Wine Corner ARM 15 User Manual

USER GUIDE

WINE ARM 15

DEFYING

CONVENTION

CONTENTS

1. CABINET LAYOUT 5

1.1. Evacuation 5

1.2. Cabinet insulation 5

1.2.1. Walls, ceiling and floor insulation 6

1.2.2. Doors 6

2. INSTALLATION OF THE WINEMASTER® CONDITIONING UNIT 7

2.1. Cutting the ceiling 7

2.2. Installation of the conditioning unit 8

2.2.1. Insertion of the appliance from the inside of the cabinet 8

2.2.2. Insertion of the appliance from above 8

2.2.3. Installation of the water drain-off 9

2.2.4. Duct ventilation 9

2.2.5. Installation of the thermostat 10

2.2.6. Installation of the hood 10

3. SWITCHING ON THE WINEMASTER® CONDITIONING UNIT 11

3.1. Connecting the conditioning unit 11

3.2. Switching on 11

3.2.1. Setting the temperature 11

3.2.2. Standby mode 12

3.2.3. Automatic defrost 12

4. SERVICING & MAINTAINING THE WINEMASTER® CONDITIONING UNIT 13

4.1. Maintaining the dust filter 13

4.2. Condensate evacuation pipe 13

5. WARRANTY 14

5.1. Statutory warranty 14

5.2. 2-year contractual warranty 14

5.3. Warranty application conditions 14

5.4. Warranty exclusions and limitations 14

WINEARM 15 USER GUIDE

2

INTRODUCTION

You have just purchased a WINEMASTER® conditioning unit. Thank you for the confidence you have

placed in us.

From design to marketing, we have done everything to offer you an exclusive and very high-quality

product. Mindful of this philosophy and produced from the work of a whole team increasingly

motivated by customer satisfaction, we hope that your WINEMASTER

with the optimal conservation and ageing conditions for your wines and incomparable pleasure.

Because the customer is central to all our work, we want to assist you in the initial stages to help you

optimise the daily use of your conditioning unit. In this User Guide, you will find technical information

and practical advice ensuring you progress simply through the essential installation and usage phases.

®

conditioning unit provides you

To ensure your tastings are privileged moments to share, WINEMASTER

®

guarantees you our sincere

commitment, dedicated know-how and an after-sales service available to you any time!

WINEMASTER

WINEARM 15 USER GUIDE

3

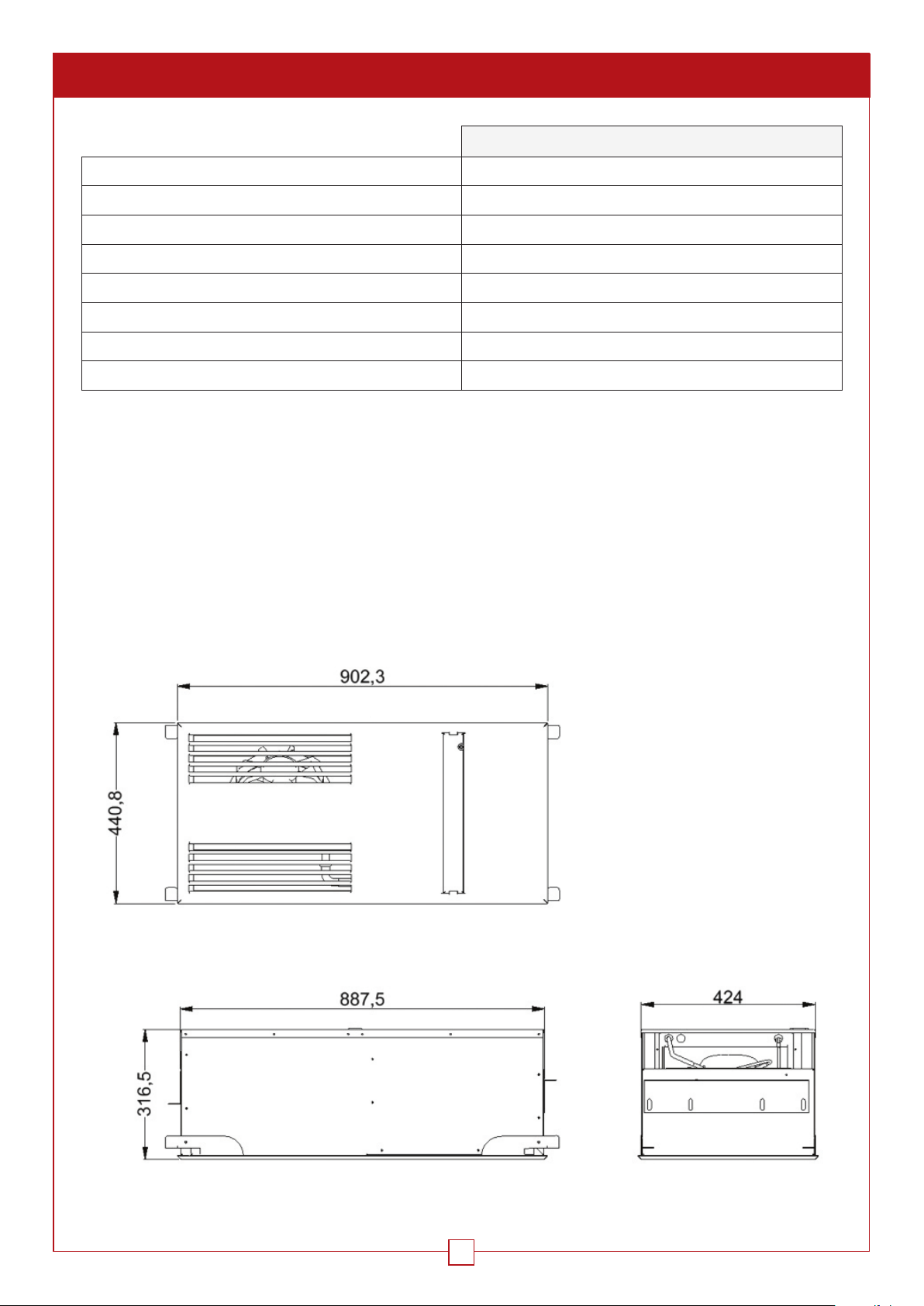

CHARACTERISTICS

WINEARM15

Weight of appliance 31 kg

Dimensions of appliance L908xD439xH316

Cut-out dimensions 890 x 428

Temperature setting preset to 12°C, adjustable between 4 and 15°C *

Max. outside temperature 35°C **

Cooling power 500 W at 15°C **

Electrical power supply 235V-50 Hz + 3 metre cable

Absorbed electrical power 400 W

The circuit breaker must be ≥ 16 Amps

* With insulation appropriate to the temperature and volume of the cellar.

** Since the power diminishes as a function of the outside temperature, the appliance might lose its capacity to

maintain 12°C if the outside temperature nears 35°C.

If the thermal safety function is triggered too frequently, this may damage the compressor prematurely. In all cases,

you should ensure the temperature of the evacuation room is not 35°C on a permanent basis. This high temperature

should furthermore be limited to summer seasons only.

TECHNICAL & DIMENSIONAL DRAWING

WINEARM 15 USER GUIDE

4

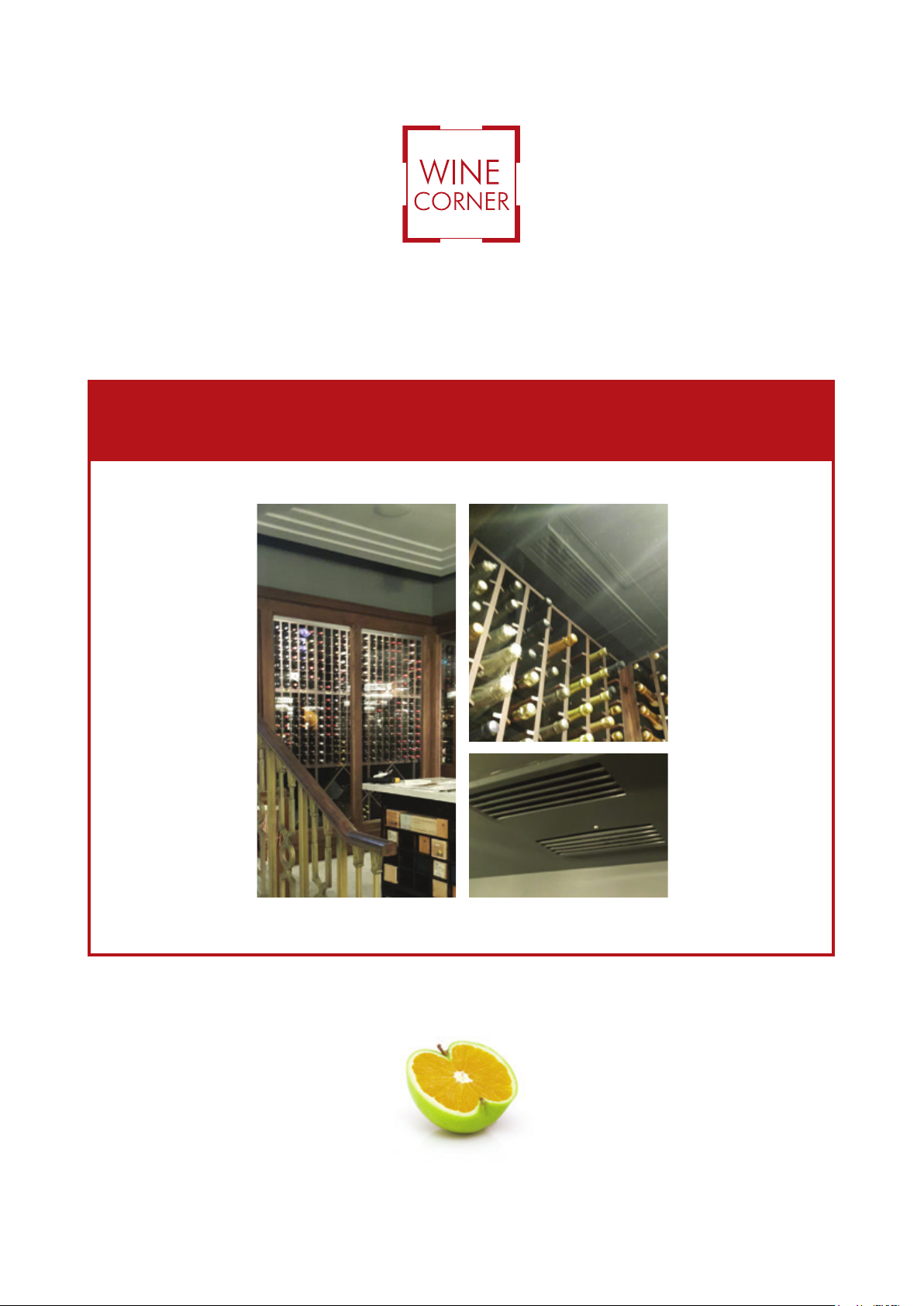

1. CABINET LAYOUT

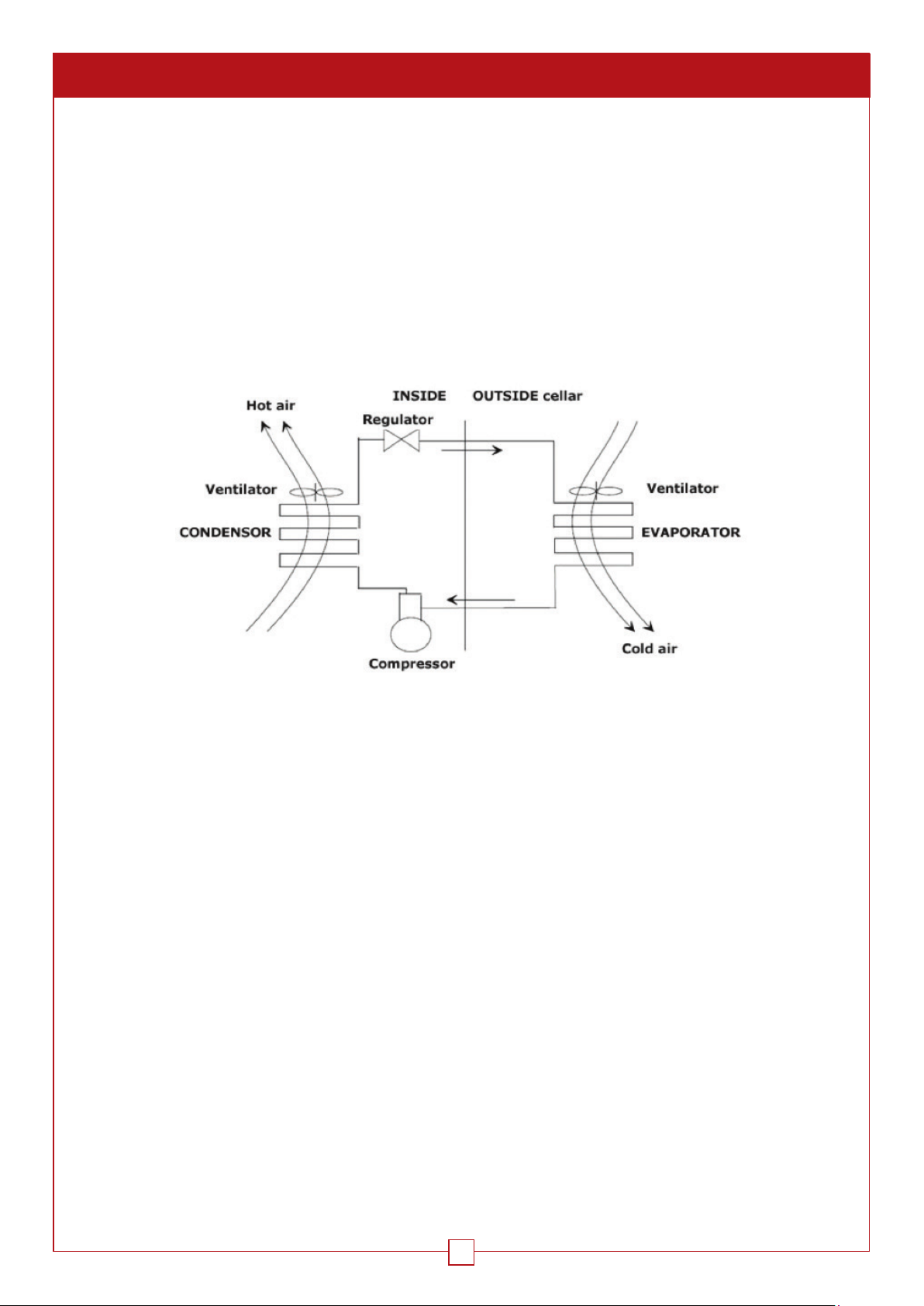

The conditioning unit is installed in the ceiling of the wine cabinet. To work correctly, the appliance evacuates the air

outside at approximately 20°C above the inlet temperature.

1.1. EVACUATION

The hot air produced by the conditioning unit must be correctly evacuated so that it is not reused for the cooling

function.

Maximum and non-permanent inlet temperature ≤ 35°C

Optimal inlet temperature ≈ 20°C

VENTILATED COOLING OR “NO FROST”

The benefits of ventilated cooling:

• No frost formation other than on the evaporator.

• Automatic defrost producing maximum refrigeration efficiency.

• Cold circulation improved by continuous air movement, no air stratification.

• Air circulation allows for rapid return to the preset temperature.

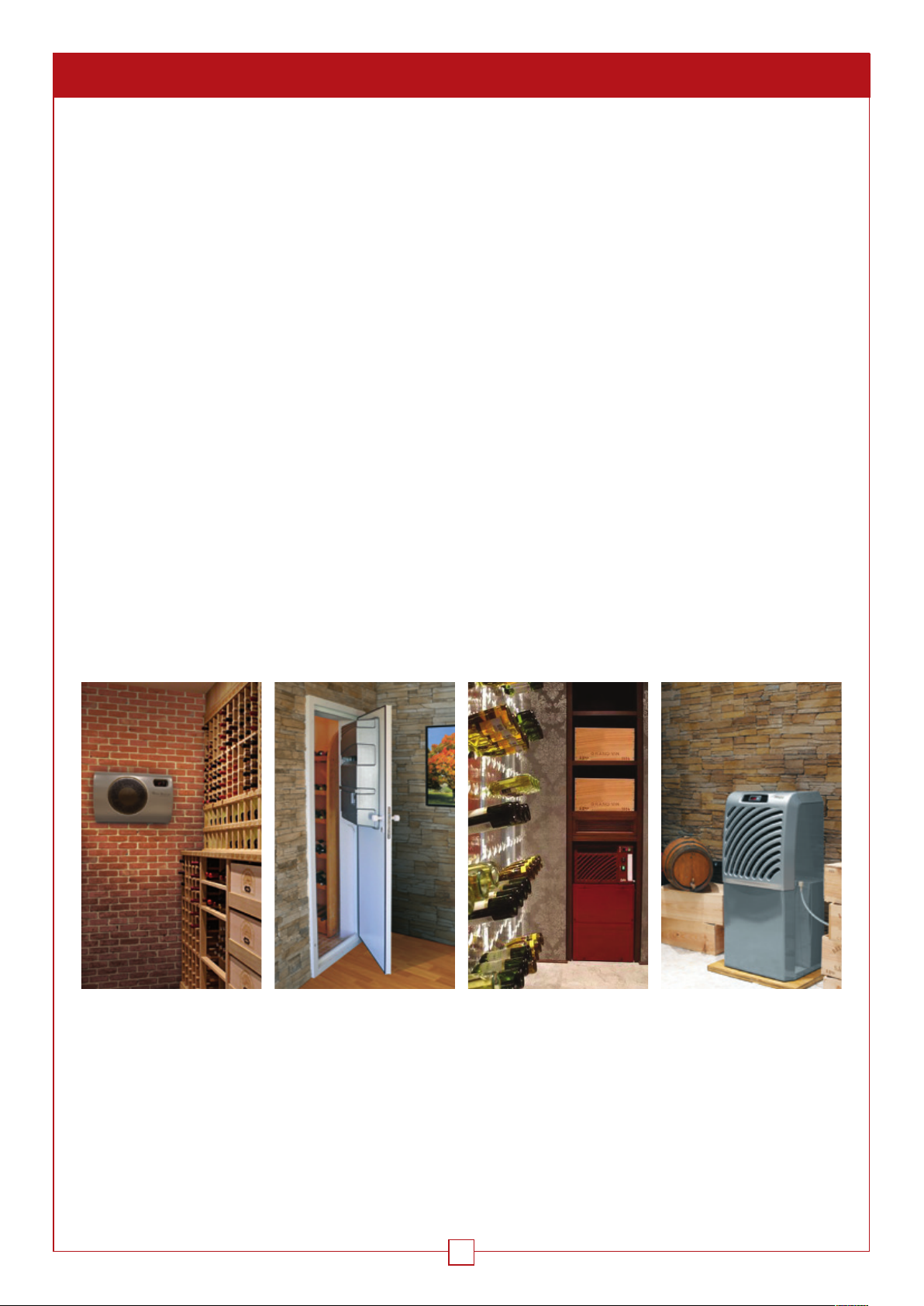

1.2. CABINET INSULATION

This is vital to ensure the efficient operation of the WINEMASTER

temperature and humidity stability. The table below (Choice of insulation) assists with determining the type and

thickness of the necessary insulation as a function of the outside volume of the cellar and the WINEMASTER

and based on an interior temperature of 12°C.

INSULATION CONTINUITY

The insulation elements should preferably be assembled:

• By “tongue and groove” panels, or

• By bonding the panels together

OBJECTIVE: To prevent the unwanted entry of heat and moisture which would damage their tightness.

To prevent moisture migration in the cellar, a vapour barrier should be fitted at the cabinet installation site.

®

. Adequate insulation will help to ensure a better

®

model,

WINEARM 15 USER GUIDE

5

Loading...

Loading...