Page 1

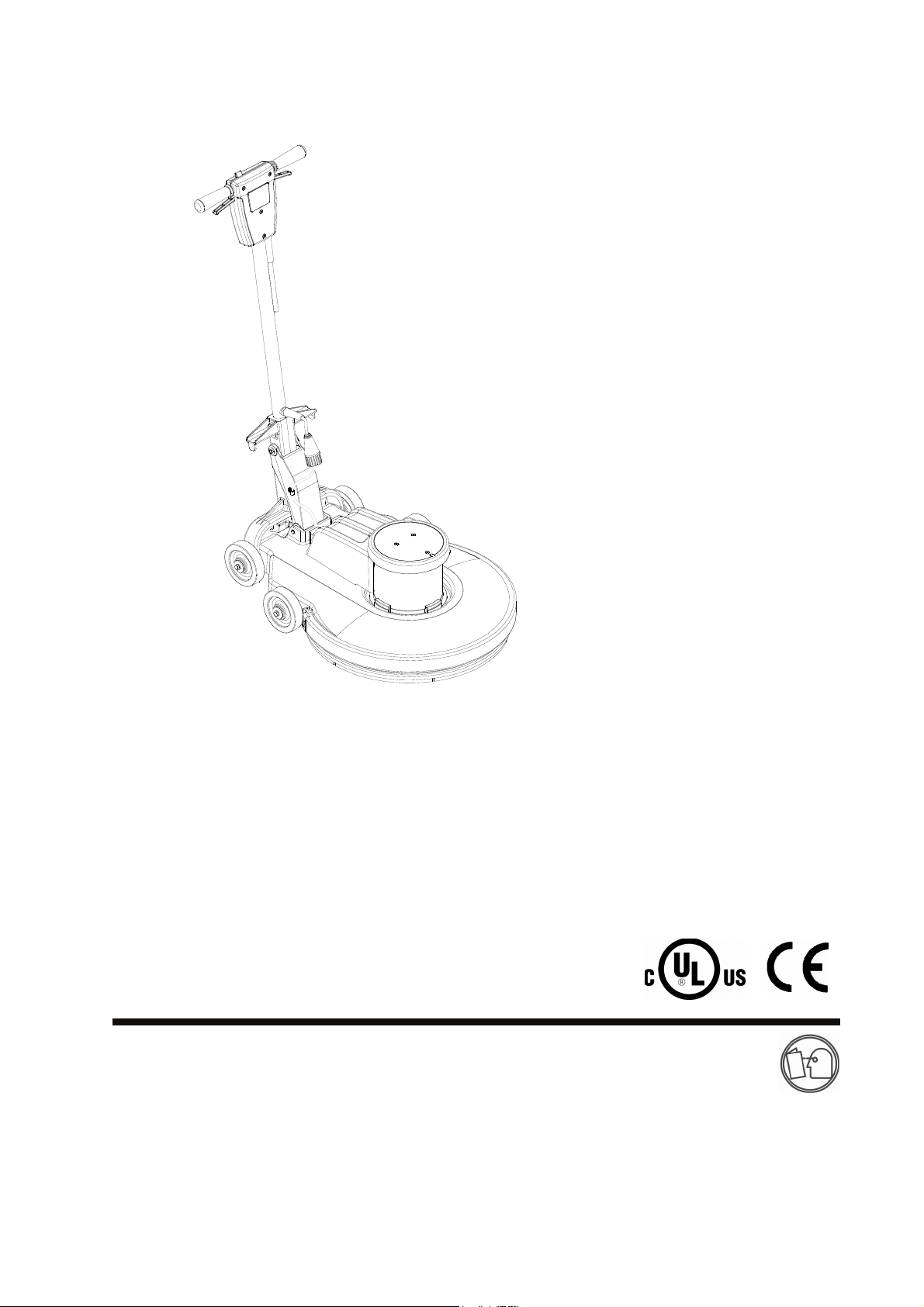

HIGH SPEED BURNISHER

MODELS:

LB2000I LB2000IA UB2000F LB2000

10090200 10090210 10090620 10090190

Operating Instructions (ENG)

86309600-B

01/29/09

Page 2

MACHINE DATA LOG/OVERVIEW

Model:

Date of Purchase:

Serial Number:

Sales Representative:

Address:

Phone Number:

OVERVIEW

The High Speed Burnisher is a mains powered, portable floor burnisher intended for commercial

use. The appliance can be fitted with a variety of pads to perform various floor care functions. The

appliance employs active dust control, and automatically adjusted pad pressure.

2

86309600 (2000) BURNISHER 10/08/08

Page 3

TABLE OF CONTENTS

3

Machine Data Log/Overview................................2

Table of Contents.................................................3

HOW TO USE THIS MANUAL

How to use this Manual........................................1-1

SAFETY

Important Safety Instructions ...............................2-1

Hazard Intensity Level..........................................2-2

Grounding Instructions.........................................2-3

OPERATION

Technical Specifications.......................................3-1

Handle Installation................................................3-2

Operation..............................................................3-3

Pad Driver Installation..........................................3-3

MAINTENANCE

Machine Troubleshooting.....................................4-1

Wiring Diagram/Service Schedule.......................4-2

GROUP PARTS LIST

Deck Group..........................................................5-1

Electrical...............................................................5-3

Handle-Lower.......................................................5-5

Handle-Upper.......................................................5-7

Motor....................................................................5-9

Pad/driver...........................................................5-11

Wiring-120V ....................................................... 5-13

Wiring-230V ....................................................... 5-14

Suggested Spare Parts......................................5-15

86309600 (2000) BURNISHER 10/08/08

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized dealers.

When placing an order for parts, the machine

model and machine serial number are important.

Refer to the MACHINE DATA box which is filled

out during the installation of your machine. The

MACHINE DATA box is located on the inside of

the front cover of this manual.

The SAFETY section contains important

information regarding hazard or unsafe practices

of the machine. Levels of hazards are identified

that could result in product or personal injury, or

severe injury resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

The PARTS LIST section contains assembled

parts illustrations and corresponding parts list. The

parts lists include a number of columns of

information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- PRV NO. - Reference No.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – If this column

has an (*) and a Reference number,

see the SERIAL NUMBERS page in

the back of your manual. If column

has two asterisk (**), call manufacturer

for serial number. The serial number

indicates the first machine the part

number is applicable to. The main

illustration shows the most current

design of the machine. When a boxed

illustration is shown, it displays the

older design.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The number on the lower left corner of the

front cover is the part number for this manual.

1-1

86309600 (2000) BURNISHER 10/08/08

Page 5

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To r educe the risk of fire, electric shock, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer’s recommended components and attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water,

return it to an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine

near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories,

shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

During operation, attention shall be paid to other persons, especially children.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, unplug the machine.

Do not handle the plug or machine with wet hands.

Do not unplug machine by pulling on cord. To unplug, grasp the plug, not the cord.

Do not use with damaged cord or plug. Follow all instructions in this manual concerning grounding the

machine.

Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp e dges or

corners.

Do not pull/run machine over cord. Keep cord away from heated surfaces.

Connect to a properly grounded outlet. See Grounding Instructions.

If the supply cord is damaged it must be replaced by a special cord from an authorized service agent.

Unplug before cleaning or servicing.

Operational hazard may occur when running the machine over the supply cord.

This appliance has been designed for use with pads specified by the manufacturer. The fitting of other pads

may affect its safety.

This machine is for dry use only and shall not be used or stored outdoors in wet conditions.

SAVE THESE INSTRUCTIONS

86309600 (2000) BURNISHER 10/08/08

2-1

Page 6

SAFETY

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices, which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices, which could result in minor personal injury or product or

property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist.

Locate all safety devices on the machine. Please take the necessary steps to train the machine

operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use approved replacement parts.

2-2

86315410 (BU2000) BURNISHER 10/08/08

Page 7

SAFETY

p

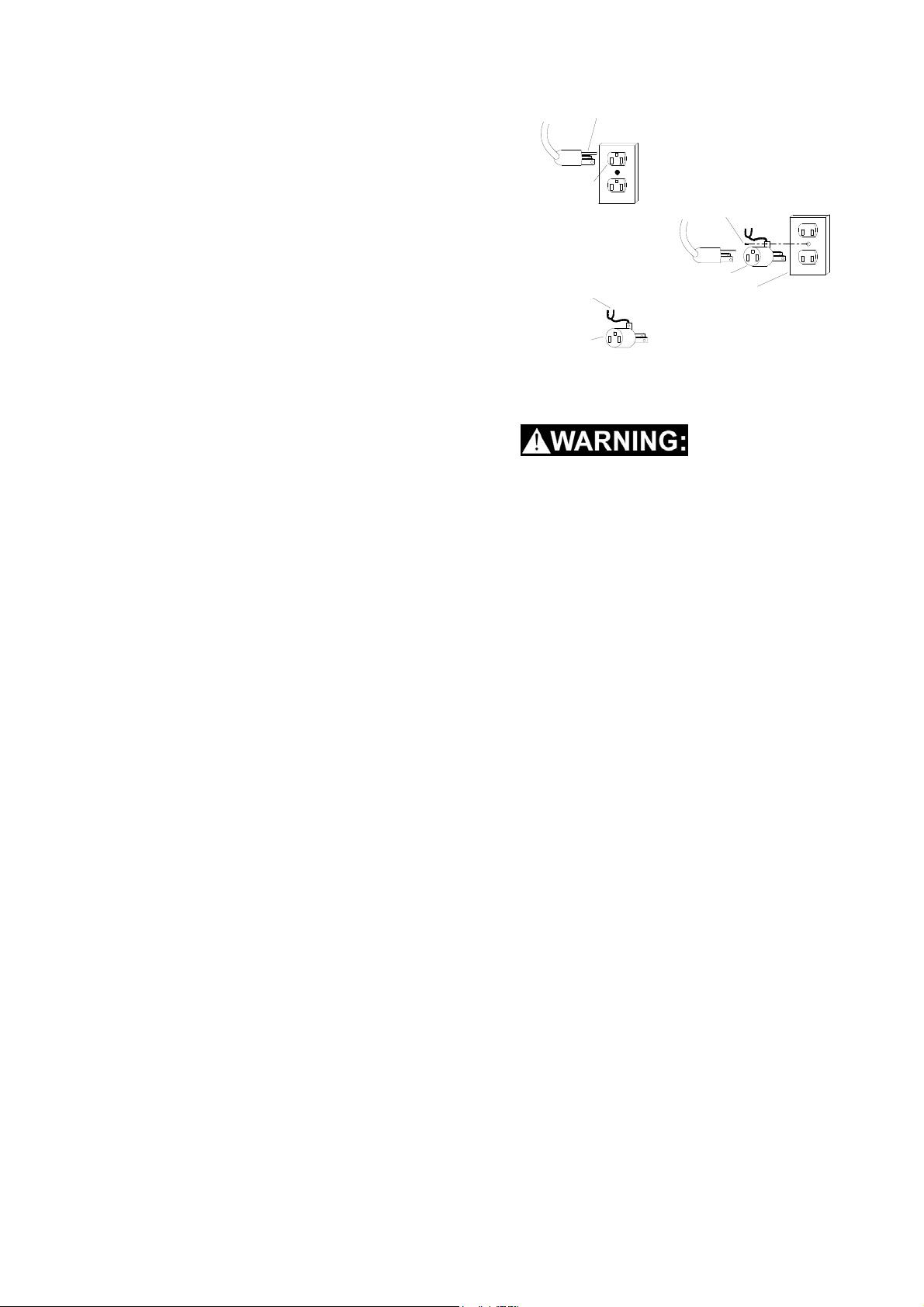

GROUNDING INSTUCTIONS-120V

THIS PRODUCT IS FOR COMMERCIAL USE

ONLY.

ELECTRICAL:

In the USA this machine operates on a one 15

amp nominal 120V, 60 hz, A.C. power circuit. The

amp, hertz, and voltage are listed on the data label

found on each machine. Using voltages above or

below those indicated on the data label will cause

serious damage to the motors.

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to

reduce the risk of electric shock. This appliance is

equipped with a cord having an equipmentgrounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet

that is properly installed and grounded in

accordance with all local codes and ordinances.

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like the

plug in “Fig. A”. A temporary adaptor that looks

like the adaptor in “Fig . C” may be used to

connect this plug to a 2-pole receptacle as shown

in “Fig. B”, if a properly grounded outlet is not

available. The temporary adaptor should be used

only until a properly grounded outlet (Fig. A) can

be installed by a qualified electrician. The green

colored rigid ear, lug, or the like extending from

the adaptor must be connected to a permanent

ground such as a properly grounded outlet box

cover. Whenever the adaptor is used, it must be

held in place by a metal screw.

86309600 (2000) BURNISHER 10/08/08

Grounding Pin

GROUNDING CONNECTION

USING AN ADAPTOR

Grounded

Outlet

FIGURE A

Tab for Grounding

Screw

Adaptor

FIGURE C

Note: Ada

tors are not allowed in Canada.

Metal Screw

Adaptor

Grounded

Outlet Box

FIGURE B

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in doubt

as to whether the outlet is properly grounded.

Do not modify the plug provided with the

appliance - if it will not fit the outlet, have a

proper outlet installed by a qualified

electrician.

2-3

Page 8

SAFETY

GROUNDING INSTRUCTIONS-230V

THIS PRODUCT IS FOR COMMERCIAL USE

ONLY.

ELECTRICAL:

The amp, hertz, and voltage are listed on the data

label found on each machine. Using voltages

above or below those indicated on the data label

will cause serious damage to the motors.

EXTENSION CORDS:

If an extension cord is used, the wire size must be

at least one size larger than the power cord on the

machine, and must be limited to 50 feet (15.5m) in

length.

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to

reduce the risk of electric shock. This appliance is

equipped with a cord having an equipmentgrounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet

that is properly installed and grounded in

accordance with all local codes and ordinances.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in doubt

as to whether the outlet is properly grounded.

Do not modify the plug provided with the

appliance - if it will not fit the outlet, have a

proper outlet installed by a qualified

electrician.

2-4

86309600 (2000) BURNISHER 10/08/08

Page 9

SAFETY

2

-

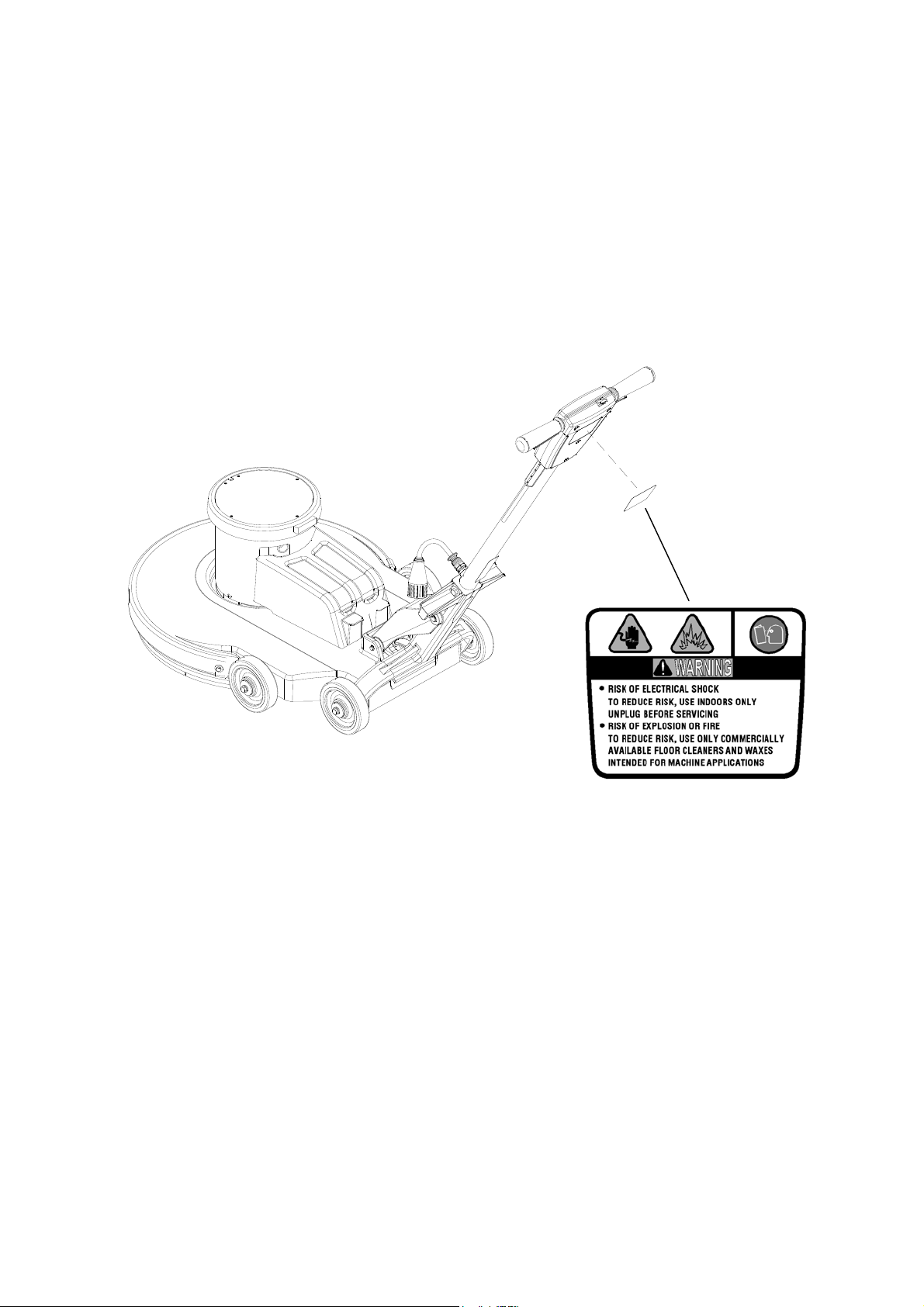

SAFETY LABEL LOCATION

NOTE: These drawings indicate the location of safety labels on the Machine. If, at any time,

the labels become illegible contact your authorized representative for prompt replacement.

86309600 (2000) BURNISHER 10/08/08

WARNING LABEL

P/N 86219740

PRV NO. 500194

5

Page 10

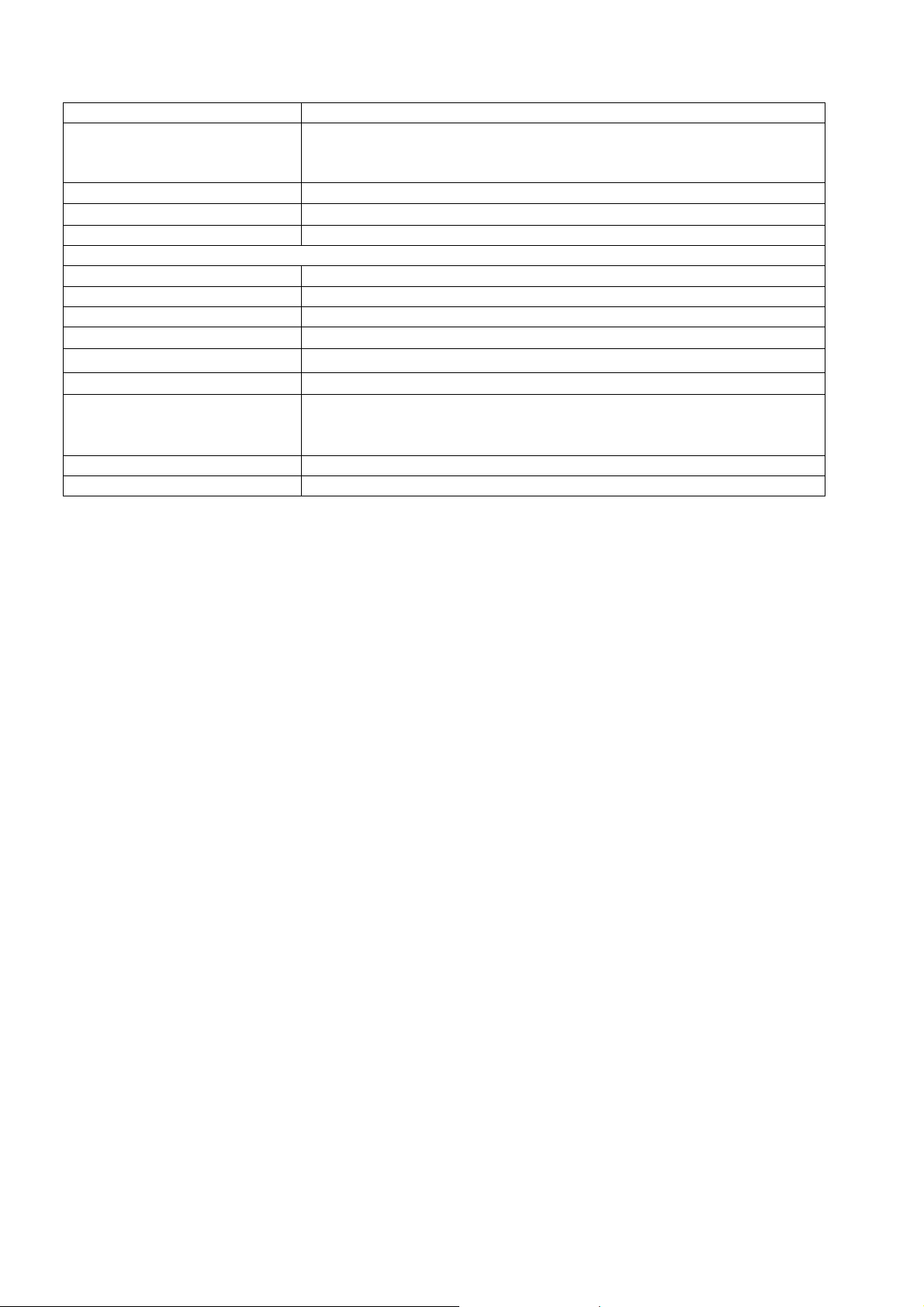

TECHNICAL SPECIFICATIONS

ITEM DIMENSION/CAPACITY

Construction Heavy-duty die cast aluminum deck with heavy-duty rubber

bumper, tubular steel self adjusting handle with die cast aluminum

handle housing.

Motor 1.5 hp

Transmission Direct drive from motor shaft.

Pad speed 2000 rpm

Electrical system:

LB2000I, LB2000IA 230 volts, 50Hz

LB2000, UB2000F 115 volts, 60Hz

Cable

Switches Dual levers with safety lock.

Pad Holder

Wheels

Handle

Dimensions (L x W x H) 32” [81.3 cm] X 23.9” [60.2 cm] X 48.4” [122.9 cm]

Pad size (See note) 20” diameter x 1” thick

NOTE: Always use a pad, which has been designed for electric ultra high speed burnishing of at

least 2000 rpm.

The sound pressure level at the operator’s ear was measured to be 70 dBA. This was a nearfield,

broad-band measurement taken in a typical industrial environment on a tile floor. This appliance

contains no possible source of impact noise. The instantaneous sound pressure level is below 63 Pa.

75’ [22.9 m]

∅20” [50.8 cm] flexible disc

Four ∅5” [∅12.7 cm], 1.25” [3.2 cm] wide, non-marking tread.

∅1.5” [∅3.8 cm] tubular steel, self adjusting handle consistently

maintains full contact with the floor, and easy to use thumb

activated safety lock.

3-1

86309600 (2000) BURNISHER 10/08/08

Page 11

OPERATION

2

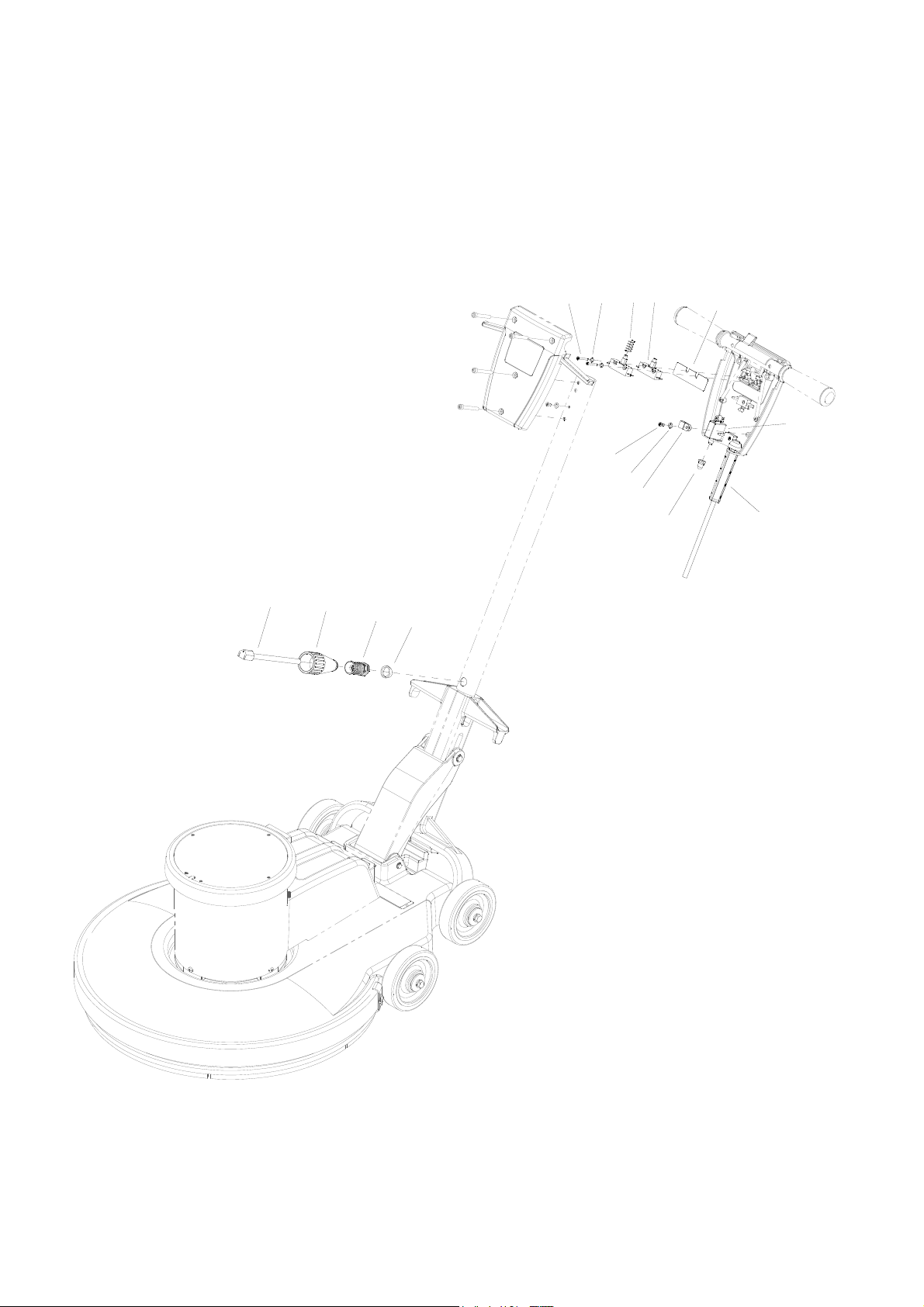

HANDLE

ASSEMBLY

2

3

1

HANDLE

MOUNT BRACKET

HANDLE INSTALLATION

The machine is shipped with handle unassembled.

Follow these steps for installation:

1. Remove handle and deck assembly from

carton.

2. Remove bolt (item 3), washers (item 2), and

nut (item 1) from deck assembly.

3. Install Handle Assembly as shown.

DECK

ASSEMBLY

4. Slide Bolt (item 3) through, washers (item 2),

Handle Mount Brackets and Handle Assembly as

shown. Tighten bolt (item 3) and nut (item 1) until

the handle cannot twist in the mount bracket (4550 foot pounds).

5. Check handle for movement up and down.

6. Plug cord into handle cord receptacle.

86309600 (2000) BURNISHER 10/08/08

3-

Page 12

OPERATION

CONTROLS

1. Safety Lock – Prevents unintended operation

of the machine.

2. Switch Levers – Turns machine on/off.

22

OPERATION

For indoor use only.

When using the pad, always keep the machine

moving when in contact with the floor.

High starting torque. Hold machine firmly with

both hands.

1. Ensure that the pad driver is in good shape.

Install or change pad if necessary.

2. Plug the machine into a wall outlet as

described in the grounding instructions.

3. Release latch, lower the handle and move into

position.

4. Push the safety lock forward, unlocking the

switch levers.

5. With the safety lock forward, squeeze one or

both of the switch levers, turning the machine

on. (These levers can be operated

independently of each other). The safety lock

will not re-engage until both levers are

released.

1

6. To stop the machine, release the switch

levers.

7. Do not let machine rest on pad. When

finished with the machine, return handle to the

storage position.

NOTE: The machine is equipped with a circuit

breaker to protect the motor in the event an

overload condition occurs. The circuit breaker is

located on the handle. Push the reset button to

restart the machine. If the breaker trips again,

correct the cause of overloading before

proceeding.

DAILY MAINTENANCE

1. Inspect power cord for wear. To prevent

electrical shock replace cords with frayed or

cracked insulation immediately.

2. Place machine in the storage position.

3. Check pad condition. Change if soiled or torn.

PAD INSTALLATION

1. Lay machine back, exposing the under

side.

2. Remove center lock by turning counter-

clockwise.

3. Ensure pad is centered on pad driver. Pull

pad to edge of pad driver in several

directions to check for proper

engagement.

4. Replace center lock by turning clockwise

firmly compressing the center of the pad.

HANDLE

RELEASE LATCH

3-3

86309600 (2000) BURNISHER 01/29/09

Page 13

MACHINE TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Machine will not run

Electrical shock

Repeated circuit breaker tripping

Tripped circuit breaker Reset

Circuit breaker tripped in

building.

Fuse in motor is blown Replace

Power switch failure Test switch for continuity and

Faulty power cord Replace

Equipment not grounded Follow grounding instructions

Receptacle not grounded Have an electrician inspect

Internal wiring problem Ensure that the machine wiring

Mechanical problem Higher amp draws indicate a

Faulty circuit breaker Test circuit for continuity. Replace

Pad not centered Re-center pad.

Check and reset

CAUTION: To reduce the risk of

electrical shock, unplug the

machine before opening fuse

holder.

Fuse will only open under extreme

conditions.

Investigate cause before replacing.

replace if necessary.

exactly.

building’s wiring.

matches the appropriate wiring

diagram. Replace any wires or

components, which are shortcircuiting.

mechanical problem; find the

problem before using the machine.

circuit breaker if necessary.

MAINTENANCE

Excessive vibration

Damaged or unevenly

worn pad.

Damaged pad driver. Replace.

86309600 (2000) BURNISHER 10/08/08

Replace pad. Do not rest machine

on pad when not in use.

4-1

Page 14

MAINTENANCE

y

SERVICE SCHEDULE

MAINTENANCE DAILY MONTHLY

Check pad wear to prevent buildup of chemicals

Check pad driver system for damage

Check handles, switches, and knobs for damage

Store with pad off the floor

Check all bearings for noise

Check skirt/bumpers for damage and replace as necessar

Check overall performance of machine

*

*

*

*

*

*

*

4-2

86309600 (2000) BURNISHER 10/08/08

Page 15

NOTES:

86309600 (2000) BURNISHER 10/08/08

4-3

Page 16

DECK

1

2

3

5

6A-B

4

7

8

9

11

10

5-1

15

14

16

12

13

86309600 (2000) BURNISHER 10/08/08

Page 17

DECK

REF PART NO. PRV NO. QTY DESCRIPTION

1 86216280 140449 4 BUMPER, RUBBER

2 86217520 27918 1 COVER, FILTER BAG

3 86001390 140441 1 BAG, DUST (PACKAGE OF 10 BAGS)

4 86223430 67463 1 RETAINER, CORD

5 86276810 70738 2 SCR, M5 X .8MM X 10 MM PPHMS BLK

6A 86217640

6B 86289010

7 86216270 140423 1 BUMPER, EXTRUSION

8 86137340 87211 2 WASHER, M6 FLAT BLK

9 86276570 70691 2 SCR, M6 X 25 HHMS

10 86271550 57220 2 NUT, M6 X 1 HEX NYLOCK PLTD

11 86216600 27871 2 CAP EXTRUSION

12 86215020 05156 2 AXLE, FRONT

13 86225720 87203 4 WASHER, 14MM ID X 36 MM OD

14 86137280 87054 2 WASHER, M8 FLAT DIN125A PLT

15 86136640 70262 2 SCR, M8-1.25 X 20 HHMS PLTD

16 86288740 70709 2

29244BLU

29244GRY 1 DECK, 20 IN BURNISHER, GRY UB2000UF

1 DECK, 20 IN BURNISHER, BLUE

SCR, SET M8 X 1.25 X 8MM CUP

POINT

SERIAL NO.

FROM

LB2000,

LB2000I,

LB2000IA

NOTES:

86309600 (2000) BURNISHER 10/08/08

5-2

Page 18

ELECTRICAL

1

2

4

3

15

14 A-B

5

6

7

12

13 A-C

11

10

9

8

5-3

86309600 (2000) BURNISHER 10/08/08

Page 19

ELECTRICAL

REF PART NO. PRV NO. QTY DESCRIPTION

1 86136780 70801 2 SCR, M 3.5 X 40 PHTF TYPE B

2 86137290 87057 2 WASHER, M4 SHAKEPROOF

3 86224750 73993 1 SPRING, COMP, .48OD X .91L

4 86007110 72123 2

5 86288450 70689 1 SCR, M4.8 X 10 HHTF TYPE B

6 86137330 87208 1

7 86198450 20005 1 CLAMP, 5/16 NYLON

8 86227300 730021 1 SPACER, POLISHER HANDLE

9 86224930 730012 1 STRAIN RELIEF, 14/3 STRAIGHT

10 86215430 14407 1 BOOT, CORD END

11 86216940 23209 1 CORD SET, 14/3 X 38 IN,SJT, BLK

12 86002010 14942 1 BOOT, 3/8 CIRCUIT BREAKER

13A 86234140 23154 1 CORD SET, 14/3 ST C 75’ YLW

13B 86216950 23212 1

13C 86216970 23217 1 CORD SET, SAA/3 1.5MM X 75 LB2000IA

14A 86312460 - 1 BREAKER, 14A, VDE CIRCUIT

14B 86291460 - 1 BREAKER, 11A, VDE CIRCUIT

15 86215140 140674 1 BARRIER SHEET

SWITCH, 25A SPST 125-250V

SNAP

WASHER, M5 SHAKEPROOF

PLTD

CORD SET, EURO 1.5MM X 75

BLK

SERIAL NO.

FROM

LB2000,

LB2000,

LB2000I,

NOTES:

UB2000F

LB2000I

UB2000F

LB2000IA

86309600 (2000) BURNISHER 10/08/08

5-4

Page 20

HANDLE-LOWER

16

15

17

14

19

17

18

24

7

23

6

9

1

2

5

11

3

4

13

12

22

10

8

5-5

25

86309600 (2000) BURNISHER 10/08/08

21

20

8

Page 21

HANDLE-LOWER

REF

1 86276810 70738 1 SCR, M5 X .8MM X 10 MM PPHMS BLK

2 86198450 20005 1 CLAMP, 5/16 NYLON

3 86223490 67468 2 RING, 10MM EXT SNAP, DIN 471

4 86222570 66340 1 PIN, DOWEL 10MM DIA X 124 MM LG

5 86215480 140421 1 BRACKET, HANDLE LINK

6 86223500 67469 2 RING, 13MM EXTERNAL SNAP

7 86288760 87234 2 WASHER, 14MM ID X 36MM OD X 2MM

8 86225720 87203 6 WASHER, 14MM ID X 36 MM OD

9 86224310 730052 1 SPACER, LINKAGE

10 86288770 500542 1 LABEL, HANDLE RELEASE

11 86221720 51358 1 LATCH, HANDLE

12 86226020 89206 2 WHEEL, 5D X 1.25 X 13MM ID GRY

13 86224590 730055 1 SPRING, 180 DEGREE TORSION

14 86215390 140420 1 BLOCK, SPRING COMPRESSION

15 86224580 730054 1

16 86005770 57119 1 NUT, 3/8-16 HEX NYLOCK

17 86279510 87171 2 WASHER, 3/8 FLAT

18 86274000 70069 1 SCR, 3/8-16 X 3 HHCS GR5

19 86215470 140419 2 BRACKET, HANDLE MOUNT

20 86136640 70262 2 SCR, M8-1.25 X 20 HHMS PLTD

21 86137280 87054 2 WASHER, M8 FLAT DIN125A PLT

22 86215030 05157 1 AXLE, REAR

23 86223710 70733 4 SCR, M6 X 25 SHCS PLTD

24 86225010 730053 1 STRIKER, LATCH

25 86288740 70709 2 SET SCR, 8MMX1.25MM CUP PT

NOTE: Grease contact surfaces of Items 14 and 15 as necessary when servicing.

PART

NO.

PRV

NO.

QTY DESCRIPTION

SPRING, COMP 1.140 OD X 8.40 L X

.150 W

SERIAL

NO.

NOTES:

86309600 (2000) BURNISHER 10/08/08

5-6

Page 22

HANDLE-UPPER

12

13

4

6

5

1

2

10

8

11

10

3

7

8

9

5-7

86309600 (2000) BURNISHER 10/08/08

Page 23

HANDLE-UPPER

REF PART NO.

1 86136670 70686 2 SCR, M6 X 45 SHCS BLK

2 86136680 70687 2 SCR, M6 X 50 SHCS BLK

3 86224740 73990 2 SPRING, EXT, .50D X 3.5L

4 86225370 78437 1 TUBE, GRIP HANDLE

5 86004070 36196 2 GRIP, POLISHER HANDLE

6 86005160 51327 2 LEVER, SWITCH

7 86136350 57274 4 NUT, M6 HEX FINISH

8 86279080 87058 3 WASHER, M4 FLAT DIN125A PLT

9 86311810 - 1

10 86288450 70689 3 SCR, M4.8 X 10 HHTF TYPE B

11 86225390 78473 1 TUBE, HANDLE

12 86311820 - 1

13 86005150 51326 1 LOCK, SAFETY HANDLE

PRV

NO.

QTY DESCRIPTION

HOUSING, POLISHER HANDLE RR,

CD

HOUSING, POLISHER HANDLE FRT,

CB

SERIAL

NO.

NOTES:

86309600 (2000) BURNISHER 10/08/08

5-8

Page 24

MOTOR

3

2

1 A-B

6

5-9

4

5

86309600 (2000) BURNISHER 10/08/08

Page 25

REF

1A 86312260 - 1

1B 86312250 - 1

2 86217490 27884 1 COVER, MOTOR 1.25HP

3 86223690 70702 3 SCR, M5 X .8 X15MM BLK

4 86010790 87163 4

5 86006920 70507 4

6 86219610 48082 1 KEY, 3/16 SQ X .85 LG CRS

MOTOR COMPONENTS (NOT SHOWN)

PART NO.

86223460 67499 1 RECTIFIER, 50A 1000V BRIDGE

86001720 140785 1 BRUSH SET (PKG OF 4)

86003660 34378 1 FUSE

86003670 34379 1 FUSE HOLDER

86223980 09134 1

86001020 09135 1 SEALED BALL BRNG, MOTOR

PART

NO.

PRV

NO.

PRV

NO.

QTY DESCRIPTION

MOTOR, 115V 1.5HP

20000RPM

MOTOR, 230V 1.5HP

20000RPM

WASHER, 3/8 SPLIT LOCK

PLTD

SCR, 3/8-16 X 3/4 HHCS GR5

PLT

QTY DESCRIPTION

SEALED BALL BRNG, 25 MM X

52MM

SERIAL NO.

FROM

SERIAL NO.

FROM

BOTTOM MOTOR

TOP MOTOR

LB2000, UB20000F

LB2000I, LB2000IA

BEARING

BEARING

MOTOR

NOTES:

NOTES:

86309600 (2000) BURNISHER 10/08/08

5-10

Page 26

PAD/DRIVER

8

1

9

2

4

7

5

6

3

5-11

86309600 (2000) BURNISHER 10/08/08

Page 27

2

REF

1 86010720 87086 4 WASHER, M10 X 30 PLTD

2 86006920 70507 4 SCR, 3/8-16 X 3/4 HHCS PLT

3 86222470 64108 1

4 86279210 87102 1 WASHER, 5/16 ID X 1-1/4 OD

5 86274590 70244 1 SCR, 5/16-24 X 1/2 HHMS SS

6 86276740 70720 3 SCR, #10 X 3/8 PPHST TYPE B

7 86246740 51353 1 LOCK, PAD DRIVER BLUE

8 86223660 730065 1

9 86216230 730074 1 BRUSH, STRIP (PACKAGE OF 6)

PART

NO.

PRV

NO.

QTY DESCRIPTION

PAD DRIVER, 20 INCH

BURNISHER

SHROUD, ASM. 20 IN

BURNISHER

SERIAL NO.

FROM

INCLUDES ITEMS

PAD/DRIVER

NOTES:

6 & 7

INCLUDES ITEM 9

86309600 (2000) BURNISHER 10/08/08

5-1

Page 28

WIRING-120V

3

CORD SET

WHT

GRN

120V AC 15A

BLK

-CB1

1

-SWITCH-SWITCH

GRN

REF PART NO. PRV NO. QTY DESCRIPTION

1 86311830 - 1

WIRE, 125MM, BLK/14,

76029X76029

SERIAL NO.

FROM

NOTES:

WHTWHT

BLKBLK

-MOTOR

GRN

M

5-1

86309600 (2000) BURNISHER 10/08/08

Page 29

4

120V AC 15A

CORD SET

WHT

GRN

WIRING-230V

BLK

-CB1

1

EMC FILTER

-SWITCH-SWITCH

EMC FILTER2

GRN

REF PART NO. PRV NO. QTY DESCRIPTION

1 86311830 - 1

WIRE, 125MM, BLK/14,

76029X76029

SERIAL NO.

FROM

WHTWHT

BLKBLK

-MOTOR

GRN

NOTES:

M

86309600 (2000) BURNISHER 10/08/08

5-1

Page 30

SUGGESTED SPARE PARTS

PART NO. PRV NO. DESCRIPTION

86224740 73990 SPRING, EXT .5OD X 3.5L

86224750 73993 SPRING, COMP .48OD X .91L

86007110 72123 SWITCH, 25A SPST 125-250V SNAP

86312460 - BREAKER, 14A, VDE CIRCUIT 120V

86291460 - BREAKER, 11A, VDE CIRCUIT 230V

86223460 67499 RECTIFIER, 50A 1000V BRIDGE

86003660 34378 FUSE

86003670 34379 FUSE HOLDER

86001020 09135 SEALED BALL BRNG, MOTOR

86246740 51353 LOCK, PAD DRIVER BLUE

86001390 140441 BAG, DUST (PACKAGE OF 10 BAGS)

86215390 140420 BLOCK, SPRING COMPRESSION

86216230 730074 BRUSH, STRIP (PACKAGE OF 6)

86001820 14404 BRUSH SET 120V

86001720 140785 BRUSH SET (SET OF 4) 230V

SERIAL NO.

FROM

NOTES:

5-15

86309600 (2000) BURNISHER 10/08/08

Page 31

86309600 (2000) BURNISHER

Loading...

Loading...