Page 1

FLOOR SWEEPER

MODEL: TRACER FS

QTFSD (Diesel Version)

QTFSG (Gas Version)

Operating Instructions

Read these instructions before using the machine

M

98349 11/01/03

Page 2

MACHINE DATA LOG

2

Address: _______________________________________________________________________________________________

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

DEALER NAME ________________________________

OPERATIONS GUIDE NUMBER ___________________

PUBLISHED __________________________________________

Copyright 1995 Windsor Industries, Printed in USA

YOUR DEALER

Name: __________________________________________________________________________________________________

Phone Number: _________________________________________________________________________________________

OVERVIEW

The Tracer Floor Sweeper is a gas or diesel powered, ride-on floor sweeper intended for industrial

use. The appliance sweeps the floor while vacuuming the dirt into a holding tank.

QTFSG/QTFSD 98349 05/15/03

Page 3

TABLE OF CONTENTS

3

Machine Data Log..........................................2

Table of Contents...........................................3

HOW TO USE THIS MANUAL

How to use this Manual..................................1-1

SAFETY

Important Safety Instructions.........................2-1

Hazard Intensity Level...................................2-2

Safety Label Location.....................................2-3

OPERATIONS

Technical Specifications................................3-1

Controls..........................................................3-2

Machine Operation.........................................3-7

Pre-Run Machine Inspection......................3-7

Starting Machine.........................................3-7

Sweeping.....................................................3-7

Operating on Grades ..................................3-7

Stopping Machine.......................................3-8

Storing Machine..........................................3-8

Dumping the Hopper...................................3-8

Hopper Safety Arm.....................................3-8

Machine Jacking............................................3-9

Machine Tie-Downs .......................................3-9

MAINTENANCE

Hydraulics......................................................4-1

Directional Control System............................4-2

Throttle Neutral Position.................................4-2

Main Broom. ...................................................4-3

Side Broom ....................................................4-5

Belts...............................................................4-6

Differential Drive.............................................4-9

Skirts. .............................................................4-9

Hopper..........................................................4-11

Brakes/Tires.................................................4-13

Battery Information.......................................4-14

Hydraulic Schematic....................................4-15

Hydraulic Troubleshooting...........................4-15

Propelling Troubleshooting..........................4-16

Machine Troubleshooting.............................4-17

Service Schedule.........................................4-18

GROUP PARTS LIST

Frame Group................................................5-1

Differential Group.........................................5-3

Front Wheel Drive Group.............................5-5

Impeller Group.............................................5-7

Impeller (Wet Sweep Bypass).....................5-9

Rear Clip Group...........................................5-11

Console Group.............................................5-13

Brake Group.................................................5-15

Steering Group.............................................5-17

Rear Suspension Group..............................5-19

Engine Group (GAS)....................................5-21

Engine Group (DIESEL-1)...........................5-23

Engine Group (DIESEL-2)...........................5-25

Drive Group..................................................5-27

Side Broom Group.......................................5-29

Filter Group..................................................5-31

Hydraulic Group...........................................5-33

Hopper Group..............................................5-35

Main Broom Lift Group.................................5-37

Main Broom Group.......................................5-39

Instrument Panel Group (GAS)...................5-41

Instrument Panel Group (DIESEL)..............5-43

Wiring Group (GAS).....................................5-45

Wiring Group (DIESEL)...............................5-47

Horn Wire Asm.............................................5-49

Wiring Schematic (GAS)..............................5-51

Wiring Schematic (DIESEL)........................5-52

Engine Service Parts (GAS)........................5-53

Engine Service Parts (DIESEL)...................5-54

HD Air Cleaner.............................................5-55

Notes............................................................5-57

Warranty ......................................................5-58

QTFSG/QTFSD 98349 05/15/03

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized Windsor

dealers. When placing an order for parts, the

machine model and machine serial number are

important. Refer to the MACHINE DATA box which

is filled out during the installation of your machine.

The MACHINE DATA box is located on the inside of

the front cover of this manual.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

DEALER NAME ______________________________

OPERATIONS GUIDE NUMBER __________________

PUBLISHED ________________________________

The model and serial number of your machine is on

the bottom back-end of the machine.

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

Copyright 1995 Windsor Industries, Printed in USA

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

- Hydraulics

- Directional Control System

- Throttle Neutral Position

- Main Broom

- Side Broom

- Belts

- Differential Drive

- Skirts

- Hopper

- Brakes/Tires

- Battery Information

- Hydraulic Schematic

- Hydraulic Troubleshooting

- Propelling Troubleshooting

- Machine Troubleshooting

- Service Schedule

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs. If

column has an asterisk (*), call

manufacturer for serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The 98# on the lower left corner of the front

cover is the part number for this manual.

QTFSG/QTFSD 98349 05/15/03

Page 5

IMPORTANT SAFETY INSTRUCTIONS

!

WARNING:

When using a gas or diesel powered appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

This machine is for dry use only and shall not be used or stored outdoors in wet conditions.

Use only as described in this manual. Use only manufacturer’s recommended brushes and attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water, return

it to an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine near

flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops

and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

During operation, attention shall be paid to other persons, especially children.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

The exhaust system gets very hot, keep hands, clothing and any items than can burn away from the engine

while hot.

This machine emits lethal exhaust gas. Ensure the working area is well ventilated.

Keep hands, feet, strings and ties away from all moving parts while the machine is in operation.

Keep hair, loose clothing, fingers and all parts of the body away from openings.

Disconnect battery before cleaning or servicing machine.

This machine not suitable for picking up hazardous dust.

Before use, all covers and doors shall be put in the positions specified in the instructions.

SAVE THESE INSTRUCTIONS

QTFSG/QTFSD 98349 05/15/03

2-1

Page 6

HAZARD INTENSITY LEVEL

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY . The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To identify actions which must be followed for safe operation or equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the

equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on

the machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep

sparks and flames away from the battery. Do not smoke around battery.

! WARNING

Hazardous voltage. Shock can result. Disconnect battery before working on machine. Only qualified

personnel should work inside machine. Always wear eye protection and protective clothing when working

on or near battery. Avoid skin contact with the acid contained in the battery.

Never allow metal to lie across battery tops.

Flammable materials or reactive metals can cause explosion or fire. Do not sweep these materials.

Engine emits toxic gases. Severe respiratory damage or asphyxiation can results. Provide adequate

ventilation. Consult with your regulatory agency for exposure limits. Keep engine properly tuned.

Machine can emit excessive noise. Consult with your regulatory agency for exposure limits. Hearing

loss can result. Wear hearing protection.

Lift arm pinch points. Keep clear of hopper lift arm. Raised hopper may fall. Engage hopper safety arm.

Moving belts. Keep away.

2-2

QTFSG/QTFSD 98349 05/15/03

Page 7

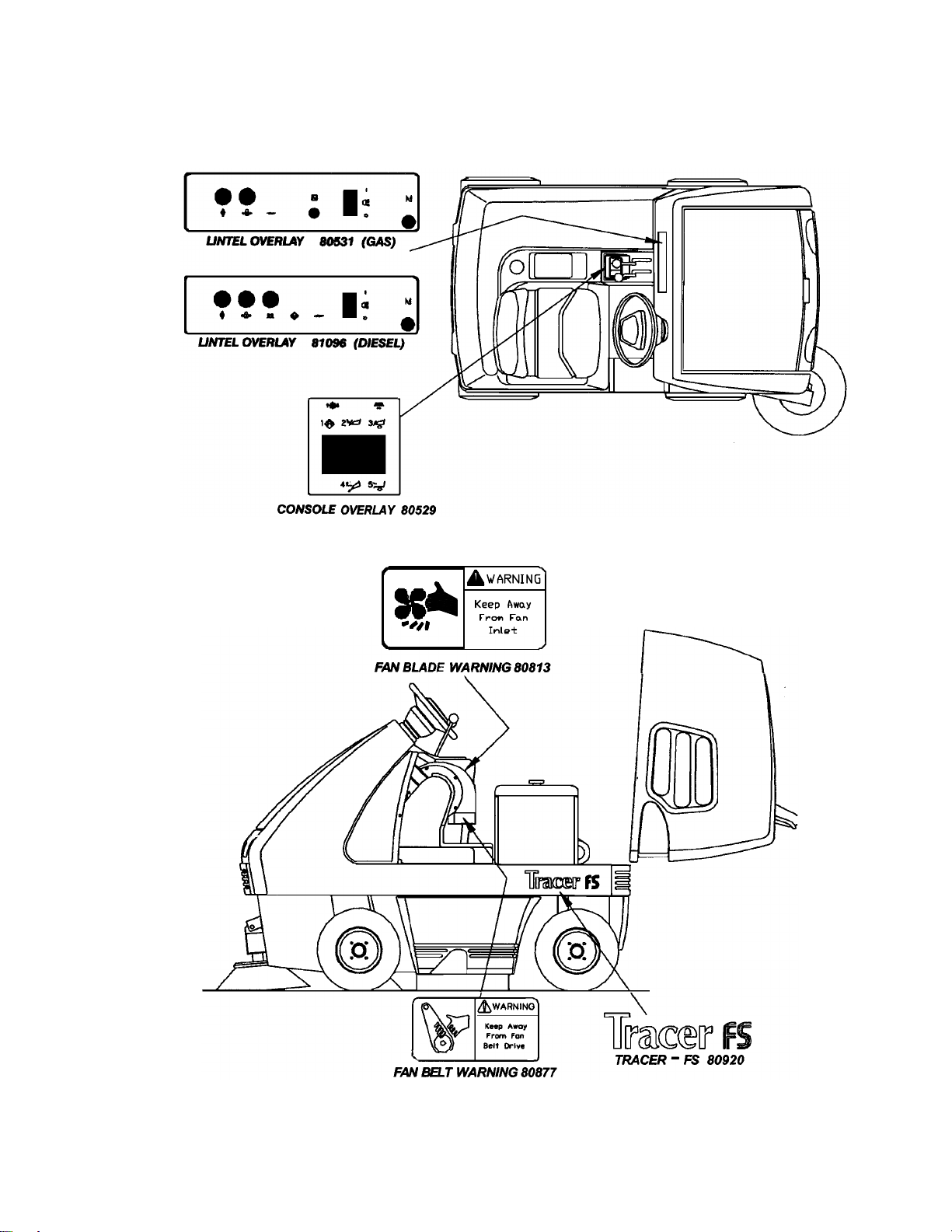

SAFETY LABEL LOCATION

NOTE: These drawings indicate the location of safety labels on the Tracer FS. If, at any time, the labels become

illegible contact your Windsor representative for prompt replacement.

QTFSG/QTFSD 98349 05/15/03

2-3

Page 8

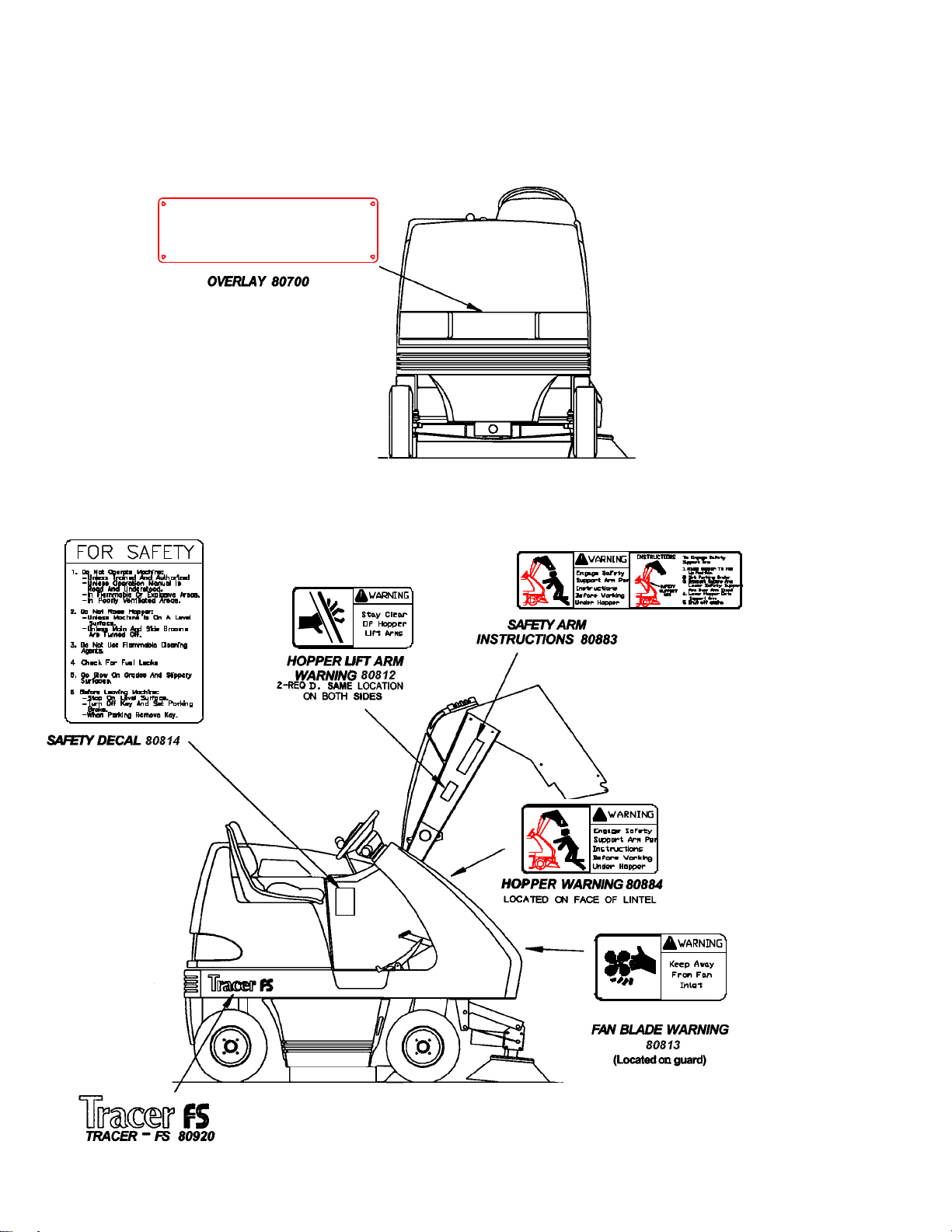

SAFETY LABEL LOCATION

NOTE: These drawings indicate the location of safety labels on the Tracer FS. If, at any time, the labels become

illegible contact your Windsor representative for prompt replacement.

2-4

QTFSG/QTFSD 98349 05/15/03

Page 9

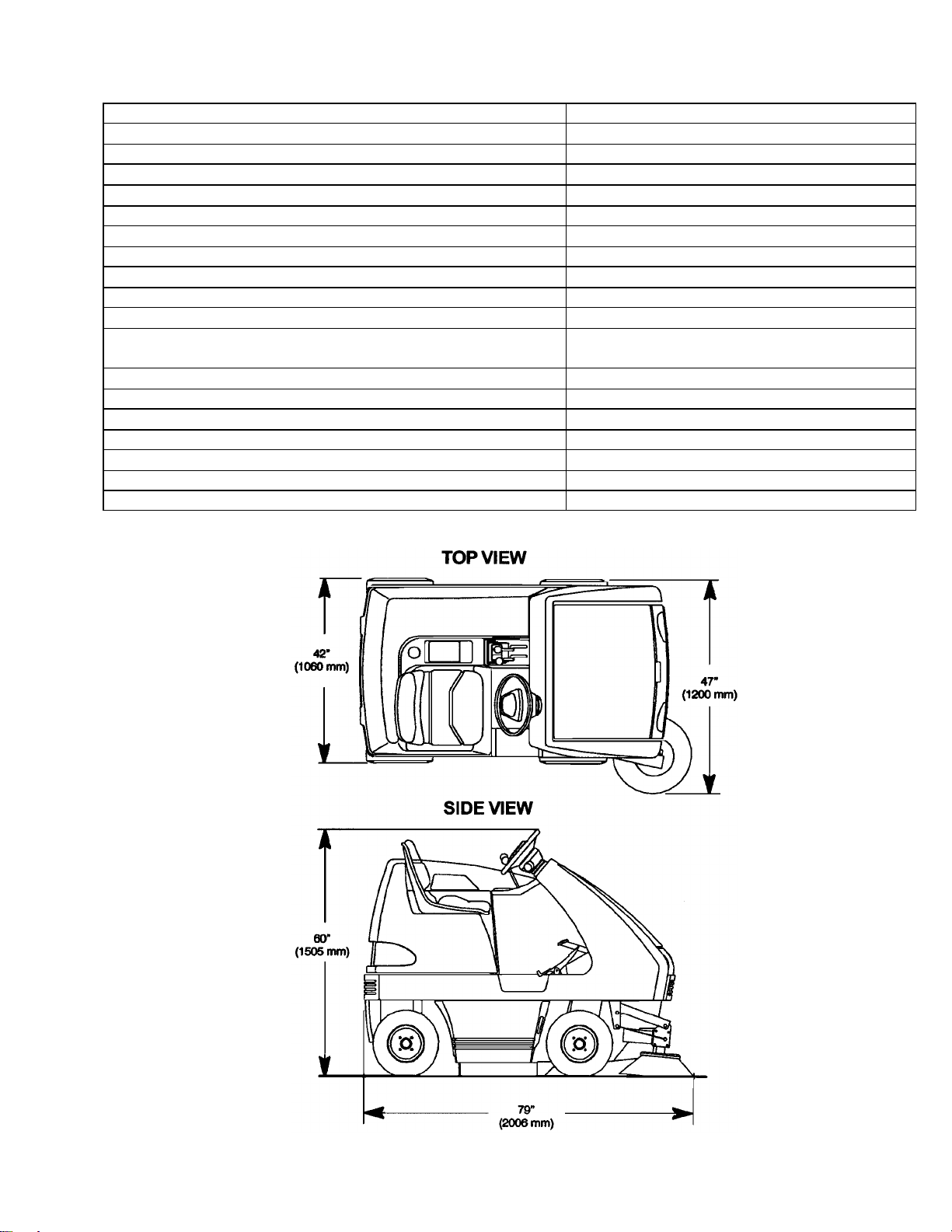

TECHNICAL SPECIFICATIONS

ITEM DIMENSION/CAPACITY

Power Source: Gas 20hp, 2 Cylinder, Liquid-Cooled

Diesel 14hp, 2 Cylinder, Liquid-Cooled

Suspension Floating I-Beam

Maximum Speed 10k/hour

Sweep Path 1200mm

Main Broom 812mm

Main Broom Diameter 355mm

Side Broom 510mm

Hopper Capacity 180 liters

Hopper Dump 1520mm

Dust Control 54ft2 (5m2) pleated filter with exclusive

cyclonic pre-filter

Brakes Dual mechanical disc with parking brake

Steering Rear wheel, rack & pinion

Tires 405mm dia. Pneumatic

Dimensions: Height 1505mm

Weight 1060 lbs.

Length 2006mm

Coverage 12,000m2/hr

QTFSG/QTFSD 98349 05/15/03

3-1

Page 10

CONTROLS

SPECIAL NOTES:

The sound pressure level at the operator’s ear was

measured to be 78 dBA for the QTFSG and 83 dBA for

the QTFSD. This was a nearfield, broad-band

measurement made during normal operation on a

composite tile floor with a white pad. This appliance

contains no possible source of impact noise. The

instantaneous sound pressure level is below 63 Pa.

The weighted root mean square acceleration at the

operator’s arms was measured to be below 2.5m/s

the QTFSG and below 3.2m/s2 for the QTFSD. The

weighted root mean square acceleration at the

operator’s posterior was measured to be below 0.5m/s

for the QTFSG and below 1.3m/s2 for the QTFSD. This

was a tri-axial, third-octave-band measurement made

during normal operation on a composite tile floor. The

measurement and related calculations were made in

accordance with ANSI S3.34-1986.

2

for

2

3-2

QTFSG/QTFSD 98349 05/15/03

Page 11

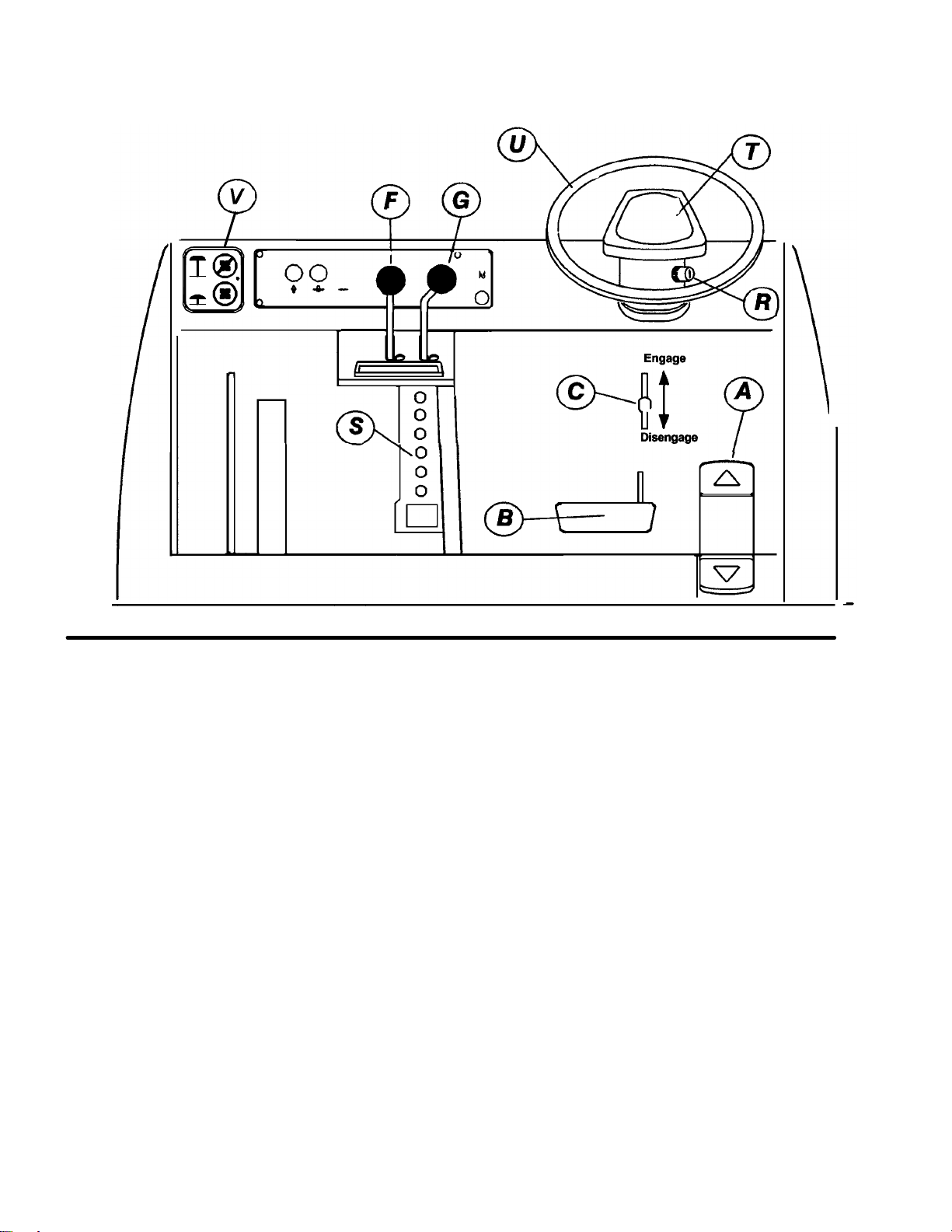

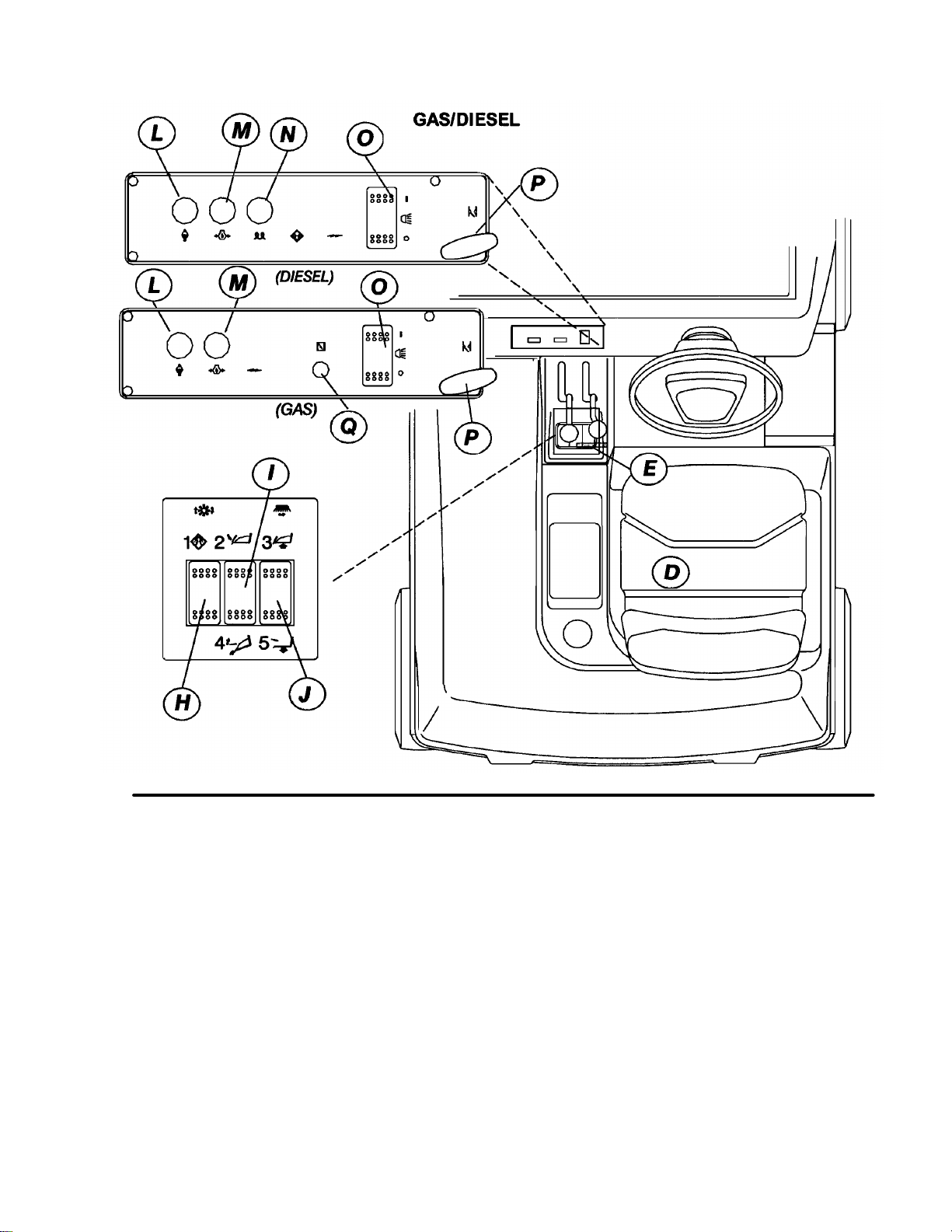

CONTROLS

A. Directional Control Pedal

B. Brake Pedal

C. Parking Brake

D. Operator Seat

E. Rear Cover Latch

F. Main Broom Lever

G. Side Broom Lever

H. Filter Shaker Switch

I. Hopper Door Switch

J. Hopper Lift Switch

K. Hopper Safety Arm

L. Engine Temperature Light

M. Oil Pressure Light

N. Engine Glow Plug Light (Diesel

Only)

O. Light Switch

P. Engine Throttle Handle

Q. Choke Cable

R. Key Switch

S. Circuit Breakers

T. Horn Pad

U. Steering Wheel

V. Wet Sweep Bypass

QTFSG/QTFSD 98349 05/15/03

3-3

Page 12

CONTROLS

A - DIRECTIONAL CONTROL PEDAL

This pedal controls the direction of travel and the

speed of the machine.

Slowly pressing the front of the pedal causes the

machine to travel forward. Pressing the rear of the

pedal causes the vehicle to travel in reverse. The

machine speed can be controlled by varying the

pressure on the front or rear of the pedal.

FOR SAFETY: The machine can coast for a short

distance after releasing the directional pedal. Use

the brake pedal to slow or stop the machine.

B – BRAKE PEDAL

This brake operates the disc brakes on the two front

tires. To slow or stop the machine, apply pressure

to the brake pedal.

C – PARKING BRAKE LEVER

The knob located above the brake pedal is the

parking brake knob. To set the parking brake, slide

the parking brake knob up to the top of its slot, then

depress the brake pedal. To release the parking

brake, slide the parking brake knob to the bottom of

its slot. The brake pedal will return to its raised

position.

FOR SAFETY: Always park on a level surface, turn

the machine off, and set the parking brake before

leaving the machine, and before servicing the

machine.

D – OPERATOR SEAT

The operators seat position is adjustable. To

change positions loosen the four lower mounting

bolts and slide the seat to the desired position.

Tighten the four mounting bolts.

E – REAR COVER LATCH

The rear cover latch locks the rear cover in the

closed position. To open the rear cover, push the

latch in and pull the rear cover back. To close the

rear cover, lower it slowly until the latch engages the

floor slot. Do not let the rear cover drop, or damage

to the latch or cover may occur.

FOR SAFETY: When the rear cover is open a

safety switch prevents the operation of the main

broom and vacuum impeller.

F – MAIN BROOM LEVER

FOR SAFETY: The main broom and the vacuum

impeller automatically begin to operate when the

main broom lever is positioned in the forward end of

its slot.

The main broom lever controls the position and the

drive of the main broom. To start the main broom

and lower it to the floor, release the main broom

lever and let it drop to the front end of its slot. To

shut off and raise the main broom, pull the main

broom lever back into its locked position.

G – SIDE BROOM LEVER

FOR SAFETY: The side broom automatically

begins to operate when the side broom lever is

positioned in the forward end of its slot.

The side broom lever controls the position and the

drive of the side broom. To start the side broom and

lower it to the floor, release the side broom lever and

let it drop to the front end of its slot. To shut off and

raise the side broom, pull the side broom lever back

into its locked position.

When parking the machine, always raise the brooms

to prevent the bristles from taking a set.

H – FILTER SHAKER SWITCH

The filter shaker switch operates the dust filter

cleaning system.

3-4

For efficient sweeping the filter must be cleaned on

a regular basis. To clean the filters, pull the Wet

Sweep Bypass knob, then push and hold the filter

shaker switch for 10-20 seconds. Clean the filters

just before dumping the hopper. In very dusty

conditions the filter may need to be cleaned more

frequently.

QTFSG/QTFSD 98349 05/15/03

Page 13

CONTROLS

3-5

I – HOPPER DOOR SWITCH

The hopper door switch opens and closes the

hopper dump door. Pushing the front half of the

hopper door switch closes the hopper dump door.

Pushing the rear half of the switch opens the hopper

dump door. A beeper sounds when the door is in

the closed position. Sweeping should not be

attempted when the hopper door is closed.

J – HOPPER LIFT SWITCH

The hopper lift switch is used to raise and lower the

hopper during dumping operations. To raise the

hopper, press and hold the front half of the hopper

lift switch until the hopper has raised to the desired

height. Then release the switch. To lower the

hopper, press and hold the rear half of the hopper lift

switch until the hopper lowers to the normal

sweeping position.

FOR SAFETY: The hopper lift switch will not raise

or lower the hopper if the key switch is in the off

position.

K – HOPPER SAFETY ARM

The hopper safety arm is used to support the hopper

in the raised position. The safety arm should be

used whenever inspection or service is performed

under the hopper. Do not rely on the hydraulic

cylinder to keep the hopper raised.

L – ENGINE TEMPERATURE LIGHT

The engine temperature light indicates when the

engine is overheating. If the light comes on, stop

the engine immediately and determine the cause.

Failure to stop the engine will result in engine

damage. Some causes of engine overheating are a

clogged radiator, clogged cooling fins in the radiator,

loose fan belt or other engine malfunction. Consult

your Engine Owners guide to help determine the

problem.

M – OIL PRESSURE LIGHT

The engine oil pressure light indicates inadequate

engine oil pressure. If the light comes on, stop the

engine immediately and determine the cause.

Failure to stop the engine will result in engine

damage.

N – ENGINE GLOW PLUG LIGHT

(DIESEL ONLY)

The glow plug light is a time-controlled light that

allows the glow plugs to heat up sufficiently before

cranking the engine. When the ignition switch is

turned clockwise to the “RUN” position, the light will

come on. After 5-30 seconds, depending on

temperature, the light will go off. Then the engine

can be cranked with the ignition switch.

O – LIGHT SWITCH

Raised hopper may fall. Engage hopper safety

arm before working under hopper.

QTFSG/QTFSD 98349 05/15/03

The light switch operates the headlights and

taillights.

P – THROTTLE

The throttle is an adjustable, lockable tee-handle.

The handle is unlocked by turning counterclockwise, and locked by turning clockwise. Start

the engine with the throttle pushed all the way in.

When the engine has adequately warmed up, unlock

and pull the throttle all the way out and lock. This

will set the engine at the maximum governed speed.

The throttle may be adjusted and locked anywhere

between idle and max. if desired. Consult engine

service guide.

Page 14

CONTROLS

Q – CHOKE (GAS ONLY)

By pulling this knob out, the choke is engaged for

cold starting. To release choke, push the knob in.

R – KEY SWITCH

The key switch controls starting and electrical power

for most machine functions. To start the machine,

turn the key clockwise past the “RUN” position to the

crank position. After engine has started release key.

(For starting diesel engines, see “Glow Plug Light”).

To stop engine, turn key counter-clockwise.

S – CIRCUIT BREAKERS

The circuit breakers are circuit protection devices

designed to interrupt the flow of current in the event

of an electrical overload. When tripped, the circuit

breakers must be reset by pressing the exposed

button on the face of the affected circuit breaker. If

the circuit breaker continues to trip, the cause of the

electrical overload should be found and corrected.

The following chart shows the circuit breakers and

the components they protect.

GAS:

DEVICE RATING COMPONENT

PROTECTED

CB-1 30A Voltage Regulator

CB-2 15A Igniter, Fuel Pump,

Oil Pressure Lamp,

Water Temp. Lamp

CB-3 15A Side Broom Valve,

Head Lamps, Tail

Lamps, Horn

CB-4 15A Options

CB-5 15A Hopper Dump Door,

Shaker Motor, Hour

Meter, Hopper

Raise/Lower Valves

DIESEL:

DEVICE RATING COMPONENT

PROTECTED

CB-1 30A Glow Plugs

CB-2 30A Starter Relay, Oil

Pressure Lamp,

Water Temp. Lamp,

Glow Plug Lamp,

Optional Charge

Light, Optional Air

Registration Light

CB-3 15A Side Broom Valve,

Head Lamps, Tail

Lamps, Horn,

CB-4 15A Options

CB-5 15A Hopper Dump Door,

Shaker Motor, Hour

Meter, Hopper

Raise/Lower Valves

T – HORN PAD

The horn pad is located on the steering wheel. The

horn is activated by pressing on any area of the horn

pad.

U – STEERING WHEEL

The steering wheel controls the two rear wheels.

The machine is highly receptive to the movement of

the wheel. Operators should use care until they

become experienced in driving the machine.

V – WET SWEEP BYPASS

By pulling this knob out, vacuum is cut off from filter

and hopper. To prevent damage to filter caused by

moisture, pull knob out when sweeping through

puddles. To maximize filter cleaning, pull knob out

before pressing filter shaker switch.

3-6

QTFSG/QTFSD 98349 05/15/03

Page 15

OPERATIONS

3-7

BEFORE OPERATING THE FS:

1. Complete the machine data sheet on page 2.

2. Read this manual carefully before operating or

servicing the machine.

Do not operate machine unless Operation

manual is read and understood.

3. Carefully read the Owner’s Manual that is

supplied for your gas or diesel machine.

REFERENCE FOR GAS ENGINE:

Kawasaki FD620D – Owners Manual

REFERENCE FOR DIESEL ENGINE:

Lombardini LDW series – Use, Maintenance

4. Check oil and engine fuel in the machine. See

engine Owner’s manual for complete filling

instructions.

5. Check the hydraulic fluid level in the hydraulic

power unit. See hydraulics in the maintenance

section.

6. Check the main and side broom for correct

adjustment. See brooms in the maintenance

section.

STARTING THE MACHINE

FOR SAFETY: use caution when backing machine.

Do not carry riders on the machine. Always follow

basic safety and traffic rules. Go slow on slippery

surfaces and grades.

1. The operator should be sitting on the seat with

a foot on the brake pedal or with the parking

brake on. The directional pedal should be in

neutral.

TO SWEEP

Plan the sweeping pattern in advance. For efficient

operation, the sweeping runs should be long with as

little stopping and starting as possible. Overlap the

brush paths and complete an entire section at one

time.

Use the side broom to pull debris from areas near

walls or obstructions. The side broom is also useful

for extending the sweeping paths on long runs. If

the area to be swept is very dusty, the side broom

should be raised to prevent dust clouds.

Oversized debris that can inhibit sweeping

operations should be picked up by hand. This

includes large cartons and items that could become

tangled in the brooms, such as wire or banding

material.

The machine is very responsive. Avoid turning the

steering wheel too sharply when the machine is in

motion. Avoid sudden turns except in an

emergency.

1. Put the main broom lever in the forward position

to lower the main broom.

2. Put the side broom lever in the forward position

to lower the side broom.

NOTE: The main broom and side broom lever

indicators are color-coded green.

3. Make sure that the hopper door is open. A

beeper will sound if the hopper door is not

open.

4. Sweep as required.

OPERATING ON GRADES

FOR SAFETY: Before starting machine, make sure

that all safety devices are in place and operating

properly.

2. Turn the key switch clockwise to the “ON”

position.

3. Drive the machine to the area where sweeping

is to begin.

QTFSG/QTFSD 98349 05/15/03

Operate the machine slowly on grades. Use the

brake pedal to control the machine speed.

NOTE: When operating machine, go slowly on

grades and slippery surfaces.

Page 16

OPERATIONS

STOPPING THE MACHINE

1. Remove foot from the directional pedal and

apply the brake.

2. Raise and turn off the brooms by pulling the

main and side broom levers back to the rear

locked position.

3. Set the parking brake.

4. Turn the key switch counterclockwise to the off

position. Remove the key.

STORING THE MACHINE

When storing the machine for extended periods of

time, the following procedure must be followed to

lessen the chance of rust, sludge, or other

undesirable deposits from forming.

1. Empty the hopper.

2. Raise the main broom and the side broom.

3. Park the machine in a cool, dry area.

TO ENGAGE THE HOPPER SAFETY ARM

Raised hopper may fail. Engage hopper safety

arm before working under hopper.

1. Set the machine parking brake.

FOR SAFETY: Before leaving or servicing machine;

stop on level surface, set parking brake, turn OFF

machine and remove key.

2. Raise the hopper.

3. Unhook the safety arm and swing it down into

position over the safety arm retainer. Do not let

the safety arm drop into position.

4. Slowly lower the hopper until the safety arm is

secure.

4. Remove or change the batteries for 4 hours,

once every three months.

DUMPING THE HOPPER

NOTE: The hopper dump switches are numbered

and color-coded. The filter shaker is shown in

yellow and hopper functions are shown in red.

1. Drive the machine to the dump site or dumpster.

2. The correct sequence for dumping the hopper is

shown by following the numbers on the switch

panel.

1. Clean the filter by pressing the filter shaker

switch for 10-20 seconds.

2. Close the hopper door by pushing and

releasing the front half of the hopper door

switch. The beeper will sound.

3. Press and hold the front half of the hopper

lift switch and raise the hopper to a height

that will clear the dumpster, then release the

switch. Drive forward slowly until the hopper

is positioned above the dumpster.

4. Dump the hopper by pressing and then

releasing the rear half of the hopper door

switch. After dumping, back the machine

slowly away from the dumpster.

5. Lower the hopper by pressing and holding

the rear half of the hopper lift switch.

Make sure that the lower end of the safety arm is

correctly held in the retainer on the machine

frame.

3-8

QTFSG/QTFSD 98349 05/15/03

Page 17

OPERATIONS

TO DISENGAGE THE HOPPER SAFETY ARM

1. Raise the hopper.

2. Place the safety arm in its storage position on

the inside of the hopper lift arm.

3. Lower the hopper.

TOWING OR PUSHING MACHINE

Gas and diesel powered machines may be pushed

or towed easily by bypassing the transmission. To

do this raise the rear cover and remove the belt

guard. Locate the transmission. On the rear of the

transmission is a plunger valve. Push the valve in

as far as possible and pivot up the tow bar valve just

next to the valve. This bar is supplied to lock the

valve in the “IN” position. The machine can now be

easily pushed or towed up to 4 mph (7

kilometers/hr).

Do not exceed 4 mph (7 kilometers/hr) as

damage to the transmission may result.

When towing is complete, slide tow valve bar out of

the way to release valve.

TO JACK UP MACHINE

1. Empty and lower the hopper.

2. Turn the key switch off and set the parking

brake.

FOR SAFETY: Before leaving or servicing machine;

stop on level surface, set parking brake, turn off

machine and remove key.

3. Block the tires that are not being raised to

prevent the machine from rolling.

FOR SAFETY: When servicing machine, block

machine tires before raising machine.

4. Use a jack of adequate capacity, raise the

machine using the designated jack locations.

FOR SAFETY: When servicing machine, use hoist

or jack of adequate capacity, jack machine at

designated jack locations only. Block machine with

jack stands when raised.

5. When the machine is raised, use jack at the

designated jack locations.

FOR SAFETY: Block machine at designated jack

locations with jack stands when raised.

6. Slowly lower the machine onto the jack stands.

7. Be sure that the machine is secure.

8. Service or inspect the machine as required.

9. When finished working on the machine, raise the

machine off the jack stands.

10. Remove the jack stands.

11. Lower the machine to the floor. Remove the

blocks from the tires.

MACHINE JACKING

The machine may be jacked up for service or

inspection by using the specified jack locations.

Always block the tires when jacking up the machine.

The right front jack location is the base of the side

broom, just ahead of the right tire.

The left front jack location is the lower front frame

channel just ahead of the left front tire.

The rear jack location is the steel beam mount

located at the rear of the machine, centered under

the plastic bumper.

QTFSG/QTFSD 98349 05/15/03

MACHINE TIE-DOWNS

There is a tie-down location at each corner of the

machine. The front attach points are the frame

cutouts located directly above each front tire. The

rear attach points are the right and left lower flange

of the frame channels, where they join the rear

bumper. An alternate single rear attach point is

around the pivot of the rear axle beam, located at

the center of the machine behind the rear jack point.

NOTE: When transporting the machine on a trailer

or in a truck, in addition to tie-downs, be sure to set

the machine parking brake, and block the tires to

prevent the machine from rolling.

3-9

Page 18

MAINTENANCE

HYDRAULIC FLUID

Hydraulic fluid is used with the hydraulic pump to

operate the hopper lift system and the side broom

motor. The condition of the hydraulic fluid plays a

large part in determining the life of the hydraulic

system.

The hydraulic fluid used in the Tracer Gas/Diesel

powered Floor Sweeper is Chevron 400 15W40. If a

different hydraulic fluid is used, it must closely match

the viscosity specification below.

SUS @ 100” (38º C) 404-445

SUS @ 210” (38º C) 78-84

This specification has a flat viscosity curve (high

viscosity index). This means the thickness of the oil

stays relatively constant over a wide temperature

range. DO NOT use Automatic Transmission Fluid.

NOTE: The hydraulic components in the machine

rely on system hydraulic fluid for lubrication. Dirty or

contaminated fluid accelerates wear and

malfunctions, and reduced component life.

HYDRAULIC FLUID RESERVOIR

5. Remove bolts (4) in feet of reservoir.

6. Shift reservoir forward so that short leg of

reservoir drops down and rests on lower frame.

7. Remove upper hydraulic hose from reservoir.

8. Lift reservoir out of frame and rest on outer

frame with open port above oil level.

9. Tilt reservoir back and remove last hose.

10. Reservoir may be emptied by pouring fluid out of

ports.

11. The fluid strainer may be removed for inspection

and to speed fluid drainage.

NOTE: Do not overfill the reservoir. Expansion of

the hydraulic fluid when heated to the normal

operating temperature can cause fluid to spill from

the reservoir, or cause damage to the component.

If the reservoir is overfilled, use a suction type

device to draw the excess hydraulic fluid from the

reservoir.

HYDRAULIC FLUID LEAKS

Pressurized hydraulic fluid spraying from a very

small hole can be very hard to see. Do not use

hands to locate the leak. Use a piece of cardboard

as shown below to find leaks.

The hydraulic fluid reservoir is located below the

broom levers inside the machine. To check the fluid

level remove the fill cap to read the dipstick attached

to the cap.

NOTE: Do not overfill reservoir. Expansion of the

hydraulic fluid when heated to the normal operating

temperature can cause fluid to spill from the

reservoir, or cause damage to the component.

The oil in the reservoir should be replaced every 500

hours of use. To drain hydraulic reservoir:

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing the

machine, stop on level surface, apply parking brake,

turn off machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Remove impeller.

A – Hydraulic Pump

When servicing machine, use a sheet of

cardboard to locate leaking hydraulic fluid under

pressure. Keep eyes and hands clear of leaks.

Escaping hydraulic fluid under pressure can

cause severe injury.

A – Hydraulic Line

B – Cardboard

C – Pinhole Leak

4-1

QTFSG/QTFSD 98349 05/15/03

Page 19

MAINTENANCE

HYDRAULIC FILTER

The hydraulic filter keeps the machines hydraulic

system clean to a level of 10 microns. The hydraulic

fluid filter is located just inside the left rear frame.

The filter should be changed every 500 hours.

TO REPLACE FILTER ELEMENT:

1. Stop the engine and set the parking brake.

2. Open the seat support.

3. Unthread and discard the hydraulic fluid filter

element.

4. Apply a thin coat of hydraulic fluid to the seal of

the new hydraulic fluid filter element.

5. Thread and hand tighten the new hydraulic fluid

filter element on the filter head.

6. Close the seat support.

7. Operate the machine and check for leaks.

Correct any leaks found.

8. Check the hydraulic fluid reservoir level and fill

as required.

DIRECTIONAL CONTROL SYSTEM

(Refer to the Electrical Control Group in the

Parts section)

The directional control system controls the direction

and speed of the machine. The system is made up

of the directional pedal, the throttle box, the

transistorized controller and contactors. The

controller, located in the electrical drive

compartment, is sealed and can only be serviced by

trained service personnel.

Do not use a pressure washer to clean the inside

of the electrical drive compartment.

When servicing machine, disconnect battery

connections before working on machine.

DIRECTIONAL CONTROL PEDAL ADJUSTMENT

(Refer to the Console Group in the Parts section)

The directional control pedal is designed to prevent

driver fatigue. However if a different pedal angle is

preferred, these directions should be followed.

1. Raise rear cover.

2. Disconnect batteries from machine.

3. Locate and remove the directional control pedal

stop bolt.

4. Locate the linkage rod beneath the directional

control pedal.

5. Adjusting the length of the linkage rod controls

the pedal angle. Shortening the linkage rod

causes the pedal to have a flatter angle with the

floor. Lengthening the linkage rod causes the

pedal to have a steeper angle.

6. To change the length of the linkage rod,

disconnect the upper end of the linkage rod from

the forward/reverse arm.

7. Loosen the locking nuts on both ends of the

threaded portion of the linkage rod.

8. Turning the balljoint changes the length of the

linkage rod, be sure that there is a minimum of

5/16” of threaded rod engaged in each of the

balljoints.

9. When the new length is established, reconnect

the upper balljoint to the forward/reverse arm.

10. Tighten the two locking nuts on the threaded

portion of the linkage rod.

11. Reposition the directional foot pedal stop bolt.

12. The stop bolt must be adjusted so that the

directional foot pedal comes in contact with the

stop while there is still a small amount of travel

remaining in the throttle arm. This is done to

prevent heavy foot pressure from damaging the

throttle unit.

THROTTLE “NEUTRAL POSITION”

ADJUSTMENT (Refer to the Console Group in

the Parts section)

The throttle is automatically returned to its neutral

position by a spring centering system. If the

machine tends to creep forward or reverse when the

operators foot is removed from the directional foot

pedal, the throttle “neutral position” may require

adjustment as described below:

1. Turn off machine and set parking brake.

2. Raise the rear cover.

3. Disconnect the batteries from the machine.

4. Remove the drive motor dust cover.

5. Locate the throttle and spring centering

assembly.

6. Disconnect the linkage rod from the throttle arm.

7. With the throttle arm free, the throttle will return

to its neutral position using its internal centering

spring.

8. Position the linkage rod balljoint over the hole in

the throttle arm. The balljoint should slide into

the hole without repositioning the throttle arm.

9. If required, shorten or lengthen the linkage rod

until proper engagement occurs.

10. Reattach linkage rod to the throttle arm.

11. Install the drive motor dust cover.

12. Connect batteries.

13. Lower hopper.

QTFSG/QTFSD 98349 05/15/03

4-2

Page 20

MAINTENANCE

MAIN BROOM (Refer to the Main Broom Group

and Main Broom Lift Group in the Parts section)

FOR SAFETY: The main broom and the vacuum

impeller automatically begin to operate when the

main broom lever is positioned in the forward end of

its slot.

The main broom spans the width of the machine,

and sweeps debris into the hopper. Inspect the

main broom daily for wear or damage. Remove any

obstructions found in the main broom chamber, main

broom drive hub or idler hub.

The main broom should be replaced when the

remaining bristles measure 5/8 “ (16mm) or less in

length.

NOTE: All original equipment brooms are equipped

with “Perform Alert™”. This feature tells the

operator when it is time to replace the main broom.

“Perform Alert™” brooms have bright yellow tufts

located on each end of the broom. These tufts are

pre-trimmed to indicate the length of a worn out

broom. When the main body of the broom wears to

a length that matches the yellow tufts, the broom

should be replaced.

Always check the main broom pattern when

installing a new broom.

TO REMOVE THE MAIN BROOM

TO INSTALL THE MAIN BROOM

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing the

machine, stop on level surface, apply parking brake,

turn off machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Lower the main broom lever.

5. Open right side broom door.

6. If replacing a worn broom, turn the main broom

adjustment knob so that the broom drive hub is

raised to a position that will allow a new broom

to easily slide onto the broom drive hub.

7. Slide the new brush into the broom chamber.

8. Hold the broom by the core and rotate the

broom counter-clockwise while pushing the

broom onto the drive hub. Make sure that the

broom is fully seated onto the drive hub before

attempting to install the idler arm.

9. Locate the idler arm. Align the tabs on the idler

hub with the slots on the main broom core.

Slide the idler into the main broom core, the

position the upper right end of the idler arm onto

the two locator pins.

10. Replace and tighten the D-ring retainer.

11. Close the broom door.

12. Check the main broom floor pattern and adjust

as necessary.

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing the

machine, stop on a level surface, apply parking

brake, turn off the machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Lower the main broom lever.

5. Open the right side broom door.

6. Remove the idler arm D-ring retainer.

7. Remove the main broom idler arm.

8. Grasp the broom by the core and remove.

4-3

QTFSG/QTFSD 98349 05/15/03

Page 21

4-4

CHECKING AND ADJUSTING THE MAIN BROOM

PATTERN

1. Using chalk, or similar material, coat and area of

the floor that is flat and smooth. If a suitable

material is not available, run the broom for two

minutes during the following test.

2. With the main broom raised, position the

machine so that the main broom is directly over

the chalked area.

3. Apply the parking brake to prevent the machine

from moving.

4. Lower the main broom to the floor for 10-15

seconds.

5. Raise the main broom, release the parking

brake, and back the machine away from the test

area.

6. Observe the pattern that the main broom left on

the floor. The pattern should be 1 to 1-1/2

inches (25.4 to 38.1mm) wide. The pattern

should not be tapered (wider at one end than the

other).

7. To adjust the width of the pattern, locate the

main broom adjustment knob, and loosen the

locking wing nut.

8. If the pattern is too wide, rotate the adjustment

knob clockwise to raise the broom. If the pattern

is too thin, rotate the adjustment knob,

counterclockwise to lower the broom. Tighten

the locking wing nut.

9. Check the broom pattern again. Repeat the

procedure until the pattern is correct.

A – Main Broom Pattern

B – 1 to 1-1/2” (25.4 to 38.1mm)

NOTE: If one end of the main broom pattern is more

than 1/2” (12.7mm) wider than the other end,

perform the following leveling procedure.

MAINTENANCE

A – Main Broom Adjustment Knob

The adjustable bearing block used to correct a

tapered broom pattern is located just inside the right

broom door. Only the right side of the broom can be

raised or lowered to correct the pattern. Before

attempting the following adjustment, determine if the

right side of the broom needs to be raised or

lowered to correct the tapered pattern.

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing the

machine, stop on level surface, apply parking brake,

turn off machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Open the right side broom door.

5. Remove the main broom.

6. Locate the plastic main broom bearing block just

inside the right broom door. Loosen the bearing

block retainer bolts.

7. Slide the bearing block up or down to correct the

tapered pattern condition.

8. Tighten the bearing block retaining bolts.

9. Replace the main broom, and repeat the pattern

test procedure. Readjust if necessary to

eliminate the tapered pattern condition.

QTFSG/QTFSD 98349 05/15/03

Page 22

MAINTENANCE

SIDE BROOM (Refer to the Side Broom Group in

the Parts section)

FOR SAFETY: The side broom automatically

begins to operate when the side broom lever is

positioned in the forward end of its slot.

The side broom is used to clean debris sway from

curbs and walls, and sweep it into the path of the

main broom. Inspect the side broom daily for wear

or damage. Remove any string, wire or banding

found wrapped around the side broom, side broom

hub, or shaft.

The side broom should be replaced when the

remaining bristles measure 2-1/2 inches (65 mm) or

less in length.

NOTE: All original equipment brooms are equipped

with “Perform Alert™”. This feature tells the

operator when it is time to replace the side broom.

“Perform Alert™” brooms have bright yellow tufts

located around the outside edge of the broom.

These tufts are pre-trimmed to indicate the length of

a worn out broom. When the main body of the

broom wears to a length that matches the yellow

tufts, the broom should be replaced.

TO REMOVE THE SIDE BROOM

1. Turn off machine and set parking brake.

5. Slide the side broom onto the side broom motor

shaft.

6. Install the side broom retaining pin and the

retaining pin locking clip.

7. Adjust the side broom if necessary

The side broom should contact the floor in an area

as shown below. One third to one half of the side

broom bristles should contact the floor when the

broom is down.

ADJUSTING THE SIDE BROOM

1. Raise the hopper.

2. Engage safety arm.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Raise the side broom lever.

5. Remove the locking clip from the side broom

retaining pin.

6. Push up on the base of the side broom to relieve

the tension on the retaining pin, then remove the

retaining pin.

7. Slide the side broom off the side broom motor

shaft.

TO INSTALL THE SIDE BROOM

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Raise the side broom lever.

Raised hopper may fall. Engage hopper safety

arm.

3. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

4. Raise rear cover.

5. Disconnect batteries from machine.

6. Lower the side broom lever.

7. Place a block or similar support under the side

broom to relieve the tension in the lift cable.

8. Locate the side broom adjustments links

located just above the side broom, and remove

the retaining pin passing through both

adjustment links.

9. Reposition the two adjustment links to move the

side broom up or down as required, and replace

the retaining pin.

4-5

QTFSG/QTFSD 98349 05/15/03

Page 23

MAINTENANCE

4-6

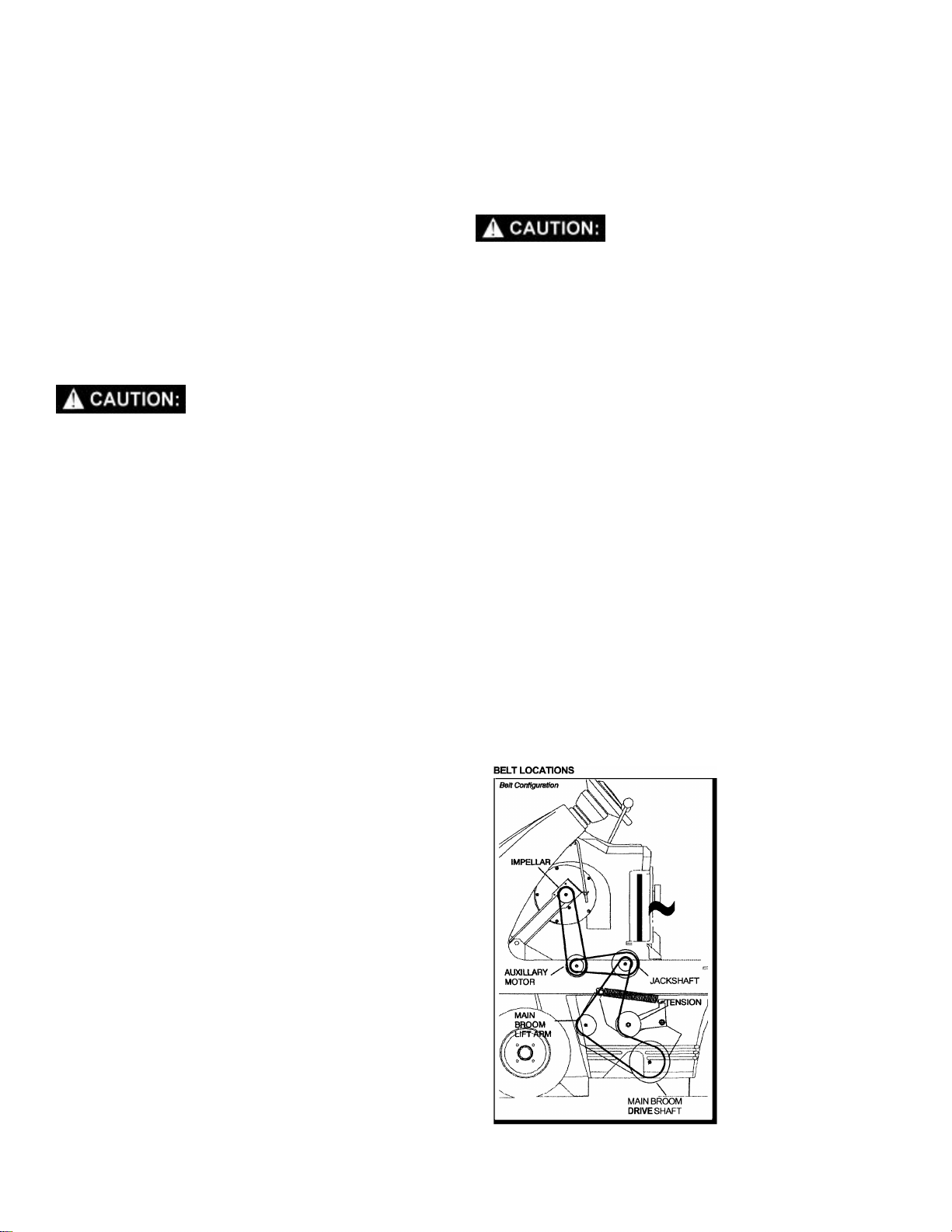

TRANSMISSION JACKSHAFT BELT

The transmission belt transfers power from the

engine to the transmission jackshaft on the gasoline

machines and from the engine jackshaft to the

transmission jackshaft on the diesel powered

machines.

TO REPLACE BELT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Remove the belt guard cover.

5. Remove the tension spring for the idler on the

transmission drive belt. Loosen tension on

impeller belt.

6. Loosen, but do not remove the four bolts in the

base of the shaft mounting bracket.

7. Slide mounting bracket toward engine to create

slack in the belt.

8. Loosen, but do not remove 4 bolts in the bases

of the rear jackshaft mount and pump mount

bracket.

9. Loosen tensioning nut and bolt on the rear of

rear jackshaft mount. Slide rear jackshaft mount

away from engine.

10. Remove the bolts retaining the bearings on

transmission jackshaft.

11. Lift the jackshaft and bearings from the mount

and remove the transmission drive belt, then the

transmission jackshaft belt.

12. Remove the bolts retaining the bearing on the

rear jackshaft. Remove the belt controller rod.

13. Loosen bearing collars on rear jackshaft

bearings.

14. Remove first the main broom belt, then the

pump drive belt.

15. Slide the rear jackshaft outward to disengage

the pump coupling, then lift the shaft up to

remove drive belt in reverse order.

16. Reinstall belt in reverse order.

ADJUSTING THE JACKSHAFT BELT

Proper alignment is important for all belts on

Tracer machines. To properly align the

transmission jackshaft belt:

Repeat Steps 1-8 from above then:

9. Move the transmission jackshaft belt off its

pulley and loosen the setscrew in the pulley.

10. Using a straightedge between the pulleys to be

aligned, move the pulley left or right on it’s shaft

until proper alignment is established.

11. After this adjustment, check the transmission

belt alignment.

12. Reverse steps 1-8.

13. If jackshaft belt idler pulley does not center on

belt, adjust by adding or removing washers

behind the idler pulley.

TRANSMISSION BELT

The transmission belt transfers power from the

transmission jackshaft to the transmission.

TO REPLACE BELT

1. Repeat steps 1-10.

11. Lift the jackshaft and bearings from the mount

and remove the transmission belt off the end of

shaft.

REAR JACKSHAFT (PUMP DRIVE) BELT

The rear jackshaft belt transfers power from

transmission jackshaft to rear jackshaft.

TO REPLACE BELT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect battery from machine.

4. Remove the belt guard cover.

5. Remove belt controller rod from rear jackshaft

mount and take main broom drive belt off double

pulley located on rear jackshaft.

6. Loosen, but don’t remove 4 bolts in base of rear

jackshaft mount and pump mount.

7. Loosen tensioning nut and bolt at rear jackshaft

mount, and slide mount away from engine.

8. Remove rear jackshaft belt.

QTFSG/QTFSD 98349 05/15/03

Page 24

MAINTENANCE

TO ALIGN BELT

1. Repeat steps 1-7

8. Loosen tension on impeller drive pulley on end

of transmission jackshaft.

9. Slide pulley side to side on shaft to make proper

alignment.

10. Retighten setscrews in pulley.

11. Reverse Steps 1 –7.

MAIN BROOM BELT (Refer to Main Broom Group

in the Parts section)

The main broom belt transfers power from the rear

jackshaft to the main broom pulley. Check the belt

condition and tension every 200 hours of operation.

The main broom and vacuum impeller

automatically begin to operate when the main

broom lever is positioned in the forward end of

its slot.

REPLACING AND ADJUSTING MAIN BROOM

BELT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Remove the belt guard.

5. Be sure main broom lift lever is in the raised

position. Remove the belt controlling rod from

rear jackshaft mount.

6. Remove belt from pulleys.

7. Install new belt and reinstall belt controlling rod.

VACUUM IMPELLER BELT (Refer to the Impeller

Group in the Parts section)

The impeller belt transfers power from the auxiliary

motor to the impeller. Check the belt condition and

tension every 200 hours of operation.

The main broom and vacuum impeller

automatically begin to operate when the main

broom lever is positioned in the forward end of

its slot.

REPLACING AND ADJUSTING THE VACUUM

IMPELLER BELT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Remove the belt guard and the side filler panel.

5. Loosen the auxiliary motor base mounting bolts.

6. Slide the auxiliary motor back and remove the

jackshaft belt.

7. Pull the auxiliary motor forward to tension the

jackshaft belt. The belt has proper tension when

the belt deflects 1/4 inch (6 mm) from a force of

6 Ibs (3 kg) applied at the midpoint of the belt.

8. While keeping the motor and jackshaft pulleys

aligned, tighten the auxiliary motor base

mounting bolts.

9. Replace the main broom belt.

10. Replace the side filler panel and the belt guard.

TO ALIGN BELT

Repeat steps 1-7 under rear jackshaft (Pump Drive)

belt.

8. Loosen set screws in double pulley located on

the rear jackshaft.

9. Slide pulley side to side to align with main broom

drive pulley below.

10. Retighten setscrews in pulley.

11. Reverse Steps 1 –7.

NOTE: This adjustment may require realignment of

the rear jackshaft belt.

4-7

QTFSG/QTFSD 98349 05/15/03

Page 25

MAINTENANCE

IMPELLER BELT

The impeller belt transfers power from transmission

jackshaft to impeller.

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Remove the belt guard cover.

5. Release tension on impeller belt using tension

bolt under impeller arm.

6. Repeat Steps 5 and 6 under Rear Jackshaft

(Pump Drive) Belt.

7. Remove rear jackshaft belt from front pulley.

8. Remove impeller belt.

9. Replace belt and reverse Steps 1 –6.

TO ALIGN BELT

6. Loosen 4 bolts holding transmission case to

mount.

7. Locate tensioning bolt at top of transmission

mount. Tighten or loosen bolt as needed to

properly tension chain.

8. Tighten 4 mounting bolts in transmission body.

If alignment of the chain and sprockets becomes

necessary, the alignment is accomplished by moving

the entire differential assembly side to side.

TO REALIGN

1. Raise the hopper and engage the hopper safety

arm.

Raised hopper may fall. Engage hopper safety

arm.

2. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

1. Loosen impeller belt, using the tensioning bolt

under the impeller arm.

2. Loosen set screws in the impeller pulley.

3. Slide the pulley side to side to make proper

alignment.

4. Tighten set screws in pulley.

5. Retighten impeller belt.

DIFFERENTIAL DRIVE CHAIN (Refer to the

Differential Group in the Parts section)

The differential drive chain transfers power from the

output sprocket of transmission to differential

sprocket. Check the chain condition and tension

every 200 hours of operation.

REPLACING AND ADJUSTING DIFFERENTIAL

DRIVE CHAIN

1. Raise the hopper and engage the hopper safety

arm.

2. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

3. Remove rear cover.

4. Disconnect battery from machine.

5. Remove the drive motor dust cover.

6. Loosen all four locking on bearings supporting

the differential.

7. Loosen the set screws in the two brake disks.

8. Loosen but don't remove the hardware attaching

the bearing flanges to the frame.

9. Make sure there is little tension on the drive

chain. Gently slide the differential in it's bearing

to restore proper alignment.

NOTE: The brake disks must remain stationary

while the differential shafts move in them.

10. Reverse Steps 1-8. Follow tensioning

instructions above.

NOTE: After aligning the differential the small

sprockets at each end of the differential may need to

be realigned with the wheel sprockets. If so, loosen

setscrews in small sprockets and slide on differential

shaft until aligned. Retighten setscrews.

3. Raise rear cover.

4. Disconnect batteries from machine.

5. Remove the drive motor dust cover.

QTFSG/QTFSD 98349 05/15/03

4-8

Page 26

MAINTENANCE

DRIVE WHEEL CHAIN (Refer to the Front Wheel

Group in the Parts section)

The drive wheel chain transfers power from the

differential shaft to the drive wheels. Check the

chain condition and tension every 200 hours of

operation.

REPLACING AND ADJUSTING THE DRIVE

WHEEL CHAINS

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover.

3. Disconnect batteries from machine.

4. Chock the rear wheels. Jack up and remove the

front tire.

5. Remove the chain guard and tensioner disk.

6. Check the drive wheel chain for excessive wear.

Replace if necessary.

7. Check the drive wheel and differential shaft

sprockets to proper alignment. If they are not

lined up, loosen the setscrews on the

differential shaft sprocket, align the sprockets,

and tighten the setscrews.

8. Replace the chain guard and tensioner disk.

9. Check the chain tension. There should be 1/2

inch (1 5 mm) slack measured midway between

the sprockets. To adjust the tension, loosen the

chain guard mounting bolt and rotate the disk.

Tighten the chain guard mounting bolt.

10. Replace the tire and slowly lower the machine

to the floor.

11. Repeat the procedure for the other drive tire.

REPLACING THE RIGHT BROOM DOOR SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Open the right broom door.

3. Loosen the lower three retaining bolts on the

side skirt mounting plate.

4. Slide the worn side skirt out of the skirt retainer.

5. Slide a new skirt into place. Tighten the three

retaining bolts.

6. Adjust the side skirt.

ADJUSTING THE RIGHT BROOM DOOR SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Open the right broom door.

3. Loosen the three upper adjustment bolts on the

side skirt mounting plate.

4. Adjust the side skirt for correct floor clearance,

then tighten the three adjustment bolts.

SKIRTS AND SEALS (Refer to the Frame Group

and the Main Broom Group in the Parts section)

The main broom skirts prevent dust from exiting the

main broom chamber. The skirts should be

inspected for wear or damage daily. When correctly

adjusted, they should clear the floor by 0 to 1/8 inch

(0 to 3mm).

NOTE: Original equipment skirts are provided with

“Perform Alert™” wear indicators. The wear

indicator is raised horizontal line near the lower edge

of the skirts. When a skirt is worn to this line it

should be replaced. A skirt can be adjusted many

times before it wears to the “Perform Alert™” strip.

During daily inspections the “Perform Alert™”

indicators are useful in determining when skirts are

close to requiring replacement.

4-9

QTFSG/QTFSD 98349 05/15/03

Page 27

MAINTENANCE

REPLACING THE LEFT BROOM SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover and disconnect the batteries

from the machine.

3. Open the left broom door.

NOTE: The left skirt is mounted to the frame. This

skirt does not have a wear indicator strip.

4. Remove the five adjustment nuts and the

retaining bars.

5. Replace the worn side skirt with a new skirt.

6. Install the retaining bars and adjustment nuts.

7. Adjust the side skirt.

ADJUSTING THE LEFT BROOM SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise rear cover and disconnect the batteries

from the machine.

3. Open the left broom door.

NOTE: The left skirt is mounted to the frame. This

skirt does not have a wear indicator strip.

4. Loosen the five adjustment nuts.

5. Adjust the side skirt for correct floor clearance,

then tighten the adjustment nuts.

6. Tighten the five broom skirt.

7. Adjust the rear skirt.

ADJUSTING THE REAR BROOM SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Loosen the five upper adjustment nuts on the

rear skirt mounting plate.

3. Adjust the rear skirt for correct floor clearance,

then tighten the adjustment nuts.

RECIRCULATION SKIRT

The recirculation skirt helps to channel debris that

has been carried over the main broom, back into the

sweeping area. The recirculation skirt should be

checked daily for wear or damage.

REPLACING THE RECIRCULATION SKIRT

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise the rear cover and disconnect the

batteries from the machine.

3. Remove the main broom.

4. Open the left broom door.

5. Remove the three retaining nuts and retaining

strip on the left side broom skirt.

6. Loosen the five retaining nuts on the

recirculating skirt retaining plate.

7. Slide the worn skirt out of the skirt retainer and

replace with a new skirt.

8. Hold the skirt firmly in place and tighten the five

retaining bolts. No adjustment is required.

QTFSG/QTFSD 98349 05/15/03

4-10

Page 28

MAINTENANCE

HOPPER SEALS

The hopper seals prevent dust from exiting around

the hopper where it meets the broom chamber.

There are two side hopper seals and one upper

hopper seal. These seals should be inspected for

wear or damage daily. When correctly adjusted, the

two hopper side seals should clear the floor by 0 to

1/8 inch (0 to 3mm).

REPLACING THE HOPPER SEALS

1. Park the machine on a smooth, level floor.

2. Raise the hopper and engage the hopper safety

arm.

Raised hopper may fall. Engage hopper safety

arm.

3. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

4. Remove the retaining bolts and retaining bar.

5. Replace the worn hopper seal with a new seal.

6. Install the retaining bar and bolts.

7. Adjust the hopper side seals.

HOPPER LIP SKIRTS

The hopper lip skirts seal the area between the lip of

the hopper and the floor. They also help deflect

debris into the hopper. The lip skirts should be

inspected for wear or damage daily. The lip skirts do

not require adjustment. They should be replaced

when the lower edge is worn down to the “Perform

Alert™” wear indicator line.

REPLACING THE HOPPER LIP SKIRTS

1. Empty the debris hopper.

2. Park the machine on a smooth, level floor.

3. Raise the hopper and engage the hopper safety

arm.

ADJUSTING THE HOPPER SIDE SEALS

1. Park the machine on a smooth, level floor.

2. Raise the hopper and engage the hopper safety

arm.

Raised hopper may fall. Engage hopper safety

arm.

3. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

4. Loosen the three adjustment bolts.

5. Adjust the hopper side seals for correct floor

clearance, then tighten the adjustment bolts.

6. Connect the batteries and lower the hopper.

Raised hopper may fall. Engage hopper safety

arm.

4. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

5. Remove the retainer plate on the right side of

the hopper.

6. Loosen the four lip skirt retaining bolts.

7. Slide the four hopper lip skirts out of the retainer

plate.

8. Slide the new hopper lip skirts into place.

9. Tighten the retaining bolts and replace lip skirt

retainer.

4-11

QTFSG/QTFSD 98349 05/15/03

Page 29

MAINTENANCE

HOPPER DOOR SEALS

The hopper door seals prevent debris from spilling

out of the hopper before dumping. There are two

hopper door side seals, one hopper door lower seal

and one hopper door upper seal. The upper seal

can only be replaced by removing the hopper door

from the hopper. The hopper door seals should be

inspected for wear or damage daily. They do not

require adjustment.

REPLACING DOOR SEALS

1. Empty the debris hopper.

2. Park the machine on a smooth, level floor.

3. Raise the hopper and engage the hopper safety

arm.

Raised hopper may fall. Engage hopper safety

arm.

4. Partially open the hopper dump door so that

both sides of the hopper door can be accessed.

5. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

6. Remove the retainer bar from the worn or

damaged seal.

7. Remove the old seal and place the new seal in

position.

NOTE: When replacing the lower door seal, a new

seal cord must be used.

8. Replace the seal retaining bar. Replace and

tighten the screws.

HOPPER

4. Check the distance from the lower rear edge of

the hopper to the floor. The correct clearance is

2 inches (51 mm). The clearance should be

equal from side to side. A good method for

checking this clearance is to slide a 2 inch

(51mm) high bar under the hopper.

5. If necessary, loosen the two rear hopper

attachment bolts, raise or lower the rear of the

hopper to obtain the correct floor clearance, and

tighten bolts.

HOPPER DUST FILTER

The hopper dust filter cleans the dust laden air that

is drawn up from the hopper by the vacuum impeller.

The filter is located above the hopper and is

accessed by raising the filter cover. The filter should

be cleaned daily by pressing the filter shaker button

for 10-20 seconds. The filter should be removed,

cleaned and inspected after every 100 hours of

operation. Replace if damaged.

TO REMOVE AND REPLACE HOPPER DUST

FILTER

1. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

2. Raise the filter cover.

3. Loosen the four filter retaining bolts.

4. Rotate the lower two filter retaining tabs down.

5. Lift the left side of the upper filter retaining bar to

clear the retaining bolt and swing the bar down

to clear the right side of the filter panel.

6. Remove the filter.

7. After inspection or cleaning, install the dust filter

with the air flow arrow pointing up.

8. Replace the filter retaining bar, and the two

lower retaining tabs. Tighten the bolts.

The hopper holds debris swept by the main broom.

The hopper should be dumped after each day of

operation and cleaned every 200 hours of operation.

For efficient sweeping, the correct hopper floor

clearance must be maintained.

1. Empty the hopper.

2. Park the machine on a smooth, level floor.

3. Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

QTFSG/QTFSD 98349 05/15/03

4-12

Page 30

MAINTENANCE

To clean the filter after removal, use one of the

following methods:

1. TAPPING Tap the filter frame gently on the

dirty side of the filter down. Be

careful not to dent the filter frame.

2. AIR Blow compressed air through the

filter opposite the direction of the

arrow on the side of the filter. This

may be done with filter in the

machine. Wear eye and dust

inhalation protection when using

compressed air.

3. WATER The filter can be soaked in water

and mild detergent. Rinse the filter

until it is clean. Air dry the filter.

NOTE: Do not install the filter until it is completely

dry.

BRAKES (Refer to the Brake Group in the Parts

section)

The brake pedal and the parking brake operate the

two front tire disc brakes. The disc brakes should be

checked every 200 hours of operation, and adjusted

if necessary. The disc brakes should be adjusted so

that the disc pads are as close to the brake disc as

possible, without causing the brakes to drag.

TIRES

Tires should be inspected after every 100 hours of

operation. Pneumatic tires should be inflated to 90

PSI.

TO ADJUST THE BRAKES

1. Raise the hopper.

2. Engage the hopper safety arm.

Raised hopper arm may fall. Engage hopper

safety arm.

3. Turn off machine. Do not set parking brake.

FOR SAFETY: Before leaving or servicing machine,

stop on level surface, apply parking brake, turn off

machine and remove key.

4. Raise rear cover.

5. Disconnect batteries from machine.

6. Locate the brake adjustment screw on each

brake caliper.

7. Loosen the locknut and turn the adjusting screw

to adjust each brake. Tighten the locknut.

8. Lower the hopper.

9. Test brakes before beginning normal operations.

4-13

QTFSG/QTFSD 98349 05/15/03

Page 31

MAINTENANCE

SPECIFIC GRAVITY

BATTERY CONDITION

BATTERY

The battery provides the power to start the machine.

The battery requires regular maintenance to keep

them operating at peak efficiency.

To get the greatest life from the battery charge it

when their charge level reaches 25%of a full charge.

Use a hydrometer to check the charge level.