Page 1

SENSOR

S12

wRB

n

Page 2

IMPORTANT

SAFETY

INSTRUCTIONS

When using an electrical appliance, basic precautions must always be followed,

including the following.

READ

ALL

INSTRUCTIONS BEFORE USING THIS MACHINE

WARN

I

NG

5

T

O

reduce the risk of fire, electric shock, or injury:

1

;

Do

not leave appliance when plugged in. Unplug from outlet when not in use and before servicing.

2.

Do

not use outdoors or on wet surfaces.

3.

Do

not use near small children.

Do

not allow to be used as a toy. Close attention is necessary when used

by or near children.

4. Use only as described in this manual. Use only manufacturer's recommended attachments.

5.

Do

not use with damaged cord or plug. If appliance is not working as

it

should has been dropped,

6

Do

not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp edges

7.

Do

not unplug by pulling on cord.

To

unplug, grasp the plug, not the cord.

8.

Do

not handle plug or appliance with wet hands.

9.

Do

not put any object into openings.

Do

not 'use with any opening blocked; keep free of dust, lint, hair,

and anything that may reduce air flow.

10. Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.,

Do

not

place fingers or other body parts under vacuum unless unplugged.

11.

Do

not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

12.

Do

not use without dust bag and/or filters in place.

13. Turn

off

all controls before unplugging.

14. Use extra care when cleaning on stairs.

15.

Do

not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may

16. Machines can cause a fire when operated near flammable vapors or materials.

Do

not operate this

17. Maintenance and repairs must be done by qualified personnel.

18. Use only identical replacement parts. See instructions for Servicing

of

Appliances.

19.

Do

not use machine as a step.

20. If used on plush carpet or carpet with thick padding, do not leave machine in one place with machine

21.

Do

not use the handle in the dust bag housing cover to carry the machine.

22. Always turn

off

this appliance before connecting or disconnecting motorized nozzle.

23. Brush may unexpectedly restart.

To

reduce the risk of injury from moving parts. - Unplug before servicing.

24. The vacuum has a manual reset thermal protector. The protector is reset by switching off the vacuum.

The thermal protector needs some time to cool down after switching

off!

Check the vacum for air blockages

or mechanical failures before switching on.

25. Store the vacuum in a dry place at room temperature. When the vacuum is not in use, you should wrap the

cord on the cable hooks.

26. Any other servicing should be performed by an authorized service representative.

damaged, left outdoors, or dropped into water, return

it

to a service center.

or corners.

Do

not run appliance over cord. Keep cord away from heated surfaces.

be present.

machine near flammable fluids, dust or vapors.

turned on.

SAVE THESE INSTRUCTIONS

Page 3

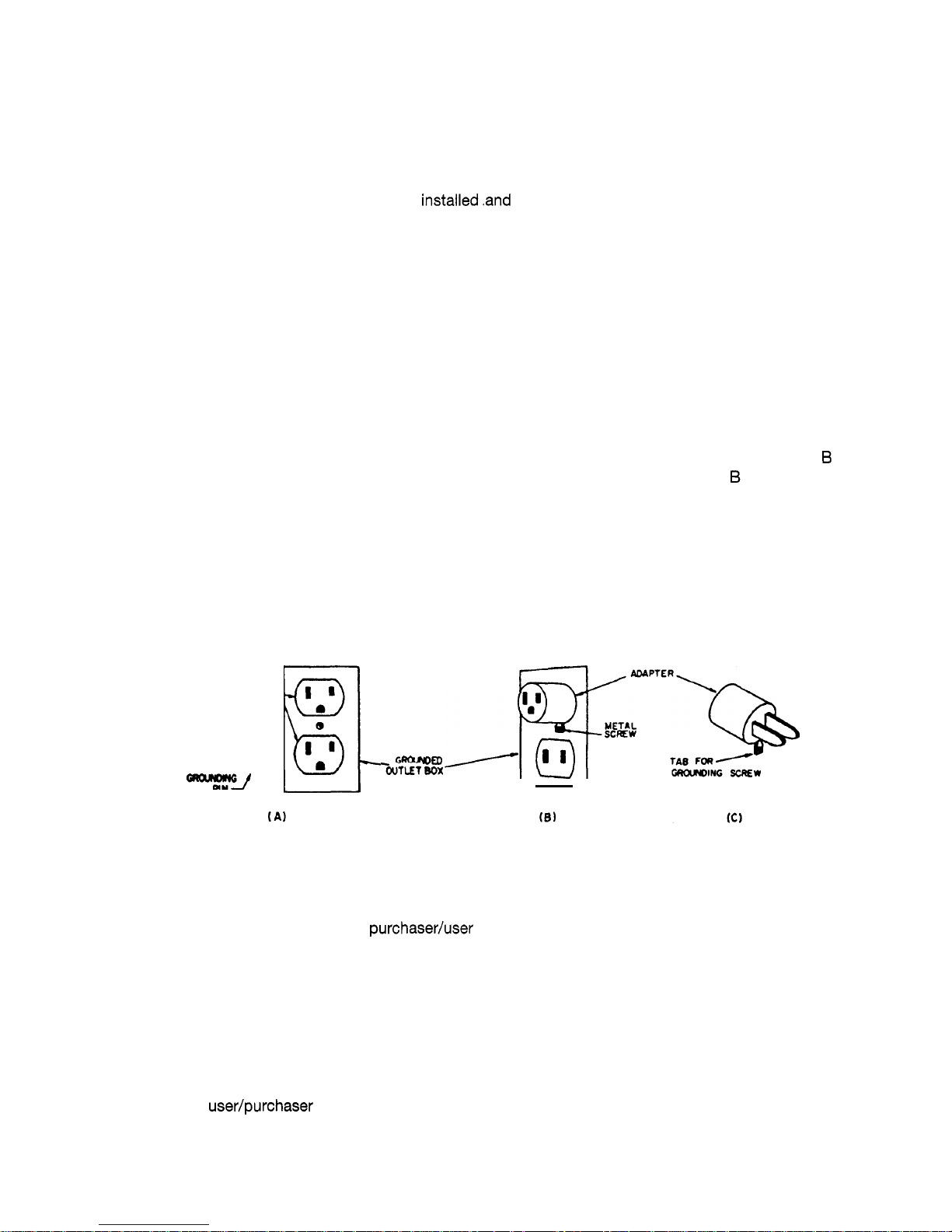

GROUNDING INSTRUCTIONS

This appliance must be grounded. If

it

should malfunction or breakdown, grounding provides a path

of least resistance, for electric current to reduce the risk of electric shock. This appliance is equipped

with a cord having an equipment

-

grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly

installed.and grounded in accordance with all local codes

and ordinances.

WARNING

Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with the appliance

-

if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

This appliance is for use on a nominal 120

-

volt circuit, and has a grounded plug that looks like the

plug illustrated in sketch

A. A

temporary apaptor that looks like the adaptor illustrated in sketches

6

and C may be used to connect this plug to a 2-pole receptacle as shown in sketch 6 if a properly

grounded outlet is not available. The temporary adaptor should be used only until a porperly grounded

outlet is not available. The temporary adaptor should be used only until a properly grounded outlet

(sketch

A)

can be installed by a qualified electrician. The green colored rigid ear, lug, or the like exten

ding from the adaptor must be connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adaptor is used,

it

must be held in place by a metal screw.

Note: In Canada, the use of a temporary adaptor is not permitted by the Canadian Electrical Code.

-J

AN

GROChlOED

-iWflEf

Box

LIMITED WARRANTY

WINDSOR warrants to the original purchaseduser that this product is unconditionally guaranteed free

from defects in workmanship and materials under normal use and service for a period of one year.

The vacuum motor and belts are warranted for a period of two years.

WINDSOR will, at its option, repair or replace without charge, except for transportations costs, parts

that fail under normal use and service when operated and maintained in accordance with the

Instructions Manual. This warranty does not apply to normal wear or to items whose life is dependent

on their use and care.

This warranty is in lieu of all other warranties, expressed or implied, and releases WINDSOR from all

other obligations and liabilities.

It

is applicable only in the

U.S.A.

and Canada, and is extended only to

the original

user/purchaser of this product. WINDSOR is not responsible for costs for repairs perfor

med by persons other than those specifically authorized by WINDSOR. This warranty does not apply

to damage from transportation, alterations by unauthorized persons, misuse or abuse of the equipment,

use of noncompatible chemicals, or damage or losses of income due to malfunctioning of the product.

If a difficulty develops with this product, you should contact the dealer from whom

it

was purchased.

Page 4

Accidents due to misuse can only be prevented by those using the machine.

To

guard against injury, basic safety

This vacuum cleaner is designed to be saf

electrical or mechanical parts, cleaner sh

using in order to avoid further damage to machine or physical injury to user.

A

ould e

aleckical

shock and mise this possibility obse

fol

ot r ner ove

old.

Avoid closing doors on power cord, pulling it around sharp edges, or placing sharp-edged objects

pon it.

cor

If

used on plush carpet or carpet with thick padding, turn

off

unit when handle is in upright position. When using

accessory tools, keep floor brush

off

carpet by keeping handle in locked position and lowering handle with one

hand to raise brush

off

flo

Always plug

your cleaner into a standard wall

out1

Use of extension cord ar

li

shock or fire hazard.

before Servicing, such as changin

e~

s@xdd switch ac

Operate accessories with other hand.

~

er from electric

b6 turned on. Dis

electrical outlet

bef

hing powerhead.

Do not use your vacuum cleaner in areas where flammable and/or explosi

possibility of fire

ar

explosion. Some cleanin$fluids can produce such vapors. Areas on which cleaning fluids

have been used should be c

To

avoid fire hazard,

do

not

pi

uumed.

al with cleaner.

I

Keep your work area well lighted

to

avoid picking up harmful materials (such as liquids, sharp objects, or burning

sub ide

ng the cleaner

on

i

al damage. Proper

aused by

trippi

S

tor

CI

llow children to play

Page 5

Picture

1

7

Frontcover

8

Housing release button

9

Base with brush

10

Cable

18

Pile adjustment knob

When the handle has been pushed down as

far as it will go press catch

(22)

down. If the

handle is not pushed fully down the machine

will not work.

Connecting tube

'(24),

so

that it clicks into

place.

Page 6

A Filter level indicator

B Brush controller

Filter level indicator

The red warning light (A) indicates a blockage or

a full bag,

so

check:

a)

Is

the dust bag full?

b) Is there a blockage in the hose or power

head?

If the red light is disregarded the machine will

shut

off

and the light will flash.

Brush controller

The electronic brush controller continuously

monitors the operation of the brush.

If the red light

(B)

stays

off,

the operation of the

brush is correct.

If the red light

(B)

turns on in positions

1-4

of

the Pile adjustment knob adjust the brush by

turning the Pile adjustment knob to a lower

position.

If the red light

(B)

burns continuously in the

position

1,

the brush must be changed for a

new one.

If

the machine turns

off

and the red light

(B)

flas

hes, the brush has become blocked and is not

turning. Switch the machine off, unplug it from

the mains and clear the blockage.

If there is no blockage, and machine turns

off

with brush light flashing, raise brush to a higher

position.

When the machine is switched on in the upright

position the brush automatically rises from the

carpet. To release the machine from the upright

position, press down the foot pedal

(19).

The

brush will automatically lower. The handle can be

lowered to an intermediate stop position in order

to lift up the brush head. To lower the

handle to a horizontal position, the foot pedal

must be pressed a second time. The stop positi

-

on can be closed off by a slider on the swivel

neck

(25)

so

that the handle will go from vertical

to horizontal in one movement.

To vacuum in corners etc.:

take hold of the telescopic handle grip, lift, it

away from the machine and stretch out the hose.

After use insert the telescopic attachment tube

into the back of the machine. Raise the handle of

the machine and the hose will automatically

retract. To use the hose without the tube as

shown in the right hand picture, the hose will pull

out of the tube while the tube is fitted to the

machine. Alternatively, press the release catch

(27)

on picture

2.

To vacuum under beds etc., the machine can be

fitted with an additional straight tune and the

floor nozzle. The machine will then perform as a

cylinder vacuum.

Never run over the cable with the brushlsuc-

tion head.

Always carry the machine over steps and sills.

Page 7

29

-

-

3

Maintenance

CAUTION - Always unplug machine at

mains outlet before dismantling any part

of machine.

If red light (A) shows, change paper filter bag.

To do this first pull cover release

(5)

picture

1

forward and lift the cover from the dust bag

housing. Slide the dust bag sealing plate (28)

from the holder (29). Slide the sealing plate (28)

of a new bag into the holder and push firmly in.

Insert cover into dust bag housing push is for

-

ward then lock

it

in place by pushing down the

cover release

(5).

The micro hygiene filter (30) needs to be

changed when it becomes clogged with dust

or after approximately 20 paper bags have

been used. To change the hygiene filter first

remove the cover then slide the filter out at the

bottom. To replace lift the lever and slide the

new filter in.

After 20 paper bags have been used also

change the exhaust filter (32). To remove the

exhaust filter push the catch (33) forward and

remove the filter cover (34) and filter.

Insert the new filter and replace the filter cover.

To change the brush roller (35) push the button

(36), remove the slide plate (37), turn the brush

clockwise a quarter of a turn and pull the brush

roller out. Slide the new brush roller into the

brush housing and turn it until it locates into

position. Push the button (36) and press the

side plate (37) back into place.

Underneath the machine is an inspection door

to check for blockages (38).

Blockages in the neck (20

-

picture

2)

can be

checked by first lifting

off

the dust bag housing

by pressing the catch (8). Then release the foot

pedal, lower the neck and check into the tube

next to the pedal.

Blockages in the hose can cleared by taking

the hose

off

the machine and replacing

it

the

wrong way round in the connecting tube (24)

holding it upright with one hand blocking the

top and switching on the machine.

(If necessary quickly lift your hand on and

off

the end of the hose).

The guarantee is invalidated

if

take out

parts not approved by

WINDSOR,

eg. bags,

filters, brush roller, etc., are

fmed!

Page 8

ZBK

SEmSI2

120

V

GREY

P

U

1-

23

-

/

/'

I

25

u

16

15

W

J

-3a

/

-39

50

/-49

i

c1

06747 C-09.2002

Pos.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Product-

No.

5625

UL

5296

EW

5359

hg

2301

1

0532

EW

5160

bl

5161

hg

5162

01

03

0846

5256

ER

01

29

51 87

01

02

5040

hg

5045

hg

5803

hg

5319

5706

bl

5324

5360

5091

5800

WI

5300

5301

ER

5380

HG

51

64

5208

5210

1073

5099

5098

hg

01

87

5145

hg

5146

5144

hg

5424

dg

5281

hg

1823

hg

5084

5255

ER

5266

5043

5289

51 63

5085

hg

5082

bl

5083

5215

UL

1491

JE

1092

JE

Description

Handle with cable, cpl.

Handle grip (incl.

Pos.

7

+

10)

Grommet

Power supply cord

Switch, cpl.

Switch cap, blue

Switch cap holder

Cable clamp

Screw C

3,9 x 16

DIN

7981

Antistatic-wire, cpl.

Handle cable

Screw,

M4 x 12

Handle tube

Screw F

3,9 x 13

DIN

7981

Hose, cpl.

Extension tube

Cover

Bag holder spring

Cover release, blue

Bag holder cpl.

(incl.

Pos.

20+21)

Safety catch

Safety catch spring

Front cover cpl.

Paper bag

Micro Hygiene Filter

Internal cover, compl.

(incl. Pos.

43 +44)

Cable clamp

Filter safety catch

Return spring

Clamp

Handle lock plate

Lock catch

Lock pin

4 x 33,5

Carrying handle

Stop spring

Cable hook

Retaining ring

Dust bag housing

Attachment clip

Spring for locking rod

Internal cable

Cable clamp

Seal

Seal

Seal

Dust bag hous. bumper base

Dust bag housing locking

Locking rod

Dust bag housing

Upholstery nozzle

Crevice nozzle

Page 9

120

V

GREY

06747 C-09.2002

POS. Product-

No.

100 2831

WI

101 2846

102 2820

BL

103 2827

UL

104 2886

105 2494

106 0102

107 2835

108 0869

109 2825

110 2824

Ill

5479

112 5717

113 2890

ER

114 0864

115

5713bl

116 5103

117 5051

hg

118 5053

119

5059dg

120 2010

121

5055

hg

122 2014

123 5813

124 5287

bl

125 2869

hg

126 2868or

127 5303

128 5304

129 2861

130 5174

hg

131 2849

132 01010

133 2860

hg

134 2833

135 2862

hg

136 2834

137 2856

138 2867

139 2821

HG

140 5411

hg

141 2829

hg

142 0197

143 5401

144 5402

145 5005

hg

146 5469

05117

S

147 5462

148 5100

149 2826

BL

150

2839

sw

151

5129

153

5112sw

154 2881

ER

155 0107

156 0143

157 5464

158 511711

159 0104

160 5463

161 5110

162 5766

hg

163 0103

164 0140

165

0176TL

152 5107-1

Description

Power head cover S

12,

cpl

Exhaust filter

Exhaust filter cover

Swivel neck assembly

Male contact holder

Cable clamp

Screw

F

3,9x13

DIN

7981

Bypass valve

Internal cable

Swivel neck bearing r.h

Swivel neck support r.h

Swivel neck support

1.h

Swivel neck bearing 1.h

PCB Power supply

Internal cable

Brush roller release

Spring

Axle assembly

Axle

Foot pedal

Axle spring

Wheel, cpl.

Axle clamp

Brush roller

Bearing block right hand

Rubbing plate

Access door

(incl. Pos.

127 + 128)

Access door axle

Access door spring

Pile adjustment axle

Pile adjustment wheel

Axle clamp

Screw

AM4

x 16,

DIN

7985

Cover

Thrust member

Pile adjustment knob

Thrust member

Clamp

Spring

Chassis

S12,

cpl.

Front bottom plate, cpl

Rear bottom plate, cpl

(incl. Pos.

142)

Srew

M4x12

Wire tie

Wire tie

Bumper, set

Motor

1

OOOW

I

120V

Carbon brush set

Motor pulley

2MR

Rubber mounting

Motor cover

Cover for air channel

Support lever

Support spring

Motor pulley cover

Computer controller

Screw C

2,9 x 13

Washer

3,2

DIN

125

Sensor

X4

cpl.

Motor pulley

Screw C

3,9x25

DIN

7981

Belt

2MR-310-6

Belt

219 3M

HTDII-6

Bearing block

1.h cpl.

Screw C

3,9x 16

DIN

7981

Washer

4,3

Screw

AM4x30

DIN

7985

TL

Page 10

IB

I

2~

1

U

I

C

2

1

A Attachments

1

Upholstery Nozzle

2

Crevice Nozzle

B

Optional Attachments

1

Extension Hose

2

Straight Tube

3

Dusting Brush

4

Upholstery Nozzle, special

5

Wall- and Floor Brush

C Service Parts

1

Paper Bag

2

Micro-Hygiene-Filter

3

Exhaust Filter

3

Brush Roller

WARNING

!

Electric shock could occur

A

if

used outdoors or

on

wet surfaces

I

Technical Details

Vacuum motor..

.........

Water lift

...............

Air

flow

................

Dust

bag capacity.

.......

Working width

...........

Brush drive

.............

Brush speed

............

Floor adjustment.

........

Cable

.................

Weight

.................

Radio supression.

........

1200

Watt

2300

mm

(90”)

50

US

(105

CFM)

5,3

liters

308

mm

(1

2’3

tooth belt

2700

rpm

automatically sensor

advised

12’2

m

(40

ft)

7’4

kg

(162

Ibs)

EN

5501 4 Verf.

242/91

Wiring diagram

.c

mvr

P

PP

dm

WINDSOR”

INDUSTRIES,

INC.

1351

West Stanford

Ave.

Englewood, Colorado

801 10

USA

800-444-7654

303

-

762-1 800

FAX:

303-762-081 7

06747

-

09.200:

Loading...

Loading...