Page 1

Equipment Basics Course

“With everything else dropping out of the competitive equation,

knowledge has become the only source of long-run, sustainable,

competitive advantage”

-Lester Thurow

Page 2

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Vacuum Products

Vacuums are the most versatile product of all cleaning equipment. Every

location you encounter will need vacuum products. The style of vacuum required

depends on the application. Vacuuming should be done before any carpet

cleaning is attempted.

Fan or Impeller Vacuums

Fan or impeller vacuums are the most common style of vacuum.

Impeller vacuums use a fan attached to a high speed motor that creates

air flow. Similar to a propeller, these fans spin at high speed and create

suction. Impeller vacuums are not “true” vacuums, since no sealed

containment bin is present. These units pick up the soil and force it into a

containment bin. In most cases, the containment bin is a paper bag

housed inside of a cloth shake-out bag. In some instances, the

collection bin is a dust cup collector that does not require a bag. This

system is commonly referred to as a “dirty air system.” The dirt and debris

passing directly through the impeller will damage it over a period of time.

Impeller vacuums generally employ the use of a beater bar/brush combination.

Over time, the beater bar can damage carpet by breaking off fibers. The filtration

level on this style of vacuum is usually low because of the soil being forced

through the collection bag. These vacuums make up a large percentage of all

vacuums sold in the commercial market. The prices range from $130-$250

depending upon the make and model. These vacuums generally have a short

life expectancy and require repeated maintenance. Common brands include

Eureka Sanitaire, Oreck, Hoover, Panasonic and Royal. Windsor does not

manufacture or promote this style of vacuum.

Single Motor Uprights

Single motor uprights use an electric motor that creates a vacuum and

propels the brush roller. While only employing a single motor like an

impeller style vacuum, these vacuums are considered “clean air

systems” based on the soil never traveling through the vacuum motor.

The air movement created is pulled through the containment bin or

bag housing where the soil is collected in a disposable bag. The air

then exits the compartment through a filter system. There are many

differentiation points on these units--some have automatic adjustments, lights

that identify a full bag or clogs and many other features you will not find on the

fan-style vacuum. Many of these units provide indoor air quality (IAQ) features

with 99.6% filtration at .3-microns. These units will take a little more sales skill,

but studies have shown that over 50% of the fan-style purchasers would buy this

type unit over the existing fan model given the opportunity and the proper value

explanation. The pricing varies significantly with features and benefits and range

Page 3

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

from $225-$500. Common brands include Windsor, Advance, Clarke, NSS,

Tennant, Hoover, and Panasonic. Windsor products include:

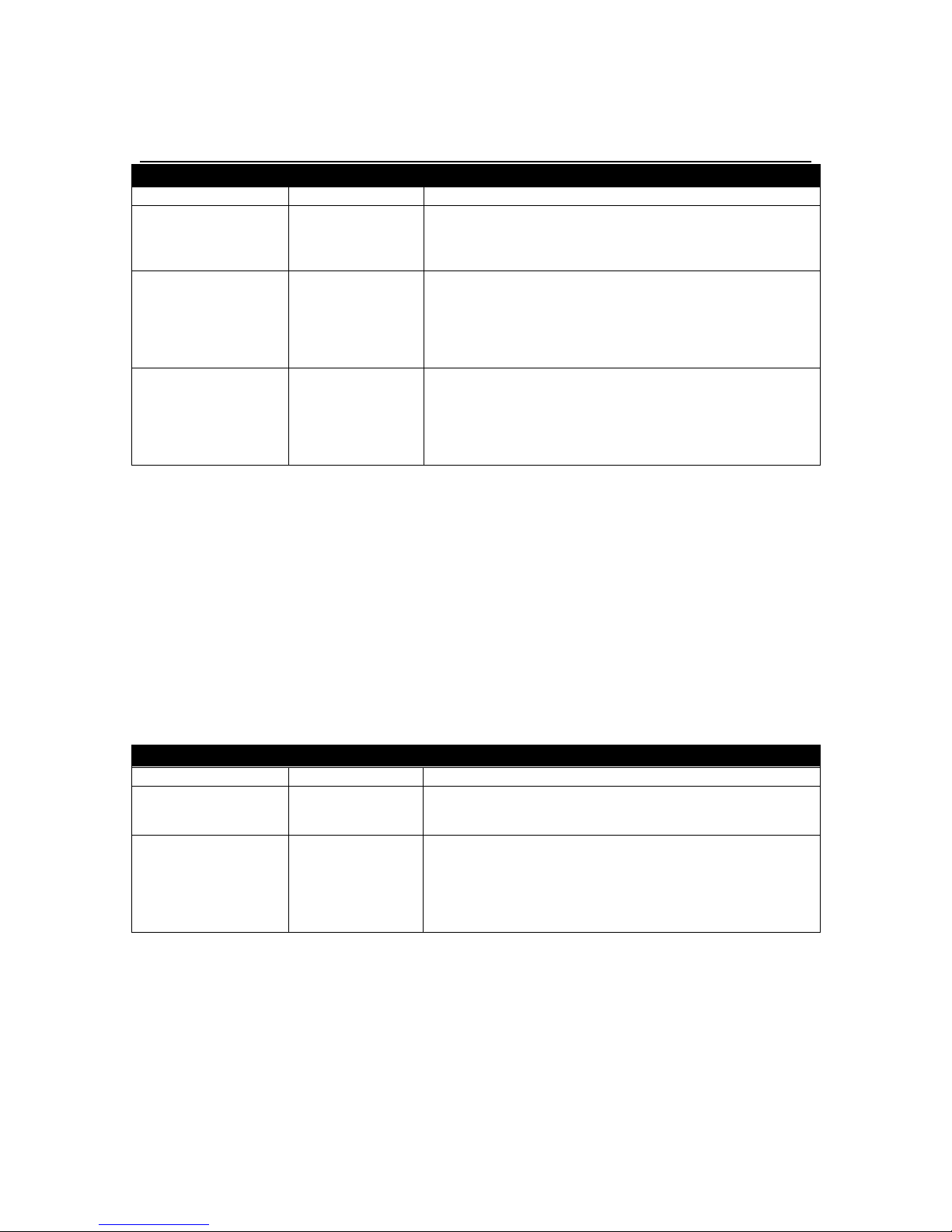

Windsor Single Motor Upright Products

Product

Stock #

Advantages

Sensor XP 12

Sensor XP 15

Sensor XP 18

1.012-024.0

1.012-027.0

1.012-030.0

• Automatic adjustment of the vacuum brush for any

surface

• Wand for detail work

• Sensor automatically shuts down when the bag is

full

• Sensor automatically shuts down when brush motor

is clogged

• 99.6% efficient at .3 microns

Sensor S 12

Sensor S 15

1.012-021.0

1.012-022.0

• Wand for detail work

• Sensor automatically shuts down when the bag is

full

• Sensor automatically shuts down when brush motor

is clogged

• 99.6% efficient at .3 microns

Dual Motor Upright Vacuums

Considered the “work horse” model because of its durability,

dual motor vacuums are for high usage applications. Dual

motor vacuums are designed to run significant hours in a day

and have high duty cycles. These units use an independent

vacuum motor and a brush motor to keep performance high

and failures low. This makes them more of an investment

when compared to single motor vacuums. These vacuums

generally have a long life expectancy due to their simple reparability. Repairs

can be more costly, but occur less frequently that lower priced vacuums. Like the

single motor uprights, dual motor uprights are “clean air systems,” so soil never

travels through the vacuum motor. Dual motor uprights are true vacuums.

These vacuums employ a disposable paper bag and occasionally have a cloth

bag option housed in the containment housing. Dual motor uprights are

excellent choices in facilities that have heavy traffic and require years of service

from their vacuums. Applications such as education, healthcare, large public

facilities and hospitality are excellent fits. Anywhere you can sell value and

longevity; this will be the vacuum of choice. This product requires more sales

skill than any of the others since you are selling quality, productivity and

longevity over price. The price point runs anywhere from $450-$900 depending

upon manufacture and model. Common brands include Windsor, Advance,

Clarke, NSS, and Tennant. Windsor products include:

Page 4

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Windsor Dual Motor Upright Products

Product

Stock #

Advantages

Versamatic 14

Versamatic 18

1.012-034.0

1.012-036.0

• The oldest dual motor vacuum still available

• Removable brush strip allows replacement of the

strip rather than the entire brush roll

Versamatic Plus 14

Versamatic Plus 18

1.012-038.0

1.012-040.0

• Removable brush strip allows replacement of the

strip rather than the entire brush roll

• As on all the Windsor vacuums, the belt that drives

the brush is completely enclosed and protected

• Utilizes the same bags as the Sensor, which allows

the customer to only stock one bag

Axcess 12

Axcess 15

1.012-061.0

1.012-062.0

• Axcess steers right and left with a turn of the wrist

• 20% faster than a conventional vacuum in

congested areas

• Better for people with Carpal Tunnel Syndrome

• Burnisher head available to turn Axcess into small

area active filtration burnisher

Wide Area Vacuums

Any vacuum that employs a vacuum shoe of 20” and higher is

considered a wide-area vacuum. Most models range from 24”-30”.

Wide area vacuums operate on the same “clean air system” as dual

motor uprights, only in a larger capacity. In most cases, these units

will employ dual vacuum motors to compensate for the larger

opening. These units are designed to be used in large open areas of

carpet or long hallways. Wide area vacuums can offer high filtration and

increased productivity over uprights. Most wide area vacuums utilize a single

brush-roller, some (including the NuWave) employ dual counter-rotating brush

technology. Windsor products include:

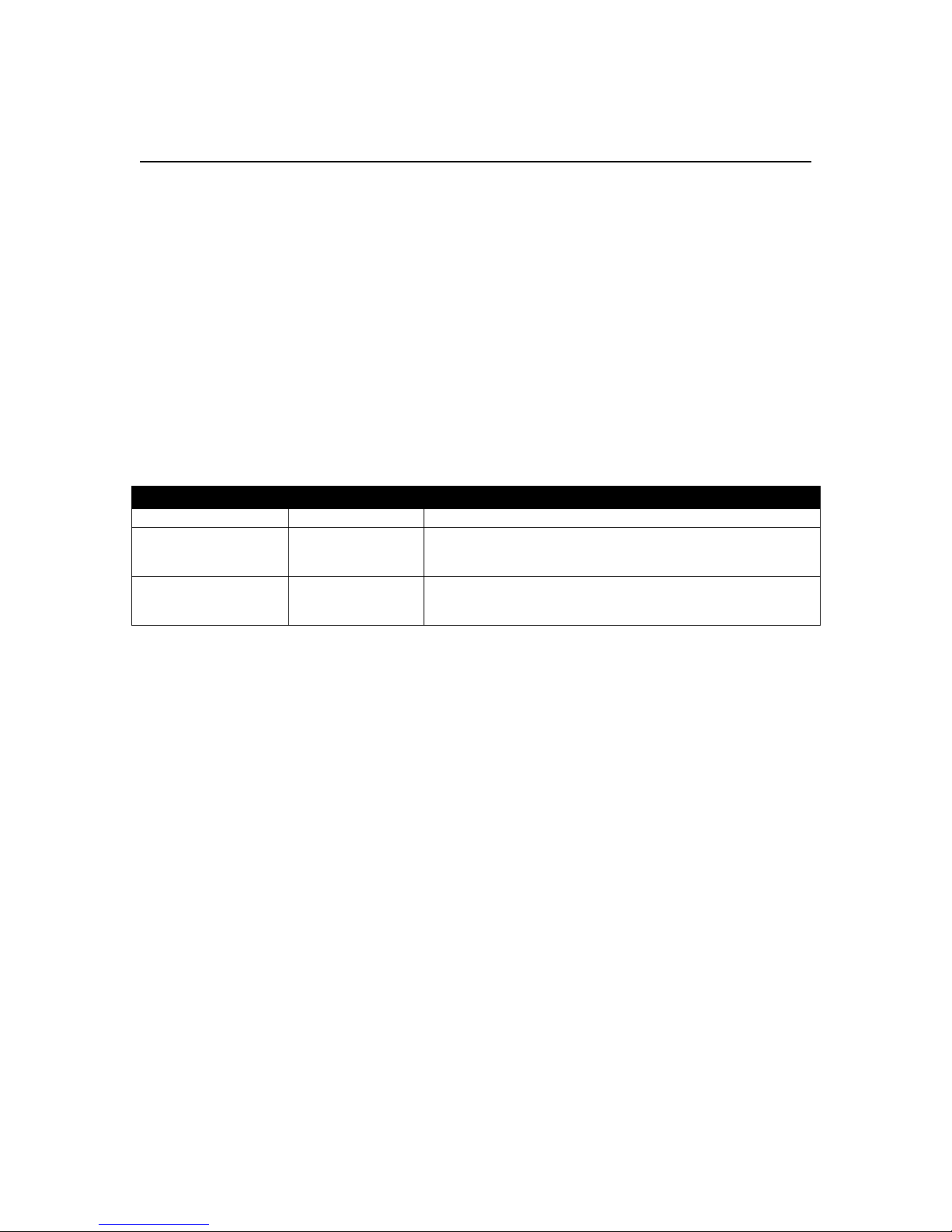

Windsor Wide Area Vacuum Products

Product

Stock #

Advantages

Wave 1.012-505.0

• 75’ cord

• 6 position height adjustment

• On-board tools & wand

NuWave

1.012-533.0

• Dual counter rotating brushes for front & back pass

in single stroke

• Floating brush deck requires no operator

adjustments

• Brushes are removable with no tools for easy

cleaning

Sweeper/Vacs

Over the past five years, sweeper/vacs have seen a steady

increase in replacing cord electric wide area vacuums. This

is based primarily on the tremendous increase in

productivity with a sweeper/vac that is obtained by

eliminating the cord and by utilizing battery power.

Sweeper/vacs operate similar to impeller vacuums, except

Page 5

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

the soil and debris do not travel through the fan. The impeller in a sweeper/vac

only creates a small amount of airflow that assists in collecting lighter dust and

soil. The large main broom “sweeps” the soil and debris into a hopper. These

machines can be used in outdoor or indoor applications, but never both with the

same machine. These work well in environments where larger objects are being

picked up. A movie theater would be a location that you might sell a sweeper.

Areas that have hard floors and carpet floors that want a dual-purpose unit might

be another. Sweeper/Vacs lack high quality filtration and are not true vacuums.

The prices and styles vary greatly and range from $1000 for low-end sweepers to

$6000 for very large ones. Brands include, Windsor, IPC Eagle, Tennant and

Advance. Windsor products include:

Windsor Walk Behind Sweeper/Vacs

Product

Stock #

Advantages

Radius 280 Deluxe

1.517-206.0

• Battery powered

• Vacuum fan provides active dust control

• Easy main and side broom adjustments

• Side broom fold up for cleaning in dusty

environments

Radius 300

9.840-664.0

• 1.4 ft3 (40 l) hopper capacity

• Active dust control system

Canister Vacuums

Canister vacuums employ a wand and hose connected to a

“canister” that sets on the ground. In some models the vacuum

head contains an electrically powered brush roller. In other models

no brush roller or power is present. Canister vacuums have become

a popular replacement for back pack style vacuums since they have

similar components. A canister vacuum can trail along with the user

but do not have to be carried on the back. Many canister vacuums are quieter

than their upright counterparts and are great to use in noise sensitive areas such

as call centers and lobbies. Canister vacuums have better filtration than fan or

impeller vacuums and therefore are preferable replacements to that style.

Canister vacuums are considered “clean air systems” and are “true vacuums”.

Pricing varies significantly from low 100’s up to $1000.

Common brands include Windsor, North American, and Advance. Windsor

products include:

Windsor Canister Vacuum Products

Product

Stock #

Advantages

Trekvac 2

1.527-104.0

• Washable nylon main filter

• Quick connect hose system

• Onboard floor tool storage

Trekvac 3

1.355-107.0

• Washable nylon main filter

• Quick connect hose system

• Onboard floor tool storage

• 61 dB allows for cleaning in sound sensitive areas

• 99% efficient at .3 microns

Page 6

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Back Pack Vacuums

Back pack vacuums have made a strong impact on the

market in applications where quick vacuuming is a necessity.

Back pack vacuums are essentially canister vacuums that

the operator wears. They offer similar features and options

as canister vacuums. This is the only style of cleaning

equipment an operator wears. Back packs utilize a single

motor but the performance is not as high as a standard vacuum because it lacks

brush agitation. Building service contractors represent the largest segment of

end-users for this product. Prices range from $350-$700. Common brands

include Windsor, ProTeam, Clarke, Advance, Tennant, and NSS. Windsor

products include:

Windsor Back Pack Vacuum Products

Product

Stock #

Advantages

Vac Pac 6

1.014-007.0

• Spacer between belt and motor to reduce heat on

lower back

• Wide variety of tools

Vac Pac 10

1.014-005.0

• Spacer between belt and motor to reduce heat on

lower back

• Wide variety of tools

Wet/Dry Vacuums

Wet/Dry vacuums are a very commonly used piece of equipment used

primarily for wet pick up. It can be used for dry applications but a filter

bag must be placed in the tank of the machine to prevent dust from

being pulled into the vacuum motor. Wet/dry vacuums have

increasingly become commodity products over the past 10 years. With

a large influx of consumer products into the market, the profitability of

these units has dropped dramatically in the commercial segment. Virtually every

facility has the need for a wet/dry vacuum. A bypass motor of 1.5 to 3

horsepower is the standard. The machine is traditionally used with a 2-bend

wand and a squeegee floor tool. Front mount squeegee units are very effective

for fast recovery of liquid. Inexpensive units designed for consumer use do not

usually have a commercial bypass vacuum as part of the machine. They are

rated to run 30 minutes a week versus 8 hours per day on a commercial wet/dry.

Windsor products include:

Page 7

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Windsor Wet/Dry Vacuums

Product

Stock #

Advantages

Titan 8

Titan 16

Titan 20

1.013-006.0

1.013-008.0

1.013-010.0

• 87” of waterlift

• Made with strong blow-molded plastic

• Comes with 8 piece tool kit

Recover 7

Recover 12

Recover 17

Recover 12 w/FMS

1.428-513.0

1.428-609.0

1.667-142.0

9.840-844.0

• Onboard cleaning tools storage

• 94.3” of waterlift on Recover 17

• 80” of waterlift on Recover 7 & 12

Chariot iVac ATV 24 & 34

Recently, a new category was created by Windsor with

the introduction of the Chariot Stand-Up riding vacuum

cleaner. The unique feature of the iVac ATV is its’ ability

to vacuum all types of surfaces, hard or soft, effectively

and thoroughly. The Chariot ATV utilizes a specially

designed vacuumized brush deck that employs dual

counter-rotating brushes and a vacuum tray to allow the ATV to vacuum virtually

any surface. The 24” machine also comes standard with off-board cleaning

feature that allows the operator to clean remote locations up to 20 feet from the

machine. Each Chariot ATV is equipped with HEPA filtration as a standard

feature. With production rates of 23,000-34,000 sq ft per hour respectively, the

Chariot iVacs can outperform wide area vacuums, uprights and back packs.

Windsor Stand-On Vacuums

Product

Stock #

Advantages

Chariot iVac 24 ATV

HEPA Vacuum

Varies

• Multi-surface cleaning HEPA stand-on vacuum

designed for carpet, tile, wood, concrete, stone,

rubber, VCT

• 24" cleaning path , 8" standard side broom

• HEPA standard, 68 dBA

• On-board tool storage

• Dual counter-rotating brushes with easy no-tool

removal

Chariot iVac 34 ATV

HEPA Vacuum

Varies

• The Chariot iVac ATV is a high performance, multi-

surface cleaning HEPA stand-on vacuum designed

for carpet, tile, wood, concrete, stone, rubber, VCT

• 34" cleaning path

• HEPA filtration standard, 68 dBA

• Dual counter-rotating brushes with easy no-tool

removal

Chariot iVac 34” Deluxe

Varies

• 28,600 square feet per hour; over 3 times as

productive as a standard wide area vacuum

• 34” wide vacuum path

• Dual counter rotating brushes

Page 8

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Carpet Extractors

A carpet extractor utilizes hot or cold water, dispensed through spray jets directly

onto the carpet. In most machines the carpet is agitated by a brush, and

recovered by a vacuum system and deposited into a recovery tank. All this action

is completed in a very short time resulting in a washing action to the carpet.

Extraction is the most thorough way to preserve carpet life and appearance;

however, it is also the most labor intensive method for carpet cleaning.

Spotters

A spotter extractor is designed to be lightweight and easily

transported to the job site to remove spots from carpet before the

spill turns into a stain. Spotters are designed to encourage cleaners

to attend to spots and spills quickly. These units have relatively

limited solution/recovery capacity (2 gallon) with lower than average

psi (around 50 psi or lower.) The unit consists of a solution tank,

recovery tank, vacuum motor and pump. Windsor products include:

Windsor Spotter Extractors

Product

Stock #

Advantages

Presto 3

Presto 3 Deluxe

9.840-068.0

9.840-069.0

• 2 gallon solution & recovery tanks

• Presto Deluxe comes with the standard hand tool

and the Double Dry hand tools for upholstery,

drapes, and cubicle partitions

Priza 1.100-122.0

• Upright wand and hand tool standard

• 14 psi pump delivers spotter to the surface of the

carpet pile and reduces wicking

• Recovery tank removes for easy cleaning

Portable (Box) Extractors

These machines depend on high psi (pounds per square inch) and

superior vacuum performance to clean carpet. They can also be fitted

with heating units to improve cleaning capability. These are designed to

be an adequate substitution for cleaners who normally utilize truckmount extractors. Solution/recovery capacity is much larger than most

extractors, yet are quite easily transported from site to site. This makes

the unit ideal for the contract cleaner. Portables are used in conjunction

with a wand (drag tool). This tool does not have brush agitation. The high psi and

heat do the job. Windsor products include:

Windsor Portable (Box) Extractors

Product

Stock #

Advantages

Dominator 13

1.006-669.0

• Productive cleaning power and versatility

• 13 gallon solution capacity, 11 gallon recovery tank

• Adjustable 0-500 psi spray pressure provides

versatility to clean delicate upholstery and the

power to clean the dirtiest carpet

• Available with lightweight, ergonomic AquaFoil

Page 9

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Wand Kit

• Available with or without heat

Dominator 17

1.006-670.0

• Productive cleaning power and versatility in a

portable carpet extractor

• 17 gallon solution capacity 14 gallon recovery tank

• Adjustable 0-500 psi spray pressure provides

versatility to clean delicate upholstery and the

power to clean the dirtiest carpet

• Large compact wheels and compact size make

Dominator easy to move around the facility or

transport from job site to job site

• Models available with 1850W internal water heater

for additional cleaning power

• Available with lightweight, ergonomic AquaFoil

Wand Kit

Self-Contained

Self-contained extractors apply solution directly to the carpeted

surface, agitate with a brush and recover dirty solution in a single

pass. Self-contained extractors have a single cylindrical brush or

dual brushes incorporated into the machine to increase cleaning

power. Water lift and psi are not as high as portables as the

brush agitation plays a larger role in the cleaning effectiveness.

Self-contained extractors can be either standard “pull backward”

machines or “walk-behind” machines. Some machines may have the ability to be

pushed or pulled. Brush width and solution/recovery capacity vary in sizes to

accommodate the scope of the application. Windsor products include:

Windsor Self Contained Extractors

Product

Stock #

Advantages

Mini Pro

1.008-039.0

• Easy fold handle for storage and transportation

• Mesh screen protects fresh water tank from debris

• Simple operation

Cadet 7

1.008-022.0

• Roto-molded handle for durability

• Brush removes with not tools for easy maintenance

• Floating vacuum shoe

Admiral 8

1.008-017.0

• Handle adjusts to accommodate users of different

heights

• Brush removes with not tools for easy maintenance

• Floating vacuum shoe

Clipper 12

1.008-025.0

• Handle flips for pull-back and walk behind cleaning

• Brush removes with not tools for easy maintenance

• Floating vacuum shoe

Clipper DUO

1.008-048.0

• Handle flips for pull-back and walk behind cleaning

• Dual counter rotating brushes provide superior

cleaning

• Self adjusting brush deck

• On-board upholstery & spotting tool

Page 10

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Walk-Behind Extractors

Larger walk-behind extractors operate exactly like their smaller selfcontained versions. Walk-behind extractors are designed for large

square footage applications, where a small machine would be far

less productive. They have large tanks, wide scrub path and are

traditionally battery powered, but cord electric machines are

available as well. Battery units can cover expansive areas without

the need for an electric outlet. Windsor products include;

Windsor Walk Behind Extractors

Product

Stock #

Advantages

Commodore 20

1.008-605.0

• Efficient operation in large areas

• Traction driven

Commodore DUO

Basic

9.840-421.0

• Can perform either standard deep extraction or

encapsulation cleaning

• Dual counter rotating brushes

• Simple operation dial

Commodore DUO

Deluxe

9.840-429.0

• Onboard solution tanks dispense chemical for inline

mixing allowing the user to switch between

chemicals without dumping, rinsing, and re-filling

• Dual counter rotating brushes

• Simple operation dial

Voyager DUO Basic

9.840-438.0

• Can perform either standard deep extraction or

encapsulation cleaning

• Dual counter rotating brushes

• Simple operation dial

Voyager DUO Deluxe

9.840-445.0

• Onboard solution tanks dispense chemical for inline

mixing allowing the user to switch between

chemicals without dumping, rinsing, and re-filling

• Dual counter rotating brushes

• Simple operation dial

Truck Mount Units

Professional carpet cleaners utilize truck mount extractors in order to

maximize portability, heat, high pressure, large recovery and high

productivity. These units allow professionals to travel from job to job

quickly with minimal set up and tear down time. Building Service Contractors also

purchase these units for their mobile floor crews. These machines are internal

combustion powered for unlimited runtime with ultra high performance. Truck

mount extractors are generally installed in vans designated specifically for this

purpose or in some cases an enclosed trailer. The high psi incorporated with

tremendous water recovery and heated water clean very effectively. The Windsor

brand does not offer truck mount units, however the Prochem & C400 brands do.

Page 11

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Chariot iExtract

The Chariot iExtact has become the preferred the riding extractor in

the industry today. The Chariot can clean areas of carpet that

normally have to be cleaned using a wand due to its’ small footprint

and tight turning radius. The Chariot allows operators the ability to

deep extract for restorative cleaning, fast-tract for light cleaning and

interim clean by changing jets and applying encapsulation

chemical. Dual vac shoes and dual vac motors ensure high

recovery and faster dry times. Production rates from 9000-12,000 sq ft per hour,

the iExtract cleans more than 1/3 more carpet per hour than traditional walk

behind battery extractors.

Windsor Stand-On Extractor

Product

Stock #

Advantages

Chariot iExtract

Varies

•

Designed with Windsor's Chariot Patented Stand-

On Cleaning Technology* that significantly

increases productivity and cleaning quality.

•

Reduces operator fatigue and increases productivity

versus the traditional walk-behind extractors.

•

Provides greater floor coverage than ride-on or

walk-behind extractors due to its compact size and

maneuverability.

•

Easy to replace battery pack option enables the

Chariot iExtract to run for longer periods; especially

in larger facilities that need additional run time.

•

Large 25 gallon solution capacity extends run time

between fill ups

Floor Machines

Floor machines are the workhorses of the cleaning industry. Standard speed

floor machines were the very first commercial cleaning equipment ever

manufactured. The simplicity of floor machines (they are often referred to as a

motor on a stick) and their versatility allow them to clean everything from hard

floors to tile to carpet. These machines are simply a motor spinning a pad or

brush.

Standard Speed

These cord electric machines rotate at approximately 175

revolutions per minute (rpm) and are used for carpet pre-spray

agitation, as well as sanding, stripping, scrubbing and polishing

virtually all types of hard flooring. Ranging in size from 13” to

20” in diameter, these machines have rear wheels for transport

that are lifted when the machine is put to work. Operating floor

machines can be one of the most difficult tasks a new cleaner has to learn. They

employ tremendous torque when started and can be difficult to control for

Page 12

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

beginners. Brushes and/or pads are attached directly to the bottom of the

machine. Typically a red pad is used for daily scrubbing and a black pad is used

for stripping. Windsor products include:

Windsor Low Speed Machines

Product

Stock #

Advantages

Storm 13“

Storm 17” Deluxe

Storm 20” Deluxe

1.009-022.0

1.009-028.0

1.009-032.0

• All metal construction

• Dual Capacitors

• Conveniently placed handle release

Dual Speed

These floor machines are similar to the above units, but their higher

speeds — up to 300 rpm — make them better suited for spray buffing

and stripping. Since these units are dual-speed, the user can switch

between the higher (300 rpm) and lower rpm for scrubbing or stripping

and faster rpm for polishing. Windsor products include:

Windsor Dual Speed Machines

Product

Stock #

Advantages

Storm Dual Speed

1.009-035.0

• All metal construction

• DC Rectified motor provides more stable amp draw

• Conveniently placed handle release

Ultra High Speed Burnishers

These machines range in size from 17” to 20” and rotate at 1000 to

more than 2,500 rpm. Ultra high speed burnishers are used to

increase shine and repair scratched floors on today’s floor finishes.

High speed machines employ the use of specially coated pads that

when spinning, “cut” the finish to create a smooth (shiny) surface.

This dry process is called “burnishing”. Because of this higher speed

and friction, they are able to produce the “wet look” many facility

managers prefer. High speed burnishers are available in cord electric, battery or

propane models. Some burnishers have built in dust control systems that are

able to contain the powder or dusting created by the high rpm’s of the machine.

Windsor products include;

Windsor Ultra High Speed Burnishers

Product

Stock #

Advantages

Lightning 1500

1.009-016.0

• Top mounted handle lock

Lightning 2000

1.009-019.0

• Top mounted handle lock

• Passive dust control system

Lightning 20

9.840-061.0

• Passive dust control system

Lightning 20 Traction

9.840-063.0

• Passive dust control system

• Traction drive

Page 13

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Chariot iGloss

The Chariot iGloss is a perfect replacement for walk-behind

battery burnishers. Operating at speeds up to double the average

walking pace the Chariot iGloss is twice as productive as

comparative walk-behind machines. Equipped with passive dust

control to minimize particulates, the iGloss protects indoor air

quality that most burnishers ignore. The Chariot iGloss also

contains a large storage area where operators can carry additional floor pads.

Equipped with the Quick Change Productivity Battery Pack system the iGloss

can run up to 6+ hours and burnish over 120,000 sq ft of floor.

Windsor Stand-On Burnisher

Product

Stock #

Advantages

Chariot iGloss 20”

9.840-046.0

• Soft start reduces instances of “donuts”

• Specially designed motor maintains an actual and

constant 2000 rpms on the floor for a superior shine

Auto-Scrubbers

An auto-scrubber is a specially designed machine that applies solution, scrubs

the floor and recovers the solution in one pass. When auto-scrubbers are used

by properly trained operators these machines can dramatically cut labor time and

increase productivity. Auto-scrubbers are most commonly battery powered, with

cleaning widths ranging from 17” up to 34” in the commercial market. Autoscrubbers over 36” are usually considered industrial machines. Recently, the

industry has seen an influx of “mini” auto scrubbers enter the market. These units

are often cord electric machines ranging in size from 12” up to 17”. Productivity

can be increased by up to 50% when using a battery machine vs. a corded

machine. Scrubbing is accomplished by pads (most effective on flat surfaces) or

brushes (most effective on uneven surfaces) which can be rotary or cylindrical.

Mini Auto Scrubbers

Mini auto-scrubbers produce the same quality cleaning results

as larger versions but can clean much smaller and confined

areas. Areas of less than 5000 sq/ft are good choices for these

machines. These units are excellent replacements for

applications that would have been historically cleaned with a

mop and bucket. These units range in size from 12” to 16” and

are usually cord electric operated. Mini auto-scrubbers are simple to operate and

can be utilized by operators with little training. Windsor products include;

Page 14

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Windsor Mini Auto Scrubbers

Product

Stock #

Advantages

Saber Blade 12

1.783-206.0

• Simple operation

• Cleans small congested areas quickly

• Low dBa

Saber Blade 16

9.840-710.0

• Dual cylindrical brush scrubber

• Up to 80lbs down pressure

• Multiple cleaning application when combined with

various brushes

• Recovery & solution tank remove from machine for

complete cleaning

Compact Auto-Scrubbers

Compact auto-scrubbers range in size from 16” to 22”.

Capacities are generally 6 to 12 gallons of cleaning solution

with recovery tanks holding an equal amount. These

machines are ideal for smaller facilities or for highly

congested applications. These machines are small enough

that they can easily be transported from one facility to

another on a frequent basis. Facilities with 5000 to 25,000 sq/ft are best fits for

these machines. Windsor products include:

Windsor Mini Auto Scrubbers

Product

Stock #

Advantages

Saber Compact 16

SP

9.840-531.0

• Cylindrical scrubber

• Intuitive controls on one dial

• Recovery tank opens up for complete cleaning

Saber Compact 17

9.840-327.0

• On-board charger standard

• Easy pad release and replacement

Saber Compact 20

9.840-140.0

• Vacuum mounted above the recovery tank to

reduce incidents of water being pulled through the

motor

Saber Compact 20

Traction

SC20TD3

• Vacuum mounted above the recovery tank to

reduce incidents of water being pulled through the

motor

• Traction drive

Saber Compact 20

Deluxe

SCX20TD3

• Vacuum mounted above the recovery tank to

reduce incidents of water being pulled through the

motor

• Traction drive

• Deluxe squeegee with adjustments

Walk Behind Auto-Scrubbers

These units range in size from 24” to 36” in scrub path. Larger

solution/recovery tanks allow the operator to be productive by

extending the time between dumping and refilling the machine.

Walk-behind auto-scrubbers in this size range are designed for

larger facilities with square footage of 30,000-60,000. Machines

in this category are battery powered and available in either 24V

or 36V configurations. Larger auto-scrubbers can be difficult to

operate and require an aggressive training program to ensure

Page 15

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

operator and building safety. Machines in this category should be operated by a

professional cleaner. Windsor products include:

Windsor Walk Behind Scrubbers

Product

Stock #

Advantages

Saber Cutter 26

Mechanical Deck

SC264D3

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

Saber Cutter 26

Actuated Deck

SCX264D3

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

• Actuated Deck

Saber Cutter 32

Actuated Deck, 24V

SCX324D3

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

• Actuated Deck

Saber Cutter 32

Mechanical Deck, 36V

SC326D3

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

Saber Cutter 32

Actuated Deck, 36V

SCX326D3

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

• Actuated Deck

Saber Cutter Squeeze

Play

SCX364D3

• Excellent sightlines for increased safety

• Deck expands from 28” to 36” for increased

productivity

Rider Auto-Scrubbers

These scrubbers are utilized in a wide variety of applications.

Rider scrubbers are available in sizes from 26”-36” In the past,

rider scrubbers were used mainly in industrial applications,

however, this has changed in recent years, as riders have

gradually decreased in size. The machines are now also being

utilized in commercial applications. One of the changes in the

product design is the capability of driving the rider through a standard 36”

doorway, thus gaining access to multiple rooms in the facility. Benefits of riding

are increased productivity, less operator fatigue, and employee morale.

Operators also experience improved visibility and better turning radius. Rider

scrubbers require intense training both on operation and maintenance issues.

Applications for rider scrubbers include large education facilities, arenas,

convention centers, large healthcare facilities or any facility with over 60,000 sq/ft

of hard surface. Windsor products include:

Windsor Rider Scrubbers

Product

Stock #

Advantages

Saber Glide 28

9.840-245.0

• One touch button starts and stops all cleaning

functions for simple operation

• Open operator area for maximum visibility and

safety

Saber Glide 32

9.840-255.0

• One touch button starts and stops all cleaning

functions for simple operation

Page 16

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

• Open operator area for maximum visibility and

safety

Saber Glide Squeeze

Play

9.840-264.0

• One touch button starts and stops all cleaning

Chariot iScrub The industry’s first stand-on platform of floor care

equipment, the Chariot significantly increases productivity and cleaning

quality by reducing operator fatigue. Chariots are easy to use and

operators have superior full-circle visibility of obstacles. The Chariot’s

small footprint and ultra-tight turning radius make it ideal for cleaning in

busy, complex building layouts without disrupting workflow. Windsor’s Chariot

iScrub models include:

Windsor Stand-On Scrubbers

Product

Stock #

Advantages

Chariot iScrub 20

9.840-810.0

• 20" cleaning path

• 10 gallon solution and recovery tank

• 50% more productive than a conventional 20" walk-behind

scrubber

• Unparalleled visibility in congested areas and small spaces

Chariot iScrub 20

Deluxe

9.840-898.0

• Outside fill port

• On-board charger for AGM models

• Easy access to batteries

Chariot iScrub 24”

9.840-691.0

• Aqua-mizer system saves water and chemical while

increasing productivity

• Excellent sightlines for increased safety

• Squeegee swings out 14” on either side to recover water,

even in tight turns

Chariot iScrub 26”

Cylindrical

9.840-705.0

• Dual counter rotating brushes

• Wet pre-sweep capability

Sweepers

Sweepers are an important component of a solid flooring program. The primary

function of a sweeper is to capture soil before it enters a facility. Once soil enters

a facility the damage to flooring surfaces is a snowball effect. Sweepers can be

either direct throw or overthrow. Direct throw sweepers utilize a main broom to

sweep soils into a hopper much like a broom would sweep soil into a dust pan.

Overthrow sweepers utilize a main broom that is designed to pick up debris,

usually large debris, and carry it up and over the broom to dump it into a top fill

container. Generally, direct throw sweepers work well on small soils and sand

while overthrow sweepers work well on larger debris like paper and cigarette

butts.

Page 17

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Manual Sweepers

These machines do the job that three or four individuals do with

brooms. This category of equipment is classified as a manual

push sweeper. The brushes in the unit are powered by pulleys

off the back wheels. The main broom throws the debris into a

hopper that is relatively small. These sweepers have no real

dust control systems. No drive motors or vacuum motors. This

keeps the machine light on price and weight. The machine

works best on rough surfaces like concrete or carpet. The sweeping path ranges

from 26’” to 32”. Windsor products include:

Windsor Manual Sweepers

Product

Stock #

Advantages

Radius Mini

1.545-113.0

• Designed for commercial use

• Battery powered

• Cleans within 1/8 of an inch from the wall

Radius Manual

Sweeper

1.517-104.0

• Easy main and side broom adjustments

• Main broom is driven by metal gears on both wheels

and operates whether the unit is turning right or left

• Side broom fold up for cleaning in dusty

environments

Walk Behind Sweepers

These units range in sweeping path size from 24” to 36”.

These units are available most commonly with battery power,

however some manufacturers offer gas powered machine.

Sweepers utilize a hopper for soil and debris collection, as the

machines increase in size the hopper capacity increases as

well. Some of the machines have drive motors to propel them.

Applications for these units include entrance cleaning and lighter duty outdoor

areas. Warehouses and light manufacturing are also excellent applications.

These units are now being used for both indoor hard and soft floors. Windsor

products include:

Windsor Walk Behind Sweepers

Product

Stock #

Advantages

Radius 280 Deluxe

1.517-206.0

• Battery powered

• Vacuum fan provides active dust control

• Easy main and side broom adjustments

• Side broom fold up for cleaning in dusty

environments

Radius 300

9.840-665.0

• 30" sweeping path with side broom

• Chain driven

• On-board charger

• Self-propelled with 400 watt drive motor

• 1.5 ft3 (40 liter) hopper capacity

Page 18

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Rider Sweepers

These machines range in size from 36” to 66”. They are battery or

internal combustion engine powered. The larger sized units are

most seen in warehouse or factory applications. Smaller sized

riders are being used in large carpeted areas. Best applications for

the smaller riders are entrance cleaning, small parking garages,

drive up areas and warehouses. Windsor products include:

Windsor Rider Sweepers

Product

Stock #

Advantages

Radius 360

9.840-665.0

• 36" sweeping path

• Overthrow sweeping

• 2 hoppers for ease of dumping

Interim Cleaning Machines

The iCapsol system is used in conjunction with our iCapsol Carpet

Chemical which is based on encapsulation technology. The iCapsol

solution is mixed at 8 ounces per gallon and misted lightly over the

area to be cleaned. It is then agitated into the carpet pile with the

iCapsol machine. The solution comes in contact with the soils that

are stuck to the carpet fibers, pulls them from the fibers and holds

them in solution. Once the soils are held in solution the iCapsol Chemical dries

to a light, non-sticky crystal that is vacuumed out of the carpet at the next

scheduled vacuuming.

The entire process, from spraying the iCapsol chemical, to working it in, until it is

dry enough to vacuum, generally takes about 20 minutes. This process is a

great replacement for bonnet cleaning, which can leave heavy residues in the

carpet and cause damage to the carpet backing. Encapsulation extends the

period of time between restorative extraction processes. Windsor products

include:

Windsor iCapsol Encapsulation Machines

Product

Stock #

Advantages

iCapsol Mini

9.840-302.0

• Dual counter rotating brushes which are removable

with no tools

• Debris hopper

iCapsol Mini Deluxe

9.840-304.0

• Onboard 2 gallon solution tank and spray jet

• Dual counter rotating brushes which are removable

with no tools

• Debris hopper

Page 19

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Specialty Cleaning Machines

Specialty cleaning machines are machines that allow our customers to increase

productivity and save money by performing tasks faster or with less labor. In any

facility cleaners can be faced with cleaning tasks that traditional machines were

not designed to handle. Specialty machines are products created to address very

specific cleaning tasks. These range from restroom cleaning machines to steam

machines to escalator cleaners.

Multi-Surface Cleaning Machines

Multi-Surface Cleaning Machines are primarily used for restroom

cleaning but can also be used for carpet extraction, kitchen cleaning or

general pressure washing. On-board chemical dilution with dirty water

recovery is the unique features of this style of machine. With the

flexibility to clean multi surfaces by adding specific tools, this machine

can be an excellent tool for any facility. The main competitors in this

category are Kaivac, Advance, and Tennant/Nobles. Windsor’s products include:

Windsor All Surface Cleaning Machines

Product

Stock #

Advantages

Compass 2

1.007-056.0

• Onboard dilution control

• Chemicals sit in a protected area, not on top of the

machine

Escalator Cleaners

The Treadway Escalator Cleaner provides a wet cleaning solution

for a wide variety of escalators and moving walkways. It is only wet

cleaning machine in the industry with a price tag of less than $20K.

This machine is an excellent solution for facilities that have

multiple escalators. Escalators can be cleaned quickly with short

shut-down times using this machine. Windsor’s products include:

Windsor Treadway Escalator Cleaner

Product

Stock #

Advantages

Treadway for Otis,

Thyssen-Krupp,

Fujitel, Montgomery

9.840-525.0

Treadway for

Schindler,

Westinghouse,

Mitsubishi

9.840-527.0

Treadway for Kone,

O&K 9.840-526.0

Treadway for CNIM,

Dong Yang, Hitachi,

Toshiba

9.840-528.0

• Wet cleaning with vacuum pick-up

• Typical escalator is cleaned in under an hour

Page 20

Equipment Basics Course

!

!

A!Member!of!KÄRCHER!North!America!

Steam Cleaners

Steam Cleaners allow the user to clean without chemicals by

harnessing the power of steam. Steam is generated in a boiler,

applied to the surface with various tools where the soil can be

easily wiped away. At 212 degrees steam is also considered an

excellent way to sanitize surfaces. Steamers can aid in

eliminating beg bugs in a facility and removing annoying odors from upholstery.

Steamers are also a vital tool in kitchen areas to sanitize food prep surfaces

without chemicals and clean cooking equipment. Windsor’s product includes:

Windsor Zephyr Steam Cleaner

Product

Stock #

Advantages

Zephyr 1.092-803.0

• Two tank system, boiler and refill tank

• 1.2 gallon capacity

• Continuous refill capability

Loading...

Loading...