Winget PW170PH13/15, PW100PH10/11/12, PW140PH12, PW150PH8/11/12/14, Taskman PW170DY15 Operator's Handbook Manual

...

OPERATORS

HANDBOOK

TASKMAN

PRESSURE WASHERS

WINGET LIMITED

PLODDER LANE

BOLTON

GT MANCHESTER

U.K.

BL4 0LR

Tel: ++ 44 (0) 1204 854650

Fax: ++ 44 (0) 1204 854663

www.winget.co.uk

Issue 3 2010

EDGEFOLD INDUSTRIAL ESTATE

P.O. Box 41

CONTENTS

1 Introduction

2 Declaration of Conformity

4 Identification

5 Warranty Terms & Conditions

7 Safe Working

12 Operation

18 Maintenance and Service

22 Technical Information

25 Parts Listings

INTRODUCTION 1

The contents of this Handbook although correct at the time of

publication, may be subject to alteration by the manufacturers

without notice.

Winget Limited operate a policy of continuous product development.

Therefore, some illustrations or text within this publication may differ

from your machine.

WARNING: The operator must read both this handbook and the

Engine Operators Handbook and be familiar with all the controls

before attempting to operate this machine.

The contents of this handbook are designed as a guide to the

machines controls, operation, working capacities and maintenance. It

is not a training manual.

These are the original Instructions in the English Language

issued by Winget Limited & TASKMAN to comply with the requirements

of Directive 2006/42/EC

DECLARATION

OF

CONFORMITY

We: Winget Limited,

Of P.O. Box 41, Plodder Lane, Bolton, Lancs, England BL4 0LR declare that

the following TASKMAN Pressure Washers:Models:- PW100PH10/11/12, PW140PH12, PW150PH8/12/14, PW170PH15

PW170DY15, PW200PH13/15/21, PW200DY15, PW90PH12

Serial Numbers:- . 1000-99000 .

To which this declaration relates, with a maximum net installed power of

6.5Kw. Having been tested in accordance with the Conformity Assessment

Procedure detailed in Annexe V of Directive 2000/14/EC is in conformity with

the provisions of the “Noise Emission in the Environment by Equipment for

use Outdoors Directive 2000/14/EC”. Representative samples of this

equipment was tested and Sound Power Levels (Lwa) recorded of:-

PW100PH10 102db

PW100PH11 97db

PW100PH12 101db

PW140PH12 105db

PW150PH8 102db

PW150PH12 105db

PW150PH14 103db

PW170PH15 104db

PW170DY15 111db

PW200PH13 107db

PW200PH15 107db

PW200PH21 105db

PW200DY15 110db

PW9012 104db

We guarantee under the provisions of the above Directive (2000/14/EC) that

the Sound Power Levels for these equipment models will not exceed :-

PW100PH10 104db

PW100PH11 99db

PW100PH12 104db

PW140PH12 107db

PW150PH8 104db

PW150PH12 107db

PW150PH14 106db

PW170PH15 106db

PW170DY15 114db

PW200PH13 109db

PW200PH15 109db

PW200PH21 108db

PW200DY15 114db

PW9012 106db

We also declare that the above equipment is also in accordance with the

following EC Directives:-

2006/42/EC 2004/108/EC

Bolton 24.03.10 S. Hodge .

Place and date of issue Name and signature or equivalent

The above named person is also responsible for holding the Technical Documentation

applicable to the product to which this declaration relates and may be contacted at the

address which appears at the head of this declaration

Please take care of this document, as duplicate copies are not available.

This document is in accordance with EN45014:1989

marking of authorised person.

Joint Managing Director

Position

IDENTIFICATION 4

PW90PH12 PW100PH11 PW140PH12

PW100PH12

PW140PH12T PW100PH10GC PW170PH15

PW150PH12GC PW200PH13

PW150PH14

PW200PH15 PW200DY15E PW200DY15ES

PW200PH21

WARRANTY TERMS & CONDITIONS 5

Winget Limited assures you that if any of the parts identified within

the Parts section of this manual become defective due to faulty

manufacture or materials within 6 months from the date of purchase

when used commercially, or 12 months for domestic customers, the

part will be repaired or replaced under warranty free of charge by any

authorised Winget Limited Distributor.

Warranty repairs must be carried out by an authorised distributor,

unless prior agreement has been agreed in writing with the Warranty

Department at Winget Limited.

This warranty is given to the first owner and may be transferred to

subsequent owners for the balance of the Warranty period.

Winget Limited’s liability only extends to the costs of repair or

replacement of the faulty parts and necessary labour charges

involved in the repairs. The company accepts no liability for any

consequential loss, damage or injury, resulting directly or indirectly

from any defect in the goods.

Items not covered by Warranty and considered to be the customers

responsibility include normal maintenance services; replacement of

service items and consumables; replacement required due to abuse,

accident, misuse or improper operation; replacement of wearable

items e.g. hoses, lances, pins bushes etc.

All Warranty repairs on the petrol or diesel engine must be carried out

by the engine manufacturers authorised distributor.

The Warranty will not apply where the equipment is modified,

converted, or used for purposes other than those for which it was

designed, unless clearance for the modifications etc. have been

granted by Winget Limited in writing.

The Pre-delivery Inspection & Warranty Registration Document must

be completed correctly and returned to Winget Limited within 7 days

of the date of sale. Failure to do so could result in any subsequent

Warranty claim being rejected.

No claim will be considered if other than genuine Winget Limited

parts, which must be obtained via an authorised distributor,

WARRANTY TERMS & CONDITIONS 6

are used to effect a repair, or if lubricants other than those

recommended by Winget Limited and the engine manufacturers are

used.

The equipment must be serviced and maintained in accordance with

the service schedules laid down in this handbook. Evidence that

these have been complied with may be required before Warranty

claims are reimbursed.

Winget Limited have a policy of continuous product improvement

and reserve the right to change specifications without notice. No

responsibility will be accepted for discrepancies, which may occur

between the specification of machines and the descriptions

contained in publications.

SAFE WORKING 7

Safety is the responsibility of all persons working with and around

this machine. Think “SAFETY” at all times. Read and remember the

contents of this and the Engine Operators Handbook.

Any modifications to the machine will affect its working parameters

and reduce built in safety factors. Refer to Winget Limited before

fitting any non-standard equipment or parts. Winget Limited accept

no responsibility for any modifications made after the machine has

left the factory, unless previously agreed in writing. Winget Limited

will accept no liability for damage to property, persons or the

machine if failure is brought about due to such modifications, or

fitment of spurious parts.

This machine produces water at HIGH PRESSURE and as such is

potentially dangerous in operation. The high pressure water jet must

never be directed at any person, animal or at any electrical

equipment under any circumstances. If in doubt as to the suitability

of this machine for a particular task refer to Winget Limited.

Never commence work until the daily service checks have made

carried out.

Always report faults as soon as they are discovered.

Never fill fuel tanks whilst the engine is running.

Never leave the machine unattended with the engine running.

Never attempt to disconnect the high pressure hose from the

machine without first dumping any residual water pressure by first

pulling the trigger gun (Engine stopped)

Never use this equipment in areas of poor lighting.

Always wear eye and ear protection when using this machine.

Always keep the working area clear of people and animals

Always stay alert and watch what you are doing.

SAFE WORKING 8

Always be aware of the Lance Reaction Force when operating this

machine.

Always know how to stop the machine and bleed the water pressure

quickly.

Never over reach or stand on unstable supports, keep your footing

and balance at all times.

Never operate this machine from ladders or step ladders.

Never allow the machine to run dry of water or serious permanent

damage will be caused to the pump unit.

Never run the machine for more than 5 minutes with the trigger gun

in the closed position, this could result in a rapid rise in the water

temperature, which may damage the seals in the pump.

Never operate this machine under the influence of alcohol or drugs,

(many forms of medication can cause drowsiness) or when tired.

Never connect the machine to a hot water supply unless it is

specifically designed to handle hot water.

Always observe local Water Authority and Environment Agency

Bylaws when connecting this equipment to a mains water supply.

Always ensure the water supply is clean and free from contaminants.

Never allow contaminated water to enter drains, sewers or local

water courses.

Never allow unauthorised or untrained personnel to operate this

machine.

Never operate on any inclined or unstable surface.

Always drain the water from the hoses and pump on completion of

work, especially in cold weather, to prevent serious damage do not

allow the machine to freeze, protect from Frost.

Never use ether based cold start aids in aerosol cans to aid cold or

difficult starting.

SAFE WORKING 9

Never smoke whilst filling the fuel tank, mop up any fuel spills

immediately and in any event before running the engine and allow

time for any vapours from the spilled fuel to disperse before starting

the engine.

Never run the engine in an enclosed or confined area, exhaust fumes

in enclosed areas can kill.

Never stop diesel engines by means of the decompression lever,

serious damage can be caused to the cylinder head, piston and

valves.

Always avoid contact with the exhaust muffler, this can get very hot

when the engine is running and remains so for some time afterwards.

Always “dump” residual water pressure from the system before

leaving the machine. With the engine stopped pull the trigger until all

pressure is dissipated

Never leave the machine unattended with pressure in the water

system.

Always, where possible, work on or close to engines or machinery

when carrying out servicing or any maintenance, only when they are

stopped, if this is not practical, remember to keep tools, test

equipment and all parts of your person well away from moving parts.

Always wear correctly fitting clothing when carrying out servicing,

loose or baggy clothing can be extremely dangerous when working

on running engines or machinery.

Always “dump” pressure from the water system before carrying out

any kind of maintenance or adjustment.

Never allow unqualified personnel to attempt to repair, remove or

replace any part of the machine.

Always obtain advice before mixing oils; some are incompatible, if in

doubt completely drain, flush and refill.

SAFE WORKING 10

Many liquids used in this machine are harmful if taken internally or

splashed into the eyes. In the event of accidentally swallowing oils or

fuels, seek qualified medical assistance and advice.

Always dispose of waste oils and fuels into designated waste oil

storage tanks. If storage tanks are not available, consult your

distributor or local authority for the addresses of local designated

disposal points. Improperly discarded waste oils pose a threat to

wildlife. It is illegal to dispose of waste oil into drains, or water

courses or to bury it. The Environment Agency have the power to

impose heavy fines for breaches of the above advice.

Never allow oils and fuels to come into regular contact with skin.

This can lead to serious skin diseases, including, medical evidence

suggests, skin cancer. ALWAYS wear protective gloves when

handling oils and fuels whether topping up, draining or refilling.

Always wash your hands if oils or fuels come into contact with the

skin.

Always store fuels in small quantities in the correct specially

designed containers, which can be securely fastened. Store fuel in a

cool, well ventilated store away from sources of ignition.

Always top up the fuel tank at the end of a working day or shift to

prevent the formation of condensation on the inside of the fuel tank.

Always ensure that any Warning, Safety or Advisory Decals attached

to the machine are legible and clean, replace if damaged, defaced or

missing.

DIESEL POWERED UNITS ONLY

To avoid damage to the water pump and gearbox never allow the

engine to run on idle/tick over speed for prolonged periods of time.

ELECTRICAL STARTING SYSTEMS

Starting engines fitted flywheel charge windings with the battery

disconnected will cause irreparable damage unless the stator leads

to the rectifier/regulator have been removed.

SAFE WORKING 11

ELECTRICAL STARTING SYSTEMS (Continued)

Never remove any electrical cable while the battery is connected in

the circuit.

Only disconnect the battery with the engine stopped and all switches

in the off position

Always ensure that cables are fitted to their correct terminal, a short

circuit or reversal of polarity will ruin diodes and transistors.

Never connect a battery into the system without checking that the

voltage and polarity are correct.

Never flash any connection to check the current flow.

Never experiment with any adjustments or repairs to the system.

Always disconnect battery and charge windings before commencing

any electric welding when a pole strap/earth lead is connected

directly or indirectly to the engine.

Batteries contain sulphuric acid, which can cause severe burns, if

acid is splashed onto the ski, eyes or clothes flush with copious

amounts of fresh water and seek immediate medical aid.

WARNING & ADVISORY DECALS

The following warning and advisory decals are applied to the

machine

‘CE’ Decal Wear Eye Protection read operators manual

OPERATION 12

Never commence work until the daily service checks have been

carried out.

WATER SUPPLY CONNECTION

High speed pumps can be fed from mains water tap pressure

(POSITIVE PRESSURE) or draw from a tank or sump via suction

(NEGATIVE PRESSURE) however if used on suction (NEGATIVE

PRESSURE) for prolonged periods premature seal wear is likely to

result.

To run on either option please follow the instructions below :MAINS TAP PRESSURE (POSITIVE)

A clean water supply with a minimum of 15 Litres (3.3gallons) per

minute flow rate with a minimum pressure of 2 Bar (30psi) is

required. The inlet/supply hose should preferably have an internal

bore dimension of 19mm (3/4”) the minimum acceptable internal bore

dimension is 13mm (1/2”)

DRAWING FROM A TANK OR SUMP-SUCTION (NEGATIVE)

To use the machine to draw from a tank or sump the suction hose

assembly should be used. The suction hose has an internal bore

dimension of 19mm (3/4”) and should be as short as possible. The

“suction head “ should be kept to a minimum and in any event

should not exceed 610mm (2.0”) The water should be clean and the

tank/sump of sufficient capacity to prevent the pump running dry

whilst in use.

OPERATION 13

Never commence work until the daily service checks have been

carried out.

PRIMING THE WATER PUMP

Each time the machine is put into operation the water pump will

require priming before it will operate correctly. Priming the pump and

hoses removes any air which may be trapped in the system and

which may affect the correct operation of the pump and prevent the

full working pressure from being reached.

To prime the water pump follow the instructions below :-

Connect up the suction hose, if drawing from a tank keep the suction

hose as short as possible and never exceed 3 metres.

Start the engine and run up to 3/4 full speed

Hold the trigger gun open until a constant flow of water emerges, this

can take as long as 30 seconds, if after 30 seconds no water has

emerged stop the engine and investigate the cause.

Close trigger, increase the engine speed and use in normal manner.

OPERATION 14

Never commence work until the daily service checks have been

carried out.

LOW PRESSURE CHEMICAL APPLICATION

The Low Pressure Chemical Application facility is an optional extra

and may/may not be available on the machine.

Totally immerse the filter on the chemical suction hose in the

chemical solution container, connect the opposite end of the hose to

the chemical induction on the water pump.

The model PW9012 is provided with a metering control knob on the

front panel of the machine when the Low Pressure Chemical

Application facility is available. Turn the knob Anti-Clockwise to

increase the flow of chemical, turn Clockwise to reduce the flow.

Dependant on the type of Lance supplied follow the instructions

below induce the flow of chemical through the LANCE, Note chemical

will only be induced at low pressure.

One-Piece Lance assembly, turn the chemical applicator at the end of

the Lance anti-clockwise when viewed from the trigger gun. After a

short delay chemical will be automatically dispensed. To stop the

chemical application, turn the chemical applicator at the end of the

lance clockwise. After a short delay whilst the residue of chemical

works its way through the system the chemical flow will turn off

completely.

Two-Piece Lance, the end of the lance has a Multireg nozzle system,

this allows the angle of the spray to be adjusted by rotating the

nozzle and the pressure to be lowered by pushing the nozzle away

from the end of the lance. The amount of chemical flow induced is

regulated by the knob on the control panel. To stop the flow of

chemical, pull the nozzle assembly back towards the lance.

If chemicals have been used through the machine it is essential that

clean water is allowed to flush through the system until the chemical

residue completely disappears before the engine is stopped.

After the engine is stopped ensure all residual pressure in the

system is released by pulling the trigger gun.

OPERATION 15

Never commence work until the daily service checks have been

carried out.

STARTING THE ENGINE

Petrol Driven Units

Read the engine operators manual before attempting to start the

engine.

Connect the inlet/suction hose to a suitable tap or completely

immerse the inlet filter in the tank or sump. Turn on the tap

Ensure the lance is securely stowed

Turn on the fuel tap.

Close the choke lever, do not use the choke if the engine is warm or

the ambient air temperature is high.

Turn the engine on/off switch to “on”

Move the throttle lever slightly to increase the speed, do not fully

open the throttle at this stage.

Pull the starter grip lightly until resistance is felt, then pull briskly. Do

not wrap the starter cord around the hand, serious personal injury

could be sustained if the engine “kicks back” or backfires.

Open the choke as the engine warms up.

Prime the water pump as described above.

Open the throttle to the fully open position.

Do not allow the engine to run for more than 5 minutes with the

trigger gun closed, the water temperature will rapidly rise and will

cause damage to the water pump seals.

MODEL PW200 ONLY

As water enters the pump it will discharge through the EASYSTART

valve in the pump to atmosphere, this is correct. When the trigger

OPERATION 16

gun is operated the EASYSTART valve will close and the water will

stop discharging. Each time the trigger gun is closed water will

discharge through the EASYSTART valve again. This is a built in

safety feature of this unit to avoid overheating the pump and to ease

starting. The EASYSTART valve also releases any residual pressure

in the system automatically when the engine is stopped.

Never commence work until the daily service checks have been

carried out.

STARTING THE ENGINE

Diesel Driven Units

Read the engine operators manual before attempting to start the

engine.

Connect the inlet/suction hose to a suitable tap or completely

immerse the inlet filter in the tank or sump. Turn on the tap

Ensure the lance is securely stowed

Turn on the fuel tap, if fitted.

Move the governor lever/engine stop control to the start position.

Most small diesel engines are fitted with automatic decompression

levers, operate the lever as described in the engine operators

manual.

Grasp the starter grip and pull lightly until resistance is felt, then

return to the normal position. Still grasping the starter grip pull

briskly with a “jerking” motion. The engine should now start running

normally. If not, repeat the starting procedure. Do not wrap the

starter cord around the hand, serious personal injury could be

sustained if the engine “kicks back” or backfires.

Do not allow the engine to run for more than 5 minutes with the

trigger gun closed, the water temperature will rapidly rise and will

cause damage to the water pump seals.

OPERATION 17

To avoid damage to the water pump and gearbox (if fitted) never

allow the diesel engine to run on idle/tick over speed for prolonged

periods of time.

MODEL PW200 ONLY

As water enters the pump it will discharge through the EASYSTART

valve in the pump to atmosphere, this is correct. When the trigger

gun is operated the EASYSTART valve will close and the water will

stop discharging. Each time the trigger gun is closed water will

discharge through the EASYSTART valve again. This is a built in

safety feature of this unit to avoid overheating the pump and to ease

starting. The EASYSTART valve also releases any residual pressure

in the system automatically when the engine is stopped.

STOPPING THE ENGINE

Petrol Driven Units

If the machine has been used to apply chemical ensure it is

thoroughly flushed through with clean water before stopping the

engine.

Close the fuel tap and turn the engine switch to off, release any

residual pressure in the system by pulling the trigger gun.

In an EMERGENCY turn the engine switch to off.

STOPPING THE ENGINE

Diesel Driven Units

If the machine has been used to apply chemical ensure it is

thoroughly flushed through with clean water before stopping the

engine.

In an EMERGENCY move governor lever/engine stop control to the

stop position.

Never stop diesel engines by means of the decompression lever,

serious damage can be caused to the cylinder head, piston and

valves.

MAINTENANCE AND SERVICE 18

DAILY SERVICE CHECKS

Read the engine operators manual for items in addition to those

listed below.

Check condition of suction and pressure hose and lance.

Check suction filter, (if fitted)

Check the fuel level.

Check condition of air filter element, and clean replace as

necessary.

Check the oil levels in the engine, gearbox if fitted, and pump.

Refer to the engine operators handbook for advice on checking

engine oil level and for the correct grade of engine oil.

Pumps and gearboxes are fitted with either sight glasses or level

plugs/dipsticks.

In the case of sight glasses the oil level is correct when it is halfway

up the glass, some sight glasses are marked with a red dot to

indicate the correct level.

In the case of level plugs the oil level is correct when the oil is level

with the bottom of the threaded hole or if it just begins to trickle out

when the plug is removed.

In the case of dipsticks the correct level will be marked on the

dipstick.

Top up with the correct grade of oil, refer to the engine operators

handbook or the Technical Information section later in this

handbook.

If fitted, check tyre pressures.

Check the security of any covers or guards, do not use if any are

missing.

Check the security of engine/gearbox/water pump retaining nuts and

bolts.

MAINTENANCE AND SERVICE 19

Check all controls for correct operation.

Report any faults or missing equipment or damage immediately.

WEEKLY SERVICE CHECKS

Read the engine operators manual for items in addition to those

listed below.

All the daily service checks plus check condition of water filter and

clean as necessary, the water filter is normally located in the water

inlet port of the pressure relief valve, see page 20 to identify the type

of filter installed.

FIRST 20 HOURS

Change engine, pump and gearbox oils. Refer to the engine

operators manual for the correct grade of engine oil. Refer to the

Technical Information section later in this manual for the correct

grade of pump and gearbox oils.

EVERY 150 HOURS

Read the engine operators manual for items in addition to those

listed below.

Change pump and gearbox oils.

Refer to the Technical Information section later in this manual for

the correct grade of pump and gearbox oils.

Every 500 HOURS OR ANNUALLY

Read the engine operators manual for items in addition to those

listed below.

Change pump and gearbox oils.

Refer to the Technical Information section later in this manual for

the correct grade of pump and gearbox oils.

MAINTENANCE AND SERVICE 20

INLET FILTERS-IDENTIFICATION

CLEAN OR REPLACE INLET FILTERS FREQUENTLY

Filter Type A

Filter Type B

MAINTENANCE AND SERVICE 21

FAULT CAUSE REMEDY

Inlet Filter blocked or dirty

Pump running normally but

pressure low on installation

Pump running normally but

pressure low on installation

Fluctuating pressure

Pressure low after period of

normal use

Pump noisy

Presence of water in the oil

Water dripping from below

pump

Oil dripping Oil seal worn Check & replace if required.

Pump sucking air

Valves sticking

Unloader valve seat faulty

Inlet Filter blocked or dirty

Nozzle incorrectly sized

Worn piston packing

Inlet Filter blocked or dirty

Valves worn

Blockage in valve

Pump sucking air

Worn piston packing

Inlet Filter blocked or dirty

Nozzle worn

Suction or delivery valves

worn or blocked

Worn piston packing

Inlet Filter blocked or dirty

Air in suction lines

Broken or weak suction or

delivery valve springs

Foreign matter in the valves

Worn bearings

Excessive temperature of

water

Oil seals worn

High Humidity in the air

Piston packing worn

Piston packing worn

Plunger retainer O ring worn

Leaking connections

Check & Clean Inlet Filter

Check water supply &

possibility of air ingress.

Check & clean or replace.

Check & replace if required.

Check & Clean Inlet Filter

Check & replace if required

Check & replace if required

Check & Clean Inlet Filter

Check & replace if required.

Check & clean if required.

Check water supply & air

ingress at joints in suction

line.

Check & replace if required.

Check & Clean Inlet Filter

Check & replace if required.

Check & replace if required.

Check & replace if required.

Check & Clean Inlet Filter

Check water supply &

connections in suction line.

Check & replace if required.

Check & clean if required.

Check & replace if required.

Reduce below 75

centigrade.

Check & replace if required.

Check & reduce oil change

intervals.

Check & replace if required.

Check & replace if required.

Check & replace if required.

Check & tighten or reseal.

Excessive vibration in the

delivery line

Engine will not start

No water from nozzle

Inlet Filter blocked or dirty

Valves probably blocked

Switch in correct position

Fuel line is switched off.

Battery flat

Oil Alert activated (if fitted)

Inlet Filter blocked or dirty

Unloader in constant bypass

Blocked nozzle

Check & Clean Inlet Filter

Check & clean if necessary.

Check & correct.

Check fuel line & tank.

Check battery connections.

Check engine oil level.

Check & Clean Inlet Filter

Check & turn knob to

pressure.

Check & clean if necessary.

TECHNICAL INFORMATION 22

Model

PW90PH12

PW100PH11

PW100PH12

PH150PH8

PW140PH12

PW140PH12T

PW100PH10GCC

PW150PH12GC

PW150PH12GCC

PW150PH14

PW170PH15

PW200PH13

PW170DY15E

Pressure

Psi/Bar

1350/90

1500/100

1500/100

2250/150

2000/140

2000/140

1500/100

2250/150

2250/150

2250/150

2450/170

3000/200

2450/170

Engine

Honda

Petrol

GX120

Honda

Petrol

GX120

GX160

GX160

Honda

Petrol

GX160

Honda

Petrol

GX160

Honda

Petrol

GC135

GC190

GC190

Honda

Petrol

GX200

GX270

GX270

Yanmar

Diesel

L70

Flow

Ltr/min

12 N/A W1210 30 440x340x520

Gearbox

Type

11

N/A

12

8

12 YES W140 42 510x450x600

12 YES W140 48 640x600x1000

10

N/A

12

12

14

YES

15

N/A

13

N/A

15

N/A

Pump

Type

WW909

WW909

TT1508

AXD2520

TT512C

AXD3026

W154

WW961

UH2013

WW961

Weight

(Kg)

30

32

34

34

44

56

57

75

Dimensions

HxWxL(mm)

470x410x540

820x530x790

800x550x660

PW200PH15

PW200PH21

PW200DY15E

3000/200

3000/200

3000/200

Honda

Petrol

GX340

GX390

Yanmar

Diesel

L100

15

21

15

YES

YES

YES

WS201

WS202

WS201 128 780X660X1015

85

86

720x600x990

TECHNICAL INFORMATION 23

PW200DY15ES

3000/200

Yanmar

Diesel

L100

15 YES WS201 148 850x600x100

TECHNICAL INFORMATION 24

LUBRICANTS

Water Pumps

SAE20W/50 Engine oil

Gearbox

SAE90 Gear Oil

Engines

Yanmar L100 Diesel:- 10W30 or 20W40 API Classification CD

Honda Petrol Engines:- 10W30, 10W40, 15W40 API Classification

SF or SH

PARTS INFORMATION 25

TASKMAN WATER

PUMPS

PARTS SECTION

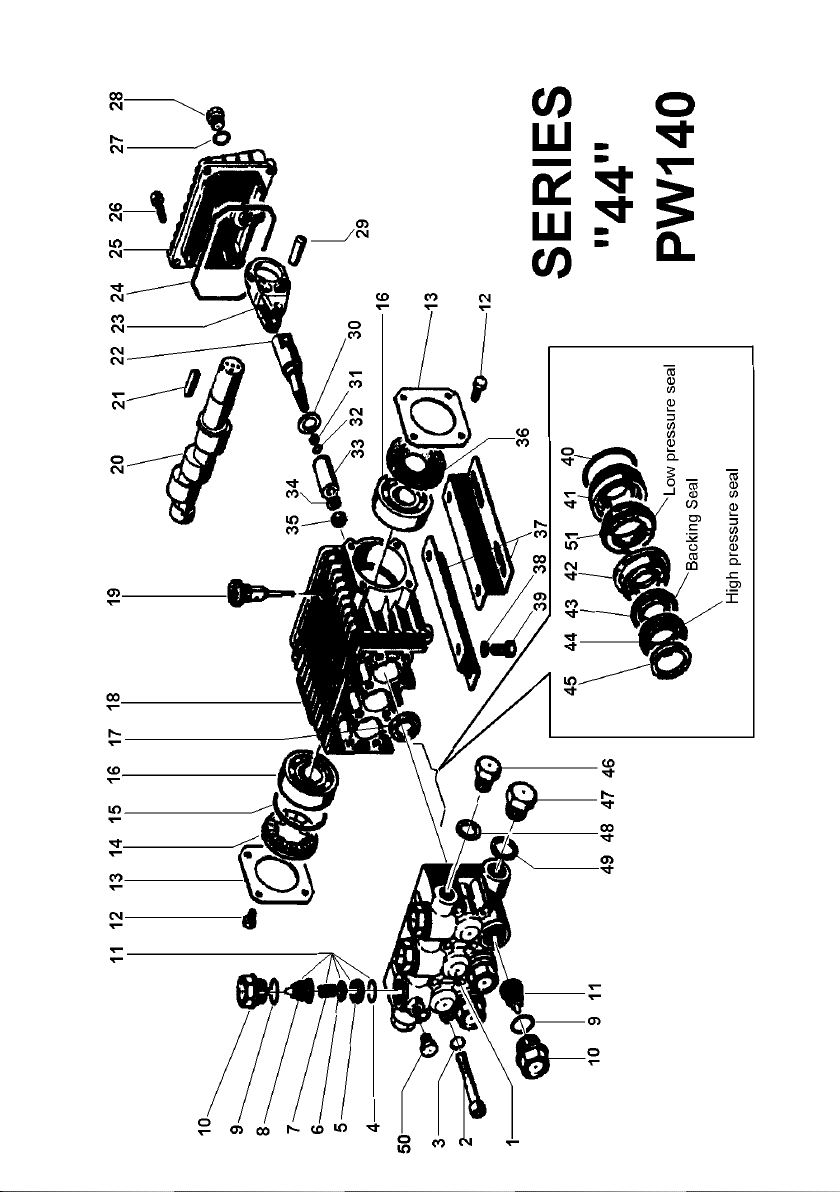

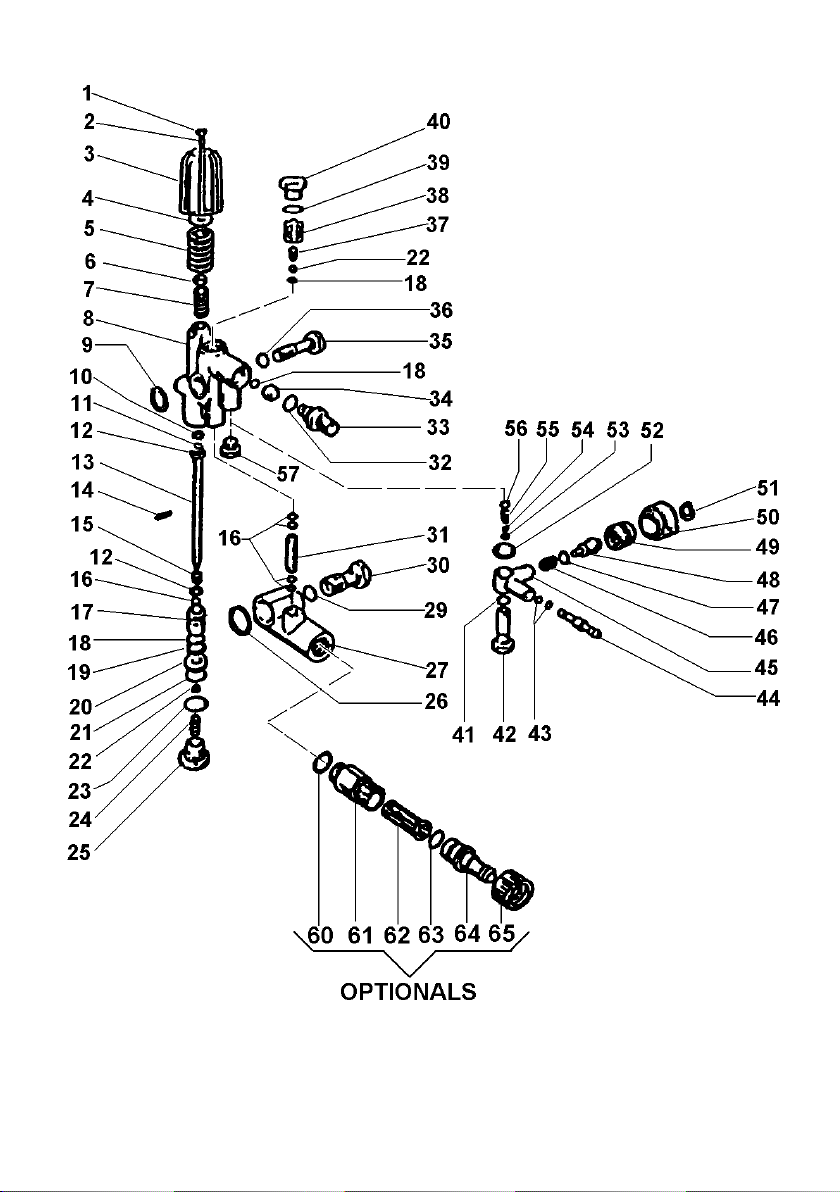

SERIES 44 PLUNGER PUMP FOR MODEL PW140

CONTROL SET W2-W2L FOR MODEL PW140

RS99 REDUCTION GEARBOX FOR MODEL PW140

VERSION V BUILT IN UNLOADER FOR PW140

Series 44

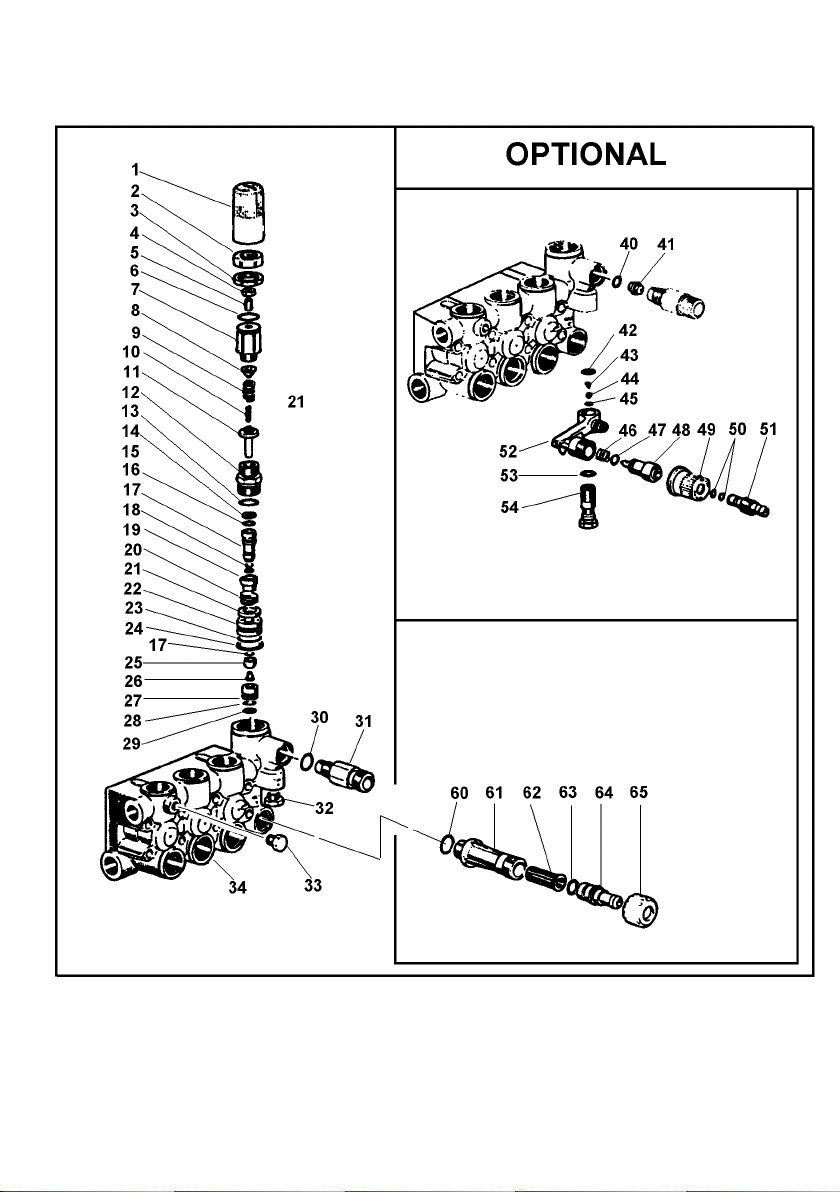

SERIES WS201 PLUNGER PUMP FOR PW200

RS151 REDUCTION GEARBOX FOR PW200

VRM UNLOADER VALVE ART612 FOR PW200

QUICK CONNECTION FOR PW200

SERIES W1507 PUMP FOR PW9012 (NPP12/9)

VERSION V UNLOADER VALVE FOR PW9012

SHAFTS & FLANGES VERSION A-B-C FOR PW9012

SERIES 1511 PLUNGER PUMP FOR PW100PH11

WW1511V UNLOADER VALVE FOR PW100PH11

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and

some of its constituents are

known to the State of

California to cause cancer,

birth defects and other

reproductive harm

Loading...

Loading...