WING TUNG MACHINERY WTD 002 Instruction Manual

WTD 002

Ultra-precision Double Head

Extra-Long Drilling Machine

Instruction Manual

永東機械廠

永東機械廠

WING TUNG MACHINERY FTY.

WING TUNG MACHINERY FTY.

香港葵涌大連排道162-170號金龍工業中心第二期14樓G座

香港葵涌大連排道162-170號金龍工業中心第二期14樓G座

14 /F., Fi at G, State 2, Golden Dragon Indus trial Centre,

14 /F., Fi at G, State 2, Golden Dragon Indus trial Centre,

162-170, Tai Lin Pai Road, Kwai Chung, N.T., Hong Kong.

162-170, Tai Lin Pai Road, Kwai Chung, N.T., Hong Kong.

TEL: (852) 2426 4 630 FAX: (852) 2489 9320

TEL: (852) 2426 4 630 FAX: (852) 2489 9320

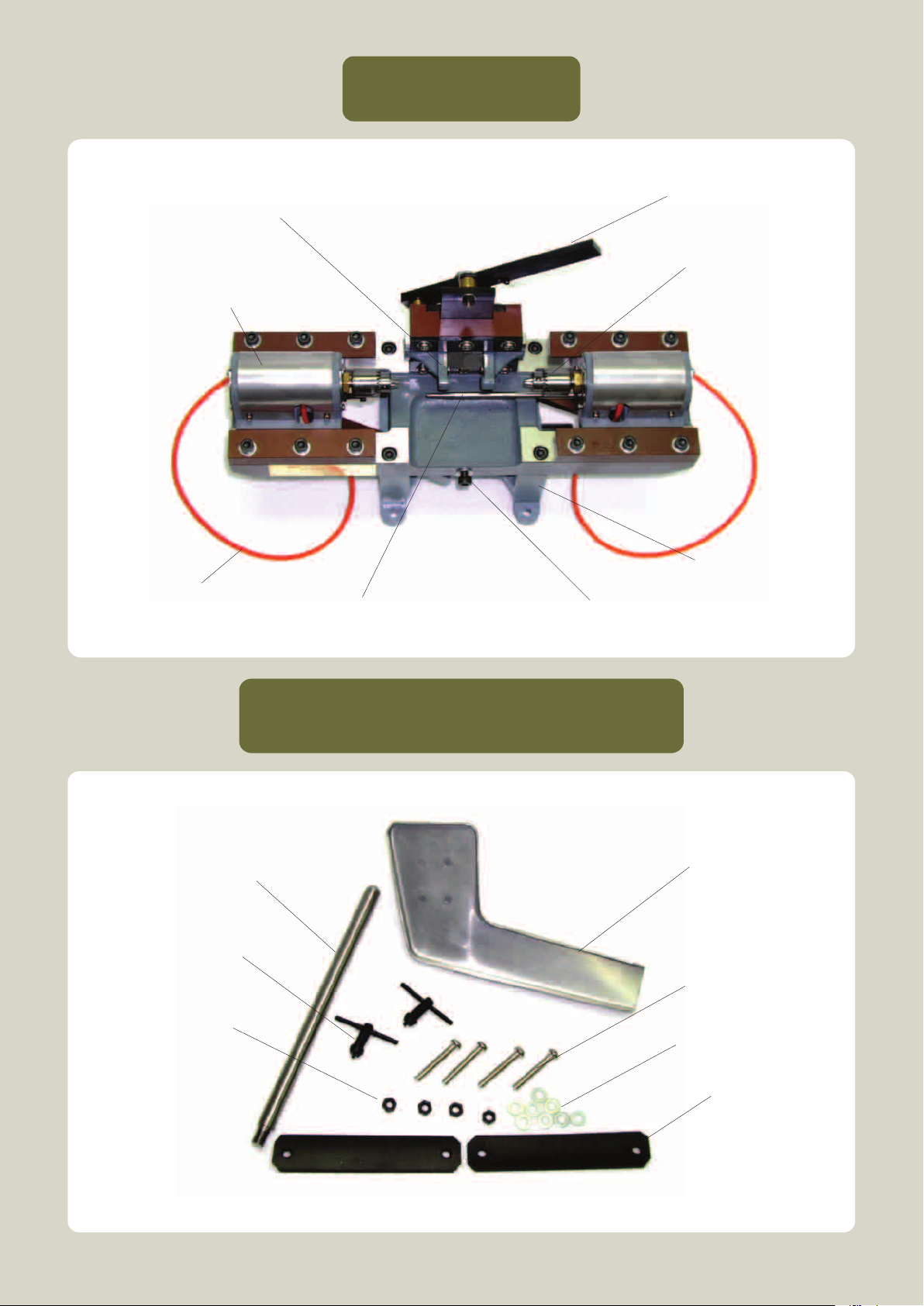

2. Pearl Clamp

1. Drilling Roller

Main Body

3. Mounting Handle

4. Drilling Chuck

8. Rotary Belt

9. Drilling Handle

15. Chuck Key x 2

7. Location Pin

6. Locking Screw

Main Body Accessories

5. Bench Top

10. Transfer Pan

11.Round Head

Bolt x 4

14. Nuts x 4

12. Rings x 8

13. Plastic Pad x 2

MAIN FEATURES FOR THE COMPONENTS (Main Body)

1. Drilling Roller

– To drive the Drilling Chuck with a maximum speed of 16,000 R.P.M.

2. Pearl Clamp

3. Mounting Handle

– To control the movement of Pearl Clamp for mount up or release the Pearl.

4. Drilling Chuck

– To mount up the Ground Bit Insert in proper location.

5. Bench Top

– Support the drilling machine on the worktable and minimize the vibration while

operating.

– To mount up the Clamping Head in proper position.

6. Locking Screw

– For locking the Transfer Pan on the drilling machine.

7. Location Pin

– To adjust the minimum length between the ends of two Ground Bit Inserts in order to

avoid collision when drilling.

8. Rotary Belt

– To connect the Pulleys between the Driving Motor and the Drilling motor.

9. Drilling Handle

– For control the movement of Drilling Motors to drill the Pearl.

10. Transfer Pan

– For storage and transporting drilled Pearls.

11. Round Head Bolts

– For fabricate the drilling machine on the worktable.

12. Rings

– For fabricate the drilling machine on the worktable.

13. Plastic Pad

– Supporting the drilling machine on worktable and absorbing vibration.

14. Nuts

– For fabricate the drilling machine on the worktable.

15. Chuck Key

– For locking the Ground Bit Inserts on the Drilling Chuck.

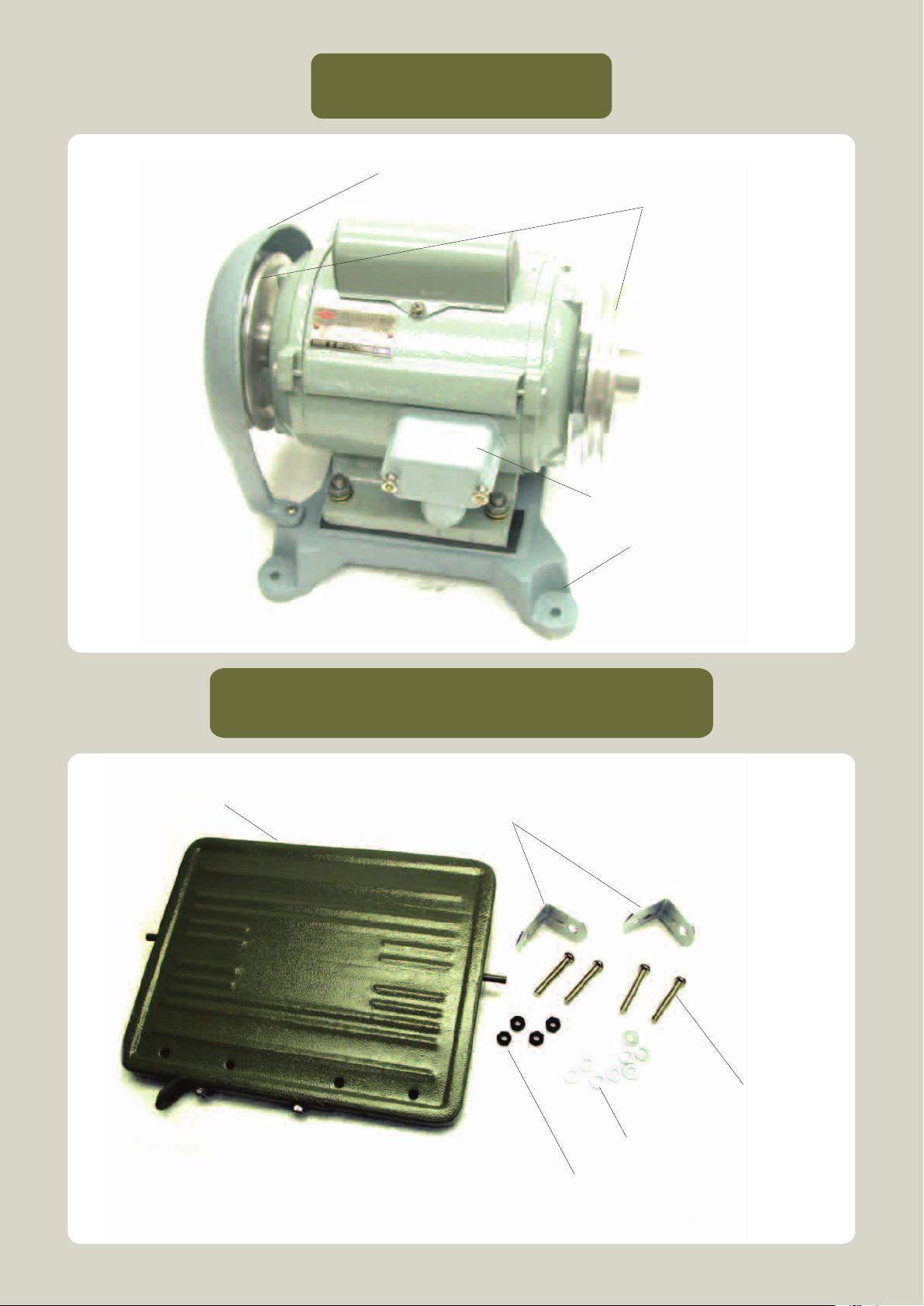

Driving Motor

4. Protective Case

1. Pulley x 2

2. Power Source Cover

3. Mounting Stand

Driving Motor Accessories

5. Stepping Pan

6. L-Joint X 2

7. Round Head Bolt X 4

8. Rings X 8

9. Nuts X 4

MAIN FEATURES FOR THE COMPONENTS (Driving Motor)

1. Pulley

2. Power Source Cover

3. Mounting Stand

– For connecting the Driving Motor on the worktable.

4. Protective Case

– To prevent the Rotary Belt fly off from the Pulley while operating.

5. Stepping Pan

– For controlling the movements of the Pearl Clamp by human footstep operations.

6. L-Joint

– To link up the Stepping Pan and the base of worktable.

– To drive the Drilling Roller by connecting with the Rotary Belt.

– To protect the voltage terminals and avoid current leakage.

7. Round Head Bolts

– For fabricate the Driving Motor on the worktable.

8. Rings

– For fabricate the Driving Motor on the worktable.

9. Nuts

– For fabricate the Driving Motor on the worktable.

Loading...

Loading...