Page 1

Page 2

When using an electrical appliance, basic precaution must

always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

1.

Use

only as described in this manual. Use only manufacturer’s recommended attachments.

2.

Use

indoors only.

3.

Machine can cause a fire when operating near flammable vapors or materials.

machine near flammable fluids, dust or vapors.

4.

5.

6.

7.

Do not

Do not

Do not

Do not

pick up flammable fluids, dust or vapors.

vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

handle the plug or machine with wet hands.

leave the machine unattended. Unplug machine from outlet when in use and before servicing.

Do not

use outdoors and do not expose to rain.

Do not

operate this

8.

Do not

9.

Do not

machine.

10. If the machine is

water, return it to an Authorized service center.

11.

Do not

sharp edges or corners.

12.

Do not

13.

Do not

14.

Do not

airflow.

15.

Keep

parts.

16.

Use

unplug machine by pulling on cord. To unplug, grasp the plug, not the cord.

use with damaged cord or plug. Follow all instructions in this manual concerning grounding the

not working properly,

pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around

pull/run machine over cord.

allow to be used as a toy.

operate machine with any openings blocked. Keep openings free of debris that may reduce

hair, loose clothing, fingers, and all parts of the body away from openings and moving

extra caution when cleaning on stairs.

Keep

Close attention

has been dropped, damaged, left outdoors, or cropped into

cord away from heated surfaces.

is necessary when used by or near children.

17.

Do not

18. Connect to a

19.

Maintenance and repairs must be done by qualified personnel.

20. “Warning of Potential Injury” .

unplug machine before servicing.

use machine as a step.

properly

grounded outlet. See Grounding Instructions.

This product contains moving parts. To reduce the risk of injury

SAVE THESE INSTRUCTIONS

2

Page 3

THIS PRODUCT IS FOR COMMERCIAL USE

ONLY.

ELECTRICAL:

In the USA this machine operates on a standard

15 amp 115 volt A.C. power circuit

nominal).

Special voltage models are available for international applications. The amp, hertz and voltage

are listed on the data label found on each machine.

Using voltages above or below those indicated on

the data label will cause serious damage to the

motors.

EXTENSION CORDS:

If an extension cord is used, the wire size

must

be

the same type and at least one size larger than the

power cord on the machine. Do not use over 50

ft.

equipped with a 50 ft.

of extension cord(s). The machine is

power

cord.

NOTE:

If connected to a circuit protected by fuses,

use time-delay fuses with this proctuct.

WARNING:

ADVERTISSEMENT:

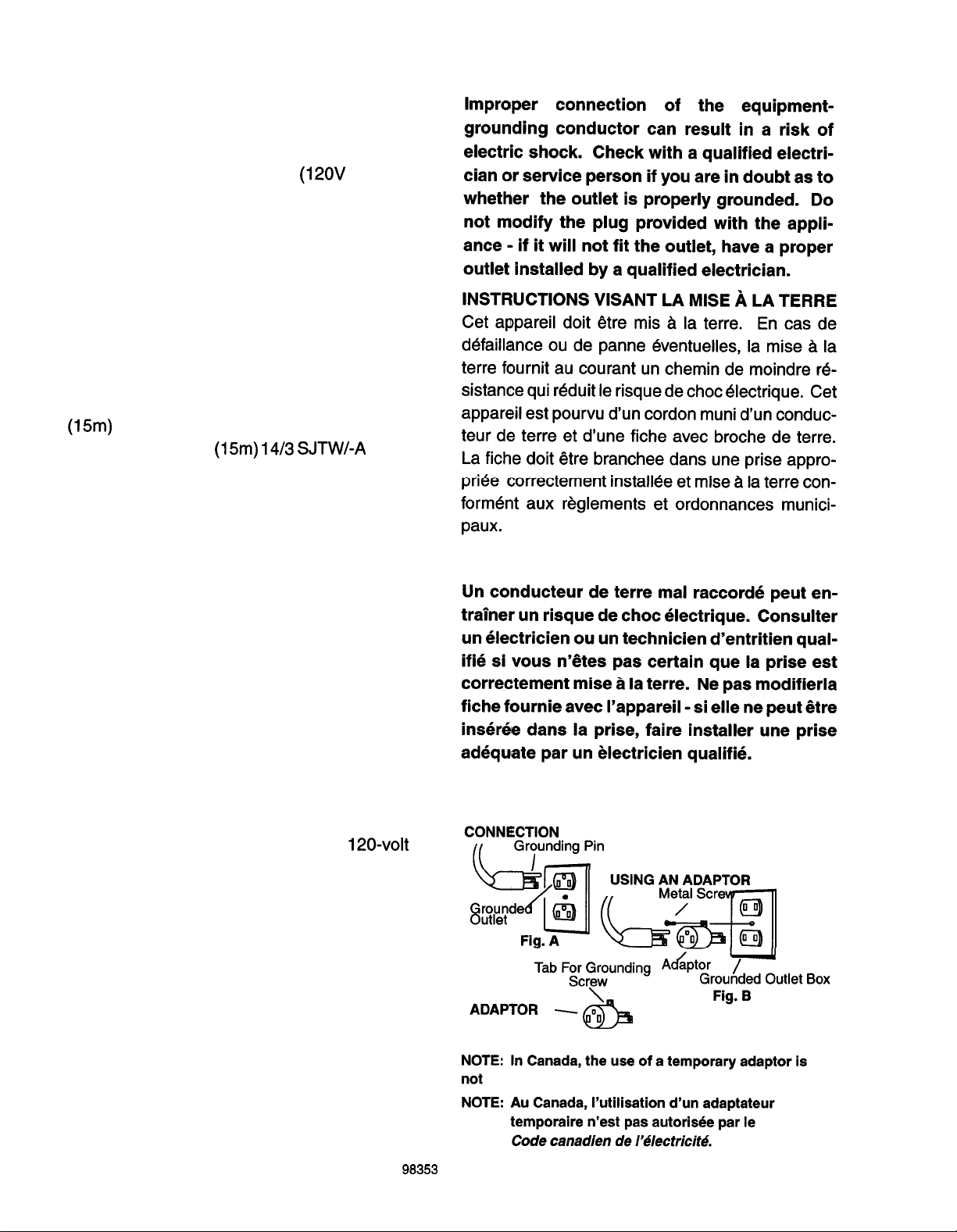

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to re-

duce the risk of electric shock. This appliance is

equipped with a cord having an equipment-

grounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

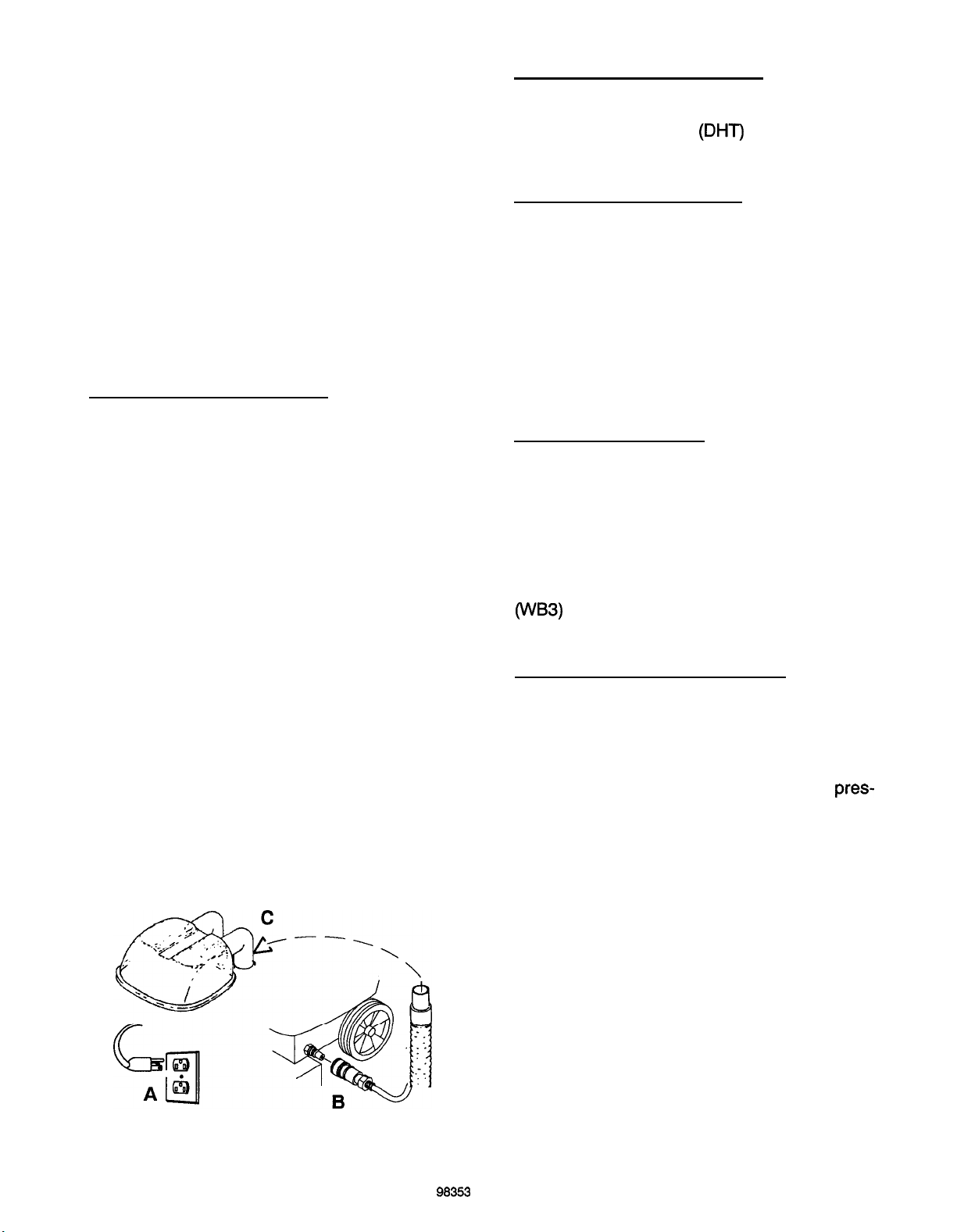

This appliance is for use on a nominal

circuit, and has a grounded plug that looks like

the plug in Fig. A. A temporary adaptor that looks

like the adaptor in Fig. C may be used to connect

this plug to a 2-pole receptacle as shown in Fig.

B if a properly grounded outlet is not available.

The temporary adaptor should be used only until

a properly grounded outlet (Fig. A) can be installed by a qualified electrician. The green colored rigid ear, lug, or the like extending from the

adaptor must be connected to a permanent

ground such as a properly grounded outlet box

cover. Whenever the adaptor is used, it must be

held in place by a metal screw.

PROPER GROUNDING

GROUNDING CONNECTION

Fig. C

3

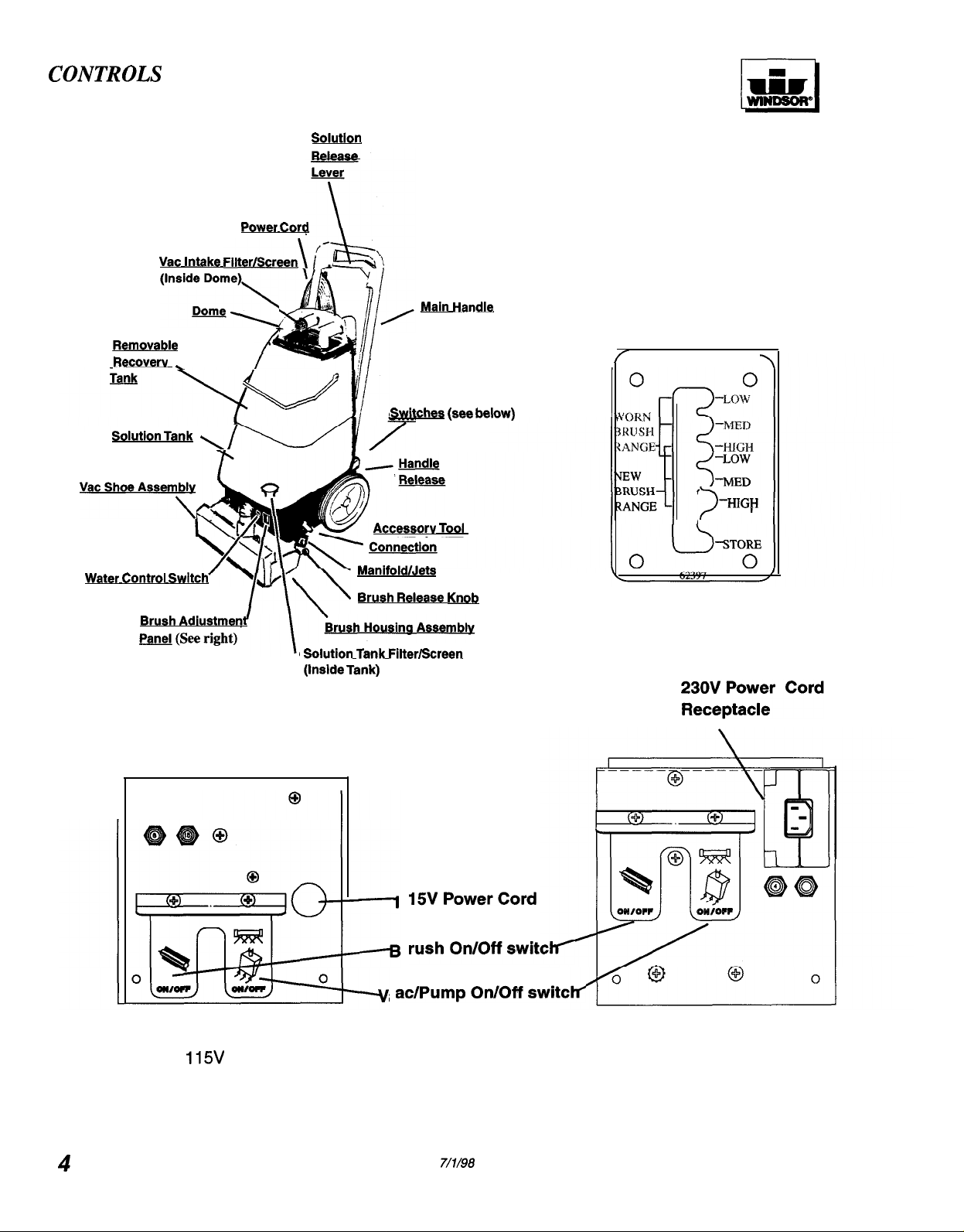

Page 4

Adjust brush to proper cleaning position by using

lever located on the front of the frame. Start at No.

1 “new brush” (black) position. If more carpet pile

agitation is desired, lower brush setting one position at a time. (See fig. 1 below)

Fig. 1

Model

Rear Panel

230V Model

Rear Panel

SPD 98353

Page 5

Preparing the SPIRIT DUAL:

For Hard Floor:

Install the optional kit : Vac Shoe Squeegee (p/n

1.)

02285). Raise the SPD vac shoe and place the squeegee

assembly over the vac shoe intake. Center the squeegee

on the vac shoe and secure by tightening the two retaining knobs.

CAUTION: Make sure that the machine is unplugged, switches are turned off and both solution

tanks are empty before beginning brush removal or

replacement.

Now install the hard floor brush. Tilt the machine

2.)

back far enough to grasp the brush. If the carpet brush

is already installed, proceed with step 3 to remove it.

If no brush is installed, proceed with step 4.

To remove brush, pull the brush release knob

3.)

back until the brush can be swung out from the housing

and pull the brush off of the drive end.

To replace, align the pulley drive pins on the knob

4.)

driver in the housing with the slots in the brush and

slide over the knob driver.

Filling Solution Tank:

1.)

Set dome and recovery tank to the side.

2.) Use a clean bucket to fill the solution tank

with hot water.

3.)

If necessary add a cleaning concentrate for

use in hot water extractors. Closely follow manufacturer’s instructions found on container. Read

ingredients listed on the container to ensure com-

CAUTION: Use only the suitable chemicals

listed below. Using incompatible chemicals will

damage the machine. Damages of this type are

not covered under warranty. Carefully read

ingredients on manufacturer’s label before using any product in this machine.

Pull the brush release knob back, align

5.)

sides of the brush stub axle in the housing and swing

the brush into place. Then release the knob, returning

to the locked position.

Refer to page 17 for parts

flat

outlined in these steps.

Set the water control switch on the front of the

6.)

machine to “LOW”.

NOTE: If water does not spray

after 5 seconds when the switch is in the “LOW”

position it may be necessary to place it in the

“HIGH” position to start the flow, then return it to

the “LOW” position for hard floor use.

For Carpet:

Remove squeegee from vac shoe by loosening

1.)

the two retaining knobs.

Install carpet brush as described above.

2.)

Set the water control switch on the front of the

3.)

machine to “HIGH”.

SUITABLE INCOMPATIBLE

CHEMICALSCHEMICALS

Alkalis

Clorox II Bleach*

Defoaming Agents

Detergents

Hydroxides

Oxygen Bleaches

Soaps

Sta-Puf Fabric Softener*

Vinegar

White Monday Bleach*

l

Registered Trademark

4.)

Place the recovery tank onto the solution tank.

5.) Set the dome in place on the recovery tank.

Dome must be seated correctly to ensure

Aldehydes

Aromatic Hydrocarbons

Butyls

Carbon Tetrachloride

Chlorinated Bleaches

Chlorinated Hydrocarbons

D-Limonene

Methyls (MEK)

Perchlorethylene(perc)

Phenols

Trichlorethylene

proper vacuum seal.

5

Page 6

SPIRIT

1.

A.

NOTE: Starting the machine with dry brush resting on floor may trip the brush motor circuit

breaker.

10.

11.

12.

into the vacuum intake can damage the vacuum-

motor. Always be aware of the waste water level

and foam in the recovery tank, es ecially when

using an accessory tool. BEFOREfoam or

tion is pulled into vac intake empty the recovery

tank.

(8-9

An overflow of foam from in the recovery tank

When not using the machine put the brush in

the storage position. (see daily maintenance on

page 8) Leaving the brush on the floor for long periods of time may ruin It.

Never put defoaming compound in the solution

tank. Damage to pump will result.

NOTE:The vac motor is protected by a circuit

breaker which will only trip under conditions of

abuse, such as an overflow of foam into the

dome. When an overflow does occur the vac

motor must be allowed to dry thoroughly before

continuing work.

Remove source of overflow.

2. Run motor to dry.

6

Page 7

15.) Ventilate the room when cleaning has

been completed. Keep all traffic off the

floor until it is thoroughly dry.

16.)

When done cleaning for the day bring

the machine to a utility sink and floor

drain. Perform the daily/regular

maintenance. Set the recovery tank

aside so solution tank will dry.

CAUTION:

When not using the machine put the

brush in the storage position.

(see daily maintenance on page 8)

Leaving the brush on the floor for

long periods of time may ruin it.

To Use an Accessory Tool:

1.)

Turn the machine completely off and

unplug it from electrical outlet.

2.)

Connect the solution hose to the brass

fitting on lower left side of machine.

3.)

Connect the vac hose to the left side of

the dome (side with white hose cuff).

4.)

Fill the solution tank.

5.)

Plug the machine in and turn on only

the vac/pump switch. Also place the

water control switch in the “HIGH”

position.

CAUTION:

Using accessory tool with brush

switch on may damage floor.

6.)

Turn off the machine and unplug it

from electrical outlet before

disconnecting accessory tool.

Approved Accessory Tools:

Standard Floor Wands

(SFW, SW, or SW-PRO)

Deluxe Hand Tool

Upholstery Hand Tool (UPH3)

Floor Surface Inspection:

Determine precisely what areas you are going to

clean. Note the problem areas in the carpet or

hard floor. Look for loose carpet, heavily damaged areas, discolored stains or grease spots

that will require prespotting. Note the carpet or

hard floor type. Check the availability of hot water, drains, and suitable electrical outlets. If the

carpet is loose or worn or there is hard floor surface flaking, have it repaired

to clean it.

before

attempting

Plan Cleaning Route:

Work from the most remote area towards the

exit. Try not to travel over the cleaned areas

when getting fresh water or dumping old. Furniture should be moved away from the walls before cleaning. If furniture is moved back in place

before floor is completely dry, place plastic or foil

protectors under the legs to prevent possible

staining. When possible use a Windblower

and open all windows and doors to speed

drying.

General Cleaning Information:

Vacuum carpet or sweep hard floor first!

ways take the time to thoroughly vacuum carpet

or sweep floor before using the extractor.

On heavily soiled floors, or on areas of high

foot traffic,

pray or traffic lane cleaner applied with a sepa-

rate sprayer. Do not add presprays to the ma-

chine’s solution tank. If a spotter is used, follow

the manufacturer’s instructions exactly as

printed on the label. Spotter left on the floor may

bleach or brown it permanently.

it may be necessary to use a pres-

Al-

Shag or deep pile carpets

passes from different directions, but the operator must be careful not to over saturate the car-

pet. Make several passes without spray to extract as much moisture as possible.

Rinse carpet after cleaning

build-up will not cause carpet to quickly become

soiled again. Go back over carpet using only

clean warm water in solution tank.

may require several

so that sticky soap

7

Page 8

This product contains moving parts.

To reduce the risk of injury; unplug the

machine before servicing.

Maintenance and repairs must be done

by qualified personnel ONLY.

CAUTION:

Using non-Windsor parts to repair this

machine will void the 6-3-1 warranty.

Warranty information is located on the

back of this manual.

Suggested Service Parts List

DESCRIPTION

Belt

Brush Bearing

Cord Assembly (USA/Japan) 23572

230V Cord Assembly (Europe)

Dome Assembly

Dome Gasket

Hose Cuff. Short Blue

Hose Cuff. Longer Blue

Hose Cuff, White

Jet Assembly

Jet

Jet Seal

Jet Body w/Seal

Manifold Assembly

Pump Service Kit

Screen/Filter, Dome

Screen/Filter, Solution Tank

Solution Release Cable

Solution Release Lever

Switch

230V Switch

Valve

PART NUMBER

11031

09019

23178

28034

35060

27508

27354

27079

44055

44061

44051

44052

54094

47176

34140

73250

27665

51200

72074

72121

84134

Dailv Maintenance:

These procedures are followed at the end of

each work period to extend the life of the machine.

Empty unused cleaning solution by

1.)

disconnecting clear hose on back of

machine and pouring into floor drain.

Inspect and clean solution filter screen

2.)

inside tank and vac intake screen

inside dome.

Flush the system. Fill solution tank

with 1 or 2 gallons (4

8 liters) of clean

hot water. With machine over floor

drain turn on vac/pump switch until

solution tank is empty.

Inspect spray pattern of jets.

Remove jets and rinse if clogged.

5.)

fresh water. Periodically inspect the

recovery tank and decontaminate if

necessary, using a Hospital Grade

Virucide or a l-l 0 bleach to water

solution. Waste water should be disposed

of properly.

Remove any lint or debris from brush.

6.)

Inspect power cord. Remember, this

7.)

cord will lay on a damp surface.

Warning:

IMMEDIATELY REPLACE WORN OR

FRAYED POWER CORDS.

8.)

Inspect hoses. Worn or cracked

hoses may cause loss of vac pressure.

9.) Place the brush in the storage

position. Press back slightly on the

main handle, and place the brush

adjustment lever in the “STORE”position.

For infrequent use or long periods of storage,

flush the system with a neutralizing solution

of 1 quart (1 liter) white vinegar mixed with 2 gallons (8 liters) hot water. Flush the system with

clean hot water after neutralizing.

8

Page 9

Periodic Maintenance:

These procedures are performed by a

trained service technician. The regularity of

these procedures may depend on the ma-

chine's use.

Flush the system with a special

1.)

solution to reduce scaling (alkaline

build-up).

Use acetic acid (white vinegar) or an

anti-browning solution. Mix one quart

acetic acid with 2 gallons

hot water in the solution tank (if an

anti-browning solution is used follow

manufacturer’s instructions). Turn on

the vac/pump switch and allow the

machine to run over a floor drain until

the solution tank is empty

(approximately once a month).

Inspect hoses and cords, replace as

needed.

Inspect filter screens, clean or replace

as needed.

liters) of

CAUTION:

Do not allow this machine to remain in a

vehicle or area where the temperature

will be below 40°F (4°C). Allowing this

machine to freeze will cause damage not

covered by the 6-3-1 warranty.

CAUTION:

Protect this machine from freezing if it

becomes necessary to store it at temperatures below 40°F (4°C).

Use a methyl hydrate window washer type

anti-freeze; mix a gallon or two (4-8 liters) of

anti-freeze solution, following the manufacturer’s instructions. Add the anti-freeze

solution to the solution tank. With the hoses

in place run the machine until the anti-freeze

begins spraying out (don't empty solution

tank).

freeze solution in the solution tank. Disconnect the hoses and empty the recovery bucket. Always allow the unit to return to room

temperature before filling with hot water or

operating.

Vacuum out the remaining anti-

Inspect spray pattern of jets, replace or

4.)

clean as needed.

Check the tension of the solution valve

5.)

cable, tighten if necessary.

Inspect the vac motor, remove any lint

6.)

build-up at cooling intake, service

carbon vac motor brushes

(Approximately every 750

operation hours).

With the machine running, the brush

should rotate freely without rattling or

grinding. Replace bearings if

necessary.

CAUTION:

Do not use Ethylene Glycol or any

cooling system anti-freezes.

Page 10

Troubleshooting Chart

Condition

No Power To Machine:

Dead electrical circuit breaker in fuse box

Faulty power cord

Power switch failure

Faulty circuit breaker

Internal wiring problem

Electrical Shock:

Equipment not grounding

Receptacle not grounded

Internal electrical problem

Nuisance Tripping of Circuit Breaker:

Brush “buried” More than

(1 cm)

Corrective Action

Check building circuit breaker.

Replace

Test switch for continuity/Replace if necessary.

Test circuit breaker for continuity/Replace if necessary.

With the machine unplugged, check for, and correct, any loose wire

connections inside the machine at the switches and terminal block.

Follow grounding instructions exactly.

Have an electrician inspect the building’s wiring.

Ensure that the machine’s wiring matches the appropriate wiring diagram.

Check for and correct any loose wire connections. Replace any wires

or components which are short circuiting.

Brush is adjusted too low, adjust position using the adjustment control

at the front of machine. Best cleaning results are achieved with a minimal

brush/surface contact of less than 3/8” (1cm).

Dry brush

Faulty circuit breaker

Mechanical problem

Vacuum Motor Speed Varies or Doesn’t Run:

Worn motor brushes

Motor worn out

Faulty switch

Faulty circuit breaker

Internal wiring problem

Loss Of Vacuum:

Loose vac dome

Crack in dome or poor joint

Loosecuffsonvacuum hose

Damaged Dome Gasket

Turn brush motor and pump switches on with machine tilted rearward

(brush off floor). Lower machine back to carpet slowly.

Test circuit breaker for continuity/Replace if necessary.

Higher amp draws may indicate a mechanical problem. Find parts which

are not moving freely and repair or replace.

Replace

Replace

Replace

Replace

Check for and correct any loose wire connections,

Center dome over tank.

Replace or repair using acrylic plastic cement only.

Tighten cuffs (turn counter clockwise).

Replace gasket.

Lint or dirt clogging vacuum intake screen

Accessory tool clogged

Vac hose damaged

Internal electrical problem

10

With power off clean vac intake screen found in dome.

Clean out tool, ensure free airflow.

Replace

Have a trained service technician inspect and repair the machine.

98353 7/1/97

Page 11

Troubleshooting Chart

Condition

Accessory Tool Fitting Difficult to Connect:

Corrosion on fitting

Floor Not Getting Clean:

Severe soil conditions

Floor Too Wet:

Worn spray jet(s)

Floor Not Getting Wet:

Solution filter screen clogged

Spray jet(s) clogged

Corrective Action

Clean with steel wool.

Remove and soak in acetic acid (white vinegar).

Lubricate lightly with silicone base lubricant.

Make several passes at right angles to each other.

Use a prespray.

Replace spray jets which are producing more than a fine mist.

Clean solution filter screen located inside lower tank near the front.

Clean or replace jets.

Do not use a wire to clean jet.

Damaged jets will cause over-saturation.

Pump not running

Faulty pump

Solution valve adjustment

Brush Not Turning:

Belt broken

Faulty switch

Faulty circuit breaker

Faulty brush motor

Worn Bearings:

Squeeling or grinding sound in brush housing

Check for and correct any loose wires

Repair or replace

Adjust solution valve cable until valve operates when handle is pulled.

Remove belt cover on right side of machine.

Replace if necessary.

Replace.

Replace.

If the belt, circuit breaker, and switch have been tested and found to be

in good working order, the brush motor may need to be replaced.

Replace bearings.

Inspect belt.

98353 7/1/97

Page 12

Servicing the Vac Motor

To access the vac motor first remove the solution tank. There are (2) screws which attach the

vac motor mounting bracket to the chassis. Loosen the clamp to remove the hose. To replace

the motor assembly it will be necessary to remove the (3) screws which attach the motor to the

vac motor mounting bracket.

See page 18 for the complete vac motor and mounting equipment parts list.

Wire

Important:

These brushes wear

quicker as the length

shortens due to increased heat.

Spring inside brush

housing will damage

motor if brushes are

The green ground wire

must attach the motor to

the power cord for safe

operation.

wiring diagram.

I

I

allowed to wear away

completely.

If armature commutator is not concentric,

extremely pitted, or grooved the motor will

need to be replaced or sent to a qualified

service center to restore vac performance.

Wire Terminal

Note:

When replacing carbon vac motor brushes

loosen wire terminal

screws on bracket.

BEFORE

removing

Periodically check the length of the

carbon brushes.

Replace both carbon brushes when

either is less than

long.

12

Page 13

Vac

Shoe Assembly

Reverse

10

13

Page 14

&

RECOVERY TANK

SOLUTION TANK

SPD 98353

Page 15

RECOVERY TANK PARTS LIST;

2

10

11

12

13

14

87013

3

73280 Spacer, 1/4 ID x

4

38088

5

75078

6

14042

7

39343

8

39411

9

27079

27508

Washer,

Handle, Recovery Tank

Tank, Recovery

Hose, 1.5 x 34”

Hose, 1.5 x

Cuff, White 1.5

Cuff, Short Blue

Hose cuff, blue

Dome Asm

Label, Warning

Label, Warning For Safety

Flat

1.63 ID

Vac

Vac

Hose

Explosion Vert

3/8 Nylon

Snap

Hose

RECOVERY &

ASSEMBLY

List

SOLUTION TANK PARTS LIST:

602449

602449

602449

SPD 98353 8/10/98

15

Page 16

Spray Jets

Rinse in hot water or use compressed air to

clean. Nozzles can also be soaked in an acetic

acid solution (white vinegar).

CAUTION:

Do not use

pins or wires to clean

or unclog jets.

Using wires or

pins to unclog

jets may ruin

spray pattern.

Replace jets that no longer produce a fine

mist spray or over saturate carpet.

16

Page 17

Page 18

Ground

Arrangement

See page 4 for panel

configuration

18

SPD 98353

Page 19

2

57104

3

Open

4

89114

41236

6

70249

7

73636

8

73596

9

51193

38269

11

41302

12

57047

13

36123

14

41144

15

70361

16

57238

17

51251

18

27561

19

27699

202127371

57113

22

70105

23

87030

24

70272

25

50498

26

72147

27

62322

28

57028

29

27376

30

70406

31

73169

32

50638

33

70066

34

87016

35

27711

36

70434

37

23572

38

70537

39

57234

40

57138

41

99817

42

50182

43

35229

44

62755

35198

45

35228

46

Nut, 10-32 w/Star Washer

Wheel, 10”

Hub Cap,

Scr,

Spacer, 5/16 x 1.2”

Spacer,

Linkage, Handle Adjustment

Handle, SPD II

Housing, Solution Lever

Nut, l/4-20 Nylock

Grip, 9.5” Handle

Hook, Cord

Scr, 10-32 X

Nut, 10-24 Joint Connector

Lever, Solution

Clip, Solution Cable

Cable,.06X41.3.0707.

Clip, Power Cord

Nut, 5/l6- 18 Nylock

Scr,

Washer,

Scr,

Label, 15 Amp Time Delay Fuse

Switch, 250V

Panel, Electrical Panel

Nut, 10-24 Tinnerman

Clip, Switch retainer

Scr,

Strain Relief

Label, Handle Adjust

Scr, 10-32 x

Washer, #lO Ext. Star

Control Asm,

Scr, 6-32 x

Cord Asm,

Scr, 10-24 truss head pltd

Nut,

Nut,

Tape, l/32 x 1.0 25A

Label, ETL approval

Gasket, Right Frame Top

Plate, Tray Top

Gasket, 8” Clamp Seal

Gasket, Left Frame Top

Shaft

x 1.25 HHMS

x 1”

PHTR

x 1.75 HHMS

Nylon Flat

x

5/l6- 18 SHSB

x

sht metal blk

PHMS

PHTF

SJTWI-A 50

16 square

18 jam pltd

rckr SPST

SPD (pump)

602252

SPD 98353 9/18/98

Page 20

To access the belt remove

the belt cover.

To replace the belt it is

necessary to loosen the motor

and remove the brush.

The “preset” belt tension is correct

when the motor and belt

securely back in place.

Check pulley

alignment and

correct if necessary.

The brush pulley

and motor pulley can

be aligned using a

straight edge.

Ensure that both protective

covers are back in place

before operating

the machine.

are

SPD 98353

Page 21

2

09019

3

70078

4

03089

140080

140081

140156

6

87146

7

36166

8

70190

9

73181

10

70201

11

41296

12

70011

13

87025

14

70020

15

67005

66094

16

17

57123

19A

53093

19B

53173

20

87018

21

70074

22

6407 1

23 36044

24

70363

25 11031

26 57047

27

36050

28

70434

29 36043

30 87013

31

70015

32 64088

33

67094

34 70497

35

29157

36 73767

37

48063

38

27666

39

70562

40

57016

41

70118

42A 140174

42B 140086

42C

140157

Bearing, Brush

Shoulder bolt,

Axle, Pulley

Brush, SPD Carpet

Brush, SPD Hard Floor

Brush, SPD Hard Floor (Grit)

Washer, 1/2 ID x 1.0 OD x

Guard, Thread

Scr, l/4-20 x

Spacer,

Scr, l/4-20 x

Housing, Brush

Scr, l/4-20 x

Washer,

Scr, l/4-20 x 1/2 HHCS

Rivet, l/8 OD pop wht alum

Pin, Roll

Nut, l/4-20 Captive

Motor,

Motor,

Washer,

Scr, 10-32 x

Pulley, Motor

Guard, belt

Scr, 10-32 x 3/8 PHTR

Belt

Nut, l/4-32 Nylock

Gusset, Belt Guard

Scr, 6-32 x 3/8 PPHTP

Guard, Brush Pulley

Washer,

Scr, l/4-20 x

Pulley, 2 l/8 OD 7

Ring,

Scr, 1O-24 x 112 SHCS

Driver, Brush SPD

Spring, Brush retaining

Knob, Brush release

Cable, Brush release

Scr, l/4-20 x

Nut,

Set Screw, 8-32 x 5/16 KCP

Brush Asm, SPD Carpet

Brush Asm, Hard Floor

ext. snap

Dia

OD x

BHCS

ID x

Star

OD x 1.375 L

Brush

ID x

x

HHCS

HP W/O TO

KCP

OD

HHCS

groove

pltd.

L

nyl

BRUSH DRIVE ASSEMBLY Parts List

SPD 98353

Page 22

Vac Motor Assemblv

Roller

22

Page 23

Vac Motor

3/8-

Roller Assembly

Page 24

SPIRIT DUAL Squeegee Assembly

24

To attach to the SPIRIT DUAL...

the SPD vac shoe and install squeegee assembly over

the vac shoe intake. Center the squeegee on the vac shoe and se-

cure by tightening the two retaining knobs.

Page 25

98353 7/1/97

25

Page 26

LIMITED WARRANTY

Windsor Industries, Inc. warrants new machines against defects in material and workmanship

under normal use and service to the original purchaser. The warranty period is subject to the

conditions stated below.

3 YEARS FOR PARTS AND I YEAR FOR SERVICE LABOR

Exceptions: Rotationally molded polyethylene tanks carry a 6

labor warranty. VERSAMATK models carry a 3 year warranty on brush motors, vacuum

motors, and belts, and a 1 year service labor warranty. SENSOR” models carry a 2 year

warranty on vacuum motors and belts, and a 1 year service labor warranty. Extractor brush

motors, pump motors, pc boards and electronics,

SENSOR”), pumps, and

carry a 1 year parts and service labor warranty. Propane equipment has a 1 year

parts and service warranty. The

Honda@ engines have a 2 year manufacturers’ warranty. The engine warranty is administered

through the engine manufacturer and must be repaired at an authorized service center.

Normal wear items including, but not limited to, belts, brushes, capacitors, carbon brushes,

casters, clutches, cords, filters, finishes, gaskets, hoses, light bulbs, rectifiers, switches, squeegees, bearings, pulleys, relays,

manufacturing defects for 90 days from the purchase date.

The warranty commences on the purchase date by the original end user from an authorized

Windsor Agent, subject to proof of purchase. The Machine Registration Card must be

completed and returned immediately at the time of purchase. If proof of purchase cannot be

identified, the warranty start date is 90 days after date of sale to an authorized Windsor

distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the

original warranty period.

diaphragms, all RADIIUSTM, all

engines have a 3 year manufacturers’ warranty. The

cables, tires and wheels will be warranted for

year

parts and 1 year service

motors (other than VERSAMATIC” and

and

90 DAY WARRANTY EXTENSION AVAILABLE

Upon receipt of the Machine Registration Card, Windsor will extend the warranty period an

additional 90 days from the purchase date. Does not include items warranted 90 days for

manufacturing defects.

STATED WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED.

Any statutory implied warranties, including any warranty of merchantability or fitness for a

particular purpose, are expressly limited to the duration of this written warranty. Windsor will not

be liable for any other damages, including but not limited to indirect or special consequential

damages arising out of or in connection with the furnishing; performance, use or inability to use

the machine. This remedy shall be the exclusive remedy of the buyer.

This warranty shall not apply to: 1

incompatible or corrosive chemicals or overloading of capacity): 3. failure due to lack of proper

maintenance and care (including cleaning); 4.any design alterations performed by an

organization not authorized or specified by Windsor;

washing.

If difficulty develops during the warranty period, contact the authorized Windsor Agent from

whom the product was purchased. Windsor, Inc. may elect to require the return of components

to validate a claim. Any defective part to be returned must be shipped freight pre-paid to an

authorized Windsor Distributor/Service Center or to the Windsor factory.

components exposed to moisture.

in transit; 2.misuse or abuse(including the use of

and chargers. 6. high pressure

USE OF PARTS NOT APPROVED BY WINDSOR, INC.

WILL VOID ALL WARRANTIES.

This warranty is valid only for all products sold after July 1, 1995. A product sold before that

date shall be covered by the limited Warranty in effect at the date of sale to the original

purchaser.

Loading...

Loading...