Wine Cellar Cooling Systems

Installation, Operation and Maintenance Guide

Models: WG 40, WG 75, WG 100, WG 175

50Hz

Manufactured by:

Wine Guardian division of Air Innovations, Inc. Syracuse, NY

www.wineguardian.com www.airinnovations.com

Wine Guardian reserves the right, without notice, to make changes to this document at our sole

discretion. Please visit our web site for the most current version of the Wine Guardian Manual and

other literature. Wine Guardian is a registered Trademark (76/551,126) of Air Innovations, Inc.

Edition 11/2011

Table of Contents

Directory of Terms ....................................................................................................................... 2

Receiving, Inspecting and Unpacking the Wine Guardian Unit .......................................... 3

Receiving and Inspecting the Unit .............................................................................................................................. 3

Review the Packing Slip to verify: ....................................................................................................................... 3

Check the unit for: ....................................................................................................................................................... 3

General Description ............................................................................................................. 4

Standard Specifications ....................................................................................................................................................... 5

The Wine Guardian Unit Contains .............................................................................................................. 5

Accessories and Optional Equipment ................................................................................................................... 6

Heating Coils ........................................................................................................................................................................... 6

Water Cooled Option ........................................................................................................................................... 6

Duct Collars and Flexible Ducts .......................................................................................................................... 6

Extended Compressor Warranty ......................................................................................................................... 6

Low Ambient Option ...................................................................................................................................................... 6

Condensate Pump ........................................................................................................................................................ 6

Humidifier and Humidistat .................................................................................................................................... 6

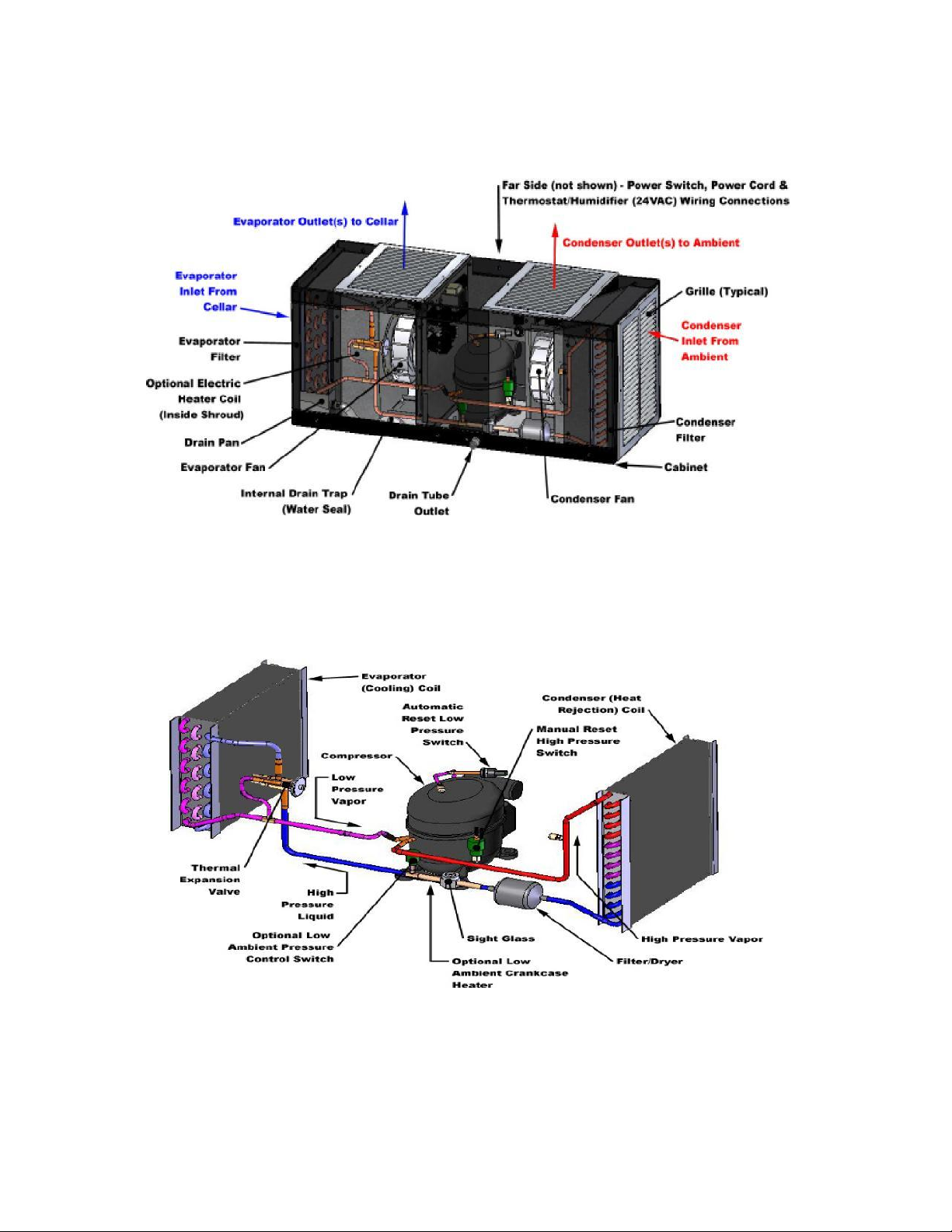

Overview of the Wine Guardian Unit ................................................................................................................... 7

Overview Illustration of the Wine Guardian Unit ........................................................................................... 8

Refrigeration Illustration - Vapor Compression System ............................................................................... 8

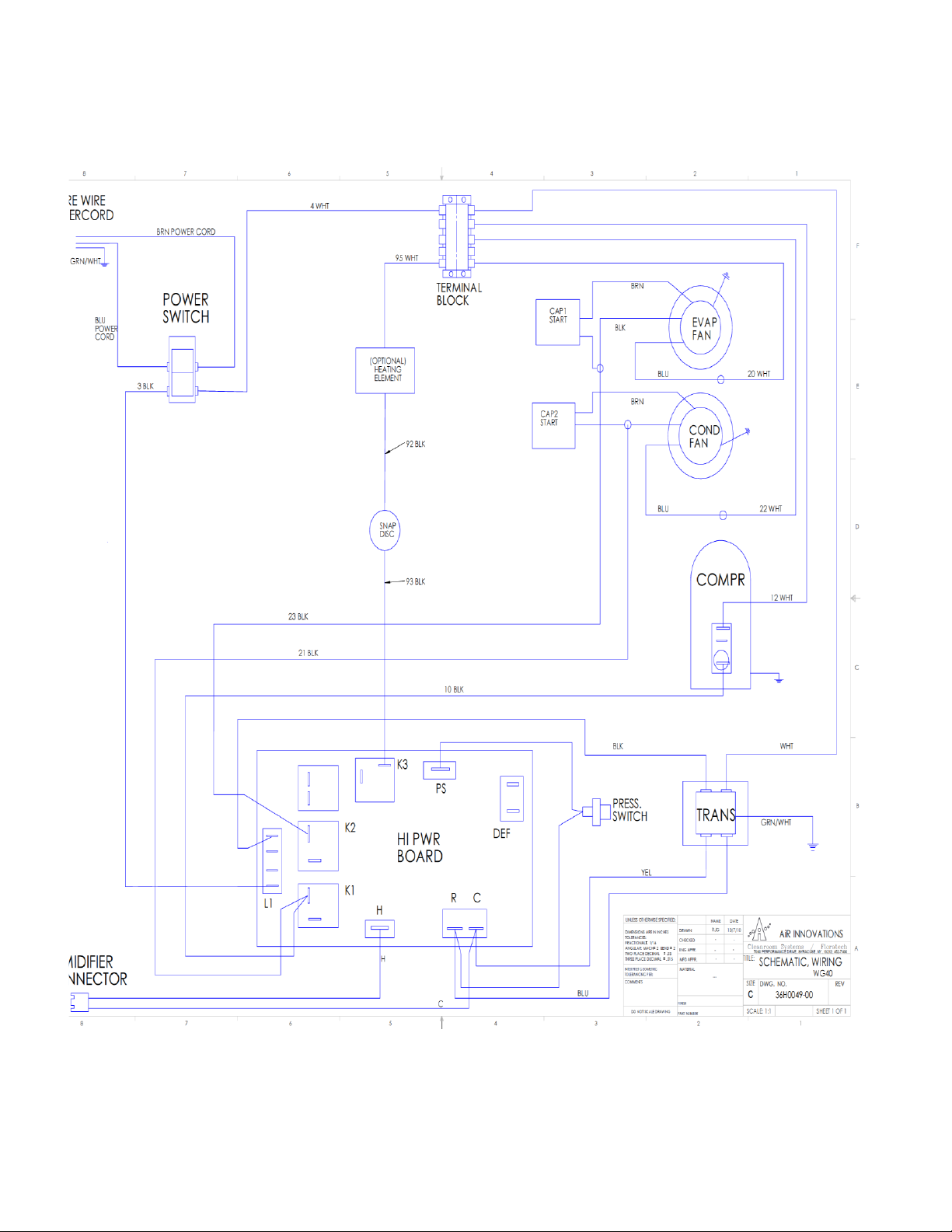

Wiring Diagram WG40 ................................................................................................................................. 9

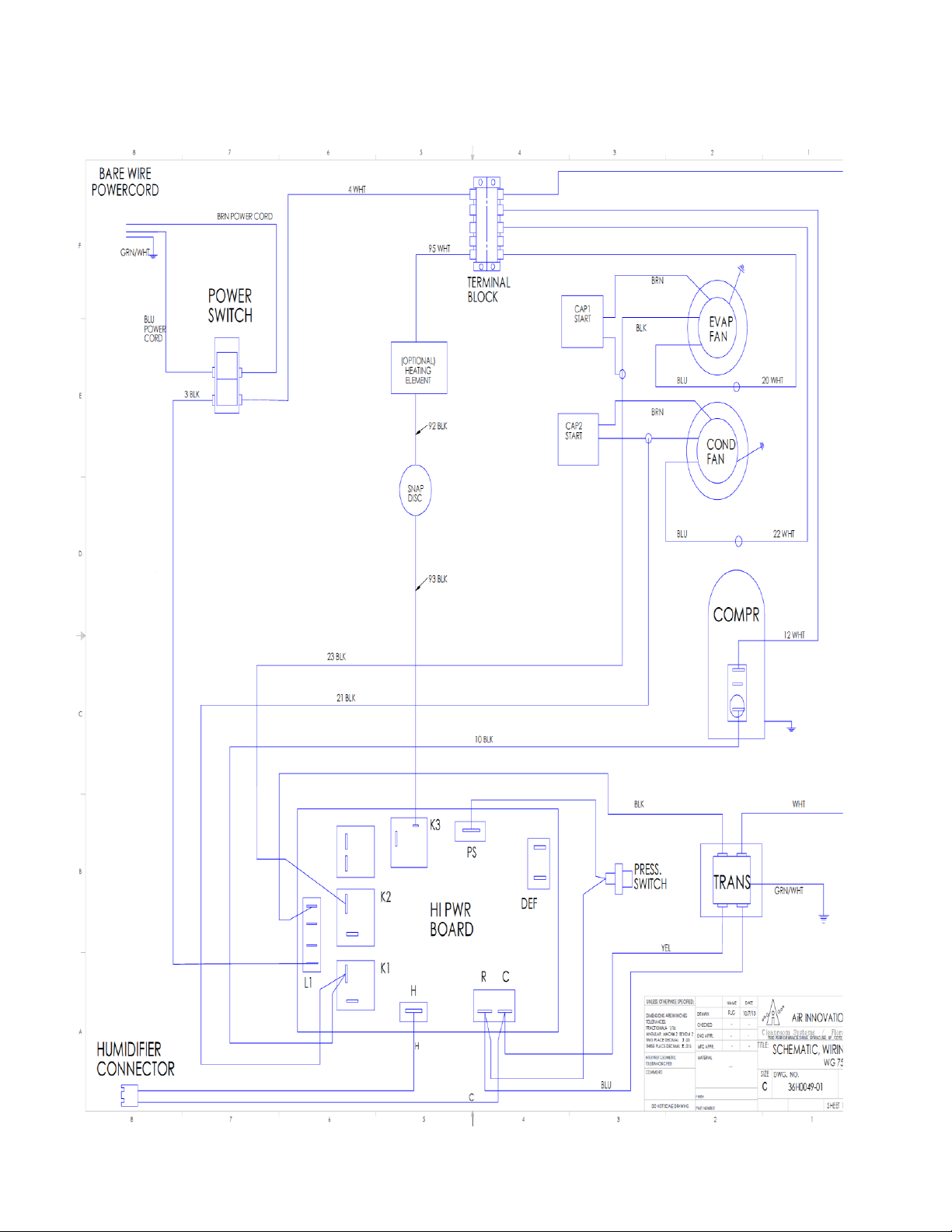

Wiring Diagram WG75 ................................................................................................................................ 10

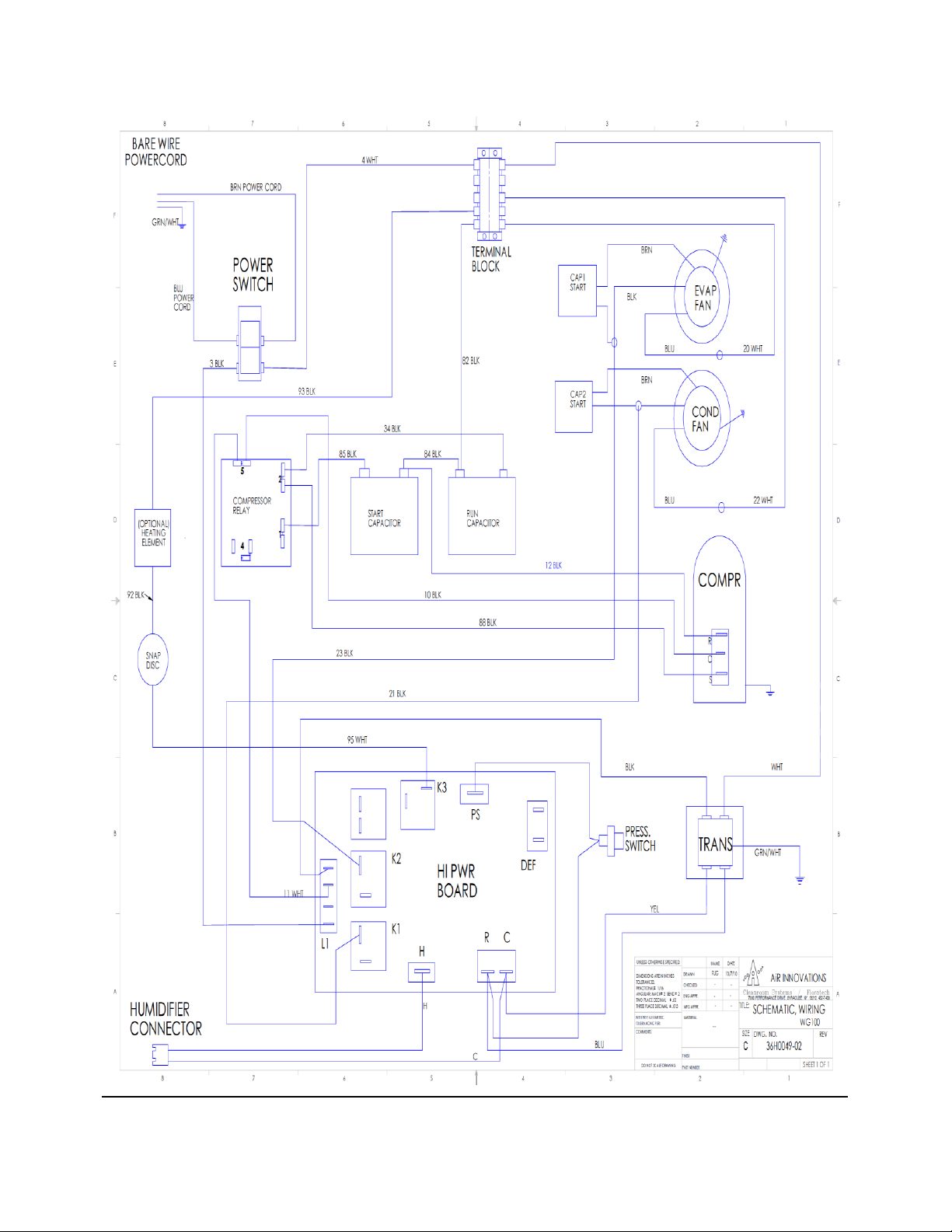

Wiring Diagram WG100 .............................................................................................................................. 11

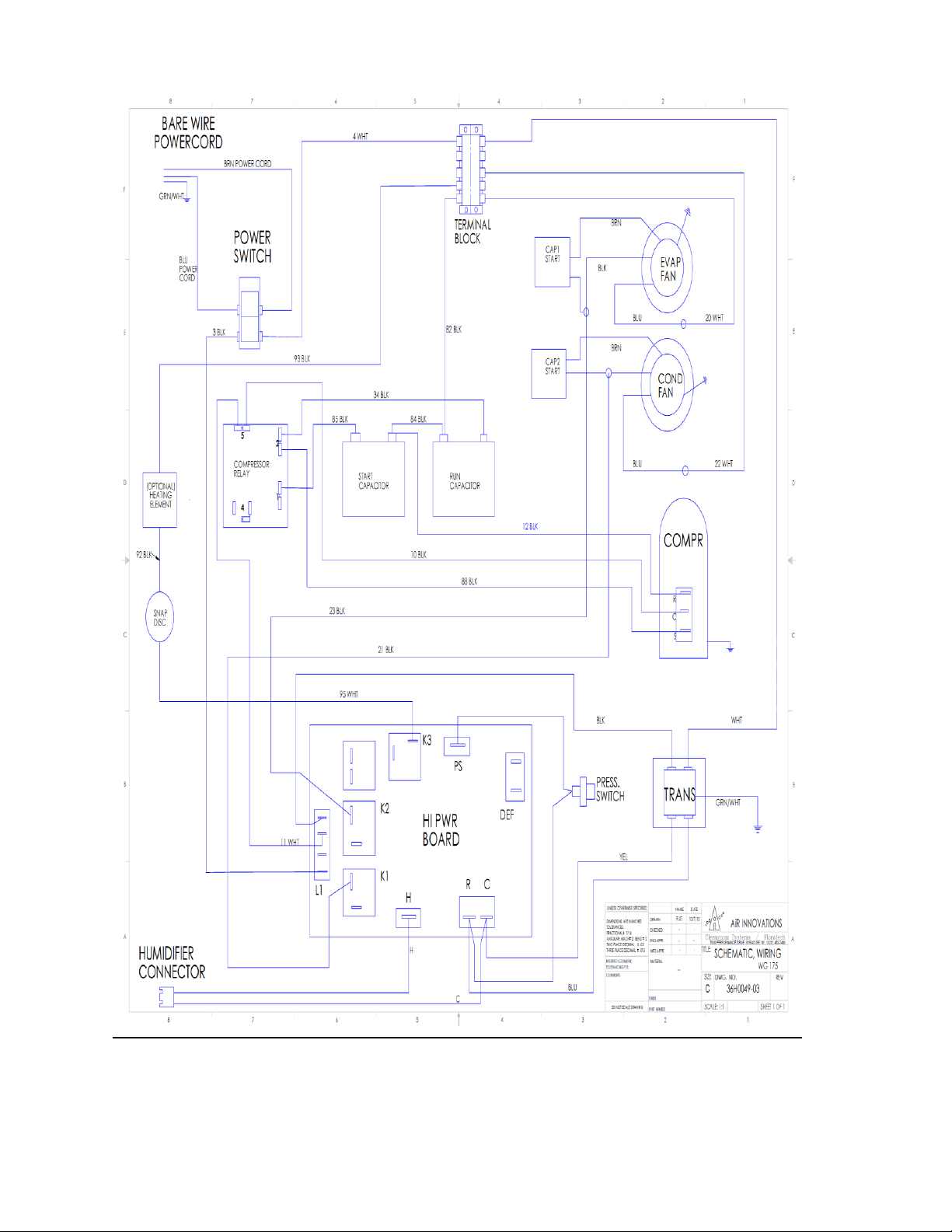

Wiring Diagram WG175 ....................................................................................................................... 12

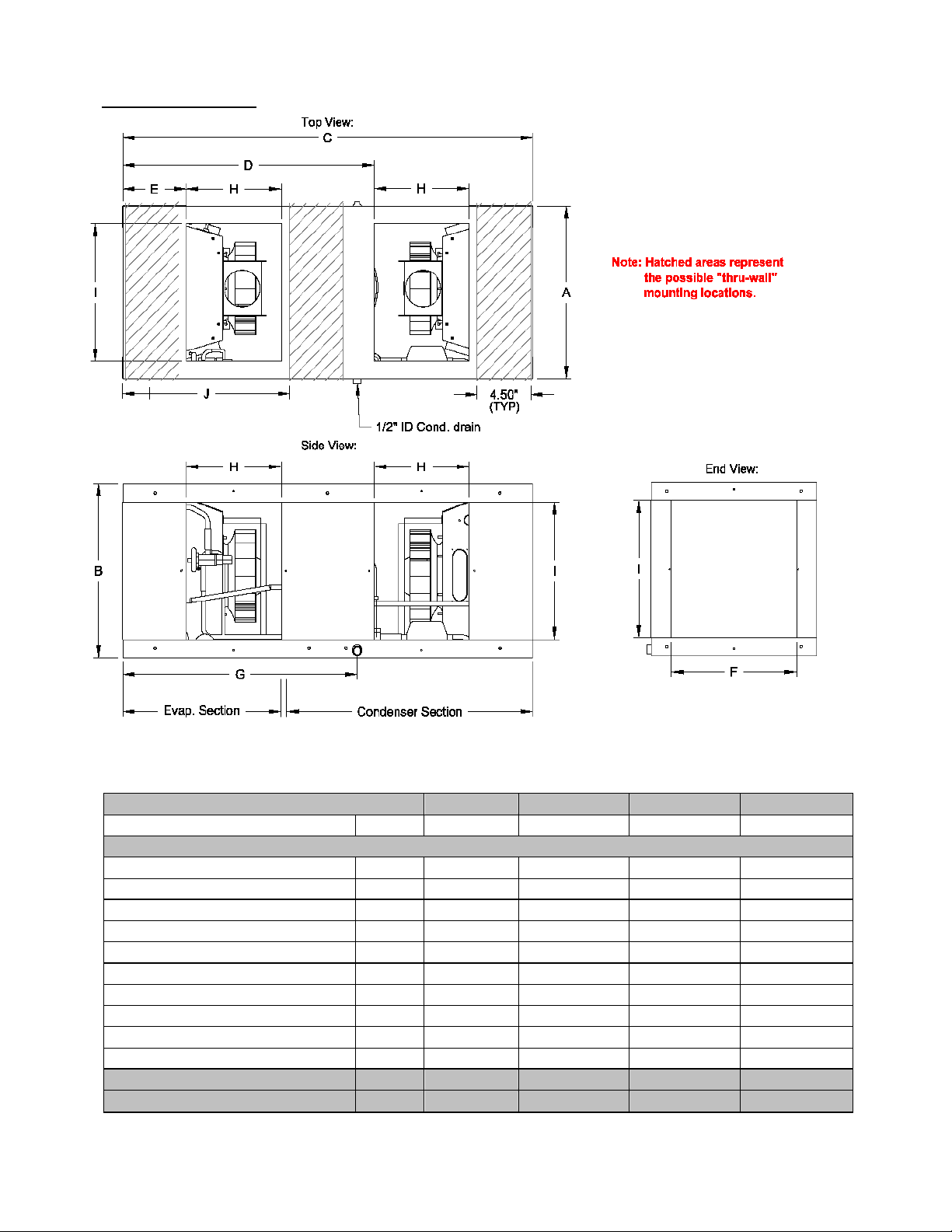

Dimensional Data ................................................................................................................................. 13

Safety ......................................................................................................................................14

Safety Message Conventions ................................................................................................................................... 14

Danger .................................................................................................................................................. 14

Warning ............................................................................................................................................... 14

Caution ............................................................................................................................................... 14

Lockout/Tag out Procedure ...................................................................................................................................... 15

Safety Considerations ....................................................................................................................................... 15

Safety Hazards .................................................................................................................................................................. 16

Electrical Hazards ....................................................................................................................................... 15

Electrical Shock Hazards ........................................................................................................................... 15

Hot Parts Hazards ...................................................................................................................................... 15

Moving Parts Hazards ........................................................................................................................................ 16

Equipment Safety Interlocks .............................................................................................................................. 16

Main Power Switch ........................................................................................................................................................... 16

Installation ................................................................................................................. 18

Pre-installation Test........................................................................................................................................................... 18

Air Flow Illustration ...................................................................................................................................... 18

Planning the Installation .......................................................................................................................................... 20

Addressing Items in the Planning Process ................................................................................................ 20

Performing a Pre-installation Check .................................................................................................... 20

Locating the Unit ........................................................................................................................................................ 20

Grilles ................................................................................................................................................................................... 21

Reducing Noise from the Unit ............................................................................................................................ 21

Installing the Unit Outdoors .......................................................................................................................................21

Mounting the Unit ............................................................................................................................................................... 22

Floor Mounting ............................................................................................................................................................ 22

Wall Mounting ............................................................................................................................................................. 22

Ceiling Mounting ........................................................................................................................................................ 22

Installing the Condensate Drain Connection ....................................................................... 22

Installing the Drain Line .............................................................................................................................................23

Priming the Drain Trap ...................................................................................................................................................... 23

Wiring the Unit for Power .............................................................................................................. 24

Serial Plate .................................................................................................................................................................................... 24

Installing the Thermostat and Communication Cable ........................................................ 25

Mounting the Remote Interface Controller ................................................................................................. 25

Installation of the Wine Guardian Remote Sensor ............................................................ 27

Mounting the remote sensor

Joining Communication Cable ................................................................................................................................................................................... 29

Changing Jumper Positions ............................................................................................................................... 29

Standard Controller Functions .................................................................................................................... 30

Alarm Codes ............................................................................................................................................................... 34

........................................................................................................................................... 27

Installing the Ductwork ............................................................................................................ 35

Location of Supply and Return Grilles ...................................................................................................................... 35

General Duct Recommendation ...................................................................................................................................... 36

Not Using Ductwork ........................................................................................................................................................... 36

Using Ductwork ................................................................................................................................................................. 36

Typical Mounting Arrangements ................................................................................................. 37

Remote Mount on Floor .............................................................................................................................................37

Ceiling Mounts .................................................................................................................................................................. 37

Outside Mounts .................................................................................................................................................................. 37

Duct Adapter Sizes ................................................................................................................... 38

Ducting Options .................................................................................................................. 38

Single Duct Installation ..............................................................................................................................................38

Dual Duct Installation ................................................................................................................................................38

Inspection and Start-up Checklists ...................................................................................... 39

Receiving and Inspecting .........................................................................................................................................39

Handling and Installing .............................................................................................................................................39

Starting-up the Unit .................................................................................................................................................................... 39

Starting-up and Operating the Wine Guardian .................................................................... 40

Turn on the Unit ........................................................................................................................................................40

Testing the Fan .........................................................................................................................................................40

Running the Unit .......................................................................................................................................................40

Cycling the Unit .................................................................................................................................................................. 41

Setting the Thermostat ...................................................................................................................................... 41

Regulating the Wine Cellar Temperature .................................................................................................................41

Changing the Air Flow Direction ..............................................................................................................................41

Maintenance............................................................................................................................... 42

General ...................................................................................................................................................... 42

Cleaning the Filters ................................................................................................................................................... 43

Cleaning the Condensate Drain System .................................................................................................................. 43

Cleaning the Humidifier ............................................................................................................................................. 43

Heating Coil Option .................................................................................................................................................. 43

Low Ambient Option .......................................................................................................................................................... 44

Maintenance Schedule .................................................................................................................................................... 44

Monthly ............................................................................................................................................................... 44

Yearly .......................................................................................................................................................................... 44

Troubleshooting ........................................................................................................................ 45

Typical Start-up Problems ........................................................................................................................................ 45

Unit Does Not Start-up ............................................................................................................................................. 45

Power Switch Light is off .................................................................................................................................... 45

Power Switch Light is on and the Thermostat Light is off .......................................................................... 45

Power Switch Light is on and the Thermostat Light is on ......................................................................... 45

Unit is Operating and Blows Evaporator Air, but the Supply Air is Not Colder than the Return Air from the

Cellar .......................................................................................................................................................... 46

Problems Controlling Cellar Temperature ................................................................................................................ 46

Cellar Temperature is Too Low (Below 11°C) When Unit is Running .................................................. 46

Cellar Temperature is Too Cold (Below 11°C) When Unit is not Running ............................................... 46

Cellar Temperature is Too High, but Supply Air is Cold ............................................................................. 47

Problems Controlling Cellar Humidity ................................................................................................................ 47

Humidity Too Low or Supply Air is Too Cold, Without Optional Humidifier .............................................. 47

Humidity Too Low and Without Optional Humidifier .................................................................................. 47

Humidity Too Low and With Optional Humidifier ........................................................................................ 47

Humidity Too High When Unit is Running But Not Cooling ...................................................................... 47

Humidity Too High When Unit is Not Running ................................................................................................. 48

Humidity Too High When Unit is Running and Cooling ............................................................................ 48

Other Miscellaneous Problems ........................................................................................................................ 48

Unit operates but the Power Switch light is not ON .................................................................................... 48

Unit is leaking water ............................................................................................................................................ 48

Unit is Running Properly, but the Sound of Unit is Objectionable ......................................................... 48

High Pressure Switch has Shut the Unit Down ................................................................................................. 49

Instructions to Reset High Pressure Switch ..................................................................................................... 49

Advanced Troubleshooting ............................................................................................................... 50

Evaporator Coil is Freezing ....................................................................................................................................... 50

High Pressure Switch Keeps Opening Even After Checking for Obstructions and Dirty Filters/Coils ......... 50

Unit Cycles On and Off More than 8 times/hr. ................................................................................................. 50

High Pitched or Loud Rubbing Noise, Clanking or Vibration ............................................................................. 50

Replacing the Blowers ...................................................................................................................................................... 50

Warranty Procedure ................................................................................................................. 51

Directory of Terms

2

Ambient Air – The surrounding area outside the cellar such as a room, basement, garage or

outdoors.

CACLS – Cubic litres per second. A unit of measurement for the amount of air handled by the fan.

Condensate / Condensation – The water formed out of the air when it is cooled below a certain temperature

(called dew point). Often referred to as “sweating” on pipes and cold surfaces. This water collects at the

bottom of the evaporator or cooling coil and drains out of the unit through the drain line.

Condenser (Heat Rejection) Section / Coil – The Condenser Section uses the compressor, condenser coil and

fan to remove heat from the refrigerant to the ambient air outside the wine cellar. The word condenser refers to

the condensation of the refrigerant from gas to liquid phase.

CE– Certificate of European conformity

Exhaust Air – The air leaving the evaporator or condenser section of the Wine Guardian unit.

Evaporator (Cooling) Section / Coil – The Evaporator Section uses the cooling coil and the fan to remove

heat from the air inside the wine cellar to the refrigerant, cooling the air and condensing moisture out of the

air. The word evaporator refers to the evaporation of the refrigerant from liquid to gas phase in the coil. The

Evaporator Section is connected to or inside the wine cellar.

Flexible Duct – Round ducts with steel reinforced plastic liners, a layer of insulation and an outer plastic

layer used to convey the air from the unit to the cellar or ambient space.

Grille or Diffuser – Inlet or outlet plates to direct the airflow or protect the inside of the unit.

Heat Gain / Loss – The amount of cooling or heating expressed in watts transferred between the wine

cellar and the ambient space. The Wine Guardian must offset this load.

Inlet Air – The air entering the evaporator and condenser sections of the Wine Guardian unit.

NEC– National Electrical Code

Recovery – The amount of cooling the unit does to return the cellar to its set point temperature after some

new load is introduced, such as people or new cases of warm wine entering the cellar.

Return Air - The air leaving the cellar and returning to the inlet of the evaporator coil.

SP – Static pressure. Unit of measurement (mm of water or pascals of water column) of the pressure of the air

handled by the fan.

Set Point – The desired temperature or humidity set on the thermostat or humidistat.

Supply Air - The air entering the cellar from the discharge of the evaporator coil.

Receiving, Inspecting and Unpacking the

3

Wine Guardian Unit

Receiving and Inspecting the Unit

NOTE

Wine Guardian units are factory assembled and tested prior to shipment.

Wine Guardian units are shipped in individual cardboard boxes.

Lift at the designated handhold locations only or fully support from underneath. A

shipment may include one or more boxes containing accessories.

Before opening the container, inspect the packing crates or boxes for obvious signs of

damage or mishandling.

Write any discrepancy or visual damage on the bill of lading before signing.

Inspect all equipment for any sign of damage caused during transit.

Report all visual or concealed damage to the carrier and file a claim immediately.

Thoroughly inspect the contents for any visible damage or loose parts.

IMPORTANT

If this procedure is not followed, the shipping company may reject the claim

and the consignee may suffer the loss. Do not return the shipment to the

factory.

Review the Packing Slip to Verify:

Model number

Factory installed options

Unit accessories

If any items listed on the packing slip do not match your order information, contact the place of

purchase immediately.

Check the unit for:

An electrical power cord

A thermostat with communications cable plugged into side of unit

A drain line coming out of the unit

General Description

4

View the Overview Illustration on page 8 for details.

The Wine Guardian cooling unit is a professional grade American manufactured, self-contained

climate control unit designed specifically for the storage of wine at cellar temperatures. It is

designed for easy installation and operation. Wine Guardian uses digital electronic controls and

environmentally friendly R-134a refrigerant.

All Wine Guardian 50Hz units carry the CE mark. Each unit is furnished with a sealed, CEapproved power cord and plug.

The Wine Guardian unit is completely self-contained and includes either an integral air or water

cooled condenser. The unit is functionally divided into two sections, the evaporator or cooling

section and the condenser or heat rejection section. Each section contains a coil to add or remove

heat and a fan to move the air through the coil and into or out of the cellar or adjacent space. The

Wine Guardian unit is designed to be used as a remote mounted unit with external ductwork

connections.

Air from the cellar first enters a filter to remove any airborne dust particles and then enters the

cooling coil. Air passes through the cooling coil and is cooled by the refrigerant inside the coil.

This causes any excess humidity in the air to condense and be captured in the drain pan and piped

outside the unit. Air then enters the fan where it is pressurized and discharged out of the unit.

Optional heating coils are located between the cooling coil and the fan. These coils heat the air to

prevent low temperatures in the cellar. The thermostat, located in the cellar, turns on the cooling

or heating as needed to maintain its set point. It does not allow the cooling and heating to be on at

the same time.

The compressor and condenser sections are activated whenever the unit is cooling. The condenser

fan draws air from the surrounding or ambient space either directly or through a duct. The air is

first drawn through a filter to remove any airborne dust particles to keep the coil clean. Then the

air flows through the condenser coil where it absorbs heat from the refrigerant in the coil. The air

is finally discharged out of the unit by the condenser fan.

The water-cooled Wine Guardian system requires cooling water to be piped to the unit for proper

operation. The cooling water absorbs the refrigerant heat through the unit’s water-cooled

condenser coil. Warm water is then directed out of the unit back to the cooling water system or to

a drain.

IMPORTANT

The air exhaust from the condenser fan is hot and will be 15 to 18 degrees C

above the entering temperature. This may cause overheating problems in the

summer months, especially with high humidity. Exhaust the hot air to the

outside. In the winter, this heated air can help to heat the surrounding space.

Standard Specifications

5

IMPORTANT

Design and specifications are subject to change without notice

The Wine Guardian Unit Contains

A thermal expansion valve to control the flow of refrigerant into the evaporator coil

A filter dryer to keep the refrigerant clean and free of contaminant

A sight glass to observe the level of refrigerant

An automatic low pressure switch on the discharge to protect the compressor form high

pressures

The unit uses only environmentally friendly refrigerant F-134a

A built-in condensate drain trap. No external trap is required.

The Wine Guardian meets or exceeds its rated capacities for total watts and cubic litres per second at

design cellar conditions and external static pressures. Both the evaporator and condenser fans are

capable of rated CFM against the external static pressure imposed by recommended ductwork. Both

fans are motorized impeller plug fans, statically and dynamically balanced, and use permanently

lubricated direct drive motors requiring no maintenance.

All exterior framing of the Wine Guardian is powder coated 1.6mm gauge aluminum to prevent rust

and corrosion. All coils are copper tubes with aluminum fins. The unit uses an external drain to

remove excess moisture and not reintroduce it into the cellar or ambient space. Removable, multiple

access doors are provided to facilitate cleaning and maintenance, duct connections, and access to

components and wiring.

Both the evaporator and the condenser coils have pre-filters on the inlet to prevent dust and dirt from

fouling the coils, thereby reducing capacity. Each unit has at least three discharge outlets on both the

evaporator and the condenser coils to facilitate custom installations. Water-cooled units have copper

straight tube connections for both cooling water inlet and outlet.

Each unit is provided with a pre-wired and tested electronic digital thermostat for remote mounting in

the cellar. The thermostat has multiple control functions for the fans, cooling and heating. It has a

fully automatic mode to switch between heating and cooling.

Compressors are rotary, self-lubricating, permanently sealed, hermetic reciprocating type compressors, with internal overload protection and capacitor start with a minimum of one-year manufacturer’s

warranty and an optional five-year warranty. Compressors are mounted on rubber-in-shear isolators to

reduce noise and vibration.

Electric power is supplied by a single factory furnished cord and plug. All external controls are digital

and proprietary to Wine Guardian products. Only approved communication cable and Wine Guardian

controllers are suitable for proper system operation.

6

Accessories and Optional Equipment

Heating Coils

An optional heating coil is built-in and requires no additional power source. The electric heating

option is factory installed and includes primary and secondary over-temperature protection devices

per UL and NEC.

Water Cooled Option

A water cooled option is available that uses a tube-in-tube heat exchanger in place of the condenser

coil and fan. Waste heat from the refrigerant is transferred to the water. A two-way control valve is

used to regulate the flow of water to maintain head pressure.

Duct Collars and Flexible Ducts

Ducting for the Wine Guardian is sold in kits by size for each unit. Each kit contains two adapter

collars, one 7.62 meter length of round flexible duct and two straps. The number of duct kits needed

depends on the layout. The size of the kit depends on the model Wine Guardian selected. Follow

installation instructions carefully. Poorly or incorrectly installed ducts can degrade the performance

of your unit dramatically.

Extended Compressor Warranty

The Wine Guardian uses only the best commercially available compressors on the market. However,

since the compressor is the single most expensive component in the unit, it is recommended that you

purchase the extended warranty option.

Low Ambient Option

A factory installed Low Ambient option is available which makes the Wine Guardian capable of

exposure to low ambient temperatures. This feature controls the condenser fan operation based on

head pressure and heats the oil reservoir. The Low Ambient Option (LAO) is recommended

whenever the condenser section is exposed to air temperatures below 50°C. This can occur if the

unit is placed in a garage or under an outdoor canopy or if the unit is located inside a heated space

but the condenser air is ducted in from the outside.

Condensate Pump

An optional Wine Guardian automatic condensate pump is available

outside. It requires a separate 220/240 volt electrical outlet.

Humidifier and Humidistat

Another popular option for the Wine Guardian is a humidifier. It comes with a sheet metal adapter

box and a pre-wired humidistat. The humidifier is available for field installation and can be

retrofitted onto an existing unit. Each humidifier is furnished with an electronic digital humidistat

to control the humidity in the cellar. The humidifier mounts directly onto the Wine Guardian unit

and uses the common drain. The humidifier requires a water supply and no additional external

power.

CAREFULLY FOLLOW THE INSTALLATIONS INSTRUCTIONS INCLUDED WITH THE HUMIDIFIER. REFER TO THE IN-

STRUCTIONS CONTAINED IN THE BOX FOR THE HUMIDISTAT.

CAUTION

to pump the water to a sink or

Overview of the Wine Guardian Unit

7

Refer to illustrations on page 8

Cabinet

for corrosion protection and an attractive, maintenance free appearance. Areas in contact with cold

temperatures are lined with insulation to prevent condensation.

–

The cabinet and access doors are constructed of aluminum with a powder coated finish

Condensing Section

permanently lubricated, motorized impeller blower. This section also contains the compressor and

the electrical controls. If the water cooled option is purchased, a heat exchanger is used in place of

the condenser coil and blower.

Evaporator Section

same as above. The large evaporator coil face area eliminates condensate carry-over, reduces air

pressure drop and optimizes heat transfer. A drain pan is located directly below the coil to capture

condensate and is fabricated from aluminum to prevent rust and corrosion. The electric heating coil,

if ordered, is factory installed between the evaporator coil and the blower, and is complete with

contactor(s) and limit controls.

Electrical Controls

accessible through the condenser section. Wires are numbered and color coded to match the wiring

diagrams.

Factory Tested

performance.

Filters

protect the coils from dust and dirt. These filters are washable and reusable.

– Nominal 25mm thick filters are provided on both the evaporator and condenser inlets to

–

Ambient air is circulated through the condenser section by a direct drive,

–

Cellar air is circulated through the evaporator section by another blower the

–

Most of the electrical components and controls are located in a separate area

–

All Wine Guardian units are factory run-tested and checked for operational

Humidity Option

onto the Wine Guardian without any additional electrical power wiring. It automatically adds

moisture into the cellar by the evaporation of water over a distribution pad. A cellar mounted digital

electronic humidistat automatically controls the amount of moisture added.

Internal Drain Trap

prevent air from being drawn back through the drain tube. This allows the drain pan to drain freely.

No external trap is required.

Refrigerant Circuit

external equalizer, sight glass with moisture indicator, a filter dryer, an automatic low pressure

switch, and a manual reset high pressure switch. For the low ambient option, an automatic pressure

switch controls the operation of the condenser blower and a heating element is added to the

compressor oil reservoir. See Refrigeration Illustration on next page.

Supply/return grilles

the evaporator and condenser sections. One grille is provided on an outlet. These are readily

interchangeable with access doors to control and direct the airflow. These grilles may be used in the

room on the end of the ducts in ducted systems.

–

The optional humidifier comes fully assembled and tested for field installation

-

Water condensate from the evaporator coil fills the trap and forms a seal to

– The factory charged circuit includes a thermal expansion valve with an

–

Powder-coated steel single direction grilles are provided for the inlets to

Overview Illustration of the Wine Guardian Unit

8

Refrigeration Illustration - Vapor Compression System

Wiring Diagram Model WG 40

9

Wiring Diagram Model WG 75

10

Wiring Diagram Model WG100

11

11

Wiring Diagram WG 175

12

Wine Guardian

Wine Guardian Dimensional Data

Model Number

WG4

WG75

WG100

WG175

Dimensions - Nominal - add 9.5mm for each grille

A - Width

mm

356

559

559

559

B - Height

mm

356

356

356

457

C - Length

mm

889

991

991

1092

D – Cond. discharge location

mm

540

591

591

660

E – Evap. discharge location

mm

137

137

137

137

F - Inlet opening width

mm

267

470

470

479

G - Drain outlet location

mm

502

552

552

619

H - Discharge opening width

mm

63

254

254

295

I - Inlet opening Height

mm

202

282

282

381

J - Location to wall

mm

368

419

419

457

Weight

kg

36.3

56.7

65.8

88.4

Refrigerant Charge – 134A

g

539

737

964

1417

13

Safety

F

DANGER

14

Before installing or maintaining the Wine Guardian Unit do the following:

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

IMPORTANT

The equipment described in this manual uses electricity. When using

this equipment, be sure to follow the safety procedures outlined in the

Wine Guardian Manual.

Safety Message Conventions

Safety messages contained in this manual, DANGER, WARNING, and CAUTION are

bold and highlighted in red for quick identification.

Danger

A Danger message indicates an imminently hazardous situation which, if not avoided,

results in death or serious injury. Messages identified by the word DANGER are used

sparingly and only for those situations presenting the most serious hazards.

IGH VOLTAGE - RISK OF SERIOUS INJURY OR DEATH

High voltages are present in the cabinets.

Before opening panels turn off all power.

Use the Lockout/Tagout procedure.

Warning

A Warning message indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Following is a typical example of a Warning message as it could appear in the manual

WARNING

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Modification to the equipment may cause injury.

:

Caution

A Caution message indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. It may also be used to alert against unsafe practices.

Following is a typical example of a Caution message as it could appear in the manual:

CAUTION

15

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Improper installation may result in the equipment malfunctioning and a safety hazard.

Read all of the installation instructions before installing the Wine Guardian unit.

Lockout/Tagout Procedure

1) Turn off the power switch (indicator light should be off)

2) Unplug the unit from the electrical outlet and cover the outlet to prevent

accidently plugging in the unit.

Safety Considerations

The equipment covered by this manual is designed for safe and reliable operation when installed

and operated within its designed specifications. To avoid personal injury or damage to equipment or

property when installing or operating this equipment, it is essential that qualified, experienced

personnel perform these functions using good judgment and safe practices. See the following

cautionary statements.

Installation and maintenance of this equipment is to be performed only by qualified personnel

who are familiar with local codes and regulations, and are experienced with this type of

equipment.

Safety Hazards

Exposure to safety hazards is limited to maintenance personnel working in and around the unit.

When performing maintenance, always use the Lockout/Tagout procedure, which is described in

this chapter. Observe the maintenance safety guideline in the Wine Guardian Manual.

Electrical Hazards

Working on the equipment may involve exposure to dangerously high voltage. Make sure you are

aware of the level of electrical hazard when working on the system. Observe all electrical warning

labels on the unit.

Electrical Shock Hazards

All power must be disconnected prior to installation and servicing this equipment. More than one

source of power may be present. Disconnect all power sources to avoid electrocution or shock

injuries

.

Hot Parts Hazards

Electric Resistance heating elements must be disconnected prior to servicing. Electric Heaters may

start automatically, disconnect all power and control circuits prior to servicing the unit to avoid

burns.

18

Moving Parts Hazards

WARNINGS

16

The Motor and Blower must be disconnected prior to opening access panels. The motor can start

automatically. Disconnect all power and control circuits prior to servicing to avoid serious injuries or

possible dismemberment.

The fans are free-wheeling after the power is disconnected. Allow the fans to stop completely before

servicing the unit to avoid cuts or dismemberment.

Rotating Fan Blades are present in the Wine Guardian unit. Sticking a hand into an exposed fan

while under power could result in serious injury. Be sure to use the Lockout/Tagout procedure when

working in this area or remove the power cord.

Equipment Safety Interlocks

There are no electrical safety lockouts installed within the unit. The power cord attached to the

control box must be disconnected from the power sources prior to working on any part of the

electrical system.

Main Power Switch

The main power switch is located on the side of the Wine Guardian unit. (See Overview Illustration

on page 8) It shuts off the power to the unit.

Energy Type Electrical

Hazard ................................ Electrocution, electrical burns and shock

Magnitude .................................. 230 volts AC 1 phase, 50 cycles

Control Method ................. Disconnect power cord and On/Off Switch

Never reach into a unit while the fan is running.

Never open an access door to a fan while the fan is running.

Disconnect the power cord switch before working on the unit. The unit may have

more than one power source to disconnect.

Avoid risk of fire or electric shock. Do not expose the unit to rain or moisture.

Check weights to be sure that the rigging equipment can support and move the Wine

Guardian unit safely. Note any specific rigging and installation instructions located in

the Installation section of the Wine Guardian Manual.

DANGER

All supports for the unit must be capable of safely supporting the equipment’s weight

and any additional live or dead loads encountered.

17

All supports for the unit must be designed to meet applicable local codes and

ordinances.

Do not remove access panels until fan impellers have completely stopped.

Pressure developed by moving impellers can cause excessive force against the

access panels.

Fan impellers continue to turn (free-wheel) after the power is shut

off

.

CAUTION

Clean only with a dry cloth.

Never pressurize equipment above specified test pressure. See Wine Guardian

Specification Sheet

Do not use the Wine Guardian near water.

Do not block any supply or return air register or duct. Install in accordance

with the instructions in the Wine Guardian Manual. Do not defeat the safety

purpose of the polarized or grounding type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades

and a third grounding prong. The wide blade or the third prong is provided for

your safety. If the provided plug does not fit into your outlet, consult an

electrician for replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched, particularly at the

outlet plugs, convenience receptacles, and the point where it exits the unit.

Only use attachments/accessories specified by the manufacturer.

Always operate this equipment from a 230 VAC, 1 phase 50Hz power sources

only.

Always ground the outlet to provide adequate protection against voltage surges

and built-up static charges

Refer all servicing to qualified service personnel. Servicing is required when

the unit has been damaged in any way. such as:

The power supply cord or plug is damaged

Liquid has been spilled or objects have fallen into the unit

The unit has been exposed to rain or moisture

The unit does not operate4 normally

The unit has been dropped

Installation

CAUTION

18

SHARP EDGES

RISK OF SERIOUS INJURY

Sharp edges are present inside the Wine Guardian system.

Pre-installation Test

Test the system before installing it to check for non-visible shipping damage.

To test the system:

Set the system on the floor or a sturdy level surface.

Plug in the system.

Press the on/off switch, control illuminates. This indicates the system has power.

The built in timer prevents short cycling and keeps the system from turning

on right away. The system comes on and runs as long as the temperature of the

space is above the thermostat set point. After several minutes, cold air comes out

of the system from the evaporator section side and hot air comes from the

condenser section. Listen for any unusual noise or vibration.

Air Flow Illustration

WARNING

19

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Modification to the equipment may cause injury or damage to the equipment

.

DANGER

This equipment is heavy. Place the unit on the floor or on a level and stable

surface that can support the full weight of the unit.

Do not modify the equipment, it may cause damage to the equipment and will

void the warranty.

Never place anything on top of the unit.

Never block or cover any of the openings or outlets to the unit.

Never allow anything to rest on or roll over the power cord.

Never place the unit where the power cord is subject to wear or abuse.

Do not use extension cords.

Never overload wall outlets.

Do not remove or open any cover unless the unit is turned off and the power

cord is plugged in.

Use only dedicated power outlet boxes of the correct capacity and configuration

for the unit model.

CAUTION

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Improper installation may result in the equipment malfunctioning and a safety hazard. Read all of

the installation instructions before installing the Wine Guardian unit

Planning the Installation

20

Addressing Items in the Planning Process

Where to locate the unit? Should it be built into the wall or mounted remote and

ducted into the cellar?

How to mount the unit?

Decide where to locate the supply and return grilles in the room to achieve the

temperature gradient and circulation preferred.

Locate the electrical power outlet close to the unit, in cellar or out. Do not use

an extension cord!

Does the condenser heat exhaust need to be ducted away?

Where to locate the thermostat?

Where to run the drain line?

Are all the parts here to complete the installation?

Performing a Pre-installation Check

Check for the proper installation of the electrical plug configuration.

Check for the properly sized breaker.

Is the cellar built with adequate insulation and vapor barriers?

Are ducts installed above the ceiling or in accessible places properly sized before

being covered?

Is enough space available around the unit for service and repair?

Locating the Unit

Wine Guardian units are typically installed indoors located near the cellar to minimize the duct

runs. Each unit is provided with one entering or return air inlet and three possible supply air

outlets for each of the evaporator and condenser sections. A maximum cumulative total length

for both supply and return ducts (including bends) of 7.5 meters is recommended. If longer runs

are needed use more than one supply opening to reduce the airflow in each duct by 1/2. See

Recommended Flexible Ductwork Sizing Chart on page 30.

Provide a 1 meter clearance around the unit for removal of grilles or ductwork, access to filters

and unit maintenance. If the humidifier is used, provide access space in front of it for service.

Grilles

21

Each of the inlets and one evaporator outlet and one condenser outlet come from the factory

with grilles over the openings. The grilles are removable. Remove the necessary grilles for

installing ductwork between the unit and the cellar. If desired, use the grilles as wall grilles

inside the cellar. The return air, or inlet, to the unit must connect to the return air outlet from the

cellar. Any of the three supply air outlets on the unit can be used for the ductwork to the supply

grille inside the cellar. The factory installed outlet grille can be relocated to any of the other two

openings. The procedures below apply to both the evaporator and the condenser sections. In

most cases, no ducts are installed on the condenser section because the unit is located in a

mechanical or storage type space. If exhaust heat is undesirable use the grilles to install

ductwork to move the heat outdoors or to another space. Also, use ductwork to direct condenser

air noise away from occupants.

Reducing Noise from the Unit

Consider noise when locating the unit close to the cellar or an adjacent occupied space. A piece

of 25 or 50mm dense rubber or Styrofoam with foil face in between the unit and the wall

absorbs and reduces the noise from the unit. For air noise use better grilles or block the noise

with a solid piece of wood or Styrofoam. Sound usually travels as a line of sight. Sound is

reduced when it turns a corner, such as, passing through a bend in ductwork. If the unit is

supported from a wall or joist, using a rubber pad under the unit will reduce vibration

transmission.

Installing the Unit Outdoors

The Wine Guardian is NOT designed nor approved for direct outdoor installation. If it is located

outdoors, it MUST be protected with a rain-proofed enclosure.

Mount it above the ground on a solid, waterproof base to protect the unit from

ground water.

Do not locate it where grass clippings or leaves can blow into the unit.

Keep the area around the unit clean and free of debris.

Protect from damage when the unit is located in a garage or unheated shed. In both

cases, the unit MUST have the low ambient controls built into the unit.

Double insulating ducts with exterior grade insulation is recommended to keep the ducts

dry and effective. Wine Guardian suggests installing one sized flexible duct inside the

next larger size duct where ductwork is exposed.

Allow enough space at both ends of the unit to remove the grilles or ductwork and

allow access to the filters.

CAUTION

22

Mounting the Unit

RISK OF PERSONAL INJURY OR DAMAGE TO EQUIPMENT

Check supporting structure for load bearing capacity to support the Wine Guardian.

All supports must be designed to meet applicable local codes and ordinances.

If in doubt, consult a qualified architect, engineer or contractor.

Note

Review the mounting illustrations on pages 32 and 33 before mounting the unit.

Floor Mounting

Mount the Wine Guardian on the floor but elevate it on frame with a plywood surface to keep

it away from water. Allow adequate space for the external drain.

Wall Mounting

If the unit is mounted through the wall, adequately support it on both sides of the wall. Use

floor or knee braces to transfer the load of the unit to the floor or wall.

Ceiling Mounting

Construct a structurally sound, level platform to place the unit on when hanging it from the

ceiling joists. The Wine Guardian is NOT designed to be suspended from the top of the unit.

Place the unit on a platform to ensure that the unit is supported on all for corners. Leave adequate space on the top of the unit to remove the access doors for service.

In all cases the unit must be level to within +/- 6mm end-to-end and +/- 3mm side-to-side for

proper operation. Locate the unit as close to the wine cellar as possible to reduce the length of

the duct runs. If possible, use short and straight ducting on all ductwork. The addition of 6mm

thick rubber pads helps prevent the transmission of vibration and noise.

Installing the Condensate Drain Connection

The Wine Guardian unit provides dehumidification for the inside of the wine cellar. It cools the

air down to the dew point corresponding to the temperature set point of the thermostat. If the

vapor barrier of the wine cellar is poorly constructed or excess moisture is in the basement, the

unit has to remove excessive amounts of moisture from the wine cellar. The moisture appears in

the condensate drain of the unit.

Note

If moisture becomes excessive, install a room type dehumidifier to dehumidify the basement

so as to not overload your Wine Guardian.

Installing the Drain Line

23

The drain line must extend from the unit to an external drain or disposal site.

Do not use drain tubing any smaller than 12mm inside dimension on the unit.

Splice the drain extension onto the drain outlet with a sort piece of 12mm

copper tubing and secure with claps.

If no drain is available, use a bucket. Do not extend the drain below the rim of

the bucket. Empty the bucket periodically.

The Guardian Unit is provided with a built-in drain trap. The drain trap creates a water seal to

prevent air from backing up into the drain pan and causing the drain pan to overflow. Do not

create secondary traps in the external drainline.

Allow enough height for the drain line to function properly. If draining into a nearby sink, the

unit must be elevated higher than the rim of the sink in order for the water to drain by gravity.

Install with a 10mm per linear meter. Do not tie the condensate drain line directly into the

sanitary sewer system. See Accessories and Optional Equipment section for information about

the Condensate Pump.

Priming the Drain Trap

The internal drain trap primes itself automatically once the unit has run for a period of time and

after the unit cycles off. This is confirmed by water dripping from the drain.

Wiring the Unit for Power

DANGER

24

23

Electrical 240/1/50 Electric Heat Amps (Opt.) 4.4

Locked Rotor Amps 18.5 Humidifier Amps (opt.) 0.3

Compressor RLA 2.4 Crankcase Htr. Amps (opt.) 0.4

Condenser Fan Amps 0.7 Min. Circuit Amps (w/o opt.) 4.4

Evaporator Fan Amps 0.7 Refrigerant R-134-A

Condensate Heater N/A System Charge 1lb. 3oz.

Total Unit Amps (w/o opt.) 3.8 Test Pressure 275psi

00 1 315-452-7400 * Fax: 00 1 315-452-7420

Model No. WG40

Serial No.

Air Innovations, 7000 Performance Drive, North Syracuse, New York 13212

ELECTRICAL SHOCK HAZARD

RISK OF SERIOUS INJURY OR DEATH

The electrical outlet and wiring installation must meet the national and local

building codes.

DO:

Match the electrical outlet to the plug provided on the Wine Guardian.

Provide dedicated circuit and wiring for the system.

Match the wiring and breaker size to the rated load as shown on the serial

DO NOT:

plate and in this guide. See sample serial plate illustration on the following page.

DO NOT MODIFY THE PLUGS IN ANY WAY!

Do not use extension cords.

Installing the Thermostat and

IMPORTANT

Wine Guardian units are supplied with 15 meters of Cat 3, 6-wire twisted pair

communication cable with RJ-11 connectors. Failure to use this type of communication

cable WILL cause product damage and WILL void any equipment warranty.

Installation instructions should be followed CAREFULLY as improper splicing and/or

joining of twisted pair cables can ca use equipment failure .

1. Disconnect the communication cable from the side of

the Wine Guardian unit and the Remote Interface

Controller.

a) Install the communication cable within the wall

and/or ceiling structure of the wine cellar to the

desired controller mounting location.

b) Mount the remote interface controller on a solid

surface away from doors, corners, air outlets, drafts or

heat generating equipment. Do not mount the Remote

Interface Controller directly on an outside wall or wall

adjacent to a boiler room.

25

Communication Cable

The Wine Guardian Remote Interface

Controller is a combination temperature and

humidity controller with single stage cooling,

heating and humidifier control. Each Wine

Guardian unit is supplied with a Remote

Interface Controller and 15 meters feet of

communication cable. It is wired at the factory

for testing prior to shipment.

In most applications the Remote Interface

Controller will be mounted within the wine

cellar. The remote interface controller can also be mounted directly outside of the wine cellar or

in any other room of the home or building. When mounted outside of the wine cellar, a remote

sensor kit must be purchased and installed within the wine cellar. See below for remote sensor

installation details.

Mounting the Remote Interface Controller

2. Remove the back plate of the controller and mark the

mounting points at the desired location. (Fig. 2)

a) Mark the location of the communication

cable connection as this area will require

sufficient clearance for instance, a 3.8cm hole in the

wall for flush mounting of the back plate. (Fig. 3)

3. Drill two (2) .32cm holes and insert anchors (provided)

within the mounting surface. Anchors may not be

required if securing to a wall stud or racking system.

4. Plug in the communication cable to the back of the

Remote Interface Controller backing plate. (Fig.4)

a) Attach backing plate to wall using the two screws

provided with the system. (Fig.5)

5. Re-install plastic face plate on to backing plate.

6. Re-attach the communication cable to the side of the

Wine Guardian cooling unit. (Fig.6)

26

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Installation of the Wine Guardian Remote Sensor

1. Disconnect the communication cable from the side of

the Wine Guardian unit and the remote sensor. Install

the communication cable within the wall and/or ceiling

structure of the wine cellar to the desired controller

mounting location.

2. Mount the Remote Sensor on a solid surface away from

doors, corners, air outlets, drafts or heat generating

equipment. Do not mount the Remote Sensor directly on

an outside wall or wall adjacent to a boiler room. Use a

piece of foam insulation behind the sensor to insulate it

from a hot or cold surface. The recommended height is

1.2 to 1.5 meters above the finished floor.

3. Remove the sensor cover plate by removing the two

allen head screws at the top of the cover using the allen

head wrench provided in the kit.(Fig.2) Mark the

mounting points at the desired location within the wine

cellar. Also mark the location of the communication

cable connection as this area will require sufficient

clearance, for instance 3.8cm hole in the wall for flush

mounting of the sensor plate.

Fig.2

Important

A splitter device has been supplied within the Remote

Sensor kit. The splitter device must be mounted at the

WG unit as shown. DO NOT mount the splitter device at

the back of the Remote Interface Controller or to the

back of the Remote Sensor as this WILL cause

component or system damage.

27

The Remote Sensor is a combination temperature and

humidity sensor only. It is designed to be mounted within the

wine cellar and can be used in combination with the Remote

Interface Controller or up to three additional Remote Sensors

to read and control multiple areas within the wine cellar.

Mounting the remote sensor

Fig.1

4. Drill two (2) .32cm holes and insert anchors

(provided) within the mounting surface. Anchors

may not be required if securing to a wall stud or

racking system. (Fig.3)

5. Plug in the communication cable to the back of

the Remote Sensor and attach to the wall using

the two screws provided in the kit. (Fig.4)

6. Plug the Remote Sensor cables into the splitter

device at the WG unit along with the

communication cable for the Remote Interface

Controller. (Fig.5)

If using multiple Remote Sensors in one wine room

continue to mount the remaining sensors before

installation of the sensor cover plates. When multiple

sensors are used the sensor jumper position must be

adjusted in order for proper averaging of temperature

and humidity readings. See page 27 for jumper set up.

Fig.3

Fig 4

Fi

Fig.5

Fig 6

28

Joining Communicati

Joining Communication Cable

If using multiple Remote Temperature/Humidity

sensors in your application, refer to the photos

showing the need to change the jumper locations

internal to the control board on each remote

sensor (up to 3 maximum).

For the control to average all of the sensors

utilized (if more than one), the jumper must be in

different positions on the pins.

As you can see, there are three pin settings. To

access the jumper:

1. Remove the two-set screws holding on the

plastic cover. This procedure allows the control

to go to each remote sensor in sequence to

average. Failure to perform this procedure will

result in the system reading only one sensor

and not the average of multiple sensors.

NOTE: If multiple sensors control the WG

unit, change factory default in configuration

setting 10 to “averaging.” You will need access

code from Air Innovations service to use in

configuration 8 to reach configuration 10.

Jumper position 1

Jumper position 2

Jumper position 3

Important

Wine Guardian cooling systems are supplied with 15 meters of 6 wire, Cat 3 twisted

pair communication cable with RJ11 type connectors. Caution must be taken when

connecting two lengths of communication cable (splicing) to ensure uniform wire color

before and after splice. An RJ11 Modular 6 wire STRAIGHT THROUGH type

coupler is the ONLY coupler approved for splicing Wine Guardian twisted pair

communication cable.

29

Changing Jumper Positions (Averaging readings from Remote Sensor)

How to:

Turn system on/off

Press the On/Off” button once. Note: There

is a five (5) second time delay before the

system turns on or turns off.

Change Temperature

Press the “Up” arrow once. The display will

show the existing temperature set point.

Press the up or down arrow buttons to adjust

the temperature to the desired set point.

Change Humidity

Press the “Up Arrow” once. This display

will show the existing temperature set point.

Press the “Mode” button once to display the

Humidity setpoint.

Press the “Up” or “Down” arrows to adjust

the humidity to the desired set point. Note –

a Wine Guardian humidifier must be

installed and setting six (6) set to “1” or “2”

before the controller will let you change

percent humidity.

.

Change Mode -Cooling/Heating/Auto

Press the “Mode” button once to display the

“Set” function at the bottom of screen. The

existing mode will display next to the word

“Set” at the bottom of the screen.

Press the mode button again to scroll

through settings for “Cool” (cooling only),

“Heat” (heating only) or “Heat Cool”

(Auto).

STANDARD CONTROLLER FUNCTIONS

Humidity

Temperature

Alarm Indication

Area

Mode Area

Up Button

Down Button

Mode button (right side)

On/Off (left side)

30

Settings – Press and hold the “Mode” button for five (5) seconds to access the following

Deg F or Deg C

Setting 1

Press the “Down” arrow to change temperature

from Deg F to Deg C.

Press the “Up” arrow to change temperature from

Deg C to Deg F.

Low temperature alarm

set point

Setting 2

Press “Mode” button to advance to Setting 2.

Press the “Up” or “Down” arrow buttons to adjust

to the desired set point. Factory default is 10 Deg.

C..

High temperature

alarm set point

Setting 3

Press “Mode” button to advance to Setting 3.

Press the “Up” or “Down” arrow buttons to adjust

to the desired set point. Factory default is 18 Deg

C.

Low humidity alarm set

point

Setting 4

Press “Mode” button to advance to Setting 4.

Press the “Up” or “Down” arrow buttons to adjust

to the desired set point. Factory default is 5%.

High humidity alarm

set point

Setting 5

Press “Mode” button to advance to Setting 5.

Press the up or down arrow buttons to adjust to the

desired set point. Factory default is 95%.

Add or remove

humidifier

Setting 6

Press “Mode” button to advance to Setting 6.

Press the up or down arrow buttons to adjust to the

desired set point. Factory default is zero (0).

Zero (0) = No humidifier

One (1) = Stand-alone remote mounted humidifier

Two (2) = Integral Wine Guardian mounted

humidifier

Fan AUTO or ON

Setting 7

Press “Mode” button to advance to Setting 7.

Press the “Up” or “Down” arrow buttons to adjust

number to the desired set point. Factory default is

zero (0).

Zero (0) = Auto – fan only turns on when there is

a call for cooling or heating

One (1) = Fan On – fan remains on continuously

31

settings.

Advanced Settings--

Special access required.

Contact Wine Guardian

Service Department for

access code

Setting 8

Press “Mode” button to advance to Setting 8.

Press the up or down arrow buttons to adjust

number to the access code. Press “Mode” button to

continue onto setting 9 through 19.

Compressor anti-short

cycling time

Setting 9

Press “Mode” button to advance to Setting 9.

Press the “Up” or “Down” arrow buttons to adjust

to the desired time in one (1) minute increments.

Maximum is 10 minutes, minimum is 0 minutes.

Compressor anti-short cycling time is the amount of

allowable time between compressor stop and restart.

Rapid start/stop of compressors can cause premature

failure. Factory default is 5 minutes.

WINE GUARDIAN DOES NOT RECOMMEND

SETTINGS LOWER THAN FACTORY DEFAULT.

Set up remote sensor

or thermostat

Setting 10

Press “Mode” button to advance to Setting 10.

Press the “Up” or “Down” arrow buttons to adjust

to the desired setting.

rS = Remote sensor

rI = Remote interface

LI= Local interface – Through-the-wall unit only

A = Averaging – Jumper position within sensors

must be adjusted. See page 27.

Room sensor

calibration

Setting 15

Press “Mode” button to advance to Setting 15.

Press the “Up” or “Down” buttons to adjust to the

desired set point. Maximum setting is +2°C,

minimum setting is -2°C. Factory default is zero

(0). Sensor calibration set point changes the actual

display reading (temperature only) by the value of

this setting.

Example: Sensor reading = 13 Deg C

Setting 15 set to +2

Display reading = 15 Deg C

32

Differential

temperature

adjustment

Setting 16

Press “Mode” button to advance to Setting 16.

Press the “Up” or “Down” buttons to adjust to the

desired set point.

This setting changes the system/compressor. Turn on

temperature above set point. Factory default is set to

1°C.

Example: Sensor reading = 13°C

Setting 16 set to +1°C

System/compressor turns on at 14 Deg. C.

Deadband setting

Setting 17

Press “Mode” button to advance to Setting 17.

Press the “Up” or “Down” buttons to adjust to the

desired set point.

This setting is the minimal allowable temperature

difference between heating and cooling set points.

Maximum is 3°C, minimum is 1°C. Factory default is

set to 1°C

Test mode setting

Setting 18

Press “Mode” button to advance to Setting 7.

Press the “Up” or “Down” buttons to adjust to the

desired set point. When set to one (1) the controller

will automatically turn on all outputs with the

exception of electric heat. Factory default is zero

(0).

Zero (0) = Off

One (1) = On

System Selection

Setting 19

DO NOT CHANGE

33

Alarm Codes

High temperature

alarm

Press the “Up” or “Down” arrow once to change

screen from alarm to normal Temperature and

Humidity indication. “Hi Temp” will remain on

screen until temperature falls below the High

Temperature Alarm set point (Setting 3).

Low temperature alarm

Press the “Up” or “Down” arrow once to change

screen from alarm to normal Temperature and

Humidity indication. “Lo Temp” will remain on

screen until temperature rises above the Low

Temperature Alarm set point (Setting 2).

High humidity alarm

Press the “Up” or “Down” arrow once to change

screen from alarm to normal Temperature and

Humidity indication. “Hi Hum” will remain on screen

until humidity falls below the High Humidity Alarm

set point (Setting 5).

Low humidity alarm

Press the “Up” or “Down” arrow once to change

screen from alarm to normal Temperature and

Humidity indication. “Lo Hum” will remain on screen

until humidity rises above the Low Humidity Alarm

set point (Setting 4).

Open Fault

Press the “Up” or “Down” arrow once to change

screen from alarm to normal Temperature and

Humidity indication.

THIS ALARM FORCES THE SYSTEM TO

SHUT DOWN. “Alarm” will remain on screen until

the High Pressure reset switch has been reset. See the

trouble shooting guide page 47 for “Instructions to

Reset High Pressure Switch”

34

Installing the Ductwork

Model Inlet Outlet

Single Double

WG40 200 200 200 150

WG75 250 200 250 150

WG100 250 250 250 200

WG175 300 300 300 300

Condenser (heat rejection) Coil

Recommended Insulated Flexible ductwork Sizing Chart

Inlet (Return Air)

Outlet (supply air)

Single

200

250

Double

150

150

200

250

250

300

Evaporator (cooling) Coil

Notes: 1. The above references izes are internal diameter in mm.

2. If a single supply is used out of the unit but then splits into two (2) ducts, the above size

recommended for double is used after the split.

35

Use ductwork to connect the unit to the supply and return outlets in the wine cellar. Use only insulated

ductwork to minimize cooling loses, prevent sweating, and to reduce noise.

Use ductwork on the condenser section to redirect or absorb sound, to bring in outside air to the unit

inlet, and/or to exhaust the hot air out of the ambient space.

NOTE

Do not exceed a total of 7.5 meters for each length of ductwork run.

CAUTION

RISK OF DAMAGE TO EQUIPMENT

Avoid crimping the flexible ducts. This chokes down the inside area and reduces the airflow

causing the unit to operate erratically.

Be sure all ducts and surface in contact with the airflow are insulated

and have a vapor barrier on the outside surface.

Location of Supply and Return Grilles

Locate the supply and return grilles inside the cellar to create an airflow pattern that maximizes

air circulation in the room. Avoid short circulating of the air.

Do Not:

Install the return air grilles directly on the floor as the grilles will collect dust from the

floor.

Locate the supply or return air grille where it is blocked by bottles, boxes or cases.

Locate the supply air grille where it blows directly on the thermostat.

Relocating a grille on the Wine Guardian

1) Remove the fasteners from the grille.

2) Remove the fasteners from the access door panel to be replaced by the grille.

3) Relocate the outlet grille to its new location and secure in place using its fasteners.

4) Replace the access door panel where grille was located.

28

Uninsulated ducts and surfaces cause bare exposed metal surfaces to sweat,

36

further degradation of the insulation and a loss of equipment cooling capacity.

General Duct Recommendation

Support the flexible duct often to prevent sags or bends.

Stretch the duct to make for a smoother interior for less air resistance.

For a 90 degree bend, insert a metal elbow inside the flexible duct to avoid crimping.

Do not squeeze or reduce the inside diameter of the ducts. This restricts the

airflow.

Use short and straight ductwork.

Review the configuration schematic on the Overview Sketch on page 8 for

information about which panels are available for duct connections and service.

Remove the panels or grilles from the openings to connect the ductwork.

Check that all the fan blades move freely.

Check for loose foreign objects in any of the air paths.

Connect the round flexible ducts to the Wine Guardian using the duct collars

provided with the duct accessory kit.

Pull the outer plastic wrapping and insulation away from the end of the duct to

expose the reinforced inside duct liner.

Use tie straps of clamp around the inside liner to fasten the duct collar.

Do not clamp around the outside insulation. It compresses and loosens over time.

Secure the duct collar to the unit using the screws provided. Be careful not to damage

or bend the gasket.

Not Using Ductwork

The supply and return grilles stay on the unit if no ductwork is used.

The supply and exhaust grilles may be relocated to any of three openings. (Refer to the

manufacturers installation instructions located in the box of flexible ductwork).

Using Ductwork

Cold Air to/from Wine Cellar

Remove supply air grille or access door panels to install ductwork between the Wine Guardian

unit and the cellar.

Connect the supply air ductwork from the cellar to the supply air inlet at the Wine Guardian unit.

Connect the return air ductwork from the cellar to the return air inlet at the Wine Guardian unit.

Warm Air to/from Condenser

Connect ductwork on the condenser to direct heat and the air noise away from occupants.

Connect ductwork to another space within the basement, a building or to the outdoors if the heat

being exhausted is undesirable.

33

Typical Mounting Arrangements

Remote Mount on Floor

Condenser inlet and

exhaust – to outside

Ceiling Mounts