Page 1

WWW.MANUALS.WS

WWW.MANUALS.WS

MODEL POWER SOURCE

VGR2 BATTERY

Beginning with Serial# 1000081028

y

Read instructions before operating the machine.

H

98953 05/05/05

Page 2

WWW.MANUALS.WS

WWW.MANUALS.WS

MACHINE DATA LOG/TABLE OF CONTENTS

MODEL

- _____________________________________

TABLE OF CONTENTS

DATE OF PURCHASE - _________________________

SERIAL NUMBER - ____________________________

SALES REPRESENTATIVE - ____________________

DISTRIBUTOR NAME - _________________________

Copyright 2001 Windsor Industries, Printed in U.S.A.

Data Log / Table of Contents ............................ 2

Technical Specifications ................................... 3

Safety Precautions ........................................... 4

Battery Installation & Removal .......................... 5

Battery Information........................................... 6

Operation Controls........................................... 7

Operations....................................................... 8

Accessory Tools and Maintenance .................... 9

Maintenance .................................................... 10

Service Schedule ............................................. 13

Propel Handle Assembly. ..................................14

Drive and Brush Assembly................................16

Pump, Vac, Manifold and

Brush Motor Assemblies ...................................18

Rear Tower Electrical Assemblies ......................20

Handle, Microswitch and

Cable Assemblies.............................................22

Control Panel Assemblies .................................24

Vac Shoe Assembly..........................................26

Tank, Cover and Hardware ................................28

Wiring Diagram .................................................30

Warranty..........................................................31

2

98953 02/14/04

Page 3

WWW.MANUALS.WS

WWW.MANUALS.WS

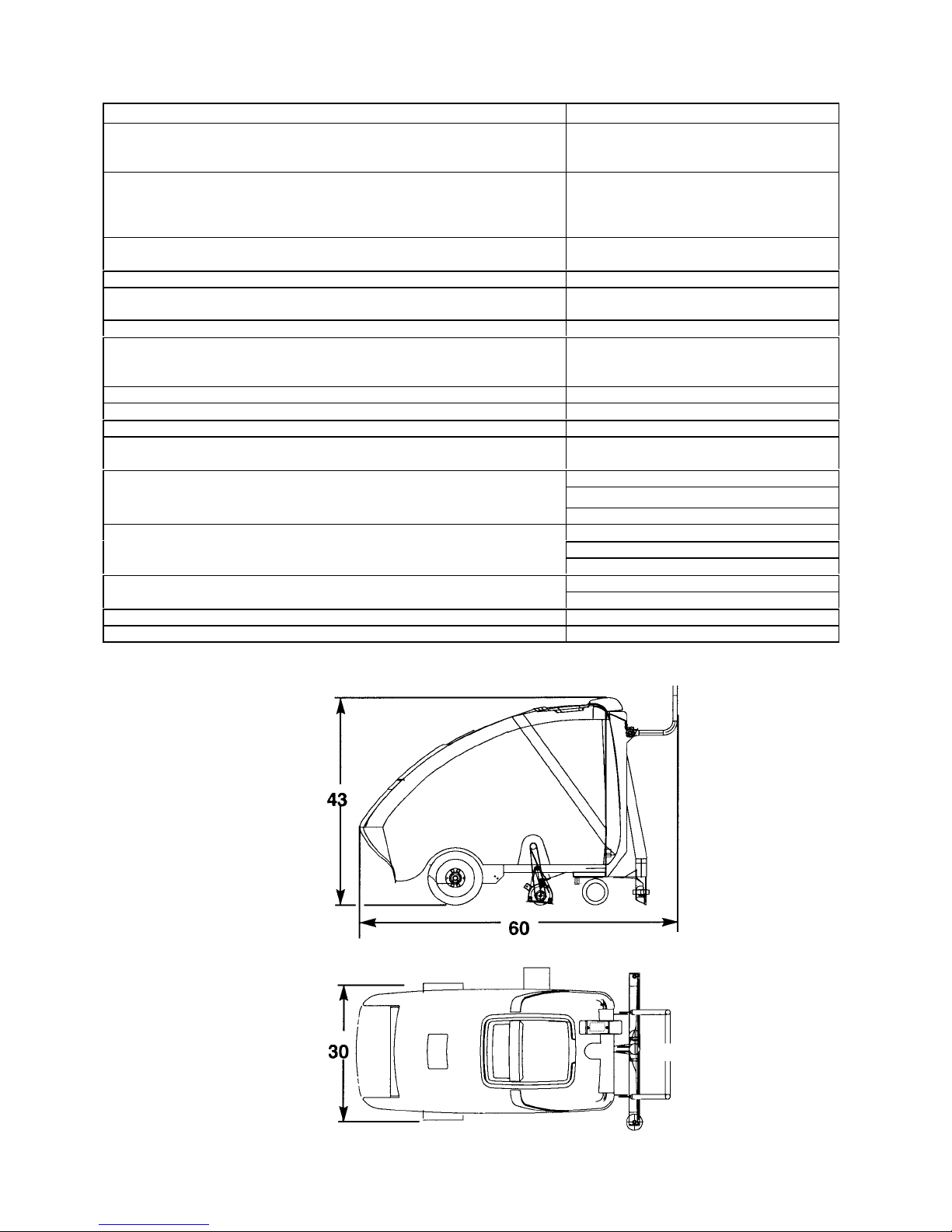

TECHNICAL SPECIFICATIONS

ITEM MEASURE

Electric Propelling Motor (1)-1/4 hp DC (186 watts) with solid state

variable speed forward and reverse with

safety shut-off.

Electric Vacuum Motors (2)- 3 stage, 1.3 hp (970 watts), 5.7 inch

(14.5cm) diameter motors in parallel,

provide 152 cfm (4.25m/min.), 74 inches

(188 cm) water lift total. Electric shut-off.

Electric Brush Motors (1)- 0.4 hp (298 watts) permanent

Electrical 36 Volt DC

Batteries (3)- 12 volt, @ 185 A/H, in a (Optional)

Solution Pump 100 PSI, diaphragm style pump

Cleaning Speed Variable speeds from 0-130 ft/min

Solution Capacity 40 gallons (151 ltr)

Recovery Capacity 35 gallons (132 ltr)

Brush Speed 1000 RPM

Vacuum Shoe 28” (71 cm) wide, cast aluminum, tension

Wheels:

Front: (2) 10” dia. (25 cm) by 2.5” wide (6.4 cm)

Rear: (2) 4” dia. (10 cm) casters

Weight:

Empty: 240 lbs. (109 kg)

W/ Batteries 645 lbs. (260 kg)

Length 60” (152 cm)

Storage Position 52” (132 cm)

Height 43” (109 cm)

Width 30” (76 cm)

magnet, DC.

removable battery pack.

(39.6m/min) Transport 0-130; Cleaning

0-110

pulley adj., floating and pivoting.

SIDE VIEW

TOP VIEW

VGR2 98953 12/18/01

3

Page 4

WWW.MANUALS.WS

WWW.MANUALS.WS

IMPORTANT SAFETY INSTRUCTIONS

!

WARNING:

When using a battery powered appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Do not use outdoors or expose to moisture.

Do not operate in standing water.

Machines can cause a fire when operated near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust, vapors or gas. Do not pickup burning materials such as cigarettes

or matches.

Operate this machine only from the rear of the machine.

Maintenance and repairs must be done by qualified personnel.

Store machine inside. Keep the electrical components of the machine dry.

Wear eye protection when working near batteries. Do not put any type of metal objects across the

battery terminals or on top of the batteries.

Lead acid batteries generate gasses which can cause an explosion. Keep sparks and flames away

from the batteries. Charge the batteries only in well ventilated area.

Make sure all warning and caution labels are legible and properly attached to the machine.

Maintain adjustments on machine as per specifications noted in the owner’s guide.

SAVE THESE INSTRUCTIONS

IMPORTANT SHIPPING NOTE

Carefully unpack your Voyager and inspect it for shipping damage. Any damages which occurred

during shipping are the responsibility of the carrier, who must be notified immediately.

4

VGR2 98953 12/18/01

Page 5

WWW.MANUALS.WS

WWW.MANUALS.WS

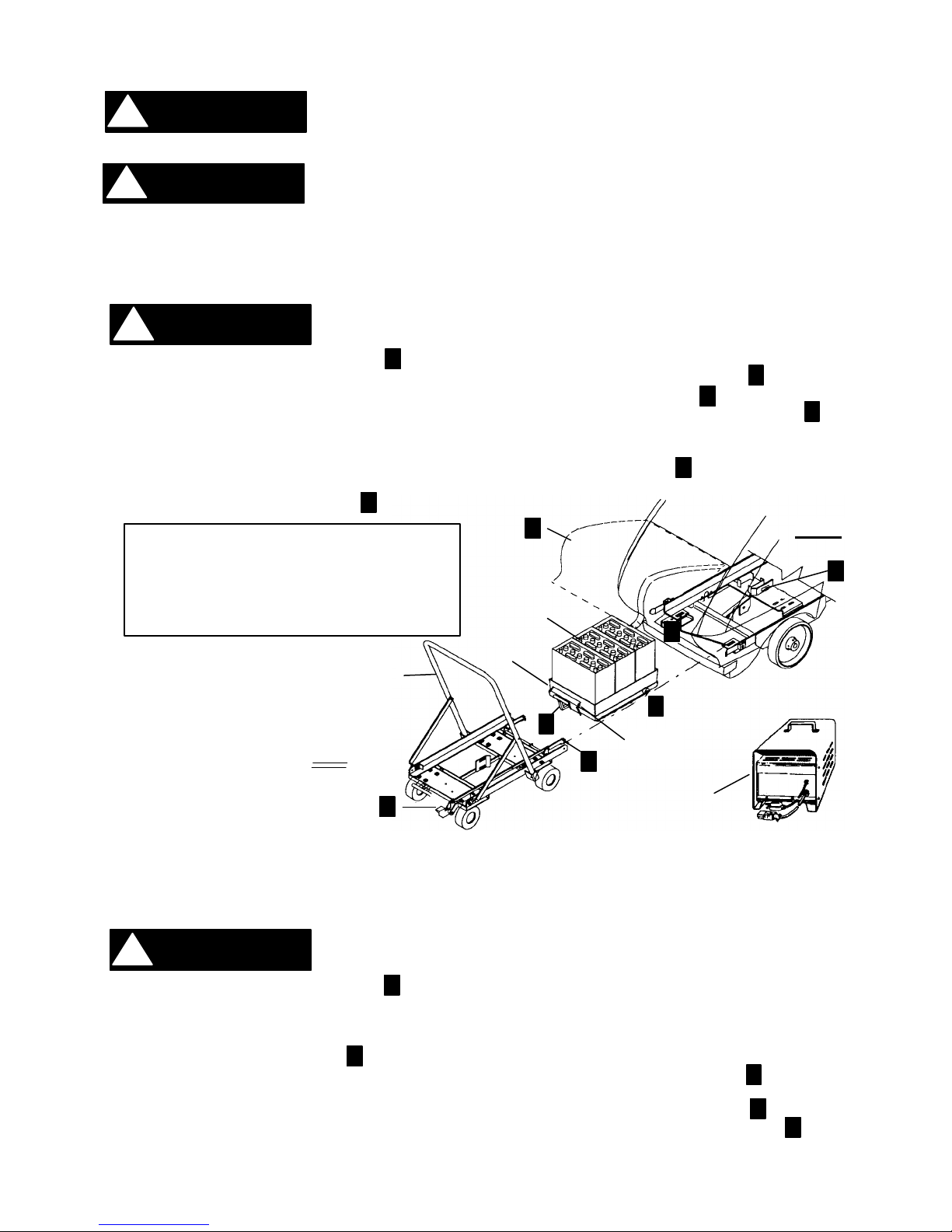

BATTERY INSTALLATION & REMOVAL (W/ BATTERY CART)

!

WARNING:

!

CAUTION:

!

CAUTION:

!

CAUTION:

A

(REF)

Key

P/N

Description

* NOTE: ONLY THE NEW “VCT”

WEAR EYE PROTECTION AND PROTECTIVE CLOTHING WHEN WORKING

BATTERY INSTALLATION AND REMOVAL

1. Remove the vac shoe hose from tank, lay dome back and slowly open tank to upright position.

2. Install (3) batteries in machine by placing them in battery tray liner provided. (See diagram page 6)

3. Connect battery wires according to diagram on page 6.

INSTALLATION OF BATTERIES

WITH BATTERIES.

FOLLOW THE PROCEDURES CAREFULLY.

FOLLOW PROCEDURES CAREFULLY, BE SURE TO KEEP HANDS AND

FEET CLEAR FROM ROLLING BATTERY TRAY.

1. Make sure the battery door is open.

2. Roll the Battery Cart up to the front of the machine, (aligning the front of the two frames).

3. Push the cart until the latches lock into the tabs on the front of the machine frame.

4. Pull the handle on the Battery Tray. (This releases the locking mechanism on the cart.) Fig 1 & 2

5. Push the batteries into the machine until the locking mechanism on the frame is engaged. (This can be heard

by a “Snapping” sound.) Fig 1.

6. Press the foot pedal on the front of the cart and roll the cart from the machine.

7. Attach battery cable from the batteries to receptacle on front of machine by pressing down on right hand side

of locking bracket. (p/n 140190)

1 VCT CART, BATTERY REMOVAL

2 78243 TRAY, VGRB BATTERY LINER

3 78369 TRAY ASSEMBLY BATTERY

4 02143 (3) BATTERY, 12 VOLT

5 02267 CHARGER, 36 VOLT

CART AND NEW TRAY ASSEMBLY

WILL WORK WITH THE VOYAGER

2. PREVIOUS CARTS AND TRAYS,

IN ANY COMBINATION, WILL NOT

WORK.

A

F

F

C

E

B

D

FIG. 1

E

1

4

C

2

B

D

140190

G

5

REMOVAL OF BATTERIES

BEFORE REMOVING BATTERY TRAY PLEASE FOLLOW THE INSTRUCTION SHEET 98439.

If you did not receive this sheet please contact Windsor Industries for this instruction sheet.

1. Make sure the battery door is open.

2. Disconnect battery cable from receptacle on front of machine.

3. Roll the cart up to the front of the machine aligning the front of the two frames.

4. Push the cart until the latches lock into the tabs located on the front of the machine. (The tabs cannot be seen

when batteries are installed.)

5. The latches are engaged when a “Snapping” sound is heard. Pull the handle on the tray. (This releases the

locking mechanism on the machine frame.) (Fig 1 & 2) Continue to pull handle until the battery pack rolls and

locks onto cart. (The locking mechanism is engaged when a “Snapping” sound is heard.)

6. Press the foot pedal located on the cart and roll the batteries and cart away from the machine.

FOLLOW PROCEDURES CAREFULLY, BE SURE TO KEEPS HANDS AND

FEET

A

B

VGR2 98953 12/18/01

D

G

F

5

Page 6

WWW.MANUALS.WS

WWW.MANUALS.WS

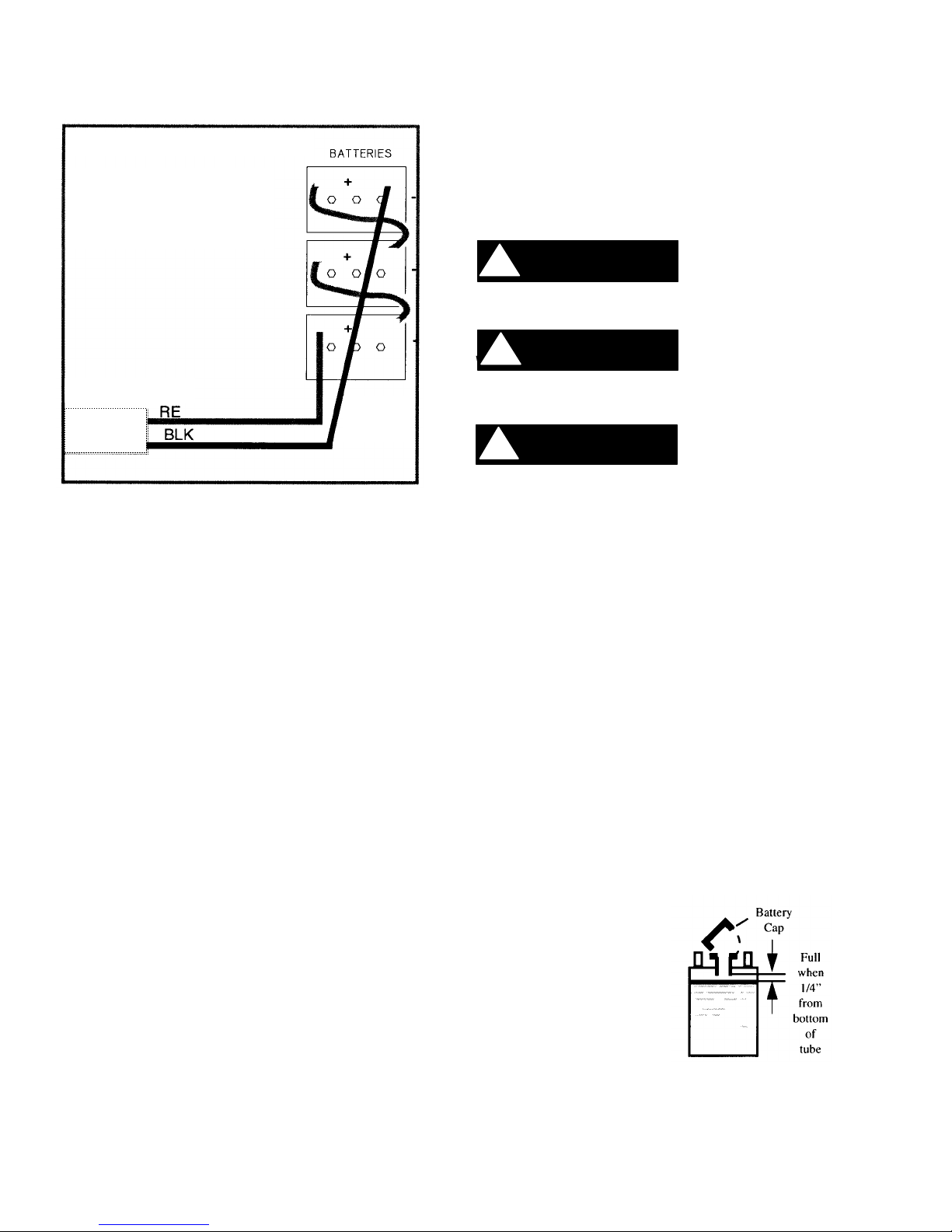

BATTERY INFORMATION

!

WARNING:

!

WARNING:

!

WARNING:

NOTE:

Following you will

ANDERSON

Molex

FRONT OF

VIEW: Looking down on machine.

find the recommended

battery arrangement for the

VOYAGER2

BATTERY CHANGING PROCEDURE:

Charge the batteries once battery level indicator is

near the level “0”. Do not let the batteries

completely drain before changing. Avoid charging

the batteries before the amber light comes on.

DO NOT SMOKE, HAVE OPEN FLAMES, OR

SPARKS NEAR BATTERIES AT ANY TIME.

WEAR EYE PROTECTION AND PROTECTIVE

CLOTHING WHEN WORKING WITH BATTERIES.

MACHINE

connector

BATTERY MAINTENANCE

1. When cleaning batteries use a solution of baking

soda and water. (Do not allow cleaning fluid to

enter inside battery cells.)

2. Keep a proper electrolyte level in the battery

cells.

3. Wipe down the battery tops at least once a

week. If a cell should accidentally overflow,

clean it immediately.

4. Test the battery connection with a hydrometer at

least once a week.

5. Ensure that all connections are tight and that all

corrosion is removed.

6. Every 4 to 6 months remove batteries from the

machine and clean the battery compartment.

7. Follow the Safety Procedures.

ACCESSORIES

02143 Battery. 12V DC, 185 Amp Hour

00267 Charger, automatic 36V (20 amp) 115V

02264 Charger, automatic 36V (20 amp) 230V

INTERNATIONAL

VCT Battery cart system for service

78243 Battery tray liner

VXK Battery Exchange Kit

ACCESSORY TOOLS:

DHTK Deluxe Hand Tool Kit

DDH Double Dry Hand Tool

HFT 14” Flip Tool

89227 Standard Wand

89226 Deluxe Professional Wand

39128 12” Hose set

CHARGE BATTERIES IN A WELL VENTILATED

AREA WITH BATTERY DOOR OPEN.

1. Use a 36 volt, 20 amp maximum output, D.C.

charger which turns itself off when the batteries

are fully charged. The charger must have a

connector that matches the machine’s battery

connection.

2. Read the instructions and warnings provided by

the battery charger manufacturer.

3. Set the charger in a well ventilated area on a

level surface. Make sure cords will easily reach

outlets on both machine and wall.

4. Connect the charger to D.C. outlet on the

machine first.

5. Connect the A.C. power cord to properly

grounded wall socket. NEVER MAKE THE A.C.

CONNECTION FIRST, HAZARDOUS SPARKS

MAY RESULT.

6. After the batteries are completely charged,

disconnect the charger from the A.C. wall

socket.

7. Once the charger is disconnected from the A.C.

wall socket it is safe to disconnect the charger

from the machine.

8. When batteries are

fully charged, check

the electrolyte level by

removing the caps on

top of batteries. If

necessary, fill the

cells with distilled

water as shown in the

diagram to the right.

Be careful not to

overfill the cells.

6

VGR2 98953 12/18/01

Page 7

WWW.MANUALS.WS

WWW.MANUALS.WS

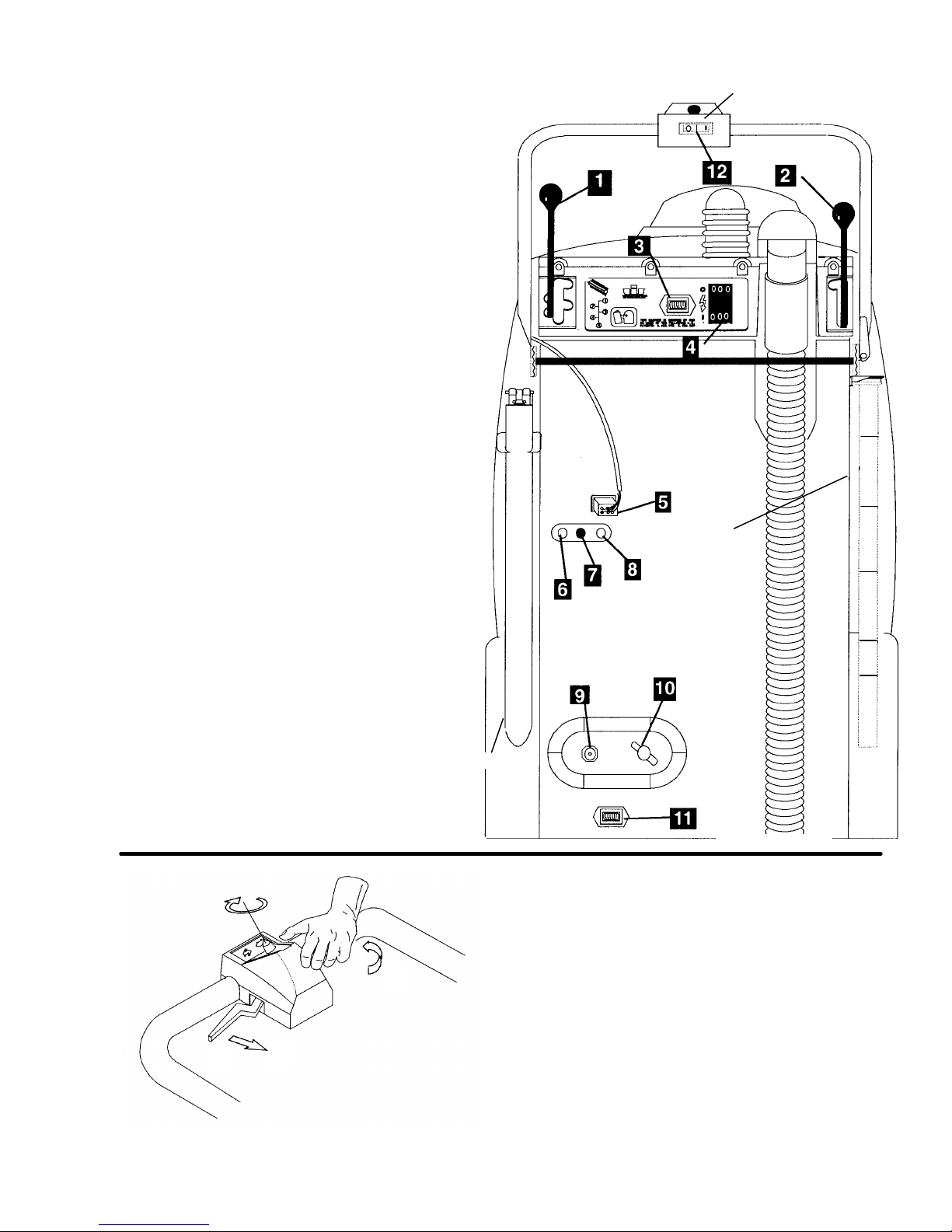

OPERATION CONTROLS

40

10

DRAIN

TO VAC SHOE

SIGHT

3

SEE BELOW

1. Brush Height Adjustment. Raises and adjusts

the height if the brush.

2. Vac Shoe Lift Lever. Lifts the vac shoe up or

down and switches vac motor off and on.

3. Battery Charge Meter. Indicates the level of

charge that the batteries are holding.

4. Main Power Switch. Turns ON and OFF the

machine.

5. Drive Handle Control Connection. This is

where Drive Control Connection Assembly is

attached to rear panel.

6. Drive Motor Circuit Breaker. 16 amp Protects

the dirve motor mechanism.

7. Vac Motor Circuit Breaker. 35 amp Protects

the vacuum motors.

8. Brush Motor Circuit Breaker. 15 amp

Protects the brush motor.

9. Accessory Tool Hookup. Used for various

auxiliary cleaning tools.

10. Spray Position Switch. Controls the spray

adjustment between manifold and accessory

tools.

11. Hour Meter. Records the use time.

12. Pump Switch. Turns ON and OFF the pump

FILL

TUBE

GAL

30

GAL

20

GAL

GAL

5

GAL

1

4

2

VGR2 98953 12/18/01

VOYAGER DRIVE CONTROLS

1. The speed the machine will travel is regulated by

the knob located on the controls which are found

on the main handle. Turn the knob to the right to

increase the speed of the machine.

2. Squeezing one or both of the control levers will

propel the machine forward are the selected

speed.

3. Releasing both control levers will stop the

machine.

4. Pressing forward on the levers moves the

machine backwards at the selected speed.

7

Page 8

WWW.MANUALS.WS

WWW.MANUALS.WS

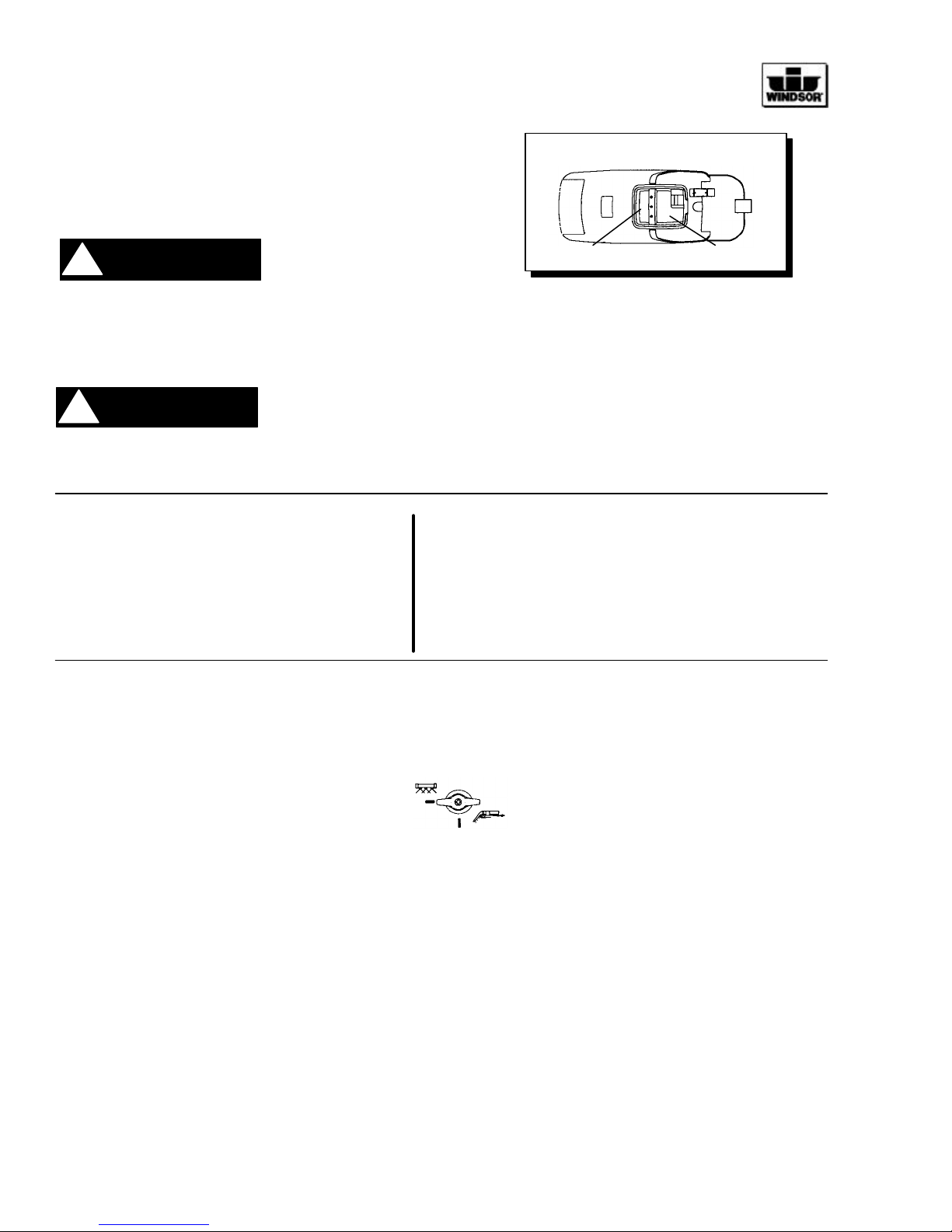

OPERATIONS

SOLUTION TANK

RECOVERY TANK

!

CAUTION:

!

WARNING:

Fill the solution tank to the desired level according to the marked

gauge on the clear hose on the right side of the tank.

DO NOT FILL PAST THE INLET LIP.

TOP VIEW OF TANK

IF A BUCKET IS USED TO FILL THE TANK, BE SURE IT IS CLEAN. DO NOT OVERFILL TO AVOID

POSSIBLE DISTORTION OF THE FLEXSOL DIAPHRAGM OR SOLUTION TANK. DO NOT USE WATER

TEMPERATURE THAT EXCEEDS 140°F (60°C). LIQUID DETERGENTS ARE PREFERRED, however if a

powered detergent is used, be sure it is fully dissolved. NOTE: If suitable powered detergent is used, premix

with hot water before filling the solution tank.

DO NOT PUT DEFOAMER, SOLVENTS, SPOTTER OR PRESPRAY

CHEMICALS IN THE SOLUTION TANK.

The internal parts of the pump used in the extractor are suitable for use with most carpet cleaning chemicals.

However, it is susceptible to chemical attack from cleaning substances, such as hydrocarbon solvents and

chlorinate bleaches. These noncombustible materials are not of the type normally used for carpet cleaning.

CHEMICALS:

SUITABLE CHEMICALS NONCOMPATIBLE CHEMCIALS

Alkalis Soaps Aldehydes Chlorinated Hydrocarbons

Detergents Vinegar Aromatic Hydrocarbons Lysol*

Hydroxides D-Limonene @ SP Butyls Methyl Ethel Ketone (MEK)

@ When properly diluted Carbon Tetrachloride Perchorethylene (perc)

* Registered Trademark Chlorox* Phenolics

Chlorinated Bleaches Trichlorethylene

FILLING THE VOYAGER

1. Remove the Dome.

2. Use a CLEAN bucket or hose to fill solution tank with hot water not to exceed 140°F (60°C). Do not fill above lower tank lip. Add non-

foaming carpet extraction chemical at recommended proportion. NOTE: If suitable powdered detergent is used, premix with hot

water filling the solution tank.

BEGIN CLEANING

1. Adjust handle to comfortable position at waist level.

2. Turn solution valve, located on bottom of rear position.

3. Turn MAIN POWER switch ON.

4. Adjust SPEED CONTROL KNOB on handle to set desired maximum speed.

5. Turn SOLUTION switch ON.

6. Lower BRUSH using left hand lever until contact with carpet is reached. Brush motor will start automatically.

NOTE: Incorrect brush height may trip circuit breaker or cause belt slippage. To correct, raise brush and reset circuit breaker

located on rear panel.

7. Lower VACUUM using right hand lever. Vacuum motor will start automatically.

8. Depress SPEED LEVER to propel machine. Speed is controlled by lever up to the maximum set on CONTROL KNOB.

NOTE: For protection, the Voyager will not operate in reverse when brush is on.

CLEANING PROCEDURE

1. Operate machine in parallel passes, overlapping 2 inches on each pass. Turn SOLUTION switch OFF on turns. Propel machine gently

into turns. Abnormal turns may activate vacuum motor shut-off. Clean perimeter last.

2. Run machine more slowly over spots or extremely soiled areas.

3. Use right side of VOYAGER when cleaning against walls.

4. Turn SOLUTION switch OFF 3 feet before completing a cleaning pass to ensure all solution is vacuumed from carpet.

CAUTION: WHILE OPERATING MACHINE, CHECK FOR EXCESSIVE FOAM BUILD-UP IN RECOVERY TANK. IF EXCESSIVE

FOAM IS PRESENT, ADD DEFOAMER SOLUTION TO RECOVERY TANK OR EMPTY RECOVERED SOLUTION.

5. To speed dry, use a WINDBLOWER fan and ensure building ventilation system is ON.

6. Empty recovery tank when full by releasing dump hose and removing stopper. NOTE: Vacuum motor will stop if recovery tank is full.

7. Turn MAIN POWER switch OFF after use.

NOTE: Check the Circuit Breaker if the Voyager does not start.

8

VGR2 98953 12/18/01

Page 9

WWW.MANUALS.WS

WWW.MANUALS.WS

ACCESSORY TOOLS & MAINTENANCE

!

CAUTION:

!

WARNING:

ACCESSORY

1. Attach the auxiliary solution hose to the output nipple A.

2. Disconnect hose at vac shoe using and connect vac hose using

coupler (22071) that is included with Voyager machine.

3. Turn the solution control valve B to

4. Press the Pump switch “ON”.

5. Lower the vac lever to the “ON” position to start the vac motor.

6. Make sure the solution control valve is returned to the

7. position before using the Voyager for self-contained

carpet cleaning.

CLEANUP AND STORAGE

Empty the Recovery Tank directly into the floor drain. After each use, rinse tank (including the float-off) with fresh

water. Periodically inspect the recovery tank and decontaminate if necessary, using a Hospital Guide Virucide or

a 1-10 bleach to water solution. This will dissipate the exposure to blood born or infectious contamination. Waste

water shoud be disposed of properly. Clean the inside of the recovery dome also.

Empty the Solution Tank by detaching the sight hose and empty directly into the floor drain.

Flush the Solution System with 1 gallon of CLEAN water.

Never allow recovered solution to remain in tank when not in use; nor allow

usused solution to remain in the solution tank when in storage. Inspect and

clean the filter located at the pump port. Remove and rinse with hot water.

PERIODIC MAINTENANCE

A

B

EVERY TWO WEEKS:

Clean the solution system by diluting 2 gallons of clean water with a quart of white vinegar (acetic acid) in the

solution tank. Run the solution through the system to remove chemical buildups which could eventually cause it to

plug up.

EVERY 500 HOURS:

Oil the front drive wheel bearings by removing the phillips screw “A” and by

loosening the (2) set screws “B” located on the outside of wheel assembly. Slide

the wheel off the axle and apply 6 drops of 10W oil to bearings. Be careful not to

lose the key in shaft.

INSPECTION

B

A

Remove the batteries (using the battery cart if available) before making any

adjustments or repiars to the Voyager2.

To expose working parts for inspection, lay dome back on handle, grasp tank at solution opening and tilt the tank

forward until “NOSE” of tank rests on floor.

VGR2 98953 12/18/01

9

Page 10

WWW.MANUALS.WS

WWW.MANUALS.WS

ACCESSORY TOOLS & MAINTENANCE

!

WARNING:

!

CAUTION:

Important:

Per

iodically check the length of the carbon brushes. Replace

Vacuum Motor Carbon Brushes Replacement (

Carbon

If armature commutator is grooved, extremely pitted or not

Note:

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not

Important:

Periodically check the length of the carbon brushes. Replace

ONLY QUALIFIED MAINTENANCE PERSONNEL

ARE TO FERFORM THE REPAIRS.

Remove the batteries (using the “Battery Cart” if

available) before making any adjustments or repairs

to the Voyager2.

WHEN REPLACING THE ELECTRICAL PARTS

REFER TO THE MACHI NE WIRING DIAGRAM

FOR PROPER CONNECTIONS.

REAR PANEL REMOVAL

Remove the vac shoe hose from tank, lay dome

back, remove handle and open the front battery

door. Open the tank slowly to upright position.

Remove (2) top and (2) bottom screws on rear

panel.

TANK REPAIR

The tanks are made of Polyethylene. Small holes or

crack can be repaired by using heat. Apply low heat

from a torch to the damaged are until the material is

softened. Use a screw driver blade or other flat head

metal tool to seal damaged area.

VACUUM MOTOR REMOVAL

1. Turn main power off.

2. Remove the rear Control Panel and open tank to

upright position.

3. Disconnect the hose from the vac motor intake.

4. Disconnect the vac motor leads from the

terminal couplers & ground post.

5. Remove the (3) screws holding the vac motor to

the rear frame and remove the vac motor.

6. To inspect the motor brushes, remove the brush

holder assembly. Brushes should be replaced

when worn to 3/8 inch or about 750 operating

hours. After second brush replacement,

armature commutator should be checked for

pitting and concentricity. Vacuum motors can be

repaired, but such repairs should be made by a

qualified motor repair shop.

7. Clean out dust using a vacuum to prevent injury

to eyes or contamination of the bearings.

Brushes

End Cap

concentric, the motor will need to be replaced or sent to a

qualified service center.

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage

motor if brushes are allowed to wear away completely.

both carbon brushes when either is less than 3/8" (9.5mm)

long.

Vacuum Motor Carbon Brushes Replacement (Windsor)

Place

stop in

groove.

concentric, the motor will need to be replaced or sent to a

qualified service center.

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage

motor if brushes are allowed to wear away completely.

both carbon brushes when either is less than 3/8" (9.5mm)

long.

3

[9.5mm]

8

Ametek)

3/8 (9.5mm)

End Cap

10

98953 02/14/04

Page 11

WWW.MANUALS.WS

WWW.MANUALS.WS

MAINTENANCE

11

BRUSH MOTOR

IDLER PULLEY

(REF.)

BRUSH

PULLEY

(REF.)

BELT

SOLUTION PUMP REMOVAL

1. Turn main power off.

2. Disconnect the two pump wire leads.

3. Remove (4) screws holding the pump to the main frame.

4. Lift the pump out to access solution inlet and disconnect from the pump head.

Refer to the pump drawing page 16 for replacement parts.

BELT / BRUSH ASSEMBLY REMOVAL

1. Turn main power off.

2. Use brush height adjustment lever to lower brush to its lowest

position.

3. Remove the belt guard.

4. Now remove the brush pulley guard.

5. Loosen tension in belt by moving idler pulley clockwise.

Simultaneously remove belt from motor pulley, while holding idler

pulley. Once belt has been removed from motor pulley, slowly let

idler pulley rotate counterclockwise. Do not loosen spring.

6. Remove the screw from each end of the brush shaft.

7. Swing the brush assembly out of the housing to remove the belt.

PULLEY (REF.)

11027

(REF.)

98953 02/14/04

Page 12

WWW.MANUALS.WS

WWW.MANUALS.WS

MAINTENANCE

SIDE VIEW OF VAC SHOE

REF.

REF.

REF.

TRACKING

REF.

NUTS. REF.

REF.

SQUARE

6

1

34 82

MANIFOLD / SPRAY JETS

To prevent clogged jets due to alkaline build -up, the spray system should be flushed with 1 gallon of clean hot

water at the end of each work day. The VOYAGER2 is equipped with “quick change” jets that can be easily

removed for cleaning. To remove – push jet in and rotate. Do not use pins or wire to remove obstruction as this

will damage jet and alter spray pattern.

1 66095 PLUG, 1/8 NPT HEX BRASS

2 44052 JETBODY, BRASS W/SEAL

3 54138 MANIFOLD ASM, 3 JET

4 40033 HOSEBARB, 1/4 MP T X 3/8 90D

5 66052 PIN, 1/8 X 1.0 ROLL

6 73576 SPRING, 2” X .600 OD

7 44060 JET, 8002 MINI-QUICK REPLACEMENT

8 44051 JET SEAL, MINI QUICK

9 54162 MANIFOLD A

VAC SHOE TRACKING

To adjust shoe tracking, move eyebolts in or out to increase or decrease spring force, respectively, until desired

tracking is reached.

VAC SHOE DOWNPRESSURE

NOTE: DOWNPRESSURE IS FACTORY SET AND SHOULD NOT REQUIRE ADJUSTMENT.

If adjustment of downpressure is required, turn black knob on top of vac shoe clockwise to increas e

downpressure and counterclockwise to decrease downpressure.

CASTER ASM.

VAC SHOE

PIVOT ASM.

VAC SHOE ANGLE

NOTE: THE ANGLE OF THE VAC SHOE IS FACTORY

SET AND SHOULD NOT REQUIRE ADJUSTMENT.

Periodically inspect the vac shoe angle by resting it

on a hard, flat surface. Use a square to verify a 90°

angle between the floor and vertical surface of the

vac shoe.

If adjustment is required, remove one socket on each

lower arm (from the vac shoe or bracket) and turn

clockwise or counterclockwise to change the angle to

the recommended 90°. Attach the socket on each

arm to its respective location and recheck the angle

using the square. Repeat if necessary.

REF.

VAC SHOE

DOWNPRESSURE KNOB

PIVOT ASM.

SOCKET

ARM

REF.

ADJUSTMENT

9

VAC SHOE

FLAT SURFACE

1

5

“Quick

Change

Jets”

VAC SHOE

VERTICAL

SURFACE

OF VAC

SHOE

90°

12

98953 02/14/04

Page 13

WWW.MANUALS.WS

WWW.MANUALS.WS

MAINTENANCE

SERVICE SCHEDULE

MAINTENANCE DAILY WEEKLY QUARTERLY

Check recovery dome and gasket for

damage and cleanliness

Check batteries after charging, add

water if necessary *

Check brush – should be clean with no

lint or strings attached *

Inspect vac shoe for blockage; remove

fibers with coat hanger, etc.

Check hoses for wear, blockages, or

damage *

Check handles, switches, and knobs

for damage *

Check vac motor intake filter and clean *

Run one gallon of water through

system

Clean out recovery tank and check

float valve to make sure it moves freely *

Clean out solution tank and remove

and clean vacuum intake screen *

Clean outside of all tanks and check for

damage

Run vac motor for at least one minute

to allow motor to dry *

Store with dome off tank to allow the

tank to dry *

Check batteries for corrosion, cracks,

and evidence of overheating

Check all bearings for noise *

Check all gaskets for wear and leakage

Check vacuum intake screen for

damage; replace if necessary *

Check pump pressure; observe spray

pattern and check with gauge if

necessary

Check and clean solution screen *

Check belts for wear and replace as

necessary *

Check brush for wear; ensure bristles

are not damaged *

Check cables for fraying *

Check the spray bar (manifold) for

damage; replace if broken or bent

Check condition of vac shoe and frame

for damage *

Check overall performance of machine *

Check vac motor carbon brushes *

Check chains for wear and lube as

necessary *

*

*

*

*

*

*

*

*

98953 02/14/04

13

Page 14

WWW.MANUALS.WS

WWW.MANUALS.WS

PROPEL HANDLE ASSEMBLY

16

17

1

2

4

15

8

9

30

10

VIEW: CONNECTION DETAIL

5

29

22

14

11

29

12

13

12

30

7

23

26

6

18

25

3

24

15

28

27

20

21

19

Color AWG Position

Blue 20 1

Black 20 2

27

14

Brown 20 3

Orange 20 4

White 20 5

Red 20 6

28

VGR2 98953 10/19/02

Page 15

WWW.MANUALS.WS

WWW.MANUALS.WS

PROPEL HANDLE ASSEMBLY

REF PART NO. QTY DESCRIPTION

1 27551 1 COVER, PROPEL HANDLE

2 70406 4 SCREW, 10B X 3/8 PHSM BLK

3 87018 4 WASHER, #10 X 9/16 OD

4 57236 2 NUT, 10-32 HEX NYLOCK BLK

5 71116 1 SUPPORT, LEVER PIVOT

6 67271 2 ROD, HANDLE LEVER PILOT

7 51186 2 LEVER, PROPEL CTRL HANDLE

8 66184 1 PIN, CLEVIS 1/4 X 2.438

9 62705 1 PLATE ASSEMBLY, PROP. CTRL.

10 70209 2 SCR, 10-32 X 1.75 PHMS

11 36136 1 GUIDE, LEVER CENTERING

12 14866 2 BUSHING, PROPEL CONTROL

13 73236 1 SPRING, COMP. .36D X .12L X .04W

14 66191 1 PIN, CLEVIS 3/16 X 1/2

15 80604 2 RING, RUE COTTER 1/4”

16 72087 1 SWITCH, 36VDC SPST ILLUM.

17 57028 4 NUT, 10-24 TINNERMAN

18 48043 1 KNOB, PT26/32 SPEED CONTROL

19 880092 1 WIRE ASM, HANDLE TO POWER

20 57024 1 NUT, 3/8-27 PANEL

21 70084 1 SET SCREW, 8-32 X 3/16 KCP

22 66183 1 PIVOT, POTENTIOMETER

23 36123 2 GRIP, CLP HANDLE, X 9.5”

24 51184 2 LOCK, HANDLE ADJUSTMENT

25 70228 4 SCREW, 10-32 X 1/4 PHSM

26 38183 1 HANDLE, VGRB MAIN

27 88748 1 WIRE ASM., VGR. HANDLE

28 27554 1 CONN., MOLEX 6 PIN RECEPT. (M)

29 70088 4 SCR, 10-32 X 1/2 PPHMS

30 87016 6 WASHER, #10 LOCK EXT. STAR

SERIAL NO.

FROM

NOTES:

Installation and adjustment of potentiometers for drive control speed

STEP PROCEDURE

1 Turn the speed potentiometer fully clockwise. (Max. speed)

2 Measure the potentiometer resistance at connector (#27) BROWN and BLACK wires.

The resistance should measure 2200-2800 ohms in neutral, 4800-5000 ohms in forward,

and 0-200 ohms in reverse. If adjustment is necessary loosen set screw (#21) and adjust

potentiometer T for 2500 ohms in Neutral. Tighten set screw (#21).

3 Turn the main switch power on.

4 If the machine moves when control lever is in neutral adjust the direction potentiometer

until movement stops.

VGR2 98953 10/19/02

15

Page 16

WWW.MANUALS.WS

WWW.MANUALS.WS

DRIVE & BRUSH ASSEMBLY

TO BELT #35

PAGE 20

16

VGR2 98953 10/19/02

Page 17

WWW.MANUALS.WS

WWW.MANUALS.WS

DRIVE BRUSH ASSEMBLY

Replacement of Drive Motor brushes (p/n 40063):

REF

1 89078 2 WHEEL, 10” X 2 –1/2” BORE

2 81003 3 FLANGETTE, 1” BEARING PAIR

3 70305 4 SCREW, 5/16-18 X 3/4 HHCS

4 57113 4 NUT, 5/16-18 NYLOCK PLTD

5 81002 3 BEARING, 1” BORE

6 29156 1 DIFFERENTIAL

7 48052 2 KEY, 1/4 X 1/4 X 2-1/2

8 87008 2 WASHER, 1/4 ID X 1-1/4 OD

9 41288 1 HOUSING, BRUSH

10 27569 1 CHAIN, #40 1/2 PITCH X 39

11 27343 1 CHAIN, MASTER LINK, #40 1/2

12 73567 1 SPROCKET, #40 11 TOOTH

13 53610 1 MOTOR ASM, VGR 36V

14 70432 4 SCREW, 5/16-24 HHCS SS

15 87166 4 WASHER, 5/16 EXT. LOCK

16 87090 8 WASHER, 1/4 ID X 3/4 OD PLTD

17 41320 1 HOUSING ASSEMBLY

18 70104 2 SCREW, 3/8-16 X 3/4 BHMS

19 12022 1 BRUSH, VGRB

20 09019 2 BEARING, BRUSH

21 57104 7 NUT, 10-32

22 73606 2 SPACER, .50 OD X .38 ID X .260 L

23 64103 1 PULLEY, BRUSH VGRB

24 27607 1 COVER, BRUSH CORE

25 03091 1 AXLE, BRUSH DRIVE

26 36175 1 GUARD, VOYAGER SPLASH

27 67106 1 RETAINER, SPLASH GUARD

28 70088 7 SCREW, 10-32 X 1/2 PPHMS

29 73578 1 SPRING, 4.00 .75 OD EXT

30 87025 4 WASHER, 1/4 LOCK EXT STAR

31 70011 4 SCREW, 1/4-20 X 5/8 PPHMS

32 09025 2 BEARING, 1/2 ID NYLINER

33 67094 2 RING, 1/2 EXT. SNAP

34 70088 8 SCREW, 10-32 X 1/2 PPHMS SS

35 67098 1 RING, TOLERANCE

36 140063 1 BRUSH SET, 36V VGR DRIVE

37 70267 1 SHOULDER BOLT, 5/16 OD X 1.25

38 64101 1 PULLEY ASM., VGR

39 87029 1 WASHER, 5/16 FLAT SAE

40 87030 1 WASHER, 3/8 ID X 3/4 OD NYL

41 73307 1 SPRING, COMP. .88D X 1.4L X .1W

42 57047 1 NUT, 1/4-20 NYLOCK PLTD

43 67093 1 RING, 1 1/8 INT. SNAP

44 87074 1 WASHER, WAVE

45 12508 1 BRUSH ASM, VGR

46 62820 1 PLATE, VGR PULLEY

PART

NO.

QTY DESCRIPTION

SERIAL NO.

FROM

NOTES:

1. Using a standard head screwdriver, remove cap

covering brush inlet.

2. Using a pair of needle nosed pliers, gently remove brush (including spring) and replace with new part.

VGR2 98953 10/19/02

17

Page 18

WWW.MANUALS.WS

WWW.MANUALS.WS

PUMP, VAC, MANIFOLD & BRUSH MOTOR ASSEMBLIES

!

CAUTION:

112518

13

*45624

26

30

13

*38

(REF)

ASM PAGE 20

13

246*45

(REF)

272236271232823517161433154813233634

*3832101813

40

31

29

3941892010181384421433757

REPLACEMENT PART FOR THIS ITEM 19

ON PAGE 19

181312

42

461347

Replacement of Motor brushes (#28)

TURN POWER OFF.

1. Using a standard head screw driver,

remove cap covering brush inlet.

2. Using a pair of needle nose pliers,

gently remove brush (including

spring) and replace with new part.

SEE VALVE

*NOTE: HOSES ARE MARKED AS SUCH

TO CLARIFY FLOW PATH OF SOLUTION,

NOTE: ORDER (73785) TO GET

REPLACEMENT SCREEN FOR STRAINER

(73573) ITEM 20.

18

VGR2 98953 10/19/02

Page 19

WWW.MANUALS.WS

WWW.MANUALS.WS

PUMP, VAC, MANIFOLD & BRUSH ASSEMBLIES

19

PUMP HEAD REPLACEMENT

VALVE ASM

DIAPHRAM ASM.

REF

1 53622 1 MOTOR ASM, 36VDC VGR2

2 64022 1 PULLEY, POLY-V BELT

3 70074 2 SET SCREW, 10-32 X 1/4 KCP

4 99873 2 TAPE, 5/8 X 1/4 X 3” PORON

5 20005 2 CLAMP, 5/16 NYLON

6 70011 16 SCREW, 1/4-20 X 5/8 HHCS

7 70088 1 SCREW, 10-32 X 1/2 PPHMS

8 57104 12 NUT, 10-32 W/ STAR WASHER

9 14454 1 BRACKET, VALVE

10 22003 2 COUPLER, 3/8 FPT X FPT

11 70253 4 SCREW, 10-32 X 1.25 PHMS

12 39486 1 HOSE, 3/8 NYLOBRAID X 2”

13 20042 8 CLAMP, 3/8 HOSE (D-SLOT)

14 040-03 2 CASTER SWIVEL 4” 250# CPCTY

15 70305 8 SCREW, 5/16-18 X 3/4 HHCS

16 62394 2 PLATE, SPRING HOOK

17 73240 2 SPRING, 1/2 X 2.25L EXTENSION

18 40034 4 HOSEBARB, 3/8 MPT X 3/8 90D

19 65166 1 PUMP ASM, 36VDC VGR2

20 73573 1 STRAINER, 3/8 NPT 80 MESH

21 880101 1 WIRE ASM, VGR MAIN POWER

22 70329 4 SCREW, 1/4-20 X 3/4 PHMS

23 70066 5 SCREW, 10-32 X 3/4 PPHMS

24 87025 12 WASHER, 1/4 LOCK EXT STAR

25 87018 4 WASHER, #10 X 9/16 OD

26 73566 6 SPACER, 1/2 OD X 3.0 W/ 1/4-20

27 57047 4 NUT, 1/4-20 NYL SELF LOCK

28 140066 1 BRUSH, 36V VGR BRUSH MTR

29 73576 1 SPRING, 0.6 OD X 2.0L COMPR

30 53782 2 VAC MOTOR ASM, 36VDC

- 140658 1 BRUSH SET, VAC MTR 53204 SERVICE ONLY

- 140686 1 BRUSH SET, 24V/36V VAC WINDSOR SERVICE ONLY

31 66095 2 PLUG, 1/8 MPT HEX BRASS

32 54139 1 MANIFOLD ASM, VGR 3-JET

33 87067 8 WASHER, 5/16 LOCK INT STR.

34 14902 1 BRACKET, VGR MANIFOLD

35 11027 1 BELT, BRUSH DRIVE ASSEMBLY

36 40033 1 HOSEBARB, 1/4 MPT X 3/8 90D

37 34270 1 FRAME, VGR2 MAIN

38 39204 1 HOSE, 3/8 NYLOBRAID X 29”

39 44060 3 JET, 8002 MINI -QUICK

40 66052 1 PIN, 1/8 X 1” ROLL

41 44052 3 JETBODY, MINI-QUICK W/ SEAL

42 34308 1 FRAME, VGR2 REAR

43 70261 2 SCREW, 6-32 X 1.0 PHMS PLTD.

44 57116 2 NUT, 6-32 E/ STAR WASHER

45 39365 1 HOSE ASM, 3/8 ID NYLOBR X 25

46 39499 1 HOSE, 3/8 X 13

47 12-800398 1 Y FITTING

PART

NO.

QTY DESCRIPTION

SERIAL NO.

FROM

PUMP REPLACEMENT PARTS

NOTES:

(65151)

(84145)

98953 02/14/04

(29188)

Page 20

WWW.MANUALS.WS

WWW.MANUALS.WS

REAR TOWER ELECTRICAL ASSEMBLIES

3331185333114

REAR TOWER

CUTAWAY

2213191618120171421SUPPLIED W/ VALVE ASM.

COVER.

2

1

NOTE: SUPPLIED WITH RELAY

TO #*45

SEE DETAIL “A”

2

1

DETAIL “A”

84140 – VALVE ASM.

PARTS BREAKDOWN

15

32

23

24

29

26

28

25

7

27

10

1

REF.

PAGE

16

2

31

TO #*38

PAGE

16

NOTES:

12

INSTALLED ON OUTSIDE OF

LOCATE @ PORT MARKED “P” OR “2”

30

LOCATE @ PORT MARKED “A” OR “1”

9

6

20

VGR2 98953 10/19/02

Page 21

WWW.MANUALS.WS

WWW.MANUALS.WS

REAR TOWER ELECTRICAL ASEMBLIES

NO.

NO.

REF

1 40038 HOSEBARB, 1/4 MPT X 3/8 H 45DEG.

2 51184 LOCK, HANDLE ADJ.

3 57125 NUT, 5/16-24 HEX JAM

4 62561 PLATE, NEGATIVE POST

5 67005 RIVET, 1/8 OD WHT AL

6 70162 SCREW, 10-32 X 3/8 PHMS SS

7 70228 SCREW, 10-32 X 1/4 PHMS SS

8 70289 SCREW, STUD, 5/16-18 X 2.12 BRASS

9 87016 WASHER, #10 LOCK EXT STAR

10 87018 WASHER, #10 X 9/16 OD

11 87092 WASHER, 5/16 X 3/4 BRASS

12 84140 VALVE ASM, 36V

13 22072 COUPLING, 1/4 ANCHOR

14 31016 ELBOW, 1/4 NPT

15 87095 WASHER, #10 FLAT PLTD.

16 56012 NIPPLE, 1/4 FPT QD

17 56014 NIPPLE, 1/4 CLOSE

18 56048 NIPPLE, 1/4 X 1.75

19 78308 TEE, 1/4 STREET

20 84168 VALVE, 120V 110PSI SOLENOID

21 84065 VALVE, 1/4 FPT BALL

22 36019 GROMMET, 5/16 ID X 9/16 GRV.

23 57116 NUT, 6-32 W/ STAR WASHER

24 14020 TERMINAL BLOCK, 115V (3-4-3)

25 57106 NUT, 8-32 W/ STAR WASHER

26 73734 SPACER, .166ID X .313OD X .75L

27 27672 CONTROLLER, 36VDC PROPEL MOTOR

28 57047 NUT, 1/4-20 NYLOCK PLTD.

29 67315 RELAY, 36VDC 100AMP HVY DUTY

30 36020 GROMMET, 5/8 ID X 1.12 OD

31 70488 SHOULDER BOLT, 5/16 OD X 3/4 L

32 87029 WASHER, 5/16 FLAT SAE

33 57113 NUT, 5/16-18 NYLOCK PLTD

PART

DESCRIPTION

SERIAL

NOTES:

VGR2 98953 10/19/02

21

Page 22

WWW.MANUALS.WS

WWW.MANUALS.WS

HANDLE, MIRCOSWITCH AND CABLE ASSEMBLIES

NOTE: FOR BRUSH AND REVERSE SWITCHES, ALIGN THE TWO SWITCHES AND CHECK TO

789

6

12101

2

BRUSH HOUSING

6

1

872

3

4

5

4

5

VIEW: LEFT SIDE OF

REAR PANEL

VIEW: RIGHT SIDE

OF REAR PANEL

BRUSH & REVERSE SWITCH

SHOWN.

REF.

REF.

11

20

3

REF.

18

4

5

1

2

REF.

REF.

20

3

19

REF.

REF.

9

REF.

12

13

REF.

REF.

10

11

15

16

17

14

18

19

BEND UP

ALIGN

&

HOLD

REF.

SEE THAT THE ACTUATOR TABS ARE EVEN TO WITHIN 1/16 INCH. IF REQUIRED, BEND THE

LOWER TAB UP TO MATCH THE HIGHER TAB.

INSTALL THE SWITCHES WITH THE SCREWS LOOSE ENOUGH TO ALLOW THE TOP SCREW

TO SLIDE IN THE MOUNTING SLOT. WITH THE LEVER IN THE TOP POSITION, SLIDE THE

SWITCHES BACK UNTIL THEY BOTH CLICK, TIGHTEN THE SWITCHES IN THIS POSITION.

22

VGR2 98953 10/19/02

Page 23

WWW.MANUALS.WS

WWW.MANUALS.WS

HANDLE, MICROSWITCH & CABLE ASSEMBLIES

NO.

NO.

REF

1 48030 2 KNOB, PT17/20 BLACK

2 38186 2 HANDLE, BRUSH/VAC CONTROL

3 27559 2 CLEVIS, 3/8-16 UNC ROD END

4 51170 2 LEVER ASM, HANDLE PIVOT

5 70117 2 SHOULDER BOLT, 5/16 OD X 1.0 L

6 73220 2 SPACER, EPB CABLE/CASE HARD

7 87013 2 WASHER, 1/4 ID X 5/8 OD SS

8 87025 2 WASHER, 1/4 LOCK EXT STAR SS

9 70011 2 SCREW, 1/4-20 X 5/8 HHCS SS

10 72082 3 SWITCH, SOL LEVER BENT

11 57163 4 NUT, 4-40 W/ STAR WASHER

12 70401 4 SCR, 4-40 X 1.25 PHMS

13 27486 1 CABLE, BRUSH LIFT

14 27488 1 CABLE, VAC SHOE LIFT

15 70187 2 SCREW, 10-24 X 1/2 PHTC –F16 87018 2 WASHER, #10 X 9/16 OD

17 36179 1 GUARD, SPLASH

18 66073 3 PIN, COTTER 1/16” X 3/4” L PLTD

19 66116 3 PIN, CLEVIS 1/4” X 3/4” PLTD

20 70088 4 SCR, 10-32 X 1/2 PPHMS SS

PART

QTY DESCRIPTION

SERIAL

NOTES:

VGR2 98953 10/19/02

23

Page 24

WWW.MANUALS.WS

WWW.MANUALS.WS

CONTROL PANEL ASSEMBLY

29

NOTE: HARDWARE

320191715111086

12823132213021974

333435

SUPPLIED WITH METER.

2

15

17

24

VGR2 98953 10/19/02

Page 25

WWW.MANUALS.WS

WWW.MANUALS.WS

CONTROL PANEL ASSEMBLY

NO.

NO.

PROPEL

REF

1 27710 1 COVER, REAR VOYAGER 2 TRIMMED

2 54144 1 METER, 36V BATTERY CHARGE LEVEL

3 72130 2 SWITCH, SPST 2-POSITION ROCKER

4 70056 2 SCREW, 6-32 X 1/2 PPHMS

5 OPEN - -

6 57109 1 NUT, 7/16-28 PANEL

7 54092 2 METER, 0-60 VDC HOUR

8 57132 2 NUT, 3/8-27 DRESS PANEL

9 57116 1 NUT, 6-32 W/ STAR WASHER PLTD

10 14944 1 BREAKER, 16A 250 VAC 50 VDC

11 14688 1 BREAKER, 35 AMP 50 VDC MTR.

12 14700 1 BREAKER, 15 AMP BRUSH MTR.

13 04082 1 ADAPTER, “Y” FITTING MODIFIED

14 51142 1 LEVER, HANDLE LOCK

15 87018 4 WASHER, #10 X 9/16 OD

16 87090 2 WASHER, 1/4 ID X 3/4 OD PLTD

17 70066 4 SCREW, 10-32 X 3/4 PPHMS

18 OPEN - 19 39481 1 HOSE, VAC X 20”

20 34308 1 FRAME, REAR W/O PLENUM

21 39313 2 HOSE, 1.5 BLUE VAC X 20”

22 20063 4 CLAMP, 1.75 WORM GEAR X .312

23 20046 1 CLAMP, 2.25” WORM GEAR

24 57032 1 NUT, 3/8-16 SERRATED FLG. PLT.

25 80604 1 RING, RUE COTTER 1/4”

26 66133 1 PIN, CLEVIS 3/16” X 7/8” I

27 67273 1 ROD, VOY HANDLE ADJ.

28 78271 1 TUBE, VOY HANDLE ADJ.

29 47200 1 KIT, VOYAGER ADJUSTMENT PLATE

30 50776 1 LABEL, WARNING FOR SAFTEY

31 98721 1 SERVICE TAG NOT SHOWN

32 14382 1 BAND, SERVICE TAG NOT SHOWN

33 500548 1 LABEL, MAIN SWITCH

34 500547 1 LABEL, CIRCUIT BREAKER

35 50540 1 LABEL, VALVE POSITION

PART

QTY DESCRIPTION

SERIAL

NOTES:

HANDLE

ASM.

24

16

16

28

25

14

27

26

VGR2 98953 10/19/02

15

25

Page 26

WWW.MANUALS.WS

WWW.MANUALS.WS

VAC SHOE ASSEMBLY

7

5

811910121314

REAR

25

9

(REF)

GREASE

1

2

17

19

20

24

15

3

6

5

4

NOTE: #24 SPRINGS

ATTACH TO #17

EYEBOLT.

16

VAC SHOE ASM.

18

21

22

17

22

23

25

26

9

10

MAIN

FRAME

17

27

26

VGR2 98953 10/19/02

Page 27

WWW.MANUALS.WS

WWW.MANUALS.WS

VAC SHOE ASSEMBLY

A

REF PART NO. QTY DESCRIPTION

1 70351 13 SCREW, 10-32 X 3/8 HHTR W/ STAR

2 62391 1 PLATE, VAC SHOE COVER

3 35124 1 GASKET, VGR VAC SHOE PLATE

4 85031 1 VAC SHOE, VGR2 28”

5 87003 4 WASHER, 3/8 ID X 7/8 OD SS

6 89059 2 WHEEL, PT20 SQUEEGEE BUMPER

7 70368 2 SCREW, 3/8-16 X 1-3/4 HHCS

8 140197 1 BRACKET, VAC SHOE LINKAGE PLTD

9 87025 9 WASHER, 1/4 LOCK EXT STAR

10 70011 5 SCREW, 1/4-20 X 5/8 HHCS PLTD

11 05070 2 ARM ASM, SQUEEGEE

12 70298 4 SHOULDER BOLT, 5/16 X 3/8L

13 87029 4 WASHER, 5/16 FLAT SAE

14 87030 8 WASHER, 3/8 ID X 3/4 OD NYL

15 57047 4 NUT, 1/4-20 NYLOCK

16 140192 1 BRACKET ASM, VAC SHOE PIVOT

17 70263 3 EYEBOLT 8-32 X 1; 1/4 EYE PIT

18 57026 2 NUT, 8-32 NYLOCK

19 48031 1 KNOB, VAC SHOE ADJ.

20 87013 1 WASHER, 1/4 ID X 5/8 OD SS

21 54-501623 2

22 57029 12 NUT, 1/4-28 HEX SS

23 14029 4 BALL JOINT ASM, 1/4-28 HD

24 73426 2 SPRING, EXT. .43D X 2.50L X .047W

25 14820 2 BUSHING, FLANGED 3/4 ID X 7/8 OD

26 87008 1 WASHER, 1/4 ID X 1-1/4 PD PLTD

27 90006 1 ZERK, GREASE

RD, 1/4-28 X 2-1/2 SST

SERIAL

NO.

NOTES:

MOUNTING OF VAC SHOE

AND CASTER SPRING

ASSEMBLY.

VAC SHOE

CABLE ASM.

(REF)

NOTE: USE 90° TOOL TO VERIFY

THAT VAC SHOE IS ADJUSTED

CORRECTLY TO 90° ANGLE.

NOTE: SPRING ATTACHES

FROM CASTER TO VAC SHOE

BRACKET (BOTH SIDES).

NOTE: ANGLE

DJUSTMENT NUTS

FOR VAC SHOE.

VGR2 98953 05/05/05

27

Page 28

WWW.MANUALS.WS

WWW.MANUALS.WS

TANK, COVER & HARDWARE ASSEMBLY

58

535747

34

8

94061

*10

26

27

47

34

59

60

29

16

64

68

7

29

14

51

28

18

41

62

42

44

67

43

36

26

40

26

22

20

21

17

63

19

11

56

66

35

5

30

55

54

29

6

27

70

23

1

33

69AB

27

26

4

32

13AB

52

49

49

31

41

15

25

50

52

48

12

38

39

45

24

46

37

17

3

27

*65

2

28

VGR2 98953 06/28/03

Page 29

WWW.MANUALS.WS

WWW.MANUALS.WS

TANK, COVER AND HARDWARE PARTS LIST

REF PART NO. QTY DESCRIPTION

1 75393 1 TANK ASM., VGRB W/ DIAPHRAGM

2 27472 1 COVER, LEFT TANK VGRB

3 27673 1 COVER, BELT GUARD VGRB

4 27684 1 COVER, BATTERY COMP.

5 27473 1 COVER, RIGHT SIDE TANK

6 28054 1 DOME, VOYAGER TANK

7 27557 1 COVER, SIGHT WINDOW

8 35199 1 GASKET, VGR SIGHT WIN

9 62345 2 PLATE, REAR FRAME TANK MNT

10 34305 1 FLOAT, SHUT OFF

11 78122 1 TUBE, 1.5 PVC X 1.88 IN

12 40090 2 HOSEBARB, 1/4 MPT X 3/8 45°

13A 66251 1 PIVOT ASM., TANK RIGHT

13B 66250 1 PIVOT ASM., TANK LEFT

14 39476 1 HOSE ASM., 2” DIA.

15 70085 4 SCREW, 1/4-20 X 1/2 PPMHS

16 39481 1 HOSE, 2” VAC X 20”

17 20064 2 CLAMP, 2.0” WORM GEAR X .312W

18 20063 1 CLAMP, 1.75” WORM GEAR X .312

19 04032 1 ADAPTER, 1.5 MPT X 1.5FS PVC

20 78499 1 TETHER, DRAIN PLUG

21 40019 1 HOSEBARB, 1.5 DOUBLE MCHD

22 66227 1 PLUG, DRAIN HOSE

23 70481 6 SCREW, 1/4-20 X 3/4 BHCS

24 89059 2 WHEEL, PT20 SQG. BUMPER

25 89231 1 BRACKET ASM., GUIDE WHEEL

26 70361 14 SCREW, 10-32 X 1/2 PHTR PLT

27 87018 12 WASHER, #10 X 9/16 OD

28 70201 4 SCREW, 1/4-20 X 3/4 FHMS PLTD

29 20046 3 CLAMP, 2.25” WORM GEAR

30 73198 1 SPACER, 2.26 OD X 1.91 ID X 2.51

31 41305 1 HINGE, VGR DOOR LEFT

32 41303 1 HINGE, VGR DOOR RIGHT

33 40036 1 HOSEBARB, 1.5 MPT X 1.5

34 81379 2 FITTING, SEALED BULKHEAD

35 35095 1 GASKET, VGRB DOME

36 39408 1 HOSE, SOL. DRAIN W/ STAMP

37 39472 1 HOSE, 1.5 DRAIN X 24”

38 20042 4 CLAMP, 3/8 ID HOSE

39 39451 2 HOSE, 3/8 NYLOBRAID X 11

40 87016 4 WASHER, #10 LCK EXT STAR

41 70011 5 SCREW, 1/4-20 X 5/8 HHCS

42 14899 1 BRACKET, DRAIN HOSE PLUG

43 40053 1 HOSEBARB, SOL. HOSE MTG

44 57047 1 NUT, 1/4 X 20 NYLOCK PLTD

45 70368 2 SCREW, 3/8-16 X 1.75 HHMS

46 57022 2 NUT, 3/8-16 LOCK SS

47 57044 2 NUT, HEX BRASS 3/8 NPT

48 87151 6 WASHER, 1/4 SPLIT LOCK

49 87025 8 WASHER, 1/4 LOCK EXT STAR SS

50 57236 2 NUT, 10-32 HEX NYLOCK BLK.

51 40051 1 HOSEBARB, 3/4 MPT X 1” HOSE PV

52 41304 2 BRACKET, VOYAGER HINGE

53 57104 8 NUT, 10-24 W/ STAR WASHER

54 78211 1 TUBE, 1.5 PVC X 3.31

55 04075 1 ADAPTER, 1.5 FPT X 1.5 FS PVC

56 34140 1 FILTER, VAC INTAKE 10 MESH

57 140193 1 BRACKET, VGR FLOAT

58 70209 2 SCR, 10-32 X 1.75 PHME PLTD

59 87131 2 WASHER, #80R #10 FLAT W/NEO.

60 20005 1 CLAMP, 5/16 NYLON

61 140194 1 BRACKET, RECOVERY HOSE MTG.

62 87013 1 WASHER, 1/4 ID X 5/8 OD SS

63 28056 1 DOME ASM., VGR2

64 04082 1 ADAPTOR, Y-FITTING MODIFIED

65 70088 2 SCREW, 10-32 X 1/2 PPHMS

66 500009 1 LABEL, WARNING EXPLOSION

67 66380 3 PLATE, SPACER

68 70114 2 SCR, #10 X 3/4 TYPE B

69A 50917 1 LABEL, TANK RIGHT

69B 50918 1 LABEL, TANK LEFT

70 50941 1 LABEL, WINDSOR LOGO

SERIAL NO.

FROM

NOTES:

VGR2 98953 06/28/03

29

Page 30

WWW.MANUALS.WS

WWW.MANUALS.WS

WIRING DIAGRAM VOYAGER 2

30

VGR2 98953 10/19/02

Loading...

Loading...