage to the generator, injury to personnel or even death.

The generator set and fuel tank may or may not be shipped as a

complete unit. If the fuel tank is shipped separate from the generator, place the tank on the cement pad first, and then place the generator on top of the fuel tank.

***************

***** WARNING ****

***************

NEVER - attempt to lift the fuel tank while filled with fuel. Sloshing of the fuel can cause a shift in the balance of the fuel tank,

making for a DANGEROUS, unbalanced lifting load. If the generator was shipped on the fuel tank, use the lifting points located on the fuel tank to move the entire Generator Set into

place. DO NOT place fuel in the tank prior to lifting.

Depending on generator set size and configuration, the exhaust

system may ‘ship loose’ with the generator set for installation on

site. The muffler and its attaching brackets must be mounted on

top of the generator housing prior to operating the engine

generator set.

INSTALLATION

60708-142

Page 7

8122-00

***************

***** WARNING ****

***************

PERSONAL INJURY - Before proceeding with the installation,

be sure the DGC-2020 is in the "stop" position. Before

proceeding with the installation, be sure the Generator MLCB

(Main Line Circuit Breaker) is in the ‘OFF’ position and the

unit starting battery is disconnected.

FUEL INSTALLATION

The fuel supply should be as close to the engine as possible. This

will reduce the installation cost of fuel runs and minimize line losses.

The diesel fuel supply should be no more than 3 feet below the fuel

inlet on the pump. If your fuel supply is lower than three feet you may

have to install an additional lift pump to bring the fuel up to the

mechanical fuel pump on the engine.

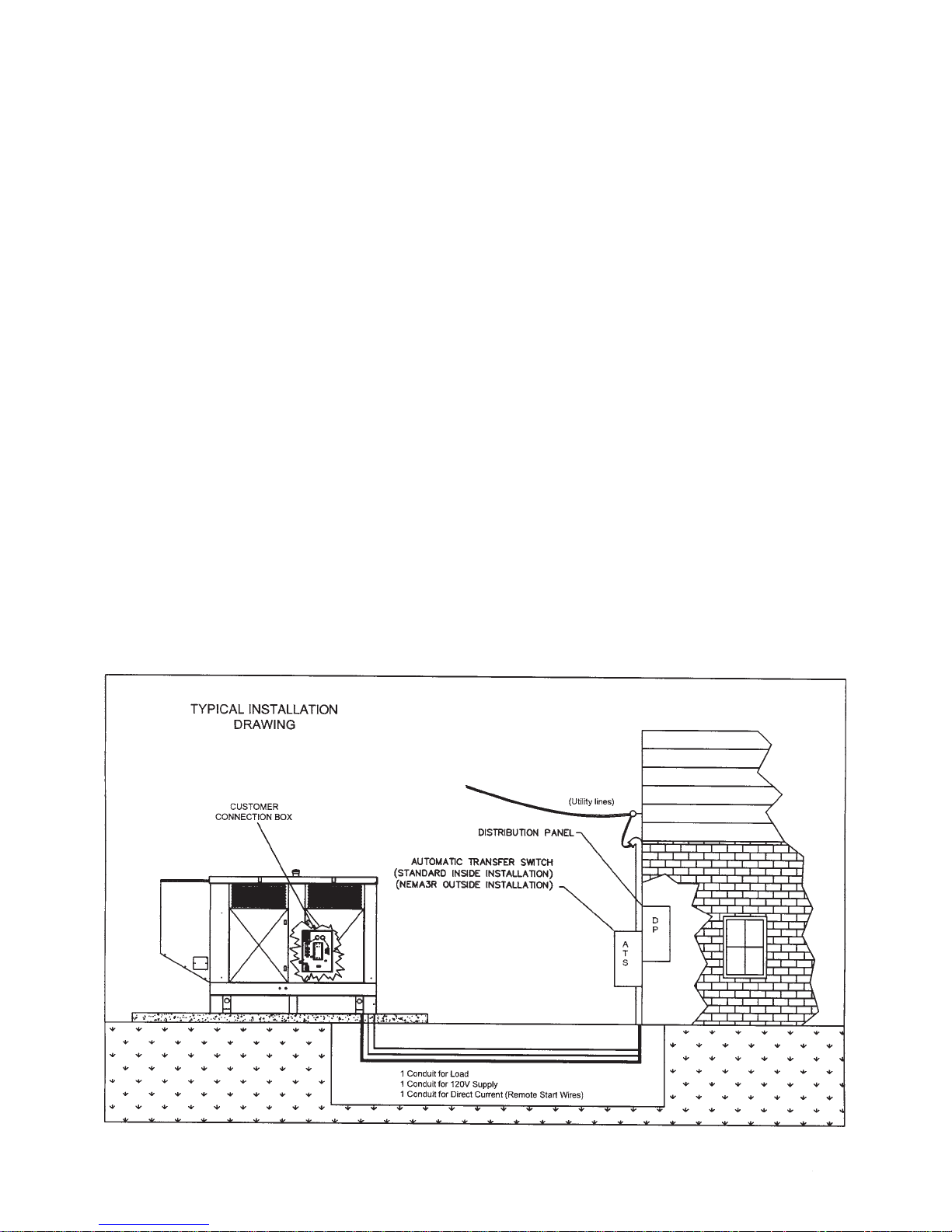

GENERAL INFORMATION

These engine/generator sets are generally supplied as weather

enclosed packages for quick installation on an outdoor concrete

pad. They are also available as open skid mounted units for indoor

installation in a building or protective enclosure supplied by the

installer. The factory weather enclosures are available as standard

or acoustical housing intended for outdoor installation only. Factory

weather enclosed units are not intended to be used indoors and

no support is available to assist in re-engineering finished

packaged units.

All versions must be bolted to a solid base for proper operation. A

properly designed concrete pad is necessary for stationary operation. A substantial DOT certified trailer is required for mobile applications. Consult a qualified, licensed electrician or contractor to

install and wire this Generator Set. The installation must comply

with all national, state, and local codes.

Before beginning the installation process, recheck the voltage,

phase and amperage rating of the Generator Set and ATS (Automatic Transfer Switch). Be certain they can handle the intended load

and are compatible with the entrance voltage, phase and current

ratings. Plans for installation should be prepared with proper

attention to mechanical and electrical engineering detail to assure a

satisfactory system installation.

The information in this manual is offered only as a guide to finalizing

your installation plans.

The information in this manual is offered to assist you in providing the

proper fuel for your engine. However, this information is only provided to inform you of the engine’s requirements and assist in

making you aware of the decisions you must make. In no case

should the instructions or information provided be interpreted to

conflict with any local, state or national codes. If in doubt, always

consult your local fire marshal or fuel supplier.

INSTALLING THE FUEL LINE

Engine generator sets are properly adjusted before they leave the

factory. Connecting a fuel supply with adequate supply volume is

critical to reliable operation. Diesel units with optional base mounted

fuel tanks are pre-plumbed to the mechanical fuel pump on the

engine.

Open skid mounted Diesel units are often supplied with capped inlet

and return lines. The use of a suitable customer supplied flexible fuel

line is essential between the engine and fuel supply to provide a

vibration break between your fuel supply and the engine.

***************

***** WARNING ****

***************

FIRE DANGER - Connecting rigid fuel line (i.e. steel or copper

line) directly to the inlet fuel filter or fuel pump may cause the

fuel line to crack during operation creating a serious fire

hazard.

NOTICE

For full service switching of the entire load, the ATS must be ‘SE’

(Service Entrance) rated or must have a properly rated fusible

disconnect installed before the ATS to protect the contacts.

.

ENGINE GENERATOR SET MOUNTING

The unit’s main frame must be bolted solidly to a 4 to 6 inch thick

cement pad. The engine-generator is mounted on a sub-frame

which is attached with special shock mounts to the main frame.

This allows the engine-generator free movement without affecting

the control panel which is mounted on the main frame.

Do not shock mount the main frame. Engine vibration will be

transmitted to the control panel causing erroneous start/stop

cycles and premature control failure.

The unit should be mounted to allow for ample working room

around it. A general rule to follow is five (5) feet of clearance on

all sides. (Code NFPA 37)

8122-00

LUBRICATION

Before starting the engine, check the oil level in the crankcase. If

it is low, refill to the full mark with the proper weight/grade of oil as

recommended by the engine manufacturer’s maintenance

instructions. The necessity of using the correct oil, and keeping

the crankcase full cannot be over emphasized. Failure to use the

proper oil and keep the crankcase properly filled will cause

excessive engine wear and shorten its useful life.

COOLANT

Before starting the engine, check the coolant level in the radiator.

If it is low, refill as specified in the engine manufacturer’s maintenance instructions. The radiator should be filled to about 1 inch

below the filler neck. For additional information on engine coolant

requirements see engine manufacturer’s maintenance instructions.

Page 8

60708-142

Loading...

Loading...