Page 1

TITA

N

M

WET/DRY VACUU

Record the model and serial number

located on the blue data label.

Owner’s Guide

WARNING

Unplug this machine before making

repairs or adjustments. Be sure all

electrical connections are correct and

that the wiring matches APPROPRIATE

diagram before plugging this machine

into an electrical outlet.

1. Maintenance and repairs

Use these numbers when calling upon the

Windsor dealer for parts and service.

MODEL : ______________________

SERIAL NO. : __________________

PURCHASE DATE : ____________

Contents:

1. Product Information

2. Warnings (English)

3. Warnings (French)

4. Warnings (Spanish)

5. Grounding Instructions

6. Maintenance

must only be done by

qualified personnel.

2. Using non-Windsor parts to

repair this machine will

void the warranty.

8. Servicing Vac Motor

9. Wiring Diagrams

10. Tank Squeegee Assemblies

12. Duct-Cord-Cover Assemblies

14. Lower/UpperHead Assemblies

16. Trouble Shooting

17. Notes

18. Warranty

D

TITAN 98165 2/14/01

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution must

always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

WARNING

• Do not operate without filters (dry or wet) in place.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Use indoors only. Do not use outdoors and do not expose to rain.

• Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

• Do not pick up flammable fluids, dust or vapors.

• Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not handle the plug or machine with wet hands.

• This machine is not suitable for picking up health endangering dust.

• Do not leave the machine unattended. Unplug machine from outlet when not in use and before servicing.

To reduce the risk of fire, electric shock, or injury:

This machine is for commercial use.

• Do not unplug machine by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not use with damaged cord or plug. Follow all instructions in this manual concerning grounding the

machine.

• If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an Authorized service center.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around

sharp edges or corners.

• Do not pull/run machine over cord. Keep cord away from heated surfaces.

• Do not allow to be used as a toy. Close attention is necessary when used by or near children.

• Do not operate machine with any openings blocked. Keep openings free of debris that may

reduce airflow.

• Keep hair, loose clothing, fingers, and all parts of the body away from openings and moving

parts.

• Use extra caution when cleaning on stairs

. Do not use machine as a step.

• Connect to a properly grounded outlet. See Grounding Instructions.

• Maintenance and repairs must be done by qualified personnel.

• Rotating fan blades inside the cover. Before opening cover, switch off machine. Wait until the

fan/brush stops completely or dust and debris may be ejected.

SAVE THESE INSTRUCTIONS

2

98165 07/01/97

Page 3

IMPORTANTES MESURES DE SÉCURITÉ

L’utilisation d’un appareil électrique demande certaines précautions:

LIRE TOUTES LES INSTRUCTIONS AVANT DE FAIRE

FONCTIONNER (CET APPAREIL)

AVERTISSEMENT

Pour réduire les risques d’incendie, de choc électrique ou de

blessure:

• Cet appareil ne doit être connecter qu a des prises ayant une sortie de terre. Se

reporter aux instructions de mise à la terre.

• Ne pas laisser l’appareil sans surveillance lorsqu’il est branché. Débrancher lorsque

l’appareil n’est pas utilisé et avant l’entretien.

• Avertissement. Pour reduire les risques de choc electrique, ne pas utiliser à

l exterieur et ne pas aspirer de matières humides.

• Ne pas permettre aux enfants de jouer avec l’appareil. Une attention particulière est

nécessaire lorsque l’appareil est utilisé par des enfants ou à proximité de ces derniers.

• N’utiliser que conformément à cette notice avec les accessoires recommandés par le

fabricant.

• Ne pas utiliser si le cordon ou la fiche est endommagé. Retourner l’appareil à un atelier de

réparation s’il ne fonctionne pas bien, s’il est tombé ou s’il a été endommagé, oublié à

l’extérieur ou immergé.

• Ne pas tirer soulever ou traîner l’appareil par le cordon. Ne pas utiliser le cordon comme une

poignée, le coincer dans l’embrasure d’unée porte ou l’appuyer contre des arêtes vives ou

des coins. Ne pas faire rouler l’appareil sur le cordon. Garder le cordon à l’écart des

surfaces chaudes.

• Ne pas débrancher en tirant sur le cordon. Tirer plutôt la fiche.

• Ne pas toucher la fiche ou l’appareil lorsque vos mains sont humides.

• N’insérer aucun objet dans les ouvertures. Ne pas utiliser l’appareil lorsqu’une ouverture est

bloquée. S’assure que de la poussière, de la peluche, des cheveux ou d’autres

matières ne réduisent pas le débit d’air.

• Maintenir les cheveux, les vêtements amples, les doigts et toutes les parties du corps à

l’écart des ouvertures et des pièces mobiles.

• Ne pas aspirer de matiéres en combustion ou qui dégagent de la fumée, comme des

cigarettes, des allumettes ou des cendres chaudes.

• Ne pas utiliser l’appareil si le sac à poussière ou le filtre n’est pas en place.

• Mettre toutes les commandes à la position ARRÊT avant de débrancher l’appareil.

• Usser de prudence lors du nettoyage des escaliers.

• Ne pas aspirer des liquides inflammables ou combustibles, comme de l’essence, et ne pas

faire fonctionner dans des endroits où peuvent se trouver de tels liquides.

• Ventilateur sous ce couvèrcle. Arretèr la machine avant D’ouvtir le couvercle. Attendre

que le ventilateur ait fini de tourner.

• Cette machine ne peut être utilisée pour aspirer des poussières dangereuses pour

la santé

CONSERVER CES INSTRUCTIONS

98165 2/1/99

3

Page 4

INSTRUCCIONES IMPORTANTES PARA

SU SEGURIDAD

Durante la utilzación de un dispositivo eléctrico hay que tener en cuenta una

serie de medidas básicas de precaución, que incluyen las siguientes

AD VERTENCIA

Para reducir el riesgo de incendios, descargas eléctricas

o lesiones:

• Conecte la aspiradora solamente a tomas de corriente con puesta a tierra. Tenga en

cuenta las instrucciones.

• No deje nunca el aparato conectado a la red. Después de su uso, y antes de cualquier revisión o

reparación, desconecte el aparato de la toma de corriente.

• No usar nunca el aparato al aire libre, ni sobre superfivies húmedas.

• No permita que se utilice el aparato como un juguete. Hay que prestar especial atencion al

utilizarlo en las cercanias de ninos.

• Utilzar el aparato sólo como se describe en este manual. Emplear exclusivamente los

accesorios recomendados por el fabricante.

• No poner en marcha el aparato con un cable eléctrico deteriorado. Si el aparato no funciona

como deberia, si se ha caido, danado, si ha permanecido al aire libre o si se ha caido al agua,

dirijase a un taller de servicio.

• No tire del aparato ni lo transporte utilzando el cable eléctrico; no use el cable a modo de asa, ni

cierre una puerta con el cable pillado; no tienda el cable en torro a aristas vivas o esquinas. No

pase con el aparato por encima del cable. Mantenga el cable simpre lejos de superficies

calientes.

• No desconecte el enchufe de la red tirando del cable. Para desconectar el aparato

hay que tirar del enchufe, no del cable..

• No maneje el enchufe ni el aparato con las manos húmedas..

• No introduzca ningún objeto en las aberturas del aparato. No utilice el aparato mientras esta

bloqueada uns de las aberturas; evite la penetración de polvo, hilachas, pelos o cualquier objeto

que pueda inhibir la circulación del aire.

• Mantenga su cabello, la ropa suelta, los dedos y todas las partes de su cuerpo alejadas de las

aberturas y piezas en movimiento.

• No utilice el aspirador para recoger cuerpos en llamas o humeantes, tales como cigarrillos,

cerillas o cenizas calientes.

• No utilizar nunca el aspirador sin la bolsa y/o los filtros colocados en su lugar

previsto.

• Desconecte todos los interruptores antes de desenchufar el aspirador..

• La aspiradora no es adecuada para recoger agentes que dañen la salud.

• Tenga especial cuidado al manejar la aspiradora en una escalera..

• No utilice el aspirador para recoger liquidos inflamables o combustibles, tales como

gasolina, ni maneje el aspirador en zonas donde pueda haber liquidos de este tipo..

CONSERVE ESTAS INSTRUCCIONES A MANO

4

98165 07/01/97

Page 5

THIS PRODUCT IS FOR COMMERCIAL USE ONLY.

t

p

A

A

A

A

A

ELECTRICAL:

In the USA this vacumm operates on a standard 15 amp

115 volt A.C. power circuit (120V nominal). Special

voltage models are available for international

applications. The amp, hertz, and voltage are listed on

the data label found on each machine. Using voltages

above or below those indicated on the data label will

cause serious damage to the motors.

EXTENSION CORDS:

If an extension cord is used, the wire size must be at least

one size larger than the power cord on the machine, and

must be limited to 50 feet (15.5m) in length.

ADVERTISSEMENT:

Un conducteur de terre mal raccorde peut entrainer

un risque de choc electrique. Consulter un elctricien

ou un technicien d’entretien qualifie si vous n’etes

pas certain que la prise est corectement mise a la

terre. Ne pas modifier la fiche fournie avec l’appareilsi elle ne peut etre inseree dans la prise, faire

installer une prise adequate par un electricien

qualifie.

PROPER GROUNDING

Grounding Pin

Prise de cou r an t av ec mi se a la terre

Vis metallique

Metal Screw

Fig. B

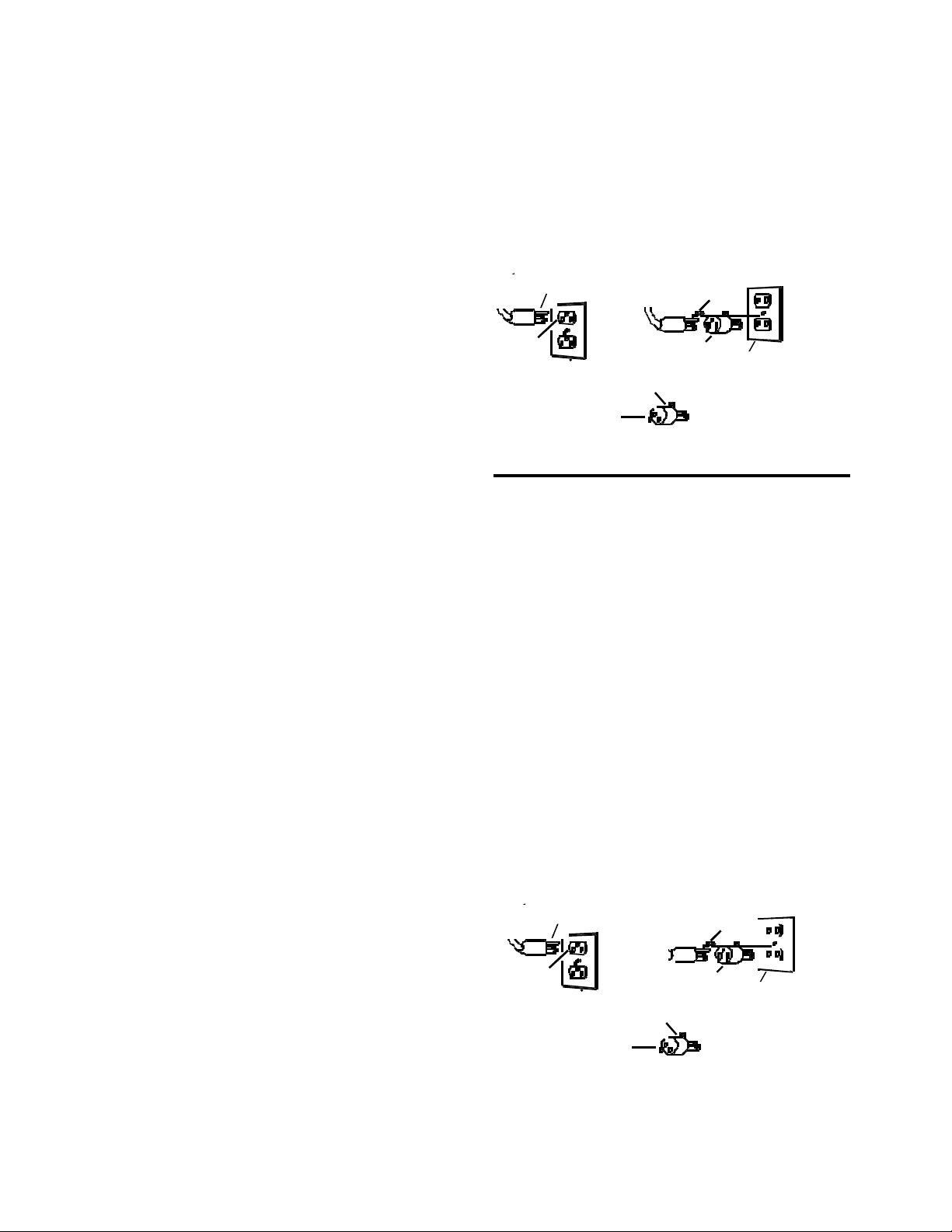

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a path of

least resistance for electrical current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and grounding

plug. The plug must be inserted into an appropriate

outlet that is properly installed and grounded in

accordance with al local codes and ordinances.

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug in “Fig.

A”. A temporary adaptor that looks like the adaptor in

“Fig. C” may be used to connect this plug to a 2-pole

receptacle as shown in “Fig. B”, if a properly grounded

outlet is not available. The temporary adaptor should be

used only until a properly grounded outlet (Fig. A) can be

installed by a qualified electrician. The green colored

rigid ear, lug, or the like extending from the adaptor must

be connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adaptor is

used, it must be held in place by a metal screw.

WARNING:

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the

appliance-if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

INSTRUCTIONS VISANT LA MISE A LA TERRE

Cet appareil doit etre mis a la terre. En cas de

defaillance ou de panne eventuelles, la mise a la terre

fournit au courant un emin de moindre resistance qui

reduit le risque de choc l’electrique. Cet appareil est

pourvu d’un cordon muni d’un conducteur de terre et

d’une fiche avec broche de terre. La fiche doit etre

branchee dans une prise appropriee correctement

installee et mise a la terre conformement aux reglements

et ordonnances municipaux.

Grounded

Outlet

roche

e mise

la terre

NOTE: In Canada, the use of a temporary adaptor is no

ermitted by the Canadian Electrical Code

NOTE: Au Canada, l’utilisation d’un adaptateur temporaire

n’est pas autorisee par le Code canadien de l’electricite.

Fig. A

INSTRUCCIONES PARA LA PUESTA A TIERRA

Este dispositivo tiene que ser puesto debidamente a

tierra.Si se produce una avena o rotura, la conexion a

tierra constituye el camino de menor resistencia para la

corriente electrica, reduciendose el riesgo de descargas

peligrosas. El aparato cuenta con un cable conductor de

puesta a tierra y un enchufe con clavija de puesta a

tieraa de acuerdo con las normas y ordenanzas locales.

ADVERTENCIA

Si se conecta de modo inadecuado el conductor de

puesta a tierra del aparato pueden producirse descargas

electricas peligrosas para el usuario. En caso de dudas,

pedir a un electricista debidamente cualificado o a un

tecnico del serviso postventa que verifique que la toma

de corriente esta bien puesta a tierra. Si el enchufe

suministrado con el aparato no se adapta a la toma de

corriente disponible, no hay que modificar el enchufe,

sino dirigirse a un electricista para que instale una toma

corriene adecuada.

PROPER GROUNDING

Clavija de puesta a tierra

Torna de

corriente

conectada a

tierra

DVERTENCIA: En Canada, la Canadien Electrical

Code prohibe el uso de adaptadores temporales.

T/SG 98165 03/24/00

daptateur-

Platte destinee a la vise

de terre

Tab For Grounding

Adaptor

daptateur

Fig. A

pendice para tornillo

de conexion a tierra

daptador

Adaptor

Fig. C

Tornillo metalico

Adaptador

Fig. C

Grounded Outlet Box

Boite de sortie mise

a la terre

Fig. B

Apendice para tornillo

de conexion a tierra

5

Page 6

6

T/SG 98165 7/1/97

Page 7

Caution: Strippers and some detergents

produce foam which will damage the vac motors.

The vac shut-off may not be sensitive to all

foams. Be sure to check that the tank is not

filling with foam. Use a defoaming agent to

avoid pulling foam through vac motor. Should

vac motor become wet, remove source of

overflow and immediately run vac motor open to

dry.

DAILY MAINTENANCE:

(At the end of each working day):

1. After each use, rinse tank with fresh water.

Periodically inspect the recovery tank and

decontaminate if necessary, using a Hospital

Grade Virucide or a 1:10 bleach to water

solution. Waste water should be disposed of

properly.

2. Remove head assembly and allow tank to dry.

3. Remove filters for cleaning or to allow to dry.

4. Inspect hoses for wear. Frayed or cracked

hoses should be replaced to avoid vacuum loss.

5. Inspect power cord for wear. This cable will lay

on wet surfaces. To prevent electrical shock

replace cords with frayed or cracked insulation

immediately.

PERIODIC MAINTENA NCE:

(Every six to twelve months):

1. Check filter for wear, replace dirt saturated filters

that do not respond to normal cleaning.

2. Inspect gasket seals and replace those which

have begun to leak.

3. Examine carbon motor brushes and

commutator, replace or repair as necessary.

See page 8.

SERVICING THE FILTER:

The filter is accessed by lifting the head assembly

off the tank.

To remove the filter, pn 341 93, loosen the black

knob, pn 48046, located in the center. This knob

should always be “finger tight”, don’t over-tighten.

With both wet and dry applications be sure to

frequently clean the filter. This is especially true

when the vacuum is being used with strippers and

wax.

Allow the filter to dry after being used for wet pickup.

NOTE: Filters used for wet pick-up including stripper

must be thoroughly cleaned before being allowed to

dry.

Worn filters can affect vacuum performance.

Replace the filter when it becomes worn out and

normal cleaning will not restor e vac perfor mance.

GASKETS:

There are several gaskets in the Titan which must

have a good seal for the machine to operate

properly.

The gaskets on the vac motors should be replaced

together in the event that one wears out and begins

to leak.

The gasket inside the head assembly must contact

the tank all around. When repairing this gasket, pn

99862, apply glue to the ends and at the corners to

insure long life. Any instant adhesi ve which does

not attack ABS plastic will work, (CA40H by 3M or

equivalent).

There is a large gasket between the tank plate, pn

62307, and motor support/sound plate, pn 62370

(twin), pn 62371 (single). In the unlikely event this

gasket begins to leak, separate the two plates as

shown in the assembly drawing on page 9 and

remove the old gasket completely, then apply the

new gasket pn 35107 (both twin and single), taking

care to line it up correctly.

To replace the vac hose elbow gasket, pn 35103, it

will be necessary to remove the main cover and

loosen the nut which holds the elbow in place.

Always be sure the cover seats in the groove on the

elbow when putting it back on.

The gasket, pn 35066, located inside the filter cage,

pn 27240, must be in place to insure that no fluid

enters the vac motor if an over flow should occur.

T/SG 98165 7/1/97

7

Page 8

Servicing the Vac Motor

To access the vac motor (s) remove the (6) screws which attach the main cover to the head

assembly and set the cover to one side. The carbon motor brushes can now be serviced, to replace

the motor assembly or service the vac motor gasket it will be necessary to open the vac exhaust

chamber, remove the (9) screws around the edge of the exhaust chamber plate and remove the two

screws from each vac motor connecting it to the vac chamber plate. When re-installing the vac

motor(s) be sure the vac shut-off disc(s), pn 62798, are in place. See page 9.

Attach Ground Wire to the post nearest the

terminal block.

WARNING

Ground wire, pn 88623, must attach the motor to

the terminal block, and the terminal block must

be attached to the ground wire from the power

cord for safe operation.

8

T/SG 98165 7/1/97

Page 9

WIRING DIAGRAMS

100V Twin

T16/2-J

T/SG 98165 7/1/97

T10J, T16J

9

Page 10

TANK ASSEMBLY

SQUEEGEE ASSEMBLY

(SUPER GULP MODELS ONLY)

30

31

30

10

T/SG 98165 10/18/99

Page 11

TANK ASSEMBLY

REF PART NO. DESCRIPTION

1A 75166 Tank, 16 Gallon

1B 75169 Tank, 10 Gallon

2 18011 Caster, 3” Swivel

3 87025 Washer, ¼ Star

4 70011 Scr, ¼-20 x 5/8 HHMS

5 78258 Tube, Squeegee Pivot

6 87008 Washer, ¼-20 x 1.25 Flat

7 70019 Scr, ¼-20 x 1.25 HHMS

8 62357 Plate, Squeegee Lock

9 67104 Ring, 5/8 External Snap

10 87088 W asher, 5/8 Flat

11 89074 W heel, 8” Dia. W/ .62 Bore

12A 03064 Axle, 16 Gallon Tank

12B 03071 Axle, 10 Gallon Tank

13 87090 W asher, 1/4ID x 3/4OD pltd.

14A 39404 Hose, 1.5 Drain 20” (16)

14B 39244 Hose, 1.5 Drain 14.5” (10)

15 66152 Plug, Drain Hose

16 27188 Cord Assembl y, Drain Plug

17 40019 Hosebarb, 1. 5 Double Machined

18 20002 Clamp. 2” Nyl on Ratc het

19 70052 Scr, 8-32 x 3/8 PHMS

20 87007 W asher, #8 Star

21 87017 Washer, #8 Flat

22 14520 Bracket , Drain Hose

23 66016 Plug, 7/8 Dress

24A 38178 Handle, 16 Gallon

24B 38179 Handle, 10 Gallon

25 50543 Label, Main Tank

26 50545 Label, Super Gulp

27 70018 Scr, ¼-20 x 1.0 HHCS SS

28 70020 Scr, ¼-20 x 1/2HHMS

29 87013 W asher, 1/4ID x 5/8OD SS

30 51281 Latch, Flexible Draw

31 70170 Scr, 10-24 X ¾ PPHMS PLTD

SERIAL NO.

FROM

NOTES:

SQUEEGEE ASSEMBLY (SUPER GULP MODELS ONLY)

REF PART NO. DESCRIPTION

1 57112 Nut, 5/16 External Snap

2 14926 Brkt, Squeegee Rev. Wheel

3 66108 Pin, Squeegee Roller

4 67103 Ring, 5/16 External Snap

5 87024 Washer, 3/8 Star

6 89058 Wheel, Squeegee Roller

7A 70469 Scr, 3/8-16 x 1/2HHMS

7B 70470 Scr, 3/8-16 x 5/8 HHMS

8 87016 Washer, #10 Lock Ext.

9 87029 Washer, 5/16 Flat SAE

10 73600 Shoe Asm, Outter Squeegee

11 73557 Shoe, Squeegee Asm 24” Inner

12 73605 Squeegee Blade, 27” Maize

13 66016 Plug, 7/16 Dress

14 57113 Nut, 5/16-18 Lock

15 70195 Scr, 10-32 x 1.25 SS

16 51178 Lever, Squeegee

17 57104 Nut,10-32 w/ St ar Washer

18 62384 Plate, Squeegee Pivot

19 34225 Frame, Assembly Squeegee

T/SG 98165 10/18/99

SERIAL NO.

FROM

NOTES:

11

Page 12

VAC COOLING DUCT

12

T/SG 98165 2/14/01

Page 13

VAC COOLING DUCT

REF PART NO. DESCRIPTION

1 34216 Foam, Duct Bottom

2 OPEN

3A 29168 Duct, 120V TT Vac Cooling Twin

3B 29167 Duct, 120V T Vac Cooling Single

4A 29169 Duct, w/ Foam, 120V Twin

4B 29166 Duct w/ Foam, 120V Single

5 70430 Scr, #8-18 x 3/8 PHP Single

6 87017 Washer, #8 Flat Single

7 71112 Support, 115V Vac Duct Single

SERIAL NO.

FROM

NOTES:

MAIN COVER ASSEMBLY

REF PART NO. DESCRIPTION

1 26006 Cord End, 125V 15A NEMA

2 73505 Strain Relief, 1/2NPT

3 57040 Nut, 1/2NPT Conduit

4A 27443 Cover, Standard Single

4B 27529 Cover Twin Only

5 34217 Foam, Cover

6A 72125 Switch, 16 (4) SPST 16 (4) a rckr 16/2 & 16/2J’s

6B 72076 Switch, 16 (4) A DPST Rckr. Singles & I Twins

7 27376 Clip, Switch Retaining

8 87095 Washer, #10 Flat

9 70440 Scr, 10-24 x 5/8 PHMS

10A 50544 Label, Twin

10B 50542 Label, Single

11A 50567 Label, 1017 UL/CSA Warning

11B 50577 Label, Warning Caution Japan

12 50742 Label, Warning Explosion Hrz.

13 50776 Label, For Safety

SERIAL NO.

FROM

NOTES:

T/SG 98165 2/14/01

13

Page 14

UPPER HEAD ASSEMBLY

LOWER HEAD ASSEMBLY

18

14

19

T/SG 98165 10/18/99

Page 15

UPPER HEAD ASSEMBLY

REF PART NO. DESCRIPTION

1 35107 Gasket, Support Plate

2 62798 Plate, Vac Shut-Off Disc

3A 62370 Plate, Twin Motor Support

3B 62371 Plate, Single Motor Support

4 87017 Washer, #8 Flat

5 70429 Scr, #8-18 x 3/4PHP H-L

6A 53742 Motor Asm, 115V Twin

6B 53751 Motor Asm, 115V Single

6C 53756 Motor Asm, 100V Twin & Single

7A 27539 Chamber, Twin Exhaust

7B 27540 Chamber, Single Exhaust

8 87095 Washer, #10 Flat

9 OPEN

10 OPEN

11 OPEN

12 OPEN

13A 50686 Label, 115V Twin Wiring

13B 50546 Label, 115V Single W iring

13C 50687 Label, 100V Twin Wiring

13D 50592 Label, 100V Single Wiring

14 57104 Nut, 10-32 w/ Star Washer

15 70386 Scr, 10-32 x 1.0 PHMS

16 70114 Scr, #10 x ¾ Polyfast

SERIAL NO.

FROM

NOTES:

REF PART NO. DESCRIPTION

1 35103 Gasket, Hose Elbow

2 31061 Elbow, Swivel

3 22037 Clip, Hose Lock

4 62307 Plate, Tank

5 35179 Gasket, Tank Plate

6 34193 Filter, Wet/ Dry Cartridge

7 48046 Knob, ¼-20

8 73516 Standoff, ¼-20 x ½

9 87025 Washer, ¼ Star

10 87087 Washer, M8 x 25 pltd

11 27240 Cage, Wet/Dry Filter

12 34116 Float, Vac Shut-Off Ball

13 35066 Gasket, Float Shut-Off

14 57164 Nut, 2” NPT

15 62470 Plate, Su ppor t Basket

16 57047 Nut, ¼-20 Loc k

17 70430 Scr, #8-18 x 3/8 PHP

18 48070 Keeper, Front Mount Blk

19 70608 Scr, 1 ¼” Coarse Blk Deck

LOWER HEAD ASSEMBLY

SERIAL NO.

FROM

NOTES:

T/SG 98165 10/18/99

15

Page 16

DAILY MAINTENANCE:

(At the end of each working day):

1. Rinse tank

2. Remove cover and allow to dry.

3. Remove filters for cleaning or to allow to dry.

4. Inspect hoses for wear. Frayed or cracked

hoses should be replaced to avoid vacuum

loss.

5. Inspect power cord for wear. This cable will

lie on wet surfaces. To prevent electrical

shock replace cords with frayed or cracked

insulation immediately.

TROUBLESHOOTING CHART:

PROBLEM POSSIBLE CAUSE

No Power to Machine Dead electric al circuit

Power switch failure

Faulty power cord

Electrical Shock Equipment not grounding

Receptacle not grounded

Internal wiring problem

Vac motor speed Worn motor brushes

varies or doesn’t run

Loss of vacuum Broken vac hose

NOTE: Maintenance and repairs must be done by qualified personnel. Using non-Windsor parts to repair this machine wil l void

the warranty. A complete service manual is available upon request which includes wiring diagrams, parts lists, part diagrams and

basic repair instructions for the entire machine. Contact an authorized Windsor dealer for complete details.

Motor worn out

Motor has overheated

Faulty switch

Worn out vac motor

Lint clogging vac motor

Loose cuffs on vac hose

Vac motor seals leaking

Lint or dirt clogging vacuum

hose or tool

Faulty vac housing seals

SOLUTION

Check building circuit breaker or fuse box.

Replace.

Replace.

Follow grounding instructions exactly.

Contact an electrician to check buildings wiring.

Have a trained service technician check machine’s wiring.

Replace.

Replace.

Clear air obstruction and wait for motor to cool down.

Replace.

Replace.

Replace.

With power off, clean motor.

Tighten cuffs turning counterclockwise.

Replace.

With power off, clean out obstruction.

Replace.

16

T/SG 98165 7/24/97

Page 17

NOTES:

T/SG 98165 7/1/97

17

Page 18

LIMITED WARRANTY

Windsor Industries, Inc. warrants new machines against defects in material and workmanship

under normal use and service to the original purchaser. The warranty period is subject to the

conditions stated below.

3 YEARS FOR PARTS AND 1 YEAR FOR SERVICE LABOR

Exceptions: Rotationally molded polyethylene tanks carry a 6 year parts and 1 year service

labor warranty.

motors, and belts, and a 1 year service labor warranty. SENSOR

warranty on vacuum motors and belts, and a 1 year service labor warranty. Extractor brush

motors, pump motors, pc boards and electronics, vac motors (other than

VERSAMATIC

SENSOR®), pumps, and FLEXSOL™ diaphragms, all RADIUS™, all AXCESS™ and

TITAN™1 carry a 1 year parts and service labor warranty. Propane equipment has a 1 year

parts and service warranty. The Onan® engines have a 3 year manufacturers’ warranty. The

Honda® engines have a 2 year manufacturers’ warranty. The engine warranty is administered

through the engine manufacturer and must be repaired at an authorized service center.

Normal wear items including, but not limited to, belts, brushes, capacitors, carbon brushes,

casters, clutches, cords, filters, finishes, gaskets, hoses, light bulbs, rectifiers, switches, squeegees, bearings, pulleys, relays, actuating cables, tires and wheels will be warranted for

manufacturing defects for 90 days from the purchase date.

The warranty commences on the purchase date by the original end user from an authorized

Windsor Agent, subject to proof of purchase. The Machine Registration Card must be

completed and returned immediately at the time of purchase. If proof of purchase cannot be

identified, the warranty start date is 90 days after date of sale to an authorized Windsor

distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the

original warranty period.

®

models carry a 3 year warranty on brush motors, vacuum

®

models carry a 2 year

VERSAMATIC® and

90 DAY WARRANTY EXTENSION AVAILABLE

Upon receipt of the Machine Registration Card, Windsor will extend the warranty period an

additional 90 days from the purchase date. Does not include items warranted 90 days for

manufacturing defects.

STATED WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED.

Any statutory implied warranties, including any warranty of merchantability or fitness for a

particular purpose, are expressly limited to the duration of this written warranty. Windsor will not

be liable for any other damages, including but not limited to indirect or special consequential

damages arising out of or in connection with the furnishing; performance, use or inability to use

the machine. This remedy shall be the exclusive remedy of the buyer.

This warranty shall not apply to: 1.damage in transit; 2.misuse or abuse(including the use of

incompatible or corrosive chemicals or overloading of capacity); 3. failure due to lack of proper

maintenance and care (including cleaning); 4.any design alterations performed by an

organization not authorized or specified by Windsor; 5.batteries and chargers. 6. high pressure

washing. 7.electrical components exposed to moisture.

If difficulty develops during the warranty period, contact the authorized Windsor Agent from

whom the product was purchased. Windsor, Inc. may elect to require the return of components

to validate a claim. Any defective part to be returned must be shipped freight pre-paid to an

authorized Windsor Distributor/Service Center or to the Windsor factory.

USE OF PARTS NOT APPROVED BY WINDSOR, INC.

WILL VOID ALL WARRANTIES.

This warranty is valid only for all products sold after July 1, 1995. A product sold before that

date shall be covered by the limited Warranty in effect at the date of sale to the original

purchaser.

ã 1999 Windsor Industries, Inc. All rights reserved. REVISED 0 3/24/99

Loading...

Loading...