Page 1

RRB 360

English 3

Français 20

Español 38

5.962-788.0 2015942 01/08

Page 2

2

Page 3

Operator Qualifications

Only trained and authorized persons shall

be permitted to operate a powere d un i t.

Operators of powered units shall be qualified as to visual, auditory, physical, and

mental ability to operate the equipment

safely according to the following points.

Operator Training

– Personnel who have not been trained to

operate powered units may operate a

unit for the purposes of training only,

and only under the direct supervision of

the trainer. This training should be conducted in an area away from other

units, obstacles, and pedestrians.

– The operator training program should

include the user’s policies for the site

where the trainee will operate the unit,

the operating conditions for that location, and the specific unit the trainee will

operate. The training program shall be

presented to all new operators regard-

less of previous experience.

The training program shall inform the trainee that:

A The primary responsibility of the opera-

tor is to use the unit safely following the

instructions given in the training pro-

gram.

B Unsafe or improper operation of a pow-

ered unit can result in: death or serious

injury to the operator or others; damage

to the powered unit or other property.

The training program shall emphasize safe

and proper operation to avoid injury to the

operator and others and prevent property

damage, and shall cover the following areas:

A Fundamentals of the powered unit(s)

the trainee will operate, including:

(1) characteristics of the powered

unit(s), including varations between the

units in the workplace;

(2) similarities and differences from au-

tomobiles;

(3) significance of nameplate data,

warnings, and instructions affixed to the

unit;

(4) operating instructions and warnings

in the operating manual for the unit, and

instructions for inspection and mainte-

nance to be performed by the operator;

(5) type of motive power and its charac-

teristics;

(6) method of steering;

(7) braking method and characteristics;

(8) visibility, forward and reverse;

(9) stability characteristics with and

without load, with and without attach-

ments;

(10) controls-location, function, method

of operation, identification of symbols;

(11) battery charging;

(12) guards and protective devices for

the specific type of unit;

(13) other characteristics of the specific

unit;

B Operating environment and its effect on

unit operation, including:

(1) floor or ground conditions including

temporary conditions;

(2) ramps and inclines;

(3) battery charging facilities;

(4) narrow aisles, doorways, overhead

wires and piping, and other areas of limited clearance;

(5) areas where the unit may be operated near other powered units, other vehicles, or pedestrians;

(6) operation near edge of dock or edge

of improved surface;

(7) other special operating conditions

and hazards which may be encountered.

C Operation of the powered unit, includ-

ing:

(1) proper preshift inspection and approved method for removing from ser-

vice a unit which is in need repair;

(2) parking and shutdown procedures;

(3) other special operating conditions

for the specific application.

D Operating safety rules and practices,

including:

(1) provisions of the section „OPERAT-

ING SAFETY RULES AND PRACTICES“ in this document.

(2) other rules, regulations, or practices

specified by the employer at the location where the unit will be used.

E Operational training practice, including:

(1) if feasible, practice in the operation

of a powered unit shall be conducted in

an area separate from other workplace

activities and personnel:

(2) training practice shall be conducted

under the supervision of the trainer;

(3) training practice shall include the actual operation or simulated performance of all operating tasks such as

maneuvering, traveling, stopping, starting, and other activities under the conditions which will be encountered in the

use of the unit.

Testing, Retraining, and Enforce-

ment

A During training, performance and oral

and/or written tests shall be given by

the employer to measure the skill and

knowledge of the operator in meeting

the requirements of the Standard. Employers may delegate such testing to

others but shall remain responsible for

the testing. Appropriate records shall

be kept.

B Operators shall be retrained when new

equipment is introduced, existing

equipment is modified, operating conditions change, or an operator’s performance ins unstatisfactory.

C The user shall be responsible for en-

forcing the safe use of the powered unit

according to the provisons of this manual.

NOTE: Information on operator training is

available from such sources as powered

unit manufacturers, government agencies

dealing with employee safety, trade orgaizations of users of powered units, public

and private organizations, and safety consultants.

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

– Safe operation is in the responsibility of

the operator.

– The operator shall develop safe work-

ing habits and also be aware of hazardous conditions in order to protect

himself, other personnel, the unit, and

other material.

– The operator shall be familiar with the

operation and function of all controls

and instruments before undertaking to

operate the unit.

– Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular unit

being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

– Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require additional

safety precautions or special operating

instructions.

General

Before starting to operate the unit:

A be in operating position;

B place directional controls in neutral;

C turn switch to ON position.

– Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designated

operator’s position.

– Keep hands and feet inside the opera-

tor’s designated area.

Understand unit limitations and operate the

unit in a safe manner so as not to cause injury to personnel. Safeguard pedestrians at

all times.

A Do not drive a unit up to anyone stand-

ing in front of an object.

B Ensure that personnel stand clear of

rear swing area before conducting turns

and maneuvers.

C Exercise particular care at cross aisles,

doorways, and other locations where

pedestrians may step into the path of

travel of the unit.

– Do not permit passengers to ride on

powered units unless a safe place to

ride has been provided by the manufacturer.

– A powered unit is attended when the

operator is less than 25 ft (7.6 m) from

the unit, which remains in his view.

English 3

Page 4

– A powered unit is unattended when the

operator is more than 25 ft (7.6 m) from

the unit, which remains in his view, or

whenever the operator leaves the unit

and it is not in his view.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B place the directional controls in neutral;

C appl y the pa rki n g brake;

In addition, when leaving the unit unattend-

ed:

A stop the engine or turn off the controls;

B if the unit must be on an incline, block

the wheels.

– Maintain a safe distance from the edge

of ramps, platforms, and other similar

working surfaces.

– When powered units are driven on and

off highway trucks or trailers, the brakes

on the highway trucks or trailers shall

be applied and wheel chocks or other

positive mechanical means shall be

used to prevent unintentional move-

ment of highway trucks and trailers.

– When powered units are driven on and

off semitrailers that are not coupled to a

tractor, supports may be needed to pre-

vent upending or corner dipping.

– Care shall be taken not to contact over-

head installations such as lights, wiring,

pipes, sprinkler systems, etc.

– Report all accidents involving person-

nel, building structures, and equipment

to the supervisor or as directed.

– Do not add to, or modify the unit.

– Do not block access to fire aisles, stair-

ways or fire equipment.

Traveling

– Observe all traffic regulations including

authorized plant speed limits. Under

normal traffic conditions, keep to the

right. Maintain a safe distance, based

on speed of travel, from the unit ahead;

keep the unit under control all times.

– Yield the right of way to pedestrians and

emergency vehicles such as ambulanc-

es and fire trucks.

– Do not pass another unit traveling in the

same direction at intersections, blind

spots, or at other dangerous locations.

– Slow down and sound the audible warn-

ing device(s) at cross aisles and other

locations where vision is obstructed.

– Cross railroad tracks at an angle wher-

ever possible. Do not park closer than 6

ft (1800 mm) to the nearest rail of a rail-

road track.

– Keep a clear view of the path of travel

and observe for other traffic, personnel,

and safe clearances.

– Ascend or descend grades slowly, and

with caution. Avoid turning, if possible,

and use extreme caution on grades,

ramps, or inclines; normally travel

straight up and down.

– Under all travel conditions, operate the

unit at a speed that will permit it to be

brought to a stop in a safe manner.

– Make starts, stops, turns, or direction

reversals in a smooth manner so as not

shift load and/or overturn the unit.

– Do not indulge in stunt driving or horse-

play.

– Slow down for wet and slippery floors.

– Before driving over a dockboard or

bridge plate, be sure that it is properly

secured. Drive carefully and slowly

across the dockboard or bridge plate,

and never exceed its rated capacity.

– Do not drive units onto any elevator un-

less specially authorized to do so. Do

not exceed the capacity of the elevator.

Approach elevators slowly, and then

enter squarely after the elevator car is

properly leveled. Once on the elevator,

neutralize the controls, shut off power,

and set brakes. It is advisable that all

other presonnel leave the elevator be-

fore the unit is allowed to enter or leave.

– When negotiating turns, reduce speed

to a safe level consistent with the oper-

ating environment. Make the turns

smoothly.

The operation of a counterbalanced, center

control, high lift unit with a sit-down, nonel-

evating operator requires special safety

considerations, as follows:

A An unit may tip over if an operator fails

to slow down to a safe speed before

making turns. Indications that an unit is

being driven at an excessive speed dur-

ing turning maneuvers include:

(1) tire skidding;

(2) unit side sway;

(3) wheel lift; and

(4) the need to grip the steering wheel

tightly to keep from sliding out of the

seat.

B The likelihood of lateral tipover is in-

creased under any of the following con-

ditions, or combinations of them:

(1) braking or accelerating shar ply while

turning;

(2) traveling on an uneven surface;

(3) traveling at excessive speed.

C Tipping forward can occur and its likeli-

hood is increased under the following

condition: hard braking while traveling

forward.

D The operator should stay with the unit if

it falls off a loading dock or ramp. The

operator should hold on firmly and lean

away from the point of impact.

E Where the environment presents a se-

vere hazard, or there are other unusual

operating conditions, the user may

need to establish different and/or addi-

tional safety precautions and special

operating instructions appropriate for

the conditions.

Operator care of the unit

At the beginning of each shift and before

operating the unit, check its conditon, giving special attention to the following:

A condition of tires

B if pneumatic tires, check inflation pres-

sures

C warning and safety devices

D lights

E battery

F controls

G chains and cables

H limit switches

I steering mechanism

J additional items or special equipment

as specified by the user and/or manu-

facturer

If the unit is found to be in need of repair or

in any way unsafe, or contributes to an unsafe condition, the matter shall be reported

immediately to the user’s designated authority, and the unit shall not be operated

until it has been restored to safe operating

condition.

– If during operation the unit becomes un-

safe in any way, the matter shall be re-

ported immediately to the user’s

designated authority, and the unit shall

not be operated until it has been re-

stored to safe operating condition.

– Do not make repairs or adjustments un-

less specifically authorized to do so.

– Do not use open flames when checking

electrolyte level in storage batteries.

MAINTENANCE AND RE-

BUILD PRACTICES

– Operation of the unit may be hazardous

if maintenance is neglected or repairs,

rebuilds, or adjustments are not per-

formed in accordance with the manu-

facturer’s design criteria. Therefore,

maintenance facilities (on or off pre-

mises), trained personnel, and detailed

procedures shall be provided.

– Parts manuals and maintenance manu-

als may be obtained from the unit man-

ufacturer.

– In unusual cases not covered by the

manuals referred above, consult the

unit manufacturer.

Maintenance and inspection of the unit

shall be performed in conformance with the

following practices:

A a schedules planned maintenance, lu-

brication, and inspection system shall

be followed; consult the manufacturer’s

recommendations;

B only trained and authorized personnel

shall be permitted to maintain, repair,

adjust, and inspect the unit, and in ac-

cordance with manufacturer’s specifi-

cations.

When lifting units for repair or inspection,

units shall be lifted in a safe, secure, stable

manner. Removal of components such as

counterweights or uprights will change the

center of gravity and may create an unstable condition.

Before starting inspection and repair of the

unit:

A raise drive wheels free of floor or dis-

connect battery and use chocks or oth-

er positive unit positioning devices;

4 English

Page 5

B block chassis before working on them;

C disconnect battery before working on

the electrical system;

D the charger connector shall be plugged

only into the battery connector and never into the unit connector.

Operation of the unit to check performance

shall be conducted in an authorized area

where safe clearance exists.

A Before starting to operate the unit:

(1) be in operating position;

(2) place directional controls in neutral;

(3) turn switch to ON position;

(4) check function of steering, warning

devices, and breaks;

B Before leaving the unit:

(1) stop unit;

(2) place directional controls in neutral;

(3) stop the engine or turn off power;

(4) turn off the control circuit;

(5) if the unit must be left on an incline,

block the wheels.

– Avoid fire hazards and have fire protec-

tion equipment present in the work area. Do not use any open flame to check

the level or to check for leakage of any

fluid, especially battery electrolyte. Do

not use open pans of fuel or flammable

cleaning fluids for cleaning parts.

– Properly ventilate work area, vent ex-

haust fumes, and keep shop clean and

dry.

– Brakes, steering mechanisms, control

mechanisms, warning devices, articulating axle stops, and frame members

shall be carefully and regularly inspected and maintanined in safe operating

condition.

FIRE SAFETY STANDARD

Maintenance

– Any unit not in safe operating condition

shall be removed from service.

– Precautions. Repairs shall not be

made in Class I, Class II, and Class III

locations.

Repairs to the electrical system of battery-powered units shall be performed

only after the battery has been disconnected.

– Operating Temperature. Where tem-

perature of any part of the unit is found

to be in excess of its normal operating

temperature and creates a hazardous

condition, the unit shall be removed

from service and shall not be returned

to service until the cause for such overheating has been eliminated.

– Fire Prevention. The unit shall be kept

in a clean condition and reasonably free

of lint, excess oil, and grease. Noncombustible agents are preferred for cleaning the unit. Flammable liquids [those

having flash points at or above 100°F

(37,8°C)] are not allowed. Precautions

regarding toxicity, ventilation, and fire

hazard shall be appropriate for the

agent or solvent used.

– Nameplate Visibility: The unit type des-

ignations as shown on the nameplate

and the type markers shall not be covered over with paint so that their identification information is obscured.

– The unit shall not be used in classified

areas.

Changing and Charging Storage

Batteries

– This section shall apply to batteries

used in electric units. The two types of

batteries commonly used are lead and

nickel-iron. They contain corrosive

chemical solutions, either acid or alkali,

and, therefore , present a chemical hazard. While being charged, they give off

hydrogen and oxygen, which, in certain

concentrates, are explosive.

Battery-charging installations shall be located in areas designated for that purpose;

such areas shall be kept free of extraneous

combustible materials. Facilities shall be

provided for the following:

A Flushing spilled electrolyte;

B Fire protection;

C Protecting charging apparatus from

damage by trucks; and

D Adequate ventilation for dispe rsa l of

fumes from gasing batteries.

Where on-board chargers are used, charg-

ing shall be accomplished at locations designated for that purpose, taking into

account the electrical requirements of the

charger and facilities for fire protection.

Exception: Flushing faclilties shall not be

required if charging is accomplished without removing the battery from the vehicle.

– Where handling acid concentrates

greater than 50 percent acid (above

1.400 specific gravity), an eye-wash

fountain shall be provided.

– A conveyor, overhead hoist, or equiva-

lent material handling equipment shall

be provided for handling batteries.

– Chain hoists shall be equipped with

load-cabin containers. Where a hand

hoist is used, uncovered battries shall

be covered with a sheet of plywood or

other nonconducting material to pre-

vent the hand chain from shorting on

cell connectors or terminals. A properly

insulated spreader bar shall be used

with any overhead hoist.

– Reinstalled or new batteries shall meet

or exceed the battery type marked on

the unit. Reinstalled batteries shall be

positioned properly and secured in the

unit.

– A carboy tilter or siphon shall be provid-

ed where acid in carboys is used. When

diluting concentrated sulfuric acid to

make up electrolyte, the acid ALWAYS

shall be added to the water - not the re-

verse. Battery maintenance personnel

shall wear protective clothing such as

eye protection, long sleeves, and

gloves.

Exception: Removal and replacement

of batteries shall not require the use of

protective clothing.

– Electrical installations shall be in accor-

dance with NFPA 70, National Electrical

Code, and any local ordinances.

– Trained and authorized personnel shall

change or charge batteries.

– Units shall be positoned properly and

brakes shall be applied before attempting to change or charge batteries.

– Where charging batteries, the vent

caps shall be kept in place to avoid

electrolyte spray. Care shall be taken to

ensure that vent caps are functioning.

The battery (or compartment cover(s)

shall be open to dissipate heat and gas.

– Smoking shall be prohibited in the

charging area.

– Precautions shall be taken to prevent

open flames, sparks, or electric arcs in

battery-charging areas.

– Tools and other metallic objects shall

be kept away from the tops of uncovered batteries.

English 5

Page 6

Please read and comply with

these instructions prior to the

initial operation of your appliance. Retain

these operating instructions for future reference or for subsequent possessors.

Before first start-up it is definitely necessary to read the safety indications Nr.

5.956-250!

Contents

Safety instructions 6

Function 6

Proper use 7

Environmental protection 7

Operating and Functional Elements 8

Before Startup 10

Start up 11

Operation 11

Shutdown 13

Maintenance and care 13

Accessories 16

Troubleshooting 17

Technical specifications 18

Safety instructions

General notes

Your sales outlet should be informed about

any transit damage noted when unpacking

the product.

– Warning and information plates on the

machine provide important directions

for safe operation.

– In addition to the information contained

in the operating instructions, all statutory safety and accident prevention regulations must be observed.

Drive mode

Danger

Risk of injury!

Danger of tipping if gradient is too high.

– The gradient in the direction of travel

should not exceed 12%.

Danger of tipping when driving round

bends at high speed.

– Drive slowly when cornering.

Danger of tipping on unstable ground.

– Only use the machine on sound surfac-

es.

Danger of tipping with excessive sideways

tilt.

– The gradient perpendicular to the direc-

tion of travel should not exceed 12%.

– It is important to follow all safety instruc-

tions, rules and regulations applicable

for driving motor vehicles.

– The operator must use the appliance

properly. He must consider the local

conditions and must pay attention to

third parties, in particular children, when

working with the appliance.

– The appliance may only be used by per-

sons who have been instructed in han-

dling the appliance or have proven

qualification and expertise in operating

the appliance or have been explicitly

assigned the task of handling the appliance.

– The appliance must not be operated by

children, young persons or persons

who have not been instructed accordingly.

– It is strictly prohibited to take co-pas-

sengers.

– Ride-on appliances may only be started

after the operator has occupied the driver's seat.

Î Please remove the key, when not in

use, to avoid unauthorised use of the

appliance.

Î Never leave the machine unattended

so long as the engine is running. The

operator may leave the appliance only

when the engine has come to a standstill, the appliance has been protected

against accidental movement, and the

key has been removed.

Battery-operated machines

PROPOSITION 65

WARNING

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of

California to cause cancer and reproductive harm. Batteries also contain other

chemicals known to the State of California to cause cancer. Wash hands after

handling.

Note

Warranty claims will be entertained only if

you use batteries and chargers recommended by Windsor.

– Always follow the instructions of the

battery manufacturer and the charger

manufacturer. Please follow the statutory requirements for handling and disposing batteries.

– Never leave the batteries in a dis-

charged state; recharge them as soon

as possible.

– Always keep the batteries clean and dry

to avoid battery drain. Protect the batteries and avoid contact with impurities

such as metal dust.

– Do not place tools or similar items on

the battery. Risk of short-circuit and explosion.

– Do not work with open flames, generate

sparks or smoke in the vicinity of a battery or a battery charging room. Danger

of explosion.

– Do not touch hot parts of the machine

such as the drive motor (risk of burns).

– Be careful while handling battery acid.

Follow the respective safety instructions!

– Used batteries are to be disposed of

properly.

Accessories and Spare Parts

Danger

To avoid risks, all repairs and replacement

of spare parts may only be carried out by

authorized customer service personnel.

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and troublefree.

– At the end of the operating instructions

you will find a selected list of spare

parts that are often required.

Symbols on the appliance

Please do not sweep away

any burning substances

such as cigarettes, match

sticks or similar objects.

Risk of being squeezed or

hurt at the belts, sidebrushes, containers, machine cover.

Symbols in the operating instruc-

tions

Danger

indicates an immediate threat of danger.

Failure to observe the instruction may result in death or serious injuries.

몇 Warning

indicates a possibly dangerous situation.

Failure to observe the instruction may result in light injuries or damage to property.

Note

indicates useful tips and important information.

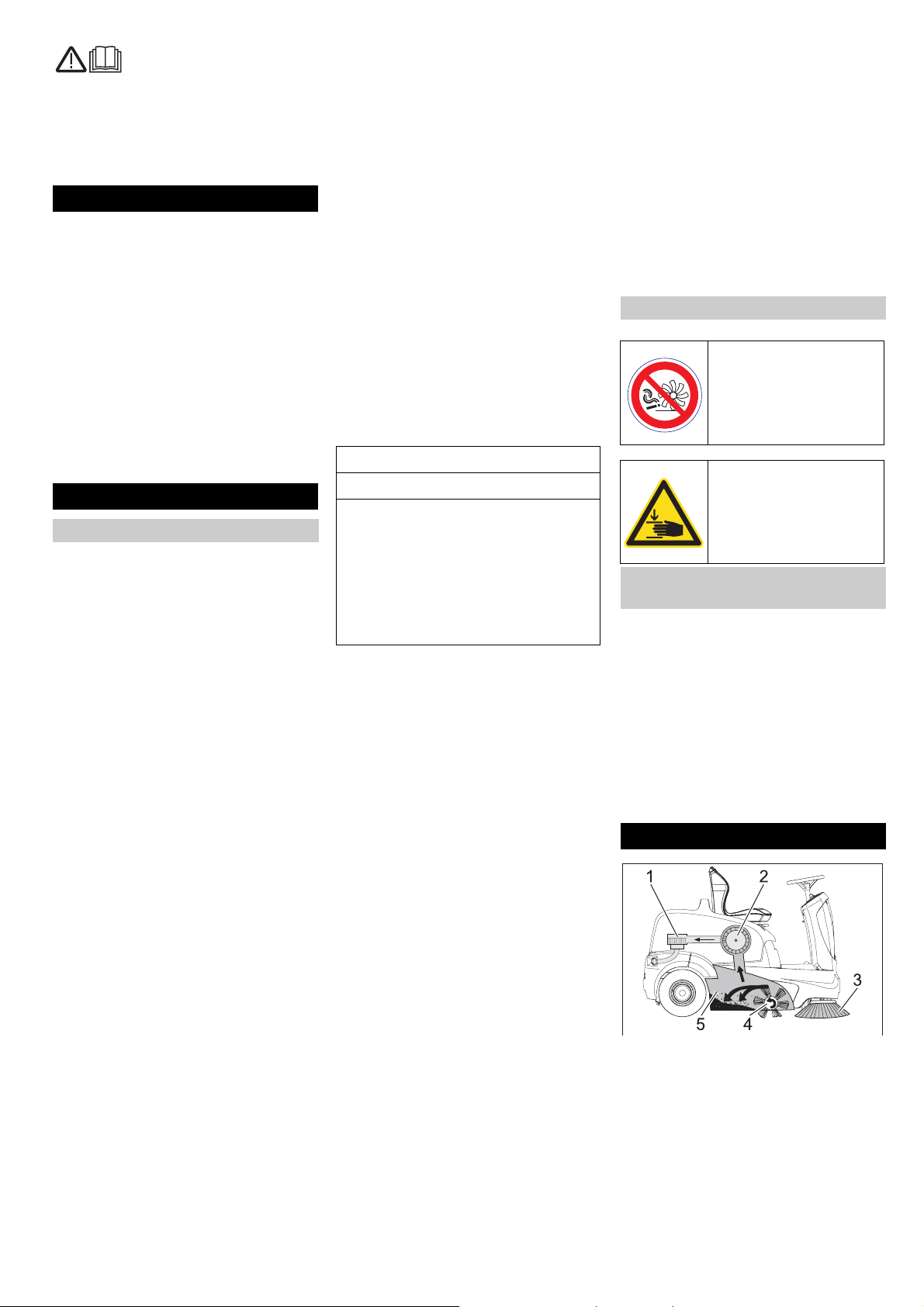

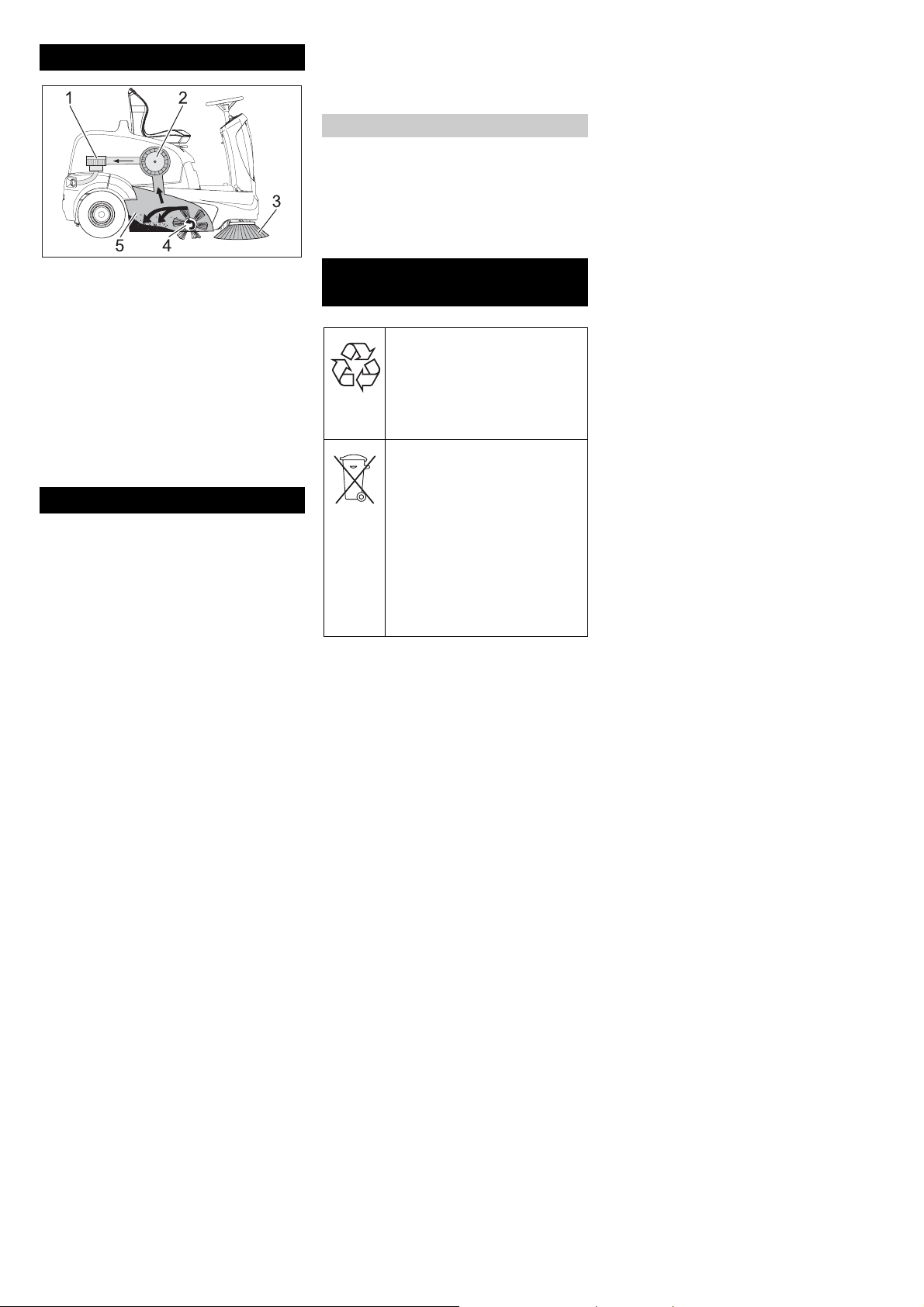

Function

The sweeper operates using the overthrow

principle.

– The side brushes (3) clean the corners

and edges of the surface, moving dirt

and debris into the path of the roller

brush.

– The rotating roller brush (4) moves the

dirt and debris directly into the waste

container (5).

6 English

Page 7

– The dust raised in the container is sep-

arated by the dust filter (2) and the filtered clean air is drawn off by the

suction fan (1).

Proper use

Use this appliance only as directed in these

operating instructions.

Î The machine with working equipment

must be checked to ensure that it is in

proper working order and is operating

safely prior to use. Otherwise, the appliance must not be used.

– This sweeper has been designed to

sweep dirt and debris from indoor as

well as outdoor surfaces.

– The machine is not suitable for being

driven on public roads.

– The machine is not suitable for vacuum-

ing dust which endangers health.

– The machine may not be modified.

– Never vacuum up explosive liquids,

combustible gases or undiluted acids

and solvents. This includes petrol, paint

thinner or heating oil which can gener-

ate explosive fumes or mixtures upon

contact with the suction air. Acetone,

undiluted acids and solvents must also

be avoided as they can harm the mate-

rials on the machine.

– Do not sweep/vacuum up any burning

or glowing objects.

– The machine is only suitable for use on

the types of surfaces specified in the

operating instructions.

– The machine may only be operated on

the surfaces approved by the company

or its authorized representatives.

– The machine may not be used or stored

in hazardous areas. It is not allowed to

use the appliance in hazardous loca-

tions.

– The following applies in general: Keep

highly-flammable substances away

from the appliance (danger of explo-

sion/fire).

Suitable surfaces

–Asphalt

– Industrial floor

– Screed

– Concrete

– Paving stones

– Carpet

Old machines contain valuable

materials that can be recycled;

these should be sent for recycling. Batteries, oil, and similar

substances must not enter the

environment. Please dispose

of your old machines using appropriate collection systems.

Environmental protection

The packaging material can be

recycled. Please do not throw

the packaging material into

household waste; please send

it for recycling.

English 7

Page 8

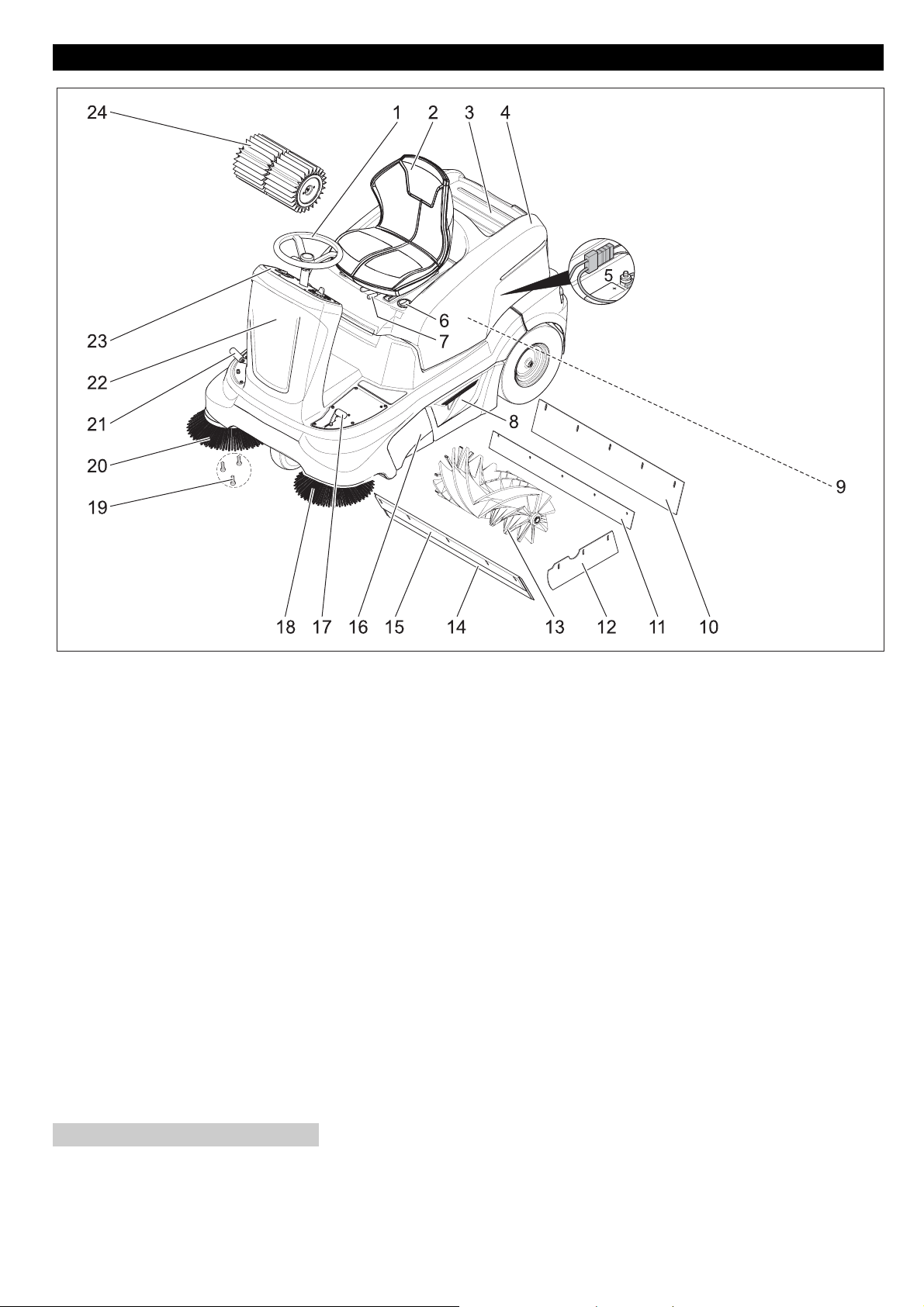

Operating and Functional Elements

1 Steering wheel

2 Seat (with seat contact switch)

3 Storage area

4Cover

5 Battery socket

6 Wet/dry flap

7 Lever for seat adjustment

8 Waste container (both sides)

9 Fuses (under the appliance hood)

10 Rear sealing strip

11 Rubber strip

12 Side sealing strip

13 Roller brush

14 Front seali n g stri p

15 Bulk waste flap

16 Side panels

17 Pedal for raising/lowering bulk waste

flap

18 Left side brush (optional)

19 Fastener of the side brush

20 Right side brush

21 Drive pedal

22 Front panel

23 Operator console

24 Dust filter

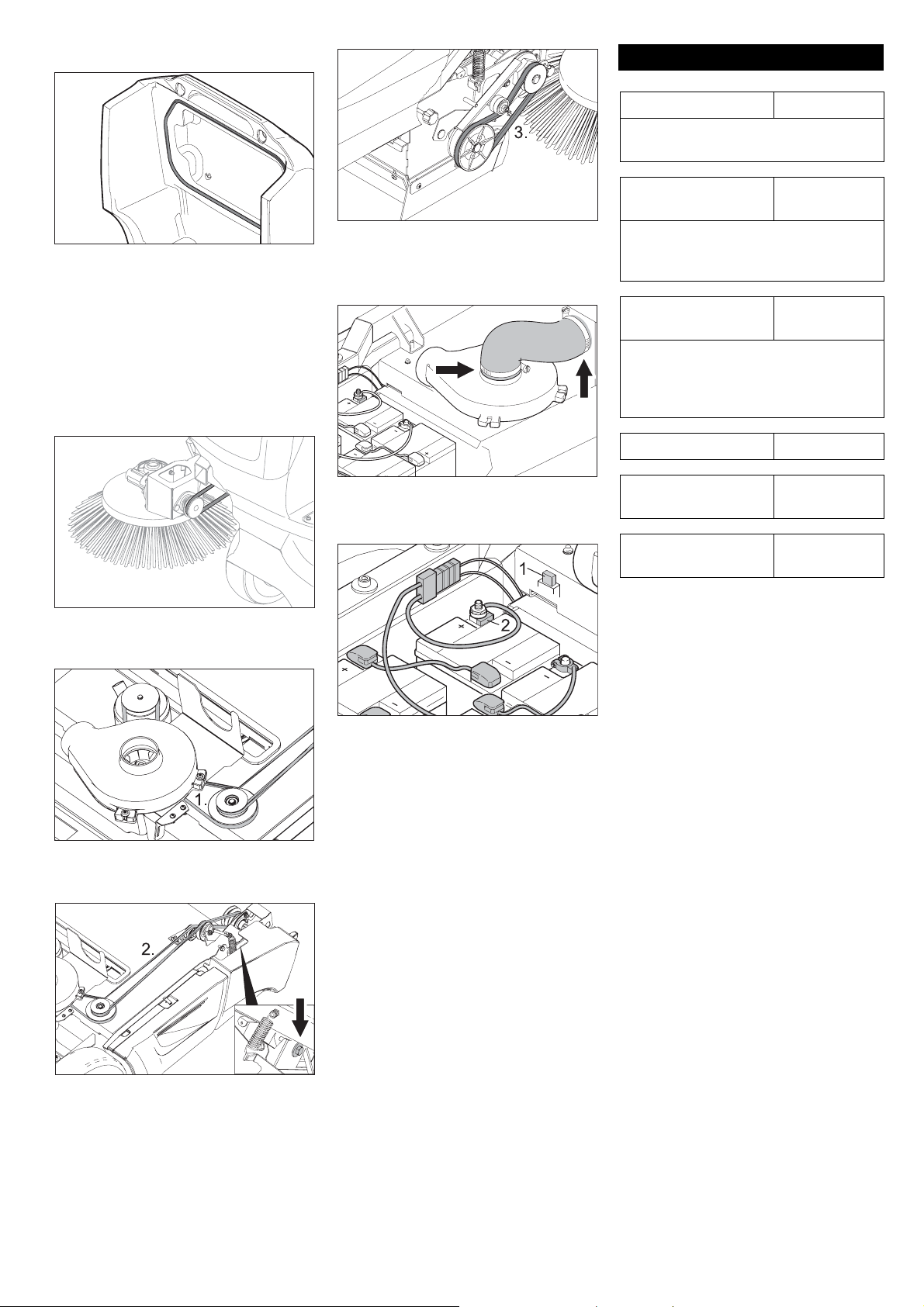

Open/ close device hood

Danger

Danger of crushing while closing the machine cover. Hence, lower the machine

cover slowly.

8 English

Page 9

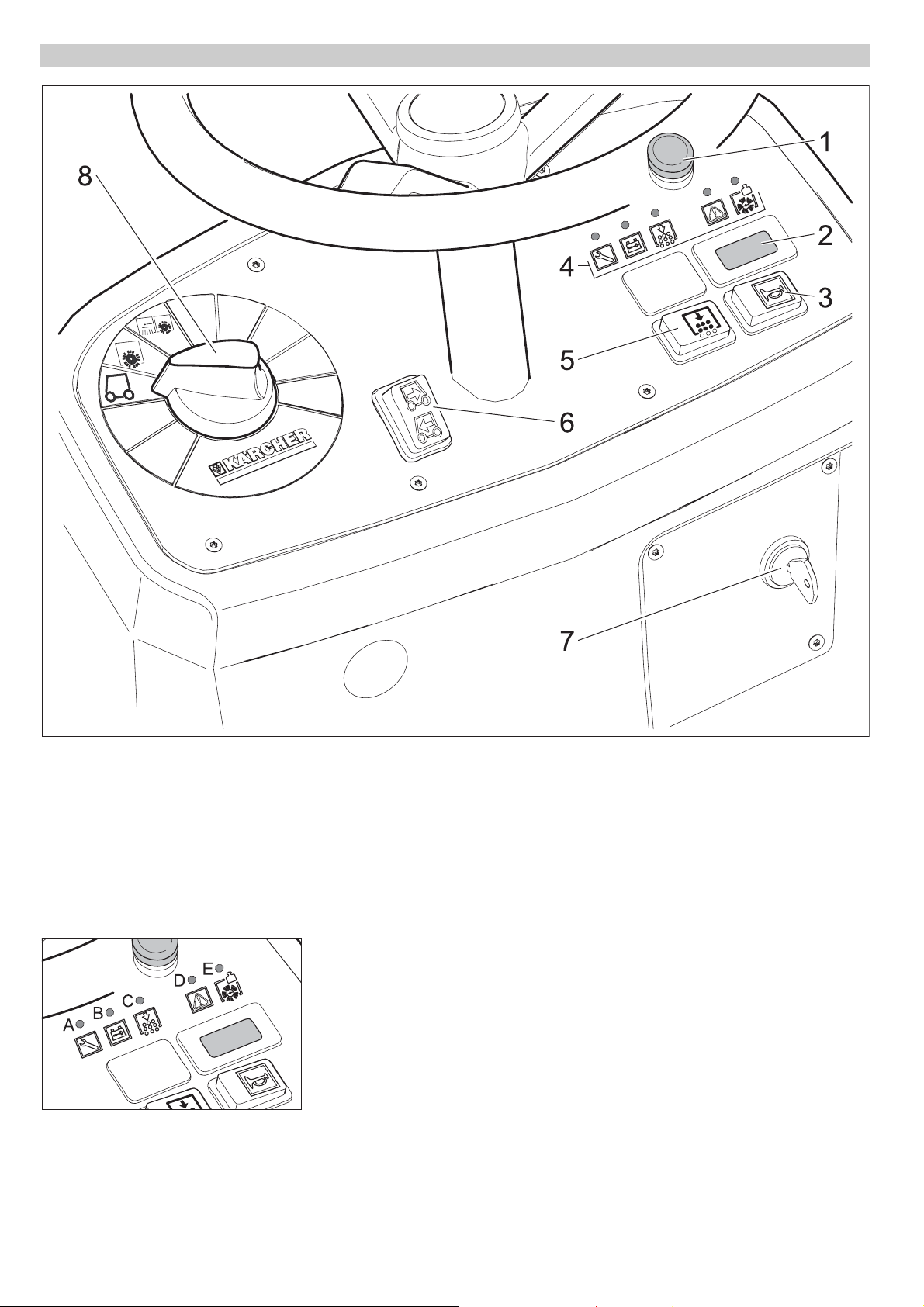

Operator console

1 Emergency-stop button

2 Operating hour counter

3Horn

4 Indicator lamps

5 Filter dedusting

6 Travel direction switch (forward/re-

verse)

7 Key switch

8 Programe switch

Indicator lamps

A Service (yellow)

B Battery charge status (red/yellow/

green)

C Overload of the filter cleaning (red)

D Overlaod of the drive motor (red)

E Overlaod of the sweep roller (red)

English 9

Page 10

Before Startup

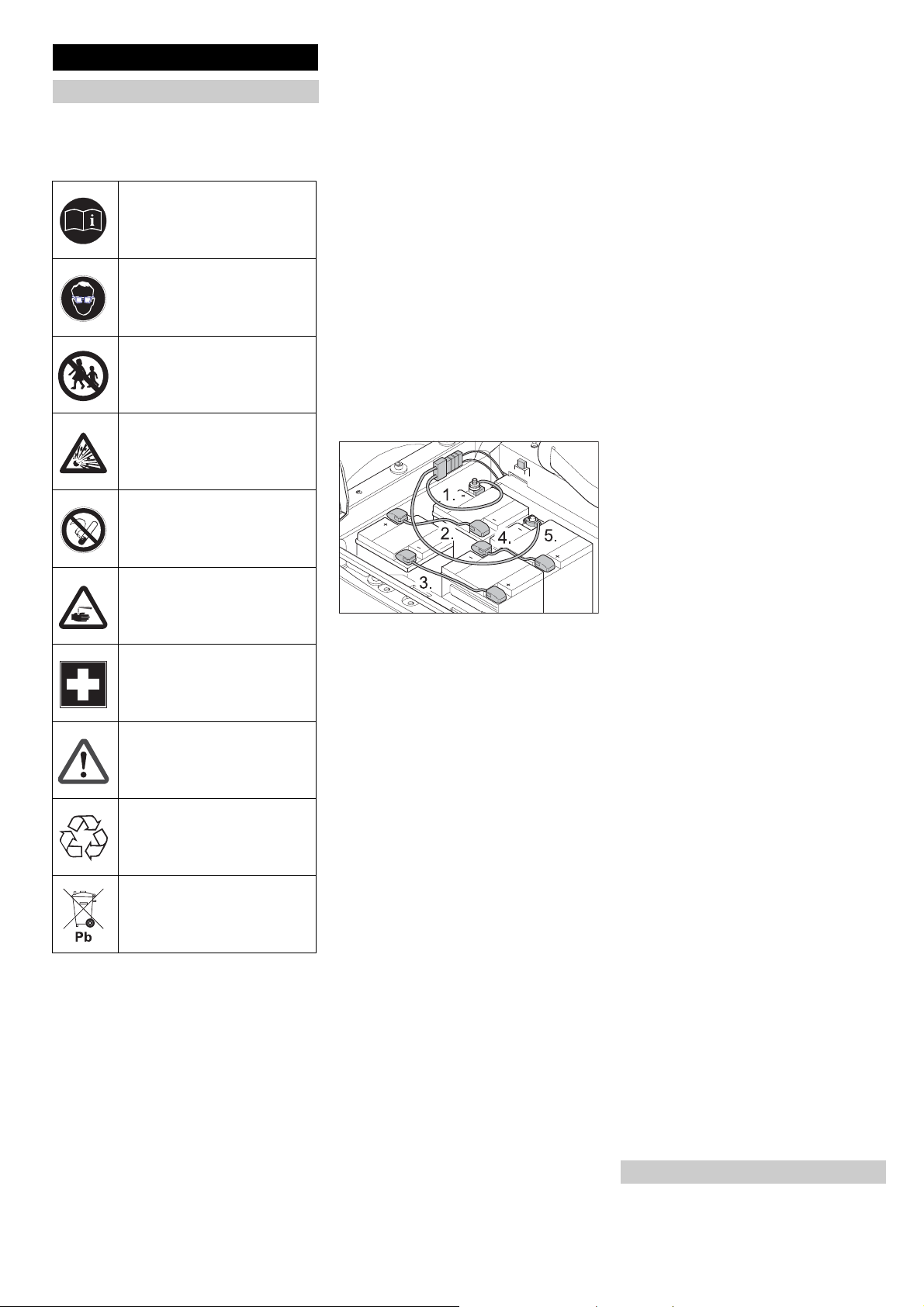

Batteries

Safety notes regarding the batteries

Please observe the following warning notes

when handling batteries:

Observe the directions on the

battery, in the instructions for

use and in the vehicle operating instructions!

Wear an eye shield!

Keep away children from acid

and batteries!

Risk of explosion!

Fire, sparks, open light, and

smoking not allowed!

Danger of caustic material!

First aid!

Warning note!

Disposal!

Do not throw the battery in the

trash bin!

Danger

Risk of explosion! Do not put tools or similar

on the battery, i.e. on the terminal poles

and cell connectors.

Danger

Risk of injury! Ensure that wounds never

come into contact with lead. Always clean

your hands after having worked with batteries.

Danger

Risk of fire and explosion!

– Smoking and naked flames are strictly

prohibited.

– Rooms where batteries are charged

must have good ventilation because

highly explosive gas is emitted during

charging.

– Batteries must not be stored outside.

Danger

Danger of cautic material!

– Rinse thoroughly with lots of clear water

if acid gets into the eye or comes in contact with the skin.

– Then consult a doctor immediately.

– Wash off the acid If it comes in contact

with the clothes.

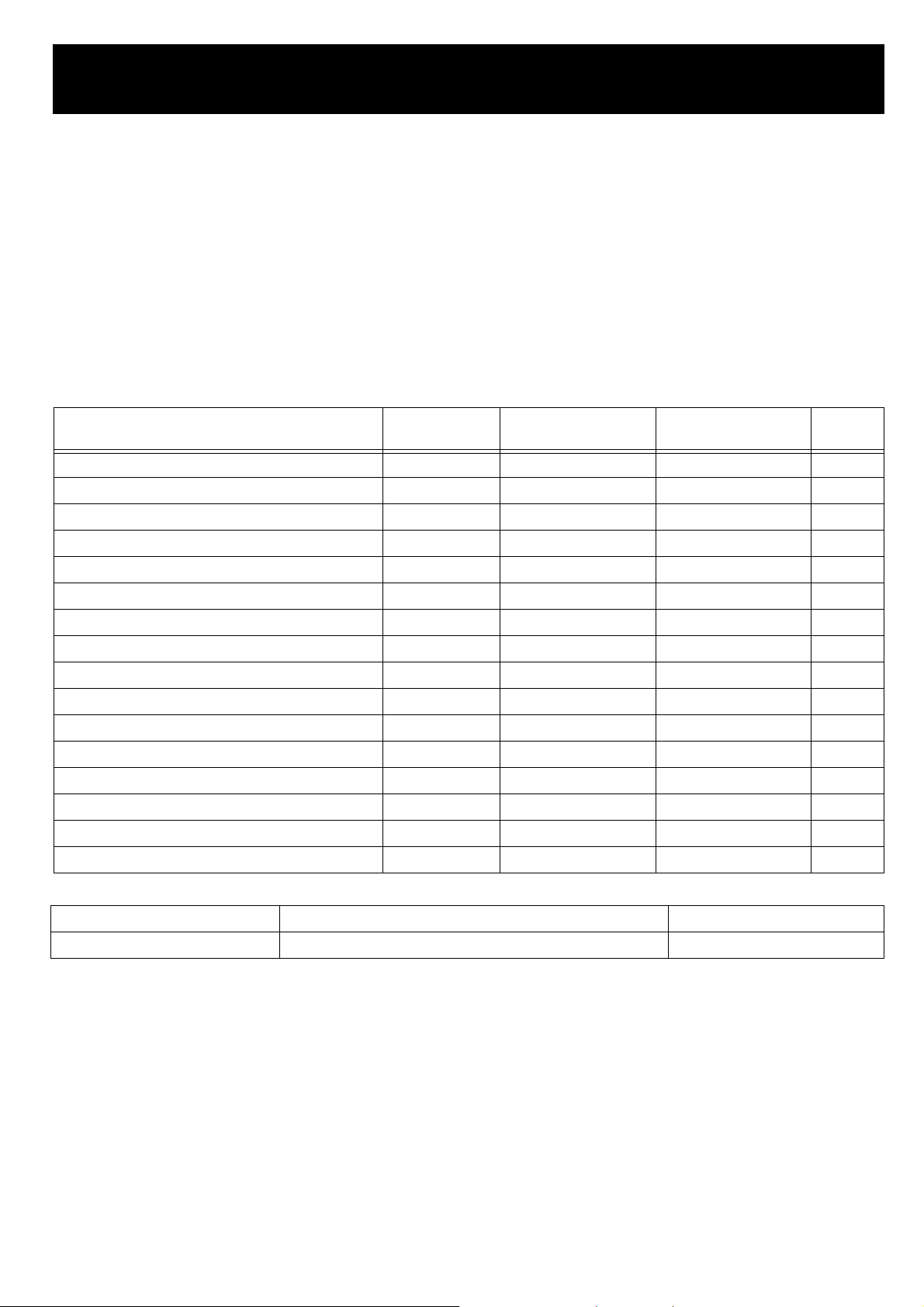

Installing and connecting the batteries

Î Open the device hood.

Î Insert batteries into the battery mount.

Î Adjust the rubber buffers to hold the

batteries properly.

몇 Warning

Pay attention to correct poles.

Note

The connection lines are not included in the

delivery scope.

Î Connect pole terminal (red cable) to

positive pole (+).

Î Screw the connection lines onto the

batteries.

Î Connect pole terminal to negative pole

(-).

Note

Before removing the battery, make sure

that the negative pole lead is disconnected.

Check that the battery pole and pole terminals are adequately protected with pole

grease.

몇 Warning

Charge the batteries before commissioning

the machine.

Charge the batteries

Danger

Risk of injury! Comply with safety regulations on the handling of batteries. Observe

the directions provided by the manufacturer

of the charger.

Danger

Charge the battery only with an appropriate

charger.

Note

When the batteries are charged, first remove the charger from the mains and then

disconnect it from the batteries.

Î Open the device hood.

Î Separate the battery plug and connect

the charger cable.

Î Plug in power cord and switch on charg-

er.

Note

The recommended chargers (matching th e

batteries used) are regulated electronically

and will automatically switch off the charging process. All functions of the machine

are automatically interrupted during the

charging process.

Maintenance-free batteries

– While charging maintenance-free bat-

teries, it is necessary to tilt the appliance hood upward.

– While charging maintenance-free bat-

teries, follow the specifications of the

battery manufacturer.

Î Add distilled water one hour before the

end of the charging process; follow the

correct acid level. There are corresponding indicators on the battery.

Danger

Danger of chemical burns. Adding water to

the battery in its discharged state can

cause the acid to leak! Use safety glasses

while handling battery acid and follow the

safety instructions to avoid personal injury

or damage to clothes. Should the acid

spray on to the skin or clothes, rinse immediately with lots of water.

몇 Warning

Risk of damage. Use only distilled or desalinated water (VDE 0510) for filling the

battery. Do not add any substances (socalled performance improving agents), else

warranty claims will not be entertained.

After charging

Î Switch off the charger and remove the

plug from the socket.

Î Pull the battery cable from the charger

cable and connect it to the appliance.

Check fluid level in the battery and adjust if required

몇 Warning

Regularly check the fluid level in acid-filled

batteries.

– The acid in a fully charged battery has a

specific weight of 10.85 lbs/gal

(1.28 kg/l) at a temperature of 68 °F

(20 °C).

– The acid in a partially discharged bat-

tery has a specific weight between 8.46

and 10.85 lbs/gal (1.00 and 1.28 kg/l).

– The specific weight of the acid must be

uniform in all cells.

Î Unscrew all cell caps.

Î Take a sample from each cell using the

acid tester.

Î Put the acid sample back into the same

cell.

Î Where fluid level is too low, top up cells

to the mark provided with distilled water.

Î Charge battery.

Î Screw in cell caps.

Unloading

몇 Warning

Do not use a forklift truck to unload the machine as this may damage it.

10 English

Page 11

Note

Press the emergency-stop button to immediately deactivate all functions and turn the

key switch to the "0" position.

To unload the machine, proceed as follows:

Î Cut plastic packing belt and remove foil.

Î Remove the elastic tape fasteners at

the stop points.

Î Four indicated floor boards of the pallet

are fastened with screws. Unscrew

these boards.

Î Place the boards on the edge of the pal-

let. Place the boards in such a way that

they lie in front of the four wheels of the

machine. Fasten the boards with

screws.

Î Slide the four support beams included

in the packaging under the ramp.

Î Remove the wooden blocks used for ar-

resting the wheels and slide them under

the ramp.

(1) Machine without built-in battery

Î Loosen immobilizing brake (see "move

sweep machine").

Î Slide the machine over the prepared

ramp from the pallet.

(2) Machine with built-in battery

Î Connect battery (see section on Care

and maintenance)

Î Release emergency-stop button by

turning.

Î Set main switch to "1".

Î Press the drive direction switch and

slowly move the machine down from

the ramp.

Î Set main switch back to "0".

Move the sweep machine

Danger

– Risk of injury! Before releasing the im-

mobilizing brake, the machine must be

secured to prevent it rolling away. After

releasing the emergency brake, the ap-

pliance will roll until a speed of 2.8 mph

(4.5 km/h) is reached. After that, the

electronics will brake the appliance.

– It is prohibited to release the emergen-

cy brake on an incline with out using the

stopper.

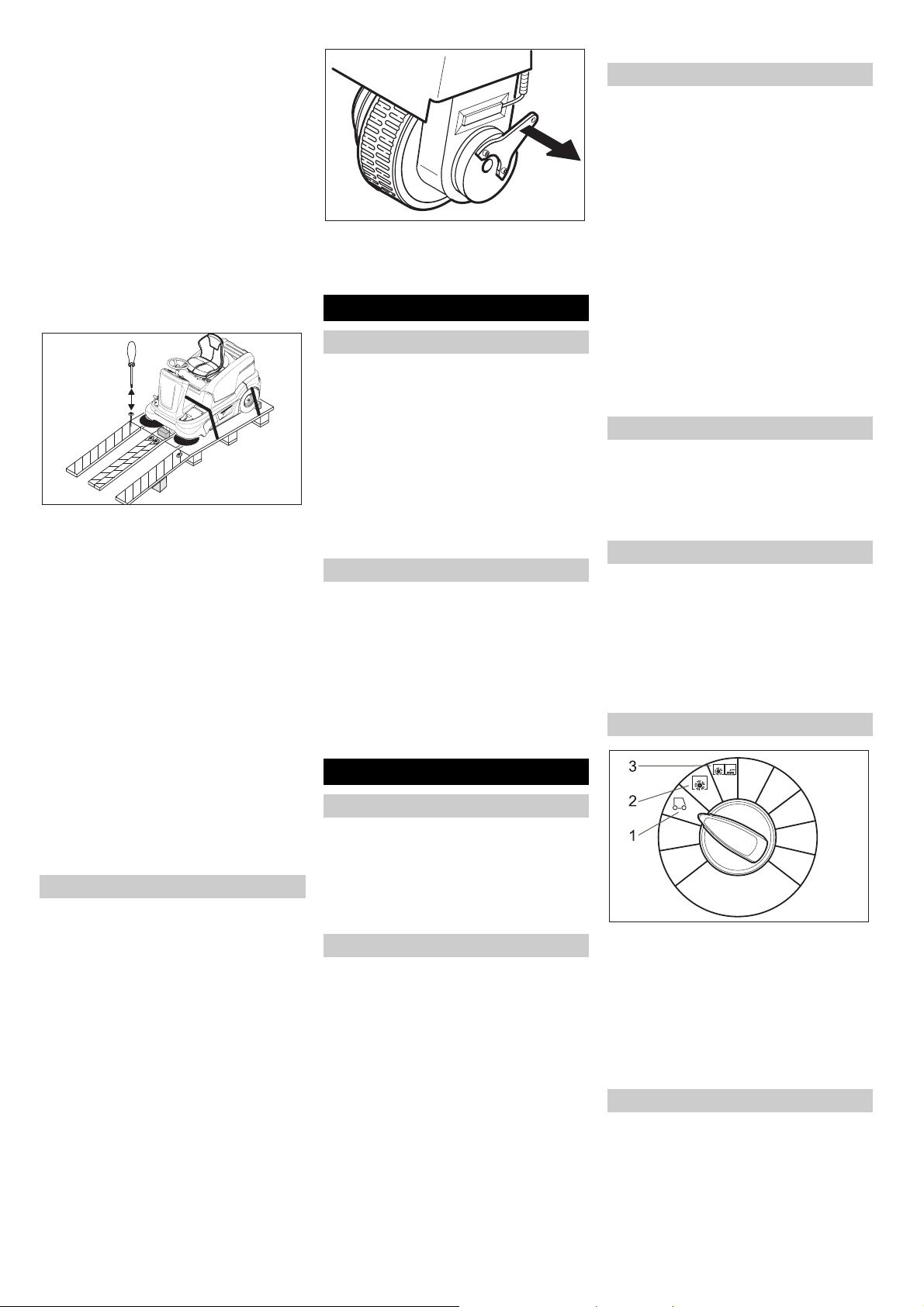

Î Remove the brake level from the wheel

and put it in its position.

The immobilizing brake is thus deactivated;

the machine can now be moved.

Start up

General notes

The appliance will brake electrically while

standing still, if one of the following conditions is met.

– Foot was removed from the pedal.

– Operator's seat was left for more than 1

second.

– Key switch was set to “0”.

The automatic emergency brake will only

work while the appliance is at a standstill.

Î Park the sweeper on an even surface.

Î Remove the key.

Inspection and maintenance work

Î Check charging status of battery.

Î Check side brush.

Î Check roller brush.

Î Shake off dust filter.

Î Empty waste container.

Î Check tyre pressure.

Note

For description, see section on Care and

maintenance.

Operation

Adjusting driver's seat

Î Pull seat adjustment lever inwards.

Î Slide seat, release lever and lock in

place.

Î Check that the seat is properly locked in

position by attempting to move it back-

wards and forwards.

Check charging status of battery

– Indicator lamp glows green

Battery is charged (100...40%).

– Indicator lamp glows yellow

Battery is discharged to 40 ... 20%.

– Indicator lamp blinks red

Battery is almost discharged. The sweeping mode will be shortly switched off auto-

matically.

– Indicator lamp glows red

Battery is discharged. The sweeping mode

will be terminated automatically (the

sweeping aggregates cannot be taken into

operation until the battery is charged).

Î Drive the machine directly to the charg-

ing station; avoid any steep gradients in

the process.

Î Charge battery.

Check immobilizing brake

Danger

Danger of accident. The immobilizing brake

must always be checked first on an even

surface before starting the machine.

Î Take the seating position.

Î Release emergency-stop button by

turning.

Î Set main switch to "1".

Î Activate the travel direction switch (for-

ward/reverse).

Î Gently depress drive pedal.

Î You must hear the brake being re-

leased. The machine must roll slightly

on a plane surface. When the pedal is

released, the brake falls in in an audible

manner. Switch off the machine and call

the aftersales service if the above-mentioned events do not occur.

Storage area

Note

The max. load of the storage area is

44.1 lbs (20 kg).

Î Fasten the load through appropriate

fasteners at the 4 eyelets.

Emergency-stop button

– The appliance has an emergency OFF

switch. If this switch is pressed, the appliance will stop abruptly and the automatic emergency brake will be

activated.

– In order to restart the appliance, first un-

lock the emergency OFF switch, then

turn the key switch on and off.

Programme selection

1Driving

Driving to the Place of Use.

2 Sweeping with sweep roller

Roller brush is lowered. The roller brush

and the side brush will rotate.

3 Sweeping using roller brush and side

brushes

Roller brush and side brushes are low-

ered.

Turning on the Machine

Note

The machine is equipped with a seat contact switch When you quit the driver seat,

the machine comes to a halt after a delay of

approx. 1.5 seconds and the activated

sweep function is switched off.

Î Sit on the driver's seat.

English 11

Page 12

Î Do NOT press the accelerator pedal.

Î Set programme switch to step 1 (driv-

ing).

Î Set main switch to "1".

Drive the machine

Danger

Danger of accident. If the machine does not

brake, then proceed as follows:

– If the device does not come to a halt on

a ramp with a gradient of 2% when you

release the drive pedal, then the emergency-stop button may be pressed for

safety reasons only if the mechanical

functioning of the immobilizing brake

has been checked properly before commissioning the device.

– Switch off the machine only after it

comes to a complete halt (on an even

surface) and call up the aftersales service!

– Further, follow all warning instructions

for braking.

Î Release emergency-stop button by

turning.

Î Sit on the seat and set main switch to

"1".

Drive forward

Î Set the travel direction switch to "for-

ward".

Î Press accelerator pedal down slowly.

Reverse drive

Danger

– Risk of injury! While reversing, ensure

that there is nobody in the way, ask

them to move if somebody is around.

– During reverse drive, a pulsing warning

sound will be heard.

– The reverse drive speed is lower than

the forward speed for safety reasons.

Î Set the travel direction switch to "back-

wards".

Î Press accelerator pedal down slowly.

Note

Driving method

– The accelerator pedal can be used to

vary the driving speed infinitely.

Brakes

Î Release the accelerator pedal, the ma-

chine brakes automatically and stops.

Driving over obstacles

Driving over fixed obstacles which are

2.0 in (50 mm) high or less:

Î Drive forwards slowly and carefully.

Driving over fixed obstacles which are

more than 2.0 in (50 mm) high:

Î Only drive over these obstacles using a

suitable ramp.

Overlaod of the drive motor

In case of overloading, the drive motor automatically switches off after a certain period. The indicator lamp "Overlaod of the

drive motor" will illuminate red as soon as

the drive motor current is limited. If the control is overheated, all drives (except for the

horn and the filter cleaning) will be switched

off.

Î Allow machine to cool down at least for

15 minutes.

Î Turn the main switch to "0" and turn it

back to "1".

Sweeping mode

Danger

Risk of injury! If the bulk waste flap is open,

stones or gravel may be flung forwards by

the roller brush. Make sure that this does

not endanger persons, animals or objects.

몇 Warning

Do not sweep up packing strips, wire or

similar objects as this may damage the

sweeping mechanism.

몇 Warning

To avoid damaging the floor, do not continue to operate the sweeping machine in the

same position.

Note

To achieve an optimum cleaning result, the

driving speed should be adjusted to take

specific situations into account.

Note

During operation, the waste container

should be emptied at regular intervals.

Note

When cleaning surfaces, only lower the

roller brush.

Note

Also lower side brush when cleaning along

edges.

Sweeping with sweep roller

Î Set programme switch to step 2. Roller

brush is lowered. The roller brush and

the side brush will rotate.

Sweeping with bulk waste flap raised

Note

To sweep up larger items up to a height of

2.0 in (50 mm), e.g. cigarette packs, the

bulk waste flap must be raised briefly.

Raising bulk waste flap:

Î Press the pedal for the bulk waste flap

forwards and keep pressed down.

Î To lower it, take foot off pedal.

Note

An optimum cleaning result can only be

achieved if the bulk waste flap has been

lowered completely.

Sweeping with side brushes

Î Set programme switch to step 3. Side

brushes and roller brush are lowered.

Note

Roller brush and side brush start operating

automatically.

Sweeping dry floors

Note

During operation, the waste container

should be emptied at regular intervals.

Note

During operation, the dust filter should be

shaken off and cleaned at regular intervals.

Î Close wet/dry flap

Sweep in fibrous and dry waste (such as

dry grass, hay)

Î Open wet/dry flap.

Note

You can thus preven the filter system from

getting blocked.

Sweeping damp or wet floors

Î Open wet/dry flap.

Note

This protects the filter from moisture.

Filter dedusting

– Switch on manual filter shake off.

Î Press Filter shake off button. The filter

will be cleaned for 15 seconds.

Emptying waste container

Note

Wait until the filter shaking process is finished and the dust has settled before you

open or empty the waste container.

Î Raise the waste container slightly and

pull it out.

Î Empty waste container.

Î Push in the waste container and lock it.

Î Empty opposite waste container.

Turn off the appliance.

Î Set programme switch to step 1 (driv-

ing). The side brush and roller brush are

raised.

Î Turn main key to "0" and remove it.

Note

– Once the machine has been switched

off, the dust filter is shaked automatically for approx. 15 seconds. Do not open

the machine hood during this period.

– The appliance has an automatic switch-

off function to protect the batteries from

discharging. If the appliance is not in

use (with the key switch turned on) for

longer than 30 minutes, it will switch off

automatically.

Transport

Î Turn main key to "0" and remove it.

Î Secure the wheels of the machine with

wheel chocks.

Î Secure the machine with tensioning

straps or cables.

12 English

Page 13

Note

Observe markings for fixing points on base

frame (chain symbols). When loading or

unloading the machine, it may only be operated on gradients of max. 12%.

Shutdown

If the sweeper is going to be out of service

for a longer time period, observe the following points:

Î Park the sweeper on an even surface.

Î Set programme switch to step 1 (driv-

ing). The roller brush and side brushes

are raised to prevent the bristles being

damaged.

Î Turn main key to "0" and remove it.

Î Lock the sweeper to ensure that it does

not roll off.

Î Clean the inside and outside of the

sweeper.

몇 Warning

Danger of damage to the machine because

of water penetrating into the machine! The

machine should not be sprayed using a

high pressure water jet.

Î Park the machine in a safe and dry

place.

Î Disconnect battery.

Î Charge battery and recharge it approx.

every 2 months.

Maintenance and care

General notes

Î First switch off the appliance and re-

move the key before performing any

cleaning or maintenance tasks on the

appliance, replacing parts or switching

over to another function.

Î Pull out the battery plug or clamp the

battery while working on the electrical

unit.

– Maintenance work may only be carried

out by approved customer service outlets or experts in this field who are familiar with the respective safety

regulations.

– Mobile appliances used for commercial

purposes aer subject to safety inspections according to VDE 0701.

– Use only roller brushes/ side-brushes

that are provided with the appliance or

specified in the Operations Manual.

The use of other roller brushes/ sidebrushes can affect the safety of the appliance.

Cleaning

몇 Warning

Risk of damage! Do not clean the appliance

with a water hose or high-pressure water

jet (danger of short circuits or other damage).

Cleaning the inside of the machine

Danger

Risk of injury! Wear dust mask and protective goggles.

Î Open the device hood.

Î Clean machine with a cloth.

Î Blow through machine with com-

pressed air.

Î Close cover.

External cleaning of the appliance

Î Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Note

Do not use aggressive cleaning agents.

Maintenance intervals

Note

The elapsed-time counter shows the timing

of the maintenance intervals.

Maintenance by the customer

Daily maintenance:

Î Check the sweeping roller and the side

brush for wear and wrapped belts.

Î Check tyre pressure.

Î Check function of all operator control el-

ements.

Weekly maintenance:

Î Check fluid level of battery.

Î Check moving parts for freedom of

movement.

Î Check the gasket in the sweeping area

for position and wear.

Î Check dust filter and clean filter box, if

required.

Maintenance to be carried out every 100

operating hours:

Î Check function of seat contact switch.

Î Check battery acid level.

Î Check tension, wear and function of

drive belts (V-belt and circular belt).

Maintenance following wear:

Î Replace sealing strips.

Î Replace roller brush.

Î Replace side brush.

Note

For description, see section on Maintenance work.

Note

Where maintenance is carried out by the

customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialized Windsor dealer may be contacted at any time.

Maintenance by Customer Service

Maintenance to be carried out after 5 operating hours:

Î Carry out initial inspection.

Maintenance to be carried out every 50 operating hours

Maintenance to be carried out every 100

operating hours

Note

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorized Windsor Customer Service in

accordance with the maintenance booklet.

Maintenance Works

Preparation:

Î Park the sweeper on an even surface.

Î Turn main key to "0" and remove it.

Î Press emergency-stop button.

General notes on safety

Danger

Risk of injury!

The engine requires 15 seconds to come to

a standstill once it has been switched off.

Do not open the appliance hood during that

period.

Danger

Risk of injury! Allow the machine sufficient

time to cool down before carrying out any

maintenance and repair work.

Check fluid level in the battery and adjust if required

몇 Warning

Regularly check the fluid level in acid-filled

batteries.

Î Unscrew all cell caps.

Î Where fluid level is too low, top up cells

to the mark provided with distilled water.

Î Charge battery.

Î Screw in cell caps.

Check the tyre pressure

Î Park the sweeper on an even surface.

Î Connect air pressure testing device to

tyre valve.

Î Check air pressure and adjust if re-

quired.

Î Set air pressure for the rear tyres to

90 psi (6 bar).

Replacing wheel

Danger

Risk of injury!

Î Park the sweeper on an even surface.

Î Remove the key.

Î When carrying out repairs on public

highways, wear warning clothing when

working close to passing traffic.

Î Check stability of ground. Also secure

the machine with wheel chock(s) to pre-

vent it rolling away.

Check tyres

Î Check tyre contact face for foreign ob-

jects.

Î Remove objects found.

Î Use suitable, commercially available

materials to carry out tyre repairs.

English 13

Page 14

Note

Observe the manufacturer's recommendations. The journey may be resumed providing that the directions supplied by the

product manufacturer have been observed.

The tyre/wheel change should nonetheless

be carried out as soon as possible.

Î Raise slightly the waste container on

the appropriate side and pull it out.

Î Position vehicle jack at the appropriate

mounting point for the front or rear

wheel.

Î Raise machine using vehicle jack.

Î Remove the hexagonal screw (rear

wheel only).

Î Remove wheel.

Î Mount spare wheel.

Î Attach the hexagonal screw (rear wheel

only).

Î Lower machine using vehicle jack.

Î Push in the waste container and lock it.

Note

Use a suitable commercially available vehicle jack.

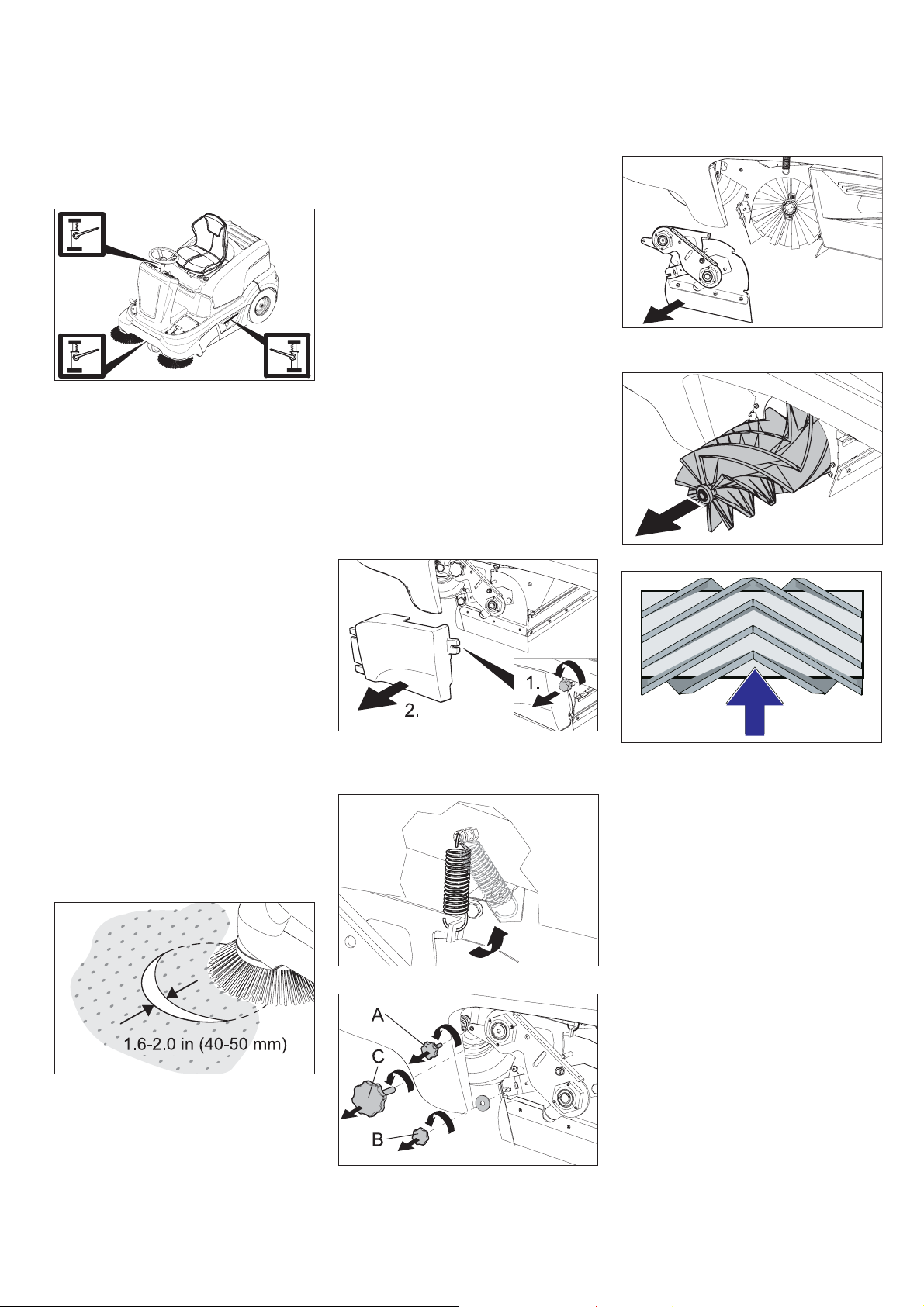

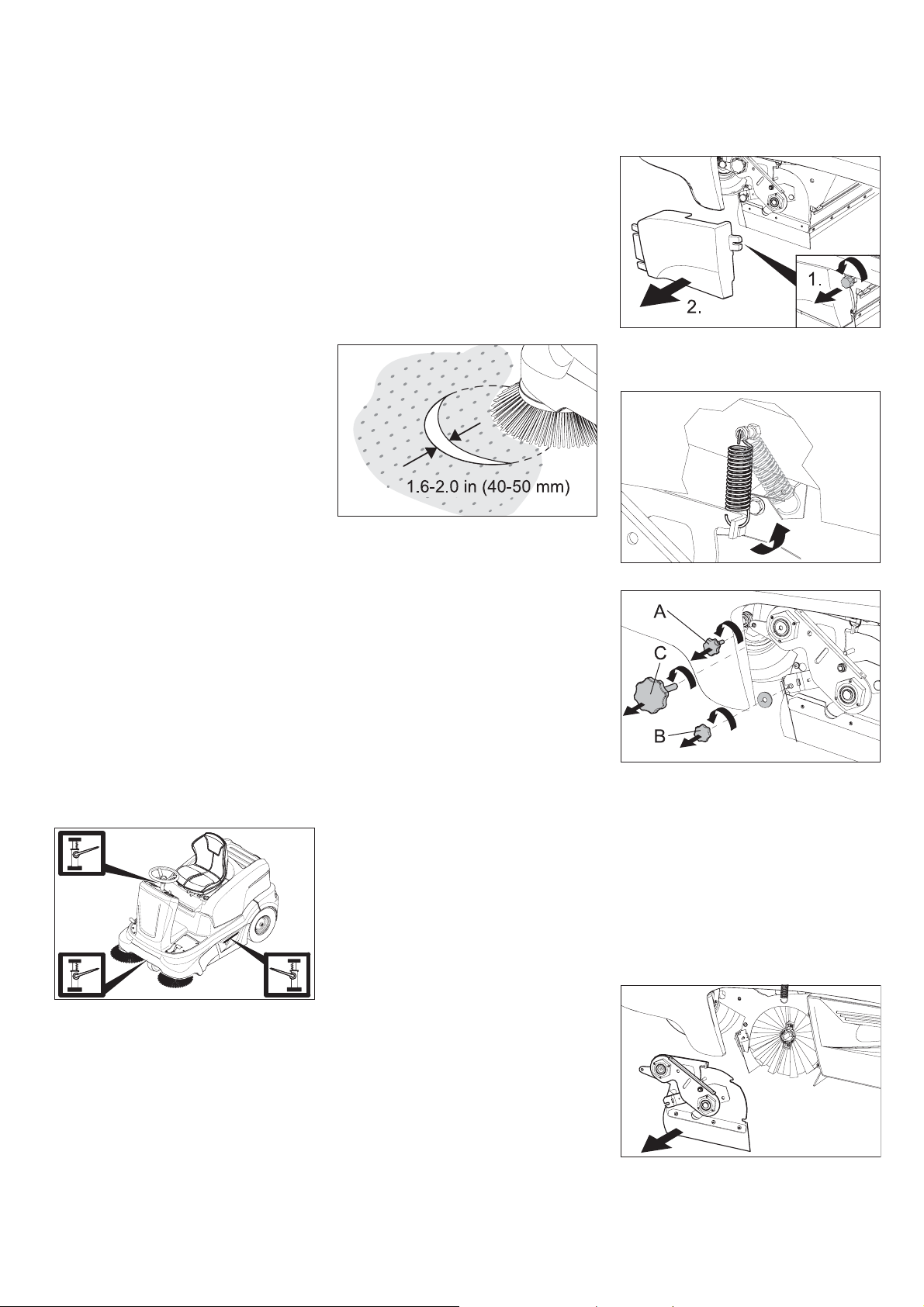

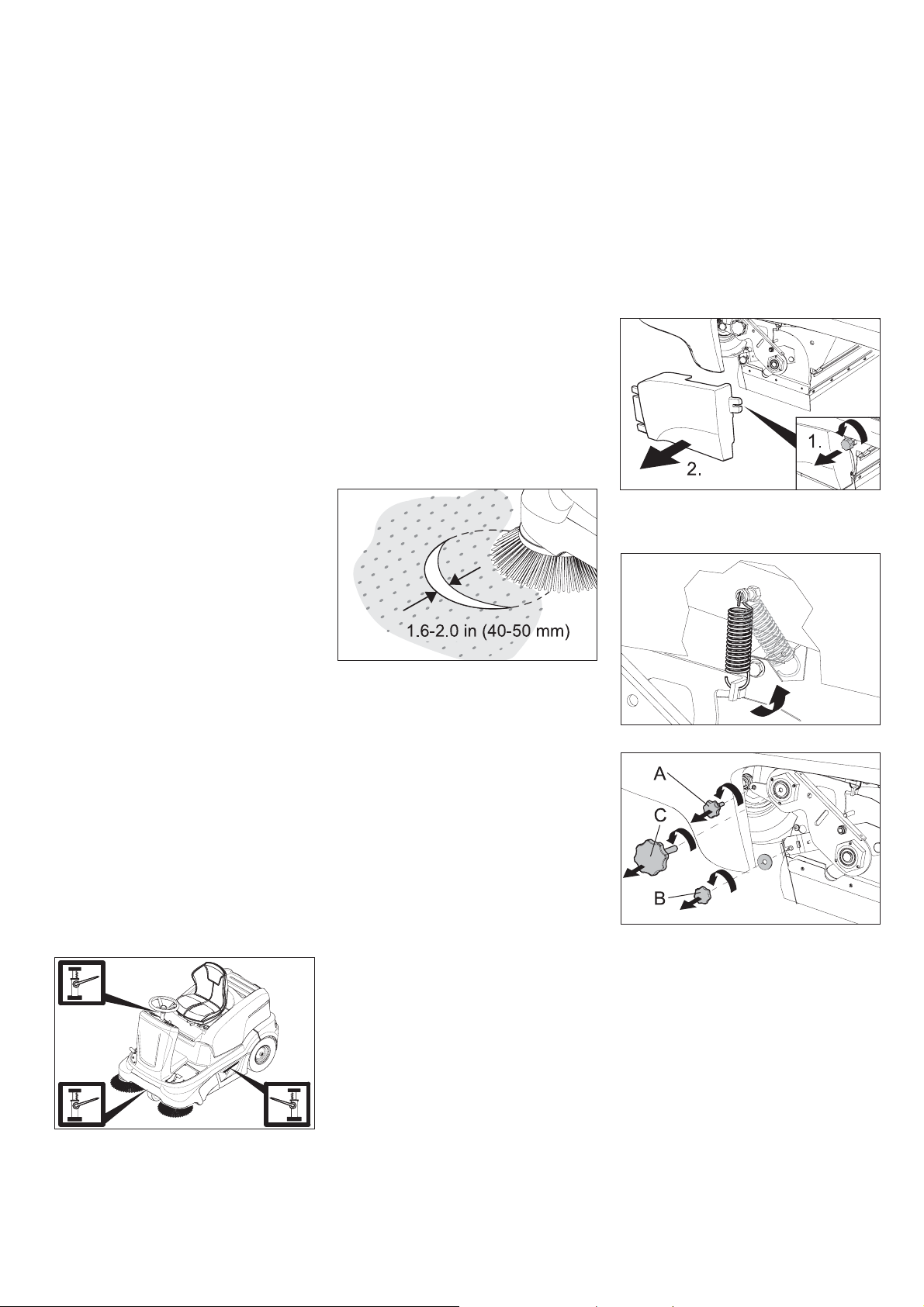

Checking the sweeping mirror of the

side-brushes

Î Check tyre pressure.

Î The side-brushes lift up.

Î Drive sweeper on to a smooth, even

surface covered with a visible layer of

dust or chalk.

Î Lower side-brushes and allow them to

briefly rotate.

Î The side-brushes lift up.

Î Drive machine backwards.

Î Park the sweeper on an even surface.

Î Check sweeping mirror.

The width of the sweeping track should lie

between 1.6-2.0 in (40-50 mm).

Note

The side brush floating mounting adjusts

the sweeping track as the bristles wear

down. The side brush must be replaced if it

becomes too worn.

Replacing side brush

Î Park the sweeper on an even surface.

Î Set programme switch to step 1 (driv-

ing). Side brushes lift up.

Î Turn main key to "0" and remove it.

Î Loosen 3 fastening screws on the un-

derside.

Î Clip side brush on to driver and screw

on.

Checking roller brush

Î Park the sweeper on an even surface.

Î Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Î Turn main key to "0" and remove it.

Î Secure the machine with wheel

chock(s) to prevent it from rolling away.

Î Remove belts or cords from roller

brush.

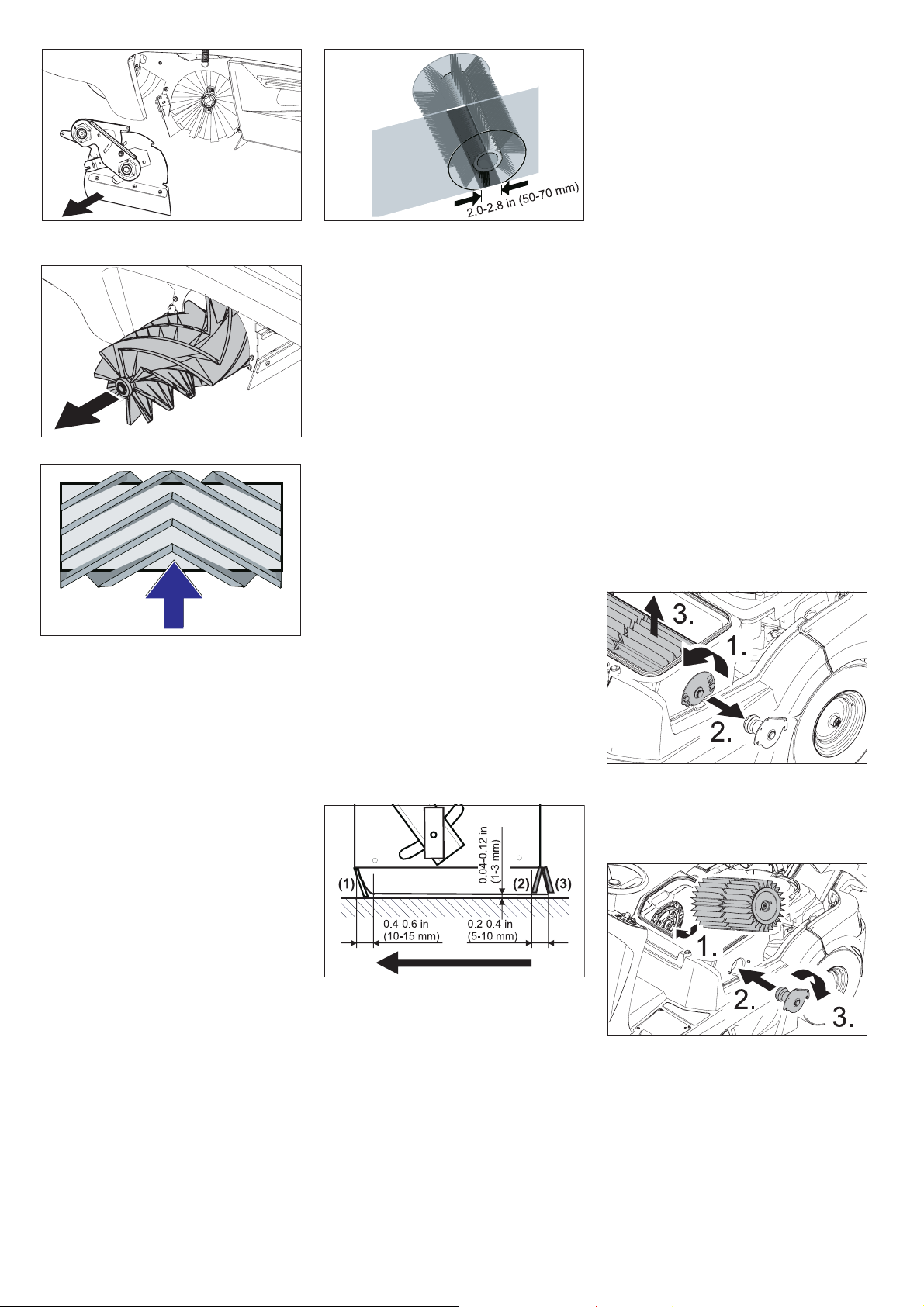

Replacing roller brush

Replacement is due if a visible deterioration in sweeping performance caused by

bristle wear is evident.

Î Park the sweeper on an even surface.

Î Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Î Turn main key to "0" and remove it.

Î Secure the machine with wheel

chock(s) to prevent it from rolling away.

Î Raise slightly the waste container on

the left side and pull it out.

Î Loosen the fastening screw on the left

side-panel.

Î Remove side panel.

Î Unhook pull spring.

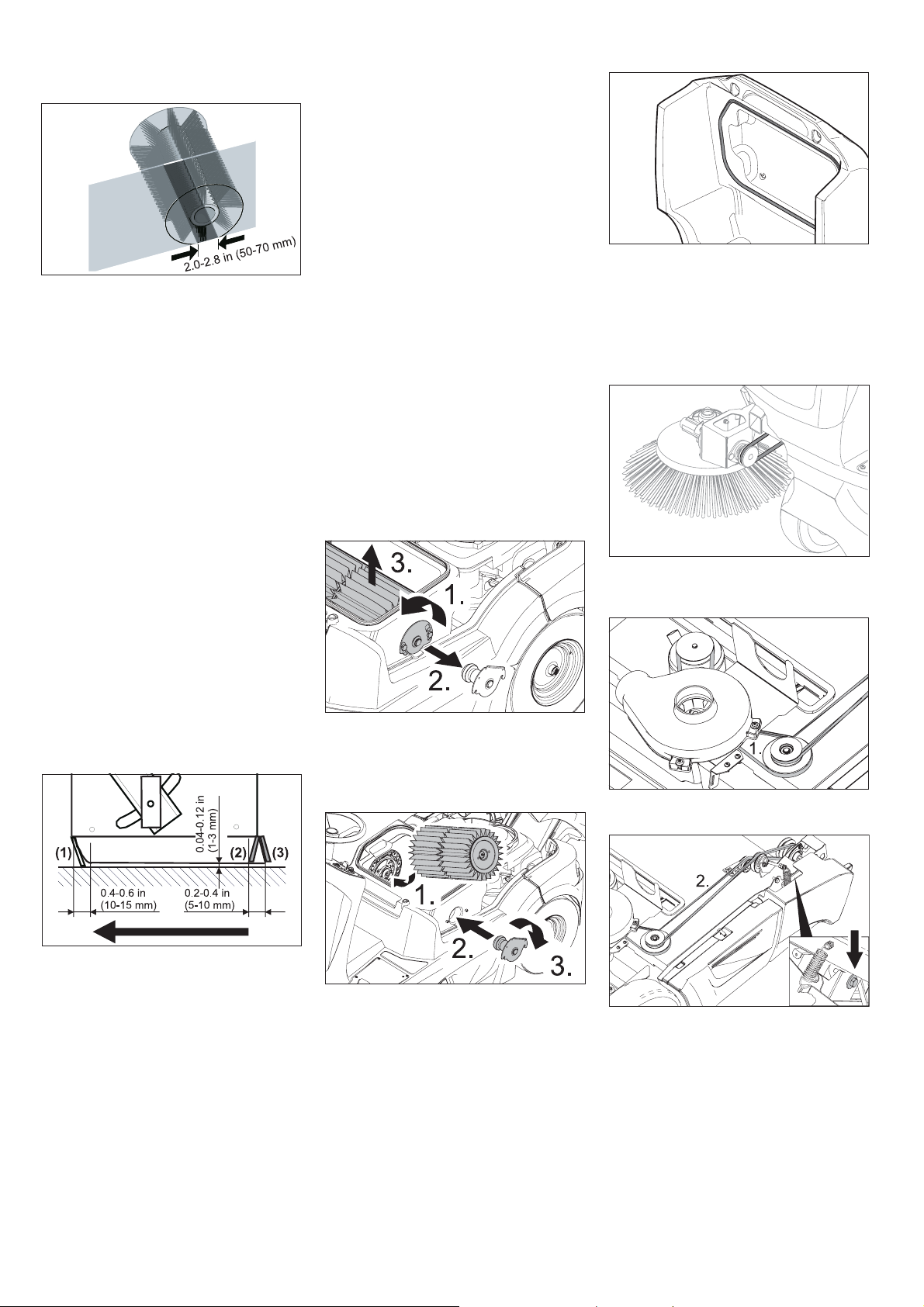

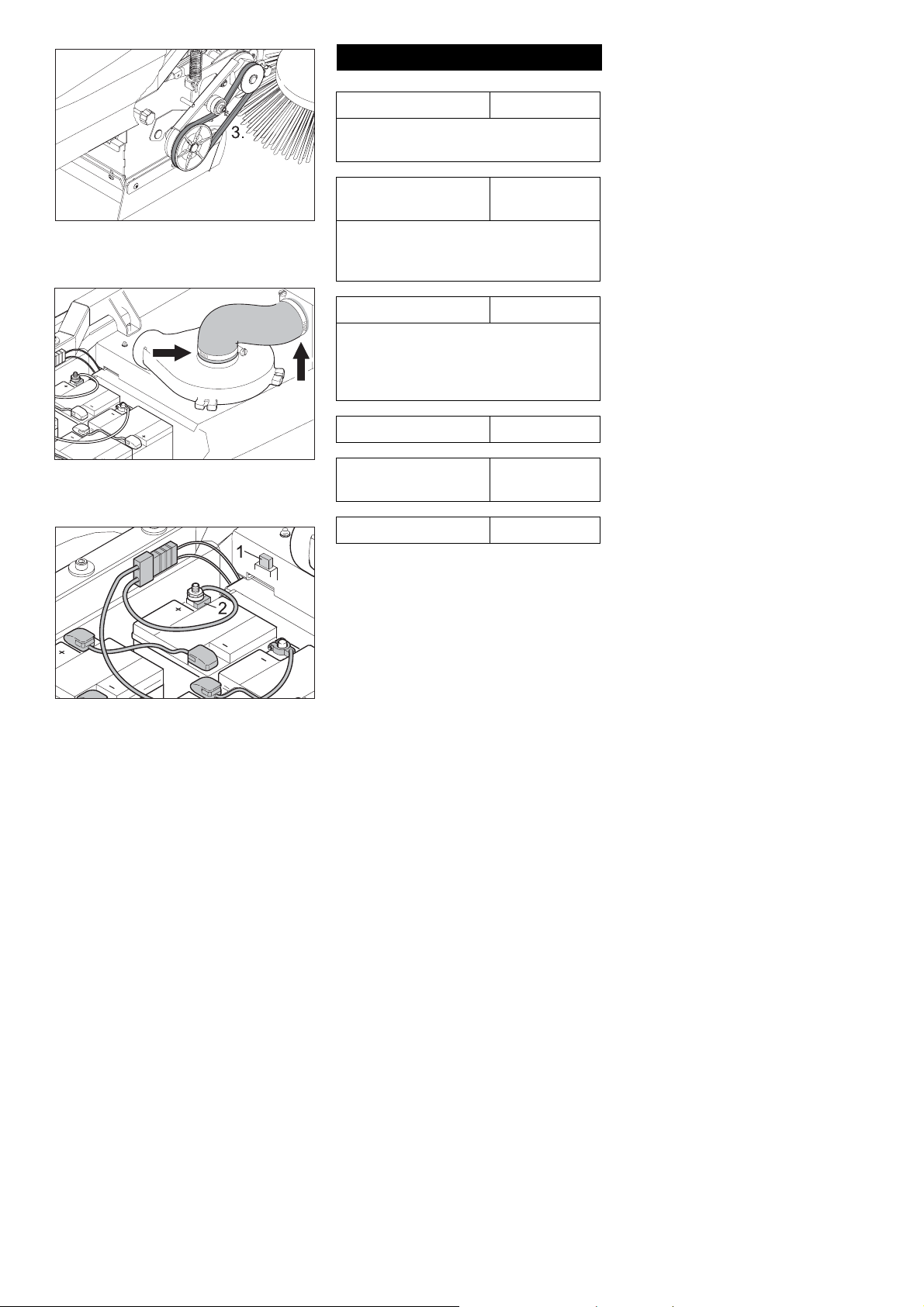

A Fastening screw of the under-pressure

can

B Fastening nut of the bulk waste flap

C Screw of the roller brush crank

Î Unscrew the fastening screws of the

vacuum socket and release the lever.

Î Turn the fastening nut of the bulk waste

flap and unhook the bulk waste flap.

Î Unscrew and withdraw bolt on the roller

brush swinging arm.

Î Push the roller brush cover backwards

and remove it.

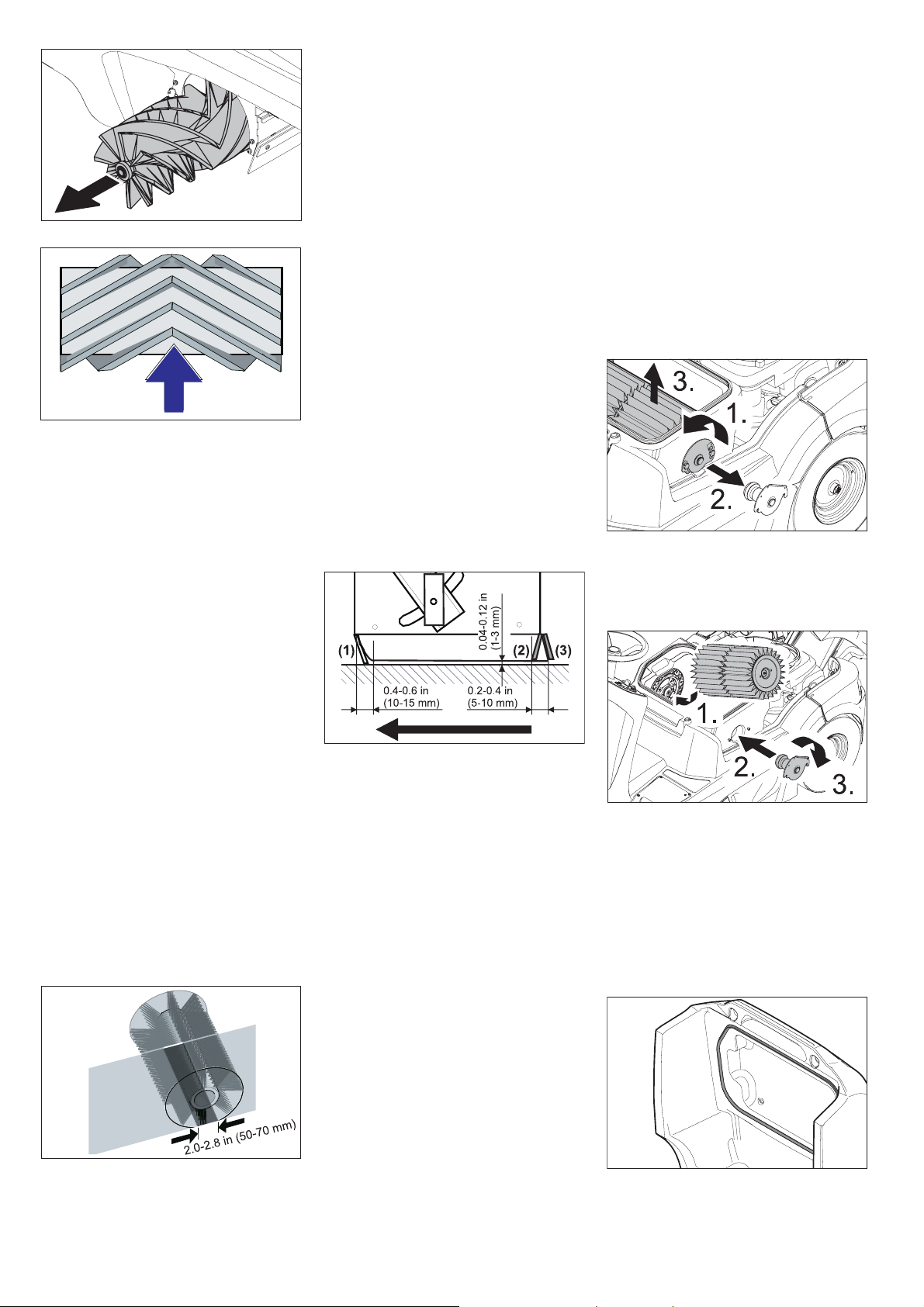

Î Pull out roller brush.

Installation position of roller brush in direction of travel

Î Push new roller brush into the roller

brush housing and onto the drive pin.

Note

When installing the new roller brush, ensure correct positioning of the bristle assembly.

Î Position roller brush cover.

Î Fit the fastening screws and nuts.

Î Hook the draw spring in.

Î Screw on side panel.

Î Push in the waste containers on both

the sides and lock them.

Check the sweeping mirror of the

sweeping roller

Î Set programme switch to step 1 (driv-

ing). The side brush and roller brush are

raised.

Î Drive sweeper on to a smooth, even

surface covered with a visible layer of

dust or chalk.

Î Set programme switch to step 2. Roller

brush is lowered. Slightly press down

on the drive pedal and allow the sweep

brush to briefly rotate.

Î Raise roller brush.

14 English

Page 15

Î Press pedal which raises bulk waste

flap and keep pressed.

Î Drive machine backwards.

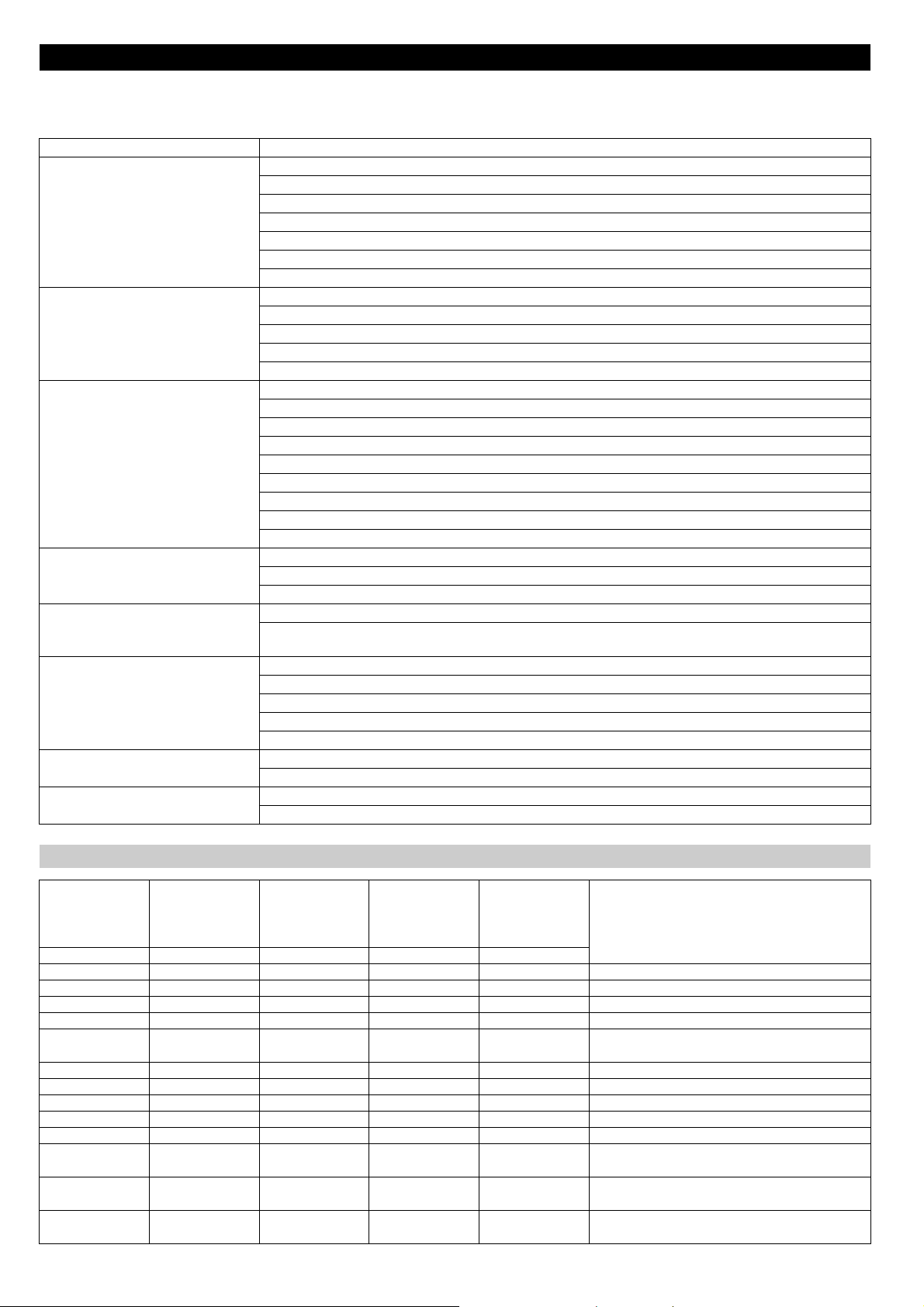

The sweeping track should have an even

rectangular shape which is between 2.0

and 2.8 in (50 and 70 mm) wide.

Note

The side brush floating mounting of the roller brush adjusts the sweeping track as the

bristles wear down. The roller brush must

be replaced if it becomes too worn.

Adjusting and replacing sealing strips

Î Park the sweeper on an even surface.

Î Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Î Turn main key to "0" and remove it.

Î Press emergency-stop button.

Î Secure the machine with wheel

chock(s) to prevent it from rolling away.

Î Raise slightly the waste containers on

both sides and pull them out.

Î Open the fastening screws of the side

panels on both sides.

Î Remove side panels.

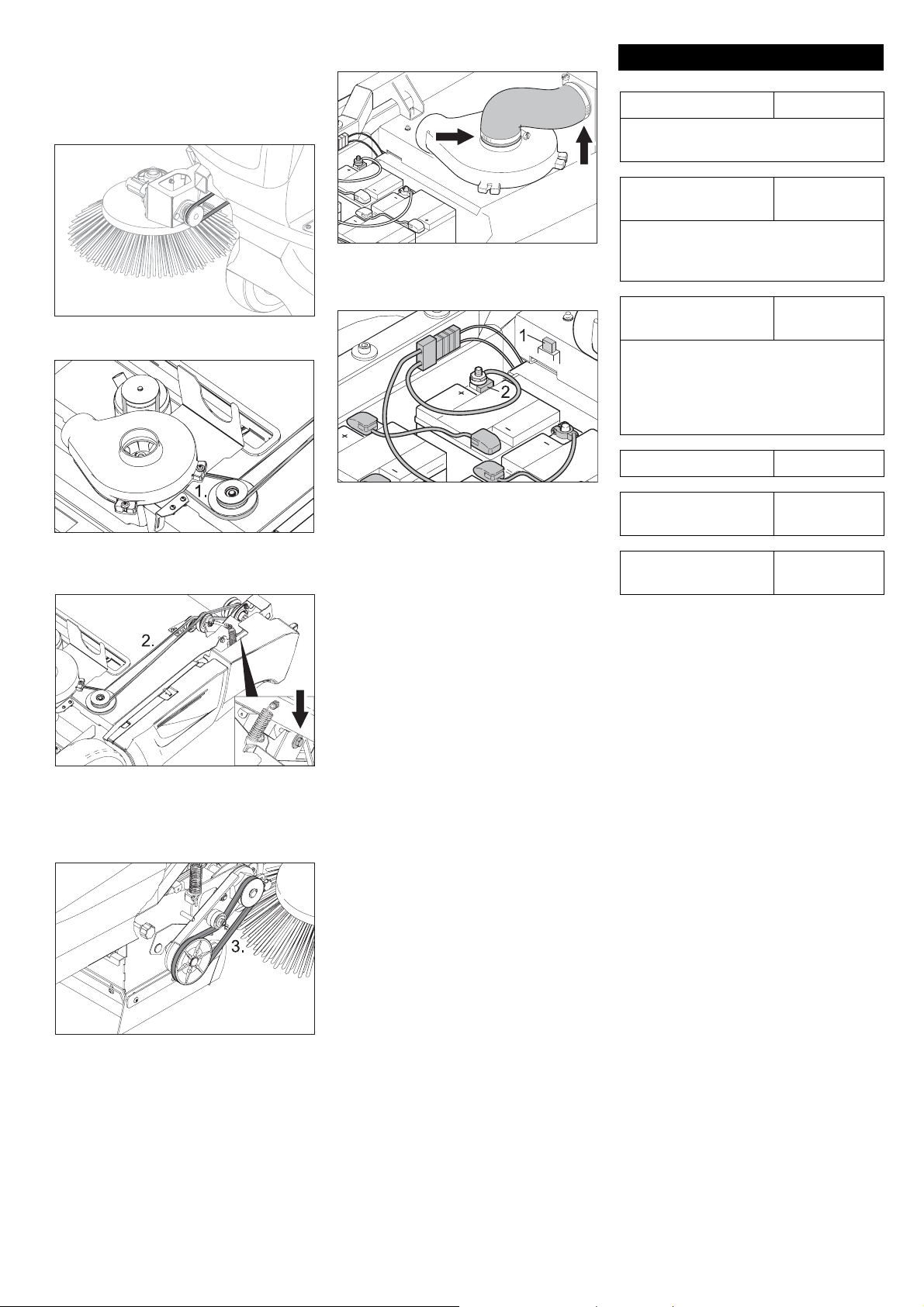

Front sealing flap

Î Loosen retaining nuts for the front seal-

ing strip (1) slightly (to replace, unscrew).

Î Screw on new sealing strip without fully

tightening the nuts.

Î Unscrew retaining nuts for rear sealing

strip (3).

Î Screw on new sealing strip.

Side skirts

Î Slightly loosen retaining nuts for the

side sealing strip (to replace, unscrew).

Î Screw on new sealing strip without fully

tightening the nuts.

Î To set the floor clearance, insert a

sheet with a thickness of between 0.04

and 0.12 in (1 and 3 mm) under the

sealing strip.

Î Adjust side skirt.

Î Tighten nuts.

Î Screw on side panels.

Î Push in the waste containers on both

the sides and lock them.

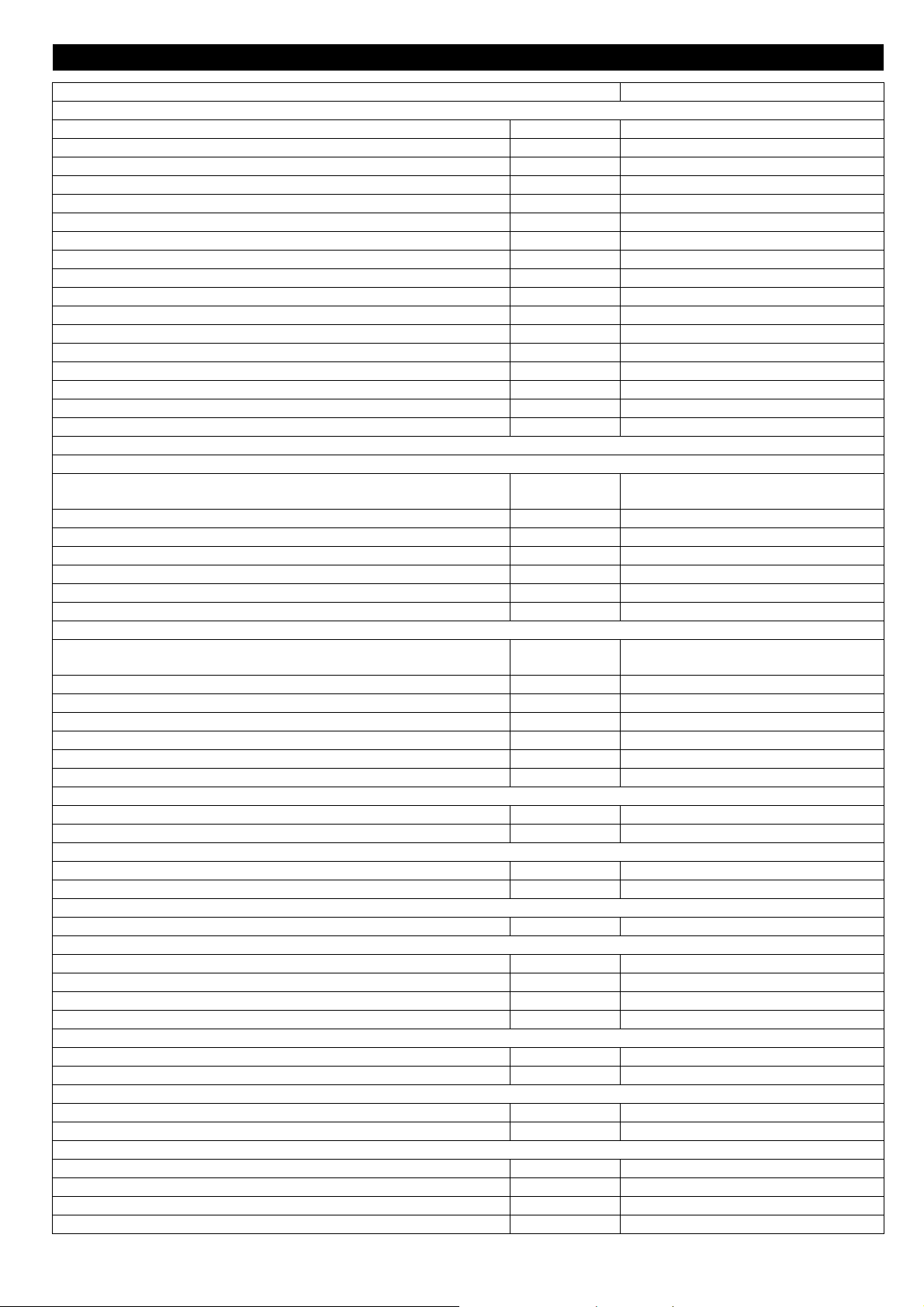

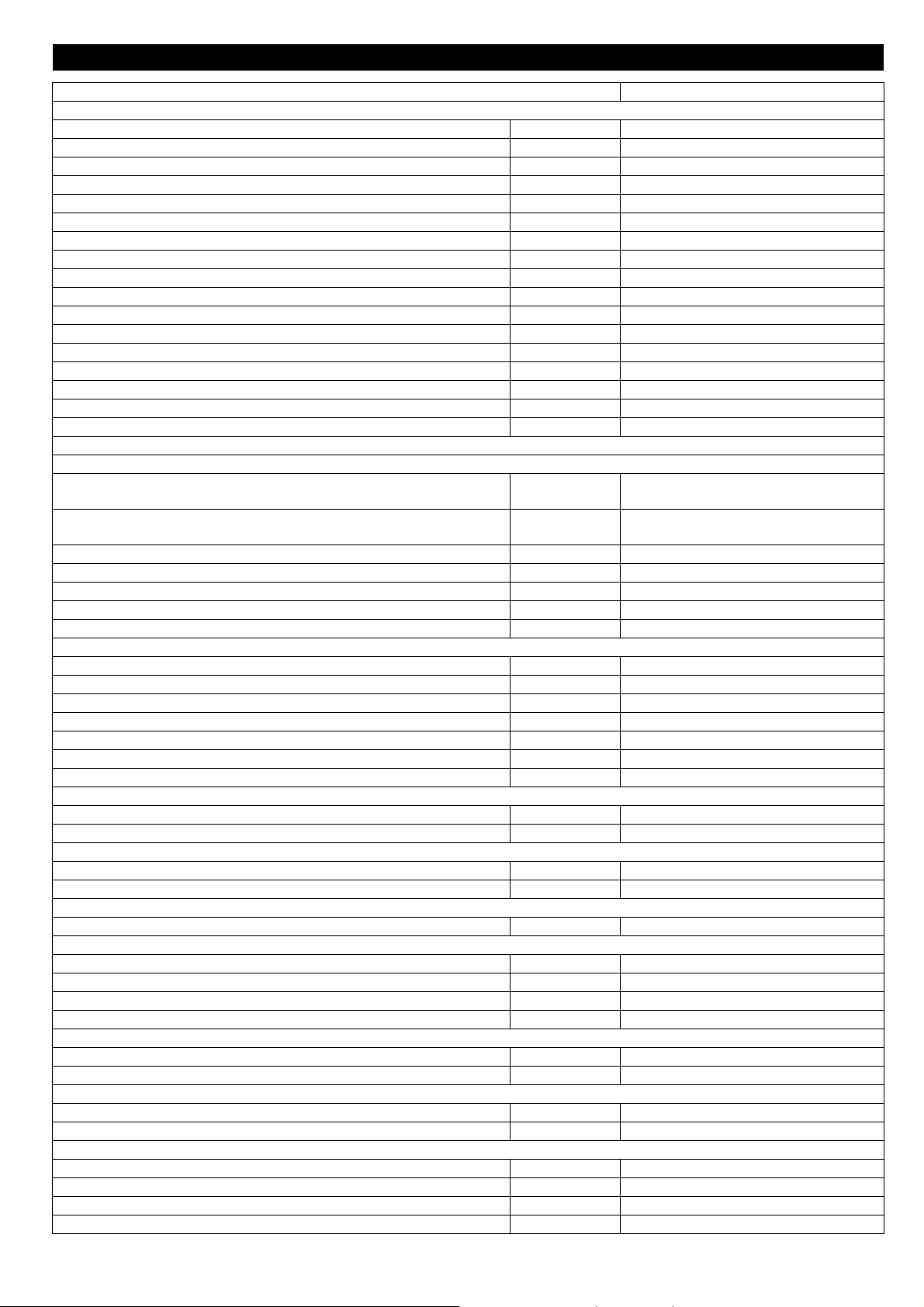

Replacing dust filter

Danger

Empty waste container before replacing

dust filter. Wear a dust mask when working

around the dust filter. Observe safety regulations on the handling of fine particulate

material.

Î Turn main key to "0" and remove it.

Î Press emergency-stop button.

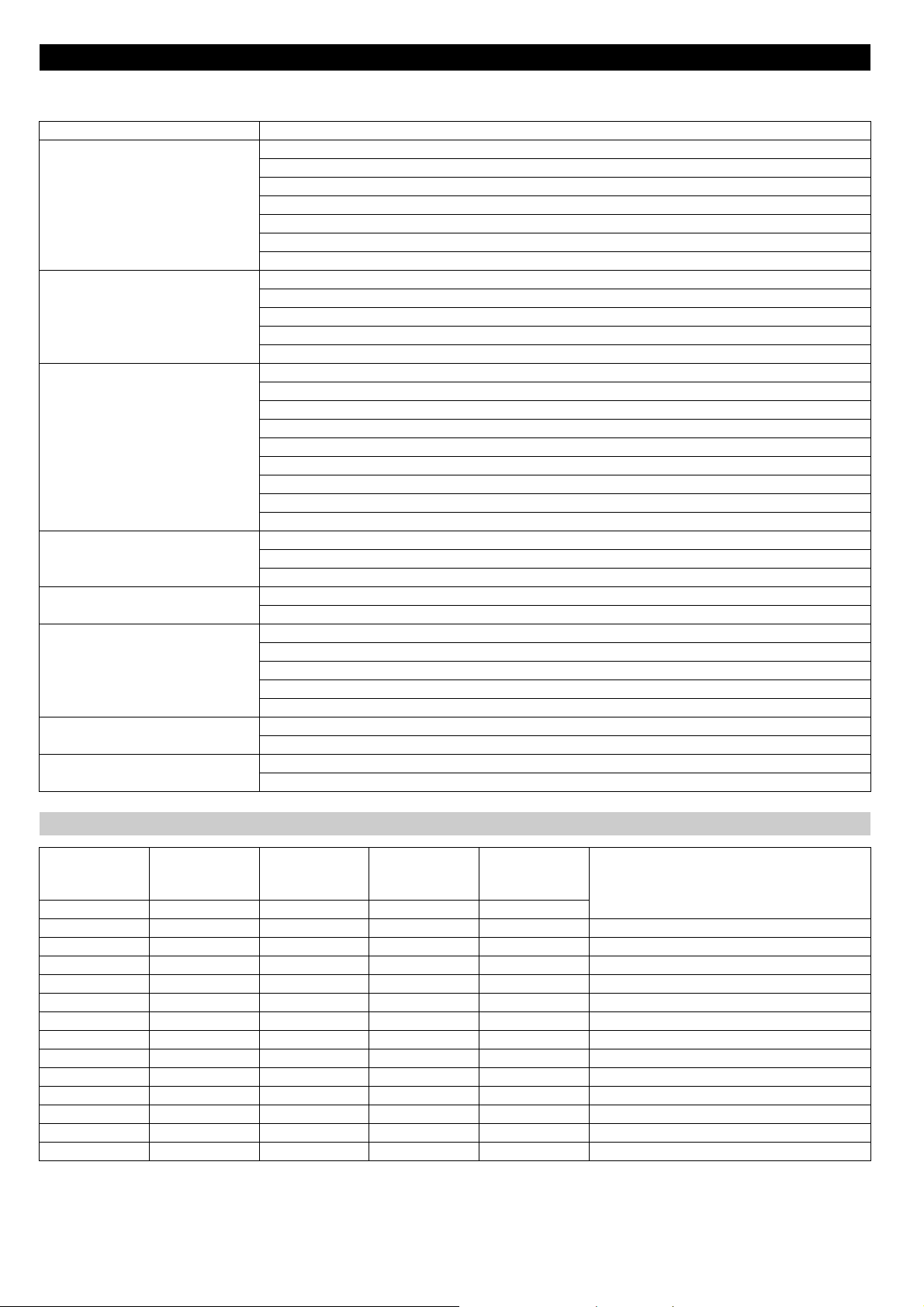

Î Open the device hood.

Î Loosen the fastening screws.

Î Press the filter holder upwards and re-

move it.

Î Remove the lamella filter.

Î Insert new filter.

Replacing filter case seal

Î Lift filter case seal out of groove in the

cover.

Î Insert new seal.

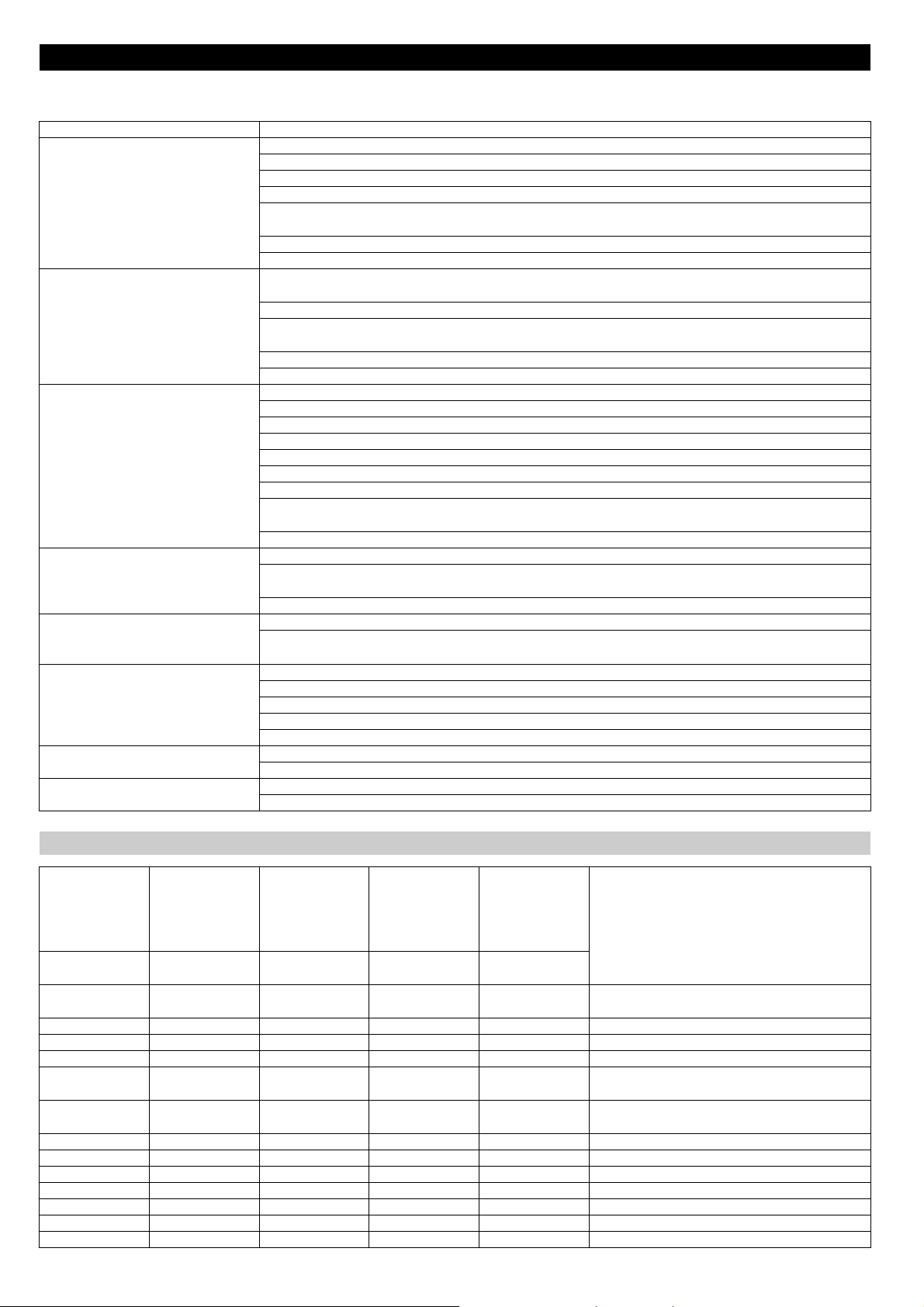

Checking drive belt

Î Turn main key to "0" and remove it.

Î Press emergency-stop button.

Î Open the device hood.

Î Check tension of circular belt of the

side-brush; also check for wear or damage.

Î Check tension, wear and damages on

the V-belt of the sweep roller drive.

Î Adjust side skirt.

Î Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of between 0.4-0.6 in (10-15 mm).

Î Tighten nuts.

Rubber strip

Î If worn, replace.

Î Unscrew retaining nuts for the rubber

strip (2).

Î Screw on new rubber strip.

Rear flap

Î Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of between 0.2 and 0.4 in (5 and 10 mm).

Î If worn, replace.

Î Make sure driver engages with holes on

drive side.

Î Insert the filter holder and press down-

wards.

Î Tighten the fastening screws.

Note

Make sure when installing the new filter

that the fins are not damaged.

Î Check tension, wear and damages on

the V-belt of the sweep roller drive.

Î Tighten the V-belt at the screw if neces-

sary.

English 15

Page 16

Accessories

Side brushes 6.905-626.0

With standard bristles for indoor and outdoor areas.

Standard sweep roll-er4.762-430.0

Î Check tension, wear and damages on

the V-belt of the sweep roller drive.

Check suction blower

Î Check hose at the suction blower for

tightness.

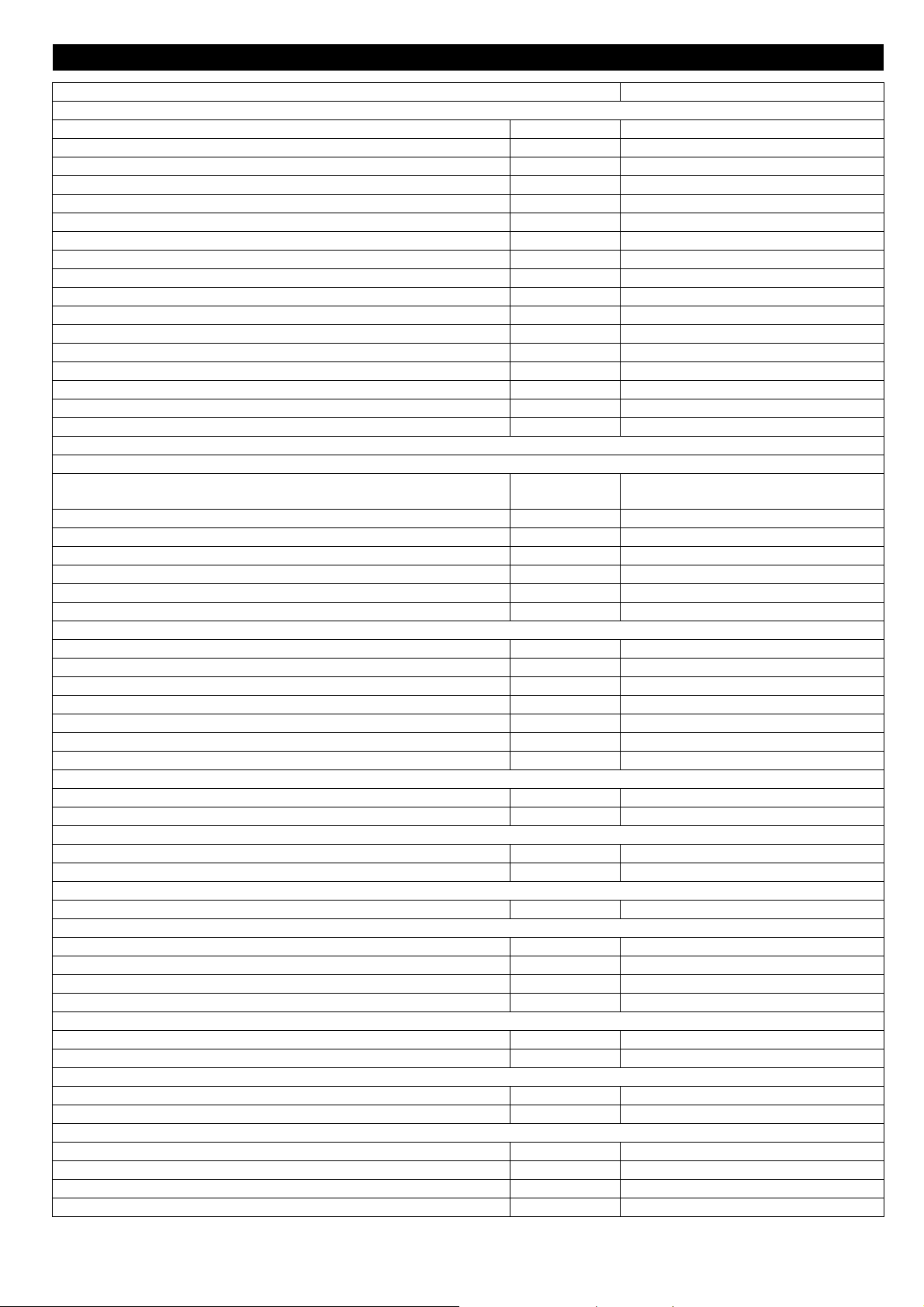

Replacing the fuse

Resistant of wear and moisture. Universal bristles for inside and outside cleaning.

Roller-brush, soft 4.762-442.0

With natural bristles especially for fine

dust sweeping on smooth indoor floors.

Not resistant to wetness; not for abrasive

surfaces.

Dust filter 6.414-576.0

Roller brush, antistatic

Carpet sweeping unit 2.641-665.0

4.762-441.0

1 Automotive flat plug fuse

2Pole fuse

– Replace the automotive flat plug fuse

with the following rating: 1 A (F2) - vacuum pump

Î Replace defective fuse.

Pole fuse

Î Replace defective fuse.

Note

A defective pole fuse may only be replaced

by a Windsor service technician or an authorised expert. If this fuse is defective,

check the usage conditions and the entire

control system.

16 English

Page 17

Troubleshooting

Danger

Risk of injury! Before carrying out any tasks on the machine, set the main key to "0" and remove it. Press emergency-stop button.

Fault Remedy

Appliance cannot be started Sit on the driver seat, the seat contact switch gets activated

Release emergency-stop button

Insert battery plug.

Set main switch to “1”

Check fuse F1, have it replaced by Windsor customer service if required

Check battery; charge it, if needed

Inform Windsor Customer Service.

Machine is not sweeping properly Check roller brush and side brushes for wear, replace if necessary.

Check function of bulk waste flap

Check sealing strips for wear, adjust or replace as required

Check belts of sweeping drive.

Inform Windsor Customer Service.

Dust gathers in the machine Empty waste container

Check suction fan drive belt

Check sealing cover on suction fan

Check hoses of suction blower for absence of leakness.

Check dust filter, clean or replace

Check filter case seal

Close wet/dry flap

Check sealing strips for wear, adjust or replace as required

Inform Windsor Customer Service.

Poor cleaning performance at edg-esReplace side brush

Check sealing strips for wear, adjust or replace as required

Inform Windsor Customer Service.

Side brush or roller brush is not being lowered

Insufficient vacuum performance Check filter case seal

Roller brush does not turn. Remove belts or cords from roller brush

Error code is displayed. Completely switch of the appliance and turn it back on.

Check fuse F2, replace if required.

Inform Windsor Customer Service.

Check sealing cover on suction fan

Check hoses of suction blower for absence of leakness.

Insert lamella filter correct; see Changing dust filter

Inform Windsor Customer Service.

Inform Windsor Customer Service.

If this error recurs, please contact the Windsor customer service department

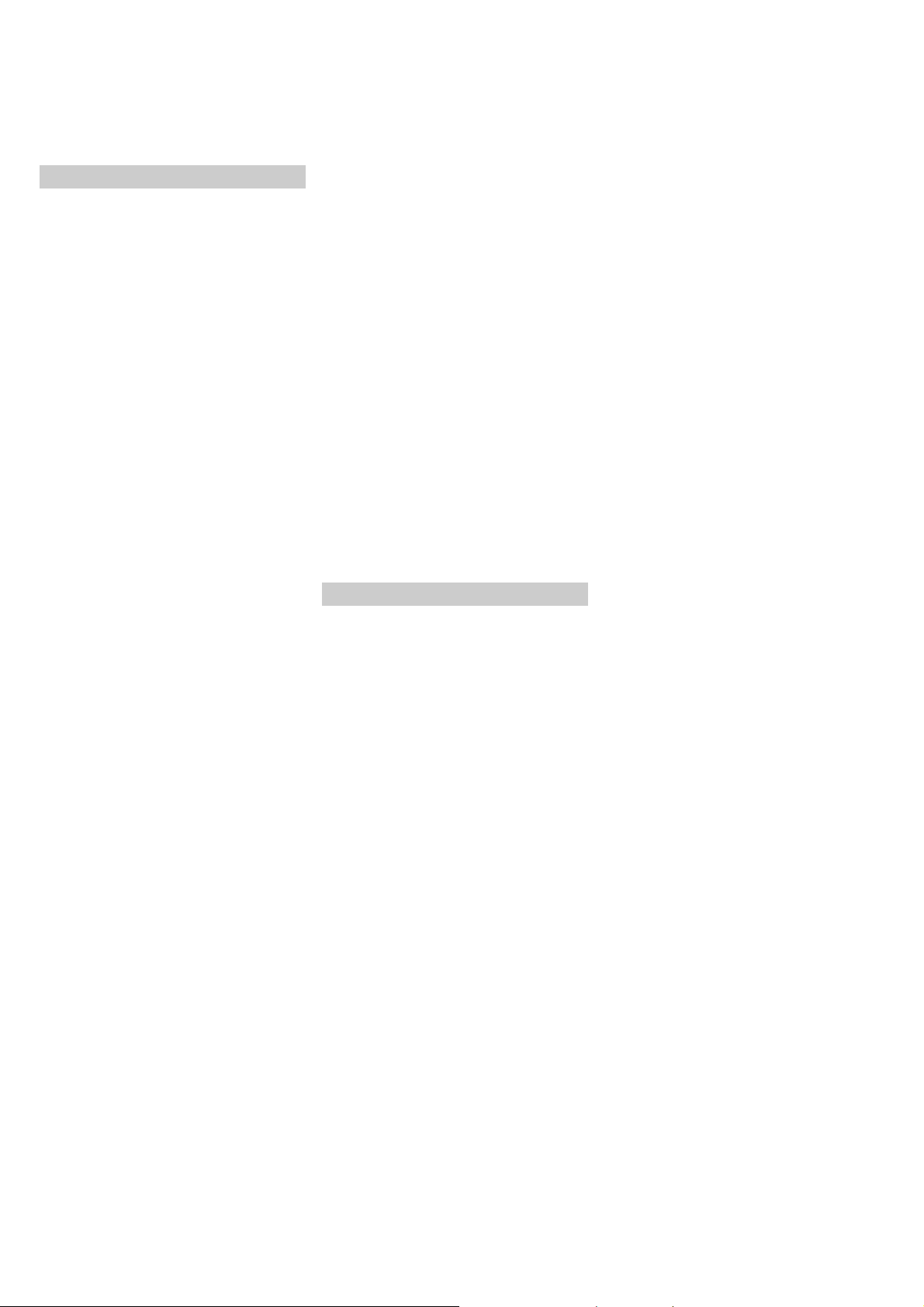

Error code

Indicator lamp service

yellow green/yellow/red red red red

blinking -- -- -- x Press emergency-stop button.

blinking -- -- x -- Overtemperature on the circuit board

blinking -- -- x x Battery voltage defective

blinking -- x -- -- Drive pedal error

blinking -- x -- x Line interruption, electrical consumers

blinking -- x x -- Short circuit, electrical consumers

blinking -- x x x Error while charging

blinking x -- -- -- Performance module defective

blinking x -- -- x Built-in charging device defective

blinking x -- x -- General contactor does not open

Off Not important x -- -- Overload of the filter cleaning

Off Not important -- x -- Overlaod of the drive motor

Off Not important -- -- x Overlaod of the sweep roller

Indicator lamp battery charge

status indicator

Indicator lamp Overload of the

filter cleaning

Indicator lamp overlaod of the

drive motor

Indicator lamp Overload of the

sweep roller

Significance

English 17

Page 18

Technical specifications

RRB 360

Machine data

Length x width x height in (mm) 64.4 x 38.6 x 49.6 (1635 x 980 x 1260)

Unladen weight lbs (kg) 440.9 (200)

Permissible overall weight lbs (kg) 1168.4 (530)

Driving speed mph (km/h) 3.7 (6)

Cleaning speed mph (km/h) 3.7 (6)

Climbing capability (max.) % 12

Roller brush diameter in (mm) 9.8 (250)

Roller brush width in (mm) 24.2 (615)

Side brush diameter in (mm) 16.1 (410)

Surface cleaning performance without side brushes ft

Surface cleaning performance with 1 side brushes ft

Surface cleaning performance with 2 side brushes ft

Working width without side brushes in (mm) 24.2 (615)

Working width with 1 side brushes in (mm) 35.4 (900)

Working width with 2 side brushes in (mm) 46.7 (1185)

Volume of waste container gal (l) 15.8 (60)

Protection type, drip-proof -- IPX 3

Motors

– Drive motor

Type -- Inverse speed motor for forward and re-

Type -- Wheel hub motor in front wheel

Voltage V 24

Rated current A 40

Rated power (mechanical) W 600

Type of protection -- IP 54

Speed 1/min Phaseless

– Sweeping aggregates and blower

Type -- DC permanent solenoid motor

Type -- B14

Voltage V 24

Rated current A 33

Rated power (mechanical) W 600

Type of protection -- IP 20

Speed 1/min 3600

Fuses

Fuse (F1) main fuse A 150

Fuse (F2) vacuum pump A 1

Tyres

Size, rear -- 4.00-8

Air pressure, rear psi (bar) 90 (6)

Brake

Operating brake, emergency brake -- electronic

Filter and vacuum system

Filter surface area, fine dust filte r ft

Category of use – filter for non-hazardous dust -- M

Nominal vacuum, suction system psi (kPa) 0.12 (0.8)

Nominal volume flow, suction system gpm (l/s) 649.1 (41)

Working conditions

Temperature °F (°C) 41...113 (+5...+45)

Air humidity, non-condensing % 0 - 90

Noise emission

Sound pressure level (EN 60704-1) dB(A) 69

Guaranteed sound power level (2000/14/EC) dB(A) 87

Machine vibrations

Vibration total value (ISO 5349)

Arms, steering wheel m/s

Feet, pedal m/s

Seating m/s

2

/h (m2/h) 39720 (3690)

2

/h (m2/h) 58130 (5400)

2

/h (m2/h) 76530 (7110)

verse drive

2

(m2) 43.1 (4.0)

2

2

2

1.15

0.93

0.35

18 English

Page 19

Maintenance Works

After the first month or 5 operating

hours

1 Check the sweeping roller and the side

brush for wear and wrapped belts.

2 Check the sweeping track and the func-

tion of the roller brush and the side

brush.

3 Check tension, wear and tear and func-

tioning of the drive belts.

4 Check moving parts for freedom of

movement.

5 Check functioning of all operating ele-

ments and control lamps.

Every 50 operating hours

1 Check tension, wear and tear and func-

tioning of the drive belts.

2 Check moving parts for freedom of

movement.

3 Check the seal strips on the dust filter

and the function of the filter shaker.

4 Check the gasket in the sweeping area

for position and wear.

5 Check the sweeping track and the func-

tion of the roller brush and the side

brush.

6 Clean and check the dust filter, replace

if necessary.

7 Check the sweeping roller and the side

brush for wear and wrapped belts.

8 Check functioning of all operating ele-

ments and control lamps.

9 Check the washers for wear, replace if

required.

10 Check the ac id level in the batteries

(only for maintenance-free batteries).

Additional maintenance work every 100

operating hours or semi-annually

1 Check current-carrying lines and con-

tacts for damages and oxidation.

2 Check drum brake for function and set-

ting.

3 Check the seal profile on the waste con-

tainer and the brush roller box.

4 Check batteries.

5 Clean the battery surfaces.

6 Check carbon brushes for wear and

tear.

Additional maintenance work every 500

operating hours or annually

1 Replace belt.

2 Replace carbon brushes.

3 Check front wheel for wear, replace if

required.

Only for authorized technicians!

English 19

Page 20

Qualifications de l'opérateur

Seules les personnes formées et habilitées

sont autorisées à utiliser une unité motorisée. Les opérateurs de ces unités doivent

avoir les aptitudes visuelles et auditives

ainsi que les capacités physiques et mentales requises pour utiliser cet équipement en

toute sécurité.

Formation de l'opérateur

– Les personnes n'ayant pas été formées

à l'utilisation des unités motorisées sont

autorisées à se servir de ce type d'appareil uniquement dans le cadre de formations, et ce sous la surveillance

directe d'un formateur. En outr e, les formations doivent être effectuées dans

des zones exemptes de tout obstacle,

d'autres unités et de piétons.

– Le programme de formation doit com-

prendre l'apprentissage du règlement et

des conditions d'utilisation propres au

site dans lequel les utilisateurs feront

usage de l'unité ainsi qu'une initiation à

l'emploi du modèle particulier d'unité qui

sera utilisé. Le programme de formation

sera proposé à tous les nouveaux utilisateurs, quelle que soit leur expérience

antérieure.

Au cours de la formation, le stagiaire sera

informé des points suivants :

A Sa responsabilité principale est d'utili-

ser l'unité en toute sécurité, en respectant les instructions prescrites dans le

cadre du programme de formation.

B L'utilisation incorrecte d'une unité moto-

risée et le non-respect des mesures de

sécurité peuvent provoquer : des blessures graves voire mortelles, l'endommagement de l'unité motorisée ou

d'autres dégâts matériels.

Le programme de formation portera essentiellement sur l'utilisation correcte et en toute sécurité de l'appareil afin d'éviter toute

blessure de l'utilisateur ou d'un tiers et de

prévenir les dégâts matériels. Elle abordera

en outre les aspects suivants :

A Caractéristiques principales de l'unité

ou des unités motorisées que le stagiaire utilisera, incluant :

(1) caractéristiques de l'unité/des unités

motorisée(s), y compris variations entre

les diverses unités présentes sur le poste de travail ;

(2) similitudes et différences avec les

automobiles ;

(3) signification des données de plaque

signalétique, des mises en garde et des

instructions apposées sur l'unité

motorisée ;

(4) consignes d'utilisation et mises en

garde du manuel d'utilisation de l'unité

motorisée et instructions relatives aux

contrôles et opérations d'entretien incombant à l'utilisateur ;

(5) type de force motrice et ses

caractéristiques ;

(6) méthode de conduite ;

(7) méthode de freinage et ses

caractéristiques ;

(8) visibilité avant et arrière ;

(9) caractéristiques de stabilité avec et

sans chargement ainsi qu'avec et sans

accessoires ;

(10) emplacement des commandes,

fonctions, instructions d'utilisation, identification des symboles ;

(11) chargement de la batterie ;

(12) dispositifs de protection et de sécurité pour le type d'unité précis ;

(13) autres caractéristiques de l'unité

précise ;

B Environnement de mise en oeuvre et

ses effets sur le fonctionnement de l'unité incluant :

(1) état du sol, avec prise en compte

des conditions temporaires ;

(2) rampes et pentes ;

(3) dispositifs de chargement de la

batterie ;

(4) allées étroites, portes, câbles aé-

riens, tuyauterie et autres zones difficiles d'accès ;

(5) zones où l'unité est susceptible

d'être utilisée près d'autres unités motorisées, d'autres véhicules ou des piétons ;

(6) utilisation à proximité d'un bord de

quai ou d'un terrain viabilisé ;

(7) d'autres conditions d'utilisation et risques peuvent se présenter.

C Fonctionnement de l'unité motorisée in-

cluant :

(1) contrôle minutieux avant la prise de

poste et méthode appropriée pour la

mise hors service d'une unité motorisée

nécessitant des réparations ;

(2) procédures relatives au stationnement et à l'arrêt ;

(3) autres conditions d'utilisation particulières pour l'application spécifique.

D Règles de sécurité et pratiques relatives

à l'utilisation, notamment :

(1) dispositions de la section "REGLES

DE SECURITE ET PRATIQUES RELATIVES A L'UTILISATION" de ce document.

(2) autres règles, réglementations ou

pratiques précisées par l'employeur

pour l'endroit où l'unité sera utilisée.

E Exercices pratiques d'utilisation,

notamment :

(1) si possible, une utilisation pratique

des unités motorisées doit être effectuée dans une zone éloignée du personnel et de toute autre activité exercée

sur le lieu de travail :

(2) cet exercice pratique sera réalisé

sous la surveillance du formateur ;

(3) il consistera en l'utilisation concrète

de l'appareil ou en des simulations de

toutes les tâches telles que les manœuvres, le déplacement, l'arrêt, le démarrage et autres commandes réalisées

dans des conditions similaires à celles

qui seront rencontrées lors de l'utilisation de l'unité.

Tests, formation de reclassement et

application

A Au cours de la formation, des tests pra-

tiques et tests écrits et/ou oraux seront

proposés par l'employeur pour évaluer

les compétences et les connaissances

du stagiaire et s'assurer qu'elles répondent aux exigences des normes. Les

employeurs pourront déléguer ces tests

à d'autres membres du personnel. Cependant ils en seront toujours responsables. Des archives pertinentes seront

tenues.

B Les utilisateurs devront suivre de nou-

velles formations en cas d'introduction

de nouveaux équipements ou de modifications des équipements existants, en

cas de changement des conditions

d'utilisation ou si leurs performances ne

se révèlent pas satisfaisantes.

C L'utilisateur est tenu pour responsable

du respect des précautions de sécurité

lors de l'utilisation de l'autolaveuse motorisée, conformément aux exigences

de ce manuel.

REMARQUE : des informations sur les formations des utilisateurs sont disponibles