Page 1

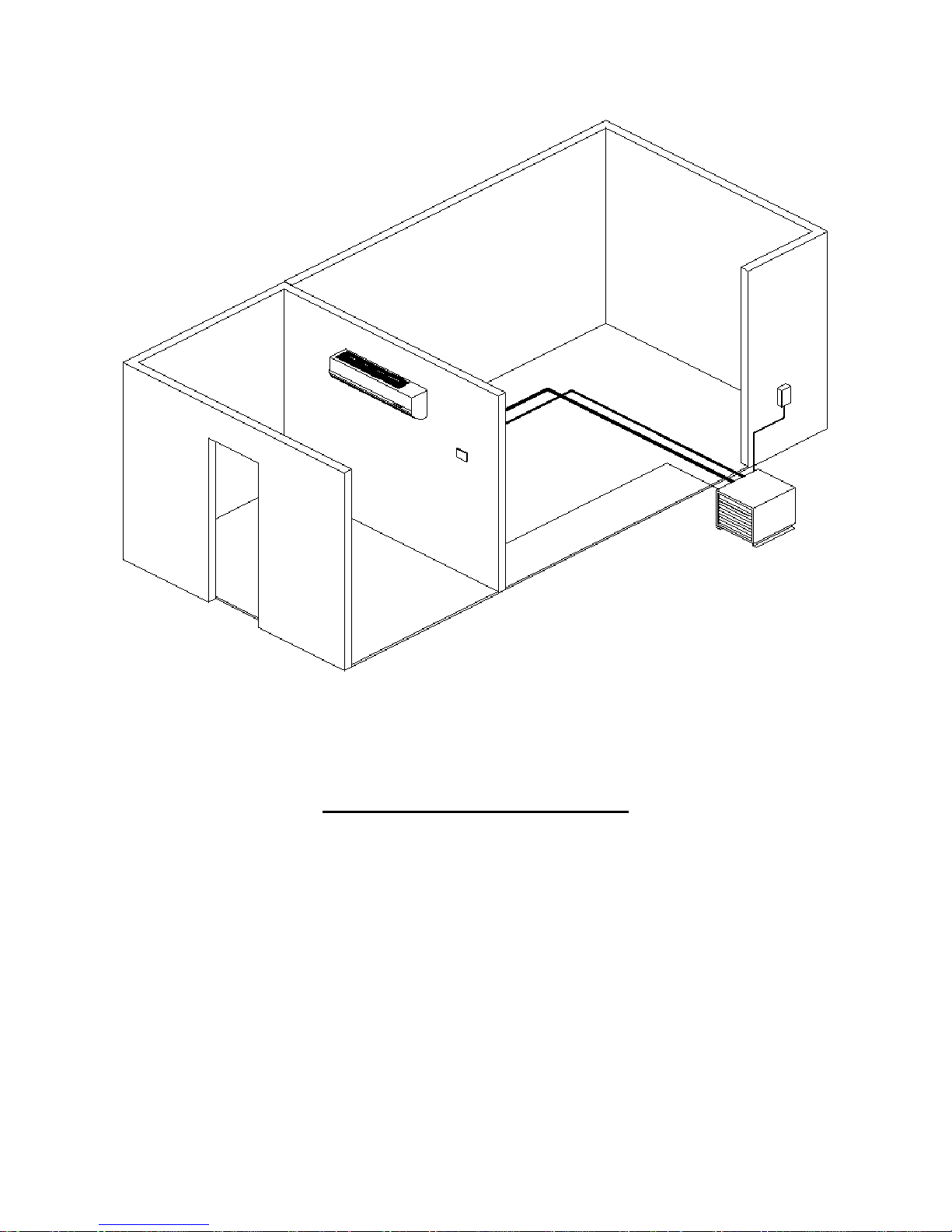

Wine Zone Ductless Split System

Requires an HVAC technician to install and charge unit

Can be charged with R-22, NU-22B, MO99, or R-427A refrigerants

Electric connections for evaporator are hard wired to the condenser

Industrial grade for longer life

Indoor and outdoor condensing units available

Field supplied drain line, refrigerant, and electric connections required

WZDS9100 #2

1

Page 2

Supplies and Materials Needed for Installation

1. Condenser pad

2. Required electrical services

A. Dedicated service for condenser

B. 5-conductor low voltage wire from thermostat to condenser control panel

3. R-22, Nu-22B, MO99, or R-427A refrigerant for system

4. Miscellaneous hardware, brackets, sealant, reducers, etc…

5. An accurate digital probe style thermometer

6. Tools and equipment needed to perform the installation

7. Additional refrigerant line if line set exceeds 50 ft. in length. All of the 3/8” x 3/4” line set for line sets

81 to 200 equivalent feet.

Supplies and Materials Furnished with Equipment

1. Condenser with pre-wired control panel

2. Pre-assembled outdoor upgrade kit, if ordered

3. Wall mounted evaporator modified for system

4. Thermostat

5. 50 ft. of 3/8” x 5/8” line set

6. Filter drier, may be factory installed

7. Sight glass, may be factory installed

8. Fan cycle control, mounted and wired.

9. Wiring diagrams

10. Installation instructions with copy of Diagnostic Sheet

11. Warranty information with copy of Diagnostic Sheet

A qualified service technician must record all of the information on the diagnostic sheet before calling for

technical assistance. The technician must be able to identify the unit with the order number and serial numbers to

receive accurate trouble shooting assistance. All recommendations for repair or adjustment will be based on the

information provided by the service technician. Any incorrect recommendations based on incorrect or insufficient

data are not covered by the warranty.

WZDS9100 #2

2

Page 3

Installation Instructions

Caution: A qualified technician must install this refrigeration equipment. Please read, understand, and

follow all instructions in this manual prior to start up. Failure to install and adjust this refrigeration unit in

compliance with these instructions will void the warranty.

This unit is suitable for use with R-22 and Icor International’s NU-22B and other R-22 replacements such

as Arkema’s R-427A or DuPont’s R-438A (MO99). We suggest using NU-22B for the following reasons:

It is about 2% to 5% more efficient than R-22

ASHRAE Designated and safety classified A1: Nontoxic/Nonflammable

EPA Snap listed

Non-Ozone Depleting with Low Gl obal Wa rming Impact

Compatible with all standard refrigeration oils so no oil change is necessary

R-22 like properties over a broad range

Low discharge temperatures

Stocking distributors nationwide

The refrigerant oil in the unit must be replaced with a like volume of POE oil when using R-427A,

R-438A and other blended refrigerants. Multiple oil changes are not necessary.

A temperature pressure chart for R-22, NU-22B, R-427A and MO99 can be found on page 26.

1. Select a suitable location for the evaporator with respect to air circulation, drain, refrigerant and electrical

lines. Adequate air circulation requires a 36” clearance in front of the unit, do not place any obstruction in

front of the evaporator. Do not attempt to duct this evaporator. Before installing any unit, the installer must

determine that the wall or ceiling can safely support the weight of the unit. Provide adequate clearance for

maintenance. Check local codes for additional precautions. The face of the evaporator should be within 4”

of the front of the racking, if placed in double deep racking you must bring the evaporator forward so it is

within 4” of the front of the rack.

2. Place the condenser at the desired location outside the wine cellar in a well-ventilated area or outdoors.

Indoor condensers must be placed in a space twice the volume of the wine cellar to prevent excessive

condensing temperatures. Check local codes for proper venting of mechanical rooms. Field supplied

vibration absorbing mounting pads and insulated compressor jackets effectively reduce noise transmitted

by the unit. Condenser face must be at least 12” from any obstruction and entering air must not exceed 110°

F. When installing an outdoor condenser, be sure that it is located so that leaves or snow do not accumulate

and block the airflow. This can be accomplished by setting the condenser on a concrete slab, blocks, etc.

Place the unit so prevailing winds do not blow rain, snow and debris into the open ends of the outdoor

cover. Avoid placing the outdoor condenser in direct sunlight, especially in warm climates. Condenser air

directed toward or away from the dwelling may cause undesirable noise for owners and their neighbors.

This must be considered when placing the unit outdoors.

3. Using a silver/phosphorus/copper alloy with between 5% and 15% silver, braze the refrigerant line set to

the evaporator and condenser with nitrogen flowing through the lines to eliminate carbon deposit build up

on the inside of the joints which could contaminate the refrigerant and restrict the drier and expansion

valve. To do this, open the system service ports. This will purge the nitrogen holding charge in the system.

Connect a nitrogen bottle to one valve and set pressure regulator to about 2 PSI. A small amount of

nitrogen will flow out the other valve.

You must install the line set according to Table 1 on the following page. Failure to do so voids the

warranty. The evaporator and/or condensing unit may have different fitting sizes than the line set, so field

supplied reducers are necessary. Run the line set according to Table 1, and reduce at the condenser and

evaporator connections.

WZDS9100 #2

3

Page 4

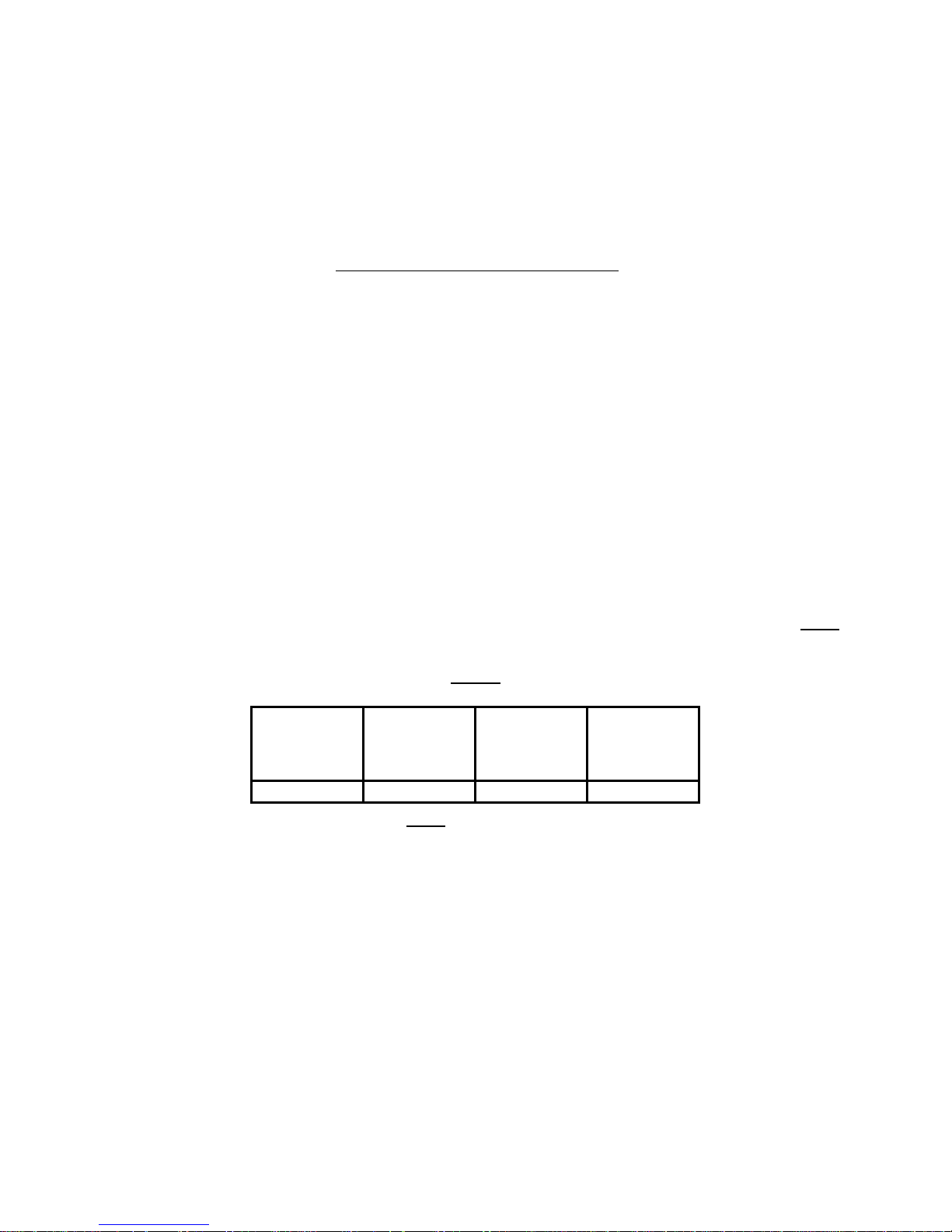

Maximum line length is 200 equivalent feet. Long sweep elbows and any bends in soft copper are

equivalent to 5 linear feet. Line lengths in excess of 200 equivalent feet may cause compressor damage and

will void the warranty. Example: To determine the equivalent length of the line set add up the linear feet of

suction line. Multiply the number of elbows required and add it to the total length of suction line.

Example:

Horizontal pipe 40 linear ft.

Vertical pipe 10 linear feet

8 elbows x 5 40 equivalent feet

Total equivalent feet 90 equivalent feet

Following Table 1 and guidelines for vertical risers below, the correct line set size is 3/8” liquid line and

3/4” suction line. The 10 linear feet of vertical suction line is 5/8”

Proper piping practices must be followed. The line set must be securely fastened to the building structure

for its entire length. The suction line must be insulated the entire length of the run. Horizontal line runs

must slope 1/2” per 10’ towards the condenser for proper oil return. No dips, sags or other low spots that

will trap refrigerant oil are permitted. This prevents starving and slugging the compressor with oil. We

highly recommend using rigid copper for this reason.

For systems with condensers 10 feet or more above the evaporator, reduce the suction line size by one. For

example, 5/8” line changes to 1/2” and 7/8” changes to 3/4” for the vertical section of the line only. Install

a P trap at the bottom of the riser of the same size as the horizontal piping.

Line sets up to 80 equivalent feet will use 3/8” liquid line and 5/8” suction line.

Line sets 81 to 200 equivalent feet will use 3/8” liquid line and 3/4” suction line.

Line sets longer than 200 equivalent feet will void the warranty. Minimum line set length is 15 linear

feet.

Table 1

Line set sizes may differ from system component fitting sizes so field supplied reducers are necessary. Run

the line set according to Table 1, and reduce at the condenser or evaporator if necessary.

Unit

WZDS9100

Minimum linear line set length is 15’

Liquid Line

Equivalent Feet

3/8 5/8 3/4

Vapor Line

Up to 80

Vapor Line

81 to 200

Equivalent Feet

For outdoor units, cut or drill a hole through the most convenient stationary side of the condenser cover large

enough for the line set to easily pass through. Cut the hole above the height of the compressor. Do not run

the line set through the bottom of the unit or the air grilles at either end. Do not run the line set through a

panel that moves when the lid is opened.

WZDS9100 #2

4

Page 5

Sample Piping Configurations

Inc o rre c t In sta lla tion

Evaporator

Condenser

Cre a te s a n o il tra p

Evaporator Evaporator

Condenser

Cre a tes an o il tra p

Oil runs away

from C on de nser.

Evaporator Evaporator

Soft copper sags

and creates an oil trap.

Evaporator Evaporator

Condenser Condenser

C or re ct I n sta llatio n

Evaporator

Condenser

Condenser

CondenserCondenser

Rule of thumb: Once the suction line leaves the evaporator and turns downward, it cannot turn and

go back up to get to the condenser. The only time a trap in the suction line is acceptable is at the

bottom of a 10’ or taller riser.

4. Install the filter dryer and sight glass, if not already factory installed. Wrap with a wet rag to prevent over

heating during brazing.

5. Perform leak test with dry nitrogen, but never expose the system to leak test pressures greater than 150

PSI. Test all fittings including factory installed flare fittings on condenser and evaporator that may

have loosened during shipping. Leaks on unit(s) from a result of loose valves, interconnecting fittings,

and/or field piping are not covered by the warranty. It is the installer’s responsibility to locate and repair

all leaks prior to start up.

6. Evacuate the system to 1000 microns for 1 hour.

7. Install electrical wiring according to the Electrical Requirements on page 14 and the appropriate wiring

diagram. Follow all applicable codes.

8. After isolating the vacuum pump from the system, break the vacuum to a positive pr essure using refrigerant

connected to the liquid line. Add approximately 20 psi of refrigerant vapor. Do not start unit for the

first time with a full charge. Adding more refrigerant prior to start up will damage the compressor.

Always charge NU-22B and other blended refrigerants in liquid state.

WZDS9100 #2

5

Page 6

9. Apply power to units for 24 hours prior to start up to allow crankcase heater to warm the

compressor and then start the unit. Complete the charging process with the compressor running and add

the balance of the charge into the suction line of the system. Liquid refrigerant should never enter the

compressor directly. Use a metering device to prevent slugging when charging with liquid.

10. The ICM333 Head Pressure Control is factory set to maintain approximately 225 psi head pressure. Verify

the head pressure remains at 225 psi or above. See page 22 and the charging table on page 23 for

instructions on how to adjust the fan speed controller. Never adjust the pressure control to bring on the

condenser fan motor above 250 psi. Slowly add refrigerant until the bubbles in the sight glass d isappear.

The condenser fan motor must be running to complete the charge

11. For R-22: After the system has run for 10 minutes check the sight glass again. During normal operation

with R-22 there should be no bubbles in the sight glass. If bubbles are present, the system is low on

refrigerant. Add refrigerant to eliminate the bubbles. Charge the system to approximately 5 of sub-

cooling. To calculate sub-cooling for R-22 subtract the liquid line temperature from the saturation

temperature corresponding to the head pressure. Measure the liquid line temperature between the receiver

and filter drier with and an accurate, digital, thermocouple style thermometer.

For Nu22B or other blended refrigerants: Some bubbles may be present with a full charge of a blended

refrigerant. Charge the system to approximately 5 of sub-cooling. To determine sub-cooling for NU-22B

or other blended refrigerants, subtract the liquid line temperature from the bubble temperature

corresponding to the head pressure. Measure the liquid line temperature between the receiver and filter

drier with an accurate, digital, thermocouple style thermometer.

12. Allow the wine room temperature to fall to 55F. Check the super heat at the evaporator. Measure the

suction pressure at compressor access port. From refrigerant pressure-temperature tables, determine the

saturation temperature (for R-22) or the dew temperature for NU-22B or other blended refrigerant at the

observed suction pressure. Measure the suction line temperature at the compressor. Subtract the saturation

temperature (Dew temperature for blended refrigerants) from the measured suction line temperature. The

difference is the superheat. Refer to the temperature pressure chart on page 26 in these instructions.

The superheat should be 8 to 16F. If the superheat is not in this range, the thermostatic expansion valve

must be adjusted. To adjust the expansion valve, remove the seal cap from the bottom of the valve. Turn

the adjustment screw clockwise to increase superheat and counterclockwise to decrease superheat.

Caution: There are 10 turns on the adjustment stem. When stop is reached while turning the

superheat adjustment stem, any further turning will damage the valve. One complete 360 turn

changes the superheat approximately 3-4F. As much as 30 minutes may be required for the system to

stabilize after the adjustment is made. Replace and hand tighten the seal cap. Always replace the

evaporator face plate between TXV adjustments.

13. Perform the final check of the refrigeration unit. The cellar temperature must be between 53 and 58 F.

Check the sight glass and gauge readings again. The super heat must be 8-16 F (see step 12). The hot gas

line temperature must not exceed 260 F. Never exceed the maximum amp draw (RLA) for the

compressor. Adjust the TXV, and charge as necessary. All measurements should be taken with the

condenser fan motor running. All temperature readings should be taken with a digital probe style

thermometer.

14. If the recommended system pressures and temperatures cannot be achieved, refer to the troubleshooting

chart on pages 24 and 25.

15. Clearly mark the unit to identify the refrigerant used.

WZDS9100 #2

6

Page 7

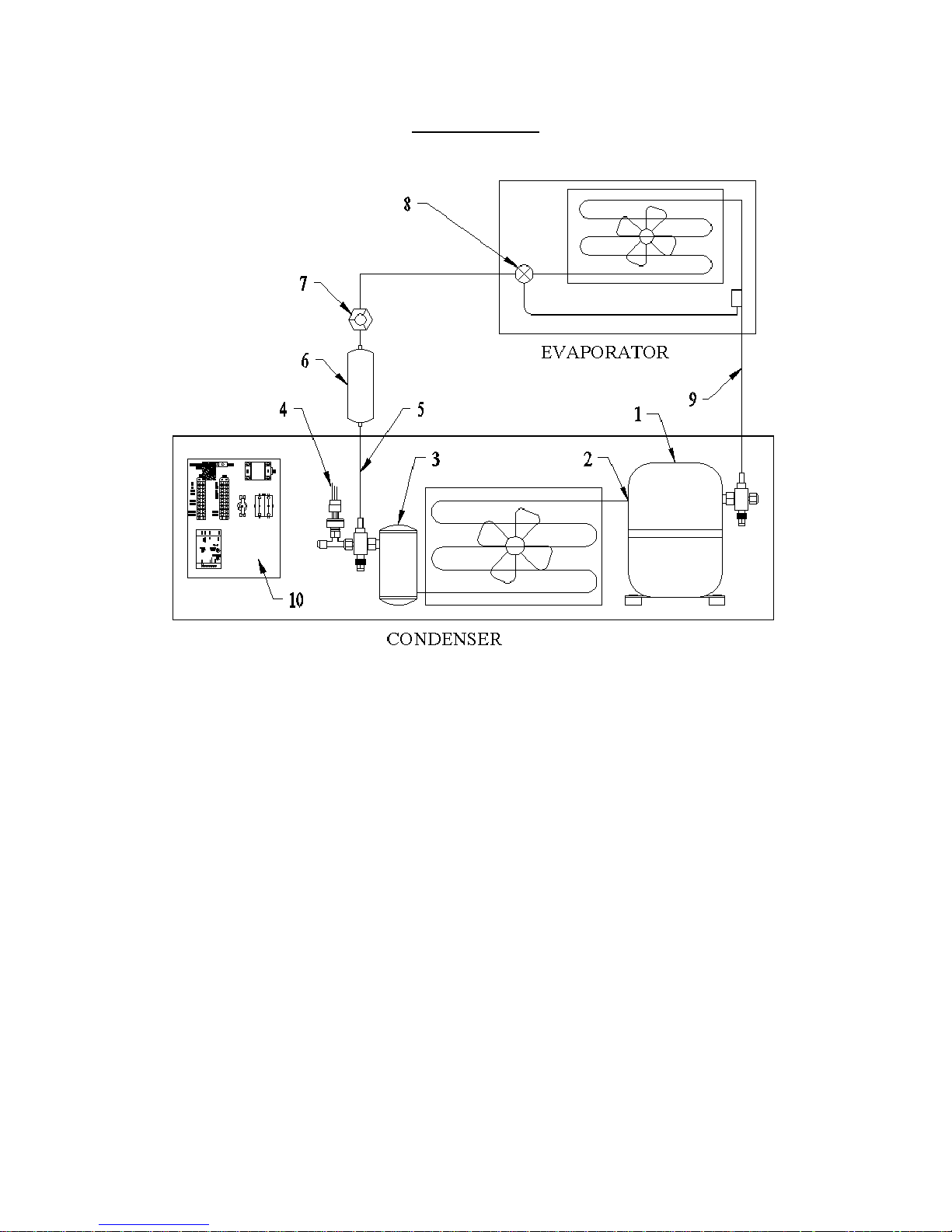

Piping Diagram

1. Compressor.

2. Discharge (hot gas) line. The vapor line between the compressor outlet and the condenser coil inlet.

Measure the discharge (hot gas) line temperature here, approximately 12” from the compressor outlet. This

temperature should never exceed 260 degrees.

3. Receiver. Measure the head pressure at the receiver service valve.

4. ICM333 Head Pressure Control. See step #10 on page 6.

5. Liquid line. Measure the liquid line temperature here to determine sub-cooling.

6. Filter drier.

7. Sight glass.

8. Thermostatic expansion valve. See step 12 on page 6.

9. Suction line. Measure the suction pressure at the compressor suction service valve. Measure the suction

line temperature near the compressor service valve. See step 12 on page 6.

10. Condenser control panel. Contains the system electrical components.

WZDS9100 #2

7

Page 8

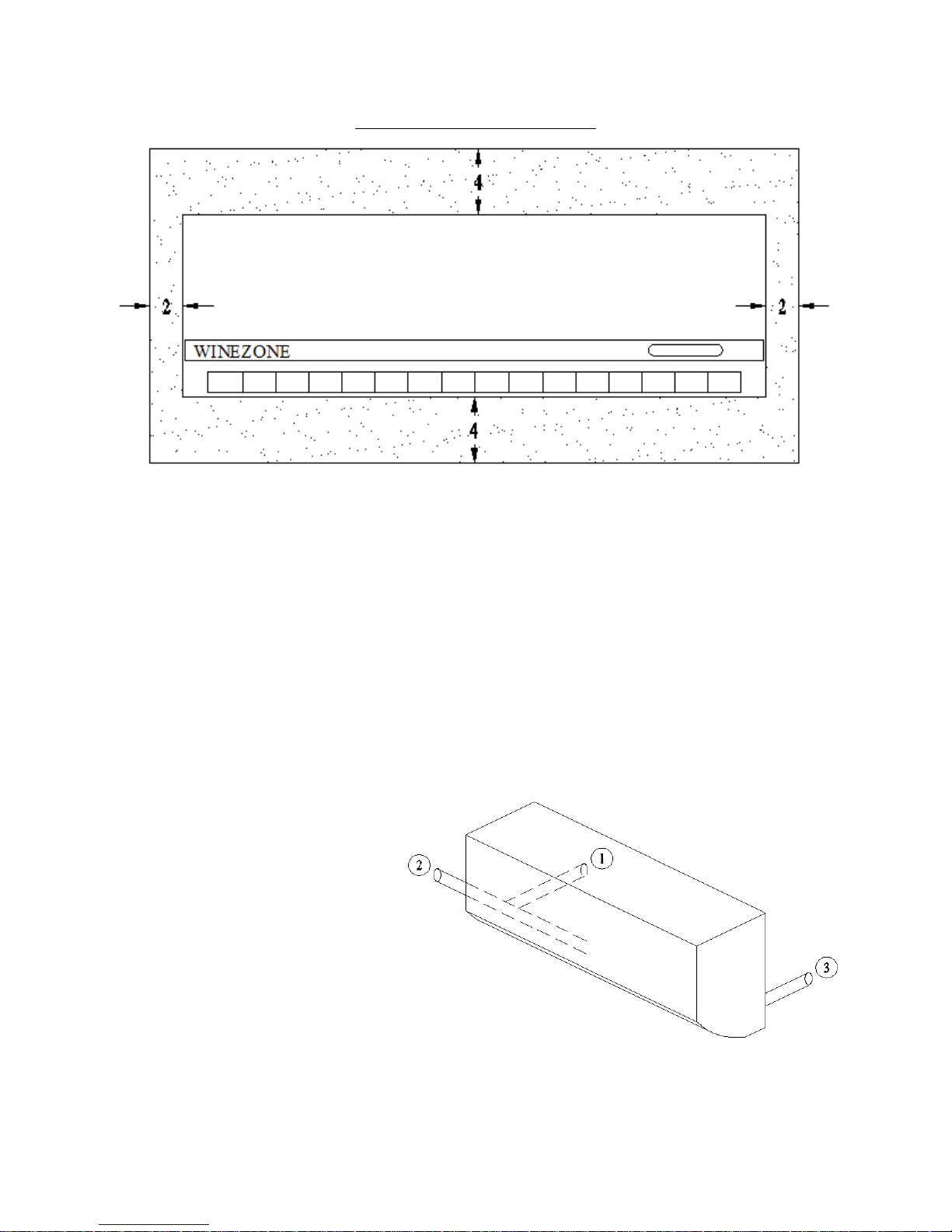

Installation of the Indoor Unit

Firmly secure the evaporator mounting plate on a wall strong enough to withstand the weight of the unit. The plate

must be level and allow for the clearances shown in the figure above. The evaporator must be installed in such a way

as to prevent short cycling of the discharge air with the return air. Adequate air circulation requires a 36”

clearance in front of the unit; do not place any obstruction in front of the evaporator. The face of the

evaporator should be within 4” of the front of the racking, if placed in double deep racking you must bring the

evaporator forward so it is within 4” of the front of the rack. Do not place the unit in direct sunlight, or above a door

or window. Do not attempt to duct this evapor ator. The location must also be suitable for refrigerant piping and

condensate drainage. The evaporator discharge air must not blow on the thermostat.

The refrigerant piping can be routed to the unit in a number of ways. Number 2 in the diagram below indicates a

cutout in the unit casing. Using the cutout will leave the refrigerant piping, condensate d rain, and electric exposed

in the cellar and should be avoided. Numbers 1 and 3 indicated below, are fo r piping routes that will leave the

refrigerant lines, drain and electric concealed, and should be used for the most attractive installation. A single, 2¼”

or 2 ½” hole will accommodate the passage of the line set, drain and electric through the wall. Slope the hole

downward through the wall and fasten the drain line to the bottom of the line set for proper drainage. These hole

locations are indicated on the mounting plate drawings as well. The refrigerant piping may be gently bent or twisted

to use any of the indicated pipe routes.

When the line set will be run on the inside

of the wall before the drywall is hung, use

the suggested route (route number 1).

Route number 1 is the preferred route.

Route 2 will leave the refrigerant piping,

electric, and drain exposed. For installations

where the line set will be accessible on the

backside of the wall, the alternate route

(route 3) can be used. Use caution when

using route 3. Secure the piping above the

bend before turning the piping to use

route 3 to prevent kinking the suction

line.

WZDS9100 #2

8

Page 9

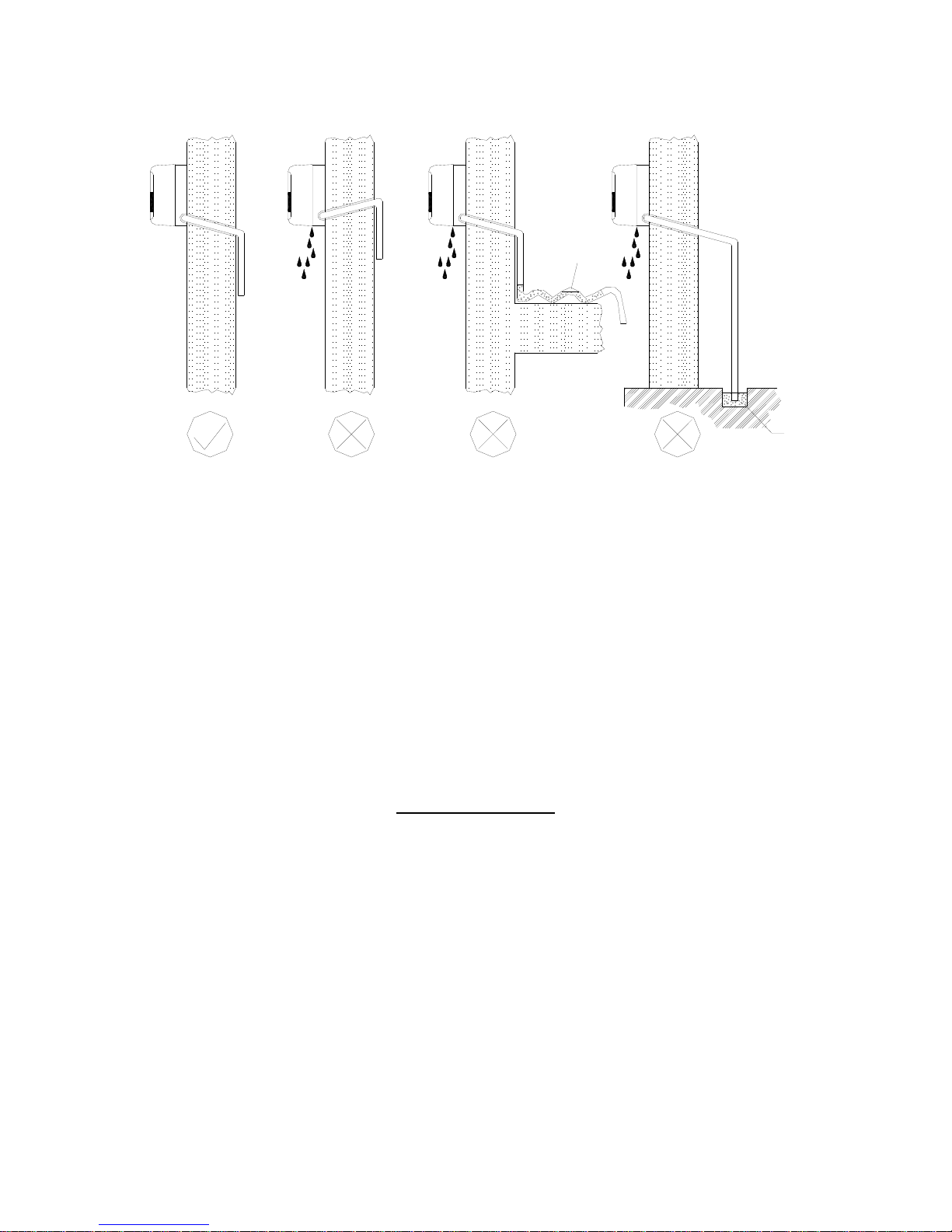

WATER

LEAKING

WATER

LEAKING

WATER

LEAKING

END DIPPED

INTO WATER

DRAIN

CORRECT

WRONG

WRONG

WRONG

The indoor drainpipe must slope downward and have no traps. The drain must be fastened to the bottom of the

refrigerant lines. The drain requires an air gap to flow properly. Place the two hooks at the rear top of the

evaporator to hang the unit from the upper edge of the mounting plate. Ensure the hooks are properly seated on the

mounting plate by sliding the unit to the left and right. Gently press on the bottom face of the evaporator to snap the

bottom of the evaporator into place on the mounting plate.

The face of the evaporator casing can easily be removed. Screws are concealed under plastic covers on the bottom

leading edge of the unit, under the air discharge louver . Remove the covers to expose the screw heads an d remove

the screws. Remove screws above the air discharge under the hinged filter cover. Pull out and lift the botto m of the

evaporator casing to uncover the electric hook up.

After installation, properly seal the hole(s) where the refrigerant, drain and electric lines penetrate the wall

or ceiling. Failure to do so may result in uncontrolled condensation and water damage.

Evaporator Electric

Securely fasten the ground wire to the terminal with the green or green and yellow striped wire. The other two wires

on the evaporator terminal block receive 230 volts from terminals marked EVAP on TB1 in the condenser control

panel.

WZDS9100 #2

9

Page 10

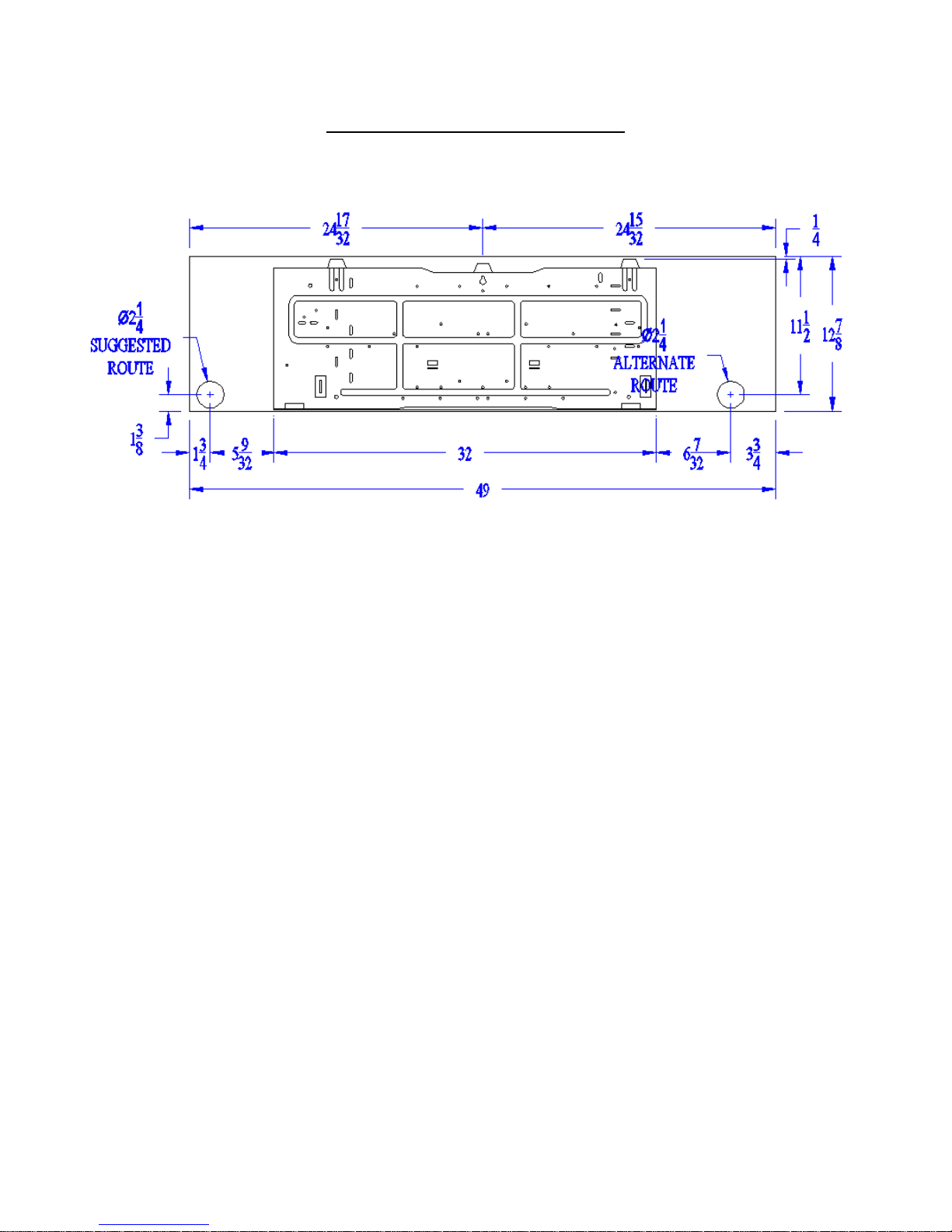

Mounting Plate for 9100 Evaporators

The holes shown are the best locations to route the refrigerant lines, condensate drain, an d electric. For installations

where the line set will be accessible on the backside of the wall, use the alternate route. When that is not possible,

and the line set will be run inside the wall before the drywall is installed, use the suggested route. This will leave the

flare connections exposed so they can be connected after the walls are finished.

Use caution when using the alternate route. Secure the piping above the bend before turning the piping to

prevent kinking the suction line.

A qualified service technician must record all of the information on the diagnostic sheet before calling for

technical assistance. The technician must be able to identify the unit with the order number and serial numbers to

receive accurate trouble shooting assistance. All recommendations for repair or adjustment will be based on the

information provided by the service technician. Any incorrect recommendations based on incorrect or insufficient

data are not covered by the warranty.

WZDS9100 #2

10

Page 11

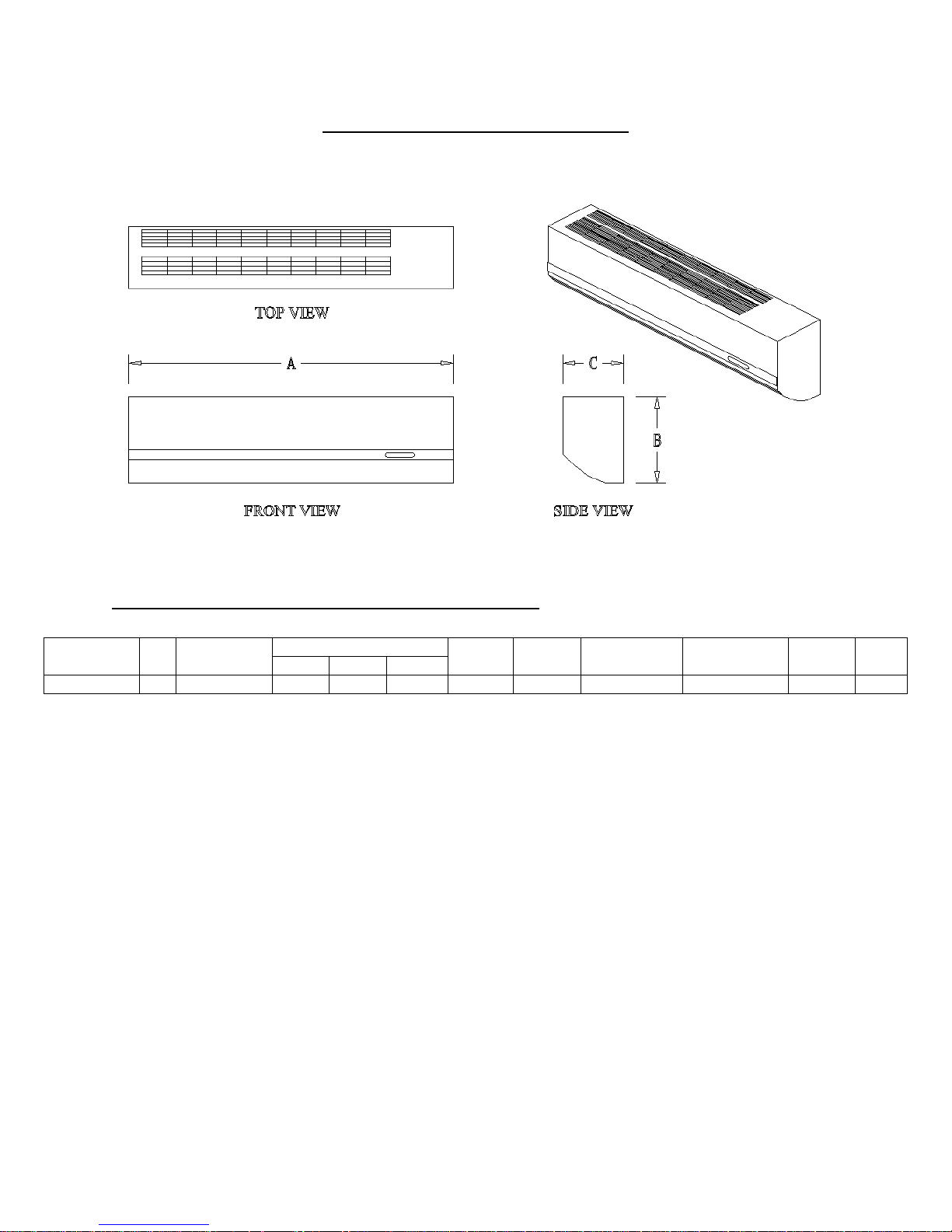

Ductless Split Wall Mount Evaporator

Specifications for Standard Ductless Split Evaporator

System dB Evaporator

WZDS9100

45 WB036 49 12 7/8 9 1/8 3/8 MF 5/8MF 5/8 Barbed 208-240/60/1 37 lbs. 15

You must install a line set according to Table 1 on page 4.

Field supplied reducers may be required. Reduce at the evaporator and condenser connections.

A minimum of 4” clearance required on top and bottom, 2” of clearance required on each side.

Dimensions In Inches

A B C

Liquid

Fitting

Suction

Fitting

Drain

Fitting

Power

Supply

Weight

Max.

Fuse

WZDS9100 #2

11

Page 12

Condenser Specifications

Outdoor Condenser

You must install a line set according to Table 1.

Field supplied reducers may be required. Reduce at the

evaporator and condenser connections.

Minimum of 12” clearance required on each side of unit.

Minimum of 36” clearance required above unit.

Model dB

WZDS9100/OC

Model dB

WZDS9100/IC

WZDS9100 #2

Length

In

inches

58 27 24.5 22 3/8 SW 5/8 SW 170 208-230/60/1 11.0 15

Width

in

inches

Height

in

inches

Liquid

Line

Fitting

Suction

Line

Fitting

Wt.

In

lbs Power Supply

Min

Circuit

Amps

Max

Fuse

Indoor Condenser

You must install a line set according to Table 1.

Field supplied reducers may be required. Reduce at the

evaporator and condenser connections.

Minimum of 12” clearance required on each side of unit.

Length

In

inches

58 28 24.5 20.25 3/8 SW 5/8 SW 139 208-230/ 60/1 11.0 15

Width

in

inches

Height

in

inches

Liquid

Line

Fitting

Suction

Line

Fitting

Wt.

In

lbs Power Supply

Min

Circuit

Amps

Max

Fuse

12

Page 13

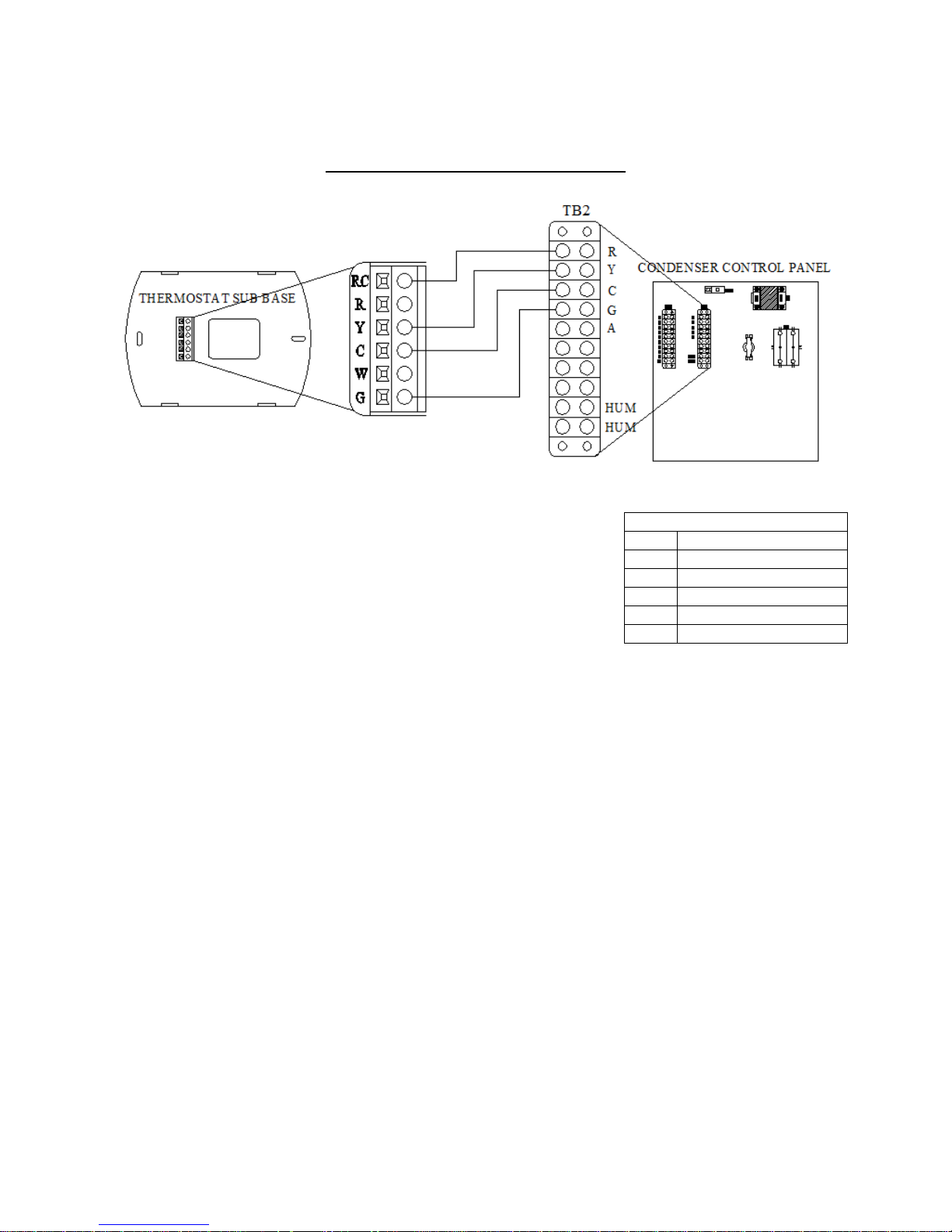

Field Wiring

Condensing unit Control Panel

Terminal Board One

Terminal L1 – *230 Line voltage for the condenser (See condenser specifications for proper fuse size)

Terminal L2 – *230 Line voltage for the condenser (See condenser specifications for proper fuse size)

Terminal EVAP – Load voltage to the evaporator fan motor. Connect to terminal block in the

evaporator

Terminal Board Two

Terminal R – Thermostat R

Terminal Y – Thermostat Y

Terminal C – Thermostat C

Terminal G – Thermostat G.

Terminal A – Thermostat A, used only with humidification

Terminal HUM – 24 volt humidifier

System Ground Lug Above Terminal Boards

Electrical Requirements

1. Check the Copeland rating plate located on top of the condenser coil, for proper voltage, maximum fuse,

run load amperage, and wire size.

2. Line voltage from service panel for cooling unit. The power circuit connects to terminals L1 and L2 on

TB1 in the condenser control panel.

3. The evaporator circuit connects to terminals marked EVAP on TB1 in the condenser control panel.

4. Low voltage wire from the thermostat goes to the condenser control panel only. No low voltage

connections are required at the evaporator. Low voltage control wiring runs from the thermostat to the

condenser control panel.

5. All equipment must be installed according to the National Electric code and all local codes and ordinances.

WZDS9100 #2

13

Page 14

Line Voltage

1. Run a 230-volt circuit from the service panel to terminals L1 and L2 on TB1 in the condenser control

panel. Check the Copeland rating plate or page 12 for the proper fuse size. Attach the ground wire to the

lug in the upper left hand corner of the condenser control panel.

2. Load voltage for the ductless evaporator will come from terminals marked EVAP on TB1 in the condenser

control panel. Connect these wires to the small terminal block with the evaporator fan motor wires

attached. Attach the ground wire to the terminal with the green or green and yellow striped wire.

3. Each unit must be installed in accordance with the National Electric code. Check local codes for additional

precautions and ordinances to installation.

WZDS9100 #2

14

Page 15

Thermostat Installation Cooling Only

Mount the Honeywell FocusPRO5000 thermostat in the cellar approximately 5

feet above the floor in an area of good air circulation of average cellar

temperature. Do not install it where it will be affected by the evaporator supply

air, lighting, wall switches, concealed pipes or chimneys, or warm exterior

walls, etc. The thermostat terminal RC connects to terminal R on TB2 in the

condenser control panel. Thermostat terminal Y connects to terminal Y on TB2

in the condenser control panel. Thermostat terminal C connects to terminal C

on TB2 in the condenser control panel. Thermostat terminal G connects to

terminal G on TB2 in the condenser control panel. Use quality 18-gauge thermostat wire. Read and follow the

manufacturer’s installation instructions.

We recommend you enter the Installer Setup in the Honeywell Installation Guide and choose the followin g settings

#1 System type to 4 for Cool only

#9 Stage 1 compressor cycle rate to 3

#14 Temperature display to 0 for Fahrenheit

#15 Compressor protection to 5

#28 Cool temperature range stop to 53

Turn the system to cool and set the temperature to 55.

Conventional Terminal Letters

24 VAC power

RC

Cooling

Y

24 VAC common

C

Not used

W

Fan

G

Not used

A

WZDS9100 #2

15

Page 16

Thermostat Installation for Cooling and Humidification

Thermostat Installation

Mount the WineZone thermostat in the cellar approximately 5 feet above the floor in an area of good air circulation

of average cellar temperature. Do not install it where it will be affected by the evaporator supply air, lighting, wall

switches, concealed pipes or chimneys, or warm exterior walls, sunlight, etc. Use quality 18-gauge thermostat wire.

Read and follow the manufacturer’s installation instructions. Carefully read and understand the instructions

supplied with the thermostat before attempting to operate or install this thermostat. The following thermostat

installation instructions are a summary of the install and set up for using this thermostat with a WineZone system.

For detailed installation and troubleshooting instructions please refer to the manufacturer’s instructions included

with the thermostat.

Install the Wallplate

1. Position the wallplate on the wall with the directional arrow pointing up and the terminal blocks facing

outward.

2. Pull equipment wires through the wallplate wiring passage.

3. Use a level to determine the best horizontal wallplate mounting position.

4. Mark positions of screw holes (two at minimum) with a pencil and remove wallplate.

5. Drill holes at pencil-marked locations (3/16” for drywall, 7/32” for plaster).

6. Insert the wall anchors in the holes, tapping them into place.

7. Mount the wallplate onto the wall and insert screws through the mounting holes. Assure that all loose

wires come through the center opening of the wallplate.

8. Cap off any unused wire and terminate properly according to local building codes.

WZDS9100 #2

16

Page 17

Attach Wires to Thermostat Wall plate

1. Select the terminal designations that correspond to the system type. Follow the table below:

Warning: Disconnect power before beginning installation.

Caution: Copper wire only. Insulate or wire-nut all unused

leads.

Use care to avoid electrostatic discharge to thermostat.

Note 1: Do not connect wire to A if a humidifier is not installed.

Note 2: Do not connect wire to Y2 or W1 if a duct heater is not

installed.

2. Using a small flathead screwdriver, loosen the screws on the terminal

blocks that correspond to the system type.

3. Strip the insulation of each wire at a proper length (about 1/4”)

Conventional Terminal Letters

Unswitched side, 24 VAC

C

Not used

W1

Not used

W2

Fan

G

Humidity

A

Not used

E

Stage 1 Cool

Y1

Not used

Y2

Power for Heating

RH

Switched Side, 24 VAC

Power for Cooling,

RC

Switched Side 24 VAC

Sensor Common, if used

SC

Not used

S1

Not used

S2

Not used

S3

4. On the wallplate, insert wires into the terminal blocks that correspond to the system type, then re-tighten

each screw for each terminal.

Note: Do not over-tighten or use excessive force.

5. Assure that no uninsulated wires are exposed: Cap off and place a wire nut on any unused wires. Assure

that the attached wires fit into the cavity on the back of the thermostat.

Connect Power to the Thermostat Wallplate

Power Options

The T12000 Series thermostat will operate on 24 VAC power and/or two AA batteries (both are recommended).

Using 24 VAC with AA battery backup is highly recommended.

Wiring 24 VAC Common

Single-Transformer system. Connect the common side of the transformer to the “C” screw terminal of the

thermostat wallplate. Assure that the metal jumper connects “RC” and “RH.” Connect power side to the RC/RH

and assure that the jumper remains in place

Install Batteries and Remove Tab

1. Insert two AA batteries (included) into the back compartment of the thermostat.

2. Remove the plastic insulator tab from the back side of the thermostat. IMPORTANT: The insulator tab

must be removed before setting the real-time clock.

Set the Clock, Month, Day

When power is first applied to the thermostat, it will activate the clock display. It is recommended that the time and

day are entered before performing advanced configuration. On the touchscreen area, press the Clock key and use

the up and down arrows to set the hour mode, clock hour, minutes, year, month, and numerical date. Press Done to

finish.

WZDS9100 #2

17

Page 18

Verify System Setting is Turned Off

1. Press any part of the touchscreen area to enter the Home Display.

2. Press System to enter system mode

3. Press System repeatedly until “Off” flashes, then press Done.

4. Press Fan key to enter fan mode.

5. Press Fan repeatedly until “Auto” flashes, then press Done.

Perform Advanced Configuration

Perform advanced configuration before attaching the thermostat to the wallplate. Advanced configuration is done

by simultaneously pressing the lower left and lower right touchscreen area for about 5 seconds, which gives user

access to Service Menus. Use the following table to set each desired Service Menu item. Advanced configuration

allows the user to configure the thermostat to match the system type and to customize several thermostat settings.

System type for WineZone systems is 1 Stage Cool/1 Sta ge Electric Heat. Changed value s are automatically

retained. Press Done only if you wish to exit Advanced Configuration. Service menu availability is dependent upon

system type and upon system configuration.

Menu Feature Options Default Recommended Setting

100 Schedule Format 0-3 1 0= Nonprogrammable

101 Daylight Saving Time 0,1 0 1= Enabled (2007 U.S. Format)

110 System Type 1-13 1 1= 1 Heat/1 Cool conventional

120 Fan Control (heating) 0,1 0

1= Electric furnace (thermostat controls heating

fan)

150 Backlight 0,1 0 0= Backlight temporarily on

170 Remote Sensor 0-5 0

0= No sensor

1= Indoor sensor (if used)

180 Heat Pump Compressor Lockout 0-45 0 0= No sensor

190 Heat Pump Auxiliary Lockout 0-60 0 0= None

230 Furnace Filter Change Reminder

0; 30; 60; 90;

120; 365

0

0= Off

240 Number of Program Periods 2; 4 4 4= 4 Events per day

250 Clock Format 12 or 24 12 12= 12-hour clock mode

260

Temperature Format

F or C

0,1 1

1= Fahrenheit

270 Fan Off Delay Heat 0-99 0 20= 20 Seconds

280 Fan Off Delay Cool 0-99 0 20= 20 Seconds

290 Range Low 50-90 50 50, Choose the lowest selectable setpoint

300 Range High 50-90 90 68, choose the highest selectable setpoint

310 Setback Low Off, 50-82 55 0= Off

320 Setback High Off, 58-90 90 0= Off

330 Zone Temp Offset +/-9 0 0= No offset

340 Keypad Lockout 0-3 0 0= No Key pad lockout

341 Enable Pin Access 0,1 0 0= Disable

350 Fan Mode Enable 1-3 3 3= On or Auto: allows user to select

360 System Mode Enable 0-3 1 1= Off, Heat, Cool. Auto

370 Economizer/Outside Air Damper 0-4 0 0= Off

3= Selects change over deadband value between

380 Minimum Deadband Adjustment 3-10 3

heating and cooling modes to prevent short

cycling

390 Pre-Occupancy Purge 0-3 0

WZDS9100 #2

18

0= Select to energize fan for selected number of

hours (0-3) prior to all occupied events.

Page 19

395 Maximum Override Time Limit 0, 1-4 3 3= 3 Hours

400 Cycles Per Hour Cooling Stage 1 0-6 3

420 Cycles Per Hour Heating Stage 1 0-12 5

460 Heat Recovery Rate 0-18 5 0= Disable ramp recovery

470 Cool Recovery Rate 0-18 5 0= Disable ramp recovery

480 Minimum Off Time 1-10 4

490 Humidity Control Enable * 0-3 2

491 Humidity Deadband 10-50 10

500 Programmable/Intermittent Fan 0-2 0 0= Disable

510 Power Harvesting 0-3 0 0= No power harvesting available

520 Default Display Icons 0-4 0 0= Time, Temp, SP

530 Revision - - Not Adjustable

540 Factory Default Reset 0,1 0 0=Disable

600 System Test Main Output (Cool) 0-2 0 0= Disable

610 System Test Main Output (Heat) 0-3 0 0= Disable

620 System Test Fan Output 0,1 0 0= Disable

630 System Test Emergency Output 0,1 0 0= Disable emergency output

640 System Test Economizer 0,1 0 0= Disable economizer output

*IMPORTANT! Some humidity control must be selected to view the humidity on the thermostat. If

no humidity options are installed, DO NOT connect wires to terminals A or Y2. Only connect wire to

A if a humidifier is installed. Do not connect wire to Y2.

3= Defines number of cycles per hour for

cooling

5= Defines number of cycles per hour for

heating

4= 4 Minutes off time for both heat and cool

output

Selects how humidity will be controlled. When

dehumidify is enabled the Y2 terminal becomes

dehumidify. Note: If option 3 is selected,

Service Menu 491 becomes available.

0= Disable (Humidity not displayed on

touchscreen).

1= Dehumidify

2= Humidify

3= Dehumidify and Humidify

10= 10% RH deadband between humidi fy and

dehumidify

Mount the T12000 Onto the Wallplate

1. Position the thermostat slightly above the mounted wallplate, then secure the hooks on the backside of the

thermostat to hinge pockets on the wallplate. Note: The top of the thermostat should slip into the hinge

pockets easily. Do not use excessive force.

2. Align the pins on the back side of the thermostat with the terminal blocks on the wallplate.

3. Gently bring down the thermostat onto the wallplate so the pins on the back of the thermostat fit into the

terminal blocks on the wallplate.

WZDS9100 #2

19

Page 20

Verify Thermostat Operation

Press the desired button until the preferred selection blinks. Press Done to select and save the selection.

1. Set the system to Off. Nothing should operate, including the Fan.

2. Set the fan to Auto

3. Set the system to On. Press the up and down arrows to adjust the temperature. Adjust the temperature

setpoint above the cellar temperature displayed on the touchscreen.

4. Set the Fan to On. The indoor fan should come on.

5. Set the Fan to Auto. The indoor fan should go off.

6. Adjust the temperature setpoint below the cellar temperature displayed on the touchscreen. The condenser

and indoor fan should come on.

7. If a humidifier is installed, adjust the Humidity setpoint above the humidity displayed on the touchscreen.

The humidifier should come on. Set the humidity setpoint below the humidity displayed on the

touchscreen. The humidifier should go off.

8. Adjust the temperature setpoint above the cellar temperature displayed on the touchscreen. The condenser

and indoor fan should go off. Nothing should be running.

9. Set the Humidity setpoint above the humidity displayed on the touchscreen. The humidifier should come

on.

10. Set the temperature to 55 and the Humidity to 65%.

Humidifier Installation

Install the Wine Guardian® Freestanding Humidifi er. Ru n

the humidifier prior to installation as the warranty does not

cover removal of the unit. Please read and understand the

owner’s manual and installation instructions prior to start

up. Follow the manufacturer’s manual to locate and mount

the free-standing humidifier. Install the hot water line and

drain according to the manufacturer’s instructions.

Disregard wiring instructions that include humidistat

wiring. The Wine Guardian® humidistat and transformer

are not necessary when used with the WineZone thermostat.

Cut off the plug end of the 24 volt control wire on

humidifier and connect the wires directly to the terminals

marked HUM on TB2 in the condenser control panel.

Do not install the humidifier directly underneath the

evaporator. Do not install the humidifier where the

evaporator will blow directly on the humidifier.

WZDS9100 #2

20

Page 21

WZDS Condenser Control Panel

COMP

CR

CCH

FM

FR

GND

TB

TR

Legend

Compressor

Compressor relay

Crankcase heater

Fan motor

Evaporator fan relay

Ground

Terminal Board

Transformer

WZDS9100 #2

L1

L2

CCH

CCH

EVAP

EVAP

COMP

COMP

TB1

230V line voltage from service panel

230V line voltage from service panel

Crankcase Heater

Crankcase Heater

230V load voltage to evaporator

230V load Voltage to evaporator

Compressor

Compressor

21

R

Y

C

G

A

HUM

HUM

TB2

Thermostat R

Thermostat Y

Thermostat C

Thermostat G

Thermostat A, Humidity

Humidifier

Humidifier

Page 22

Condenser Fan Speed Control

The WineZone condensing unit uses an ICM333 fan speed

controller to maintain the proper head pressure.

When the condenser fan motor starts running it will start for a

length of time dictated by the hard start dial setting. After the

hard start time has elapsed, the motor speed is controlled by

the pressure transducer reading. The green light turns on

when the motor runs at full speed.

As the sensed pressure decreases, the output voltage

decreases. The yellow light turns on during motor variable

speed . The output voltage may decrease to the determined

cutout speed dictated by the cutout speed dial. Upon

reaching the cutout speed setting, the output voltage goes to

zero volts and the yellow light turns off.

The fan cut out speed is factory set to the minimum speed for sleeve bearing motors.

The fan hard start time is factory set to the minimum for sleeve bearing motors.

Adjust the set point dial to maintain 225 psi head pressure when the condenser ambient is at or below 70º F. The

control will maintain condenser pressure between 20 psig ab ove and 20 psig below dialed Pressure Setpoint.

The ICM Pressure Transducer is located on the receiver backseat valve. The backseat valve must remain

open 1/2 to 1 full turn to allow the pressure transducer to sense the head pressure.

Make sure that supply voltage to the system and ICM333 Head Pressure Control are disconnected before

installation or service.

Electronic Unit Controller

To adjust the low pressure settings:

Hold DOWN and SET simultaneously for 3 seconds to enter the menu (PSI light will flash). ˅ + SET

Cycle through the menu options- ˄ ˅

Select function- SET SET

Adjust the value – UP/DOWN ˄ ˅

Store function – SET SET

Exit menu – UP and SET ˄ + SET

Recommended CUT OUT is 5 PSI.

Recommended CUT IN is 10 PSI

Read and follow the set up guide included with the condensing unit for accessing the alarm code information.

WZDS9100 #2

22

Page 23

Installation Check List

1. Ensure the electric voltage, breaker and wire size are correct for all electrical components.

2. Make sure the line set is less than 200 equivalent feet in length, the proper diameter and contains no oil

traps.

3. Make sure the line set has passed a leak test and has been evacuated below 1000 microns.

4. Check the evaporator drain and make sure it is clear of obstructions, free of traps, and has sufficient slope.

Quick Start Procedure

Caution: A qualified technician must install this refrigeration equipment. The following quick start

procedure is not a substitute for proper installation techniques and procedures. Please read, understand,

and follow all instructions in this manual prior to start up. Failure to install and adjust this refrigeration

unit in compliance with the installation instructions will void the warranty.

1. Break the vacuum to a positive pressure of approximately 20 PSI. DO NOT start the unit for th e first time

with a full charge.

2. Apply power to the unit for 24 hours to allow the crankcase heater to warm the compressor.

3. Start the unit.

4. Slowly add charge to system through the compressor suction access port. DO NOT allow liquid refrigerant

to directly enter the compressor. Use a metering device to prevent liquid from directly entering the

compressor. Always charge blended refrigerants in liquid state.

5. Adjust the condenser fan cycle control to maintain 225 PSI head pressure with condenser ambient

temperatures at or below 90º F.

6. Continue to add refrigerant until the sight glass is clear.

7. Allow the unit run and cool the room to 55º F.

8. Compare the saturation temperature corresponding to the suction pressure at the compressor to the sensible

suction line temperature at the compressor. Adjust the thermostatic expansion valve as necessary to ensure

a superheat of 8º to 16º.

9. Add refrigerant to maintain approximately 5º of sub-cooling.

10. Check the discharge (hot gas) line temperature midway between the compressor outlet and condenser coil

inlet. It should never exceed 260º.

11. Check the compressor amp draw. It should never exceed the RLA on the condensing unit rating plate.

12. Disconnect refrigerant gauges.

13. Clearly mark the unit to identify the refrigerant used.

14. Record the collected values on the Diagnostic Sheet and submit it to Wine Cellar Innovations for review.

Normal Operating Pressures for R-22

Outdoor Condenser Inlet

Temperature (ºF Dry bulb)

110 60 282

90 57 220

70 56 225*

Approximate charge weight of 11 lbs. R-22 refrigerant with 50’ line set.

Approximate weight of R-22 per foot of liquid line is .58 ounces.

Adjust pressures accordingly when using alternative refrigerants.

Suction

Pressure

Head

Pressure

Return air temperature of 55º dry bulb, 49º wet

bulb. Supply air temperature of 40º -44º dry bulb.

*Fan speed controller may influence head

pressure.

Charge to 5 º sub-cooling. Superheat 8-16 º

WZDS9100 #2

23

Page 24

Service and Maintenance

b

t

g

Service Parts Maintenance Procedures Period

Indoor Air Filter

Evaporator

3. Check drain pan. Wipe or vacuum clean as necessary.

Condenser

1. Remove any dust on filter with vacuum cleaner or warm

water and gentle detergent. Rinse and dry thoroughly

efore placing in unit.

1. Clean dirt and debris from grille or panel wi

cloth, soap, and water.

2. Inspect evaporator coil, gently remove, brush off dirt

and debris

Check water flow; blow out drain as necessary.

1. Wash condenser coil with appropriate cleanser and

garden hose. Check safety devices. Check refrigerant

char

e. Check system operation

h a soft

Monthly

As necessary

As necessary

Monthly

Twice per year

By qualified technician

Trouble shooting

Fault Cause Solution

Unit does not run 1. Blown fuse or circuit breaker Replace fuse/reset breaker

2. Room at set point Lower set point

3. Thermostat not calling for

cooling

4. Faulty thermostat or wiring Check low voltage wiring,

Unit runs but does not cool 1. Lack of air flow Check filter, make sure louvers

2. Unit low on charge Add refrigerant

3. Compressor not running Check compressor and starting

4. Unit undersized Call a qualified technician

Evaporator coil freezes 1. Air filter dirty Clean air filter

2. Coil and/or fan wheel dirty Clean the coil and/or fan wheel

3. Temperature set point too low

4. Head pressure is too low Adjust condenser fan speed

5. System low on charge Add refrigerant

6. Thermostatic expansion valve

faulty or improperly set

Water leaking from unit 1. Condensate drain clogged Clear out drain

2. Evaporator coil frozen See above

3. Hole behind evaporator not

sealed

4. Trap or no air gap in drain

Lower set point

replace thermostat

and fan are unobstructed. Clean

evaporator if necessary

components

Set thermostat to 55

controller to maintain 225 PSI

head pressure.

Adjust TXV. See step #12 on

page 6

Seal both sides of wall around

line set, wiring, and drain

Remove trap or install air gap in

drain. See page 9

WZDS9100 #2

24

Page 25

Evaporator fan runs but

prop

t

compressor does not

1. Compressor and/or starting

components faulty

Call a qualified technician

Compressor runs but evaporator

1. Faulty fan motor Replace fan motor

fan motor does not

2. Faulty fan relay Replace fan relay

Compressor short cycles 1. Evaporator blows on

Move thermostat

thermostat

2. Unit low on charge Add refrigerant

3. Condensing fan

motor/capacitor faulty

4. Compressor and/or starting

components faulty

Replace condenser fan motor

and/or capacitor

Replace compressor and/ starting

components

Super heat in evaporator too high 1. Unit low on charge Add refrigerant

2. Thermostatic expansion valve

out of adjustment or faulty

Adjust TXV, see step #12

Replace TXV

Super heat in evaporator too low 1. Unit over charged Reclaim refrigerant

2. Evaporator coil frozen See above

3. Evaporator fan motor not

See above

running

4. Thermostatic expansion valve

out of adjustment or faulty

Adjust expansion valve, see step

#12, replace valve

Hot gas line temperature exceeds

260 or

Suction pressure in evaporator

1. Thermostatic expansion valve

out of adjustment or faulty

Check TXV operation. Lower

superheat, see step #12

2. Unit low on charge Add refrigerant

too low or

Suction line temperature at

compressor too high

Humidity in cellar too low 1. Cellar vapor barrier not

Install proper vapor barrier

sufficient

Condenser fan motor short cycles 1. Condenser fan motor pressure

control im

2. Condenser fan motor or

erly se

capacitor faulty

3. Condenser fan speed controller

does not sense pressure

Adjust condenser fan speed

controller to maintain 225 PSI

Replace faulty fan motor or

capacitor.

Receiver backseat valve closed

Unit low on charge.

4. Unit low on charge. Add refrigerant

A qualified service technician must record all of the information on the diagnostic sheet before calling for

technical assistance. The technician must be able to identify the unit with the order number and serial numbers to

receive accurate trouble shooting assistance. All recommendations for repair or adjustment will be based on the

information provided by the service technician. Any incorrect recommendations based on incorrect or insufficient

data are not covered by the warranty.

WZDS9100 #2

25

Page 26

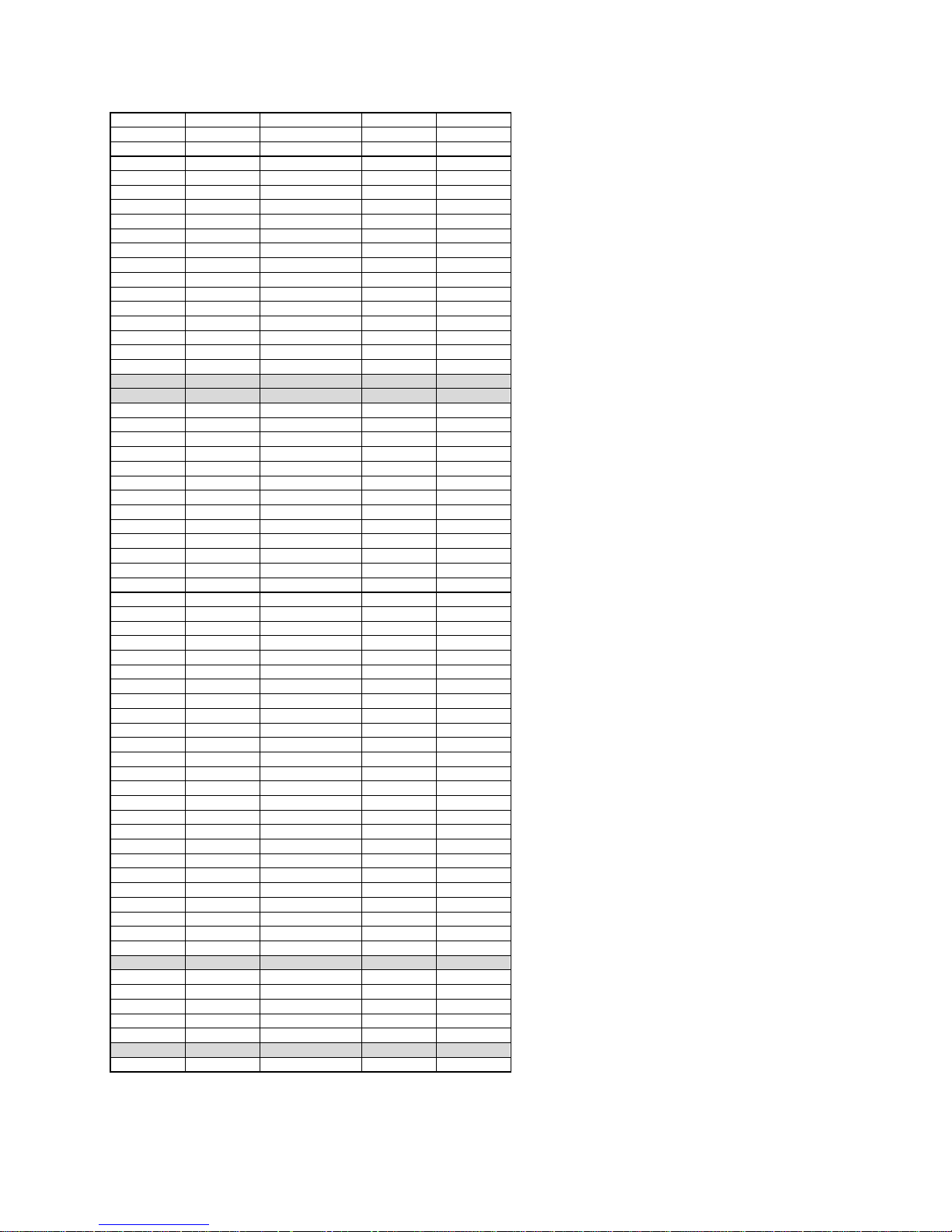

NU-22B R-22 MO99 R-427

A

PSIG PSIG PSIG PSIG

°

0 18.0 24.0 18.5 17.5

2 19.5 25.7 20 19.1

4 21.1 27.4 21.5 20.7

6 22.7 29.1 23 22.3

8 24.3 31.0 25 23.8

10 26.1 32.8 26.5 25.4

12 27.8 34.8 28.5 27.2

14 29.7 36.8 30 29.0

16 31.6 38.8 32 30.9

18 33.5 40.9 34 32.8

20 35.5 43.1 36 34.7

22 37.6 45.3 38.5 36.8

24 39.7 47.6 40.5 38.9

26 41.9 50.0 43 41.1

28 44.2 52.4 45 43.4

30 46.6 55.0 47.5 45.7

32 49.0 57.5 50 48.2

34 51.5 60.2 52.5 50.7

36 54.0 62.9 55 53.3

38 56.6 65.7 58 56.0

40 59.3 68.6 60.5 58.7

42 62.1 71.5 63.5 61.5

44 65.0 74.5 66.5 64.2

46 67.9 77.6 69.5 67.1

48 71.0 80.8 72.5 70.2

50 74.1 84.1 75.5 73.3

52 78.0 87.4 79 76.6

54 81.0 90.8 82 79.9

56 84.1 94.3 85.5 83.3

Bubble SATURATION Bubble Bubble

60 103.0 101.6 110 109.6

62 106.8 105.4 114 113.7

64 110.7 109.3 118 117.8

66 114.7 113.2 122 122.1

68 118.8 117.3 126.5 126.4

70 123.0 121.4 131 130.8

72 127.2 125.7 136 135.4

74 131.6 130.0 140.5 140.1

76 136.1 134.5 145.5 144.8

78 140.7 139.0 150 149.7

80 145.3 143.6 155 154.6

82 150.1 148.4 160 159.8

84 155.0 153.2 165.5 165.0

86 160.0 158.2 170.5 170.3

88 165.1 163.2 176 175.8

90 170.4 168.4 181 181.2

92 175.7 173.7 187 187.0

94 181.1 179.1 193 192.7

96 186.7 184.6 199 198.6

98 192.4 190.2 205 204.7

100 198.2 195.9 211 210.8

102 204.1 201.8 217 217.2

104 210.1 207.7 223 223.6

106 216.3 213.8 229.5 230.2

108 222.6 220.0 236 236.9

110 229.0 226.4 243 243.6

112 235.6 232.8 250 250.6

114 242.2 239.4 257.5 257.7

116 249.0 246.1 264.5 264.9

118 256.0 253.0 272 272.3

120 263.1 260.0 279 279.7

125 281.4 278.0 298 299.1

130 300.6 296.9 319 319.4

DEW SATURATION DEW DEW

Superheat - Use Dew Column for blended

Subtract the saturation or dew temperature

corresponding to the suction pressure in the

evaporator from the suction line temperature to

determine superheat.

Values for MO99 are approximate and rounded to

the nearest 0.5 PSIG.

Adjust thermostatic expansion valve to maintain

8-16° superheat.

Sub-cooling - Use Bubble Column for blended

Subtract the liquid line temperature from the

saturation or bubble temperature corresponding to

the head pressure to determine sub-cooling.

Always charge blends in liquid state.

Charge to 5° sub-cooling when using blended

refrigerants. The sight glass may show some

bubbles.

Charge to 5° sub-cooling and a full sight glass

with R-22.

WZDS9100 #2

26

Page 27

DIAGNOSTIC SHEET for customer order #______________________

A qualified service technician must record all of the information on the diagnostic sheet

before calling for technical assistance. The technician must be able to identify the unit with

the order number and serial numbers to receive accurate trouble shooting assistance. The

condenser fan motor must be running and the return air temperature must be between 53

and 58F when recording this data.

Refrigerant: ________________________

Condenser Model # __________________________

Condenser Serial # __________________________

Evaporator Model # __________________________

Evaporator Serial # __________________________

Voltage at compressor: __________________________

Compressor amp draw: __________________________

Line set size: _____________X____________

Line set length: __________________________

Number of elbows in suction line, including __________________________

all 45 and 90 degree bends in soft copper:

Suction pressure at compressor: __________________________

Head pressure: __________________________

Suction line temperature at compressor: __________________________

Discharge (hot gas) line temperature: __________________________

Liquid line temperature: __________________________

Condenser ambient temperature: __________________________

Return air temperature, see above: __________________________

Supply air temperature: __________________________

This area to be filled out for air handler installations only:

Supply trunk size: __________________________

Number and size of supply registers: ___________@______________

Return air trunk line size: __________________________

Customer name: __________________________________________

For the property located at: __________________________________________

__________________________________________

Diagnostic sheet filled out by: __________________________________________

Date __________________________________________

Company: __________________________________________

Telephone #_______________Fax#_______________E-Mail______________________

Wine Cellar Innovations 4575 Eastern Avenue Cincinnati, OH 45226 800-229-9813

WZDS9100 #2

27

Loading...

Loading...