Page 1

Saber Blade 12

English 3

Français 13

Español 24

5.963-137.0 10/08

Page 2

2

Page 3

IMPORTANT SAFETY IN-

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

WARNING

To reduce the risk of fire, electric shock,

or injury:

– Do not leave appliance when

plugged in. Unplug from outlet when

not in use and before servicing.

WARNING

– TO REDUCE THE RISK OF ELEC-

TRIC SHOCK-USE INDOORS

ONLY

– Do not allow to be used as a toy.

Close attention is necessary when

used by or near children.

– Use only as described in this manu-

al. Use only manufacturer`s recommended attachments.

– Do not use with damaged cord or

plug. If appliance is not working as it

should, has been dropped, damaged, left outdoors, or dropped into

water, return it to a service center.

– Do not pull or carry by cord, use cord

as a handle, close a door on cord, or

pull cord around sharp edges or corners. Do not run appliance over

cord. Keep cord away from heated

surfaces.

– Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

– Do not handle plug or appliance with

wet hands.

– Do not put any object into openings.

Do not use with any opening

blocked; keep free of dust, lint, hair,

and anything that may reduce air

flow.

– Keep hair, loose clothing, fingers,

and all parts of body away from

openings and moving parts.

– Turn off all controls before unplug-

ging.

– Use extra care when cleaning on

stairs.

– Do not use to pick up flammable or

combustible liquids, such as gasoline, or use in areas where they may

be present.

– Connect to a properly grounded out-

let only. See Grounding Instruction.

SAVE THESE INSTRUCTIONS

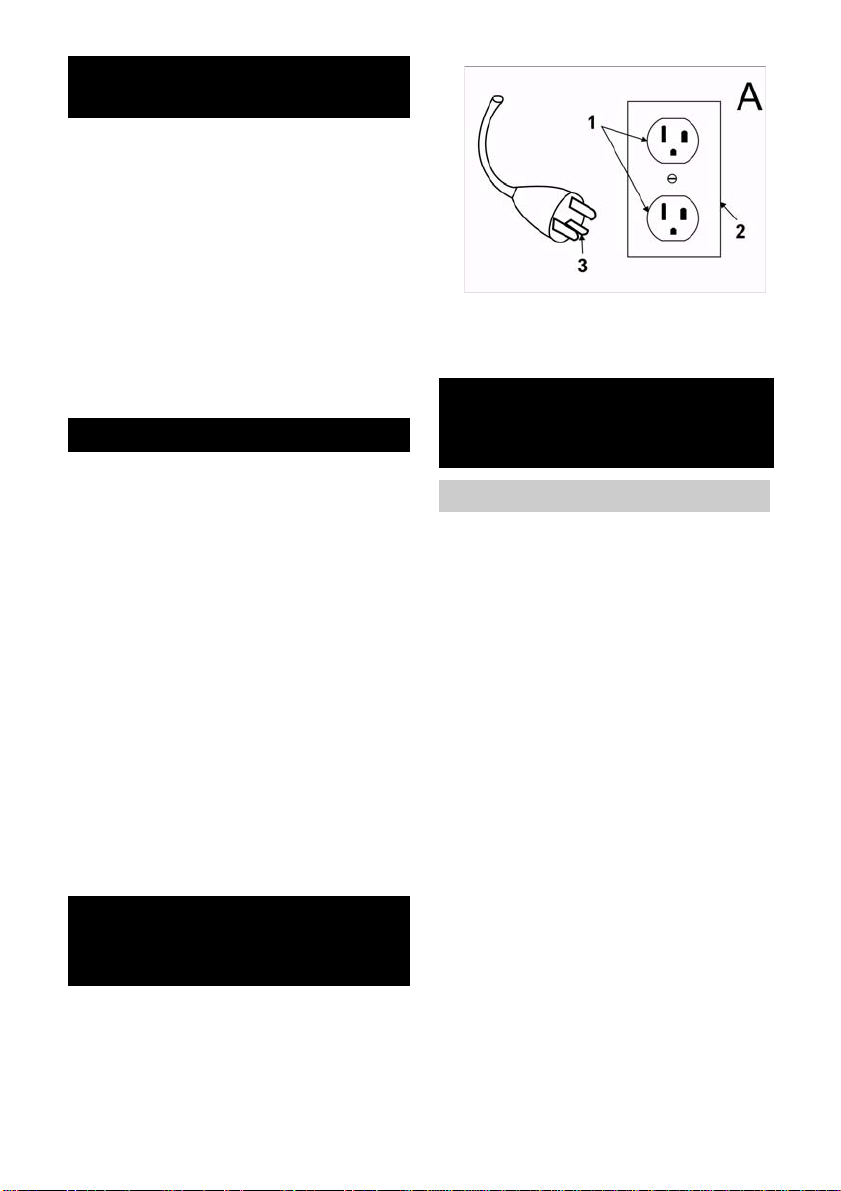

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce the

risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a

grounding plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance-if it will not fit

the outlet, have a proper outlet installed

by a qualified electrician.

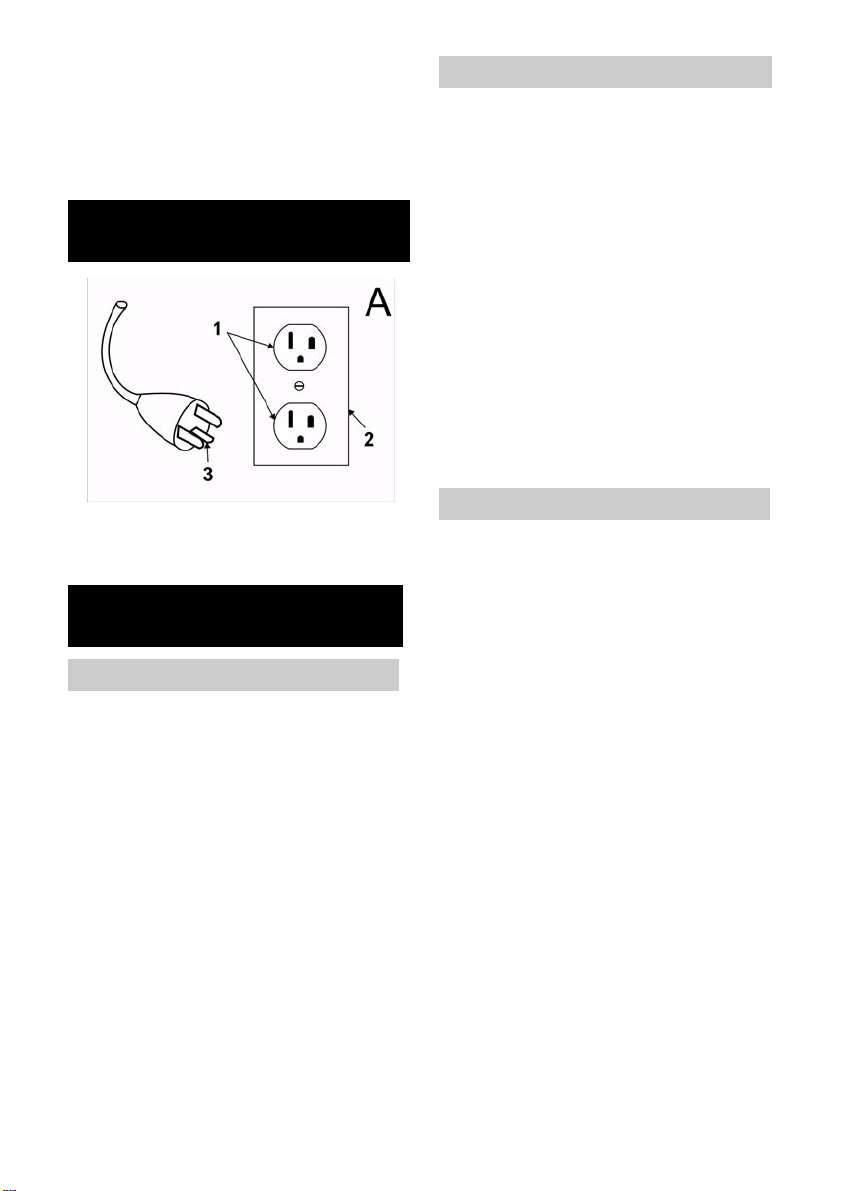

This appliance is for use on a nominal

120-volt circuit and has a grounding at-

English 3

Page 4

tachment plug that looks like the plug in

illustration A. Make sure that the appliance is connected to an outlet having

the same configuration as the plug. No

adaptor should be used with this appliance.

CONNECT TO A PROPERLY

GROUNDED OUTLET ONLY

1 Grou nded outlet

2 Grou nded outlet Box

3 Grounded Pin

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility of

the operator.

The operator shall be familiar with the

operation and function of all controls

and instruments before operating the

unit.

Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular unit

being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require additional

safety precautions or special operating

instructions.

General

Before starting to operate the unit be in

operating position.

Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designate d

operators position.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B if the unit must be on an incline,

block the wheels.

Maintain a safe distance from the edge

of ramps, platforms, and other similar

working surfaces.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Traveling

Yield the right of way to pedestrians and

emergency vehicles such as ambulances and fire trucks.

Cross railroad tracks at an angle wherever possible. Do not park closer than 6

ft (1800 mm) to the nearest rail of a railroad track.

Keep a clear view of the path of travel

and observe for other traffic, personnel,

and safe clearances.

Under all travel conditions, operate the

unit at a speed that will pernit it to be

brought to a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors.

Before driving over a dockboard or

bridge plate, be sure that it is properly

secured. Drive carefully and slowly

across the dockboard or bridge plate,

and never exceed its rated capacity.

When negotiating turns, reduce speed

to a safe level consistent with the operating environment. Make the turns

smoothly.

4 English

Page 5

Operator care of the unit

If the unit is found to be in need of repair

or in any way unsafe, or contributes to

an unsafe condition, the matter shall be

reported immediately to the user’s designated authority, and the unit shall not

be operated until it has been restor ed to

safe operating condition.

If during operation the unit becomes unsafe in any way, the matter shall be reported immediately to the user’s

designated authority, and the unit shall

not be operated until it has been restored to safe operating condition.

Do not make repairs or adjustments unless specifically authorized to do so.

MAINTENANCE AND RE-

BUILD PRACTICES

Operation of the unit may be hazardous

if maintenance is neglected or repairs,

rebuilds, or adjustments are not performed in accordance with the manufacturer’s design criteria. Therefore,

maintenance facilities (on or off premises), trained personnel, and detailed

procedures shall be provided.

Maintenance and inspection of the unit

shall be performed in conformance with

the following practices:

A a schedules planned maintenance,

lubrication, and inspection system

shall be followed; consult the manufacturer’s recommendations.

B only trained and authorized person-

nel shall be permitted to maintain,

repair, adjust, and inspect the unit,

and in accordance with manufactur-

er’s specifications.

Avoid fire hazards and have fire protection equipment present in the work area.

Do not use open pans of fuel or flammable cleaning fluids for cleaning parts.

FIRE SAFETY STANDARD

Any unit not in safe operating condition

shall be removed from service.

Fire Prevention: The unit shall be kept in

a clean condition and reasonably free of

lint, excess oil, and grease. Noncombustible agents are preferred for cleaning the unit. Flammable liquids [those

having flash points at or above 100°F

(37,8°C)] are not allowed. Precautions

regarding toxicity, ventilation, and fire

hazard shall be appropriate for the

agent or solvent used.

Nameplate Visibility: The unit type designations as shown on the nameplate

and the type markers shall not be covered over with paint so that their identification information is obscured.

English 5

Page 6

Please read and comply

with these instructions prior

to the initial operation of your appliance.

Retain these operating instructions for

future reference or for subsequent possessors.

Contents

Safety instructions 6

Function 6

Proper use 6

Environmental protection 7

Control elements 7

Initial startup 8

Operation 8

Maintenance and care 9

Faults 10

Technical specifications 12

Spare parts 12

Safety instructions

Before using the appliance for the first

time, read and observe these operating

instructions and the accompanying brochure: Safety information for brush

cleaning units and spray-extraction

units, 5.956-251.

Symbols

The following symbols are used in this

operating manual:

Danger

Indicates an immediate threat of danger. Failure to observe the instruction

may result in death or serious injuries.

몇 Warning

Indicates a possibly dangerous situation. Failure to observe the instruction

may result in light injuries or damage to

property.

Note

Indicates useful tips and important information about the product.

Function

The appliance is used for the wet cleaning of level floors.

A working width of 12 in (300 mm) and

a capacity of 1 gal (4 l) each of the fresh

water reservoirs and recovery tank enable an effective cleaning of smaller

surfaces.

The power supply operation allows a

high capacity without a restriction of the

working time.

Note

The appliance can be equipped with

various accessories depending on the

cleaning task. Please request our catalogue .

6 English

Proper use

Use this appliance only as directed in

these operating instructions.

– The appliance may only be used for

the cleaning of hard surfaces that

are not sensitive to moisture and polishing operations.

Page 7

The application temperature ranges

from 41°F1 to 104°F (+5°C to

+40°C).

– The appliance is not suited for the

cleaning of frozen surfaces (e.g. in

cold stores).

– The appliance may only be equipped

with original accessories and spare

parts.

– The appliance was designed for the

cleaning of floors inside or covered

surfaces.

– The appliance is not intended for the

cleaning of public traffic routes.

– The appliance is not suited for the

use in potentially explosive environments.

Environmental protection

The packaging materials

are recyclable. Please do

not throw packaging in the

domestic waste but pass it

on for recycling.

Control elements

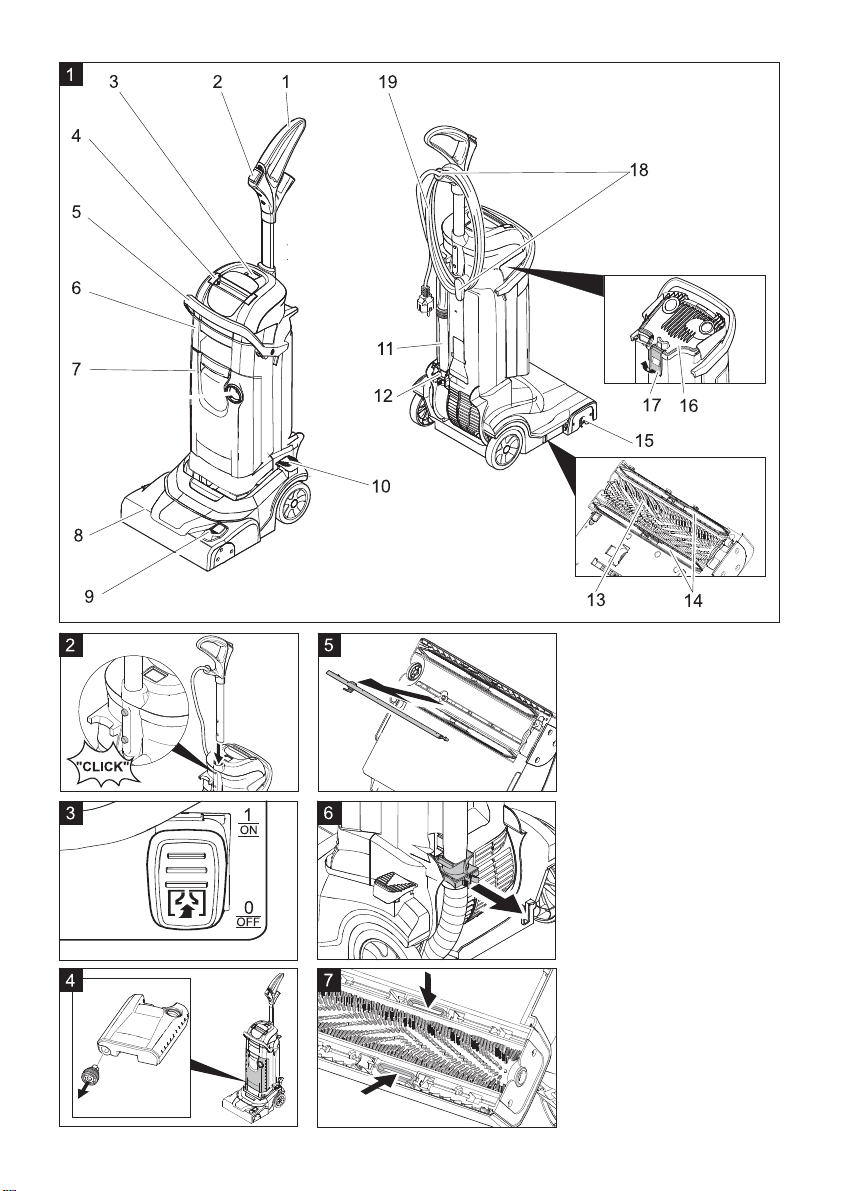

Figure 1, see cover page

1 Handle

2 Water pump switch

3 Main switch for bru shing/vacuuming

operations

4 Carrying handle

5 Support bow in recovery tank

6 Recovery tank

7 Solution tank

8 Cleaning head

9 Squeegee lift pedal

10 Release, park position

11 Suction tube

12 Suction tube connection

13 Cylindrical brush

14 Squeegee

15 Unlocking button for the changeable

brush

16 Cover recovery tank

17 Lock

18 Cable hook, rotating

19 Mains cord with mains plug

Old units contain valuable

recyclable materials. Batteries, oil and similar substances may not be released into

the environment. Therefore

please dispose of old units

through suitable collection

systems.

Initial startup

Figure 2, see inside cover page

Î Insert tube into the opening of the

appliance at the end of the handle.

Î Press down and slide the handle into

the appliance until it clicks.

English 7

Page 8

Operation

Fill solution tank

몇 Warning

Risk of damage. Only use the recommended detergents. With respect to different detergents the operator bears the

increased risk regarding the operationa l

safety, accident risk and reduced product life of the appliance. Only use detergents that are free from solvents,

hydrochloric acid and hydrofluoric acid.

Note

Do not use highly foaming detergents.

Observe the chemical measuring notes.

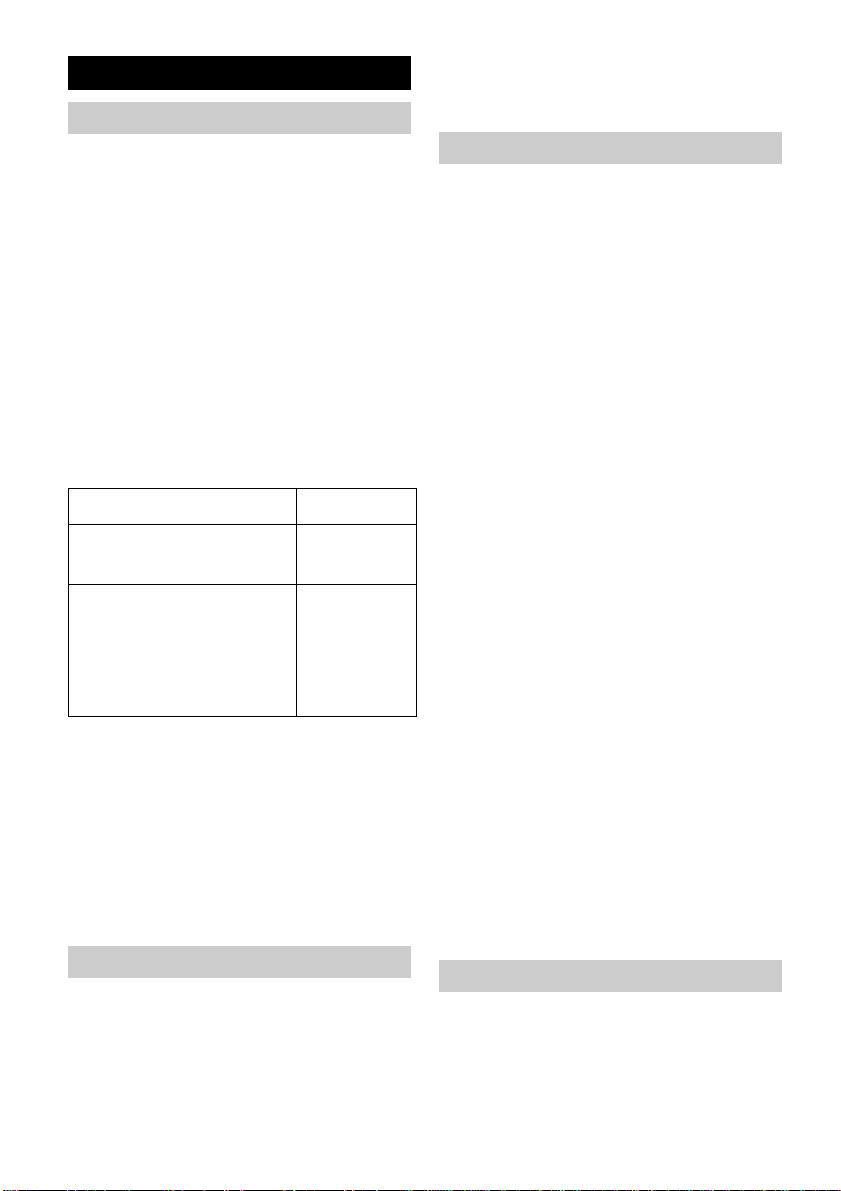

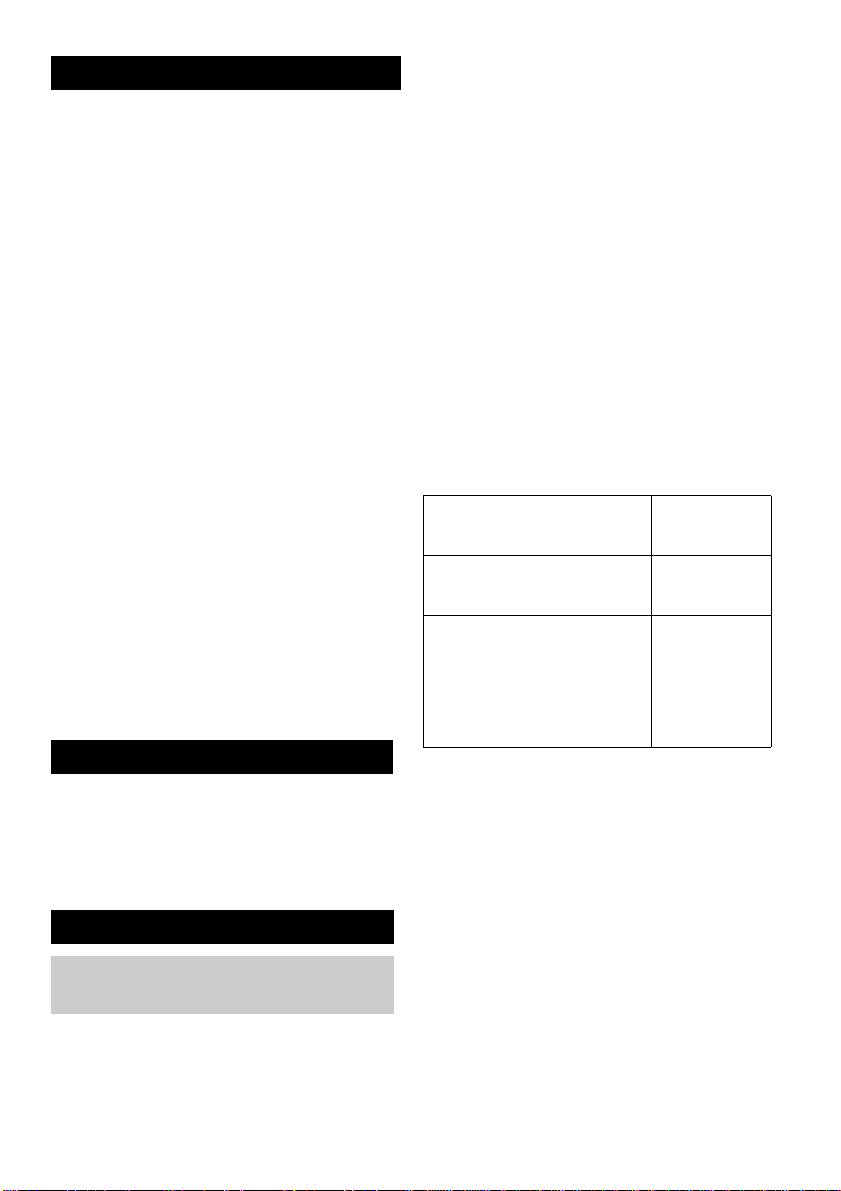

Recommended detergents:

Application Detergent

Everyday cleaner, alkali-based

Everyday cleaner, acidic, for sanitary applications, swimming pools,

etc. Removes limestone

deposits.

Î Remove the solution tank from the

appliance.

Î Open the cover of the solution tank.

Î Pour in water/detergent mixture.

Maximum temperature of the liquid

50 °C.

Î Close the cover of the solution tank.

Î Insert the solution tank into the appli-

ance.

Establish mains contact

Î Swivel bottom cable hook upward

and remove cable.

Î Check mains cable and plug for

damage or breakage. Get them re-

RM 743

RM 738

placed only through customer service agent or an electrician.

Î Insert the plug into the socket.

Cleaning

몇 Warning!

Risk of damage to the floor covering. Do

not operate the appliance for extended

period on the spot.

Normal soiling

Î Move the squeegee lift pedal to posi-

tion „suction off“ (Fig. 3 - position "1/

ON", see inside front cover).

Î Press the park position release and

swivel the handle toward the rear.

Î Set main switch for brush/vacuum

operation to “1”.

Î Activate the water pump switch.

Î Move the appliance over the surface

to be cleaned.

Severe soiling

몇 Warning

Risk of damage to the floor covering.

The cleaning method for severe soiling

must only be used on floors suitable for

this kind of cleaning.

Î Move the vacuum bar lift pedal to po-

sition „do not suction off“ (Fig. 3 - position "0/OFF" see inside front cover)

and perform the cleaning as you

would with normal soiling. The detergent liquid remains on the surface to

be cleaned and has time to settle in.

Î Move the squeegee lift pedal to posi-

tion "suction off" and reclean the surface.

Complete cleaning

Î Turn off the water pump switch.

Î Push the appliance a little further to

vacuum up the remaining water.

8 English

Page 9

Î Set main switch for brush/vacuum

operation to “0”.

Î Swivel the appliance handle forward

and arrest in the park position.

Î Disconnect the main plug from the

socket.

Emptying the recovery tank

Note

If the recovery tank is full the float closes the suction channel. The suction operation is interrupted. Empty the

recovery tank.

몇 Warning

Please observe the local provisions regarding the wastewater treatment.

Î Turn off the machine.

Î Position the appliance upright and

arrest it in the park position.

Î Remove the solution tank from the

appliance.

Î Swivel support bow downward and

remove the recovery tank.

Î Lift the lock and remove the lid of the

recovery tank.

Î Pour out dirt water.

Î Rinse the recovery tank with clear

water.

Î Replace the lid of the recovery tank

and lock it.

Î Insert the recovery tank into the ap-

pliance.

Transport

Î Swivel the appliance handle forward

and arrest in the park position.

Î Swivel the pushing handle back-

wards and push the appliance.

or

Î Lift appliance by the carrying handle

and carry it.

Maintenance and care

Danger

First pull out the plug from the mains before carrying out any tasks on the machine.

몇 Warning

Risk of damage to the appliance on account of water leakage. Empty the

waste water reservoir and the fresh water reservoir prior to performing maintenance on the appliance.

Emptying the solution tank

Î Remove the solution tank from the

appliance.

Î Open the cover of the solution tank.

Î Pour out the cleaning liquid.

Î Close the cover of the solution tank.

Î Insert the solution tank into the appli-

ance.

English 9

Page 10

Maintenance schedule

After the work

몇 Warning

Risk of damage. Do not wash down the

appliance with water and do not use aggressive detergents.

Î Empty the recovery tank.

Î Clean the seals between the recov-

ery tank and the appliance.

Î Empty the solution tank.

Î Rinse the appliance: Fill the solution

tank with water (without detergent)

and let the appliance run for one

minute with the brush water supply

turned on.

Î Empty the solution tank.

Î Clean the outside of the appliance

with a damp cloth which has been

soaked in mild detergent.

Î Clean the squeegee, check for wear

and replace if required (see "Maintenance tasks").

Î Check the brush for wear and re-

place if required (see "Maintenance

tasks").

Yearly

Î Have the prescribed safety inspec-

tion carried out by an electrician.

Maintenance Works

Replace the squeegee.

Note

The squeegee is attached to the appliance with snaps and can simply be

pulled off.

Î Move the squeegee lift pedal to posi-

tion „suction off“ (Fig. 3 - position "1/

ON", see inside front cover).

Î Remove the solution tank from the

appliance.

Î Remove the recovery tank.

Î Lay the device down on the back-

side.

Î Pull off the squeegee downwards.

Î Insert the new squeegee and lock

them into place.

Replacing the brush

Î Remove the solution tank from the

appliance.

Î Remove the recovery tank.

Î Lay the device down on the back-

side.

Î Press the release button for the

brush and swivel the brush toward

the bottom and pull it off the driver.

Î Place the new brush on the driver

and lock into place on the opposite

side.

Frost protection

In case of danger of frost:

Î Empty the solution and recovery

tank.

Î Store the appliance in a frost-pro-

tected room.

Faults

Danger

First pull out the plug from the mains before carrying out any tasks on the machine.

몇 Warning

Risk of damage to the appliance on account of water leakage. Empty the

waste water reservoir and the fresh water reservoir prior to performing maintenance on the appliance.

In case of faults that cannot be remedied using the table below please contact the customer service.

10 English

Page 11

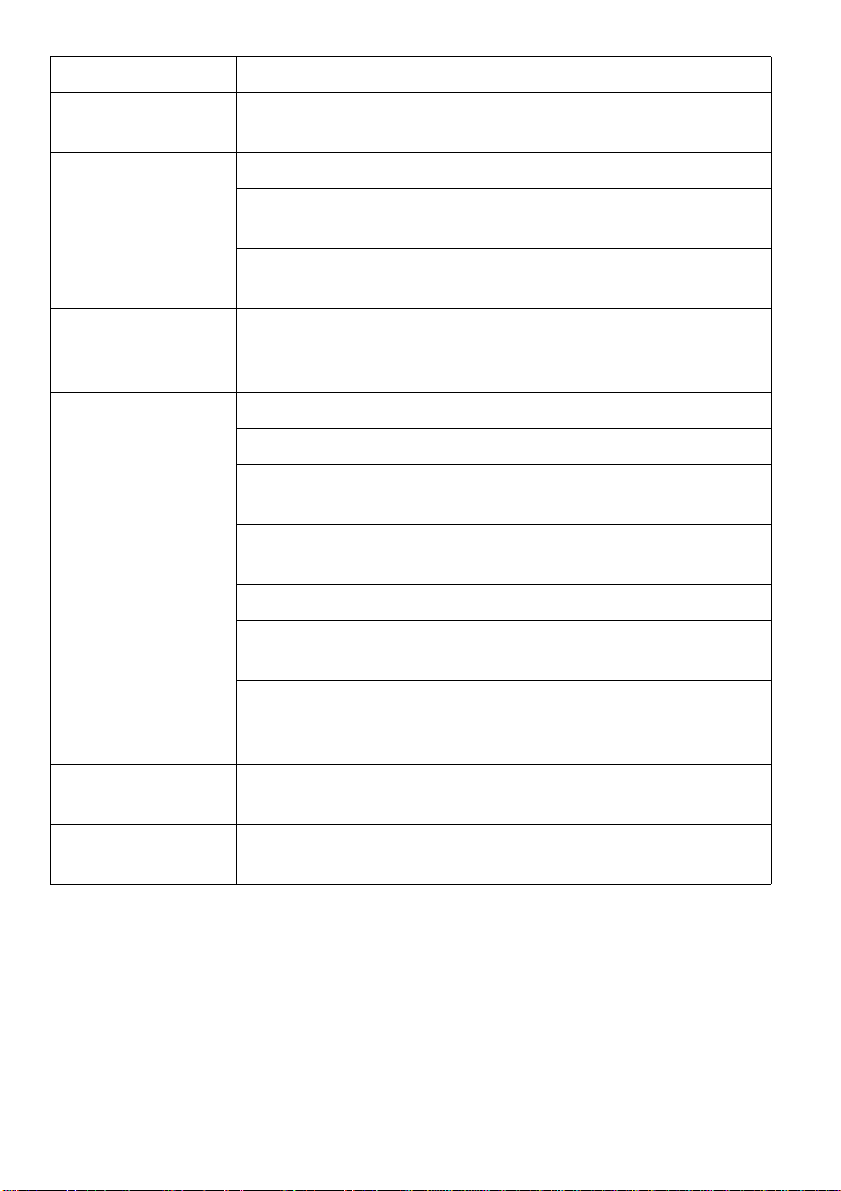

Error Remedy

Appliance cannot

be started

Insufficient water

quantity

Fresh water reservoir drips when refilled

Insufficient vacuum performance

Check if the mains plug is connected.

Check clean water level, refill tank if necessary.

Clean the water distributor (see chapter "Cleaning the water

distributor").

Pull off the valve on thesolution tank (Fig. 4, see inside front

cover) and rinse in lukewarm water.

Pull off the valve on the solution tank (Fig. 4, see inside front

cover) and rinse in lukewarm water.

Empty the solution tank.

Lock the recovery tank in place on the appliance.

Clean the seals between recovery tank and cover and

check for tightness, replace if required.

Check that all squeegee are locked into place in the clean-

ing head.

Squeegee worn, replace if required.

Check that both suction tube parts are correctly attached to

the suction tube connection.

Insufficient cleaning result

Brush does not

turn

Check the suction tube and the suction channel in the

cleaning head for obstruction and remove if necessary (see

"Cleaning suction tube").

Check the brush for wear, replace if required.

Check if foreign matters are blocking the brush; remove foreign matter if required.

English 11

Page 12

Clean water distributor

Take out the brush.

Î

Î Pull the water distribution bar out of

the brush tunnel (Fig. 5, see inside

front cover).

Î Clean the irrigation channel and the

opening in the water distribution bar

under running water.

Clean suction tube

Î Remove the solution tank from the

appliance.

Î Swivel support bow downward and

remove the recovery tank.

Î Pull the suction tube connection out

toward the rear of the appliance and

swivel out both ends of the suction

tube (Fig. 6, see inside front cover).

The suction tube is separated and

both ends are accessible for cleaning.

Î Pull the squeegee off toward the bot-

tom, the suction channel in the

cleaning head is accessible for

cleaning (Fig. 7, see inside front cover).

Î Flush the suction hose and the suc-

tion channel with water or pull or

push the obstruction out with a blunt

object.

Technical specifications

Power

Nominal voltage V/Hz 120 /

1~60

Average power consumption

Vacuuming

Cleaning power, air

quantity

W600

gpm

(l/s)

380

(24)

Cleaning power, negative pressure

psi

(kPa)

2.0

(14)

Cleaning brush

Working width in

(mm)12(300)

Brush diameter in

(mm)

2.4

(60)

Brush speed 1/min 1550

Dimensions and

weights

Theoretical surface

cleaning performance

ft²/h

(m²/

2152

(200)

h)

Fresh/dirty water res-

gal (l) 1 (4)

ervoir volume

Length in

(mm)

Width in

(mm)

Height in

(mm)

Weight (without tank

contents)

lb

(kg)

15.4

(390)

13.2

(335)

46.5

(1180)

24.3

(11)

Noise emission

Sound pressure level

(EN 60704-1)

dB(A

)

71

Machine vibrations

Vibration total value

m/s² 0,5

(ISO 5349)

Spare parts

– Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive use

of original accessories and original

spare parts ensures that the appliance can be operated safely and

troublefree.

– At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

12 English

Page 13

INSTRUCTIONS IMPORTANTES EN MATIÈRE DE SÉCU-

RITÉ

LIRE TOUTES LES INSTRUC-

TIONS AVANT DE FAIRE

FONKTIONNER

Attention

Pour réduire les risques d'incendie, de

chok électrique ou de blessure:

– Ne pas laisser l'appareil sans sur-

veillance lorsqu'il est branché. Débrancher lorsque l'appareil n'est pas

utilisé et avant l'entretien.

Attention

– Pour réquire les risques de choc

électrique, utiliser à l'interieur seulement.

– Ne pas permettre aux enfants de

jouer avec l'appareil. Une attention

particulière est nécessaire lorsque

l'appareil est utilisé par des enfants

ou à proximité de ces derniers.

– N'utiliser que conformément à cette

notice avec les accessoires recommandés par le fabricant.

– Ne pas utiliser si le cordon ou la fiche

est endommagé. Retourner l'appareil à un atelier de réparation s'il ne

fonctionne pas bien, s'il est tombé ou

s'il a été endommagé, oublie à l'extérieur ou immergé.

– Ne pas tirer soulever ni traîner l'ap-

pareil par le cordon. Ne pas utiliser

le cordon comme une poignée, le

coincer dans l'embrasure d'une porte ou l'appuyer contre des arêtes vives ou des coins. Ne pas faire rouler

l'appareil sur le cordon. Garder le

cordon à l'écart des surfaces chaudes.

– Ne pas débrancher en tirant sur le

cordon. Tirer plutôt la fiche.

– Ne pas toucher la fiche ni l'appareil

lorsque vos mains sont humides.

– N'insérer aucun objet dans les

ouvertures. Ne pas utiliser l'appareil

lorsqu'une ouverture est bloquée.

S'assurer que de la poussière, de la

peluche, des cheveux ou d'autres

matières ne réduisent pas le debit

d'air.

– Maintenir les cheveux, les vête-

ments amples, les doigts et toutes

les parties du corps à l'écart des

ouvertures et des pièces mobiles.

– Mettre toutes les commandes à la

position ARRÊT avant de débrancher l'appareil.

– User de prudence lors du nettoyage

des escaliers.

– Ne pas aspirer des liquides inflam-

mables ou combustibles, comme de

l'essence, et ne pas faire functionner

dans des endroits où peuvent se

trouver de tels liquides.

– Ne brancher qu'à une prise de cou-

rant avec mise à la terre. Voir les instructions la mise à la terre.

CONSERVER CES INSTRUC-

TIONS

Français 13

Page 14

INSTRUCTIONS VISANT LA

MISE À LA TERRE

Cet appareil doit être mis à la terre. En

cas de défaillance ou de panne, la mise

à la terre fournit au courant un chemin

de moindre résistance qui réduit le risque de choc électrique. Cet appareil est

pourvu d'un cordon muni d'un conducteur de terre et d'une fiche avec broche

de terre. La fiche doit être branchée

dans une prise appropriée correctement installée et mise à la terre conformément aux règlements et

ordonnances municipaux.

Attention

Un conducteur de terre mal raccordé

peut entraîner un risque de choc électrique. Consulter un électricien ou un

technicien d'entretien qualifié si vous

n'êtes pas certain que la prise est correctement mise à la terre. Ne pas modifier la fiche fournie avec l'appareil - si

elle ne peut être insérée dans la prise,

fair installer une prise adéquate par un

électricien qualifié.

Cet appareil est destiné à un circuit de

120 V et est muni d'une fiche de mise à

la terre semblable à celle illustrée par le

croqui A. S'assurer que l'appareil est

branché à une prise de courant ayant la

même configuration que la fiche. Aucun

adaptreur nr devrait être utilisé avec cet

appareil.

NE BRANCHER QU'À UNE

PRISE DE COURANT AVEC

MISE À LA TERRE

1 Sortie avec mise à la terre

2 Boîte avec mise à la terre

3 Fiche avec mise à la terre

REGLES ET PRATIQUES DE

SECURITE DE FONCTION-

NEMENT

Responsabilité de l'opérateur

Un fonctionnement sûr est la responsabilité de l'opérateur.

L'opérateur doit être au courant du fonctionnement et des fonctions de toutes

les commandes et de tous les instruments avant d'entreprendre de faire

fonctionner l'unité.

Avant de faire fonctionner l'unité, les

opérateurs doivent avoir lu et bien connaître le manuel d'utilisation pour l'unité

particulière en fonctionnement et ils doivent également obéir aux règles et pratiques de sécurité énoncées dans les

paragraphes suivants.

Avant de faire fonctionner l'unité, l'opérateur doit bien connaître les conditions

de fonctionnement inhabituelles qui

peuvent nécessiter des précautions de

sécurité supplémentaires ou des instructions de fonctionnement spéciales.

14 Français

Page 15

Généralités

Avant de commencer à faire fonctionner

l'unité, soyez dans une position d'opération.

Ne démarrez pas ou n'opérez pas l'unité, l'une quelconque de ses fonctions ou

accessoires, depuis tout endroit autre

que la position désignée pour les opérateurs.

Avant de quitter la position de l'opérateur :

A arrêtez complètement l'unité ;

B si l'unité doit se trouver sur un plan

incliné, bloquez les roues.

Conservez une distance de sécurité depuis le bord des rampes, plate-formes

et autres surfaces de travail similaires.

N'effectuez aucun ajout ou aucune modification à l'unité.

Ne bloquez pas l'accès aux couloirs à

incendie, escaliers ou équipement de

lutte contre les incendies.

Déplacements

Donnez la priorité aux piétons et véhicules d'urgence tels que les ambulances

et les camions de pompiers.

Traversez les voies ferrées de manière

angulaire si possible. Ne vous garez

pas à moins de 1800 mm du rail le plus

proche d'une voie ferrée.

Conservez une vision claire du chemin

de déplacement et prenez garde au reste de la circulation, au personnel et aux

dégagements sûrs.

Opérez l'unité à une vitesse qui lui permettra d'être arrêtée de manière sûre

dans toutes les conditions de déplacement.

Ne vous adonnez pas aux cascades ou

à la brutalité.

Ralentissez en cas de sols mouillés et

glissants.

Avant de passer sur un bord de quai ou

sur la chaussée d'un pont, assurezvous qu'il/elle est correctement fixé(e).

Conduisez prudemment et lentement

sur le bord de quai ou la chaussée d'un

pont et ne dépassez jamais sa capacité

nominale.

Lors de la prise de virages, ralentissez

à une vitesse sûre en correspondance

avec l'environnement de fonctionnement. Prenez les virages en douceur.

Entretien de l'unité par l'opéra-

teur

Si l'unité s'avère nécessiter des réparations ou être dangereuse d'une manière

quelconque ou contribue à une condition dangereuse, le problème doit être

rapporté immédiatement au supérieur

désigné de l'utilisateur et l'unité ne doit

pas être opérée jusqu'à ce qu'elle ait été

remise en une condition de fonctionnement sûre.

Si l'unité devient dangereuse d'une manière quelconque au cours du fonctionnement, le problème doit être rapporté

immédiatement au supérieur désigné

de l'utilisateur et l'unité ne doit pas être

opérée jusqu'à ce qu'elle ait été remise

en une condition de fonctionnement sûre.

N'effectuez pas de réparations ou de réglages à moins d'y être autorisé spécifiquement.

PRATIQUES D'ENTRETIEN

ET DE RECONSTRUCTION

Le fonctionnement de l'unité peut être

dangereux si l'entretien est négligé ou si

des réparations, reconstructions ou réglages ne sont pas effectués conformément aux critères de conception du

constructeur. Par conséquent, des installations d'entretien (sur site ou au de-

Français 15

Page 16

hors), du personnel qualifié et des

procédures détaillées doivent être fournis.

L'entretien et l'inspection de l'unité doivent être réalisés conformément aux

pratiques suivantes :

A un système d'entretien, de lubrifica-

tion et d'inspection planifié doit être

suivi ; consultez les recommandations du constructeur.

B seul du personnel qualifié et autorisé

doit être autorisé à effectuer l'entretien, réparer, régler et inspecter l'unité et ce conformément aux

spécifications du constructeur.

Evitez les risques d'incendie et disposez d'un équipement de protection contre les incendies dans la zone de travail.

N'utilisez pas de récipients ouverts d'essence ou de fluides de nettoyage inflammables pour le nettoyage des

pièces.

NORME DE SECURITE IN-

CENDIE

Toute unité ne se trouvant pas dans une

condition de fonctionnement sûre doit

être mise hors service.

Les réparations doivent être effectuées

dans les emplacements de Classe I,

Classe II et Classe III.

Prévention incendie : L'unité doit être

conservée dans une condition propre et

raisonnablement exempte de peluche,

d'huile en excès et de graisse. Des

agents non combustibles sont préférés

pour le nettoyage de l'unité. Les liquides

inflammables [ceux possédant des

points d'inflammation à ou supérieurs à

100°F (37,8°C)] ne sont pas permis.

Les précautions concernant la toxicité,

la ventilation et les risques d'incendie

doivent être appropriées à l'agent ou au

solvant utilisé.

Visibilité de la plaque signalétique : Les

désignations du type d'unité telles qu'illustrées sur la plaque signalétique et les

marqueurs de type ne doivent pas être

recouverts par de la peinture de sorte

que les informations concernant leur

identification sont obscurcies.

Lisez attentivement ce

mode d’emploi avant la première utilisation de l’appareil et respectez les conseils y figu rant. Conservez ce

mode d’emploi pour une utilisation ultérieure ou un éventuel repreneur de votre matériel.

Table des matières

Consignes de sécurité 16

Fonction 17

Utilisation conforme 17

Protection de l’environnement 18

Eléments de commande 18

Première mise en service 18

Fonctionnement 18

Entretien et maintenance 20

Pannes 21

Caractéristiques techniques 23

Garantie 25

Pièces de rechange 23

Consignes de sécurité

Lire la présente notice d'instructions

ainsi que la brochure ci-jointe Consignes de sécurité pour les nettoyeurs à

brosses n° 5.956-251 avant d'utiliser

l'appareil et respecter les instructions.

16 Français

Page 17

Symboles

Les symboles suivants sont utilisés

dans ces instructions de service :

Danger

Signalise un danger imminent. Un non

respect de cette consigne peut conduire

à la mort ou entraîner de graves blessures.

몇 Avertissement

Signalise une situation éventuellement

dangereuse. Un non respect de cette consigne peut entraîner de légères blessures

ou encore des dégâts matériels.

Remarque

Donne des conseils pour l'utilisation et

d'importantes informations relatives au

produit.

Fonction

L’appareil est mis en oeuvre pour nettoyer des sols plans par voie humide.

Une largeur de travail de 12 in (300 mm)

et une capacité respective de 1 gal (4 l)

pour le réservoir d'eau propre et le réservoir d'eau sale sont les garants pour

un nettoyage efficace de petites bouteilles

Un fonctionnement par courant permet

d'obtenir une capacité élevée sans limitation de la durée de travail.

Remarque

L'appareil peut être équipé de différents

accessoires en fonction de l'application

respective. De plus amples détails figurent dans notre catalogue ou sur notre

site Internet .

– L'appareil doit uniquement être utili-

sé pour nettoyer des surfaces dures

non sensibles à l'humidité ni au polissage.

La plage de température pour l'utilisation est de 41°F1 a 104°F (+5°C à

+40°C).

– L'appareil n'est pas approprié pour

nettoyer des sols gelés (par exemple

dans des entrepôts frigorifiques)

– L'appareil doit uniquement être équi-

pé d'accessoires et de pièces de rechange d'origine.

– L'appareil a été conçu pour le net-

toyage de sols dans le domaine intérieur ou bien de surfaces couvertes

d'un toit.

– L'appareil n'est pas destiné au net-

toyage de voies publiques.

– L'appareil n'est pas approprié pour

l'application dans des environnements à risque d'explosion.

Utilisation conforme

L'utilisation de l'appareil doit être faite

en conformité avec les consignes figurant dans les instructions de service.

Français 17

Page 18

Protection de l’environne-

ment

Les matériaux constitutifs

de l'emballage sont recyclables. Ne pas jeter les emballages dans les ordures

ménagères, mais les rendre

à un système de recyclage.

Les appareils usés contiennent des matériaux précieux recyclables lesquels

doivent être rendus à un

système de recyclage. Des

batteries, de l’huile et

d'autres substances semblables ne doivent pas être

tout simplement jetées.

Pour cette raison, utiliser

des systèmes adéquats de

collecte pour éliminer les

appareils usés.

Eléments de commande

Figure 1, cf. page de couverture

1 Poignée

2 Commutateur pompe à eau

3 Interru pteur pr incipa l mode br osse /

aspiration

4 Poignée de transport

5 Etrier support réservoir d'eau sale

6 Réservoir d ' eau sale

7 Réservoir d ' eau propre

8 Tête de nettoyage

9 Pédale levage barre d'aspiration

10 Déverrouillage position de stationne-

ment

11 Tuyau d'aspiration

12 Connexion flexible d'aspiration

13 Rouleau de brosse

14 Barre d'aspiration

15 Bouton de déverrouillage, brosse

d'échange

16 Couvercle du réservoir d'eau sale

17 Fermeture

18 Crochet de câble, rotatif

19 Câble secteur avec fiche secteur

Première mise en service

Figure 2, cf. page de couverture

Î Insérer le tube à l'extrémité de la poi-

gnée dans l'ouverture sur l'appareil.

Î Appuyer sur le cran et enfoncer la

poignée jusqu'à ce qu'elle s'enclen-

che dans l'appareil.

Fonctionnement

Remplir le réservoir d'eau fraî-

che

몇 Avertissement

Risque d'endommagement. Utiliser uniquement les détergents recommandés. Pour

tout autre détergent, l'exploitant prend des

risques plus élevés quant à la sécurité du

travail, au risque d'accident et à la durée de

vie de l'appareil. Utiliser uniquement des

détergents exempts de solvants, d'acide

chlorhydrique et fluorhydrique.

Remarque

Ne jamais utiliser de détergents extrêmement moussants. Tenir compte des

consignes de dosage.

Détergents recommandés :

Application Produit

détergent

Nettoyant d'entretien alcalin

Détergent ménager acide, pour zones sanitaires, piscines, etc.

Enlève les dépôts de

calcaire.

RM 743

RM 738

18 Français

Page 19

Î Retirer le réservoir d'eau fraîche de

l'appareil.

Î Ouvrir le couvercle du réservoir

d'eau propre.

Î Remplir de mélange détergent-eau.

Température maximale du liquide,

50 °C.

Î Fermer le couvercle du réservoir

d'eau propre.

Î Mettre le réservoir d'eau fraîche en

place dans l'appareil.

Établir le raccordement de ré-

seau

Î Basculer le crochet de câble infé-

rieur vers le haut et enlever le câble.

Î Contrôler le cable d'alimentation et

la fiche de secteur s'ils sont endommagés ou cassés. L'échanger doit

être effectuée que par le service

après-vente ou par une eléctricien.

Î Brancher la fiche secteur dans une

prise de courant.

Nettoyage

몇 Avertissement !

Risque d'endommagement pour le revêtement de sol. Ne pas exploiter l'appareil sur place.

Salissures normales

Î Amener la pédale levage de barre

d'aspiration dans la position "Aspirer" (illustration 3 - Pos. "1/ON", cf.

page de garde).

Î Appuyer sur le déverrouillage de la

position de stationnement et basculer la poignée vers l'arrière.

Î Tourner l'interrupteur principal mode

brosse / aspiration sur la position '1'.

Î Activer l'interrupteur pompe à eau.

Î Déplacer l'appareil par-dessus la

surface qui doit être nettoyée.

Fort encrassement

몇 Avertissement

Risque d'endommagement pour le revêtement de sol. La méthode de nettoyage pour le fort encrassement doit

uniquement être utilisé pour des sols

qui sont appropriés à cet effet.

Î Mettre la pédale de levage de barre

d'aspiration en position "ne pas aspirer" (illustration 3 - Pos. "0/OFF", cf.

page de garde) et procéder au nettoyage comme pour l'encrassement

normal. Le fluide de nettoyage reste

sur la surface à nettoyer et a le

temps d'agir.

Î Mettre la pédale levage de barre

d'aspiration dans la position "Aspirer" et parcourir une nouvelle fois la

surface à nettoyer.

Français 19

Page 20

Terminer le nettoyage

Désactiver l'interrupteur pompe à

Î

eau.

Î Pousser l'appareil encore sur une

courte distance pour aspirer l'eau résiduelle.

Î Tourner l'interrupteur principal mode

brosse / aspiration sur la position '0'.

Î Pivoter la poignée vers l'avant et

l'enclencher en position de stationnement.

Î Débrancher la fiche secteur.

Vidange du réservoir d'eau sale

Remarque

Si le réservoir d'eau sale est plein, le

flotteur ferme le canal d'aspiration. L'aspiration est alors interrompue. Vider le

réservoir d'eau sale.

몇 Avertissement

Tenir compte des prescriptions locales

pour le traitement des eaux usées.

Î Mettre l’appareil hors tension.

Î Dresser l'appareil et l'enclencher en

position de stationnement.

Î Retirer le réservoir d'eau fraîche de

l'appareil.

Î Pivoter l'étrier support du réservoir

d'eau sale vers le bas et retirer le réservoir d'eau sale.

Î Soulever le verrou et retirer le cou-

vercle du réservoir d'eau sale.

Î Faire couler l'eau sale.

Î Puis rincer le réservoir d'eau sale à

l'eau propre.

Î Poser le couvercle sur le réservoir

d'eau sale et l'enclencher.

Î Mettre le réservoir d'eau fraîche en

place dans l'appareil.

Vidange du réservoir d'eau pro-

pre

Î Retirer le réservoir d'eau fraîche de

l'appareil.

Î Ouvrir le couvercle du réservoir

d'eau propre.

Î Vider le liquide de nettoyage.

Î Fermer le couvercle du réservoir

d'eau propre.

Î Mettre le réservoir d'eau fraîche en

place dans l'appareil.

Transport

Î Pivoter la poignée vers l'avant et

l'enclencher en position de station-

nement.

Î Pivoter la poignée vers l'arrière et

pousser l'appareil

ou

Î Soulever l'appareil avec la poignée

et le porter.

Entretien et maintenance

Danger

Avant d'effectuer tout type de travaux

sur l'appareil, le mettre hors service et

débrancher la fiche électrique.

몇 Avertissement

Risque de dommage pour l'appareil par

eau que fuit. Vider le réservoir d'eau

sale et le réservoir d'eau propre avant

les travaux d'entretien sur l'appareil.

Plan de maintenance

Après le travail

몇 Avertissement

Risque d'endommagement. Ne pas laver l'appareil au jet d'eau et ne jamais

utiliser de détergents agressifs.

Î Vider le réservoir d'eau sale.

Î Nettoyer les joints entre le réservoir

d'eau sale et l'appareil.

20 Français

Page 21

Î Vider le réservoir d'eau propre.

Î Rincer l'appareil : Remplir le réser-

voir d'eau propre d'eau claire (sans

détergent) et utiliser l'appareil pendant une minute avec l'irrigation de

brosse en service.

Î Vider le réservoir d'eau propre.

Î Nettoyer l'extérieur de l'appareil

avec un chiffon humide et imbibé de

détergent doux.

Î Nettoyer la barre d'aspiration, en

contrôler l'usure et la remplacer si

nécessaire (cf. "travaux d'entretien").

Î Contrôler l'usure de la brosse et la

remplacer si nécessaire (cf. "travaux

d'entretien").

Tous les ans

Î L'inspection de sécurité prescrite

doit être effectuée par un électricien.

Travaux de maintenance

Remplacement du rouleau de brosse

Î Retirer le réservoir d'eau propre.

Î Retirer le réservoir d'eau sale.

Î Disposer l'appareil sur le côté arriè-

re.

Î Appuyer sur la tête de déverrouillage

du rouleau de brosse et pivoter ce

dernier vers le bas et le retirer de

l'entraîneur.

Î Enficher le nouveau rouleau de

brosse sur l'entraîneur et l'enclencher du côté opposé.

Protection antigel

En cas de risque de gel :

Î Vider le réservoir d'eau propre et le

réservoir d'eau sale.

Î Déposer l'appareil dans une pièce à

l'abri du gel.

Pannes

Remplacer la barre d'aspiration

Remarque

Les barres d'aspiration sont fixées à

l'appareil avec une connexion encliquetable et peuvent être simplement retirées.

Î Amener la pédale levage de barre

d'aspiration dans la position "Aspirer" (illustration 3 - Pos. "1/ON", cf.

page de garde).

Î Retirer le réservoir d'eau propre.

Î Retirer le réservoir d'eau sale.

Î Disposer l'appareil sur le côté arriè-

re.

Î Tirer la barre d'aspiration vers le

bas.

Î Mettre une nouvelle barre d'aspira-

tion en place et l'enclencher.

Danger

Avant d'effectuer tout type de travaux

sur l'appareil, le mettre hors service et

débrancher la fiche électrique.

몇 Avertissement

Risque de dommage pour l'appareil par

eau que fuit. Vider le réservoir d'eau

sale et le réservoir d'eau propre avant

les travaux d'entretien sur l'appareil.

En cas de pannes ne pouvant pas être

résolues grâce aux instructions de ce

tableau, appeler le service après-vente.

Français 21

Page 22

Panne Remède

Il est impossible de

Vérifier si la fiche secteur est branchée.

mettre l'appareil en

marche

Quantité d'eau insuffisante

Contrôler le niveau d'eau propre et en cas de besoin, rem-

plir le réservoir

Nettoyer le distributeur d'eau (cf. "nettoyer le distributeur

d'eau").

Retirer la soupape sur le réservoir d'eau propre (illustration

4, cf. page de garde) et rincer dans de l'eau tiède.

Le réservoir d'eau

propre goutte lors

Retirer la soupape sur le réservoir d'eau propre (illustration

4, cf. page de garde) et rincer dans de l'eau tiède.

de la remise à niveau

Puissance d'aspiration insuffisante

Vider le réservoir d'eau sale.

Enclencher le réservoir d'eau sale dans l'appareil.

Nettoyer les joints entre le réservoir d'eau sale et le couver-

cle et vérifier s'ils sont étanches, en cas de besoin rempla-

cer.

Contrôler sur la poutre d'aspiration est enclenchée d ans la

tête de nettoyage.

Barre d'aspiration usée, en cas de besoin la remplacer.

Contrôler si les deux parties du tube d'aspiration sont cor-

rectement connectées avec la connex ion de tu be d'as pir a-

tion.

Contrôler si le tube d'aspiration et le canal d'aspiration dans

la tête de nettoyage sont bouchés, si nécessaire éliminer le

bouchon (cf. "nettoyer le tube d'aspiration").

Résultat de net-

toyage insuffisant

La brosse ne tour-

ne pas

Contrôler le degré d'usure du rouleau de brosse et le cas

échéant, le remplacer.

Vérifier si des corps étrangers bloquent le rouleau de bros-

se et le cas échéant, éliminer les corps étrangers.

Nettoyer le distributeur d'eau

Î

Sortir le rouleau de brosse.

Î Retirer la barre de distributeur d'eau

dans le tunnel de brosse (illustration

5, cf. page de garde).

Î Nettoyer le canal d'irrigation et les

ouvertures dans la barre de distribution d'eau à l'eau courante.

22 Français

Page 23

Nettoyer le tube d'aspiration

Î Retirer le réservoir d'eau fraîche de

l'appareil.

Î Pivoter l'étrier support du réservoir

d'eau sale vers le bas et retirer le réservoir d'eau sale.

Î Retirer vers l'arrière la connexion du

tube d'aspiration vers l'arrière et faire basculer les deux extrémités du

tube d'aspiration vers l'extérieur (illustration 6, cf. page de garde).

Le tube d'aspiration est interrompu

et les deux extrémités sont accessibles pour le nettoyage.

Î Retirer la barre d'aspiration vers le

bas, le canal d'aspiration est accessible dans la tête de nettoyage pour

le nettoyage (illustration 7, cf. page

de garde).

Î Rincer le flexible d'aspiration et le

canal d'aspiration avec de l'eau ou

enlever ou pousser le bouchon avec

un objet émoussé.

Caractéristiques techniques

Performances

Tension nominale V/Hz 120 /

1~60

Puissance absorbée

moyenne

Aspiration

Puissance d'aspiration, débit d'air

Puissance d'aspiration, dépression

Brosse de nettoyage

Largeur de travail in

Diamètre des brosses

Vitesse des brosses 1/min 1550

W600

gpm

(l/s)

psi

(kPa)

380

(24)

2.0

(14)

(mm)12(300)

in

(mm)

2.4

(60)

Dimensions et poids

Surface théoriquement nettoyable

Volume du réservoir

ft²/h

(m²/h)

2152

(200)

gal (l) 1 (4)

d'eau propre/réservoir d'eau sale

Longueur in

(mm)

Largeur in

(mm)

Hauteur in

(mm)

Poids (sans contenu

du réservoir)

lb

(kg)

15.4

(390)

13.2

(335)

46.5

(1180)

24.3

(11)

Emissions sonores

Niveau de pression

acoustique (EN

dB(A

)

71

60704-1)

Vibrations de l'appareil

Valeur globale de vi-

m/s² 0,5

brations (ISO 5349)

Pièces de rechange

– Utiliser uniquement des accessoires

et des pièces de rechange autorisés

par le fabricant. Des accessoires et

des pièces de rechange d’origine

garantissent un fonctionnement sûr

et parfait de l’appareil.

– Une sélection des pièces de rechan-

ge utilisées le plus se trouve à la fin

du mode d'emploi.

– Plus information sur les pièces de

rechange vous les trouverez sous le

menu Service.

Français 23

Page 24

INSTRUCCIONES IMPOR-

TANTES DE SEGURIDAD

LEA TODAS LAS INSTRUC-

CIONES ANTES DE USAR LA

MÁQUINA

ADVERTENCIA

Para evitar el peligro de incendio, descarga eléctrica o heridas:

– No se aleje de la máquina mientras

esté enchufada. Saque el enchufe

de la base cuando no la esté usando, y antes del mantenimiento.

ADVERTENCIA

– PARA EVITAR PELIGRO DE DES-

CARGAS ELÈCTRICAS, LA MÀQUINA SÒLO DEBE EMPLEARSE

EN INTERIORES

– La máquina no es un juguete. Llevar

mucho cuidado si va a utilizarse

donde hay niños.

– La máquina sólo debe emplearse tal

como se describe en este manual.

Sólo deben usarse los accesorios

recomendados por el fabricante.

– No emplearla si el cable o el enchufe

están dañados. Si la máquina no

funciona correctamente, si se ha

caído, si está averiada, si ha permanecido al exterior o si ha caído al

agua, devolverla al servicio posventa.

– No tirar de la máquina ni alzarla con

el cable, no emplear el cable como

manija, no aprisionarlo con una

puerta ni pasarlo sobre esquinas o

bordes agudos. No pasar la máquina sobre el cable. Mantener el cable

alejado de fuentes de calor.

– Al desenchufar, no tirar del cable.

Para desenchufar, tomar el enchufe

y no el cable.

– No tocar el enchufe ni la máquina

con las manos mojadas.

– No colocar objetos en las aberturas.

No usar la máquina con las aberturas obstruidas; éstas deben estar libres de polvo, pelusa, pelos y

cualquier otro objeto que pueda impedir el paso de aire.

– Mantener el cabello, la ropa, los de-

dos y todas las partes del cuerpo

alejadas de las aberturas y las piezas móviles.

– Apagar la máquina antes de desen-

chufarla.

– Llevar mucho cuidado al trabajar en

escaleras.

– No emplearla para recoger líquidos

inflamables o combustibles, p.ej. gasolina, ni en zonas donde pueda haber dichos líquidos.

– Es imprescindible que la toma eléc-

trica esté debidamente puesta a tierra. Véanse las Instrucciones de

Puesta a Tierra.

GUARDE ESTAS INSTRUC-

CIONES

INSTRUCCIONES DE PUES-

TA A TIERRA

La máquina debe ser puesta a tierra. Si

no funciona bien, o si se estropea, la

puesta a tierra constituye una vía de

menor resistencia para la corriente

eléctrica, para disminuir el peligro de

descarga eléctrica. La máquina está

provista de cable con conductor de

puesta a tierra, y enchufe con puesta a

tierra. El enchufe debe insertarse en

una base de enchufe adecuada, debi-

24 Español

Page 25

damente instalada y puesta a tierra,

conforme a la legislación y las normas

válidas en el lugar de utilización.

ADVERTENCIA

Si el conductor de puesta a tierra de la

máquina está mal conectado, puede

haber peligro de descarga eléctrica.

Consulte a un electricista experto o a un

técnico de mantenimiento, si Ud. no

sabe con certeza si la base de enchufe

está correctamente puesta a tierra. No

cambie el enchufe suministrado con la

máquina - no encajará en la base de e nchufe; acuda a un electricista experto.

La máquina está diseñada para emplearla en un circuito de

120 voltios; tiene un enchufe de puesta

a tierra cuyo aspecto es como se ilustra

en la Figura A. Cerciórese de conectar

la máquina a una base de enchufe de la

misma configuración que el conector.

Con esta máquina no deben emplearse

adaptadores.

CONECTAR SÓLO A UNA

BASE DE ENCHUFE CO-

RRECTAMENTE PUESTA A

TIERRA

NORMAS Y PROCEDIMIEN-

TOS DE SEGURIDAD DU-

RANTE EL

FUNCIONAMIENTO

Responsabilidad del operario

El operario será responsable de garantizar un funcionamiento seguro.

El operario deberá estar familiarizado

con el manejo y las funciones de todos

los elementos de mando y todos los instrumentos antes de proceder al manejo

de la unidad.

Antes de poner en funcionamiento la unidad, los operarios deberán haber leído el

manual de instrucciones de la unidad particular de que se trate y estar familiarizados con él; además, deberán respetar las

normas y procedimientos de seguridad

que se describen a continuación.

Antes de poner en funcionamiento una

unidad cualquiera, el operario deberá conocer bien las posibles condiciones inusuales de funcionamiento que requieren

la adopción de determinadas precauciones especiales o para las que existen

unas instrucciones de manejo especiales.

Generalidades

1 Enchufe puesto a tierra

2 Caja de enchufe puesta a tierra

3 Pin puesto a tierra

Antes de poner en funcionamiento la

unidad, ésta deberá encontrarse en la

posición de servicio.

No ponga en marcha ni utilice la unidad

ni ninguna de sus funciones o sus aditamentos desde un lugar que no sea el

concebido para el operario.

Antes de abandonar la posición del

operario:

A pare la unidad por completo;

B si es necesario dejar la unidad en

una pendiente, bloquee las ruedas.

Guarde una distancia segura respecto a

los bordes de las rampas y las platafor-

Español 25

Page 26

mas, y respecto a los de otras superficies de trabajo similares.

No efectúe ampliaciones ni modificaciones en la unidad.

No bloquee el acceso a las salidas previstas en caso de incendio, las escaleras o los extintores.

Durante la circulación

Ceda el paso a los peatones y a los vehículos de emergencia, como son las

ambulancias y los camiones de bomberos.

Siempre que sea posible, cruce las vías

férreas formando un ángulo con ellas.

No estacione a menos de 6 ft (1800

mm) de distancia respecto a los raíles o

las vías férreas más cercanos.

Asegúrese de mantener una vista libre

de obstáculos del trayecto a recorrer,

respete las normas de tráfico, tenga cuidado con las personas y guarde las distancias de seguridad.

Sean cuales sean las condiciones de circulación, conduzca la unidad siempre a

una velocidad tal que le permita detenerse por completo de modo seguro.

Durante la conducción, no acceda jamás

a realizar acrobacias o competiciones.

Cuando circule por pisos húmedos o

resbaladizos, reduzca la velocidad.

Antes de circular por un muelle o por el

tablero de un puente, asegúrese de que

dichos elementos estén correctamente

sujetos. Conduzca con precaución y

despacio por el muelle y el puente, y no

sobrepase nunca la capacidad nominal

de los mismos.

Cuando tenga que efectuar giros, reduzca la velocidad hasta que sea seguro efectuarlos conforme al entorno en

que esté maniobrando. Realice los giros con suavidad.

Cuidado de la unidad por parte

del operario

Si se descubre la necesidad de reparar

la unidad o se detecta que ésta resulta

insegura de alguna manera o que contribuye a crear condiciones de inseguridad, se debe informar de inmediato a la

autoridad designada por el usuario.

Además, la unidad no deberá volver a

utilizarse hasta que se la haya devuelto

a un estado operativo seguro.

Si, durante el funcionamiento, la unidad

se vuelve insegura de alguna manera,

se debe informar de inmediato a la autoridad designada por el usuario. Además, la unidad no deberá volver a

utilizarse hasta que se la haya devuelto

a un estado operativo seguro.

No lleve a cabo reparaciones ni practique ajuste alguno a no ser que haya

sido expresamente autorizado para

ello.

TAREAS DE MANTENIMIEN-

TO Y ACONDICIONAMIENTO

Si se descuida el mantenimiento o se

practican en la unidad reparaciones, tareas de acondicionamiento o ajustes en

los que no se respeten los criterios de diseño del fabricante, su manejo puede resultar peligroso. Por ello, se debe

disponer de servicios de mantenimiento

(dentro o fuera de las instalaciones), contar con personal cualificado y establecer

unos modos de proceder detallados.

El mantenimiento y la inspección de la

unidad deberán llevarse a cabo respetando las tareas que se indican a continuación:

A se deben seguir unos esquemas de

mantenimiento, lubricación e inspección conforme a su planificación;

26 Español

Page 27

consulte las recomendaciones del

fabricante.

B

el mantenimiento, las reparaciones,

los ajustes y las inspecciones de la

unidad sólo podrán ser llevados a

cabo por personal cualificado y autorizado; además, dichas tareas se realizarán siempre de conformidad con las

especificaciones del fabricante.

Evite las posibles fuentes de peligro de

incendio y disponga siempre de extintores en la zona de trabajo. En la limpieza

de las piezas, no use recipientes de

combustible abiertos ni líquidos limpiadores inflamables.

NORMAS DE SEGURIDAD

CONTRA INCENDIOS

Cuando las condiciones operativas de

una unidad no sean seguras, ésta deberá ponerse fuera de servicio.

En los emplazamientos de la clase I, la

clase II y la clase III está prohibido efectuar reparaciones.

Prevención contra incendios: la unidad se

debe mantener limpia y debe estar razonablemente libre de pelusas, restos de

aceite y grasa. Para limpiar la unidad, se

recomienda usar preferiblemente agentes

incombustibles. No está permitido emplear líquidos inflamables [aquellos cuyo

punto de inflamación esté en 100°F

(37,8°C) o por encima]. Se deben adoptar

precauciones adecuadas al tipo de agente o disolvente empleado en lo que a la

toxicidad, la ventilación y el peligro de incendios respecta.

Visibilidad de la placa de características: las denominaciones de tipo y las

marcas de tipo de la unidad indicadas

en la placa de características no deben

cubrirse con pintura que oscurezca la

información identificativa allí contenida.

Antes de poner en marcha

por primera vez el aparato,

lea el presente manual de instrucciones

y siga las instrucciones que figuran en

el mismo. Conserve estas instrucc iones

para su uso posterior o para propietarios ulteriores.

Índice de contenidos

Indicaciones de seguridad 27

Función 28

Uso previsto 28

Protección del medio ambiente 28

Elementos de mando 29

Primera puesta en marcha 29

Funcionamiento 29

Cuidados y mantenimiento 31

Averías 32

Datos técnicos 34

Garantía 37

Piezas de repuesto 34

Indicaciones de seguridad

Antes de utilizar por primera vez el aparato, lea y tenga en cuenta el presente

manual de instrucciones y el folleto adjunto relativo a las indicaciones de seguridad para aparatos de limpieza con

cepillos y aparatos pulverizadores,

5.956-251.

Símbolos

En este manual de instrucciones se emplean los siguientes símbolos:

Peligro

Indica la existencia de un peligro inminente. El incumplimiento de la indicación puede acarrear la muerte o

lesiones de suma gravedad.

몇 Advertencia

Hace alusión a una situación potencialmente peligrosa. El incumplimiento de

Español 27

Page 28

la indicación puede provocar lesiones

leves o daños materiales .

Nota

Identifica consejos de manejo e información importante sobre el producto.

Función

El aparato sirve para efectuar la limpieza en húmedo de pisos llanos.

Una anchura de trabajo de 300 mm y

unos depósitos de agua limpia y de

agua sucia con una capacidad de 4 l

respectivamente permiten llevar a cabo

una limpieza efectiva de pequeñas superficies.

El funcionamiento vía red eléctrica permite obtener una elevada capacidad de

rendimiento sin limitar de modo alguno

el trabajo.

Nota

En función de la tarea de limpieza de

que se desee realizar, es posible dotar

al aparato de distintos accesorios. Solicite nuestro catálogo.

Uso previsto

Utilice el aparato únicamente de conformidad con las indicaciones del presente

manual de instrucciones.

– El aparato ha sido concebido exclu-

sivamente para la limpieza de superficies duras resistentes a la

humedad y al pulido.

El margen de temperaturas de servicio está comprendido entre los

41°F1 to 104°F (+5°C y los +40°C).

– El aparato no es apto para la limpie-

za de pisos congelados (p. ej., en almacenes frigoríficos).

– Sólo está permitido dotar al aparato

de accesorios y piezas de repuesto

originales.

– El aparato ha sido concebido para la

limpieza de pisos en interiores o superficies techadas.

– El presente aparato no es apto para

la limpieza de las vías públicas de

tránsito.

– El aparato no es apto para el uso en

entornos con peligro de explosión.

Protección del medio ambien-

te

Los materiales de embalaje

son reciclables. Por favor,

no tire el embalaje al cubo

de basura; llévelo a un lugar

de reciclaje.

Los aparatos viejos contienen materiales valiosos reciclables que debieran

aprovecharse. Evite el contacto de baterías, aceites y

materias semejantes con el

medioambiente. Deshágase

de los aparatos viejos recurriendo a sistemas de recogida apropiados.

28 Español

Page 29

Elementos de mando

Figura 1, véase contraportada

1asidero

2 Interruptor de la bomba de agua

3 Interruptor principal modo de barri-

do/aspiración

4 Asa de transporte

5 Asa del depósito de agua sucia

6 depósito de agua sucia

7 Depósito de agua limpia

8 Cabezal limpiador

9 Pedal par a subir la barra de aspira-

ción

10 Desbloqueo posición de estaciona-

miento

11 Tubo de aspiración

12 Conexión tubo de aspiración

13 cepillo rotativo

14 barra de aspiración

15 Botón de desbloqueo, cepillo cam-

biable

16 Tapa del depósito de agua sucia

17 Cierre

18 Gancho de cable, giratorio

19 Cable de alimentación con enchufe

de clavija de red

Primera puesta en marcha

Figura 2, véase contraportada

Î Insertar el tubo al final del asa en el

orificio del aparato.

Î

Presionar las muescas e introducir el

asa hasta que encaje en el aparato.

Funcionamiento

Rellenar el depósito de agua lim-

pia

몇 Advertencia

Peligro de daños. Utilice únicamente el

detergente recomendado. En caso de

usar otros detergentes, el propietariousuario asume unos mayores riesgos

en lo que a la seguridad durante el funcionamiento, al peligro de sufrir accidentes y la reducción de la vida útil del

aparato se refiere. Utilice únicamente

detergentes que no contengan disolventes, ácidos clorhídricos ni ácidos hidrofluóricos.

Nota

No utilice detergentes altamente espumosos. Respete las indicaciones de dosificación.

Detergente recomendado:

Empleo Detergen-

te

Detegente de mantenimiento alcalino

Detergente de mantenimiento ácido, para

áreas sanitarias, piscinas, etc. Elimina los depósitos de cal.

Î Extraer el depósito de agua fresca

del aparato.

Î Abra la tapa del depósito de agua

limpia.

Î Añadir mezcla de agua y detergente.

Temperatura máxima del líquid o 50

°C.

Î Cierre la tapa del depósito de agua

limpia.

Î Colocar el depósito de agua limpia

en el aparato.

RM 743

RM 738

Español 29

Page 30

Establecimiento de la conexión

a red

Î

Desplace el gancho de cable inferior

hacia arriba y extraiga el cable.

Î Comprobar si el cable de alimenta-

ción y la clavija están dañados o rotos. Sólo los puede cambiar el

servicio técnico o un electricista.

Î Enchufar la clavija de red a una toma

de corriente.

Limpieza

몇 Advertencia

Peligro de daños para el revestimiento del

suelo. No utilice el aparato en esa zona.

Suciedad normal

Î Ponga el pedal para subir la barra de

aspiración en posición „aspiración“

(Figura 3 - Posición „1/ON“, véase la

contraportada).

Î Pulsar desbloqueo posición de esta-

cionamiento e inclinar hacia atrás el

asa.

Î Coloque el interruptor principal

modo de barrido/aspiración en la posición "1".

Î Encender el interruptor de la bomba

de agua.

Î Mover el aparato sobre la superficie

a limpiar.

Mucha suciedad

몇 Advertencia

Peligro de daños para el revestimiento

del suelo. El método de limpieza para

mucha suciedad solo debe utilizarse en

suelos apropiados para el mismo.

Î Ponga el pedal para subir la barra de

aspiración en posición „no aspirar“

(Figura 3 - Posición „0/OFF“, véase

la contraportada) y efectuar limpieza

como para suciedad normal. El detergente líquido se mantiene en la

superficie a limpiar y tiene tiempo

para actuar.

Î Ponga el pedal para subir la barra de

aspiración en posición „aspiración“ y

recorra otra vez la superficie a limpiar.

Finalizar la limpieza

Î Desconectar el interruptor de la

bomba de agua.

Î Desplazar todavía un poco el apara-

to para aspirar el agua restante.

Î Coloque el interruptor principal

modo de barrido/aspiración en la posición "0".

Î A continuación girar hacia delante y

enclavar en posición de estacionamiento.

Î Saque el enchufe de la toma de co-

rriente.

Vaciado del depósito de agua

sucia

Nota

Cuando el depósito de agua sucia está

lleno, el flotador cierra el canal de admisión. La aspiración se interrumpe. Vaciar el depósito de agua sucia.

몇 Advertencia

Respetar la normativa local vigente en

materia de tratamiento de aguas residuales.

Î Desconexión del aparato

Î Colocar el aparato y enclavar en po-

sición de estacionamiento.

Î Extraer el depósito de agua fresca

del aparato.

Î Girar el asa del depósito de agua su-

cia hacia abajo y retirar el depósito

de agua sucia.

Î Levantar el cierre y extraer la tapa

del depósito de agua sucia.

Î Verter el agua sucia.

30 Español

Page 31

Î A continuación, aclare el depósito de

agua sucia con agua limpia.

Î Colocar la tapa sobre el depósito de

agua sucia y enclavar.

Î Insertar el depósito de agua limpia

en el aparato.

Vaciado del depósito de agua

limpia

Î Extraer el depósito de agua fresca

del aparato.

Î Abra la tapa del depósito de agua

limpia.

Î Verter el detergente líquido.

Î Cierre la tapa del depósito de agua

limpia.

Î Colocar el depósito de agua limpia

en el aparato.

Transporte

Î A continuación girar hacia delante y

enclavar en posición de estaciona-

miento.

Î Inclinar hacia atrás el asa y empujar

el aparato

o

Î Levante el aparato por el asa y de

sopórtelo.

Cuidados y mantenimiento

Peligro

Antes de efectuar cualquier trabajo en

el aparato, hay que desconectarlo de la

red eléctrica.

몇 Advertencia

Si se sale agua se puede dañar el aparato. Vaciar el depósito de agua sucia y

el depósito de agua limpia antes de realizar tareas de mantenimiento en el aparato.

Plan de mantenimiento

Después del trabajo

몇 Advertencia

Peligro de daños. No salpique al aparato con agua ni utilice detergentes agresivos.

Î Vacíe el depósito de agua sucia.

Î Limpiar juntas entre el depósito de

agua sucia y el aparato.

Î Vaciar el depósito de agua limpia.

Î Enjuagar el aparato: Llenar el depó-

sito de agua limpia con agua limpia

(sin detergente) y hacer funcionar un

minuto el aparato con la irrigación de

cepillos conectada.

Î Vaciar el depósito de agua limpia.

Î Limpie el aparato por fuera con un

trapo húmedo ligeramente empapado en una solución jabonosa suave.

Î Limpie las barras de aspiración;

compruebe si presentan desgaste y,

en caso necesario, cambiar (ver

"Trabajos de mantenimiento").

Î Compruebe si los cepillos presentan

desgaste y, en caso necesario, cámbielos (véase "Trabajos de mantenimiento").

Anualmente

Î Encargue a un electricista la revisión

de seguridad obligatoria.

Trabajos de mantenimiento

Cambiar la barra de aspiración

Nota

Las barras de aspiración están fijadas

con una conexión de enganche al aparato y pueden retirarse fácilmente.

Î Ponga el pedal para subir la barra de

aspiración en posición „aspiración“

(Figura 3 - Posición „1/ON“, véase la

contraportada).

Español 31

Page 32

Î

Extraer el depósito de agua limpia.

Î Extraer el depósito de agua sucia.

Î Colocar el aparato sobre la parte tra-

sera.

Î Sacar la barra de aspiración empu-

jándola hacia abajo.

Î Coloque las barras de aspiración

nuevas y encájelas.

Cambio del cepillo rotativo

Î Extraer el depósito de agua limpia.

Î Extraer el depósito de agua sucia.

Î Colocar el aparato sobre la parte tra-

sera.

Î Presionar el botón de desbloqueo

del cepillo rotativo y girar cepillo rotativo hacia abajo y extraer del

arrastrador.

Î Insertar los nuevos cepillos rotativos

en el arrastrador y encajarlos en el

lado contrario.

Protección antiheladas

En caso de peligro de heladas:

Î Vacíe el depósito de agua limpia y el

depósito de agua sucia.

Î Guarde el aparato en un lugar prote-

gido de las heladas.

Averías

Peligro

Antes de efectuar cualquier trabajo en

el aparato, hay que desconectarlo de la

red eléctrica.

몇 Advertencia

Si se sale agua se puede dañar el aparato. Vaciar el depósito de agua sucia y

el depósito de agua limpia antes de realizar tareas de mantenimiento en el aparato.

Cuando las averías no se puedan solucionar con ayuda de la tabla que aparece a continuación, acuda al servicio

técnico.

32 Español

Page 33

Avería Modo de subsanarla

No se puede poner

en marcha el aparato

Caudal de agua insuficiente

El depósito de

agua limpia gotea

al rellenarlo

Potencia de aspiración insuficiente

Compruebe si está enchufada la clavija de red

Compruebe el nivel de agua limpia y, de ser necesario, llene el depósito.

Limpiar distribuidor de agua (véase "Limpiar distr ibuidor de

agua").

Retirar válvula de depósito de agua limpia (Figura 4, ver

contraportada) y enjuagar en agua templada.

Retirar válvula de depósito de agua limpia (Figura 4, ver

contraportada) y enjuagar en agua templada.

Vacíe el depósito de agua sucia.

Encajar el depósito de agua sucia en el aparato.

Limpie las juntas situadas entre el depósito de agua sucia

y la tapa; compruebe su estanqueidad y, en caso necesario, cámbielas

Comprobar si las barras de aspiración están encajadas en

los cabezales limpiadores.

Barras de aspiración desgastadas, cámbielas si es necesario.

Resultados de limpieza insuficientes

Los cepillos no giran

Comprobar si las dos partes del tubo de aspiración están

correctamente conectadas con la conexió n de l tub o de aspiración.

Compruebe si el tubo de aspiración y el canal de aspira ción

del cabezal limpiador están obstruidos y, de ser necesario,

desatásquelos (ver "limpiar tubo de aspiración")

Compruebe si los cepillos rotativos presentan desgaste y,

en caso necesario, cámbielos.

Compruebe si hay cuerpos extraños bloqueando los cepillos rotativos y, de ser así, elimínelos.

Español 33

Page 34

Limpiar el distribuidor de agua

Extraer los cepillos rotativos.

Î

Î Sacar las tiras de distribución de

agua del canal de los cepillos (Figura 5, véase contraportada).

Î Limpiar canal de irrigación y orificios

en las tiras del distribuidor de agua

con agua corriente.

Limpiar tubo de aspiración

Î Extraer el depósito de agua fresca

del aparato.

Î Girar el asa del depósito de agua su-

cia hacia abajo y retirar el depósito

de agua sucia.

Î Sacar del aparato la conexión del

tubo de aspiración empujando hacia

atrás y extraer, girando, ambos extremos del tubo de aspiración (Figura 6, ver contraportada).

El tubo de aspiración queda interrumpido y ambos extremos son accesibles para poder limpiarlos.

Î Retirar hacia abajo la barra de aspi-

ración, el canal de aspiración del cabezal limpiador queda accesible

para la limpiezas (Figura 7, ver contraportada).

Î Enjuagar con agua la manguera de

aspiración y el canal de aspiración o

sacar la causa de la obstrucción estirando o empujando con un objeto

obtuso.

Datos técnicos

Potencia

Tensión nominal V/Hz 120 /

1~60

Consumo medio de

potencia

Aspirar

Potencia de aspiración, caudal de aire

Potencia de aspiración, depresión

Cepillo de limpieza

W600

gpm

(l/s)

psi

(kPa)

380

(24)

2.0

(14)

Anchura de trabajo in

(mm)

Diámetro cepillos in

(mm)

Nº de rotaciones de

1/min 1550

11,8

(300)

2.4

(60)

los cepillos

Medidas y pesos

Potencia teórica por

metro cuadrado

Volumen de los depó-

ft²/h

(m²/h)

2152

(200)

gal (l) 1 (4)

sitos de agua limpia y

agua sucia

Longitud in

(mm)

Anchura in

(mm)

Altura in

(mm)

Peso (con el depósito

vacío)

lb

(kg)

15.4

(390)

13.2

(335)

46.5

(1180)

24.3

(11)

Emisión sonora

Nivel de presión acús-

dB(A)

71

tica (EN 60704-1)

Vibraciones del

aparato

Valor total de la vibra-

m/s² 0,5

ción (ISO 5349)

Piezas de repuesto

– Sólo deben emplearse accesorios y

piezas de repuesto originales o autorizados por el fabricante. Los accesorios y piezas de repuesto

originales garantizan el funcionamiento seguro y sin averías del aparato.

– Podrá encontrar una selección de

las piezas de repuesto usadas con

más frecuencia al final de las instrucciones de uso.

– En el área de servicios de encontra-

rá más información sobre piezas de

repuesto.

34 Español

Page 35

WINDSOR INDUSTRIES

North American New Machine Warranty

Effective on all products shipped AFTER January 24, 2007

Limited Warranty

Windsor Industries, Inc. warrants new machines against defects in material and

workmanship under normal use and service to the original purchaser. Any statutory

implied warranties, including any warranty

of merchantability or fitness for a particular

purpose, are expressly limited to the duration of this written warranty. Windsor will not

be liable for any other damages, including

but not limited to indirect or special consequential damages arising out of or in connection with the furnishing, performance,

use or inability to use the machine. This remedy shall be the exclusive remedy of the