Page 1

OWNER’S MANUAL

INSTALLATION INSTRUCTIONS

WINEGARD

RV Digital Satellite System

with RS-1000 Antenna

Model RD-4610

U.S. PATENTS 5,532,710

and 5,554,998

Made in U.S.A.

®

IMPORTANT:

INSTALL POINT

OF BASE

TOWARD FRONT

OF VEHICLE!

Winegard Company • 3000 Kirkwood St. • Burlington, IA 52601-2000

Printed in U.S.A. ©Winegard Company 2001 2451142 Rev. 6/05/01

319/754-0600 • FAX 319/754-0787

Page 2

INSTALLATION & ASSEMBLY

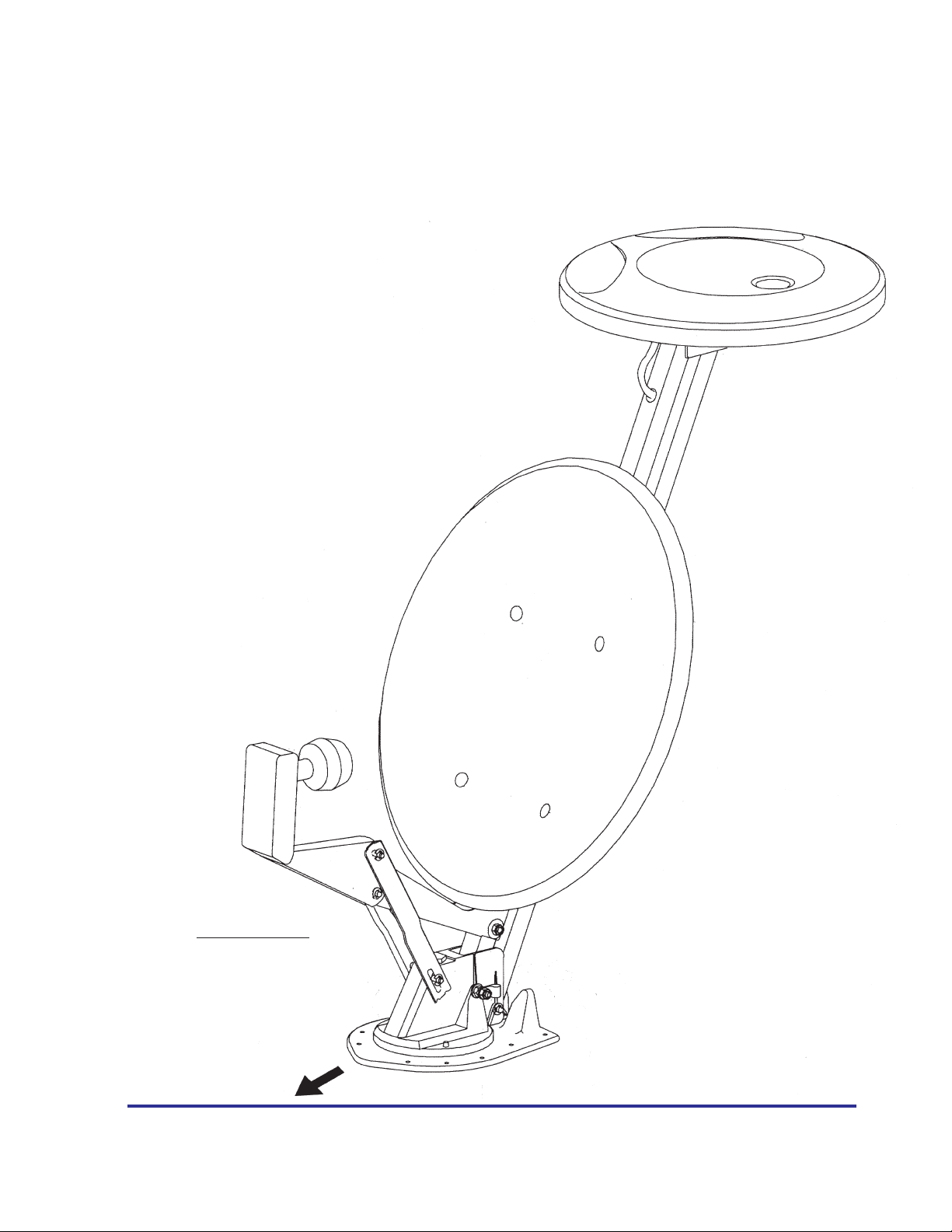

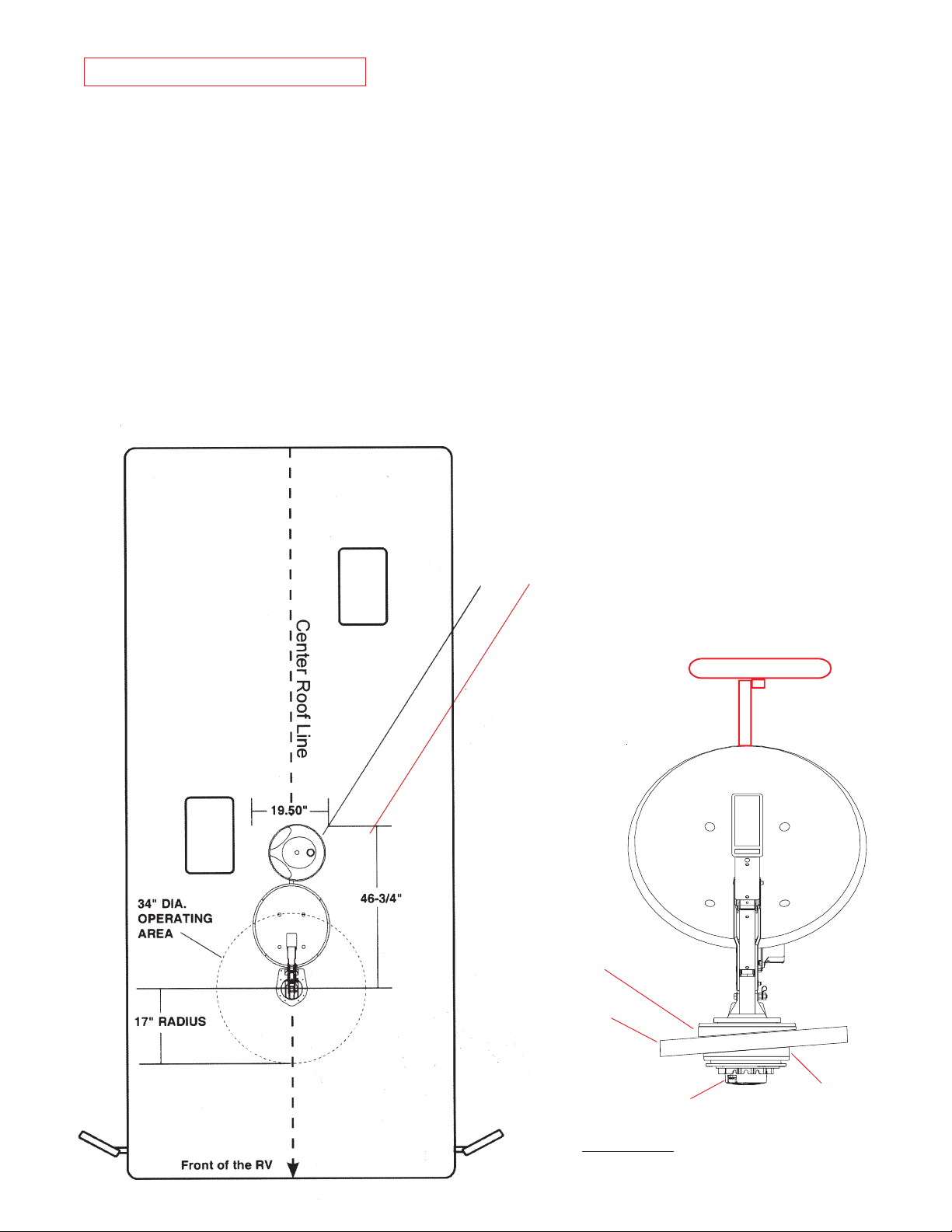

STEP 1. Choose a location for antenna that will allow it to rest in travel

position with antenna pointing toward rear of vehicle and raise and rotate

without interfering with other roof-mounted equipment. Make sure inside

ceiling area is clear where ceiling plate will mount.

NOTE: Figure 1 shows minimum distance (10") antenna should be

located from edge of vehicle roof. We recommend you check with

your dealer or the manufacturer to see what provisions have been

made in the roof for antenna mounting. A reinforced area of roof as

well as pre-wire downlead may be available.

NOTE: The system must be level for proper operation. If you have a

curved roof you should use a Winegard Model RW-1000 wedge kit to

level the system.

STEP 2. Position template on roof (last page of manual) and drill a 1-1/2"

hole through roof and ceiling of vehicle. Take care to avoid damage to

wiring which may run between roof and ceiling.

It is highly recomended that the antenna be

mounted on roof center line. Do not mount

antenna closer than 10" from edge of roof.

RW-1000

Roof Wedge

Vehicle Roof

Antenna Controls

NOT TO SCALE

2

FIGURE 1

Interior Roof

Wedge,

Optional

Rev. 2/2001

Page 3

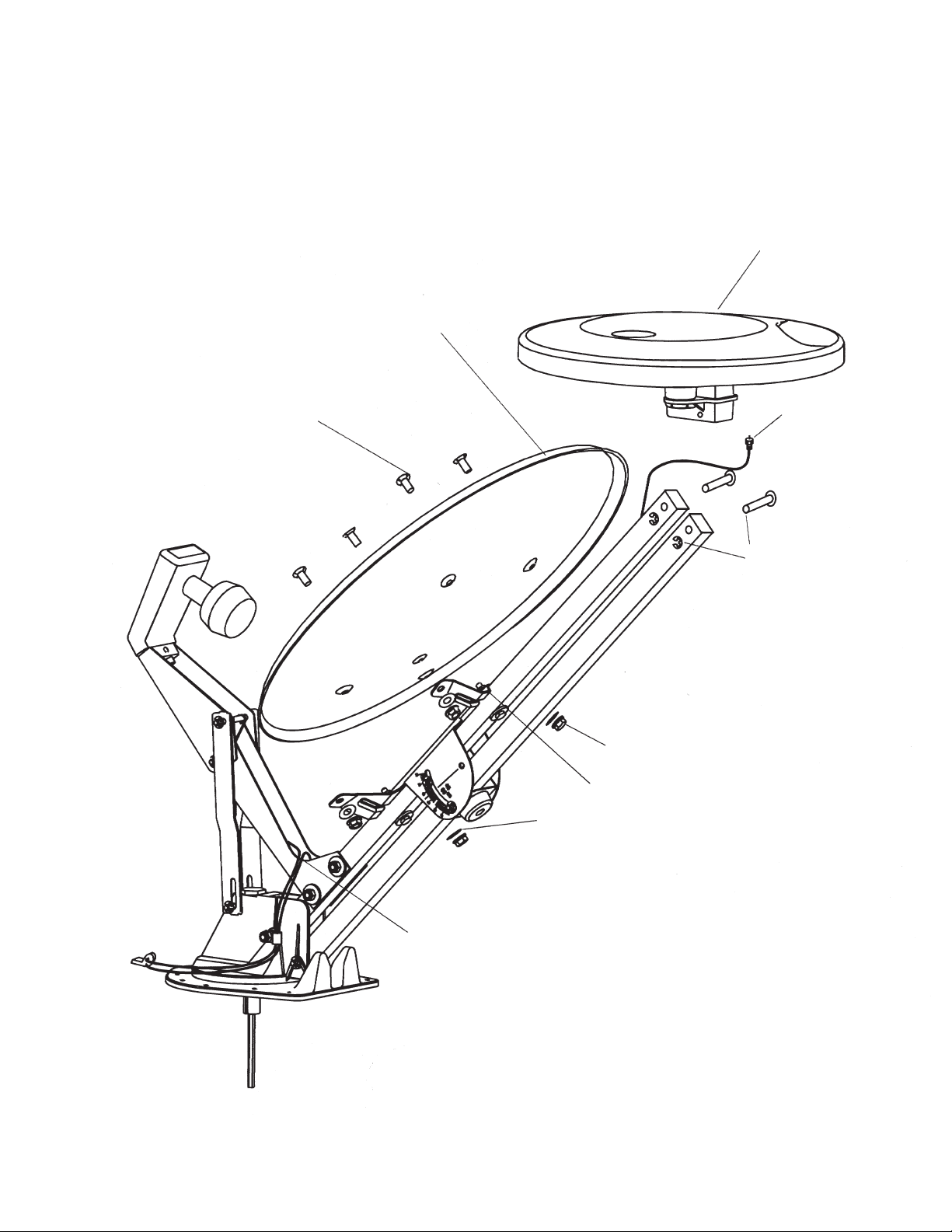

STEP 3. Attach reflector to backup assembly as shown in Figure 2.

STEP 4. Attach RS-1000 antenna to elevating tubes, see Figure 2, using the two Eclips

and pins provided. Attach coax cable to F-jack on antenna, slide weather boot over

boot collar.

RS-1000 Antenna

Reflector

(4) 5/16-18 x 5/8"

Flat Head Bolt

Attach coax cable to

F-jack on antenna,

slide weather boot

over boot collar.

Attach RS-1000 to

elevating tubes using

E-clips and pins

supplied.

(4) 5/16-18 Hex Nut

Backup Assembly

(4) 5/16" Flat Washer

FIGURE 2

NOTE: Make sure that

coax cables fits between

the reflector and the fixed

feed arm.

ANTENNA SHOWN PARTIALLY RAISED

FOR EASE OF ILLUSTRATION ONLY

Rev. 2/98

3

Page 4

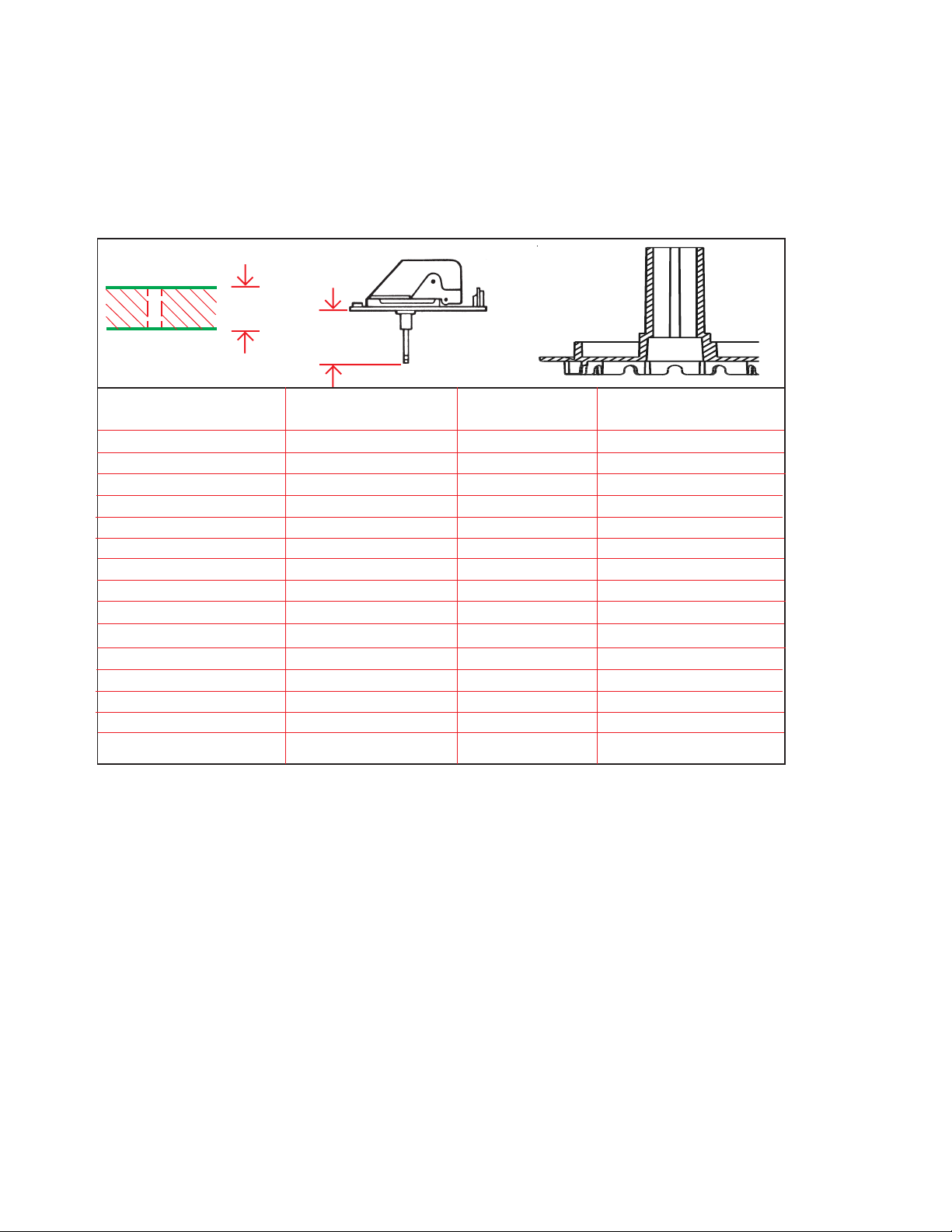

STEP 5. The mount is designed to fit roofs 1" to 4 3/4" thick. If roof is less

than 4 3/4" thick, cut elevating shft and directional handle to size. (See table

below.) If roof is more than 4 3/4" thick, the RP-2000 Thick Roof Kit

is required. See page 15, A for chart.

CAUTION: IF YOU ARE USING THE RW-1000 ROOF WEDGE,

ADD 1/2" TO ELEVATING SHAFT LENGTH GIVEN BELOW, BUT NOT

TO THE DIRECTIONAL HANDLE.

Direc-

tional

Handle

ROOF ELEVATING SHAFT W/RW-1000 DIRECTIONAL

THICKNESS LENGTH HANDLE LENGTH

4 3/4" 6 1/4" RP-4200 req. 5 3/8"

4 1/2" 6" RP-4200 req. 5"

4 1/4" 5 3/4" 6 1/4" 4 3/4"

4" 5 1/2" 6" 4 1/2"

3 3/4" 5 1/4" 5 3/4" 4 1/4"

3 1/2" 5" 5 1/2" 4"

3 1/4" 4 3/4" 5 1/4" 3 9/16"

3" 4 1/2" 5" 3 3/8"

2 3/4" 4 1/4" 4 3/4" 3 1/16"

2 1/2" 4" 4 1/2" 2 3/4"

2 1/4" 3 3/4" 4 1/4" 2 3/8"

2" 3 1/2" 4" 2 1/16"

1 3/4" 3 1/4" 3 3/4" 1 3/4"

1 1/2" 3" 3 1/2" 1 3/8"

1 1/4" 2 3/4" 3" 1"

Rev 1/2001

4

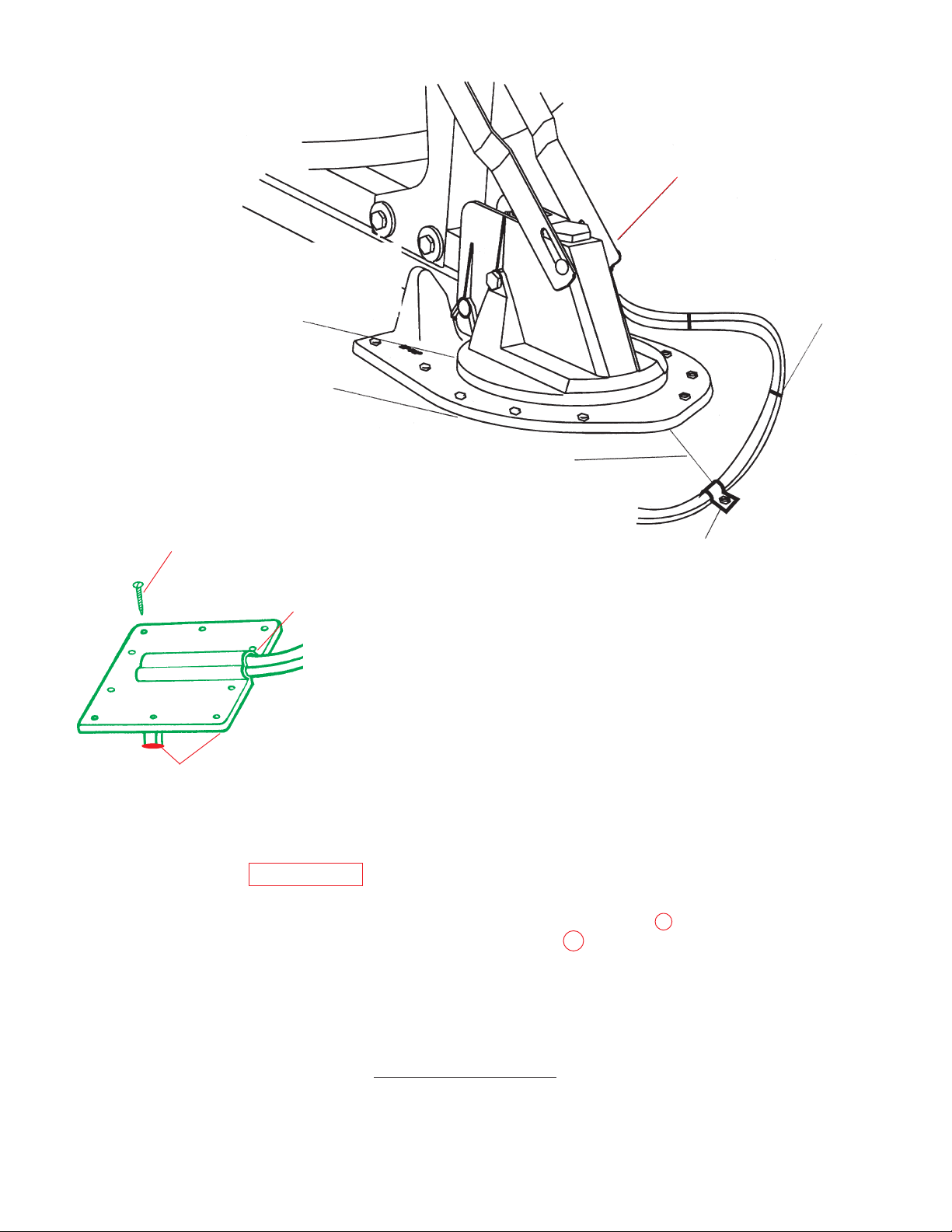

STEP 6. Mount antenna and lift on roof in travel position. Apply approved

sealing compound suitable for your vehicle roof on bottom of base plate and

roof area around hole. See Figure 3. Secure base plate with screws provided,

except for screw indicated in Figure 3*.

STEP 7. Attach cable clamp to the coax cables 16" from the cable clamp

on the gear housing.

STEP 8. Attach cable clamp to roof of RV as shown in Figure 3, use 7/16"

flat washer between screw and cable clamp, apply sealing compound over

mounting screw heads.

STEP 9. Attach satellite antenna coax cable (has "RG-6" printed on it)

to the coax cable going to the satellite receiver.

STEP 10. Attach RS-1000 coax downlead (has "RG-59" printed on it)

to coax downlead going to RV-0541 power supply. Refer to power supply

instruction sheet. You can connect the antenna output from the power

supply directly to the satellite receiver (refer to receiver manual). This

allows you to watch local channels when you turn the receiver off.

Page 5

CAUTION: DO NOT GET SEALING COMPOUND

ON BEARING SURFACE BETWEEN BASE PLATE

AND ROTATING GEAR HOUSING. DO NOT PAINT

TOP OF BASE PLATE OR AROUND ROTATING

GEAR HOUSING.

NOTE: Apply sealant approved for

your vehicle roof between Base Plate

and roof of vehicle.

Cable clamp on gear housing.

Cable Ties

3" min.

FIGURE 3

#10 x 1" Screws

Apply approved sealant

under lip and cable roof

hole

INSIDE RV

Make sure cable

entry is sealed

STEP 11. Feed downleads through roof using Winegard Model CE-2000

cover plate (included with hardware). Weatherproof cable entry by

applying approved sealant under lip of roof-thru plate and where cable

enters roof. Attach plate to roof with screws provided. Apply approved

sealant over screws and around edge of roof-thru plate, making sure cable

entry is sealed. Secure cables as necessary to prevent whipping. Use

tie-wraps provided to secure cables together.

STEP 12. Connect satellite coax downlead to satellite receiver, refer to

receiver manual on proper connections. If coax connections are made

outside the coach YOU MUST WEATHERPROOF THE CONNECTIONS!

STEP 13. Assemble ceiling plate, directional handle and crank handle as

shown in Figure 4. The circled numbers indicate placement from the

ceiling down. Example: The ceiling plate 1 is located next to the ceiling.

The elevation crank handle 8 is farthest from the ceiling. The number

also indicates sequence of assembly.

Attach cable clamp here. Make sure there are

16" of coax between the cable clamp on the gear

housing and the one here 3" in front of base

plate. TOO MUCH OR TOO LITTLE WILL CAUSE

DAMAGE TO COAX.

CAUTION: USE CAUTION WHEN INSTALLING THE ELEVATING

CRANK. ONCE SCREW TOUCHES SHAFT, TIGHTEN ONLY 1/4

TURN MORE. SCREW SIMPLY HOLDS ELEVATING CRANK ON.

DO NOT OVERTIGHTEN!

5

Page 6

CAUTION: After INITIAL

INSTALLATION,

the antenna SHOULD ROTATE

APPROXIMATELY 360

DEGREES FROM TRAVEL

POSITION.

The pointer on the

DIRECTIONAL HANDLE

should point towards the

ROTATION CLAMP when in

TRAVEL POSITION.

ASSEMBLED VIEW

FIGURE 4

1 Ceiling Base

POINT TO

FRONT OF RV

3 Directional

Handle Extension

2 (4) #10 Phillips Flat

Head Screws

POINTER

MUST POINT

TO CENTER

OF ROTATION CLAMP

WHEN IN

TRAVEL

POSITION

4 Directional

Handle

ALIGN POINTER

WITH ANTENNA

TRAVEL POSITION

5 ELEVATING

CRANK HANDLE

(When installed,

extends 2-1/4"

from ceiling).

Snap Handle

into base

when not in use.

Rotation

Clamp

POINT TO

FRONT OF RV

Tighten screw snugly

Rev 6/05/01

6

Page 7

OPERATION

Directional Handle

STEP 1. Using a compass, determine which direction is North. It is recommended that

you step outside to perform this step. Standing in or near coach/RV can give you an

incorrect reading. The more accurately you determine North, the easier it will be to find the

satellite(s).

Elevating Crank

FIGURE 5

Directional Handle

Pointer

STEP 2. Move rotation clamp to the LOCK position.

STEP 3. Rotate directional dial (see Figure 5) until the arrow is pointing North.

STEP 4. Unsnap elevation crank and turn (clockwise) in direction of "UP" arrow, about

14 - 15 turns or until some resistance is met.

STEP 5. Turn receiver ON, and access installation menus to determine antenna elevation

and direction/heading. See receiver owner manual for menu access instructions.

STEP 6. Move rotation clamp to the ROTATE position. Turn directional handle until pointer

on directional handle is pointing in direction indicated by the receiver. Example: If receiver

says point antenna at 145° then rotate directional handle so that pointer is pointing at 145

on the directional dial.

ELEVATION TURNS CCW

14 - 16

17 - 19

20 - 22

o

o

o

NONE

1/2

1

STEP 7. Refer to table below and turn elevation crank

counter clockwise (CCW) the number of turns indicated

to get the elevation shown by the receiver. One full turn

equals approximately 7° of elevation change.

Directional Dial

Rotation Clamp

23 - 26 1-1/2

27 - 29

30 - 32

33 - 36

37 - 39

40 - 43

44 - 46

47 - 50

51 - 53

54 - 57

58 - 60

61 - 64

65 - 67

o

o

o

o

o

o

o

o

o

o

o

o

2

2-1/2

3

3-1/2

4

4-1/2

5

5-1/2

6

6-1/2

7

7-1/2

o

Rev 7/97

7

Page 8

TUNING ANTENNA FOR BEST PICTURE

STEP 8. Your receiver should indicate it is receiving a signal. To tune your

antenna for the best picture, slowly move the antenna left, then right until

you have found the position that gives the highest signal strength. It is

important to turn the antenna slowly; since the signal is digital the

receiver takes a few seconds to lock on.

STEP 9. Place rotation clamp in the LOCK position. This prevents the

antenna from moving and losing the signal.

STEP 10.

signal. You are now ready to watch satellite TV!

WATCHING OFF-AIR TV

To watch off-air TV (local TV) you must use one of the following options;

Use a A-B switch between the receiver and antenna power supply Figure

6), A video switch (Figure 7), Or connect the antenna output from the power

supply to the TV ANTENNA input on the receiver (Figure 8). When you turn

the receiver off it will automatically switch you over to the off-air signal.

LOWERING ANTENNA TO TRAVEL POSITION

STEP 1. Set rotation clamp to the ROTATE position.

STEP 2. Rotate antenna until pointer on directional handle aligns with

the rotation clamp.

STEP 3. Turn elevating crank (counter clockwise) in direction of "DOWN"

arrow until resistance is met. The number of turns will vary according to

the elevation angle the antenna was set to.

STEP 4. Move rotation clamp to the LOCK position. Antenna is now

locked in travel position.

Slowly raise then lower the antenna until you have peaked the

STEP 5. Snap elevation crank into place.

CAUTION: UNDER NO CONDITIONS LOWER ANTENNA IN ANY

POSITION EXCEPT TRAVEL POSITION.

DO’S 1. Do check parking location for obstructions before raising antenna.

2. Do carefully raise, lower and rotate - if difficult, check for cause.

3. Do rotate slowly when searching for the satellite(s) and check fine

tuning on TV set to make sure it is properly adjusted.

4. Do lower antenna before moving vehicle.

5. Activate programming by calling programing service for your re-

ceiver.

DON’T’S 1. Don't move RV/coach with the antenna in the UP position. This

WILL void your warranty. This may also cause damage to your

roof.

2. Don’t force elevating crank up or down. Check for cause of trouble.

3. Don’t rotate directional handle hard against stops.

4. Don’t apply paint over top of base plate or anywhere on lift.

5. Don't apply sealing compound on gear housing.

8

Page 9

Coax

downlead

from satellite

antenna

Coax

downlead

from RS-1000

FIGURE 6

Satellite

Receiver

A-B Switch

Coax

downlead

from satellite

antenna

Satellite

Receiver

Power Supply

VCR

Coax

downlead

from RS-1000

Power Supply

TV

TV

FIGURE 7

VCR

Coax

downlead

from satellite

antenna

Satellite

Receiver

Video Switch

Coax

downlead

from RS-1000

Power Supply

VCR

Set 2

TV

FIGURE 8

9

Page 10

MAINTENANCE

MOUNT LUBRICATION

To lubricate the mount, apply a liberal amount of silicone spray lubricant to

the elevating gear, the lubricant hole and between the gear housing and

baseplate. Run the antenna up/down and rotate the antenna to distribute

the lubricant. See Figure 9.

Spray lubricant

here on elevation gear

FIGURE 9

LUBRICATING RUBBER QUAD RING

Lubricate rubber quad ring on elevating shaft which is below worm gear

with silicone spray lubricant at least twice yearly (Figure 10). This will keep

quad ring from becoming brittle which could result in leaks down elevating

shaft.

ELEVATING SHAFT

WORM GEAR

FIGURE 10

LOWER BEARING SURFACE

WAVE WASHER

Remove cap and spray

lubricant into the

lubricate hole. Be sure

place cap firmly back on.

Spray lubricant

around edges

FLAT WASHER

RUBBER QUAD RING

ELEVATING SHAFT & WORM GEAR ASSEMBLY REPLACEMENT PROCEDURE

NOTE: It is not necessary to remove rotating gear housing from base

plate or remove antenna from roof to replace the shaft & worm gear

assembly.

STEP 1. Lower antenna to travel position. Loosen screw on elevating

crank, remove crank, spring, directional handle. Parts list page 14.

STEP 2. Remove hex nuts, cable clip, and washer from bolt holding

elevating tube in rotating gear housing and remove bolt. Parts list page 12.

STEP 3. Remove worm gear nut from top of rotating gear housing,

disengage elevating gear, remove elevating shaft assembly. A, Parts list

page 12.

STEP 4. Lubricate worm gear assembly on new elevating shaft assembly

with spray silicone lubricant. Make sure wave washer, flat washer and

quad ring are on lower bearing (Figure 10) and insert assembly in

housing.

STEP 5. Reinstall worm gear nut in top of housing. Gears will mesh

automatically once elevating crank is turned.

STEP 6. Reinstall bolt, hex nuts, cable clip and washers that hold elevating

tube in rotating gear housing.

Rev 1/97

10

STEP 7. Replace directional handle, spring and elevating crank. Make

sure set screw contacts flat surface on shaft before tightening.

Page 11

TROUBLE SHOOTING

NO PICTURE 1. Check that you have a clear line of sight to the satellite (no trees,

buildings, etc.).

2. Check that you have the TV set tuned for the correct channel 3 or 4

(same channel as output of receiver).

3. Double check that you have entered the correct zip code into the

receiver. If zip code is wrong, this can cause you to look in the

wrong direction/elevation for the satellite.

4. Check connections at receiver, TV, and antenna.

5. Check TV. Does it receive pictures from off-air TV stations/VCR?

6. Retune system for best picture per procedure on page 7.

7. Inspect antenna. Make sure that it has not been damaged. If

antenna is even slightly bent, the receiver may not receive any

signal.

8. Contact Dealer or Winegard Service Department.

ANTENNA DOES NOT OR IS HARD TO ROTATE

1. Inspect antenna on roof. Make sure mount has not been damaged.

2. Check for caulking between gear housing and baseplate.

3. Lubricate mount per procedure on page 8.

4. Contact Dealer or Winegard Service Department.

ANTENNA DOES NOT OR IS HARD TO RAISE

1. Inspect antenna on roof. Make sure mount has not been damaged.

2. Check for caulking on elevating shaft.

3. Lubricate elevating shaft per procedure on page 8.

4. Contact Dealer or Winegard Service Department.

WARRANTY REPAIR WORK

Before you have warranty work done on the system, make sure the

company/person performing the work has been approved by Winegard

Company. If not, contact Winegard Co. (1-800-288-8094) before

proceeding. The Winegard warranty covers only the mount, antenna

and LNBF. For receiver warranty, refer to the manufacturers warranty.

ORDERING REPAIR PARTS

Repair parts are available at many RV dealers and/or service centers

throughout the country. Or you can call Winegard Company

1-800-288-8094 (only credit card orders accepted).

ANTENNA/LIFT/LNBF TWO YEAR LIMITED WARRANTY

Winegard Company warrants this Winegard product (excluding receiver) against any defects in materials or workmanship within two (2)

yeares from date of purchase. No warranty claim will be honored unless at the time the claim is made, you present proof of purchase to an

authorized Winegard dealer (if unknown, please contact Winegard Company, 3000 Kirkwood Street, Burlington, Iowa 52601-2000, telephone

319-754-0600).

Winegard Company (at its option) will either repair or replace the defective product at no charge to you. This warranty covers parts, but does

not cover any costs incurred in removal, shipping or reinstallation of the product. This limited warranty does not apply if the product is

damaged, deteriorates, malfunctions or fails from: misuse, improper installation, abuse, neglect, accident, tampering, modification of the

product as originally manufactured by Winegard, usage not in accordance with product instructions or acts of nature such as damage caused

by wind, lightning, ice or corrosive environments such as salt spray and acid rain.

The Two Year Warranty is provided on the condition that the equipment is properly delivered with all handling and freight charges prepaid

to your Winegard dealer for repair or return to our factory at the above address. Winegard dealers will arrange for the replacement or repair

and return to you, without charge, the product which failed due to defective material or workmanship.

WINEGARD COMPANY WILL NOT ASSUME ANY LIABILITIES FOR ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, MADE BY

ANY OTHER PERSON.

ALL OTHER WARRANTIES WHETHER EXPRESS, IMPLIED OR STATUTORY INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY ARE LIMITED TO THE TWO YEAR PERIOD OF THIS WRITTEN WARRANTY.

The foregoing shall be the sole and exclusive remedy of any person whether in contract, tort or otherwise, and Winegard shall not be liable

for incidental or consequential damage or commercial loss, or from any other loss or damage except as set forth above.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion of limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

11

Page 12

PARTS LIST

(not all parts listed

due to space constraints)

(4) 5/16" Hex Nut

P.N. 2160230

(4) 5/16" Flat Washer

P.N. 2160027

46cm (18") Reflector, White

P.N. 2745304

(2) 1/4-20 Hex Nut,

Nylock P.N. 2160220

Backup

P.N. 2745348

Digital Elevation

Device, If attached

the 1/4-20 x 1.75 Hex

Bolts are replaced

with 1/4-20 x 2" Hex

Bolts

(5) E-Clip

P.N. 5160818

(2) 1/4" Flat Washer

P.N. 2160039

(4) 1/4-20 Hex Nut,

Nylock P.N. 2160220

Worm Gear Nut

P.N. 2200045

A

(4) 1/4" Flat Washer

P.N. 2160039

(2) 1/4-20 X 1.75" Hex

Bolt P.N. 2160238

(3) 1/4 x 2-5/16" Pin

P.N. 2160814

Bumper Assembly

P.N. 3750823

(2) 1/4-20 X 1.75"

BOLT

P.N. 2160238

1/4-20 X 2.5" Hex Bolt

P.N. 2160237

(2) 1/4" Flat Washer

P.N. 2160024

REAR VIEW

Model RP-3000

Elevating Gear

Aluminum Gear

Housing

P.N. 3100520

(10) #10 x 1" Hex

Head Screw P.N.

2160178

Aluminum Baseplate

P.N. 3100524

Washer

P.N. 3200657

Retaining Nut

Rev 4/98

12

P.N. 2200047

(requires 15/16"

socket wrench)

Model RP-4000

Worm Gear &

Retaining Plug

See replacement

procedure on page 8.

Upper Elevating Tube

P.N. 3506032

Lower Elevating Tube

P.N. 3506033

Nylon Bearing

P.N. 3200656

Page 13

PARTS LIST

Upper Elevating Tub

P.N. 3506032

LNBF is attached to pivot arm

with: 1/4-20 x 1/2" Cap Screw

P.N. 2160240

Lower Elevating Tube

P.N. 3506033

RS-1000

Mount Adapter

P.N. 2200114

Bolt

P.N. 3200350

1/4-20 Nylock Hex Nut

P.N. 2160220

(2) 1/4" Washer

P.N. 2160024

LNBF Pivot Arm

P.N. 2745059

Spring

P.N. 2160820

(not shown

for clarity)

(4) Nylon Bearing

P.N. 2200726

(not shown

for clarity)

LNBF

P.N. 2780161

(4) Flat Head Bolts

(white) P.N. 2160361

(3) 1/4 x 2-5/16" Pin

P.N. 2160814

(2) Travel Link

P.N. 2745050

Fixed Feed Arm

P.N. 2745063

Travel Alignment Bracket

P.N. 2745061

Rev. 5/99

(2) 1/4 x 1-7/8" Pin

P.N. 2160694

NOT TO SCALE

(5) E-Clips

P.N. 5160818

(2) Cable Clamp

P.N. 2200060

(4) 1/4-20 Hex Nut,

Nylock P.N. 2160220

Coaxial Cable

RD-4600 20'

P.N. 2753025

RD-4646 76"

P.N. 2753064

13

Page 14

PARTS LIST

INTERIOR

HARDWARE KIT

RK-CEIL

Directional

Handle

Extension

Ceiling Base

Directional Dial

(4) #10 Phillip Flat

Head Screws

Azimuth Lock

Azimuth Lock Knob

Washer

#10 x 3/8" Phillips

CRANK HANDLE KIT

RK-HAND

#8-32 x 3/8"

Phillips Screw

#8-32 Square Nut

Directional Handle

Crank Handle Base

Crank Handle

Knob

#10 x 3/8" Phillips Screw

Washer

Rev 6/05/01

14

NOT TO SCALE

Page 15

SPECIFICATIONS

Height in the travel position 12.0" max.

Satellite antenna gain:

Cross polarization (on axis) -21 dB

RS-1000 antenna height 3.25"

Height when raised 37" max.

Operating radius 17" (34" diameter circle)

Roof space required 19.5" x 46.75"

LNB Compatible with DSS

Color White

Satellite antenna height 20.9"

Satellite antenna width 19.5"

F/D 0.59

Offset angle 24

o

Frequency range 10.95 - 12.75 GHz

11.2 GHz 33.22 dBi

12.1 GHz 33.89 dBi

12.6 GHz 34.23 dBi

Aperture efficiency 73%

*Beamwidth at -3 dB 3.5

*Beamwidth at -10 dB 7.0

o

o

RS-100 antenna gain

VHF 15.5 dB avg.

UHF 19.5 dB avg.

RS-1000 antenna width 14.5"

Wind loading Up to hurricane force

Weight 19 lbs. max.

Shipping weight: 21 lbs.

®

and DISH Network

TM

DSS® is a registered trademark of DIRECTV, Inc. a unit of Hughes Electronics Corporation.

DISH NetworkTM is a trademark and a service mark of EchoStar Communications Corporation.

MODEL RP-4200 THICK ROOF KIT AVAILABLE

Winegard Company makes available Model RP-4200 which includes one

directional handle extension and elevating shaft worm gear assembly. The

RP-4200 is designed for roofs more than 4 3/4" to 6 3/4" thick. Contact

Winegard Company if roof thickness measures more than 6 3/4". Refer to

the table below for the correct directional handle and elevating shaft

measurements. Remember to glue extensions (PVC glue is recommended)

and handle together after checking that you have the correct length.

ROOF ELEVATING W/RW-1000 DIRECTIONAL Extension

THICKNESS SHAFT LENGTH HANDLE LENGTH

6 3/4" 8 1/4" 8 3/4" 5 1/8" 2 1/4"

6 1/2" 8" 8 1/2" 7 1/8" Not Required

6 1/4" 7 3/4" 8 1/4" 6 7/8" Not Required

6" 7 1/2" 8" 6 5/8" Not Required

5 3/4" 7 1/4" 7 3/4" 6 3/8" Not Required

5 1/2" 7 " 7 1/2" 6 1/8" Not Required

5 1/4" 6 3/4" 7 1/4" 5 7/8" Not Required

5" 6 1/2" 7" 5 5/8" Not Required

Rev 1/2001

Printed in U.S.A. Winegard Company • 3000 Kirkwood Street • Burlington, Iowa 52601-2000 © Winegard Company, 2001 2451142 Rev. 6/05/01

15

Page 16

Rev. 8-97

Loading...

Loading...