Page 1

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

The following symbols are used throughout this guide as

indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by

signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by

the following definitions:

WARNING

WARNING - Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices, which could

result in minor personal injury or product or property

damage.

FOR SAFETY To Identify actions, which must be

followed for safe operation of equipment.

The following information signals indicate potentially

dangerous conditions to the operator or equipment.

Read this guide carefully. Know when these conditions

can exist. Locate all safety devices on the machine.

Then, take necessary steps to train machine operators.

Report machine damage or faulty operation

immediately. Do not use the machine if it is not in proper

operating condition.

For SAFETY:

DO NOT OPERATE MACHINE:

•• Unless Trained and Authorized

•• Unless Operation Guide is Read and

understood.

•• In Flammable or Explosive areas.

WHEN USING MACHINE:

•• Go slow on grades.

•• Do not carry riders on machine.

BEFORE LEAVING OR SERVICING MA CHINE:

•• Stop on level surfaces.

•• Turn oft machine.

WHEN SERVICING MACHINE:

••Avoid moving parts. Do not wear loose jackets,

shirts, or sleeves when working on machine.

•• Use only Windsor approved replacement parts.

SAFETY

WARNING

To reduce the risk of fire, electric shock, or injury:

1. Use only as described in this manual. Use only

manufacturer’s recommended attachments.

2. Use indoors only. Do not use outdoors and do not

expose to rain.

3. Machine can cause a fire when operating near

flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

4. Do not pick up flammable fluids, dust or vapors.

5. Do not vacuum anything that is burning or smoking,

such as cigarettes, matches, or hot ashes.

6. Do not handle the plug or machine with wet hands.

7. Do not leave the machine unattended. Unplug machine

from outlet when not in use and before servicing.

8. Do not unplug machine by pulling on cord. To unplug,

grasp the plug, not' the cord.

9. Do not use with damaged cord or plug. Follow all

instructions in this manual concerning grounding the

machine.

10. If the machine is not working properly, has been

dropped, damaged, left outdoors, or dropped into water,

return it to an Authorized service center.

11. Do not pull or carry by cord, use cord as a handle, close

a door on cord, or pull cord around sharp edges or

corners.

12. Do not pull/run machine over cord. Keep cord away from

heated surfaces.

13. Do not allow to be used as a toy. Close attention is

necessary when used near children.

14. Do not operate machine with any opening blocked. Keep

openings free of debris that may reduce airflow.

15. Keep hair, loose clothing, fingers, and all parts of the

body away from openings and moving parts.

16. Do not use machine as a step.

17. Connect to a properly grounded outlet. See Grounding

Instructions.

18. Do not pickup health endangering dust or contaminants.

WAVE Instructions page 1

Page 2

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

This Owner’s Guide contains valuable information

about the operation, maintenance, serial and pail

numbers for repairs of your Windsor machine.

Please read this introductory page thoroughly to

become familiar with the contents of the owner’s

guide, making the information you are looking for

easier to locate.

The owner’s guide consists of multiple sections of

reference information, and the remainder contains

part number information for ordering pails for the

machine. At the top of each page is the name of

the particular section. This way you can quickly

locate each section more easily

REFERENCE SECTIONS

The reference information sections of this

guide

are as follows; General Information,

Grounding Information, Operation, Set Up,

Maintenance.

GENERAL INFORMATION

This section of the guide contains safety

precautions. The Safety Precautions are an

overview of the safety measures to be

observed when operating and maintaining the

machine.

OPERATION

The Operation section of the guide contains

the in formation needed to operate the

machine. There is a complete list of

instruments and controls on the machine, an

overview of machine operation, and in formation on how to transport and store the

machine.

MAINTENANCE

information on the suggested maintenance

procedures and adjustments to keeping the

machine in top operating condition. The

section includes a maintenance schedule and

the areas of the machine to be addressed.

Each subject of maintenance is covered in

more detail in such areas as Lubrication,

Motors and Electrical System.

PART SECTIONS

To easily locate the part needed, please refer

to page 2 for component locations to find the

general area where the part is located. Use

the information to quickly locate the correct

component. The remain ing sections of the

guide contain part number, information for

ordering repair parts for the machine. The

guide contains part number information on

every model of machine model available.

Therefore there will be part number

information in your guide, which you will not

need to refer to when placing an order.

ORDERING REPAIR PARTS

If you are in need of technical assistance

contact your WINDSOR Distributor or Service

Center for further assistance.

Once you have located a part to order, call

your local WINDSOR distributor. Make sure

to have the machine’s serial number and your

Owner’s Guide with you to aid in ordering the

correct

The Maintenance section contains the

component.

WAVE Instructions page 2

Page 3

1590-A N. Harvey Mitchell PKWY

979-779-9399 1-800-262-7104

WARNING

1. To avoid electric shock use indoors only.

2. To reduce risk of fire, do not use volatile substances.

INSPECTION

Carefully unpack and inspect your wide area vacuum for

shipping damage. Each unit is operated and thoroughly

inspected before shipping, and any damage is the

responsibility of the carrier, who should be notified

immediately.

ELECTRICAL

The WAVE operates on a standard 15-amp 115 volt AC

circuit. This is the typical wall receptacle found in

household and light industrial environments. Voltages

below 105 volts or above 125 volts could cause serious

damage to motors. *Special voltage models available. A

wiring diagram is mounted inside the rear control panel of

machine. A copy of the wiring diagram is included in this

Owner’s Guide.

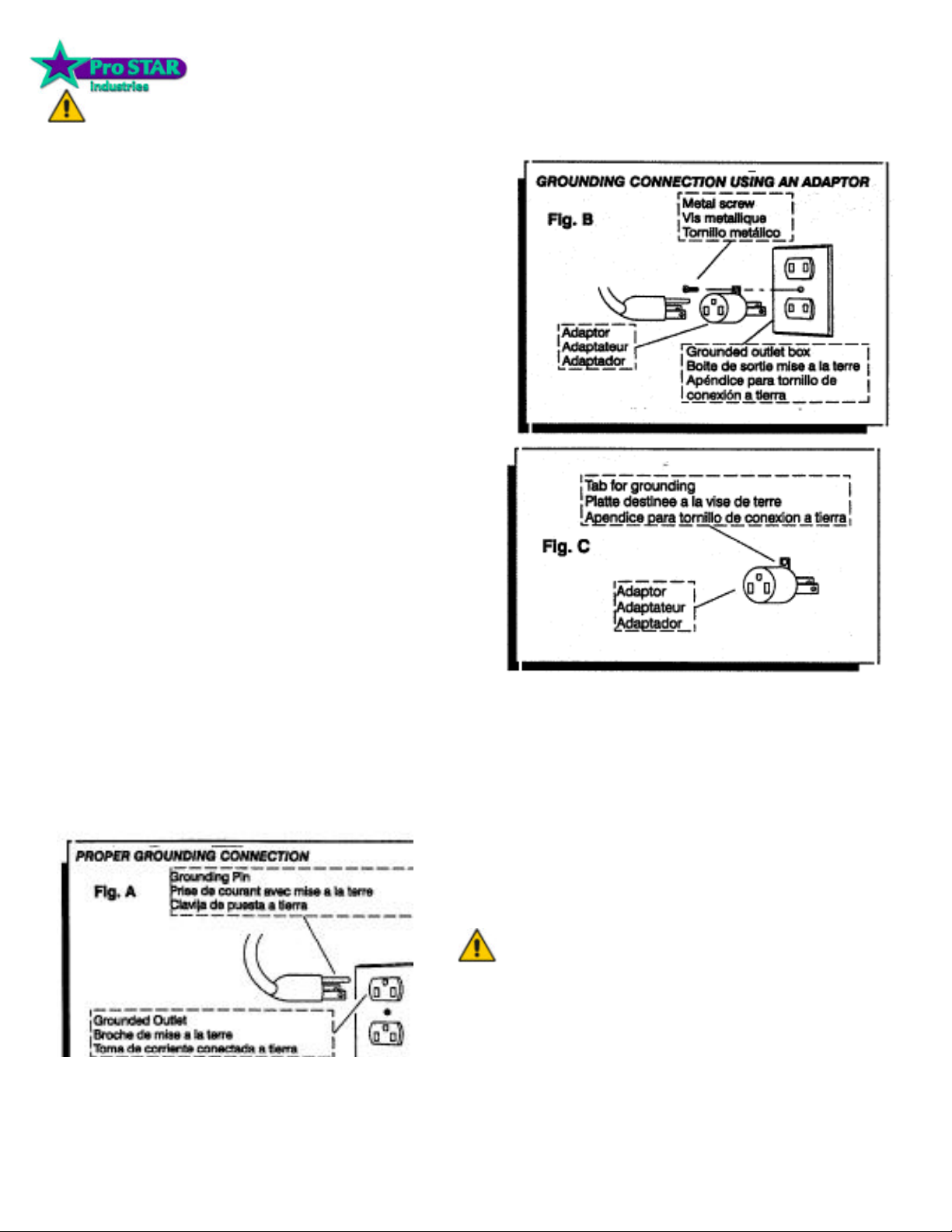

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should malfunction

or break down, grounding provides a path of least

resistance for electric current to reduce the risk of electric

shock. This appliance is equipped with a cord having an

equipment-grounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all

local codes and ordinances.

This appliance is for use on a nominal 120-volt circuit, and

has a grounded plug that looks like the plug in Fig. A. A

temporary adaptor that looks like the adaptor in Fig. B may

be used to connect this plug to a 2-pole receptacle as

shown in Fig. B, if a properly grounded outlet is not

available. The temporary adaptor should be used only until

a properly grounded outlet can be installed by a qualified

electrician.

The green colored rigid ear, lug, or the like extending from

the adaptor must be connected to a permanent ground

such as a properly grounded outlet box cover. Whenever

the adaptor is used, it must be held in place by a metal

screw.

Pro STAR Industries

Bryan, TX 44503

Grounding Information

NOTE:In Canada, the use of a temporary adaptor is not permitted by

the Canadian Electrical Code.

NOTE: Au Canada, I’utiisation d’un adaptateur temporaire n’est pas

autorisee par le Code canadien de l’electricite.

EXTENSION CORDS:

This wide area vacuum is designed to operate on a

standard 15 amp 115 volt, 60hz, AC household current.

Check the voltage shown on the serial number plate is

suitable for the supply available. Voltages below 105 volts

or above 125 volts could cause damage to the motors.

If an extension cord is used, the wire size must be at least

one size larger than the power cord on the machine: The

WAVE is equipped with a 75 ft. 14/3 power cord.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in doubt

as to whether the outlet is properly grounded.

Do not modify the plug provided with the

appliance - If it will not fit the outlet; have a

proper outlet installed by a qualified electrician.

WAVE Instructions page 3

Page 4

1590-A N. Harvey Mitchell PKWY

979-779-9399 1-800-262-7104

OPERATION CONTROLS

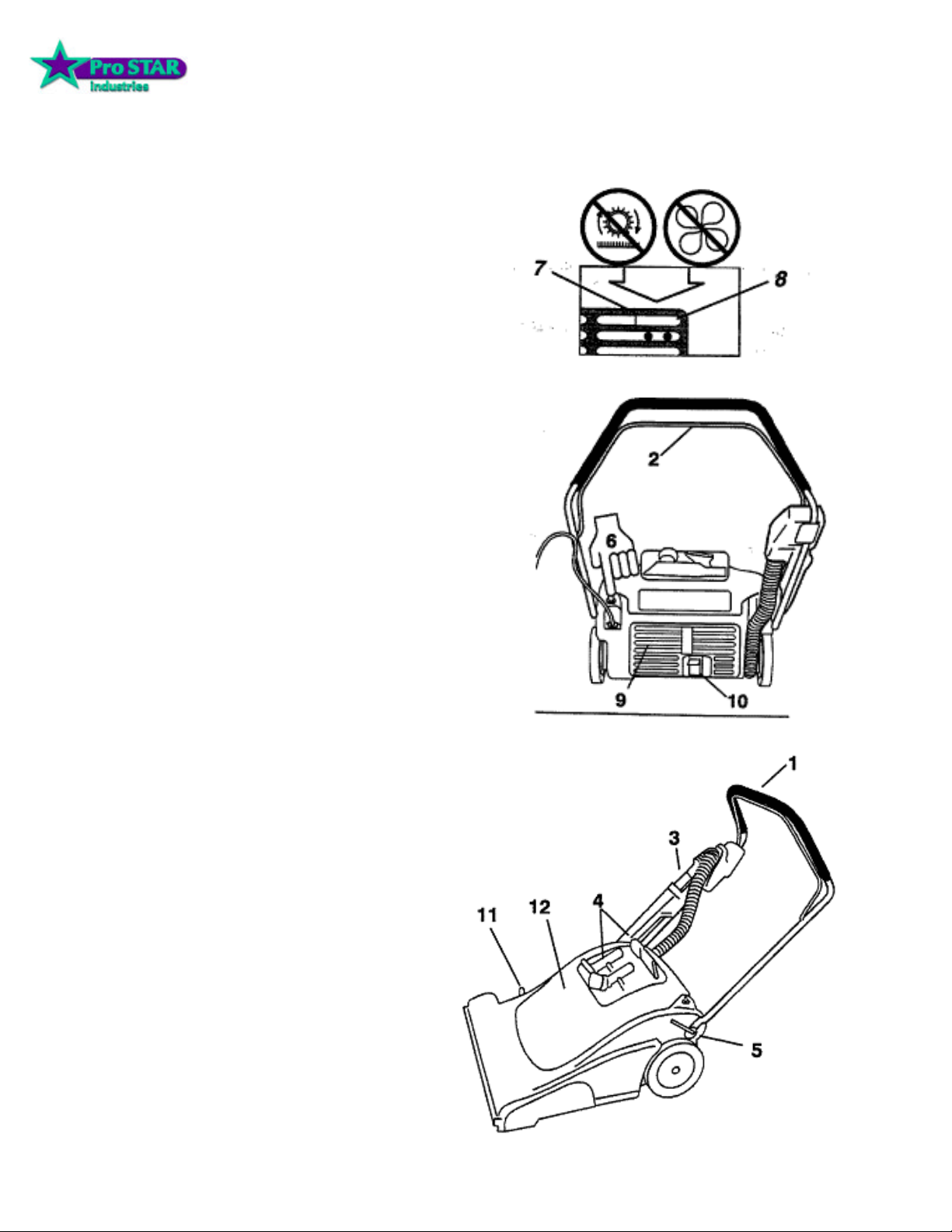

1. Main Handle. Adjusts for operator comfort and

storage.

2. Brush on/off lever. Activates brush when

depressed.

3. Accessory vacuum hoseand wand. Allows

operator to clean edges, recessed, ledges,

upholstery, etc.

4. Detail tools Dusting brush, crevice and

upholstery tools for above the floor cleaning.

Dusting brush comes with adapter for

attachment directly to hose. Upholstery and

crevice tool connect directly to both the hose

and the wand. The crevice tool fits loosely on

the wand.

5. Handle Adjustment Lever. Located on the

left side of handle. Pull away from handle to

loosen, adjust handle and press parallel to

handle to tighten.

6. Vac on/off switch. Turns on and off vac

motor.

7. Brush motor curcuit breaker. Provides

overcurrent

protection for the brush motor.

8. Vac motor circuit breaker. Provides

overcurrent

protection for the vacuum motors.

9. Exhaust filter. Filters exhaust air for safe and

quiet operation.

10. Accessory hose activation pedal. Press

pedal down to use the accessory hose. Lift up

with toe for normal use.

11. Brush adjustment lever. Allows operator to

adjust brush to proper height for the carpet. (1)

for low nap carpet, (5) for thick nap. Position

(6) is storage.

12. Dust bag cover. Raise to allow access to dust

bag and vac motors.

13. Cloth dust bag. High filtration cloth bag with

zipper opening to access paper bag.

14. Paper bag. Fits within cloth bag for clean and

easy dust removal.

Pro STAR Industries

Bryan, TX 44503

WAVE Instructions page 4

Page 5

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

WAVE SET UP

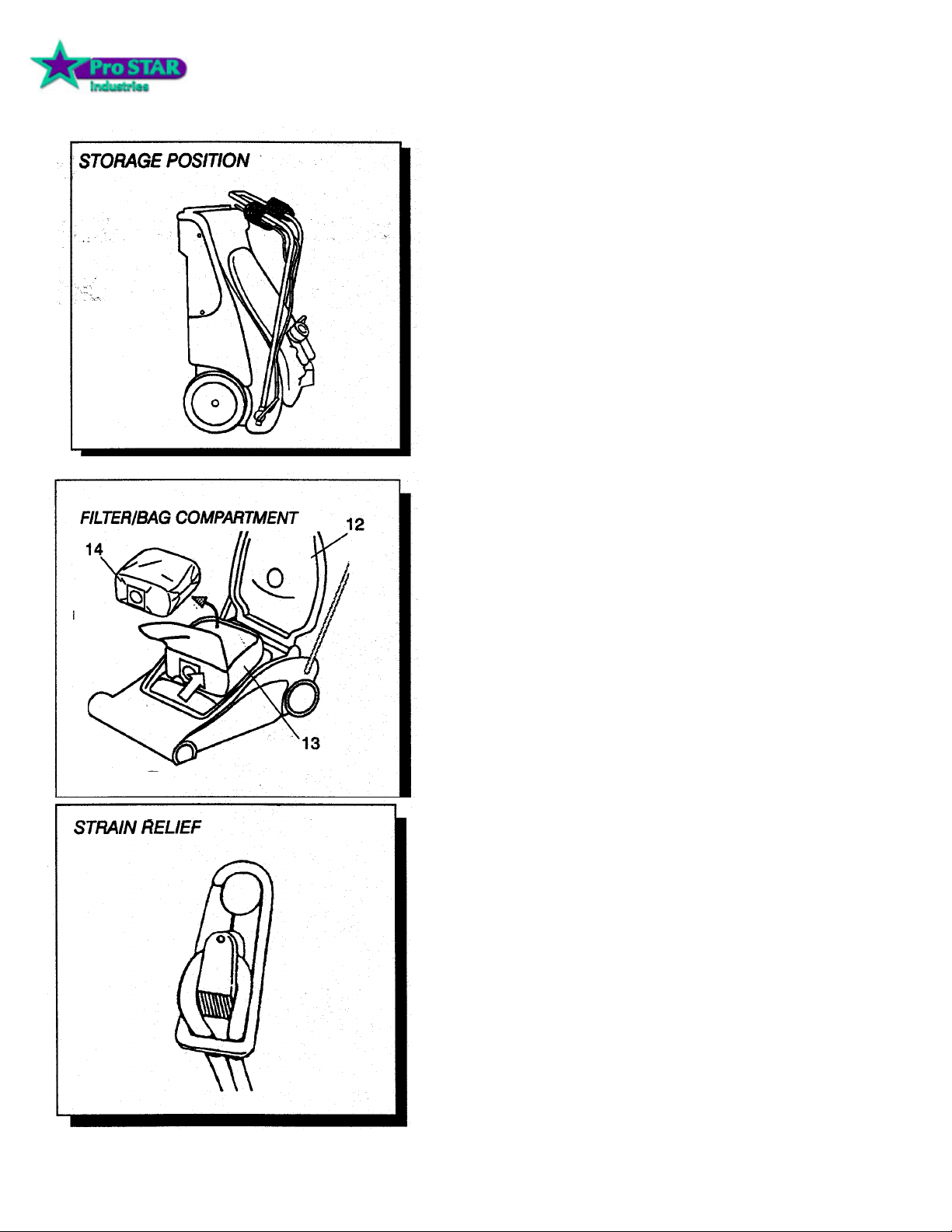

1. Take machine out of storage position

by lowering onto all four wheels.

2. Adjust handle to comfortable position

at waist level by opening adjustment lever on

left side of machine and moving handle. Lock

back into position by closing adjustment lever.

3. Install cloth filter bag inside the main

body by pushing the rubber collar over the

chute.

4. Unzip the cloth bag and place the

paper bag inside. Push the rubber gasket seal

over the chute. Zip cloth bag closed taking

care not to damage the paper bag and close

lid.

5. Attach the detail tools to the top of the

dust bag cover by pressing the appropriate

tool into the clips.

6. Take the accessory wand and attach

to the hose and insert wand into the wand

holster.

7. Strain relief.

NOTE: Attach strain relief/cord retainer

to the power cord.

1. Make a loop in power cord

approximately

12” from receptacle end.

2. Slide cord loop through slot in retainer

arm. Pull slack cord back through slot to

secure. Attach retainer to handle.

WAVE Instructions page 5

Page 6

HOW IT OPERATES

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

HOW IT OPERATES

This machine is a portable, easy to use wide area vacuum

designed for use indoors, in a commercial or light industrial

environment.

When operating as a carpet vacuum, soil is lifted from the

carpet surface by a rotating brush and carried into a removable bag by the vacuum motors.

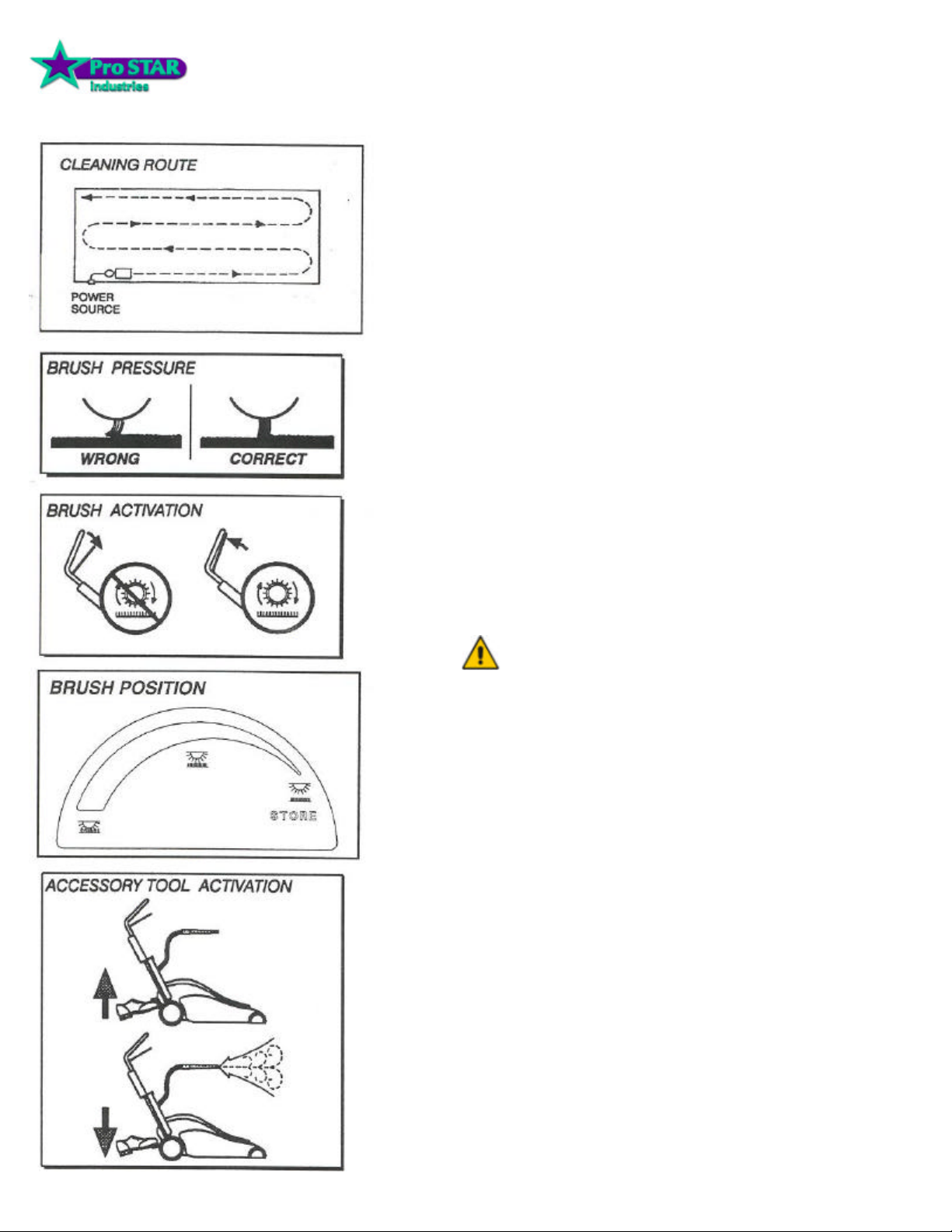

1. Large debris such as paper cups, plates, etc.,

should be picked up before starting the cleaning

process.

2. Plan your cleaning route to work away from the

electrical source. Move machine forward at a steady

pace.

CLEANING

1. Adjust handle to comfortable position at waist level

or higher.

2. Use your finger to depress the Vacuum switch at

the base of the handle to activate the vacuum.

3. To adjust brush height, move the Brush Adjustment

lever on the right side to the correct setting for the

carpet being vacuumed. Lower brush gradually until

firm brush contact is heard.

WARNING

KEEP MACHINE MOVING WHILE BRUSH ENGAGED.

DAMAGE TO CARPET COULD OCCUR IF NOT MOVING.

NOTE: Always return brush to storage position after using

machine.

4. Depress the brush lever at the handle to start the

brush.

5. Move forward at a steady pace for through cleaning.

Run machine more slowly over extremely soiled areas.

6. Use the right side of the machine for edge cleaning.

7. To use the accessory wand and detail tools,

depress the foot lever in the back of the machine.

8. To keep the vacuum operating at maximum

efficiency, check the dust bag regularly. Empty when

1/2 to 3/4 full. Always use with disposable paper bag

for best results.

9. When finished vacuuming, coil the cable by hand by

looping into about a 3 foot diameter, Hang coiled cable

over handle. Wrap the end around the cable loop to

secure.

10. Return brush to storage position.

WAVE Instructions page 6

Page 7

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

NOTE: THE FOLLOWING SERVICE ITEMS SHOULD BE PERFORMED BYAN AUTHORIZED SER VICE FACILITY ORAUTHORIZED

SERVICE PERSONNEL. ALL PARTS REFERRED TO IN THESE

INSTRUCTIONS CAN BE IDENTIFIED BY USING THE PARTS LISTS

AND ILLUSTRATIONS ON THE FOLLOWING PAGES.

WARNING

REMOVE MACHINE POWER CORD FROM ELECTRICAL

SOURCE BEFORE MAKING ANY REPAIRS OR ADJUSTMENTS

TO THE MACHINE.

TO ACCESS BELT/BRUSH MOTOR

1. Place machine in the upright storage position.

2. Remove (3) screws holding belt cover to chassis.

3. Loosen brush motor and roll belt off brush pulley.

4. Remove (5) screws holding brush housing to

chassis- (3) Located on front of housing,

(2) Located on rear of housing.

5. Remove (2) screws from each end of brush housing and remove

brush assembly.

6. Inspect/replace brush and bearings as required.

the brush is equipped with a yellow wear indicator bristIes. The brush

should be replaced when it wears down to the height of the yellow

bristles.

7. When installing belt push down on motor for proper tension.

8. When reinstalling brush, check belt for proper tension.

TO ACCESS AND REMOVE VAC MOTOR

AND FILTERS.

1. Open lid cover.

2. Remove (2) screws from each/both vac motor brackets.

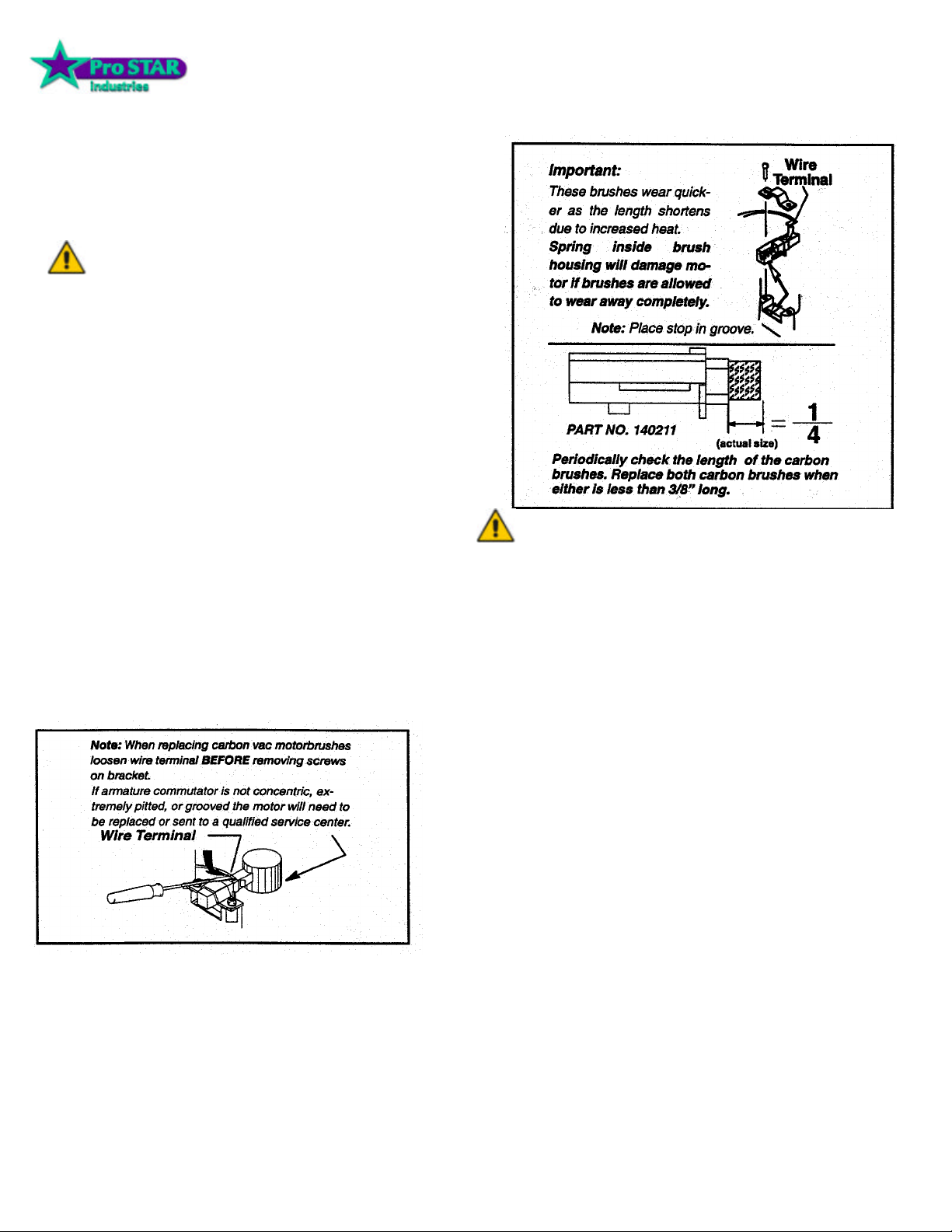

REMOVAL OF VAC MOTOR CARBON BRUSHES

1. Access vac motors as described above.

2. Vac motor can be lifted out and electrically disconnected.

—

WARNING

THE GREEN GROUND MUST ATTACH THE MOTOR TO THE

POWER CORD FOR SAFE OPERATION. SEE THE WIRING

DIAGRAM.

NOTE: WHEN REPLACING ELECTRICAL COMPONENT PARTS

REFER TO WIRING DIAGRAM FOR PROPER CONNECTION.

NOTE: THE VAC MOTOR IS PROTECTED BY A CIRCUIT BREAKER

LOCATED IN THE SWITCH PANEL. THE BREAKER WILL ONLY

TRIP UNDER CONDITIONS OF ABUSE.

BRUSH MOTOR

1. Access belt and brush as described above.

2. Disconnect spring holding frame to brush motor housing.

3. Remove (4) bolts holding motor housing to the chassis and lift out

motor asm.

4. Remove brush motor pulley and (2) bolts holding motor to bracket

lift out brush motor.

CARBON BRUSH (PART NO. 140212)

1. Access belt and brush as described above.

2. Remove brush caps. NOTE: BRUSHES SHOULD BE

REPLACED WHEN WORN TO 3/8” OR LESS.

NOTE: BEFORE REINSTALLING BRUSH MOTOR BRACKET

M

ASSEMBLY IT’S RECOMMENDED THAT THE REAR

SPRING BE RECONNECTED TO THE FLAPPER

ASSEMBLY.

WAVE Instructions page 7

Page 8

MAINTENANCE

DAILY MAINTENANCE

1. Shake down bag daily.

2. Check power cord for damaged or frayed

insulation.

3. Return brush adjustment lever to store RE”

position when the machine is not in use.

4. Check for and remove any lint or debris

around brush and brush housing.

REGULAR/PERIODIC MAINTENANCE

1. Every 4 to 6 months remove wheels, clean

axles, and apply a thin coat of silicone lubricant to axles.

2. The filter bag can be washed twice before

losing the filtering capability. This should be done using

a mild detergent in cool water and hung up to drip-dry.

3. Inspect and clean vac motor filters.

4. Periodically inspect all hoses, electrical

cables, filters, gaskets and connections on your

machine. Frayed or cracked hoses should be repaired or

replaced to eliminate v acuum loss.

5. The electrical cable must be well insulated, if

the cable insulation is broken or frayed, repair or replace

it immediately. Don’t take chances with electrical fire or

shock

SUGGESTED SPARE PARTS LIST

BELT 11041

PAPER BAGS 140168

(PACKAGE OF 10)

VAC MOTOR FILTER 34012

REAR EXHAUST FILTER 34309

CLOTH BAG 140164

VACUUM MOTOR

CARBON BRUSH 140211

BRUSH MOTOR

CARBON BRUSH

2 REQUIRED PER MOTOR 140212

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

WAVE Instructions page 8

Page 9

Pro STAR Industries

1590-A N. Harvey Mitchell PKWY

Bryan, TX 44503

979-779-9399 1-800-262-7104

Trouble Shooting Chart

Condition Corrective Action

No Power To Machine:

Dead electrical circuit breaker in fuse box Check building circuit breaker.

Faulty power cord Test power cord for continuity I Replace if necessary.

Power switch failure Test switch for continuity. Replace if necessary

Faulty circuit breaker Test circuit breakers for continuity/ Replace if necessary.

Intemal wiring problem With the machine unplugged, check for, and correct, any loose wire

connections inside the machine at the switches and terminal block.

Electrical Shock:

Equipment not grounding Follow grounding instructions exactly.

Receptacle not grounded Have an electrician inspect the building’s wiring.

Internal electrical problem Ensure that the machine’s wiring matches the appropriate wiring diagram.

Check for and correct any loose wire conneetions~ Replace any wires or

components which are short circuiting.

Vacuum Motor Soeed Varies or Doesn’t Run:

Circuit breaker tripped Reset vac motor circuit breaker (13 amp).

Faulty vac circuit breaker Check for continuity I Replace as necessary.

Intemal wiring problem With the machine unplugged, check for, and correct, any loose wire

connections inside the machine at the switches and terminal block.

Power switch failure Test switch for continuity I Replace if necessary.

Wom motor brushes Replace if less than 1I4”.

Brush Motors do not run:

Circuit breaker tripped Reset brush motor circuit breaker (2 amp).

Faulty brush circuit breaker Check for continuity / Replace as necessary.

Internal wiring problem With the machine unplugged, check for, and correct; any loose wire

connections inside the machine at the switches and terminal block.

Fautly brush switch Remove leads and check switch for continuity. Replace.

Wom motor brushes Replace if less than 3/8”.

Mechanical problems Higher amp draws may indicate a mechanical problem. Find parts which are not moving freely

Faulty brush motor If the belt, circuit breaker, and switch have been tested and found in good

Loss Of Vacuum :

Bag full Replace

Flapper in correct position FLOOR TOOL

Damaged lid gasket Replace

Accessory tool clogged Clean out tool, ensure free airflow.

Vac hose damaged Replace

Debris Chute Clogged Remove chute access PN 05125 and clean chute out.

and repair or replace.

working order, the brush motor may need to be replaced.

WAVE Instructions page 9

Loading...

Loading...