Winkhaus EAV Operating Manual

EAV

Electronic Automatic Locking

System

Operating Manual

After installation please pass on these instructions

to the end customer in accordance with Information. Disclosure Act stipulated in the Law on Product

Liability!

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

2

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

This security door locking system complies with the requirements and directives established and stipulated by the Council on the Harmonization of Legal Regulations of

Member States regarding Electromagnetic Compatibility (89/336/EEC).

The manufacturer shall hereby certify the conformity of this product and document

such by the CE marking (see Appendix).

Aug. Winkhaus GmbH & Co. KG

Berkeser Straße 6

D-98617 Meiningen

Germany

T + 49 (0) 3693 950-0

F + 49 (0) 3693 950-134

www.winkhaus.de

The following information and graphic images provided correspond to the current

status of the development and manufacture of this product.

For the purpose of customer satisfaction and operational reliability of the electronic automatic locking system, we reserve the right to make changes to this product without

notice.

All information and specications given in this operating manual have been compiled

and reviewed with the utmost care.

Due to the nature of advances in technology, or amendments to legal regulations and

other compulsory changes we do not guarantee the accuracy and completeness of the

contents’ statements. We always appreciate suggestions or comments.

The electronic automatic locking system can be easily installed, if these operating in-

structions and the door specications indicated have been adhered to.

© Aug. Winkhaus GmbH & Co. KG. All rights reserved. Last revised: 08/2009

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

3

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

Table of contents

1 Important information page 5

1.1 General information page 5

1.2 Intended use page 5

1.3 Use contrary to the intended purpose page 6

1.4 Explanation of symbols page 7

1.5 Important safety information page 7

1.6 Abbreviations/Explanations page 8

2 Product description page 9

3 Installation page 17

3.1 Routing details page 17

3.2 Cable transition KÜ-T-STV (plug-in) page 19

3.3 Installations page 21

3.3.1 General connection diagram page 22

3.4 Access control system transponder set page 23

3.5 Access control system wireless remote control page 25

3.5.1 Wireless remote control set page 25

3.5.2 Wireless receiver (separate) page 27

3.6 Non-Winkhaus access control system page 29

3.6.1 Non-Winkhaus access control system general page 29

3.6.2 Non-Winkhaus access control system finger

scanner ekey home integra page 29

3.6.2.1 Control of additional applications (only integra 2) page 31

3.6.2.2 Control of automatic door opener (integra 1 and 2) page 31

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

4

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

4 Operation/Programming page 32

4.1 Electronic automatic locking system page 32

4.1.1 Locking and unlocking page 32

4.2 Electronic automatic door locking system with transponder page 32

4.2.1 Operation page 32

4.2.2 Programming page 33

4.3 Electronic automatic locking system with

wireless remote control page 35

4.3.1 Operation page 35

4.3.2 Programming page 35

4.4 Wireless receiver for additional applications page 39

5 Maintenance and care page 40

6 Errors/Causes/Troubleshooting page 41

7 Technical specifications page 43

7.1 Power supply page 43

7.2 Antenna/Reader unit page 43

7.3 Wireless remote control page 43

7.4 Cable transition KÜ-T ... page 45

8 Accessories page 46

Table of contents

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

5

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

1 Important information

1.1 General information

Dear Customer,

We would like to thank you for your condence you have put in us by purchasing our

high-quality product.

Please read this operating manual carefully to become acquainted with the installation

and use of this security door locking system and to avoid malfunctions and safety

hazards.

Acceptance class A

„Acceptance-No.: M105301“

1.2 Intended use

The electronic automatic locking system and the Winkhaus components recommended are suitable for the following areas of application:

• relative air humidity of max. 95%

• ambient air temperature of between - 20°C and + 60°C.

The complete door ttings are designed to be used in conjunction with genuine Wink-

haus parts. Other parts which are not recommended by Winkhaus can adversely affect

the default properties of this locking system. It is assumed that the lock will be used

as intended.

The proper functions of the access control systems and the accessories included in the

scope of delivery of the Winkhaus company have been tested. If you use components

made by other companies and if you have any doubts about the suitability of these

components, you will have to contact the respective manufacturer to ensure their tness for use.

To ensure the intended use:

• the information and instructions required for this purpose have to be passed on to

the respective persons;

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

6

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

• only trained professionals should install the door ttings, locking units and accessories according to the installation instructions. DIN standards, which may also

apply are to be followed, also.

The stipulations for use as intended have been met, once the Winkhaus ttings are:

• installed according to their dened function and the installation specications,

• not used in any other way than described,

• maintained and cared for at regular intervals as instructed,

• not used if signs of wear are detected,

• repaired by trained professionals in the event of malfunctions.

The supplier/manufacturer does not accept any liability for personal injury or material

damage caused by incorrect operation or improper use.

1.3 Use contrary to the intended purpose

The locking systems are not designed to absorb or compensate for any movement

changes or in the closing mechanism of the door caused by changes in temperature or

in the structure of the building.

Doors which are used in damp rooms and in environments with aggressive corrosion

related air conditions require special door furniture.

Incorrect use of the locking systems is evident if :

• the instructions on the intended use are not being followed;

• the problem-free operation is hindered due to the installation of external items that

are not suitable or block the external outside function, the locking system or within

the center keep;

• the locking system or the center keep is manipulated in such a way that its design,

mode of operation or function is changed;

• the door is drilled through in the area of the lock housings or of the lock rod once

the lock has been installed;

• the additional opening and closing equipment or the thrown dead bolt are improperly used in order to keep the door open;

• force is used to drive the handle pin through the lock spindle;

• the locking components are wrongly installed or are tampered with, e.g. by painting

over movable parts such as the lock dead bolt or latch;

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

7

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

• the locking system is subject to loads which exceed normal manual force and are

transmitted via the cylinder key;

• the handle is not loaded in the normal sense of rotation or a a force above 150 N

is applied onto the handle in the direction of actuation;

• the gap between the door frame and sash is increased or decreased, which would

for instance result from readjusting the hinges or if the door drops;

• auxiliary lifting tools or objects are used to open or close the lock;

• the handle and the key are actuated simultaneously;

• the lock is locked/unlocked by using improper tools or equipment;

• Incorrect input values are applied in contravention of the Technical specications.

1.4 Explanation of symbols

Symbols and ags are used to identify important information in this operating manual.

Flags such as DANGER or CAUTION indicate the degree of hazard. Symbols serve to

visually emphasize the message.

It is imperative that you follow the measures listed to avoid hazard to safety!

DANGER!

Danger to life or danger of serious injuries.

CAUTION!

Danger of material damage.

+

NOTICE!

Useful information and tips.

ECO-WATCH!

Notices on complying with regulations on environmental protection.

1.5 Important safety information

Safety information described in this section is to be diligently adhered to regarding

the installation and use of this security lock. You must heed to the safety information

provided without exceptions!

• Read the operating manual and keep it easily accessible for future reference. After

installing the door pass it on to the end customer.

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

8

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

• The manufacturer shall not be held liable for damage caused by use contrary to

the intended purpose of the product.

• For security reasons, the lock has been designed to be used in conjunction with genuine Winkhaus parts. Using other parts may adversely affect the given properties

of the security lock.

• It must be ensured that the door can be closed without any difculties with the key.

• Installation/Repair of electrical equipment requires expertise, thus such work

should only be carried out by a qualied electrician.

• Arbitrary modications, changes or makeshift repairs are not permitted due to

concerns for safety. You must only use genuine Winkhaus parts for replacements.

• The manufacturer shall only be held liable for security related properties of the

locking system as stipulated within the bounds of statutory regulations, if the manufacturer himself or another instructed, authorized agent has carried out the

maintenance and service work or made the changes.

• Winkhaus shall not be liable for any type of damage caused by inadequate repair

or changes made.

1.6 Abbreviations/Explanations

The following terms and abbreviations are used in this manual:

STV Security lock

AV2 Automatic locking system

EAV Electronic automatic locking

system

Handle Door handle

Grt. Set

SB FRA Center keeps – latch/dead

bolt/adjustment plate

M2 with 2 hooks

RS DIN-right-handed

LS DIN-left-handed

mc Surface matt chrome-plated

est stainless steel

gr grey powder coated

Reader Reader unit/control unit of

the transponder set

AC Alternating current

DC Direct current

NO Make contact

NC Break contact

NO-NC Changer contact

ANT/GND Auxiliary antenna/Ground

UP-socket Flush-type box

LED Light emitting diode

PE Ground wire

N Neutral wire

L Phase

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

9

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

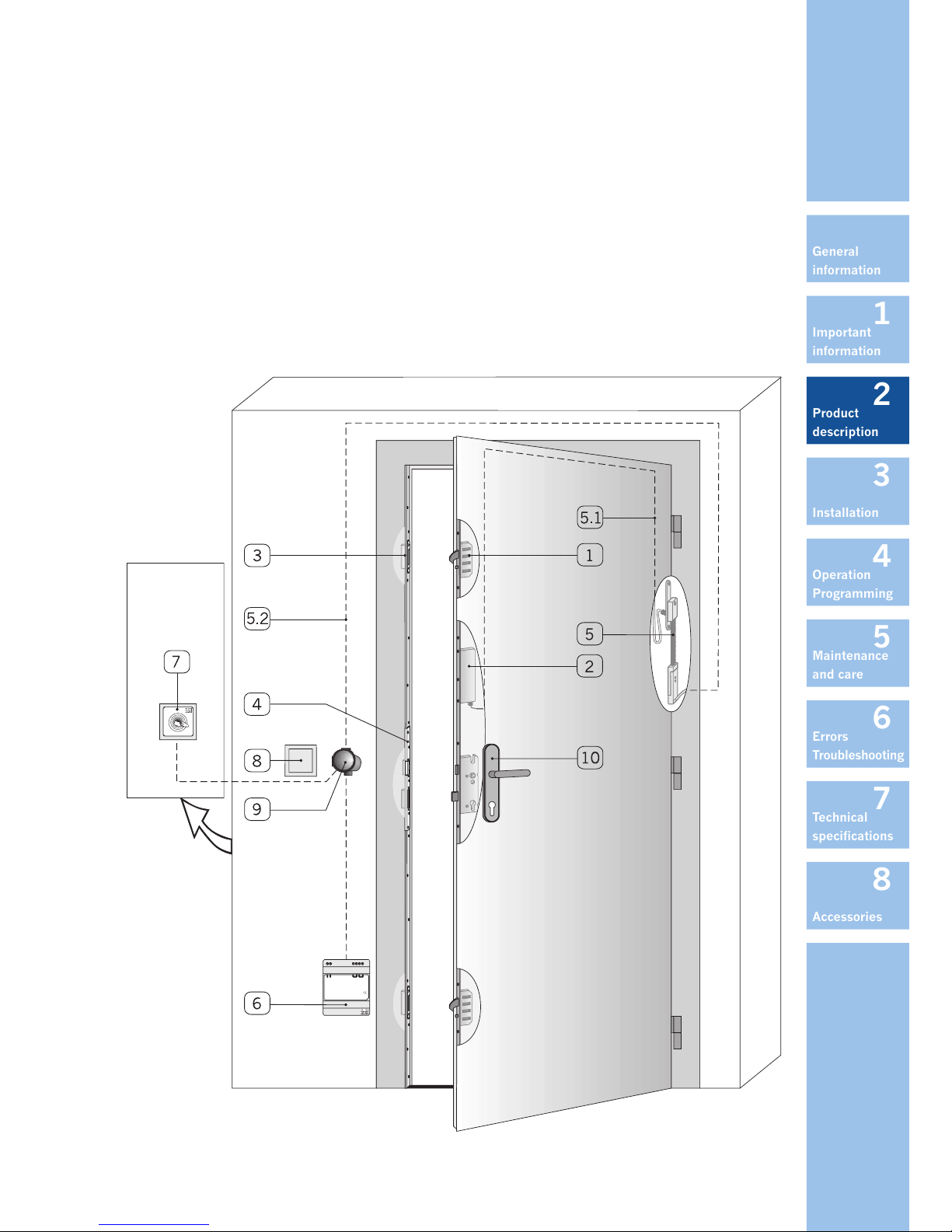

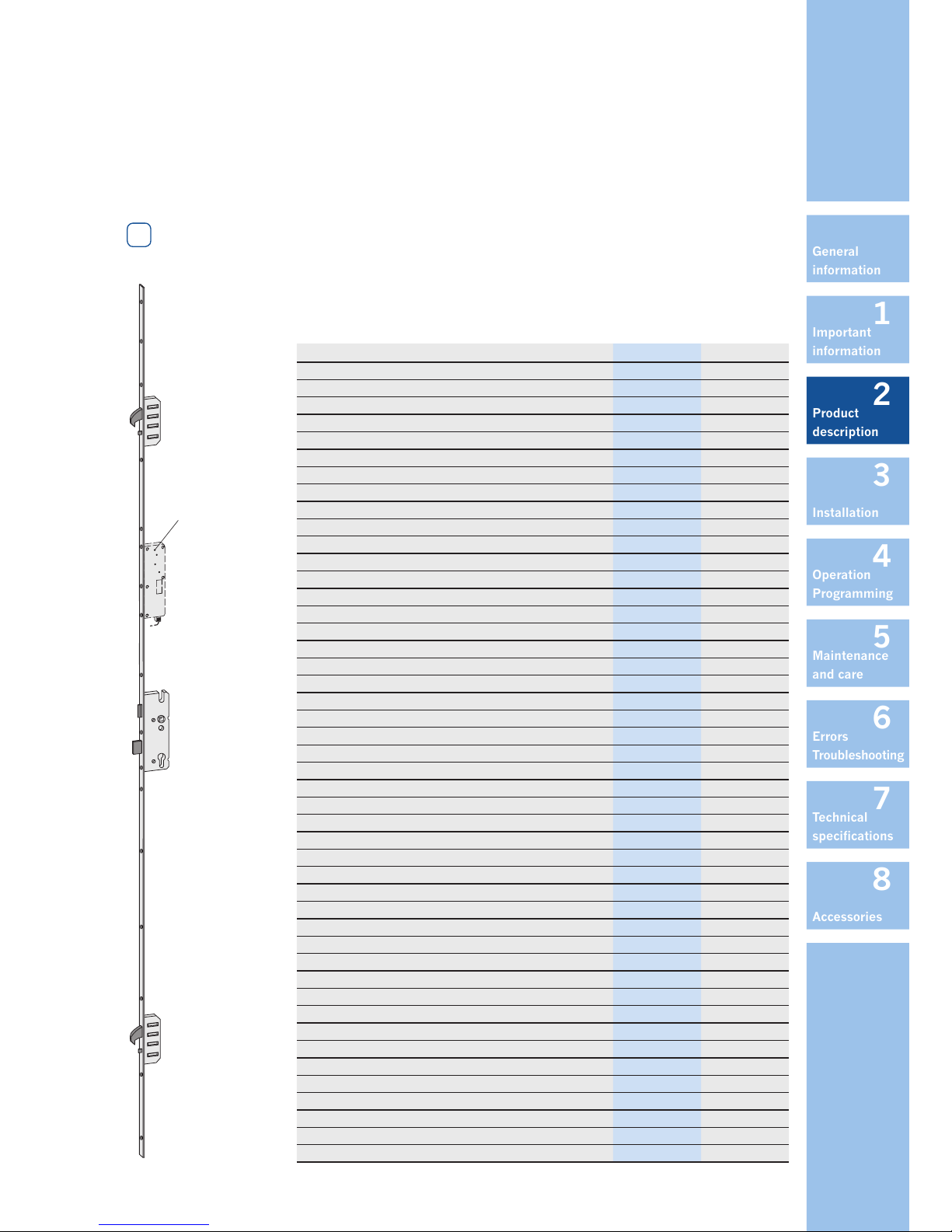

2 Product description

The electronic automatic locking system is a state-of-the-art locking unit for securing

and locking entry doors in a contact-free manner. The hooks can be retracted electrically so as to open the door.

Figure 2-1: Electronic automatic locking system with accessories

Netzteil/Powersupply

INPUT: 100 - 240 V AC; 50/60 Hz

OUTPUT: 12 V DC; 2 A

+V

-V

+ +

- -

N

L

In the

external zone

around the

entry door

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

10

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

*

remaining components recommended for use, or should be used alternatively

No. Name Included

in standard

delivery of

the security

lock

MUST!

Manda-

tory *

Available

as an

accessory

or as an

option

Supplied

by custo-

mer/not

included in

standard

delivery

1

Automatic locking AV2

(AV2-F/U ...)

X X

2

Motor housing X X

3

Extension keep set/single

keep

X X

4

Center keep FRA ... X X

5

Cable transition (KÜ-T-STV) X X

5.1

Cable at the sash side 2 m

[2.187 yd] or 3.5 m

[3.829 yd] long, plug for

motor housing included

5.2

Cable for the frame side

4 m [4.374 yd] long

6

Power supply 12V DC/2A X

7

Access control system

(shown: antenna of the transponder set)

+

NOTICE! Only install

the antenna of the transponder set in the external zone

around the entry door!

X

8

„Open” button X

9

Flush-type box X

10

Handle X

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

11

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

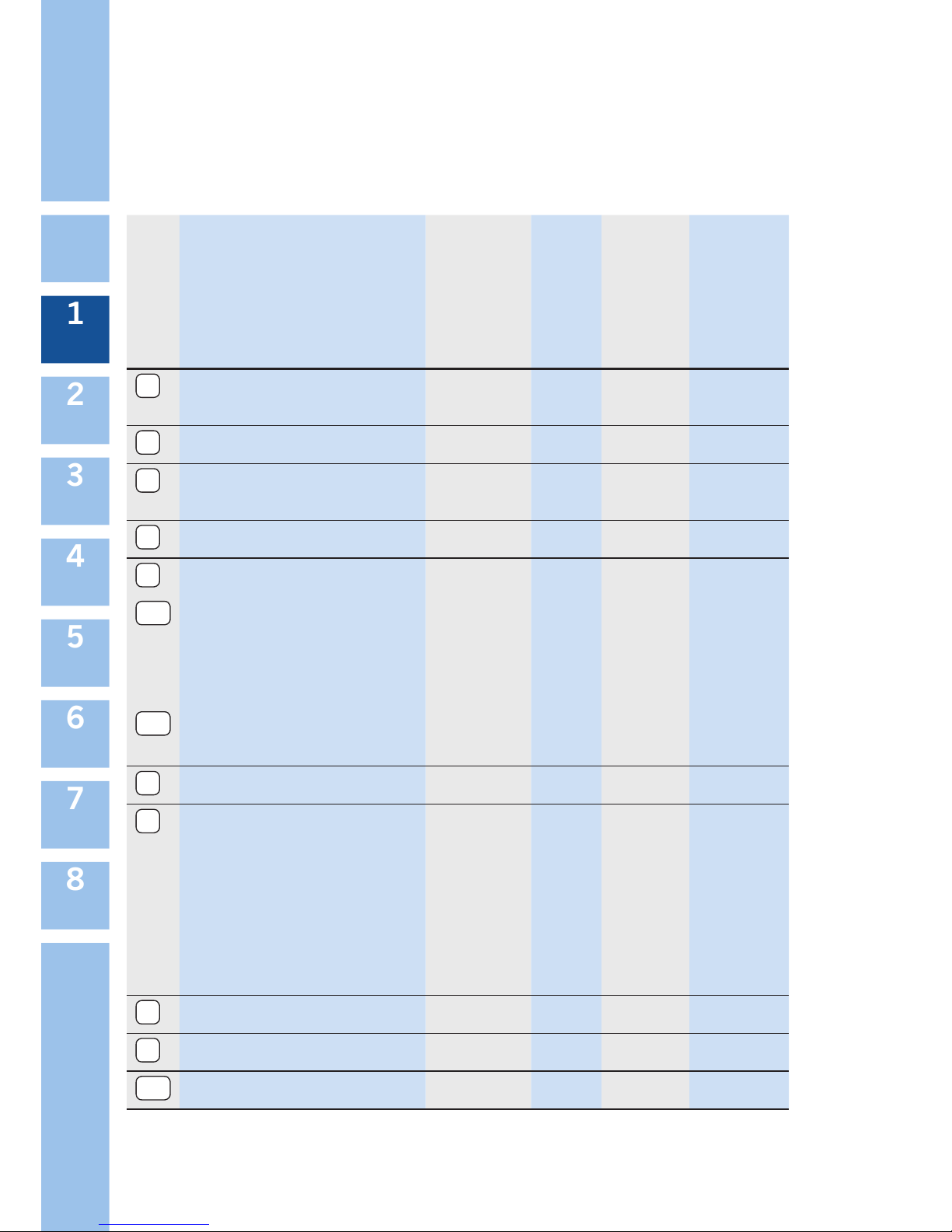

1

Automatic locking system AV2

Automatic three-point locking system with safety protection

against faulty switching, DIN RS and LS directions

Part Description DIN right DIN left

STV-AV2-F 1660SKG/35 92/8 M2 rs/ls mc 235 212 2 235 213 1

STV-AV2-F 1660SKG/35 92/8 M2 rs/ls gr 281 924 7 281 929 8

STV-AV2-F 1660SKG/40 92/8 M2 rs/ls mc 235 230 9 235 240 5

STV-AV2-F 1660SKG/40 92/10 M2 rs/ls mc 235 243 0 235 246 4

STV-AV2-F 1660SKG/45 92/8 M2 rs/ls mc 235 215 7 235 216 5

STV-AV2-F 1660SKG/45 92/8 M2 rs/ls gr 248 809 7 248 810 0

STV-AV2-F 1660SKG/45 92/10 M2 rs/ls mc 235 249 9 235 250 1

STV-AV2-F 1660SKG/50 92/8 M2 rs/ls mc 251 960 7 251 961 5

STV-AV2-F 1660SKG/55 92/8 M2 rs/ls mc 235 217 3 235 218 1

STV-AV2-F 1660SKG/55 92/10 M2 rs/ls mc 244 174 0 244 175 8

STV-AV2-F 1660SKG/65 92/8 M2 rs/ls mc 241 602 6 241 603 4

STV-AV2-F 1660SKG/65 92/10 M2 rs/ls mc 235 256 1 235 261 6

STV-AV2-F 2060SKG/35 92/8 M2 rs/ls mc 493 033 2 493 033 4

STV-AV2-F 2060SKG/40 92/8 M2 rs/ls mc 235 265 9 235 268 3

STV-AV2-F 2060SKG/45 92/8 M2 rs/ls mc 235 269 1 235 273 9

STV-AV2-F 2060SKG/45 92/10 M2 rs/ls mc 235 275 5 235 277 1

STV-AV2-F 2060SKG/50 92/8 M2 rs/ls mc 290 463 6 290 464 4

STV-AV2-F 2060SKG/50 92/8 M2 rs/ls gr 252 065 9 252 066 7

STV-AV2-F 2060SKG/55 92/8 M2 rs/ls mc 235 279 8 235 280 1

STV-AV2-F 2060SKG/55 92/8 M2 rs/ls gr 248 938 1 248 939 9

STV-AV2-F 2060SKG/55 92/10 M2 rs/ls mc 244 990 1 244 993 6

STV-AV2-F 2060SKG/60 92/8 M2 rs/ls mc 295 964 5 295 965 3

STV-AV2-F 2060SKG/60 92/8 M2 rs/ls est 290 126 7 290 129 1

STV-AV2-F 2060SKG/60 92/10 M2 rs/ls mc 235 281 9 235 287 8

STV-AV2-F 2060SKG/60 92/10 M2 rs/ls gr 254 137 0 254 138 8

STV-AV2-F 2060SKG/65 92/8 M2 rs/ls mc 235 290 7 235 292 3

STV-AV2-F 2060SKG/65 92/10 M2 rs/ls mc 235 300 2 235 301 1

STV-AV2-F 2460SKG/35 92/8 M2 rs/ls mc 235 310 9 235 311 7

STV-AV2-F 2460SKG/35 92/8 M2 rs/ls gr 291 457 8 291 454 3

STV-AV2-F 2460SKG/35 92/8 M2 rs/ls est 253 409 0 253 410 2

STV-AV2-F 2460SKG/40 92/8 M2 rs/ls mc 235 312 5 235 313 3

STV-AV2-F 2460SKG/40 92/8 M2 rs/ls gr 244 996 1 244 997 9

STV-AV2-F 2460SKG/40 92/8 M2 rs/ls est 296 829 3 296 830 6

STV-AV2-F 2460SKG/45 92/8 M2 rs/ls mc 239 011 1 239 012 9

STV-AV2-F 2460SKG/45 92/10 M2 rs/ls mc 241 277 1 241 278 9

STV-AV2-F 2460SKG/50 92/8 M2 rs/ls mc 295 320 1 295 321 9

STV-AV2-F 2460SKG/50 92/8 M2 rs/ls est 253 411 1 253 412 9

STV-AV2-F 2460SKG/65 92/8 M2 rs/ls mc 276 738 7 276 739 5

STV-AV2-F 2460SKG/65 92/8 M2 rs/ls est 259 254 8 259 255 6

STV-AV2-U 2293SKG/35 92/8 M2 rs/ls mc 240 695 2 240 696 1

STV-AV2-U 2293SKG/45 92/8 M2 rs/ls gr 239 520 2 239 521 1

STV-AV2-U 2293SKG/50 92/8 M2 rs/ls mc 256 075 7 256 076 5

STV-AV2-U 2460SKG/35 92/8 M2 rs/ls mc 235 339 5 235 340 8

STV-AV2-U 2460SKG/35 92/8 M2 rs/ls gr 253 049 4 253 050 7

STV-AV2-U 2460SKG/35 92/8 M2 rs/ls est 253 417 0 253 423 3

STV-AV2-U 2460SKG/40 92/8 M2 rs/ls mc 235 350 4 235 351 2

Optional electrical motor

housing

(for electronic

latch & hook

retraction)

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

12

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

Part Description DIN right DIN left

STV-AV2-U 2460SKG/45 92/8 M2 rs/ls mc 235 343 2 235 344 1

STV-AV2-U 2460SKG/45 92/8 M2 rs/ls gr 241 346 6 241 347 4

STV-AV2-U 2460SKG/45 92/8 M2 rs/ls est 254 369 1 254 370 3

STV-AV2-U 2460SKG/45 92/10 M2 rs/ls mc 235 341 6 235 342 4

STV-AV2-U 2460SKG/50 92/8 M2 rs/ls mc 253 849 6 253 850 9

STV-AV2-U 2460SKG/50 92/8 M2 rs/ls est 253 421 7 253 424 1

STV-AV2-U 2460SKG/55 92/10 M2 rs/ls mc 286 710 0 286 711 8

STV-AV2-U 2460SKG/60 92/8 M2 rs/ls mc 255 964 1 255 965 0

STV-AV2-U 2460SKG/65 92/8 M2 rs/ls mc 255 966 8 255 967 6

STV-AV2-U 2460SKG/65 92/8 M2 rs/ls est 255 968 4 255 969 2

STV-AV2-U 2460SKG/65 92/10 M2 rs/ls mc 255 554 4 255 555 2

STV-AV2-U 2471SKG/35 92/8 M2 rs/ls mc 235 347 5 235 348 3

STV-AV2-U 2471SKG/35 92/8 M2 rs/ls gr 244 264 6 244 265 4

STV-AV2-U 2471SKG/35 92/8 M2 rs/ls est 251 304 5 251 309 6

STV-AV2-U 2471SKG/45 92/8 M2 rs/ls mc 238 871 5 238 872 3

STV-AV2-U 2471SKG/45 92/8 M2 rs/ls gr 247 222 1 247 223 9

STV-AV2-U 2471SKG/55 92/8 M2 rs/ls mc 289 809 6 289 810 9

STV-AV2-U 2471SKG/65 92/8 M2 rs/ls mc 283 192 4 283 193 2

STV-AV2-U 2471SKG/65 92/8 M2 rs/ls est 291 798 0 291 799 8

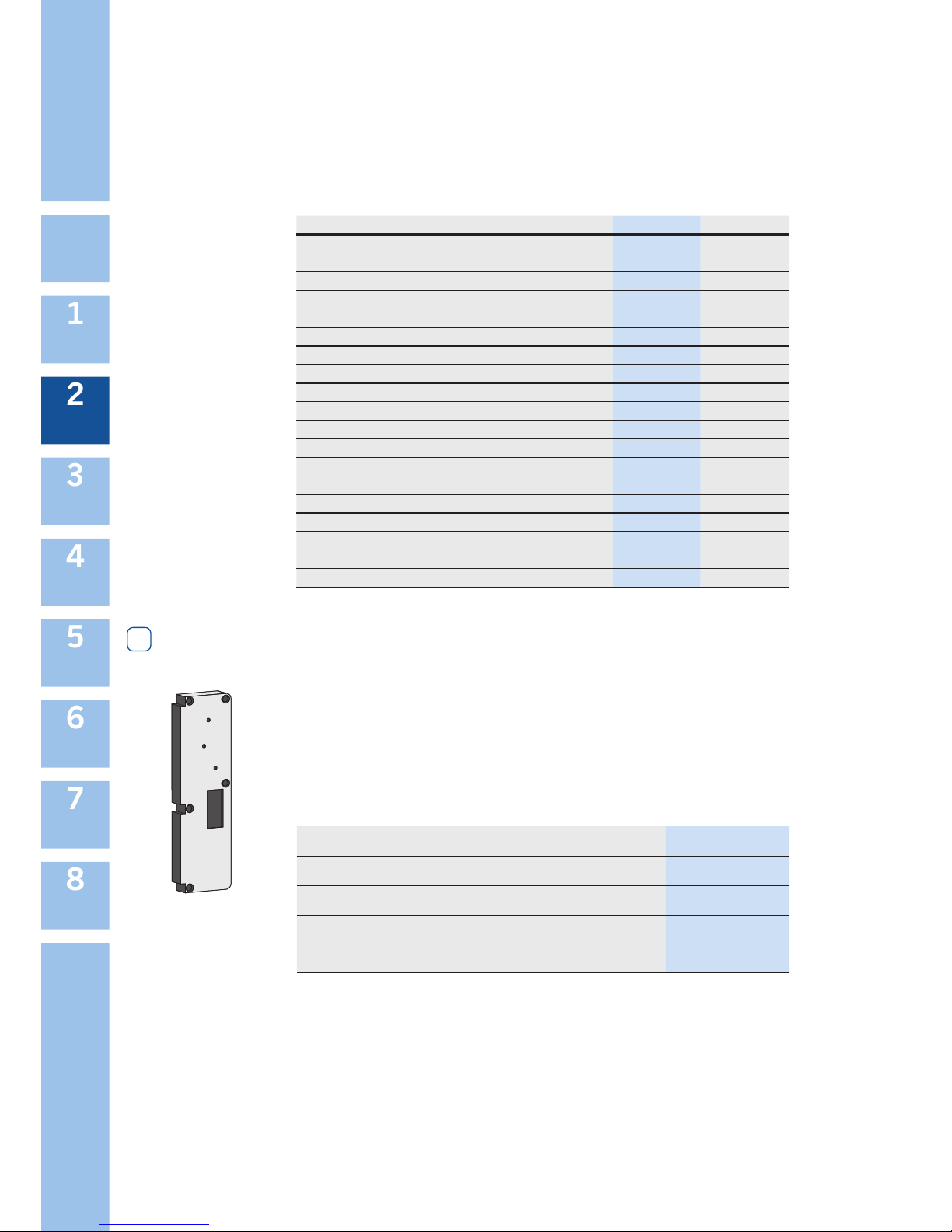

2

Motor housing

Motor housing for powered unlocking, including control, but without cable

• for transponder or wireless remote control

• switching unit for automatic door opener via oating contact

• available mounted or separate

STV-Motor housing EAV

1)

240 992 6

STV-G3 motor housing EAV mounted

2)

240 999 3

STV-Motor housing EAV (auto door opener)

3)

241 022 2

STV-G3 motor housing EAV (auto door

opener) mounted

2) 3)

241 023 1

1)

to retrot simply screw to the automatic locking system

Caution: Pay attention to left-handed thread!

2)

if an automatic locking system + motor housing EAV, moun-

ted, are simultaneously ordered Ü supply of the locking system will have the mounted motor housing

3)

incl. signal (oating contact) for automatic door opener

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

13

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

+

NOTICE! Please observe the following instructions when using a automatic

door opener:

• Ensurethatthemotorcanopentheclosingleafatanytime.

• Afterunlocking, the control unit sends a signal to the automatic door

opener which must them open out immediately.

• Ifthe automatic door drive is triggered at another point of time, mal-

functions can be caused.

• Ifthemainhookisunlockedmanually,thedoormaynotbeactuatedelec-

trically.

3

Extension keep set/single keeps

Select the corresponding standard frame parts in the current

program manual (single keeps/alternatively extension keep set):

Program Manual Wood/PVC/ALU 12/2008 493 476 7

Program Overview keep wood Group 2

Program Overview keep PVCu/Vinyl Group 2

Program Overview keep aluminum Group 2

(Example: prole INOUTIC; frame L30; sash H40 Ü extension

keep set U26-192)

When ordering always indicate the DIN direction RS or LS.

4

Center keep FRA

Center keep for latch and dead bolt of PVCu/Vinyl, aluminum

and wood/Composite entrance doors.

Select the respective keeps according to the prole systems in

the current program manual (see above).

1

2

3

4

5

6

7

8

Print-no. 250 020 1

08/2009

Operating Manual EAV

14

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

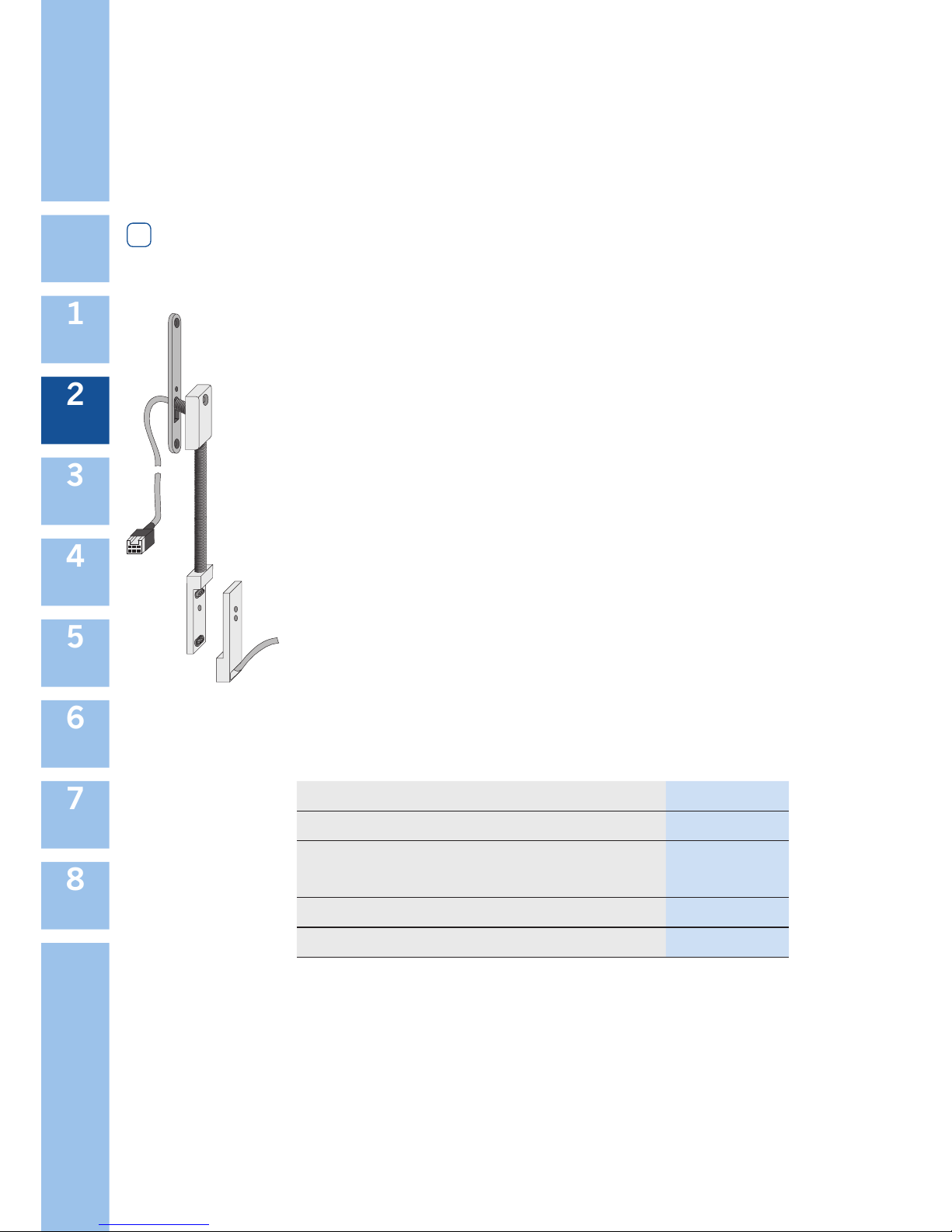

5

Cable transition KÜ-T-STV

Plug-in and lying buried cable transition

• Inserted by plug-in function with retaining screws

• sash part with spring jacket and cable of 2 m [2.187 yd] or

3.5 m [3.829 yd] (plug for motor housing included)

• for STV-SET KÜ-T-integra-EAV sash part with spring jacket

and cable of 1 m [1.094 yd] (cable end with 8-pole plug)

• frame part with cable of 4 m [4.374 yd]

• lying buried in the airgap

• used as the electric interface (max. 24V DC/2A) between the

sash of the door and the frame

• color: silver/grey

• it must not be relieved for 11 mm airgap [0.433”], suitable

for PVCu and aluminum entrance doors (depends on the

system)

• Recommendation: for timber doors (if applicable also for

PVCu/Vinyl or aluminum doors) use the cover plate F16/

F20, to hide the routering for the cable hole, and to prevent

cable damage

STV-Cable transition KÜ-T-STV FL 2 m

1)

234 148 2

STV-Cable transition KÜ-T-STV-FL 3.5 m

2)

493 042 7

STV-SET Cable transition KÜ-T-integra-EAV

FL 1 m + cable 2 m

3)

493 805 0

STV-Cover plate F16 for KÜ-T-STV 275 846 4

STV-Cover plate F20 for KÜ-T-STV 274 764 2

1)

for use with EAV (if applicable BM), sash part 2 m cable +

plug for motor housing

2)

for use with EAV (if applicable BM), sash part 3,5 m cable +

plug for motor housing

3)

for use with EAV and nger scanner ekey home integra, sash

part 1 m Kabel + 8-pole plug for control unit ekey home

integra

8

Accessories

7

Technical

specications

6

Errors

Troubleshooting

5

Maintenance

and care

4

Operation

Programming

3

Installation

2

Product

description

1

Important

information

General

information

Print-no. 250 020 1

08/2009

Operating Manual EAV

15

Aug. Winkhaus GmbH & Co. KG · Berkeser Str. 6 · D-98617 Meiningen · www.winkhaus.de

Subject to technical changes

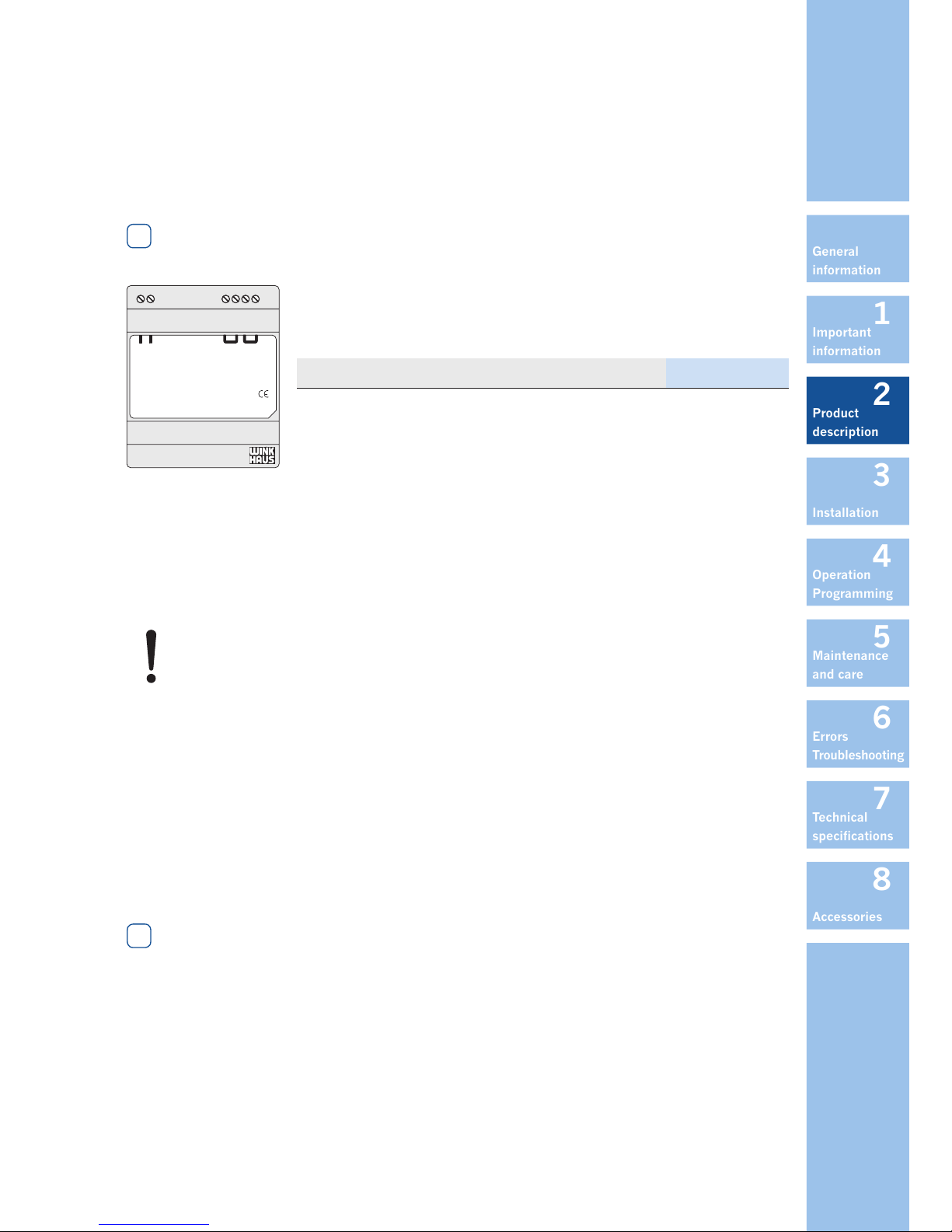

6

Power supply

Power supply unit for EAV: 100 - 240V, 50/60Hz, 12V DC, 2A, to

be installed on a top hat mounting rail

STV-Power supply 12V DC/2A 246 977 7

+

NOTICE!

Operation of a second EAV with the same power supply is not possible.

Suitableforadditionalappliance(e.g.ngerscannerekeyhome integra),

butfollowtheirpowerrequirements(seethenextnotice).

CAUTION! It is not allowed to load the power supply with more than 2A

when using EAV + access control system!

+

NOTICE!

UnlessyouareusingaWinkhauspowersupplyunit,pleasekeepinmindthe

following information:

• exclusivelyforEAV:12VDC(directcurrent),stabilized,min.1,5A

• raisethepowerbytheneedoftheadditionalcomponent(1,5A+power

of theadditional component)when usingEAV+ access control system

(e.g.ngerscanner)

7

Access control systems

From the outside the door is opened via the access control system (transponder, wireless remote control).

+

NOTICE!

VdS acceptance: Only with VdS-tested access control systems!

Netzteil/Powersupply

INPUT: 100 - 240V AC; 50/60Hz

OUTPUT: 12V DC; 2A

+V

-V

+ +

- -

N

L

Loading...

Loading...