Page 1

®

TURRET REPLACEMENT KIT RP-RM46

INSTALLATION INSTRUCTIONS

for CRANK-UP SATELLITE ANTENNAS

(Except Combination Mounts - RM-4610, etc.)

Directions for Turret Replacement

1. Crank antenna to vertical position.

2. Remove crank assembly inside vehicle

using #2 Phillips screw driver.

3. Is there a nut in the center hole of the

directional handle? Remove this nut,

using a 9/16” socket wrench.

4. Remove directional handle by pulling

down. Depending on the original installation, it may be difficult to remove.

5. To remove backup assembly from

turret, remove the two (2) clamps and

four (4) screws. Use 5/16” socket, nut

driver or wrench. Do not pull on the

wires attached to mount.

6. Remove three (3) screws fastening

turret to mount. Use 5/16” socket, nut

driver or wrench.

7. Lift mount straight up until free of all

parts. If the worm shaft stays in the

turret, remove by pulling on aluminum

hex shaft (it should come out easily).

8. Remove and clean outer bearing. Use

damp cloth to remove grime, then

replace bearing.

9. Remove and clean gear and hub area.

Add a small amount of silicone grease

to area where gear and hub rub.

10. Replace new turret assembly on mount.

Rotate assembly until the three mounting holes line up. Carefully fasten with

three screws in the existing threads.

Be sure turret turns freely on mount. Be

sure the handle lock is in the rotate

position before checking turret

movement.

11. Rotate square shaft with shaft pin, until

pin faces up at approximately 45°.

12. Replace worm shaft into top of turret.

Be sure the spring and spacer are on

the shaft.

13. Line up hex shaft with hex hole in gear.

Slide into hole.

You may need to slightly turn the

square shaft to align teeth on worm

gear to teeth on worm shaft. The

square shaft will rotate as worm shaft is

slid down into place.

14. Make sure O-ring in on plastic plug.

Carefully screw plug into turret top. Do

not cross thread. Tighten snugly. Do not

overtighten — O-ring will squeeze out

from under nut.

15. Replace backup structure. Be sure to

route wires the same as they were

before disassembling backup structure.

16. Replace the interior parts that were

removed.

To replace the directional handle, refer

to instructions on page 4 for cutting

the length.

NOTE: For thick roofs, you may need a

longer threaded rod, part number 2162031.

Order from Winegard Customer Service at

1-800-288-8094.

Winegard Company • 3000 Kirkwood St. • Burlington, IA 52601-2000 • 319/754-0600 • Fax 319/754-0787 * www.winegard.com

Printed in U.S.A. © 2003 Winegard Company 2452032

1

Page 2

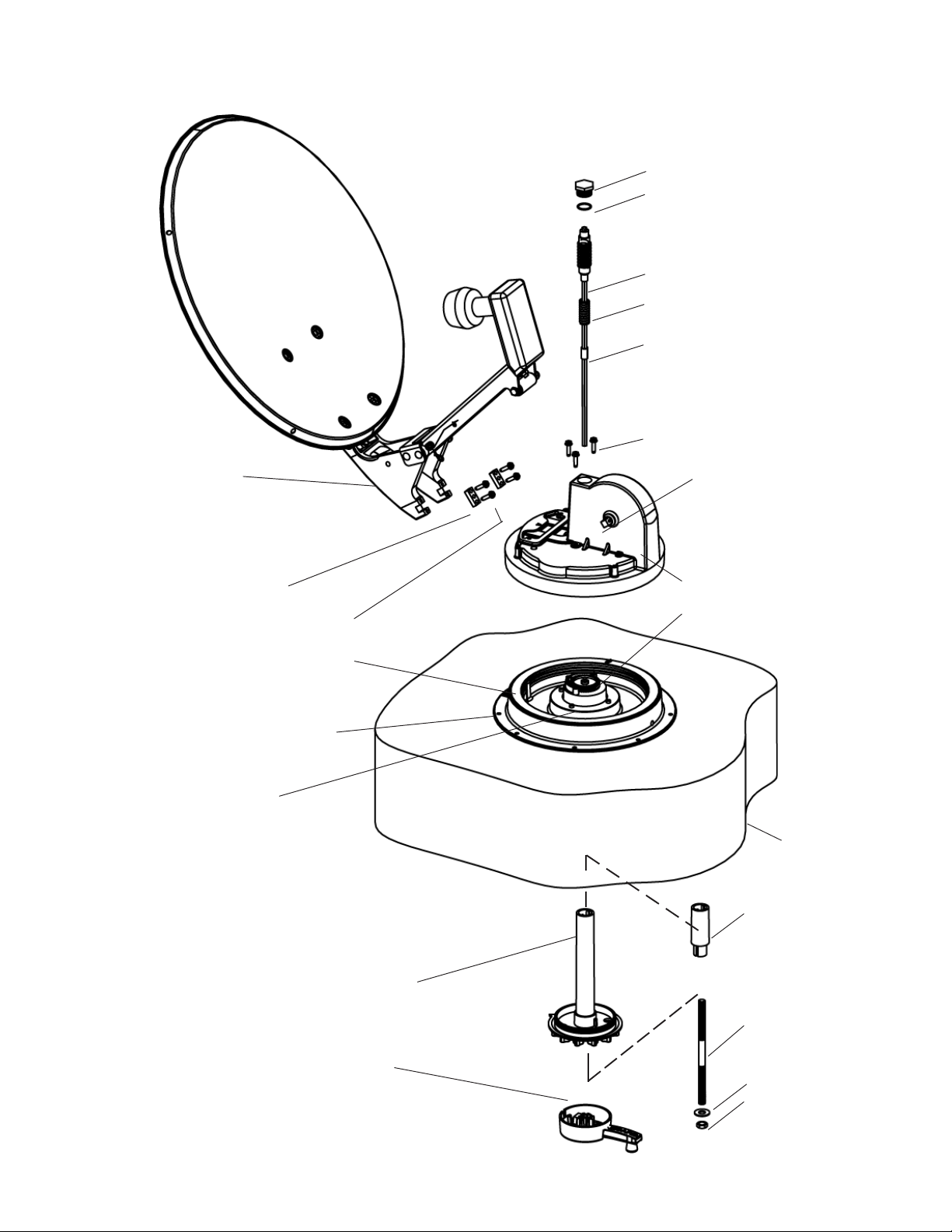

FIGURE 1

PLASTIC PLUG

O-RING

WORM SHAFT

SPRING

SPACER

SCREWS (TURRET)

BACKUP FRAME

ASSEMBLY

CLAMP

SCREWS (CLAMP)

OUTER BEARING

TURRET BASE

HUB

SHAFT PIN

(Referred to in #11.)

TURRET ASSEMBLY

ELEVATE SHAFT GEAR

ROOF

EXTENSION,

DIRECTIONAL

HANDLE

DIRECTIONAL HANDLE

CRANK ASSEMBLY

THREADED

ROD

FLAT WASHER

HEX NUT

2

Page 3

Instructions for Cutting Directional Handle Length

1. Place nut on threaded rod.

2. Measure and cut threaded rod with hack

saw. Use the chart, Figure 2, to determine the length.

3. Remove the nut over cut end of threaded

rod. This cleans the threads after cutting.

4. Thread cut end of rod into hub.

5. Install the ceiling plate. The rotate/lock

lever must point toward rear of vehicle.

Be sure rotate/lock lever is pointing toward

back of vehicle and hole in ceiling aligns

with hole in ceiling plate.

NOTE: Make sure large and small keyways

line up in the hub and directional handle!

6. Measure and cut the directional handle,

Figure 3 and chart, Figure 2. NOTE: A

tube cutter is recommended for cutting

the directional handle. This gives a

square cut; a hacksaw does not. If using

an extension, allow for extra thickness

(see #7).

Figure 4 shows what points to measure

between, with and without a roof wedge.

7. The directional handle

and threaded rod will fit

roofs up to 5-1/4” thick. If

you are using wedges to

compensate for roof/ceiling slope, be sure to

allow for this extra thick-

WITH ROOF WEDGE

ness. You may add an

extension to the

directional handle for

Measure from top of

ROOF WEDGE to ceiling.

thicker roofs. Each

extension will increase

the length of the directional handle by 2-1/4”.

FIGURE 2

Roof Directional Threaded Worm Gear

Thickness Handle Length Rod Length Shaft Length

(Figure 3) (Figure 4)

1-1/2” .......... 2-7/8”............ 2-3/4” ...........2-7/8”

1-3/4” .......... 3-1/4” ............ 3” .................3-1/8”

2” ................ 3-1/” .............. 3-1/4” ........... 3-1/2”

2-1/4” .......... 3-7/8” ............ 3-1/2” ........... 3-7/8”

2-1/2” .......... 4-1/8” ............ 3-3/4” ........... 4-1/8”

2-3/4” .......... 4-1/2” ............ 4” .................4-1/2”

3” ................ 4-3/44”.......... 4-1/4” ........... 4-3/4”

3-1/4” .......... 5” .................. 4-5/8” ...........4-7/8”

4” ................ 5-3/4”............ 5-1/2” ........... 5-3/4”

4-1/4” .......... 6-1/8” ............ 6” .................6-3/8”

4-3/4” .......... 6-5/8” ............ 6-1/8” ........... 6-3/8”

5” ................ 6-7/8”............ 6-3/8” ........... 6-5/8”

5-1/4” .......... 7-1/8” ............ 6-5/8” ........... 7”

5-1/2” .......... 7-3/8” ............ 6-7/8” ........... 7-1/4”

FIGURE 3

HANDLE

LENGTH

CEILING

PLATE

DIRECTIONAL

HANDLE

WITHOUT ROOF WEDGE

Measure from top of

ROOF to ceiling.

TOP OF ROOF

FIGURE 4

TOP OF ROOF WEDGE

CEILING

CEILING

3

Page 4

Refer to drawing to identify parts.

STEP 1. Release spring at base of feed arm.

(This allows you to remove elevating shaft and

spring without the dish popping up.) Next,

lower antenna to travel position.

STEP 2. Loosen set screw on elevating crank

handle. Remove crank, #1, directional handle,

#2 and extention, #3 (if used).

STEP 3. On roof of vehicle, unscrew plug, #4,

from top of gear housing. Use 1/4” hex head

nut driver and turn elevating shaft counterclockwise to remove. Carefully pull out

elevating shaft and spring assembly.

STEP 4. To replace elevating shaft, slide

spacer #5A, spring, #6, onto elevating shaft,

#5. Keep shaft in vertical position and slide

into gear housing. You must match the hex

shape of the elevating shaft with the hexshaped hole in the gear inside the gear

housing. Do not force. There will be some resistance as you slide the elevating shaft into

the housing. Carefully push in until the top of

the shaft is down in the top of the housing. Using 1” combination wrench, replace plug, #4,

into top of housing.

STEP 5. Raise dish and reattach spring at

base of feed arm.

STEP 6. If necessary, adjust elevating shaft

length before replacing directional handle, extensions (if used) and elevating crank handle.

See owner’s manual for instructions.

STEP 7. Replace directional handle, extensions (if used) and crank handle.

4

Loading...

Loading...