Wine Guardian WGS175 User Manual

Ducted Split

Wine Cellar Cooling Systems

酒卫分体式

酒窖冷却系统安装,使用和保养指南

型号:

Installation, Operation and Maintenance Guide

WGS40, WGS75, WGS100, WGS175

Manufactured by:

制造商

美国空气创新公司

酒卫保留权利,恕不另行通知,可自行决定更改此文件。

如需酒卫使用手册和其他最新文本请访问我们的网站。

Wine Guardian 是空气创新公司的注册商标(注册号 2,972,262)

2014 年 09月版

www.wineguardian.com www.airinnovations.com

Wine Guardian reserves the right, without notice, to make changes to this document at its sole discretion.

Please visit our web site for the most current version of the Wine Guardian manual and other literature.

Wine Guardian is a registered trademark (2,972,262) of Air Innovations, Inc.

Edition 09-2014

© Air Innovations, 2014

Syracuse, NY

1

TABLE OF CONTENTS 目录

Directory of Terms 缩写语言索引 .................................................................................... 5

Illustrations 示意图........................................................................................................... 7

Receiving, Inspecting and Unpacking the Wine Guardian Unit 接收,检查和打开酒卫设

备..................................................................................................................................... 9

Review the Packing Slip to Verify

Check the fan coil unit for:

Check the condensing unit for ...............................................................................................10

...................................................................................................10

General Description 概述 ............................................................................................... 11

The Wine Guardian Ducted Split System Contains酒卫分体式系统包含 ...............................11

Wine Guardian Fan Coil Unit 酒卫风机盘管 ...................................................................................... 12

Electrical Controls 电气控制 .............................................................................................................. 13

Condensing Unit 冷凝器 ..................................................................................................................... 13

........................................................................................ 9

Accessories and Optional Equipment

Heating Coils ....................................................................................................................................... 14

Duct Collars and Flexible Ducts ........................................................................................................... 14

Extended Compressor Warranty ......................................................................................................... 14

Low Ambient Option ........................................................................................................................... 15

Condensate Pump ............................................................................................................................... 15

Humidifier ........................................................................................................................................... 15

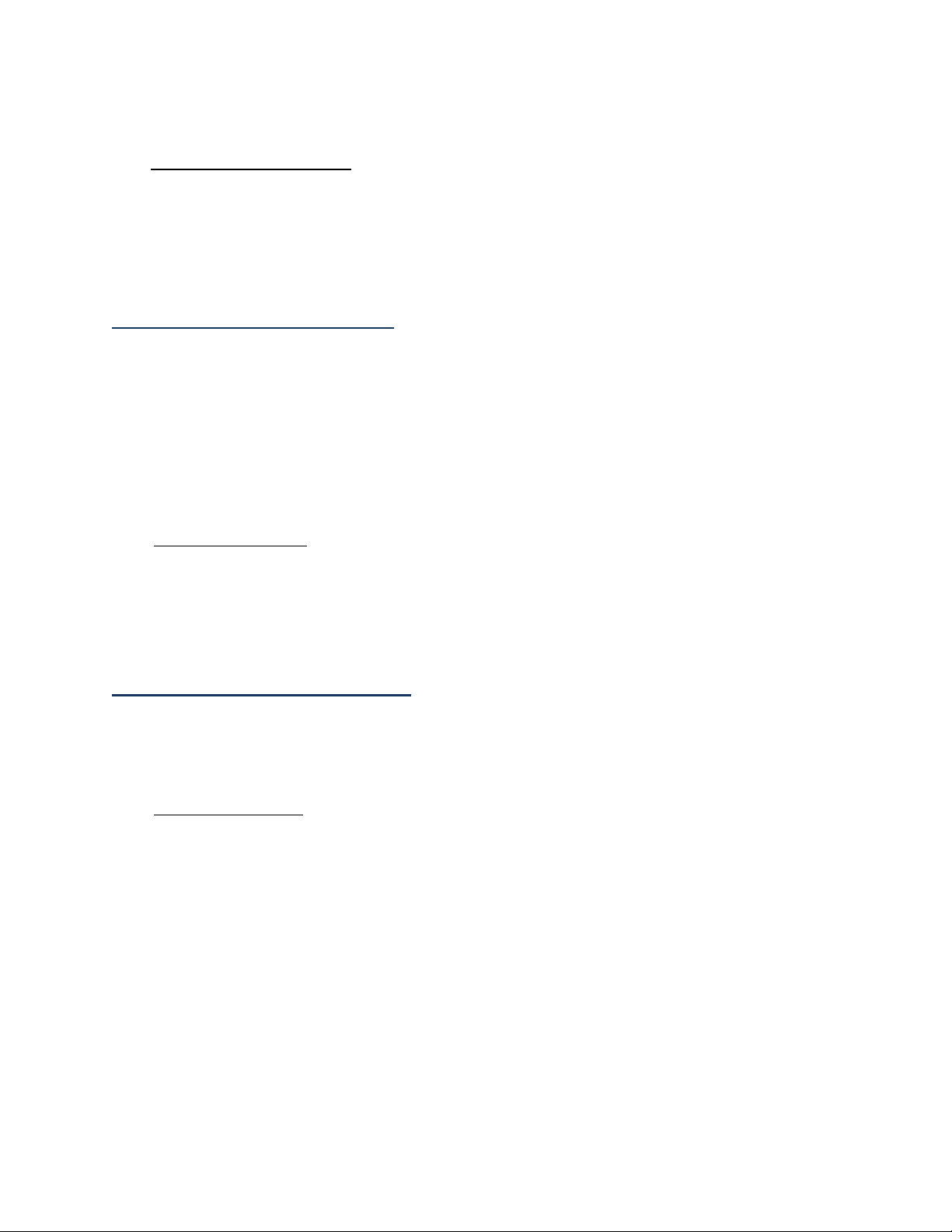

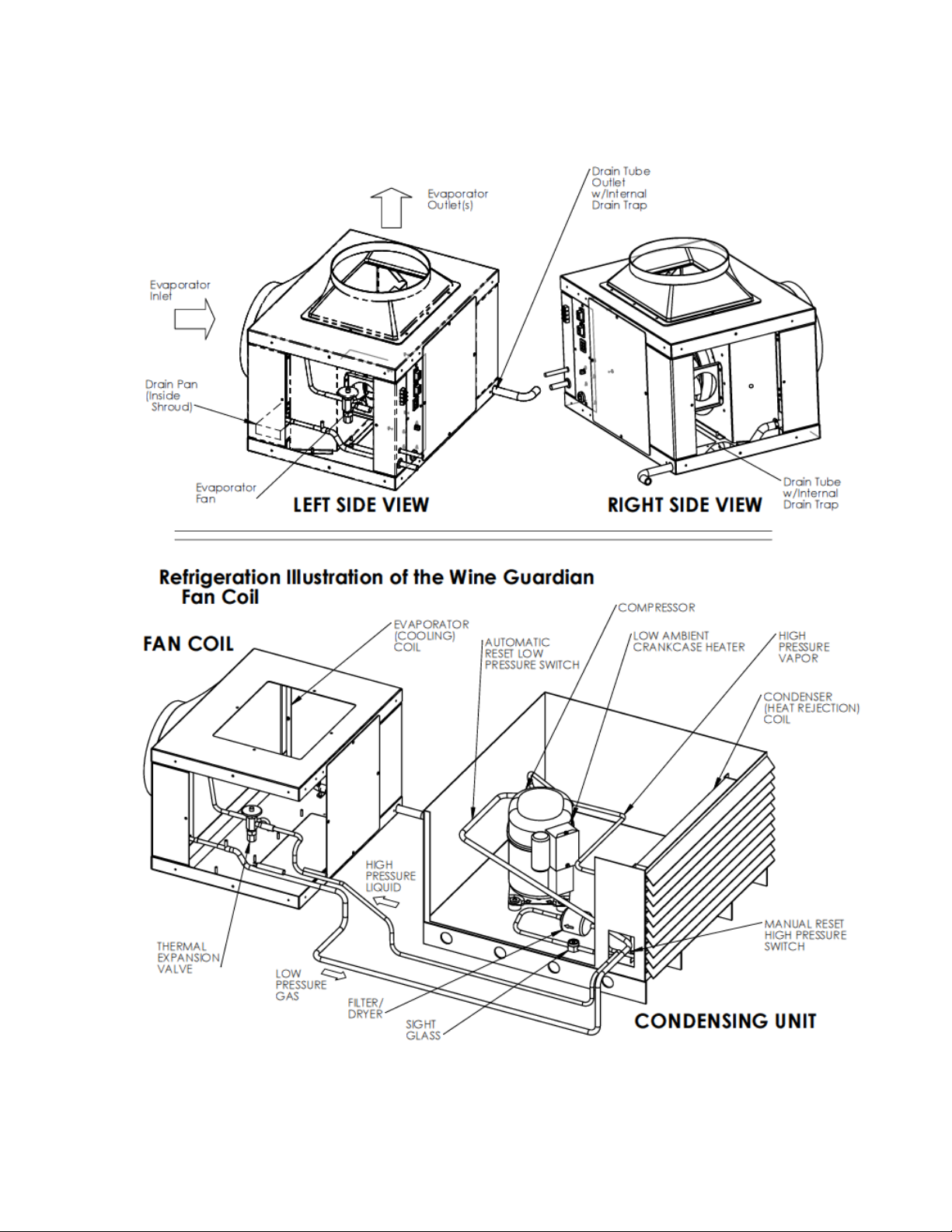

Overview of the Wine Guardian fan coil ............................................................................................. 16

Fig. 1 酒卫风机盘管概述 ................................................................................................................... 16

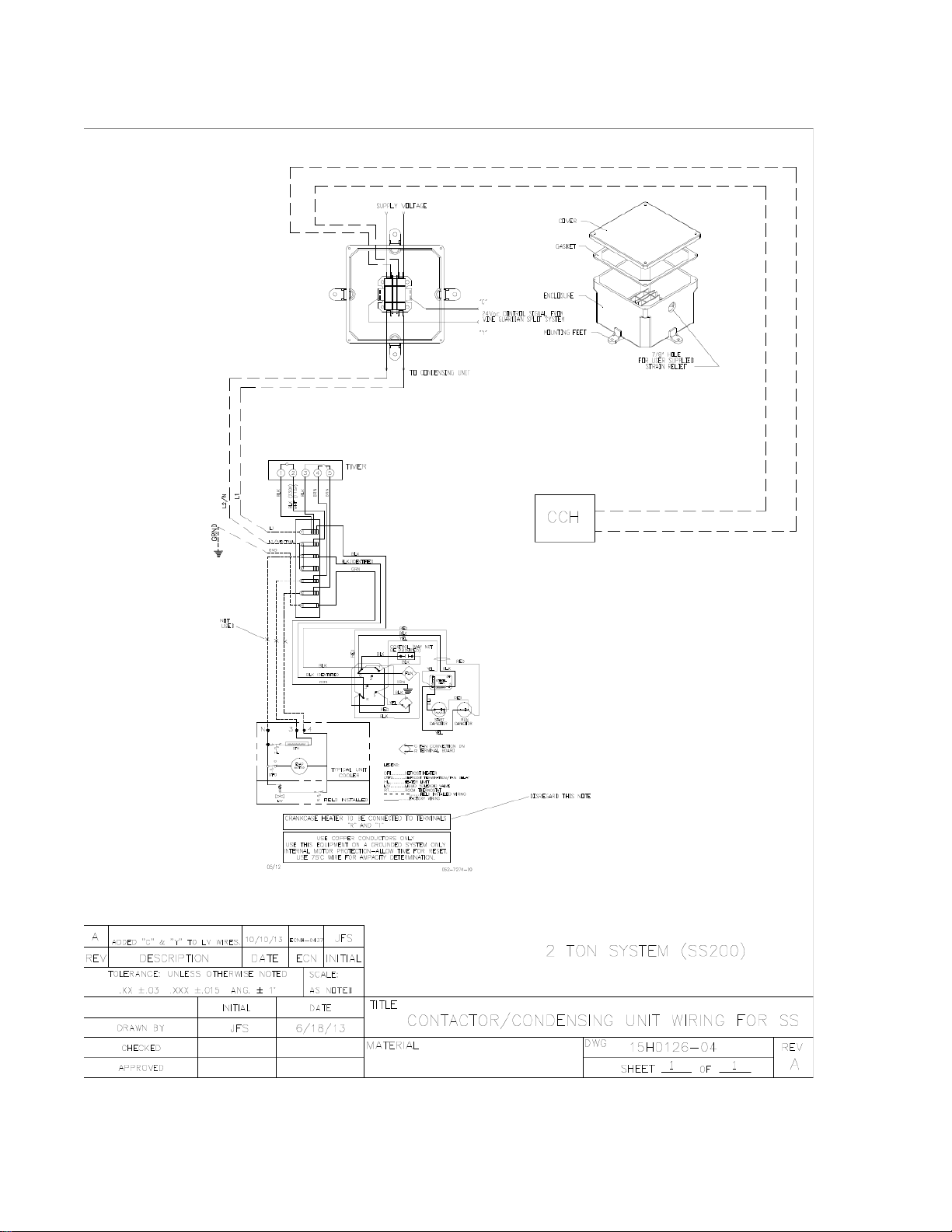

Wiring Diagram for WGS40 ................................................................................................................. 18

Wiring Diagram for WGS75 &WGS100 Units ...................................................................................... 19

Wiring Diagram for WGS175 Units ..................................................................................................... 20

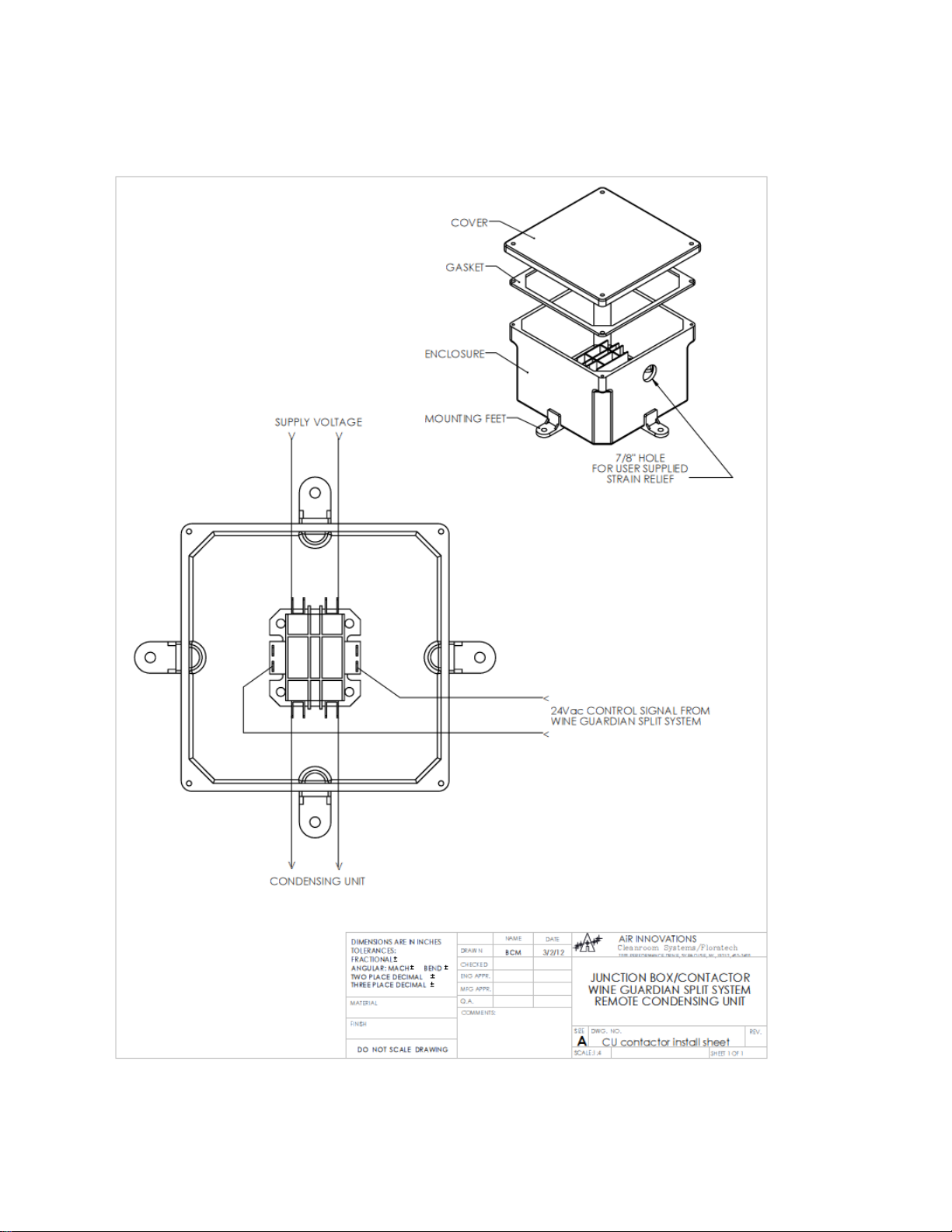

24-Volt Contactor Detail Sheet 24 伏接触器详细信息表 ................................................................ 21

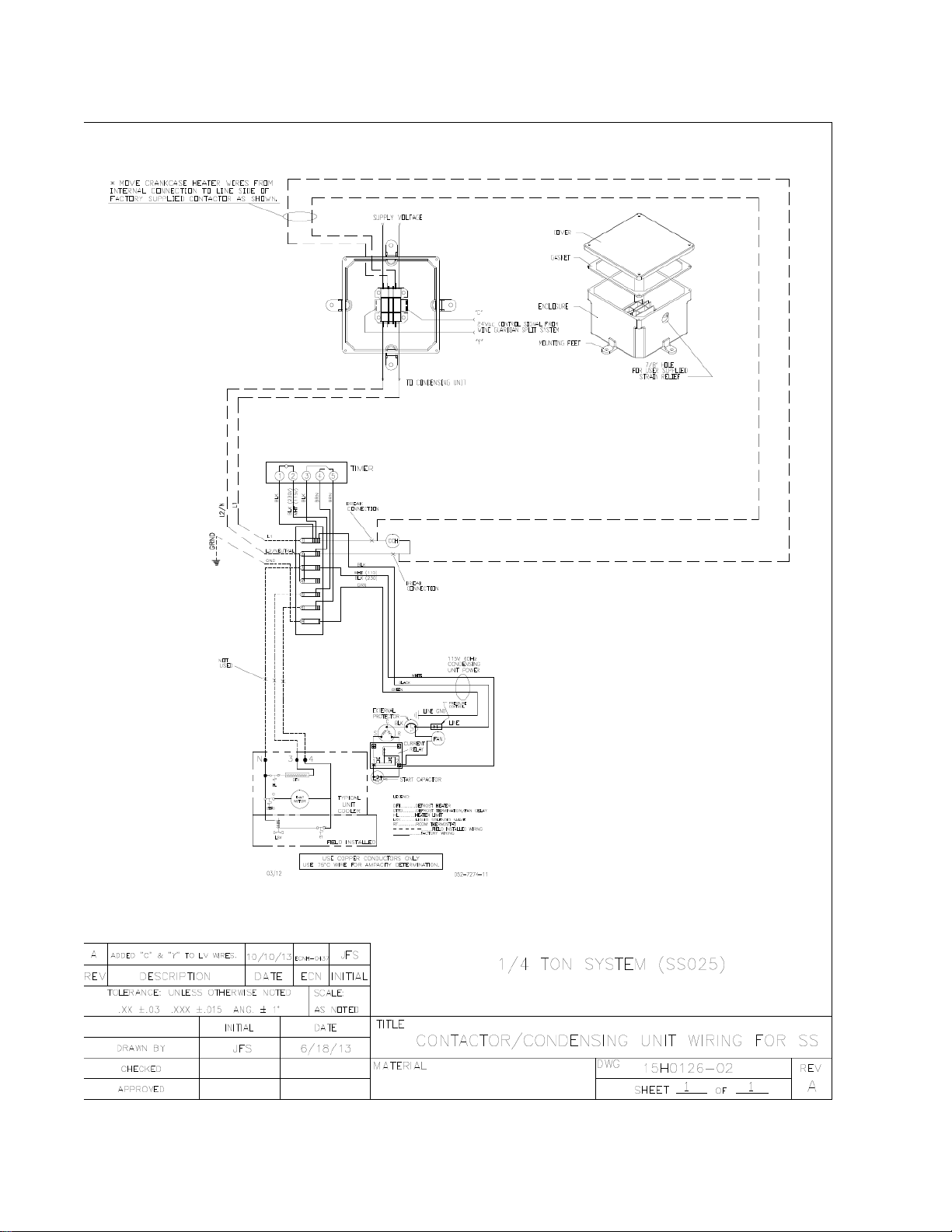

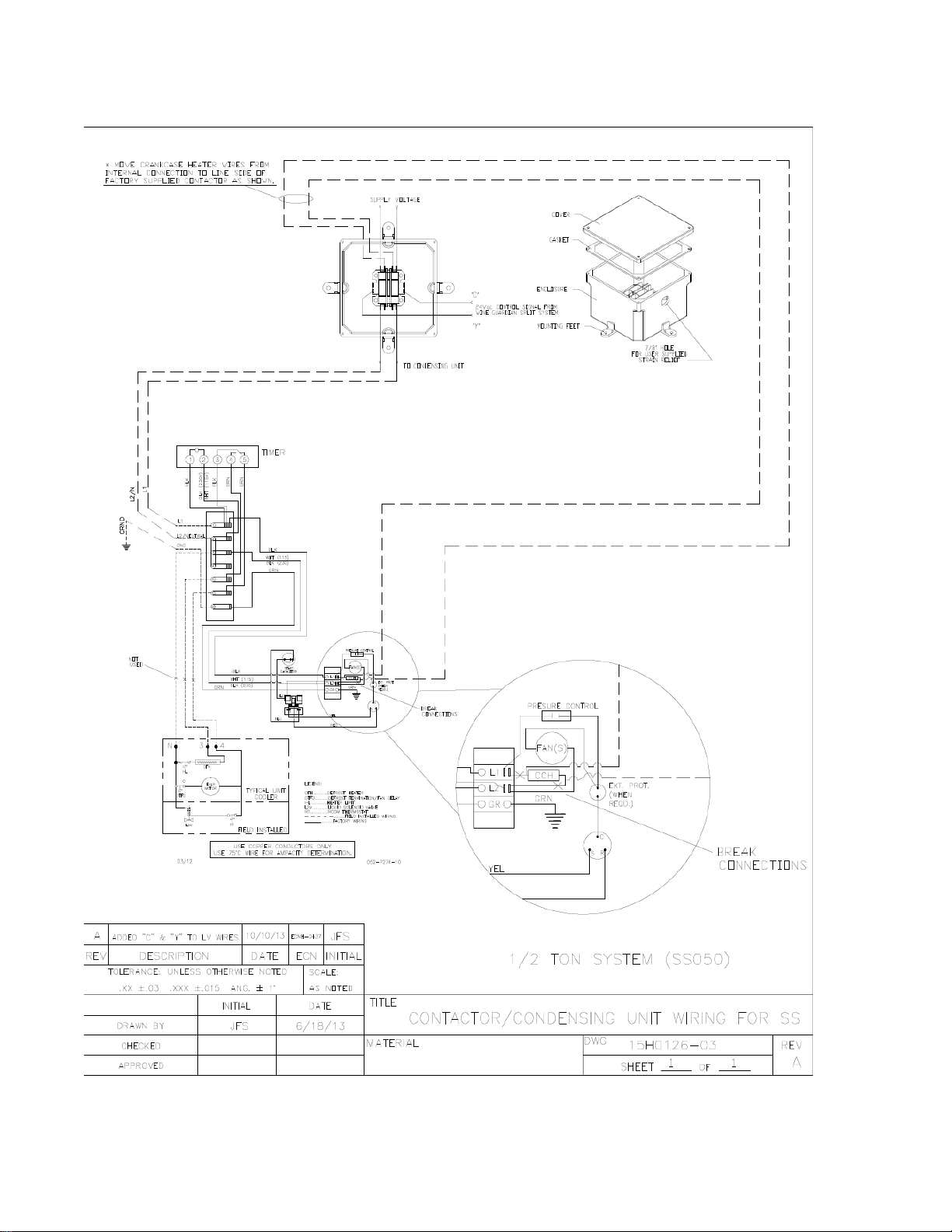

Condensing Section Wiring Schematic for SS025 冷凝段接线原理图 Condensing Section Wiring

Schematic for SS050 冷凝段接线原理图 ........................................................................................... 22

附件和选项设备 .......................................................14

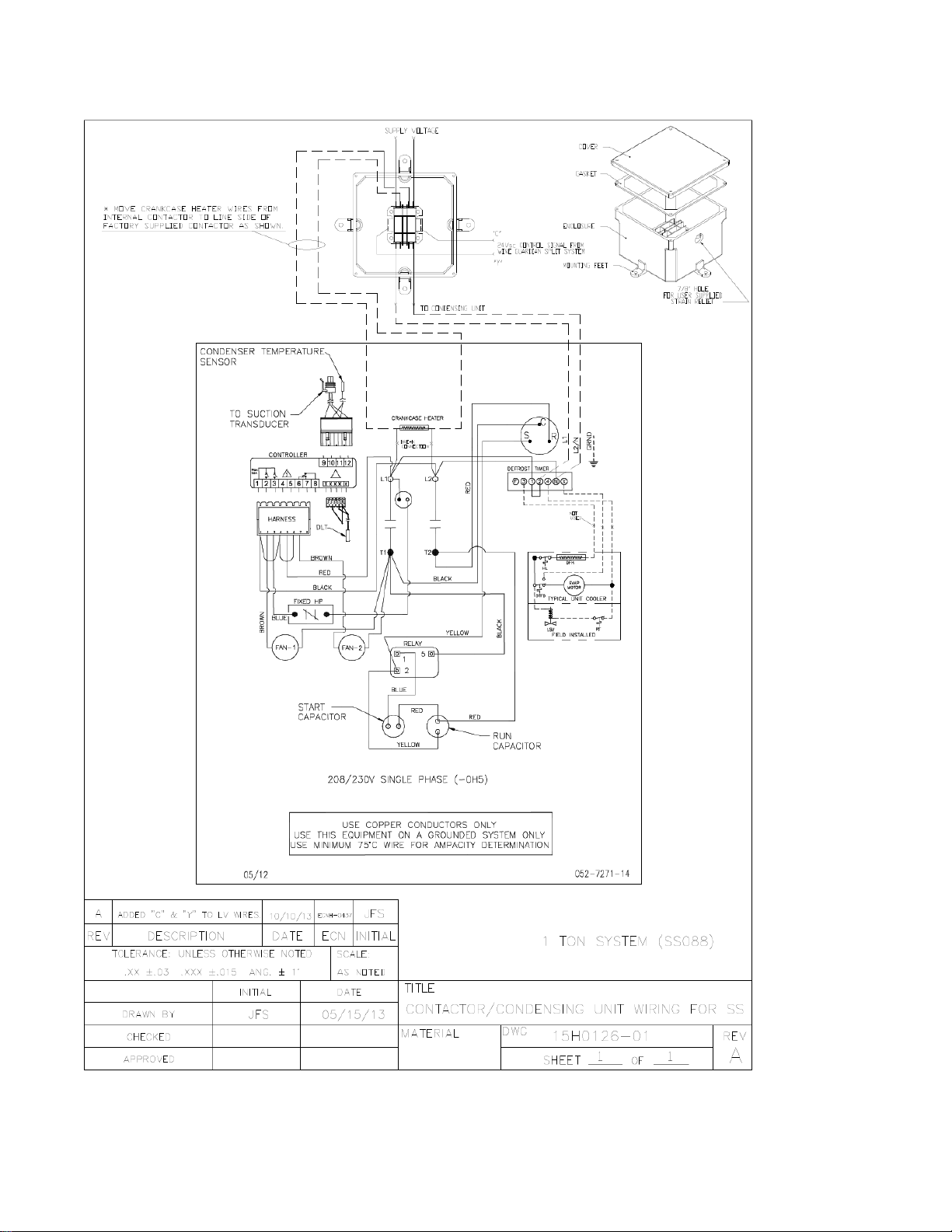

Condensing Section Wiring Schematic for WGS100 冷凝段接线原理图 .......................................... 24

Condensing Section Wiring Schematic for WGS175 冷凝段接线原理图 .......................................... 25

Safety 安全 .................................................................................................................... 26

Safety Message Conventions

Danger ................................................................................................................................................. 26

Warning ............................................................................................................................................... 27

安全信息公约

......................................................................26

2

Caution ................................................................................................................................................ 27

Lockout/Tagout Procedure

Safety Considerations ...........................................................................................................28

Safety Hazards 安全隐患 .................................................................................................................... 28

Electrical Hazards 触电危险 ............................................................................................................... 29

Electrical Shock Hazards 电击危险 ..................................................................................................... 29

Hot Parts Hazards 高温零件 ............................................................................................................... 29

Moving Parts Hazards 运动机件 ........................................................................................................ 29

Equipment Safety Interlocks

Main Power Switch主电源开关 .............................................................................................30

..................................................................................................28

设备安全联动锁

........................................................................30

Installation 安装 ................................................................................................ ............. 33

Pre-installation Test安装前的测试 ........................................................................................33

Air Flow Diagram气流插图 ....................................................................................................34

Planning the Installation 规划安装 ................................................................................. 36

Addressing Items in the Planning Process 解决规划过程中的问题 ........................................36

Performing a Pre-installation Check安装前检查 ....................................................................37

Installing the Fan Coil Unit 安装风机盘管 ...................................................................... 37

Floor Mounting 地板安装 .................................................................................................................. 39

Wall Mounting 壁挂式安装 ............................................................................................................... 39

Ceiling Mounting 天花板安装 ............................................................................................................ 39

Typical Mounting Arrangements

Handling and Installation 搬运和安装 ............................................................................................... 40

Floor Mount 地面安装 ....................................................................................................................... 40

Rod Mount 吊架安装 ......................................................................................................................... 41

Shelf Mount 三角架安装 .................................................................................................................... 41

Optional ductwork connection on same wall Fig. 4 同墙风管连接 ................................................ 41

典型的安装方式 ......................................................................... 39

Installing the Ductwork and Grilles 风管和格栅安装 ...................................................... 42

Duct Collars 卡圈 ................................................................................................................................ 42

Location of Supply and Return Grilles 送风和回风口格栅位置 ...............................................43

General Duct Recommendation一般风管安装建议 ...............................................................43

Reducing Noise from the Unit ...............................................................................................44

Installing the Condensate Drain Connection 凝结水排水连接安装 ................................ 45

Installing the Drain Line排水管线安装 ...................................................................................45

Priming the Drain Trap ..........................................................................................................46

Wiring the Fan Coil Unit for Power 风机组电力线路 ...................................................... 47

Installing the Condensing Unit 安装冷凝器(机) ......................................................... 49

Installation of Interconnecting Refrigerant Lines (Suction and Liquid) ...................................49

Split System Interconnecting Line Sizing Chart 分体式系统互连管线尺寸图 .................................. 51

Sample Piping Configurations管路安装示范 .........................................................................52

3

Leak Checking and Evacuation Process泄漏检查和方气过程 ...............................................53

Wiring 接线 ......................................................................................................................................... 54

Refrigerant Charging 充制冷剂 .......................................................................................................... 55

Determining the amount of charge .................................................................................................... 56

Procedures for Charging System with Head Pressure Control使用头压控制的冲剂程序 .......56

Superheat 过热 ................................................................................................................................... 58

Sub-Cooling 过冷 ................................................................................................................................ 59

Split System Operations Chart 分体系统操作表 ............................................................................... 60

Mounting the remote sensor 安装遥控传感器 ................................................................................. 64

Joining Communication Cable 连接通信电缆 ................................................................ 66

Changing Jumper Positions (Averaging reading from Remote Sensor) 改变条线位置 (采用传感器

平均值)............................................................................................................................................. 67

STANDARD CONTROLLER FUNCTIONS ................................................................... 68

Inspection and Start-up Checklists 检查和启动检查清单 ............................................... 77

Starting-up and Operating the Wine Guardian Split System 酒卫分体系统启动和操作 . 78

Turn on the Unit 开动主机 ............................................................................................................... 78

Testing the Fan 测试风扇 ................................................................................................................. 78

Running the Unit

Cycling the Unit 机器循环 ................................................................................................................ 79

Setting the Remote Interface Controller ................................................................................80

运行酒卫机器系统

............................................................................................. 79

Maintenance 维修......................................................................................................... 81

Cleaning the Filters 清洁过滤网 ................................................................................. 82

Cleaning the Condensate Drain System 清洁排水系统 ........................................... 83

Cleaning the Humidifier .........................................................................................................83

Heating Coil Option ...............................................................................................................83

Maintenance Schedule

维护时间表

............................................................................ 84

Monthly 每月 .................................................................................................................. 84

Yearly 每年 .................................................................................................................... 84

Troubleshooting

Advanced Troubleshooting高级故障排除 ..............................................................................93

Instructions to Reset High Pressure Switch

疑难解答

.......................................................................................... 85

.......................................................................94

Contact and Warranty Information 保修联络信息 .......................................................... 95

Contact Information联络信息 ................................................................................................95

Warranty and Warranty Procedure

保修期和手续

..............................................................95

Warranty

4

保修条款

....................................................................................................... 97

Directory of Terms 缩写语言索引

Ambient Air – The surrounding area outside the wine cellar such as a room, basement, garage or

outdoors.

环境空气 - 酒窖外的环境,如一个房间,地下室,车库或室外区域

BTU/H – British thermal units/hour. A unit of measurement to describe the power of heating and

cooling system.

BTU / H - 英热单位/小时。测量单位来描述的加热和冷却系统的电源。

CFM – Cubic feet per minute. A unit of measurement for the amount of air handled by the fan.

CFM - 每分钟立方英尺。测量的空气由风扇所处理的量的单位。

Condensate / Condensation – The water formed out of the air when it is cooled below a certain

temperature (called dew point). Often referred to as “sweating” on pipes and cold surfaces. This water

collects at the bottom of the evaporator or cooling coil and drains out of the unit through the drain line.

凝结水/冷凝 - 当低于某一特定温度时空气中的水分会凝结成水。通常被称为管道和冷表面“出

汗”。这种水通过蒸发器底部或冷却盘管或透过排水渠底的排水管线收集。

Condensing Unit (Heat Rejection) – The condensing unit uses the compressor, condenser coil and

fan to remove heat from the refrigerant to the ambient air outside the wine cellar. The word condenser

refers to the condensation of the refrigerant from gas to liquid phase.

冷凝器(散热)- 冷凝器部分使用压缩机,冷凝器线圈和风扇制冷剂去除酒窖外空气的热量。

这个词指的是冷凝器的制冷剂从气体冷凝成液体。

CSA/ETL – Canadian Standards Association/Edison Testing Laboratory (product compliance to

safety standards)

CSA/ ETL - 加拿大标准协会/爱迪生测试实验室(产品是否符合安全标准)

F – (Degrees) Fahrenheit 华氏(度)

Fan Coil Unit (Evaporator Cooling) – The fan coil unit uses the cooling coil and the fan to remove

heat from the air inside the wine cellar to the refrigerant, cooling the air and condensing moisture out

of the air. The word evaporator refers to the evaporation of the refrigerant from liquid to gas phase in

the coil. The fan coil unit is ducted to or can be placed inside the wine cellar.

风机盘管(蒸发冷却) - 风机盘管机组采用冷却盘管和风机通过制冷剂从酒窖内的空气带走热

量,冷却空气和水分冷凝出来的空气。蒸发器是指线圈中的制冷剂的蒸发从液态到气态。风机

盘管通过管道或可放置在酒窖内。

Flexible Duct – Round ducts with steel reinforced plastic liners, a layer of insulation and an outer

plastic layer used to convey the air from the unit to the wine cellar or ambient space.

柔性管道 - 钢纤维增强的塑料管 带间层绝缘材料,外面有塑料层,以用来传送从主机组到酒窖

的空气或环境空间。

5

Grille or Diffuser – Inlet or outlet plates to direct the airflow or protect the inside of the unit.

格栅或扩散片 -空气进口或出口引导板,或机器的保护板。

Heat Gain / Loss – The amount of cooling or heating expressed in watts transferred between the wine

cellar and the ambient space. The Wine Guardian must offset this heat/gain loss.

热增益/损失 - 酒窖和环境空间的冷却或加热的总额用瓦表示。酒卫主机机组必须抵消这种负

荷。

Inlet Air – The air returning from the wine room to the Wine Guardian fan coil.

进气 - 空气进入机组的蒸发器和冷凝器部分。 NEC 公司,美国国家电气规程

I.D. – Inside diameter 内径 - 内径

NEC – National Electrical Code 美国国家电气规程

O.D. – Outside diameter 外径

Psig Pounds – Force per square inch gauge PSIG 磅 - 每平方英寸力度

Recovery – The amount of cooling the unit does to return the cellar to its set point temperature after

some new heat load is introduced, such as people or new cases of warm wine entering the cellar.

恢复 – 增加新的负载后,如进人或暖酒进窖,主机恢复酒窖设定温度所需的制冷量。

Return Air - The air leaving the cellar and returning to the inlet of the fan coil. (See Inlet Air above)

回风 - 空气离开地窖并返回到蒸发器盘管的入口。

TXV – Thermal expansion valve TXV - 热力膨胀阀

VAC – Volts alternating current 伏 - 伏交流电

SP – Static pressure. Unit of measurement (inches of water column) of the pressure of the air handled

by the fan.

静压。经过风扇的空气的压力,以英寸水柱(In. w.c.)计算。

Set Point – The desired temperature or humidity set on the remote interface controller or humidistat.

设定值:在恒温或恒湿器上设定的所需温度或湿度。

Supply Air - The air entering the wine cellar from the discharge of the fan coil.

送风:从蒸发器排气口流入酒窖中的空气。

6

Illustrations 示意图

Overview of the Wine Guardian fan coil 酒卫风机盘管概述 ...................................7

Refrigeration Illustration of the Wine Guardian fan coil 酒卫风机盘管制冷过程 .....7

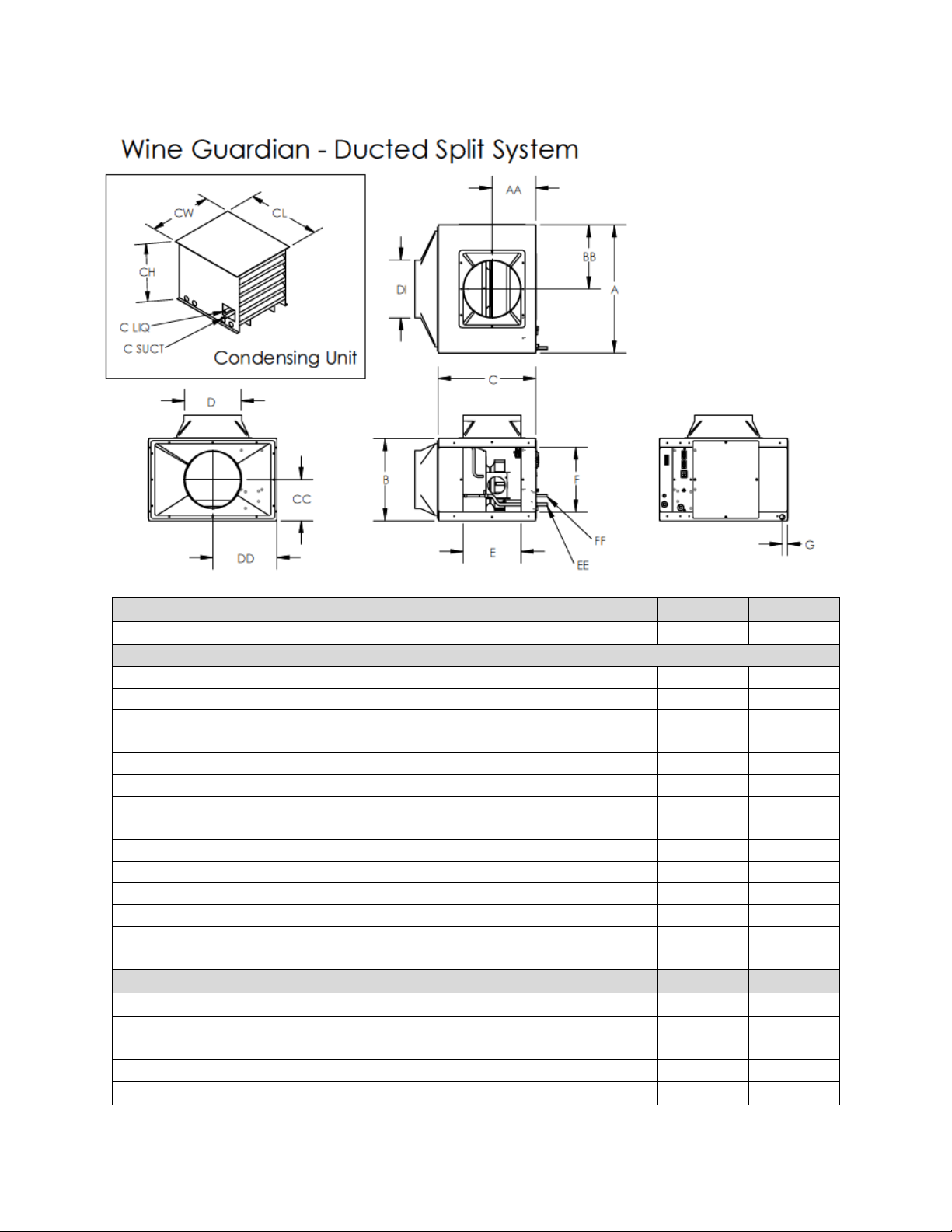

Ducted split system specifications sheet 分体式管道系统规格表 ..........................9

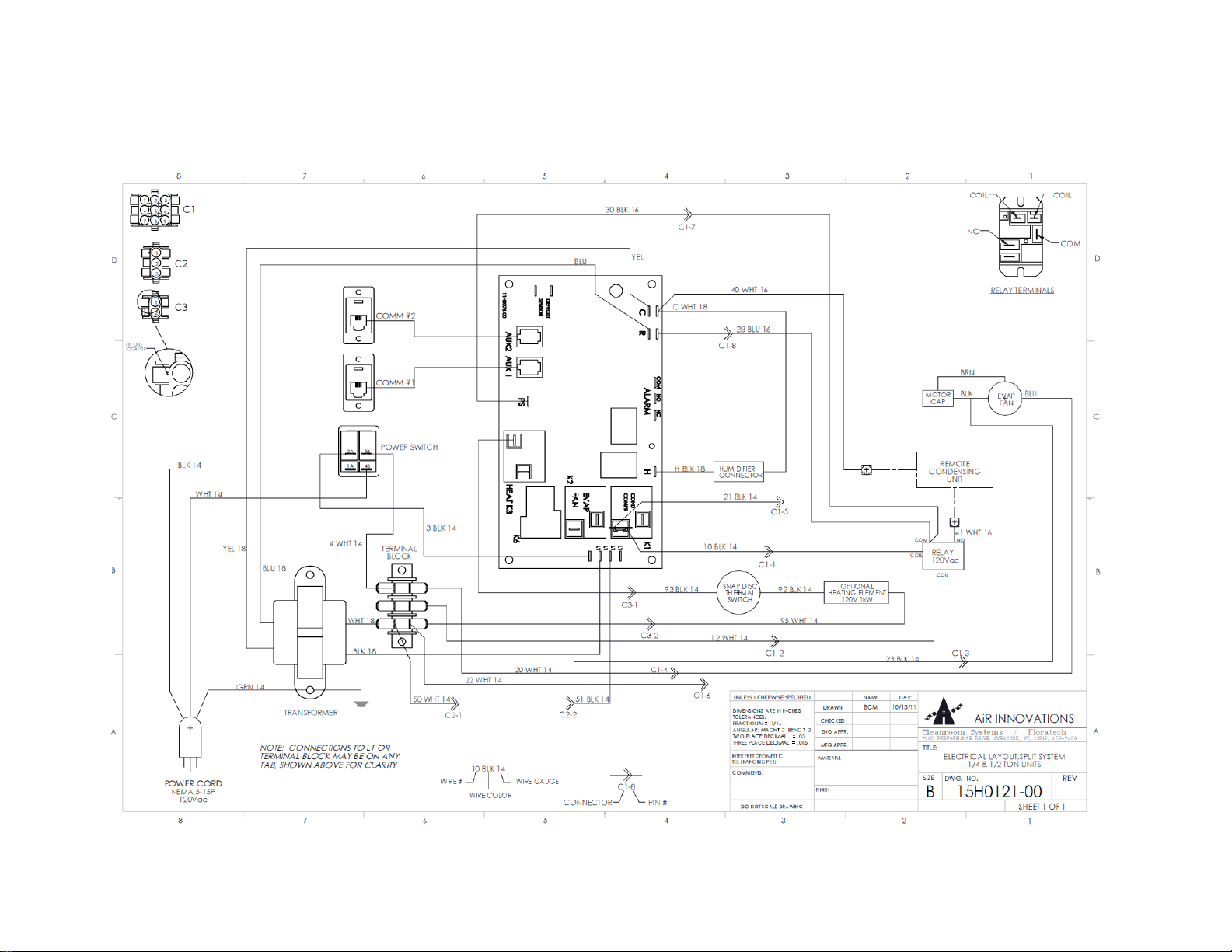

Wiring diagrams for WGS40 and WGS75 units 1/4 吨和 1/2 顿设备接线图..... 10

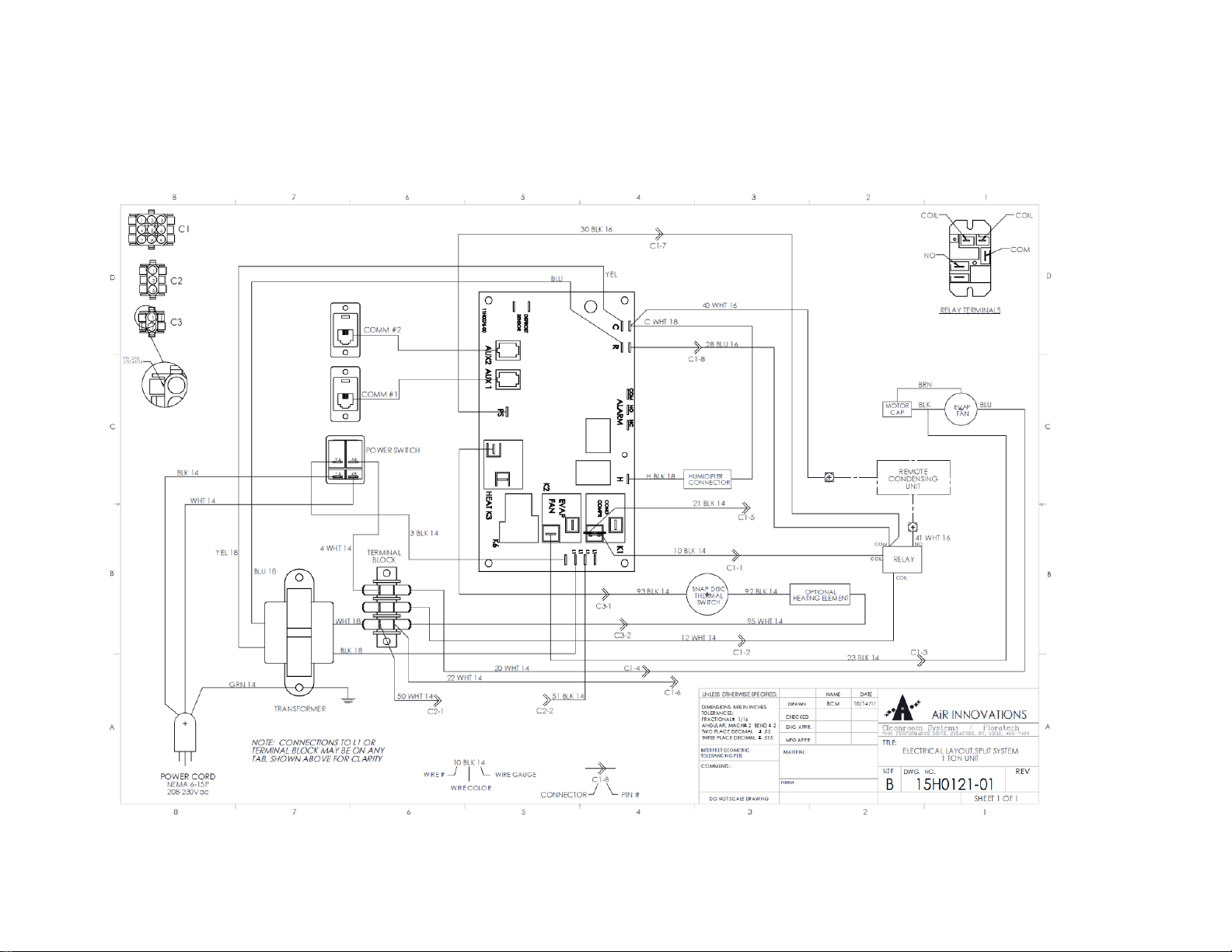

Wiring diagram for the WGS100 unit 1 顿设备接线图 ..................................... 11

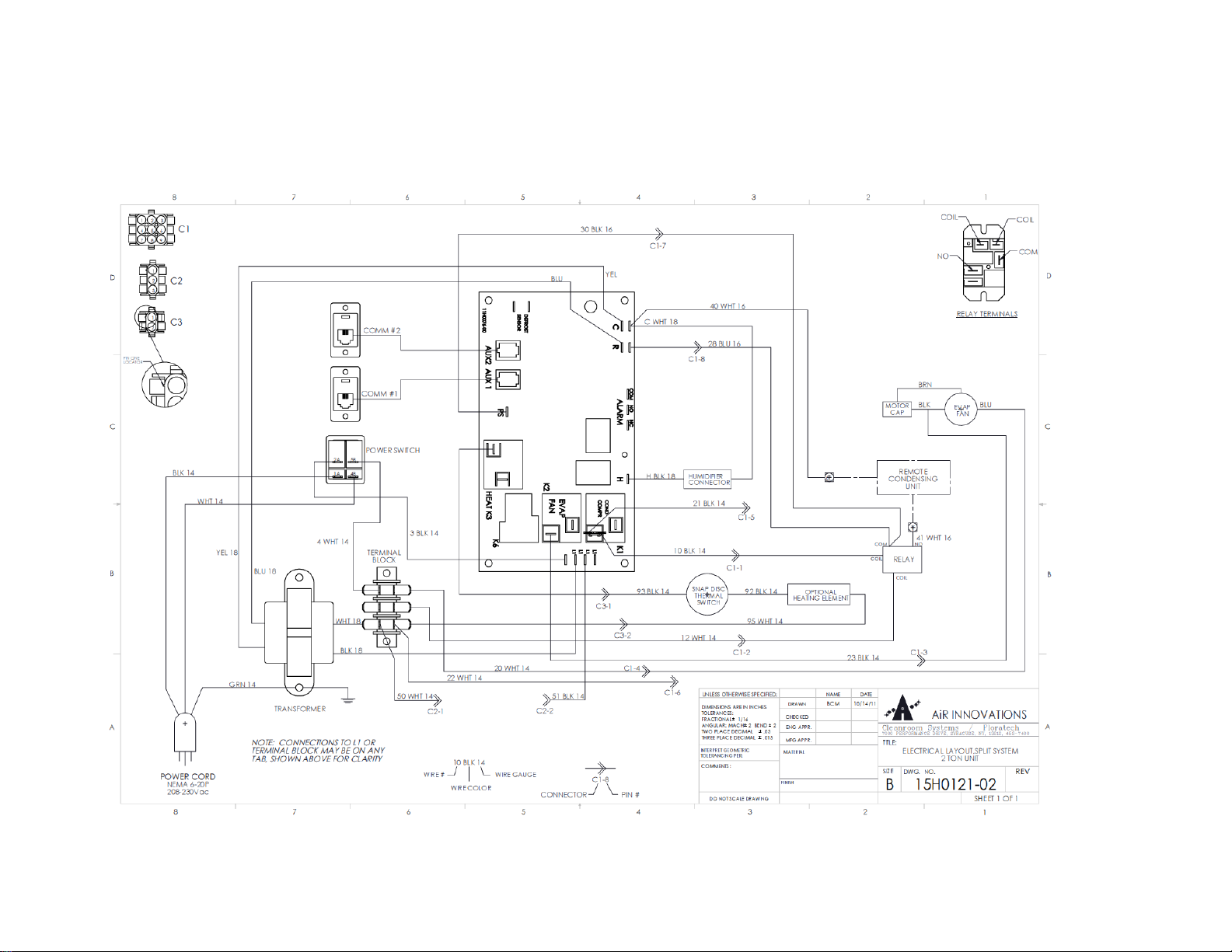

Wiring diagram for the WGS175 unit 2 顿设备接线图 .................................... 12

24-volt contactor detail sheet 24 伏的接触细节表 .............................................. 13

Condensing section wiring schematics 冷凝段接线原理图 ................................ 14

Airflow diagram 气流图 ..................................................................................... 22

Mounting illustrations 安装示意 .......................................................................... 26

Sample piping illustration 制冷剂管路配置示意 ................................. ................. 34

7

Receiving, Inspecting and Unpacking the Wine Guardian Unit

IMPORTANT

If this procedure is not followed, the shipping company may reject the claim and the

consignee may suffer the loss. Do not return the shipment to the factory.

如果不遵循这一程序,运输公司可以拒绝索赔和收货人可能蒙受的损失。请不要将

产品寄回生产厂家。

接收,检查和打开酒卫设备

NOTE: Wine Guardian units are factory assembled and tested prior to shipment. The

Wine Guardian Ducted Split System consists of two separate components, the Wine

Guardian fan coil and condensing unit. These ship from separate manufacturing

facilities and therefore may not arrive on the same date and time.

酒卫主机是工厂组装,先测试后装运.。酒卫风管分体式系统包括两个独立的组件,酒卫

风机盘管和冷凝机组。发货点来自不同的生产设施,因此可能不是同时到达。

Each Wine Guardian component is shipped in a corrugated box. A shipment may include one or

more boxes containing accessories.酒卫使用瓦楞纸箱包装,大箱里可能包括一个或多个配件包。

Lift at the designated handhold locations only or fully support from underneath.

请在指定的位置提起或只从箱下方全力支撑。

Before opening, inspect the packing crates or boxes for obvious signs of damage or

mishandling.

拆开包装之前,请先仔细检查纸箱上是否有破损或不当处置所留下的痕迹。

Write any discrepancy or visual damage on the bill of lading before signing.

将货物与实物不符之处以及可见损伤填写在提货单上,然后签名

Inspect all equipment for any sign of damage caused during transit.

仔细检查设备,看其是否有运输过程中留下的损伤。

Report all visual or concealed damage to the carrier and file a claim immediately.

马上将所有可见或隐蔽损伤报告给搬运人,并提出索赔。

Thoroughly inspect the contents for any visible damage or loose parts.

全面检查任何可见的损坏或松散的部分内容。

Review the Packing Slip to Verify

Model number

Factory installed options

Unit accessories

9

If any items listed on the packing slip do not match your order information, contact the place of purchase

immediately.

审查装箱单验证:

- 型号

- 工厂安装选项

- 设备附件

如果在装箱单所列不符合您的订单信息,请与购买地立即联系

Check the fan coil unit for:

An electrical power cord

A remote interface controller with communications cable plugged into side of unit

A drain line coming out of the unit

A 24 volt contactor and enclosure

One supply duct collar and one return duct collar

检查风机盘管:

- 电源线

- 用通信电缆远程接口控制器插入的单元

- 排水管线出来的单位

- 24 伏接触器和外壳

- 送风管道卡圈和一个回风管卡圈

Check the condensing unit for:

Weather proof enclosure, top and sides

Installation, Operation and Maintenance manual

检查冷凝器:

- 防风雨外壳,顶部和侧面

- 安装,操作和维护手册

10

General Description 概述

IMPORTANT

Design and specifications are subject to change without notice

重要提示

设计和规格若有变更,恕不另行通知

View Fig. 1 and Fig. 2 on page 13 for details 请看 13 页的图 1 和图 2

The Wine Guardian cooling unit is a professional grade, American-manufactured, split two-piece

climate control unit designed specifically for the storage of wine at cellar temperatures. It is designed

for easy installation and operation. Wine Guardian uses digital electronic controls and R-134a

refrigerant. The entire Wine Guardian fan coil section is tested at the factory and the condensing unit is

shipped separately. All components are of a high quality standard commercial grade. The entire system

is approved by ETL according to UL 1995 and CSA safety standards. All wiring complies with NEC.

Each Wine Guardian fan coil section is furnished with a sealed, UL-approved power cord and plug.

酒卫分体系统冷却装置是专业级,美国制造,它是为酒窖储酒特别设计的自给自足的气候控制

设备。安装和操作简便。本系统使用数字电子控制与 R-134a 环保制冷剂。整个酒卫风机盘管

部分是在工厂测试完毕, 冷凝器是分开运输的。所有部件都是高品质的标准商业级别。

The Wine Guardian Ducted Split System Contains 酒卫分体式系统包含

1. A Wine Guardian Fan Coil Unit with: 酒卫风机盘管包括以下

A thermal expansion valve to control the flow of refrigerant into the evaporator coil

A built in condensate drain trap. No external trap is required.

A removable control panel for ease of service

Supply duct collar

Return duct collar

Remote interface controller and control cable

- 温度膨胀阀,以控制进入蒸发器盘管制冷剂的流动

- 内置的冷凝水排放的存水弯。无需外部存水弯。

- 可移动的控制面板,

- 供应卡圈

- 回风卡圈

- 远程接口控制器和控制电缆

2. A Condensing Unit with: 冷凝器部分

A filer dryer to keep the refrigerant clean and free of contaminants

A sight glass to observe the level of refrigerant

11

A manual reset high pressure switch on the discharge to protect the compressor from high

pressures.

Auto reset low pressure switch

24-volt contactor for control of fan coil unit

Crankcase heater

Low ambient refrigeration controls

Outdoor enclosure

- 过滤器干燥器,以保持制冷剂清洁,无污染物

- 一个视镜观察制冷剂的水平位置

- 高压手动复位 开关,对放电保护压缩机。

- 低压自动复位开关

- 控制风机盘管的 24 伏接触器

- 曲轴箱加热器

- 低温环境制冷控制

- 室外机壳

Wine Guardian Fan Coil Unit

The Wine Guardian fan coil unit meets its rated capacities for total BTU/H and CFM at design cellar

conditions and external static pressures. The fan coil unit is capable of rated CFM against the static

pressure imposed by recommended ductwork. The fan is a motorized impeller type, statically and

dynamically balanced, and uses permanently lubricated direct drive motors requiring no maintenance.

酒卫风机盘管的额定容量每小时英热单位和 CFM 达到酒窖设计条件和外部静态压力要求。风

机盘管每分钟立方英尺气流达到静压力管道系统推荐的额定要求。风扇是一个电动叶轮式,静

态和动态平衡,并采用永久润滑的直驱电机无需保养。

The Wine Guardian fan coil section operates as air passes through the cooling coil and is cooled by the

refrigerant inside the coil. This causes any excess humidity in the air to condense and be captured in

the drain pan and piped outside the unit. Air then enters the fan where it is pressurized and discharged

out of the unit through one of five openings. Optional heating coils are located between the cooling

coil and the fan. These coils heat the air to prevent low temperatures in the cellar.

酒卫风机盘管通过管内的制冷剂为管外经过的空气制冷。空气中过多的湿度,经冷凝,捕获在

积水盘里, 用管道排出机外。此空气然后进入风扇机加压后排出设备的五个开口。可选的加热

线圈放置在冷却盘管和风扇之间。这些线圈加热空气,以防止地窖低温。

All exterior framing of the Wine Guardian is powder coated 0.063 inch gauge aluminum to prevent

rust and corrosion. All coils are copper tubes, aluminum fins, with an electrocoating to protect against

premature corrosion. The unit uses an external drain to remove excess moisture and not reintroduce it

into the cellar or ambient space. Removable, multiple access doors are provided to facilitate cleaning

酒卫风机盘管

12

and maintenance, duct connections, and access to components and wiring. The fan coil has at least five

discharge outlets to facilitate custom installations.

酒卫所有外部框架是铝质粉末涂层 0.063 英寸,以防止生锈和腐蚀。所有盘管采用铜管,

。铝翅片,表面具有电涂层以防止过早腐蚀。机组采用外部排水,去除多余的水分,使其不重

新引入酒窖或周围的空间。多个盖板可拆卸,为清洁和维护,管道连接,部件更换和接线提供

方便。风机盘管有至少五个排放口,以方便安装的灵活性。

Each unit is provided with a pre-wired and tested remote interface controller for remote mounting

within the wine cellar. The remote interface controller has multiple control functions for cooling,

heating and operation. It has a fully automatic mode to switch between heating and cooling.

每个主机都配备有已接好的远程接口控制器用于酒窖内远程安装。远程接口控制器有制冷,制

热和操作等多项控制功能。它具备完全自动模式,为加热和制冷之间进行切换。

Electrical Controls

The main electrical control board and components are located on a separate panel accessible through a side door

panel or by removal of the on/off panel from the system chassis.

Wires are numbered and color coded to match the wiring diagrams.

主要电气控制电路板和元件都位于一个单独的面板上。接触元件必须通过侧门盖板或打开系统

机箱的开/关盖板 。所有接线是按照 NEC 标准。导线编号,并用不同的颜色编码,与接线图相

匹配。

电气控制

All wiring is in accordance with the NEC.

Electric power is supplied by a single factory-furnished cord and plug. All external controls are digital

and proprietary to Wine Guardian products. Only approved communication cable and Wine Guardian

controllers are suitable for proper system operation.

电力线是由工厂提供的电源线和插头。所有的外部控制是数字显示和酒卫产品专有。系统的正

常运行必须使用经过批准的通信电缆和酒卫控制器。

Condensing Unit

Compressors are rotary, self-lubricating, permanently sealed, hermetic reciprocating-type compressors,

with internal overload protection and capacitor start. They include a minimum of 20 months

manufacturer’s warranty and an optional five-year warranty. Compressors are mounted on rubber-inshear isolators to reduce noise and vibration. Additional features include a liquid line filter drier,

Sporlan Head Master Controls, a liquid line receiver and refrigerant sight glass. Each unit is housed in

a painted steel enclosure suitable for outdoor installation. The outdoor enclosure has adequate area for

ventilation and refrigerant piping penetrations.

压缩机是旋转式,自润滑性,永久密封,封闭活塞式压缩机,内部过载保护和电容起动。

压缩机有至少 20 个月制造商的保修和可选的五年质保。

压缩机底部安装橡胶隔离垫,以减少噪音和振动。其他功能还包括一个液体管路干燥过滤器,

斯波兰主 头控制,液体线路接收器和制冷剂视镜。每个冷凝器采用涂漆钢质外壳元适合户外安

装。室外机柜有足够的区域用于通风和制冷剂管道穿透。

冷凝器

13

IMPORTANT

The air exhaust from the condensing unit is hot and will be 15 to 20 degrees C above the entering

temperature. The condensing units are rated for a maximum temperature of 46 degrees C. The

condensing units should be installed in a well-ventilated area to ensure proper air flow across the

condenser coil and to limit short cycling.

重要提示

冷凝机排气温度高,要比进气高于 15 至 20 华氏度以上。冷凝机组的额定参数为 46

华氏度的最高温度

冷凝机组应安装在通风良好的地方,以确保整个冷凝器盘管适当的空气流通,避免

短路循环。

Accessories and Optional Equipment

Heating Coils

An optional heating coil is built in and requires no additional power source. The electric

heating option is factory installed and includes primary and secondary over-temperature

protection devices per UL and NEC.

加热线圈一个可选的加热线圈是内置的,不需要额外的电源。电热选项是工厂安装,包

括初级和根据 UL 和 NEC 二级的超温保护装置。

Duct Collars and Flexible Ducts

Ducting for the Wine Guardian is sold in kits by size for each unit. Each kit contains two

adapter collars, one 8m length of round flexible duct and two straps. The number of duct kits

needed depends on the wine cellar layout and application. The size of the kit depends on the

model Wine Guardian selected. Follow installation instructions carefully. Poorly or incorrectly

installed ducts can degrade the performance of your unit dramatically.

卡圈和柔性管道

酒卫主机的管道按不同主机大小分别成套出售。每个套件包含两个管领适配器,一个 8

米的圆形柔性管和两根皮带。风管套件所需的数量取决于设计图纸。该套件的大小取决

于选定的酒卫主机型号。仔细按照安装说明。不佳或不正确的管道安装可以降低主机的

工作性能。

Extended Compressor Warranty

The Wine Guardian uses only the best commercially available compressors on the market.

However, since the compressor is the single most expensive component in the unit, it is

recommended that you purchase the extended warranty option.

延长压缩机保修

该机组采用了市场上最好的商用压缩机。然而,由于压缩机是在机组中最昂贵的部件,

建议您购买延长保修选项。

14

加热线圈

卡圈和柔性管道

延长压缩机保修期

附件和选项设备

Low Ambient Option – Standard on all Wine Guardian Ducted Split Systems

A factory-installed low ambient option is available that makes the Wine Guardian capable of

exposure to low ambient temperatures. This feature controls the condenser fan operation based

on head pressure and heats the compressor oil reservoir. The low ambient option is

recommended whenever the condenser section is exposed to air temperatures below 40

degrees F.

低温环境选项 – 所有酒卫分体式系统的标准件

工厂安装的低环境安装选项让酒卫主机有抵抗低环境温度的能力。在头部压力并加热储

油器的基础上此功能控制冷凝器风扇运行。在冷凝器部分暴露在低于 40 F 时, 建议使用

低温环境选项。

Condensate Pump

An optional Wine Guardian automatic condensate pump is available

remote sink, drain pipe or

outside. It requires a separate 120 volt electrical outlet.

to pump the water to a

冷凝 水泵

酒卫主机可带自动冷凝泵(选项)把凝结水抽入水槽或室外。它需要一个单独的 120 伏的

电源插座。

Humidifier

Another popular option for the Wine Guardian is a humidifier. The humidifier is available for

split system installation and can be retrofitted onto any existing Wine Guardian unit. Each

humidifier is furnished with a communication cable connection to plug into the side of the

Wine Guardian fan coil unit. It is then controlled by the same remote interface controller that

is used for the operation of the Wine Guardian unit. The humidifier mounts directly onto the

Wine Guardian unit and requires a water supply and drain for operation.

加湿机

另一种受欢迎的选择是酒卫系统加湿机。加湿机可是用于分体系统 ,也可以改装到现

有的冷却主机上 。每个加湿机都配有通讯线可直接连接到酒卫风机(内机)的一侧,

操作控制由同样的风机远程接口控制器的控制。加湿机直接连接到酒卫风机(内机)

并需要供水和排水的操作。

CAREFULLY FOLLOW THE INSTALLATIONS INSTRUCTIONS INCLUDED WITH THE

HUMIDIFIER. REFER TO THE IN-

STRUCTIONS CONTAINED IN THE BOX FOR THE HUMIDISTAT.

CAUTION

警告

仔细按照加湿机的说明安装,请参考箱内的湿度调节器说明。

15

Overview of the Wine Guardian fan coil

Fig. 1

酒卫风机盘管概述

Fig. 2

16

Model Number

WGS40

WGS75

WGS100

WGS175

Dimensions - Nominal

A – Width

cm

35.6

55.9

55.9

56.8

B – Height

cm

35.9

35.9

35.9

45.7

C – Length

cm

42.5

42.5

42.5

52.1

D – Evap. Discharge (OD)

cm

20.2

25.2

25.2

30.3

DI – Evap. Inlet (OD)

cm

20.2

25.2

25.2

30.3

E – Outlet opening width

cm

25.3

25.4

25.4

29.5

F - Outlet opening height

cm

28.3

28.3

28.3

38.1

G – Drain outlet location

cm

1.7

2.3

2.3

2.2

AA – Discharge opening height

cm

19.1

19.1

19.1

23.3

BB – Discharge opening width

cm

17.8

27.9

27.9

28.4

CC – Inlet opening height

cm

17.9

17.9

17.9

22.9

DD – Inlet opening width

cm

17.8

27.9

227.9

28.4

EE – Suction Line (OD)

cm

1.0

1.2

1.2

2.2

FF – Discharge Line (OD)

cm

0.6

0.6

0.6

1.0

Weight

Lbs.

CH – Condenser Height

cm

46.4

46.4

56.5

68.9

CL – Condenser Length

cm

61.3

61.3

76.8

81.9

CW – Condenser Width

cm

48.6

48.6

59.4

97.2

Fig. 3

Table 1

17

Wiring Diagram for WGS40

Fig. 4 线路图

18

Wiring Diagram for WGS75 Units

Fig.5 线路图

19

Wiring Diagram for WGS100, WGS175 Units

Fig. 6 线路图

20

24-Volt Contactor Detail Sheet 24

Fig. 7

伏接触器详细信息表

21

Condensing Section Wiring Schematic for WGS040

冷凝段接线原理图

22

Condensing Section Wiring Schematic for WGS75

冷凝段接线原理图

23

Condensing Section Wiring Schematic for WGS100

冷凝段接线原理图

24

Condensing Section Wiring Schematic for WGS175

冷凝段接线原理图

25

IMPORTANT

The equipment described in this manual uses electricity. When using this equipment, be

sure to follow the safety procedures outlined in this manual.

本手册中所描述的设备都使用电力。当使用

这种设备,一定要遵守使用手册中关于安全程序的概述

Safety 安全

Safety Message Conventions

Safety messages contained in this manual, DANGER, WARNING, and CAUTION are bold

and highlighted in red for quick identification. 本手册中包含安全信息,危险,警告和警

示以红色粗体标出,以帮助快速识别。

Danger

A Danger message indicates an imminently hazardous situation which, if not avoided,

results in death or serious injury. Messages identified by the word DANGER are used

sparingly and only for those situations presenting the most serious hazards.

一个危险的消息表明即将发生的危险情况,如果不避免,可导致死亡或严重伤害的

结果。少用标有“DANGER”的信息,只有那些提出最严重的危害情况下。

Following is a typical example of a Danger message as it could appear in the manual: 以下

是一个典型的会出现在该手册当中的危险信息例子:

危险

安全信息公约

26

DANGER

CAUTION

HIGH VOLTAGE - RISK OF SERIOUS INJURY OR DEATH

High voltages are present in the cabinets.

Before opening panels turn off all power.

Use the Lockout/Tagout procedure.

高电压

在打开面板前关闭所有电源。

-

严重伤害或死亡

高电压在橱柜中。

使用安全挂牌标示。

Warning

警告

A Warning message indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury. 警告信息是指潜在的危险情况,如果不避免,可能导

致死亡或严重伤害。

Following is a typical example of a Warning message as it could appear in the manual

WARNING

以下是一个典型的会出现在该手册当中的警告信息例子

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Modification to the equipment may cause injury.

警告

造成人身伤害或设备损坏

修改设备可能造成伤害。

:

Caution

A Caution message indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. It may also be used to alert against unsafe practice.

一个警示信息表明一种潜在的危险情况,如果不避免,可能导致轻微或中度的伤害。

它也可以用来警惕不安全的做法。

Following is a typical example of a Caution message as it could appear in the manual:

以下是一个警示消息,是一个典型的会出现在该手册当中的警示信息例子:

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Improper installation may result in the equipment malfunctioning and a safety hazard.

Read all of the installation instructions before installing the Wine Guardian unit.

警示

27

IMPORTANT

Installation and maintenance of this equipment is to be performed only by qualified

personnel who are familiar with local codes and regulations, and are experienced with this

type of equipment.

该设备的安装和维护只能由熟悉当地的法规和规章,并熟悉使用这种类型的设备的人来进行。

造成人身伤害或设备损坏

安装不当可能会导致设备故障和安全隐患。

安装之前,请阅读酒卫主机机组所有的安装说明。

Lockout/Tagout Procedure

1) Turn off the power switch (indicator light should be off)

2) Unplug the unit from the electrical outlet and cover the outlet to prevent

accidently plugging in the unit.

3) Turn off circuit breaker or disconnect switch at condensing unit.

安全挂牌标示程序

)关闭电源开关(指示灯应熄灭)

1

)拔掉机组电源插座和覆盖,并将插座覆盖,以防止议意外的电源接通。

2

3)关闭电闸 或断开冷凝器电源

Safety Considerations 安全注意事项

The equipment covered by this manual is designed for safe and reliable operation when

installed and operated within its designed specifications. To avoid personal injury or damage

to equipment or property when installing or operating this equipment, it is essential that

qualified, experienced personnel perform these functions using good judgment and safe

practices. See the following cautionary statements.

本手册所涵盖的设备是专为在涉及规格范围内安全安装和运行设计的。为了避免在安装

和使用设备时造成人身伤害或设备或财产损坏时,合格有经验的人员是必须的,执行这

些功能时他们拥有良好的判断力和安全技术。请参阅下面的警告性声明。

Safety Hazards

安全隐患

Exposure to safety hazards is limited to maintenance personnel working in and around the

unit. When performing maintenance, always use the Lockout/Tagout procedure, which is

described in this chapter. Observe the maintenance safety guidelines in this manual.

安全隐患暴露时仅限于维修人员在机组内或者周围工作。当进行维修时,要使用安全挂

牌标示程序,这在本章描述过遵守酒卫主机手册中的维修安全指引。

28

Electrical Hazards

Working on the equipment may involve exposure to dangerously high voltage. Make sure you

are aware of the level of electrical hazard when working on the system. Observe all electrical

warning labels on the unit.

对设备的工作可能涉及危险的高电压。确保工作时了解触电危险的级别。观察所有电击

设备的警告标签。

触电危险

Electrical Shock Hazards

All power must be disconnected prior to installation and servicing this equipment. More than

one source of power may be present. Disconnect all power sources to avoid electrocution or

shock injuries

请在安装或维护本设备之前切断所有电源(有时可能涉及多个电源),防止因电击而

造成伤亡。

Hot Parts Hazards

Electric resistance heating elements must be disconnected prior to servicing. Electric heaters

may start automatically. Disconnect all power and control circuits prior to servicing the unit to

avoid burns.

请在维护设备之前将所有电阻加热元件(如有)取下。为防止电热设备自动启动起火,

请在进行维护之前切断所有电源电路。

Moving Parts Hazards

.

高温零件

电击危险

运动机件

The Motor and Blower must be disconnected prior to opening access panels. The motor can

start automatically. Disconnect all power and control circuits prior to servicing to avoid

serious injuries or possible dismemberment.

发动机与鼓风机须在打开盖板之前与设备断开。否则发动机可能或自动启动。为防止

造成人身伤害,请在进行维护之前切断所有电源电路。

The fans are free-wheeling after the power is disconnected. Allow the fans to stop completely

before servicing the unit to avoid cuts or dismemberment.

风扇可能会在断电后继续转动。请在风扇完全停转后再进行维护操作,以避免割伤。

Rotating Fan Blades are present in the Wine Guardian unit. Sticking a hand into an exposed

fan while under power could result in serious injury. Be sure to use the Lockout/Tagout

procedure when working in this area or remove the power cord.

酒卫设备中还安装有旋转叶轮。用手接触加电状态下的叶轮,可能会造成重伤。请在

维护本部分时严格遵循隔离锁定步骤、拔掉电源。

29

Equipment Safety Interlocks

设备安全联动锁

There are no electrical safety lockouts installed within the unit. The power cord attached to the

control box must be disconnected from the power sources prior to working on any part of the

electrical system.

机组内没有安装电气安全封锁。连接到控制箱的电源线必须先从电源断开,才能使电力

系统作业。

Main Power Switch 主电源开关

The main power switch is located on the side of the Wine Guardian unit. (See Fig.1 on page

36) It shuts off the power to the fan coil unit. A separate disconnect switch will be wired to

the condensing unit. Both switches must be turned off prior to servicing equipment.

主电源开关位于酒卫主机机组的一面(见第 36 页的插图 1 概述)。此开关 切断风机盘

管电源。一个单独的隔离开关已连接到冷凝器,维修设备之前两个开关必须关闭。

电源规格

Energy Type Electrical

Hazard ................................... Electrocution, electrical burns and shock

Magnitude .............................. 120 VAC and 230 VAC, 1phase, 50 hertz cycles

Control Method ..................... Disconnect power cord and On/Off switch

危险----------------------------电击,电烧伤,休克

规格-----------------------------230 伏交流电一相,50 个周期

控制方法---------------------------拔下电源线和开/关开关

DANGER

危险

Never reach into a unit while the fan is running.

Never

Disconnect the power cord switch before working on the unit. The unit may have

more than one power source to disconnect.

Avoid risk of fire or electric shock. Do not expose the unit to rain or moisture.

. 风扇运行时切勿接触机组。

• 风扇运转正常时切勿打开检修门。

• 在机组工作前切断电源开关。该装置可以有一个以上的电源断开。

• 避免发生火灾或触电。不要让本机受雨淋或受潮。

open an access door to a fan while the fan is running.

30

WARNING

警告

Check weights to be sure that the rigging equipment can support and move the Wine

Guardian unit safely. Note any specific rigging and installation instructions located in

the Installation section of this manual.

All supports for the unit must be capable of safely supporting the equipment’s weight

and any additional live or dead loads encountered.

All supports for the unit must be designed to meet applicable local codes and

ordinances.

Do not remove access panels until fan impellers have completely stopped.

Pressure developed by moving impellers can cause excessive force against the

access panels.

Fan impellers continue to turn (free-wheel) after the power is shut

off.

•检查重量,以确保索具设备能够安全的支持和移动机组。请注意每个索具和安

装说明都在酒卫主机手册的安装部分

•所有的支撑必须能安全支撑机组的重量和遇到的任何其他活的或固定负载

•所有对机组的支持的设计必须符合适用地方的法规和条例。

•不要在风扇叶轮完全停止前移动检查口。 移动叶轮所产生的压力会对检修门产

生过强的压力。

•风扇叶轮会在电源关闭后继续旋转。

CAUTION

警示

Clean only with a dry cloth.

Never pressurize equipment above specified test pressure. See Wine Guardian

Specification sheet on page 13.

Do not use the Wine Guardian near water.

Do not block any supply or return air register or duct. Install in accordance

with the instructions in this manual. Do not defeat the safety purpose of the

polarized or grounding type plug. A polarized plug has two blades with one

wider than the other. A grounding type plug has two blades and a third

grounding prong. The wide blade or the third prong is provided for your safety.

If the provided plug does not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

31

Loading...

Loading...