Page 1

manual

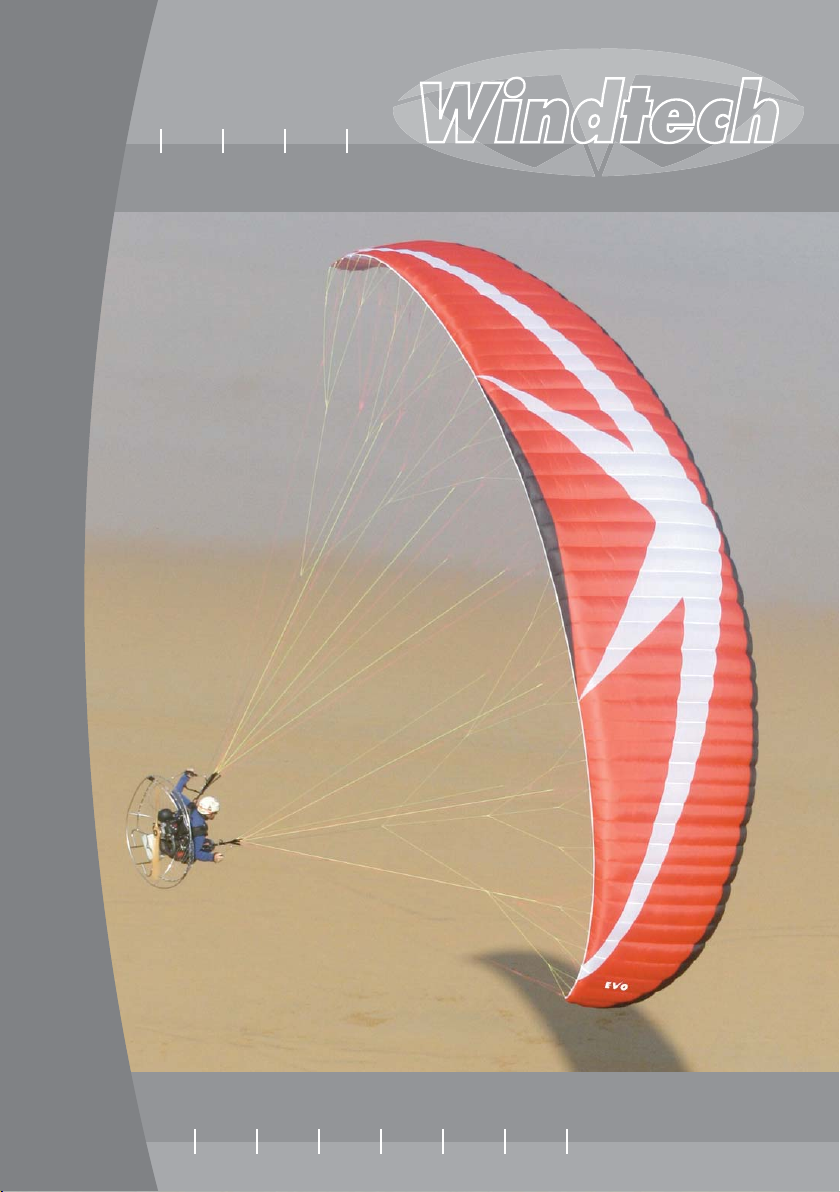

EVO

Page 2

Page 3

3

Windtech

w w w . w i n d t e c h . e s

EVO

23-25-27-30

flight manual

Page 4

4

> index

> congratulations ––––––––––––––––––––––––––––––– 5

> warning & liability ––––––––––––––––––––––––––––– 6

> design materials ––––––––––––––––––––––––––––––– 6

> best glide –––––––––––––––––––––––––––––––––––– 9

-- un-powered flight ––––––––––––––––––––––––––– 9

-- powered flight––––––––––––––––––––––––––––––– 10

> flight –––––––––––––––––––––––––––––––––––––– 10

-- inflation and take off ––––––––––––––––––––––– 11

> flying in turbulence –––––––––––––––––––––––––– 12

-- asymmetrical tuck/collapse–––––––––––––––––––– 13

-- front/symmetrical tuck collapse ––––––––––––––– 13

-- asymmetric stall (spin) ––––––––––––––––––––––––– 14

-- landing –––––––––––––––––––––––––––––––––––– 14

> weather to fly ––––––––––––––––––––––––––––––– 15

> emergency procedures & quick descent techniques – 15

-- big ears ––––––––––––––––––––––––––––––––––– 15

-- spiral drive ––––––––––––––––––––––––––––––––– 16

-- b stall ––––––––––––––––––––––––––––––––––––– 17

> maintenance –––––––––––––––––––––––––––––––– 18

> warranty ––––––––––––––––––––––––––––––––––– 18

> technical specifications–––––––––––––––––––––––––19

> speed system –––––––––––––––––––––––––––––––– 21

> line measurements –––––––––––––––––––22-23-24-25

> flight log ––––––––––––––––––––––––––––––––––– 26

Page 5

5

> congratulations

Congratulations on the purchase of your new EVO.

The EVO has been carefully thought out and designed to make paramotor flying as simple and enjoyable as possible.

We strongly recommend that before you fly the EVO you carefully read this manual in

order to be aware of any limitations, performances, take off and flight characteristics,

landing procedures, emergency situation and maintenance.

We always appreciate your feedback, so please send us your comments, positive or negative, in regard to the

Windtech

range.

You are the best feedback and support for future products, and please remember that we

are always happy to give you any help & advice.

Best winds

>

Windtech

team

Page 6

6

> warning & liability

We have produced this manual so that you can get to know your EVO better, with some

helpful tips to help you feel comfortable with it from the very first day.

Windtech

assumes that the purchasing pilot has the appropriate pilot's licence, has taken a training course, and has the suitable ability and enough experience to safely fly the EVO.

THIS INSTRUCTION

MANUAL IS NOT

INTENDED AS A “TEACH

YOURSELF PARAMOTORING” BOOKLET. We

have to make it very

clear that to fly this

wing safely and proficiently IT IS NOT

ENOUGH JUST TO READ

THIS MANUAL, and

that you, the pilot,

MUST complete a suitable paramotor flying

course, and gain a good

understanding of the

concepts of flight, both

powered and un-powered. It is also imperative that you gain a

good understanding of

the weather and flying

conditions, so that you

know when it is safe to

fly, and WHEN IT IS

NOT SAFE TO FLY.

This manual cannot be used for operational purposes. The flight log & registration card

must be filled and stamped by the dealer & returned to in order to claim on the guarantee.

The use of this paraglider is entirely at the user's own risk. As with any adventure sport

paragliding is a high risk activity-especially without taking the appropriate precautionstherefore it must be absolutely understood that

Windtech

& the dealer do not accept

any responsibility for accidents, losses, injuries, direct or indirect damage following the

use or misuse of this product.

Page 7

7

> design materials

The EVO is a glider that offers total security with beautiful handling & perfomance. The

performance is very high due to a well-defined structure with 52 cells, with an internal

structure comprised of diagonals of different types, depending on the width of the cell

and an optimized line layout to reduce the overall number of lines.

This specifically designed paramotor wing has been reinforced in key areas of the wing,

especially at all of the attachment points on both the under-surface and the cell walls.

The EVO is equipped with a double leading edge designed by

Windtech

that it provides

with higher performance and security at high speed and which enables a better take-off.

It disposes also of a mayor zone of aspiration (area) at the key areas in a different position regarding the profile thus enabling a better take-off behaviour and re-opening after

collapse. Due to this characteristic and the double leading-edge and the design of the

speed-bar, we can fly a higher speed with total security and beautiful performance.

-- cloth

The upper and lower panels are made with 45 gr. Porcher Marine Skytex nylon. The ribs

are made with stronger nylon of to prevent airofoil deformation, even after several years

of intensive use. Rib (cell wall) reinforcements are made of Dacron 310 &180 gr. Line

attachment points are made of polyester.

-- lines

The EVO´s lines are made from the highest quality Kevlar, with a polyester outer sheath

to protect the inner Kevlar core from abrasion and UV. The main (lower cascade) “A” and

“B” lines are 2.2mm, rated at 240kg, and the main “C” and “D” lines, are 1.7mm.

-- risers

We have designed the EVO´s paramotor riser system to help overcome the various complexities that powered flight entails.

The risers are shorter than usual (42cm), to allow for the different flying position and

help minimise the effects of the chassis of the engine.

Independent of using the trimmers or the spee-bar (not in combination), the risers submit the centre of gravitiy of the wing and, together wit the new profile, this offers more

pressure in the leading edge enabling us to fly at higher speed with total security.

The construction and materials have been made stronger, especially the stitching of the

main attachment points of the wing.

The travel of the webbing of the trimmers is on a pulley system, which means a greatly

reduced chance that they will slip (a big problem with normal trimmers) in normal flight

or after a sudden shock or under high pressure, such as a collapse or steep turn, offering

Page 8

8

a greater amount of security with a very effective and easy to use system.

The A-riser is splitted into two: one of them holds the central lines, marked in blue colour

and the other one which holds the exterior, marked in red colour; you should pull this

riser down to induce the big-ears; when releasing them, the big ears will open

autonomously.

Both dispose of a velcro fastener to put them together as one during take-off process.

This is important as we hold in the same hand the two risers, the handle of the speedsystem of the paramotor and the brake handle of the wing.

In order to avoid a bulk, the tape has only 20 mm.

The brake handles have not any rigid part and they are extremely conformable to wrap

it around the hand or to grab it in a more classical way.

The left handle is 25 mm. in width and it is covered with neoprene, so it is very comfortable. The right handles is in red color to easily difference in case you have to repeat

the lunch procedure and set the risers and gas throttle handle.

The rises have an elastic band that goes from the trim end to the bottom of the risers to

prevent any impact from the leftover webbing when the trim is fully closed.

The ‘trimmers’ are used to set the ‘trim speed’ of the wing and bring forward the center

of gravity, and have been carefully designed to give the best combination of efficiency

and stability across the whole speed range. When the trimmers are pulled fully ON

(pulled all the way through the ratchet, so that the rear risers are effectively pulled down

to their shortest position) the glider will fly at full slow trim speed. When the risers are

released all the way OFF (ratchet pressed, so that the webbing slips all the way and the

rear risers are in their longest position) the glider will fly at full fast speed. It is vitally

important that that you fully understand all of the effects and implications of flying at

different trim speeds, as this changes the handling, safety and performance characteristics of any wing.

There are two lines of stitching on the webbing of the trimmers which are set at “normal” trim and a faster “powered flying” position. When the trim is set to the first stitching line (normal trim), this is the speed that should be used for taking off, landing and

flying in turbulence.

If you then raise the trimmers up to the second line of stitching, this is the faster “powered flying” trim position (the actual speed will depend a lot on wing loading), in which

the trimmers are set to compensate for the pitching back effect caused by the push of

the motor, bringing the wing into a more overhead position and giving increased speed

and performance. Of course, caution should always be used when low down and one

should always fly with the trimmers in the “normal” trim position in turbulence and

when near the ground.

The trim travel will continue slightly further than the “powered flying” setting, to “full

Page 9

9

trim speed”, but one should only ever use this trim position in very smooth conditions,

and with plenty of height, due to the greatly reduced angle of attack of the wing. If the

pilot requires more speed in turbulent conditions, we recommend that the pilot leaves

the glider in “normal” trim position and makes use of the speed system.

We recommend setting the trim in the take off position and use the speed system.

We don't recommend the use of the speed system and the trims in rouge air.

The trim lock is covered with neoprene to prevent any damage in the arms during take

off. To release the lock place the forefinger and the thumb in the back of the lock, press

the lock release tab and rotate the hand the tab 90º up. This way the trim webbing slides

easily.

> best glide

-- un-powered flight

Best glide in nil wind, and still air, is obtained at “trim” speed that is brakes fully released

and no accelerator (speed bar) applied. It is always best to fly with a light pressure on

the brakes, keeping a “feel” on the wing in case of unexpected turbulence.

When flying into (against the) wind a better glide can be obtained by using the speed

system. The following is rough guide line as to how much to apply.

-With around 10 km/h of head wind, best glide is obtained with 25% accelerator applied.

-With around 15-25 km/h of head wind, best glide is obtained with 50% accelerator.

-With around +25 km/h of head wind, best glide is obtained with 75-100% accelerator.

When flying downwind (wind from behind ) the best glide is obtained between 0% brake

and 10% of brake.

The trim travel of the glider has been limited to a point where the security/safety of the

wing is still high and yet permits a gain of 12km/h. In any case it is recommended not

to use the trimmers close to the ground, or when conditions are turbulent. If turbulent

conditions are encountered, or if you are nearing the ground we recommend that you

return the trimmers without delay to the “normal” trim position, for take-off, landing and

flying turbulence.

Always fly a glider that is the correct size for you, and remember that if your flying

weight is below the stated minimum, the speed range will diminish and inflation problems may appear. Also the handling will degrade in turbulent conditions, and it will be

easier to sustain collapses. If your flying weight is above the stipulated weight range, this

will result in a higher minimum speed and faster landing speed and the stall speed of the

glider will also be higher.

Page 10

10

-- powered flight

The concept of performance under power is considerably different to that in free-flight

(without power). Factors that affect this include: thrust; power and size of the engine;

diameter of the cage; flight altitude; meteorological conditions, such as density of the

air; wing loading, etc.

We STRONGLY recommend that you try to

learn all about these

effects, by reading

books about paramotoring and speaking with

more experienced

paramotor pilots,

coaches and instructors,

BEFORE you start flying.

What is certain is that,

due to an increase in

wing loading and the

extra drag caused by

the chassis of the

motor, the sink rate, flying and handling characteristics, and per-

formance of the glider

will be affected. For this reason we consider it extremely important that the pilot chooses a motor that is most suited to the pilot’s weight, abilities, and intended uses in flight,

etc. When one takes into consideration all of the factors, one will arrive at one set of

performances and flight characteristics, or another.

> flight

Each and every glider has a checklist note passed though our strict quality control in the

factory. This includes line measurement, ground inflation and flight testing. Contact your

distributor for more information about this, and if your glider has not been pre-inflated

ask them to do so for you. Every glider should be test flown before it is sold.

Note that each glider has a unique sticker attached to the centre cell with the serial

number, type of glider, size and weight range.

We recommend that your first flight on your new glider will be realized without motor

be on a gentle slope in calm conditions before making any further higher flights, just to

check the glider and for you to get used to flying it.

Page 11

11

You should use a harness that has an ABS cross strap system and the maximum width

possible for the chest strap is 38 cm between karabiners.

For you own safety, we strongly recommend the use of back protection, helmet and

Windtech

WindSOS reserve.

-- inflation and take off

A paramotor launch is always more complicated than a free-flying (without paramotor)

one. More weight, the thrusting force of the wing, different position of the risers, accelerator throttle in one’s hand, etc, makes this usually the most difficult part of a paramotoring flight.

One has to bear in mind that a failed launch could result in the lines getting caught in

the propeller, breaking not only the lines but also the propeller itself, and in the worst

case could result in injuring oneself, or a bystander. For this reason it is very important

that you should not launch your paramotor in the vicinity of other people, and you

should always make sure that no one is near enough to sustain any injury from your

launch attempt. This could be either directly, for example from you colliding into them,

or indirectly, from flying debris blown up from the ground behind you from the thrust of

the engine, or from flying debris from a damaged propeller.

The pilot needs to always be very thorough and methodical with carefully preparing their

equipment and doing all of the required pre-flight checks, using a clear and complete

checklist. Always allow ample security margins to make room for any error, especially

during take-off and landing, and never forget that flying with a propeller that is rotating 40cm from your body carries inherent risks of serious injury and is therefore NEVER

a game!

For a good launch with the EVO always remember AT LEAST the following:

-in no wind conditions we recommend to release 2 cm of trim, therefore you will get a

better inflation in the way up of the canopy.the canopy.

Lay out the glider as perpendicular to the wind as possible, for a better inflation.

Lay the glider out in an arc, which will help the wing inflate in the centre first and come

up straight and uniformly. If there is some wind, a pre-inflation, to get some air in the

glider and clear the lines, will increase the chances of a successful launch.

Make sure that the risers are not twisted and everything is set up correctly.

Carefully check all of the lines and attachments points, to make sure there are no twists,

knots, or tangles, and that everything is correct and free running.

Carefully check that the maillons, the big-ear cleats, and the trim are secure, correctly

set and free running. Make sure that the big-ears facility is fully open (fully un-cleated),

so that the ears are not pulled in on launch.

Make sure that the trimmers are on the “normal” position for take off (first line of stitch-

Page 12

12

ing on the webbing) (bottom stitching, the 5 maillons must be level).

Make sure that the brake toggles are free running and not tangled.

- If you have attached the speed system, make sure that it is correctly set up, completely free running, and not tangled or caught up in any other part of your equipment.

- If you have a reserve parachute, make sure that this is also correctly set up, and that

nothing will either cause your parachute to deploy accidentally or prevent it from

deploying correctly should you need to do so in an emergency.

-Continue with a full check of your paramotor engine, harness, and any other equipment,

carefully following all of the checks and recommendations as stipulated in your paramotor’s manual.

- Once you have commenced the launch run and the wing is roughly in the 10 to 11

O’clock position, and flying correctly, applying a little thrust from the motor will greatly

help with the launch.

- Before you start your launch run, make 100% sure that the wind & weather conditions

are safe and correct for taking off and flying, and that your take off run and the air space

you are about to launch into is clear of people, vehicles, any obstacles, or air traffic. IF

IN ANY DOUBT, DO NOT LAUNCH.

With the wing nicely overhead in the correct flying position, a quick BUT THOROUGH

visual check to make 100% sure that everything is in order, ensuring that the wing, lines,

risers, etc, are all in perfect order before committing to take off.

Now it is very important to keep your body as vertical as you can, so that the thrust of

the engine acts horizontally, and as much away from the canopy as possible, and then

accelerate to take off speed. If you do this correctly, you should find yourself in the air

within only a few meters.

> flying in turbulence

Only an experienced and proficient pilot should ever fly in any kind of turbulent conditions. The pilot has to fly ‘actively’ (to maintain correct air speed and glider attitude) in

effect ‘absorbing’ turbulence with the controls and weight shift to keep the glider overhead and help prevent any deflations and always to be extremely careful not to stall the

wing, through bad pilot input or use of motor, especially through overuse of thrust and/or

the controls.

Always remember that by applying thrust this pushes the pilot forwards relative to the

wing, increasing the angle of attack and wing loading, at least momentarily. This in effect

shortens the available brake travel (speed range) of the glider, making it stall at a higher brake position. For this reason, under power it is not recommended to use more than

70% of the brake travel and to generally use less brake than you would when not under

Page 13

13

thrust, especially as you increase power. If the pilot encounters an area of turbulence just

as they apply power (they are pushed forward by the power of the engine and the angle

of attack of the wing therefore increases), one should be extremely careful as the control and flight behaviour of the wing is very different whilst under power.

In turbulent conditions, it is possible for your wing to suffer from either an “asymmetric” or

“symmetric” collapse. Also known as “tucks”, these are described in the following paragraphs,

along with a description of what to expect and the recovery techniques recommended.

-- asymmetrical tuck/collapse

An asymmetric collapse, is a longitudinal (lengthwise) collapse of a part of the wing (say

20 – 70%) which is normally caused by turbulence (although it is also possible to induce

collapses through poor pilot input). In un-powered flight, any tucks or collapses on the

EVO should sort themselves out automatically within 90 degrees. If you have a collapse

whilst under power, you should always ease off the thrust gradually, as the thrust of the

motor can considerably complicate the wing’s reactions and recovery behaviour. In any

case, and setting timmers to neutral position, the pilot should know how to first prevent

and, failing this, to deal with, an asymmetric collapse. They should also be familiar with

the required recovery procedures and techniques to return the glider to normal flight,

with the minimum loss of height or directional control.

If you have an asymmetric collapse, remember: “Course, then Correction”. First try to

maintain a SAFE course, WITHOUT STALLING THE WING BY OVER-CORRECTING, by first

weight shift towards the (still inflated) flying side of the wing (this will give a better wing

loading and augment the internal pressure of the wing) and apply around 20-40% brake

on the open side of the wing to try to minimise the turn induced by the collapse.

Remember that you should have gradually reduced the power of the engine.

BE CAREFUL when trying to stop the turn of the glider after a collapse not to use too

much brake and so stall the flying part of the wing, as this could cause more problems

than the collapse itself. Once you have maintained a safe course, and minimized the turn

induced by the collapse, you can apply CORRECTION to re-inflate the collapsed side of

the wing by giving smooth but firm pumps on the brake on the collapsed side, holding

down the brake until the glider re-inflates. Do not give small ‘panicky’ dabs of brake to

the collapsed side of the wing as this does not really help and will make the wing take

much longer to re-inflate. Once the wing re-inflates be careful not to hold down the

brake too much, for too long, as this could stall the wing, or induce a spin.

-- front/symmetrical tuck collapse

SET TRIMMERS TO NEUTRAL POSITION

This is when the whole leading edge of the wing, from the centre to the tips, collapses.

It is possible to have a front tuck on exit from a strong thermal, when using the speed

system or trimmers in turbulent conditions, hitting a (wind) shear layer, etc. Generally,

this situation does not require any pilot intervention as the glider will re-inflate quickly,

Page 14

14

autonomously and without problem. However, if the pilot wishes to help with re-inflation of the glider, this is the procedure to follow:

First, one should release the speed system (if one has it on) and pull both brakes approximately 50% until the glider reopens, and then immediately release the brakes so as to

not stall the wing. After the glider has re-inflated it is always a good idea to check the

trimmer’s, to make sure that they have not been pulled open by the shock of the re-inflation of he wing, and as you have suffered a collapse, it is best to make sure that the trimmers are in the “normal” position as it is clear that you are flying in a turbulent area!

-- asymmetric stall (spin)

It is extremely difficult to accidentally provoke a stall with the EVO, given the glider’s

very forgiving flying characteristics and extremely low stall speed, the pilot has to really abuse the brakes to do this. Of course, one should bear in mind that the brake travel

is substantially reduced, and the stall point easier to reach when full thrust is applied and

the trimmers are in the slower “normal” flying position for take off.

In any case, it is possible for the pilot to stall the wing if, for example, when flying very

slowly (nearly at stall point) the pilot gradually releases the outer brake (the correct thing

to do) but then also applies more inside brake (on the side of the turn), thereby stalling

the inside wing. The stalled side of the wing now drops back into stall, rotating backwards (negative), whilst the still flying outside wing rotates forwards (positive) around

the pilot. In this case, to return to normal flight, the pilot has to raise the inside brake to

reduce the angle of attack, allowing positive airflow to return over the wing, and taking

that side of the wing out of the stall. In releasing the brake on the stalled side of the

wing (which is necessary to regain normal flight), the wing will then try to regain normal airspeed which, depending on the moment at which the spin is released and how

‘flat’ the spin was, will result in a dive which is more, or less, strong. If the wing dives

forward violently then the pilot should try to damp the dive by quickly applying a bit

more than approximately half brake (only enough to stop the dive) which should be

immediately released as soon as the dive is stopped, so as to avoid stalling the wing by

over-braking.

-- landing

SET TRIMMERS TO NEUTRAL POSITION

You should pay extra care and attention for your first landings, especially if it is the first

time that you fly a paramotor. Above all, it is vital that you are 100% sure of the wind

direction in the landing area (ideally you should have a windsock and other pilots in the

landing field to guide you for this) and, once you are sure that you have enough height,

and glide, to reach the landing field easily, it is generally much better, and safer, to turn

off the engine on final approach. The rest of the landing should be the same as for a normal gliding (unpowered) landing approach. You must take in consideration that with the

engine and propeller drag the glide angle is much worst .If AT ALL unsure of the techniques

Page 15

15

and methods for setting up a good and safe controlled landing approach, you should talk

to other more experienced pilots, and/or a club coach or instructor BEFORE YOU FLY. You

should have a thorough briefing on the site, conditions, take-off, flight plan and landing

BEFORE you fly, ideally with radio guidance. It is not good realising that you do not know

how to land safely after you have already taken off, as it is TOO LATE by then.

In the last few meters the pilot should lift the brakes, to gain good airspeed (being careful to fly actively in case of turbulence, and in some cases you may have to keep some

brake pressure to give a more positive angle of attack and therefore reduce the chance

of a collapse). It is best to have plenty of airspeed on landing as this will help you, at the

last moment, to convert some of this air speed into a very positive flare, substantially

reducing your forward and downward speed and thereby leading to a softer landing.

Don’t forget that once on the ground one should always avoid allowing the glider to land

heavily on it’s leading edge, as it is possible to damage the cells, or cell walls, of the glider in this way.

> weather to fly

SET TRIMMERS TO NEUTRAL POSITION

If in doubt about the weather and flying conditions, do not launch! Before going flying

you should check the weather forecast & always ask more experienced pilots about the

conditions expected for the day. Never fly if the weather conditions are unsuitable, especially with any of the following are present or even threatening: Strong wind; Rain;

Thunderstorms; Cumuli nimbus; or Cumulus congestus. If you are already in the air then

get down safely before it's too late! Always be aware of the weather changing & if in

doubt land as quickly as is safely possible.

> emergency procedures & quick descent techniques

The following techniques are advanced & should be practiced ONLY with qualified radio

supervision and adequate safety back up. Always be prepared and consider what will

happen if things go wrong! With enough altitude it is possible to safely master these

manoeuvres ready for the day you may need them for real!

More radical’s manoeuvres such as full stall, asymmetrical stall and flat spin are not

described in our manual. In order to perform these manoeuvres you should do a special

safety course with the correct instructor & over the water with a rescue boat standing

by, and all safety precations taken.

-- big ears

SET TRIMMERS TO NEUTRAL POSITION

Page 16

16

The simplest form of descent. To do this, simply pull on the big-ears line one at a time

by taking hold of the plastic balls at the end the EVO´s big-ears cleat-ing system (first

making sure that the line is released from the cleat), then pulling them down all the way,

one at a time. Both of the cleats face in one direction, to make it easier to induce the

big-ears with just one hand, and keeping the throttle hand free. Once the big ear has

been induced on that side, you can lock it in by pulling the cleat line in an outward-andupward direction, so that it locks into the grooves of the clam cleat. To release the big

ear, pull the cleat line in an outward-and-downward movement to free the line from the

cleat grooves of the cleat and then allow the line to slip back through the cleat and, in

so doing, freeing the big ears. The big ears should re-open autonomously but, if not, then

these can cleared by giving a pump on the brake on the side that has not cleared, being

careful to do this one side at a time and not to stall the wing by over-braking.

The sink rate achieved from pulling big-ears is around 3–5 m/s. This manoeuvre is recommended close to the ground, as it allows the pilot to keep the big-ears in even until

on the ground (although of course the pilot needs be aware of the higher descent rate,

and possible hard landing that may result), whilst leaving the pilot’s hands free to steer

the glider. If one combines the big-ears with the trimmers (and possibly the accelerator

as well), one gets a very good descent rate whilst keeping an acceptable speed.

-- spiral dive

SET TRIMMERS TO NEUTRAL POSITION

The Spiral Dive is obtained by maintaining the glider in a steep turn. Little by little (the

speed at which the spiral is entered depends greatly on how much brake is induced and

also wing loading) the glider will accelerate into the spiral, especially if one aids this with

weight-shift. Once the turn has converted into a spiral dive the pilot can control the

speed of rotation and descent with small changes of interior and exterior brake, and

more or less weight shift. It is possible to achieve descent rates of 10-15m/s or more in

this manoeuvre.

It is dangerous to induce spiral dives close to the ground due to the extreme centrifugal

forces which can cause fainting and, in some cases, blackouts or blurred vision..If you are

at all susceptible to any of these conditions, or are feeling at all unwell for any reason,

then you should not induce a spiral dive for this reason.

The exit from this manoeuvre should be performed gradually and progressively, finishing

in a nice controlled gentle turn to re-stabilise the wing. To do this, the pilot has to gradually ease off the inside brake, and reduce weight shift, then gently apply a little outside

brake to ease the glider out of the spiral. The pilot must be very careful not to exit a spiral (especially if well developed) too briskly, as this could result in a steep climb out (with

the wing far behind the pilot and in a very vulnerable position, with little internal pressure, no airspeed and prone to collapses) followed by a sharp dive which may need damping to prevent a collapse.

Page 17

17

It is NOT recommended to induce a spiral dive at the same time as applying any thrust

or power from the engine, as this could result in instability.

-- b-line stall

SET TRIMMERS TO NEUTRAL POSITION

To induce a ‘B-line” stall, first take hold of both ‘B’ risers (left and right) one in each hand

(left and right respectively) FIRMLY at the maillons. Then, pull the B-risers down together to approximately the level of the karabiners, BEING VERY CAREFUL TO DO THIS SYM-

METRICALLY so as to

not induce a spin.

This will “B-stall” the

glider, by deforming

the aerofoil section

of the wing in such a

way as to stop the

airflow going over it

as normal, effectively

‘breaking’ the aerofoil

effect. If done correctly, the glider will

now enter into a “Bline stall”, which is a

kind of “parachutal”

stall, stopping the glider flying and rendering one’s trajectory effectively straight down

through the air (BUT DRIFTING WITH THE WIND). Once in the “B-line” stall one can control the descent rate to a degree by pulling down more or less on the B-risers and it is

possible (in still air) to achieve descent rates from 5-11 m/s. BE CAREFUL, AS PULLING

DOWN TOO FAR ON THE B-LINES CAN CAUSE THE GLIDER TO BECOME UNSTABLE, SO

THIS SHOULD BE AVOIDED.

To exit from the B-line stall correctly, and minimise the chance of any instability, the

pilot should keep a firm hold of the B-risers and raise them until there remains 10cm of

travel of the B-risers and then release them completely, taking care to do this SIMULTANEOUSLY. If the B-line is entered, or released, asymmetrically, it is possible to enter a

spin, and so this should always be avoided. Once the B-risers have been released in the

correct manner the glider will return to normal flight spontaneously with a small dive as

it regains “healthy” airspeed.

Obviously, one should never do a B-line stall at the same time as engaging any thrust or

power from the engine as this could result in unstable situations which could lead to

dangerous loss of control.

Page 18

18

> maintenance

Store the paraglider in a dry space away from chemical agents, UV light and high temperature. If the canopy has been packed wet it is necessary to reopen it and let it dry

before packing away for a sustained period. Keep the canopy and lines clean, as dirt may

penetrate into the fibres and damage them.

Clean the paraglider only with fresh water and a soft sponge. If you are unfortunate to

land in the sea & survive! Hose/soak the glider with fresh water & dry completely.

Absolutely avoid contact with chemical agents like oil, petrol, solvent and similar, which

can damage the fabric and its surface covering.

We strongly recommend you to have a full inspection of the paraglider by

Windtech

or

an approved

Windtech

repair centre at least once a year. Besides this you should check

periodically the lines, cloth and stitching.

Every 150 h. or once a year, which ever comes first, change all bottom lines. This is very

important to maintain the flying and safety characteristics of the wing. The rest of the

lines must also be checked and change them if they have deteriorated. Test some of the

lines that are not changed for minimum 40% of the rated strength. If the line fails you

should replace them all before using your glider.

Small tears in the sail can be repaired by using adhesive spinnaker cloth, which we supply with every new glider.

Big tears and repairs regarding sewing or structural parts of the paraglider must be carried out only by the manufacturer or authorised service centres.

> warranty

This glider carries a two-years guarantee from defects due to materials and manufacturing.

If a product is deemed to be defective by

Windtech

, the warranty covers the repair or

replacement of the defective product only.

Windtech

will not be responsible for any

costs, losses or damages incurred as a result of loss of this product.

Windtech

is not responsible for mailing costs or material costs used other than what is

found to be defective.

This warranty does not cover damage caused by misuse, abuse, neglect or normal wear

& tear including damage due to excessive sun exposure, damage caused by improper

handling & damage caused by anything other than defects in material & workmanship.

Page 19

19

Size

Area (m

2

)

Projected area (m

2

)

Span (m)

Project. span (m)

Aspect ratio

Project. aspect ratio.

Max .chord (m)

Min. chord (m)

Nº cells

Line lenght (m)

Pilot weight (kg)

Weight in fly (kg)

Certification EN

Paramotor Risers

25

25.85

22.8

11.52

9.55

5.13

4

2.82

0.63

52

6.94

52-72

70-130

paramotor

27

27.6

24.3

11.9

9.86

5.13

4

2.91

0.65

52

7.17

67-87

85-145

paramotor

30

30.15

26.6

12.44

10.31

5.13

4

3.04

0.68

52

7.49

82-107

100-165

paramotor

| technical specifications |

EVO

23

24.10

21.27

11.12

9.22

5.2

4.1

2.70

0.61

52

6.71

42-70

60-120

paramotor

Page 20

20

Page 21

21

Take-off and slow flight Fast flight in turbulent air

Trim speed Fast flight in smooth air

A = 43 cm

B = 43 cm

C = 43 cm

D = 43 cm

A = 34 cm

B = 36,5 cm

C = 43 cm

D = 43 cm

A = 43 cm

B = 43 cm

C = 52 cm

D = 60 cm

A = 34 cm

B = 36,5 cm

C = 52 cm

D = 60 cm

B

A

A"

C

D

C

B

A"

A

D

C

D

A

A"

B

C

B

A"

A

D

Trimmer & accelerator combinations depending on flight conditions

Page 22

22

20

176,5

167

174,5

11 2

11 2

11 2

11 2

50,5

322+20

193,5

193,5

193,5

193,5

1

2

194

190

126

143

187

161 136

187

190

62

52,5

62

56

455,5

187

443

56

58

64

194

187

56

56

56

451,5

54

187

439,5

190

60,5

54

60

53

187

449

190

190

190

187

440,5

187

187

450

194

195

3

4

5

6

8

7

9

10

14

187

436

187

190

444

187

189,5

15

187

187

435

441,5

187

16

17

177,5

19

18

13

11

12

50

40

49,5

119,5

48,5

43,5

57

51,5

44,5

49

47,5

467,5

75

38

st

59,5

63

61

61

59,5

26

24

23

57,5

25

21

22

113,5

119,5

119,5

119,5

119,5

EVO 23

Page 23

23

20

183

173

180,5

11 6

11 6

11 6

11 6

52,5

334+20

200,5

200,5

200,5

200,5

1

2

200,5

197

130

148

194

167 141

194

197

65,5

54

64,5

58

471,5

193,5

458,5

58,5

60,5

66,5

201

194

124

58

58

58

124

467,5

56,5

193,5

455

197

62,5

124

124

56,5

62

55,5

193,5

465

197

197

197

193,5

456

193,5

193,5

465,5

201

202

3

4

5

6

8

7

9

10

14

193,5

452

193,5

197

460

193,5

196

15

184,5

193,5

451

456,5

193,5

16

17

182

19

18

13

11

12

52

41

49

124

50,5

43

59

53,5

44

50,5

49,5

484

77,5

39

st

59,5

65

63,5

63,5

61,5

26

24

23

63,5

25

21

22

11 7

EVO 25

Page 24

24

69

67,5

52

128

200

200

200

200

329+20

66,5

207

207

207

207

1

23

470

120

483

172,5

200

200

145,5

487

56

66,5

153

60

62

474

203,5

68,5

60

134,5

60

207,5

200

200

200

64,5

128

128

60

58

60

203,5

57,5

128

64

128

480,5

58

54

186,5

466,5

200

200

208,5

200

471

203,5

481

203,5

207

207,5

475

4

5

203,5

6

7

8

9

11

10

18

200

190,5

203,5

203,5

202,5

200

465,5

178,5

120

189

120

19

492

190

120

20

21

12

13

14

15

16

17

80

500

52,5

44,5

45,5

51

61

55

42,5

121,5

25

65,5

53,5

51

65,5

63,5

40,5

st

26

22

23

61,5

24

EVO 27

Page 25

25

20

197,5

186,5

195

125,5

56,5

216,5

216,5

216,5

216,5

1

2

213

216,5

140,5

346+20

209

181

160

153

209

212,5

62,5

58,5

69,5

69,5

509

209

495

63,5

65

72

216,5

134

209

134

62,5

62,5

63

504,5

61

209

470

212,5

67,5

134

134

67

61

60

209

502

212,5

212,5

212,5

209

492,5

209

209

502,5

216,5

219

3

4

5

6

8

7

9

10

13

209

488

209

213

496,5

209

212

14

15

198

199

209

487

513

209

16

17

19

18

11

12

126,5

44,5

46,5

134

54,5

53

64

125,5

56

57,5

47,5

53

55

522,5

83,5

42,5

st

26

64,5

70,5

125,5

125,5

69

68,5

66,5

69

24

23

25

21

22

EVO 30

Page 26

26

| flight log |

ssiizzee

ddaattee ssiittee dduurraattiioonn fflliigghhtt ddeettaaiillss

EVO

Page 27

Page 28

EVO

| francisco rodríguez · 7 | 33201 g i j ó n | spain | p.o. box · 269 33280 |

| p# · +34 985 357 696 | fax · +34 985 340 778 |

| email · info@windtech.es | web · www.windtech.es |

POWERED BY WINDTECH

Loading...

Loading...