Windsor Trident Compact TC17BJ, Trident Compact TC17PK, Trident Compact TC20BJ, Trident Compact TC20X, Trident Compact TC20PK Operator's Manual

...Page 1

TRIDENT COMPACT 17"

24VDC (S/N

5000001 & BELOW) - 98096

I

QMST

.

.

.for

Continuous

Improwmant.

Windsor's

Puolity

Monopwmt

System

is

CduJ

IS0

9001.

Battery Powered

Floor Scrubber

with Removable

MODELS

TC17,

TC20,

TC17BJ, TCmBJ,

Battery System

TC2OX,

TC17PK, TC20PK

dm

WINDSOR

I

N

DUSTR

I

ES

,

INC.,

iasi

W

.

S~MM

AVO,

engkwood

co

miio

wc~~xa-iw~mx

sos-~i7

inims

b

Page 2

2

TRIDENT COMPACT

17

"

24VDC (S/N

5000001 & BELOW)

Operator Safety Instructions

WARNING:

Read the instruction

manual before operating machine.

Operate

thls

machine only from the rear

of

machine.

CAUTION: For

Indoor Use Only.

To

prevent possible damage to the floor whe using the

Brush use water or other approved cleaning solution

while operating.

When using the pad option, always keep the machine

moving when

in

contact with

the

floor.

Use caution when operating the machine on a ramp

or incline.

Do

not

turn

or leave

thls

machine unattended

on a ramp or incline.

Make sure all Warning and Caution labels are legible

and properly attached

to

the machine.

Store machine Inside. Keep

the

electrical components

of

the machine dry.

Lead acid batteries generate gasses which can cause

an explosion. Keep sparks and flames away from the

batteries, Charge

the

batteries only

in

a

well ventl-

lated

area.

Wear

eye protection when working near batteries.

Do

not

put

any

type

of

metal objects across the battery

terminals or on top of the batteries.

Maintenance and repairs

must

be

done by qualified

personnel only. Maintain adjustments on machlne

as per specifications noted

In

the service manual.

Machine

can

cause an explosion when operated near

flammable vapors and materials.

Page 3

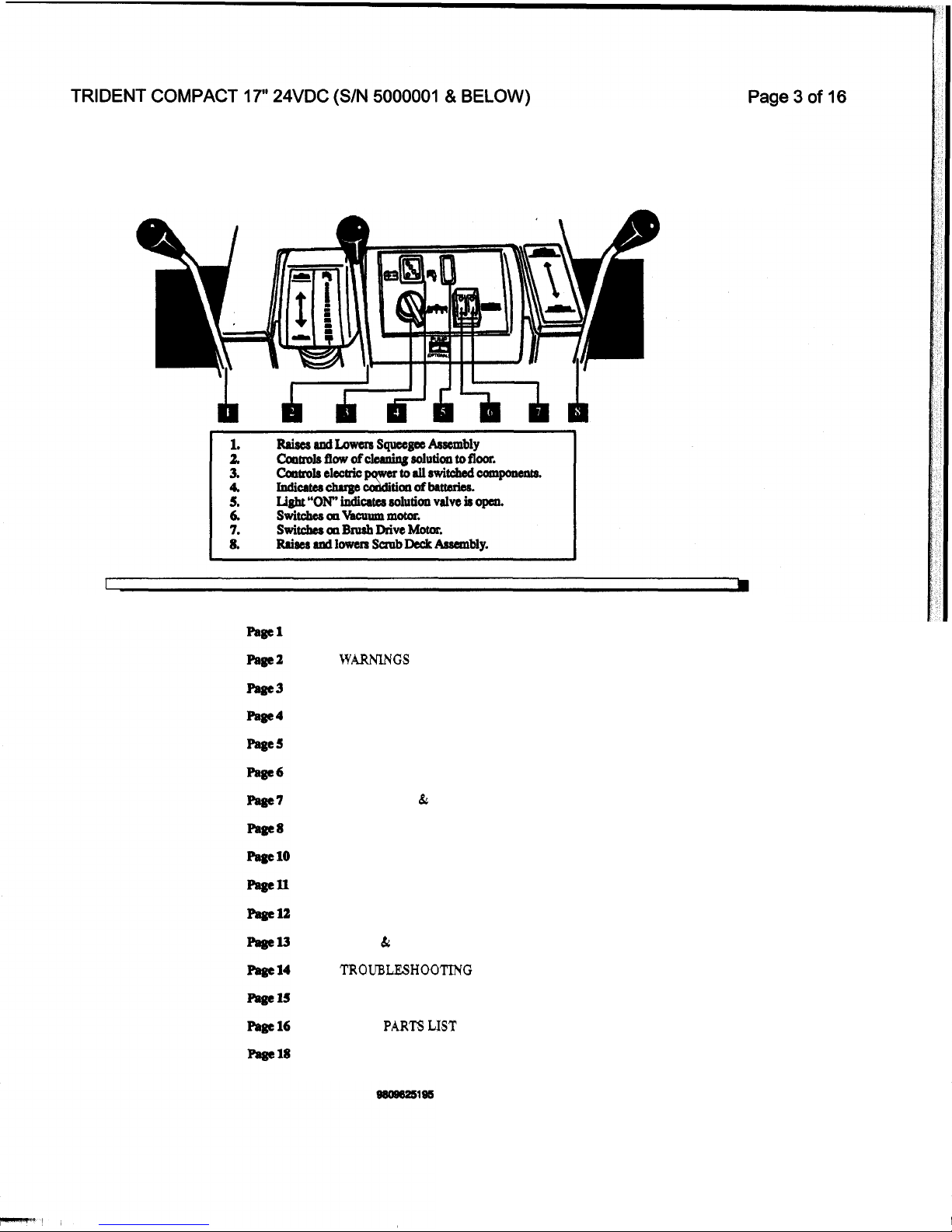

CONTROLS

CONTENTS

INTRODUCTION

WARNINGS

CONTROLS

MACHINE PREPERATION

OPERATING MACHINE

-

CHARGING

SERVICING

TANKS, VAC

k

FRAME

SCRUB

DECK

ELECTRICAL CONTROLS

MECHANICAL CONTROLS

SQUEEGEE

PUMP 6 STANDARD MODEL

TROUBLESH00"ING

WIRING DIAGRAM

SPARE

PARTS

UST

WARRANTY

3

Page 4

TRIDENT COMPACT 17" 24VDC (S/N

5000001

&

BELOW)

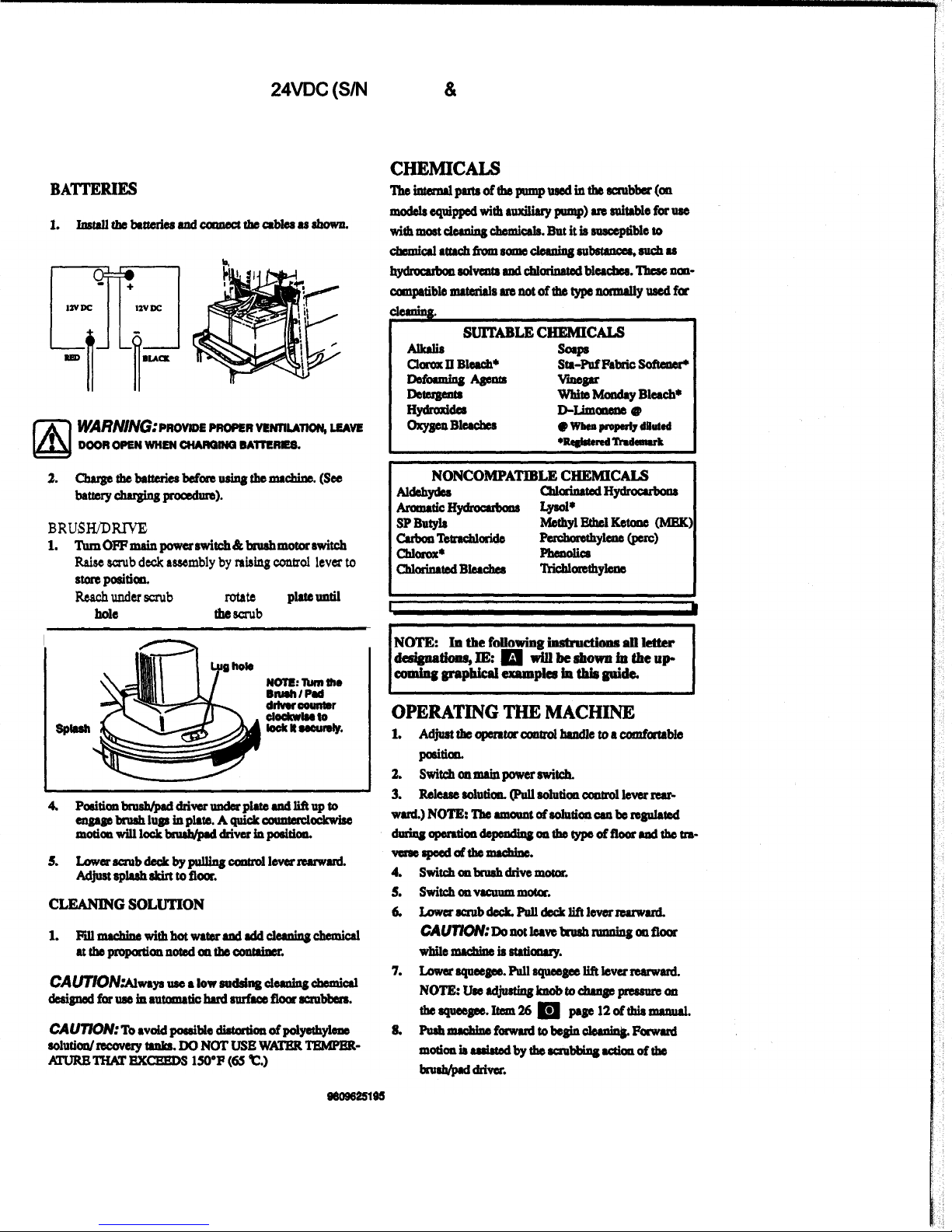

MACHINE PREPARATION

BA'ITERIES

BRUSWDRWE

PAD ASSEMBLY

2.

Raisewubdcclcaswmblybynhingoantral

leverto

3.

1.

TUm

omdv

dtch

&

bN&

mOtar

Ewitch

EtOaPdti~

Reachunder

shlb

deck

and

rotato

drive

plate

until

a

lug

hole

is

visible

through

the

wub

deck

sight

hole.

I

1

Sp-

4

9809825195

Page 5

TRIDENT COMPACT

17

"

24VDC

(S/N

5000001

&

BELOW)

OPERATING

MACHINE WITH

ACCESSORY

TOOLS

The

m

floa

tool

for

wet

pick-up

can

be

wed

011

mo&la

equipped

with

the

arurilLuy

pump

kit

option.

(NOTE:

Fao-

tayinstallcd

option

ally.)

1.

Remove

vac

hose

&om

aqucegca

and

camcctto

rcctaaoly

v.c

hose,

nsiq

metrl

hoac

caupler.

2.

~aolutionboscfranIcas~toolto

solution

outlet

nipple

located

at

lawer

right

hand

~ofrwprmet.

make

aule

dome

is

in

place.

3.

checlrsolutiontrnlcfordeaniugaolu~oarad

4.

switchmrminpawer$wi~

5.

Switchmauxiliuypumpradvacuumswitchea.

WNW":

Do

not

mriteh

on

bN8h

motor

when

opemtlng

mchine

with

t

€&I

acceuory

took.

REGULARMAINTENANCE

BEFORE STARTING

WORK

PERIOD

1.

Discoamcct

battuy

chtnget.

NOTE:

Dhamect

the

mllovitlg

the

"Dc'

Qlger

plug

fram

the

macbim.

"AC"

power

cord

fiom

ths

wall

xeceptacle

befm

2.

Check

water

level

in

battaies.

Add

&tilled

water

a$

needed.

3.

AItrchbmhordrivepadtodrivaplrte.

4.

CheckVrr:hOse~

'on

at

aqucegw

ahoc.

5.

Qleck

squeepc

blades

for

war.

6.

mumacbincwithhotwatermdidddcllningcbamicrl

at

the

proportiomnoted

OII

the

contabr.

NOTE:

Use

a

low

audaing

clernsr

dd@

for

we

in

automatic

hardsurfaccflooraaubbaa.

BEFORESTORWGMACHINEAT

THE

END

OF

WORK PERIOD:

1.

2.

Dninboth

mlutimand

mcoMly

tanks

radrinsccl~.

Aftarerch

use,

rinw

tmlwithfruh

Wlter.

paiodicrlly

inrpsct

thCrccOvSytdUUidCCOa~~if~,,l

wum

wta

rhould

be

dirporod

ofpropdy.

Removs

dams.

lift

at

nwt

Maembly

to

allow

~ClytUlktorirdIy.

upside aownahrng

on

wall.

Horpitrl

onds

Viludd8

Q

11-10

bkreh

toe

rolutioll.

3.

4.

hUOW

bnuh

OrdrlVC

p&

from

ddVC

md

5.

Wipcdown8xtsriaofmachincwithdampcloth.

6.

Raiaesquesgscasssmbryto'ktae"positioe

7.

BATTERIES - CHARGING

AND

MAINTENANCE

BATIERY CHARGING PROCEDURE

WARN/NG.Lemd

add

bplteriw

generate

guseb

which

can

cause

an

explosion.

m

Keep

sp.rk

and

flames

away

from

Mterles.

NO

SMOKING.

Alwaya

wear

eye

nwbatterisr.

Qroe

the

bnttdal

only

in

a

well

vcntilrtsd

(hrgc

battdcd.

(Sec

Battery

chruglno

proadms)

when working

area.

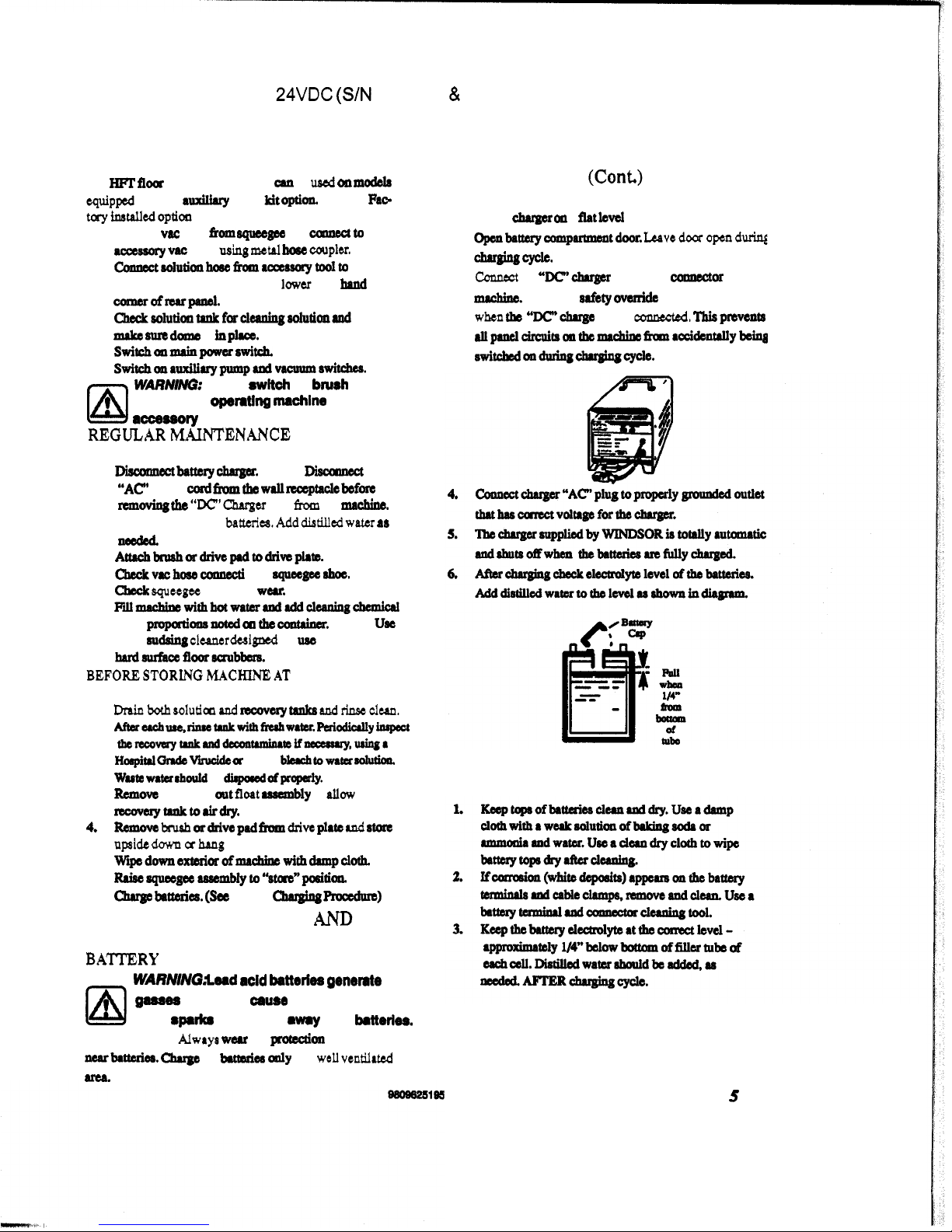

BATTERIES - CHARGING

AND

BATTERY CHARGING PROCEDURE

1.

2.

opsnba~comp~tdggp.

Lervedoaropcn~

MAINTENANCE (Conk)

Set

the

dqpr

011

a

flat

level

dace.

chargingcycle.

coanact

the

"Wchuger

plug

to

the

camctor

on

the

machine.

NOTE:

A

safety

ovaride

switch

is

activated

whml

th

"Dc.chrge

plug

is

comnscted.

Tbisprevcnta

allplnelcircpitsonthcrmchino

fmmrcCi&dybdqs

swiw

011duriIlgcht.gingcycla.

3.

BATTERY MAINTENANCE

5

Page 6

TRIDENT COMPACT 17" 24VDC (S/N

5000001

81

BELOW)

SERVICING

THE

POWERTEC

SCRUBBER

CAU77ON;

Before making

and adjustments

or

repairs

to

the

machi

ne...

1.

Onlyqulifieedrnrintsnuvxpsrsool3alrrato

w-reprita.

2.

Makembattarychuga3;1discormeotad

Make

sum

111

switchw

am

"

OFF'.

d

RCmOWboUMarepuireda-

main

battWyldS~barraitfJwhen~nprirs

toelcarical~tcm..

5.

Raferto~dia~whenreplrcinselectricll

e1ectricalpartsarepilingelactricrlsyStam.

3.

SQUEEGEE ASSEMBLY

lb

remove

squeegee

assembly.

..

ADJUSTMENT

OF

SQUEEGEE

VACUUM

MOTOR

1.

Di~tbiatteryI~andrCm~h~ea

fromcoanpsI.rmcnt.

2. Remove

(6)

acmws

holding

motor/

plate

3.

DiscoPlnsct

vacmotorlud

lpfromcamctar

4.

==lblY~rscoverYtmL.

a

and

lift

out

VIC

motor/

plate

rsscmbly.

Check

motor

brushes.

When

WOPIL

to

3/8"

npb

bothbnlshe4J.

Lp

-

_.

..

PUMP

ASSEMBLY

(On

mod&

equipped with

auxiliary

pump)

1.

2.

Removb

batteries

and

qmgce

u#mbly.

Lay

the

mrchinsanside.

Discamsctpump

motaluds.

Remove

(4)

acmws

holdingpllmptochrssis.~

EOlUtiOIl

boscsfmmDpumphsrd~

udliffautpump

dnwiogfornpl~~

Oa

SOLUTION

STRAINER

1.

Aninlinasolutianstninarhlocateduadcr~

behind

left

WW.

Remow

sadimsntbowl

ruad

(LQasn

paiodicdly

Md

rinse

clean

withhot

water.

Be

anful

not

to

misplrcs

the

Oaskct.

SCRUB DECK / BRUSH

MOTOR

Page 7

TRIDENT COMPACT

17”

24VDC (S/N 5000001

&

BELOW)

8

48-

47

I

-

.

-

..

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2s

26

27

28

29

30

31

32

33

34

35

PART

#

70251

75152

50363

51138

27416

87090

571

05

75153

70393

50485

28049

57026

87147

62433

3S141

14844

73704

35088

571

04

70088

28048

35060

70114

78294

34258

36150

20046

271

88

68061

4001

9

20002

39037

27282

3-

27079

DESCRIPTION

Sol

Scrow,

114-20 x 3.5

HHMS

lank,

Solution

Label,

soMionwamiq

Lid,

Solution

tank

cord,

Sdutkn

IM

Washer,

114

Irt

Nut,

1/4-90

hox wlwu

Tank,

Recovrry

Set

Screw,

1/4-20 x 1.25L

Label.

WINDSOR

logo

Float

Asm,

Vac

shut-ol1

NU.

8/32

Ny-kok

Washer,

#12

sod

Plate,

Float

Qasket,Rnk

Screen,

Fbat

Q~ket,

Float

shut-Oll

Nut,

10-32wlatarwa8her

su.

10-32 x 3/4

Dome,

Mod.

Pt17

Gasket,

Dome

SU,

#lo x w4

pdyfast

Tube,

V.c

motor

Filter,

virc

Intala

Oukot,

Vac

motor

Clamp, 2.25

how

Cord,

Drain

tmm

plw

Plug,

Dnin

hoes

Horrbarb,

1.5 do&e

Clamp,

r

Nylon

Hore,

1

.5 x 24’

drain

CM, 1.5

dlp

x

1.5

ho6e

HO6Okm.W

CM,l.SwMIlom

w

KEY

31

37

38

39A

39B

40

41

42

43

44

45

46

47

48

49A

498

so

51

52

53

54

56

56

57

5a

58

60

61

62

63

64

85

60

67

I

jo

-

60

Note

#67

goe8

tbru

Us

PART#

70085

87025

35122

53756

53198

62279

78004

76015

73491

62350

20605

87016

14696

701 14

50518

-19

34108

70010

61286

70020

23174

57116

70327

27268

om10

89068

73437

27408

70119

03058

57119

70266

88894

amia

DEBGRIPTION

Sw,

1/4-20 x 1/2

PHMS

Washer,

114

star

Gasket

vao

fan

soal

v.C

Mtr,

wl

COM.

24VDC 5.7

v.C

Mtr.,

24V 5.7 3

8tg.

Acwtrk

Plate,

vpc

dMdrr

Comctor,

2-pin

M-mdex

Temhl,

Female

pin

molex

Spwr,

Vac

motor

Plate,

he

OaVIc

aunR

5/16

nvkn

Wuk,

#lo

rtu

BtuBhmt,vacmotor

Sa,

110 x 9/4

Polyfrwt

W,

TC17

Wl,lGacomm~

Fnmr,

Main

Panel,

Rear

&r,

1/4-20 x 112

HHMS

We

mm,

TC

ban.

~c171po4~ca~x

Nut

W32

wMu

wash

TCI~IPO*TCBDX

Sa,

1/4-2oX3/8THMs

mCIClrdwp-k

whoel,

(WMl

ltelllll)

Spacer.

Wheel

axlo

Collar.

Me

8.1

Set,

1/4-20

x

3l6

KCP

Arb,

whd

N~t,3&16kck

Screw,

3/18-16 x 1

HHCS

Win

hm.

TC17

vao

motor

8cr,

114-20 x 1 .5

HHCS

?&?xi

8008825185

7

Page 8

TRIDENT

COMPACT

17”

24VDC (S/N

5000001

&

BELOW)

SCRUB

DECK

8

9808825195

Page 9

TRIDENT COMPACT

17

"

24VDC (S/N

5000001

&

BELOW)

REAR

COMPARTMENT

1

i

Page 10

TRIDENT COMPACT

17”

24VDC

(S/N

5000001

&

BELOW)

ELECTRICAL

CONTROLS

Page 11

TRIDENT COMPACT

17”

24VDC (S/N

5000001

&

BELOW)

MECHANICAL

CONTROLS

Page 12

TRIDENT COMPACT

17

"

24VDC

(S/N

5000001

81

BELOW)

SQUEEGEE

81

SQUEEGEE

LIFT MECHANISM

9809825196

22

Page 13

TRIDENT COMPACT 17"

24VDC

(S/N

5000001 & BELOW)

OARTS

LIST:

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

18

17

18

19

20

21

22

23

24

25

26

27

-3a

)b

J

30

31

32

PART

NO.

27507

8701 8

57104

70409

20042

40013

40022

39380

7821 2

ir3983

41

184

59021

73405

27372

70066

14454

70081

38136

84112

14617

40027

99981

5601 2

8701

5

4001 4

9881 1

40034

65104

65105

56038

40040

99297

20(305

DESCRIPTION

Cable,

Solutlon

Washer,

#lo

9116

OD

Nut, 10-32 w/SW

Wher

Scr,

+lox

1R

PH HI-Lo

Clamp,

9/8

Hose

HoMbub,

9/8

MPT

X

1R

Hembarb,

1/2 MPTx

1R

Hose,

1R

x

5"

Cleor

Toe,

9/8

FPT

stralnerm,

solutlon

Houslng,

Strainer

O-RlW,

FIIW

Sd

Scmn,80M.sh

Cap,

Strainer

SU,

10-32

x

514

PHMS

me

valve

W,

10-24 X 1R

FHMS

Handh,

Vdva

LWW

Vdva,WFPT

Brkt

SduHon

Valve

Mtg.

Hosebarb,

W0

MPTx 1R

QOdeg

Hose,

1R

ID

Cleu

x

22'

Nlpple.

114

FPTQD

Waohor,

9116

IDx 1.06

Flat

Hosebarb,

114

MPT

x

W8

HOW,

14

"

Rubb@f

Hosebarb,

3B

MPTx

9/8

9wsg

Pump

Asm,

WKOM.

24V

sopd

Pump

Asm,

wlo

Corn.

24V

SOpd

Nlpple,

We

Close

Hoeebarb,

9/8

FPT

x 1R

Hose

How,

16.

Clw

cllvnp,

5/16"

dk

pkstlc

MODE!

STANDARD MODEL

I

I.

98080111~

13

Page 14

TRIDENT COMPACT

17

"

24VDC (S/N

5000001

&

BELOW)

TROUBLE4HOOTZNG GUZDE

PROBLEM PROBABLE

CAUSE

No

Power

Battery

cabla

cormded

at

b#ery

terminrlr.

Faulty

mein

switch.

Faulty

hty

owride

switch

Vacuum

motor

Circuit

Bxeaker

@ipped.

does

not

run.

Locwccanmactl

'oa

Faulty

vlc

Switch.

Faulty

Vac

My

Faulty

Vac

Cidt

BlUllk&

Motorbnrsheswan

Faulty

Bmh

Switch.

Faulty

Br~h

Reby.

Faulty

Brush

Circuit.

Be

Matortm18heswarn.

Solution

Light

Loose

carraectioas

does

not

mrk.

Faulty

solnti00LigtIt

CORRECTIVE ACTION

Reset

vac

motor

circuit

kslksr

(25

amp).

checlrmotaludcollnectionsatterminrls.

RemawlSrdsrad~switchfa~ty.Reph

aSn#dd

Withrminmitchu0N"mdvrcswit&*'0N"checLvoltrylertpoiats

B

&

I.

Voltage

ahouIdbe22RdVDC.

WNI

main

switch

"ON"

and

vllc

switch

"ON"

check

voltage

at

pointa

B

&

J.

Wtage

rhonldbe

22/26

VDC.

checkmotakuahss.Rephw~womto3/8".wlthbatterits

filly

charged

and

motor

smu8d,

apply

battssy

voltage

dirrcrly

to

motot.

The

amp

draw

of

motor

&odd

be

between

18-24

amp.

Qeckfaloase~

'QU

at

solution

lisbt.

solution

switch

and

at

vac

faarelay

grrmnd.

Rtmove

rishr

d

apply

dirad

voltage

CMVDC)

to

light.

~eplrce

light

as

ncadad

Adjust

solution

light

switch.

14

Page 15

I

I

I

TRIDENT COMPACT

17”

24VDC (S/N

5000001

&

BELOW)

WIRING DIAGRAM

a;!%

i

r@

mm

im

I

I

I

i

I-

I

iw

I

I

I

I

I1

I

II

I

PUMP

PUMP

ASSEMBLY

115V

65019

PUNlP

MOTOR

53188

8809825195

15

Loading...

Loading...