Page 1

V

MODEL: QK32

QQK32

Operating Instructions (ENG)

Mode d’emploi (FR)

Bedienungsanweisung (GER)

Lire attentivement le mode d’emploi avant la mise en service de la machine.

V

IPX4

Read instructions before operating the machine.

Vor Inbetriebnahme der Maschine Bedienungsanweisung lesen.

QUICK 98560 09/14/01

Page 2

OPERATIONS

Machine Data Log........................................2

Table of Contents.........................................1-1

Safety...........................................................2-1

Safety Label Locations.................................2-2

Technical Specifications...............................3-1

Preparing for Operations..............................3-2

Controls........................................................3-3

Machine Operation.......................................3-8

Pre-run Inspection.................................3-8

Starting Machine...................................3-8

Emergency Stop Procedure...................3-8

Filling Machine......................................3-8

Scrubbing Operation..............................3-9

Emptying and Cleaning Tanks ............ 3-10

Machine Transport and Storage................3-11

Towing or Pushing.............................. 3-11

Tie-Downs.......................................... 3-11

Jacking............................................... 3-12

Machine Storage................................3-12

MAINTENANCE

General..................................................... 4-1

Directional Control Systems...................... 4-1

Scrub Head............................................... 4-1

Scrub Brushes.....................................4-2

Scrub Deck Removal........................... 4-3

Scrub Deck Skirt and Side Squeegee..4-3

Squeegee.................................................. 4-3

Squeegee Blades..................................4-4

Replacing/Rotate...................................4-4

Remove Squeegee Tool........................4-4

Adjusting Squeegee.............................. 4-5

Drive Chain ...............................................4-6

Brakes....................................................... 4-6

Tires and Wheels...................................... 4-6

Vacuum Motor...........................................4-6

Batteries.................................................... 4-7

To Charge Batteries...............................4-8

To Install Batteries.................................. 4-8

To Remove Batteries..............................4-9

Fuse Link ..................................................4-9

Service Schedule...................................... 4-10

Machine Troubleshooting..........................4-11

Propelling System Troubleshooting........... 4-12

User Stocking List.....................................4-13

Electrical Schematic..................................4-14

TABLE OF CONTENTS

PARTS LIST

Battery Group...........................................5-1

Brake Group.............................................5-3

Circuit Breaker Group............................... 5-5

Electrical Components Group...................5-7

Floor Group.............................................. 5-9

Front Wheel Group................................... 5-11

Pedal Group .............................................5-13

Rear Wheel Group.................................... 5-15

Safety Switch Group................................. 5-17

Recovery Tank Group...............................5-19

Scrub Brush/Pad Driver Group................. 5-21

Scrub Head Group.................................... 5-23

Side Squeegee Group.............................. 5-25

Scrub Head Lift Group.............................. 5-27

Seat Group...............................................5-29

Solution Tank Group................................. 5-31

Solution Control Group.............................5-33

Squeegee Group......................................5-35

Squeegee Lift Group.................................5-37

Decal Group............................................. 5-39

Touch Pad Group.....................................5-41

Vacuum Group .........................................5-43

Steering Group.........................................5-45

Wiring Group............................................ 5-47

Front Harness...........................................5-51

Drive Motor/Touch Pad Harness............... 5-53

Rear Main Harness................................... 5-55

Touch Pad Harness/Touch Pad................ 5-57

Warranty................................................... 5-59

QUICK 98560 09/29/00

1-1

Page 3

SAFETY

The following symbols are used throughout this

guide as indicated in their descr ipt ions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified

by signal words-WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined

by the following definitions:

! WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practices which could

result in minor personal injury or product or property

damage.

FOR SAFETY: To Identify actions which must be

followed for safe operation of equipment.

Report machine damage or faulty operation

immediately. Do not use the machine if it is not in

proper operating condition. Following is information

that signals some potentially dangerous conditions

to the operator or the equipment. Read this

information carefully. Know when these conditions

can exist. Locate all safety devices on the machine.

Please take the necessary steps to train the

machine operating pers onne l.

FOR SAFETY:

DO NOT OPERATE MACHINE:

• Unless Trained and Authorized.

• Unless Operation Guide is Read and

understood.

• In Flammable or Explosive areas.

• In areas with possible falling objects.

• Before use all covers and doors shall be put in

the positions specified on the instructions.

WHEN USING MACHINE:

• Use caution when backing when backing

machine.

• Do nut carry riders on the machine.

• During operation attention shall be paid to other

persons, especially children.

• Always follow basic safety an d traffic rules.

• Go slow on slippery surfaces and grades.

• When leaving unattended, secure against

unintentional movement.

WHEN SERVICING MACHINE:

• Avoid moving parts. Do not wear loose clothing;

jackets, shirts, or sleeves when working on the

machine.

• Block machine tires before jacking machine up.

• Use hoist or jack of adequate capacity to lift

machine.

• Disconnect battery connections bef or e work ing

on machine.

• Avoid contact with battery acid.

• Use Windsor supplied replacement parts.

! CAUTION

This machine is not suitable for picking up

health endangering or hazardous dust.

! WARNING

This appliance has been designed for use with

the brushes specified by the manufacturer. The

fitting of other brushes may affect its safety.

! WARNING

Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away.

Keep covers open when charging.

! WARNING

Flammable materials or reactive metals can

cause explosion or fire. Do not pick up these

materials.

! WARNING

Hazardous voltage. Shock can result.

Disconnect batteries before working on machine.

Only qualified personnel should work inside

machine.

! WARNING

Machine can emit excessive noise. Consult with

your regulatory agency for exposure limits.

Hearing loss can result. Wear hearing

protection.

! CAUTION

This machine is not approved for use on public

paths or roads.

BEFORE LEAVING OR SERVICING MACHINE:

• Stop on a level surface.

• Set the parking brake.

• Turn off the machine.

• Remove key from switch.

2-1

QUICK 98560 09/20/99

Page 4

SAFETY LABEL LOCATION

NOTE: These drawing indicate the location of safety labels on the floor scrubber. If at any time, the labels

become illegible contact your Windsor representative for prompt replacement.

TOP VIEW WITH COVER OPEN

CAUTION

Explosive Gas Is Given Off

By Batteries During Charge.

1. Keep Battery Compartment

Cover Open.

2. No Smoking, Flame Or

Sparks In Area.

3. Charge Only In Well

Ventilated Area.

BATTERY CAUTION 80885

MANUAL DECAL 50776

FOR SAFETY

1. Do Not Operate Machine:

-Unless Trained And Authorized.

-Unless Operation Manual Is Read.

And Understood.

-In Flammable Or Explosive Areas.

-In Poorly Ventilated Areas.

2. Do Not Raise Hopper:

-Unless Machine Is On A Level

Surface.

-Unless Main And Side Brooms

Are Turned Off.

3. Do Not Use Flammable Cleaning

Agents.

4. Check For Fuel Leaks

5. Go Slow On Grades And Slippery

Surfaces.

6. Before Leaving Machine:

-Stop On Level Surface.

-Turn Off Key And Set Parking

Brake.

-When Parking Remove Key.

7. Use Quadra Company Supplied Or

Equivalent Replacement Parts.

SAFETY DECAL 80814

PARKING BRAKE

DECAL 82802

SAFETY DECAL 81505

WARNING

Flammable

Materials Can

Cause Explosion

Or Fire.

Do Not Pick Up

Flammable

Materials.

SAFETY DECAL 81494

WARNING

Flammable

Materials Can

Cause Explosion

Or Fire.

Do Not Use

Flammable

Materials In Ta n k.

QUICK 98560 09/20/99

2-2

Page 5

TECHNICAL SPECIFICATIONS

ITEM DIMENSION/CAPACITY

Normal Power 2.8 kW

Rated Voltage 24 VDC

Rated Amperage 115 amps

Batteries 4 x 6 volt 250-250 A/H

Scrub Brush Motors 2 x .75 hp (0.56 kW)

Vacuum Motors 1 x .75 hp (0.56 kW) Standard, second motor optional

Propelling Motor .75 hp (0.56 kW)

Mass (GVW) 1780 lbs. (810 kg)

Weight empty without batteries 810 (302 kg)

Solution Control Gravity feed, fully variable with automatic shut off in neutral.

Solution tank capacity 30 gal. (113.5 liter)

Recovery tank capacity 30 gal. (113.5 liter)

Scrub brush 2 dia. X 16 in. (5 cm x 40.5 cm)

Scrub brush pressure 0-150 lbs. (0-68 kg) 4 automatic pressure settings

Scrub brush speed 200 rpm

Tires (QK32)

(QQK32)

Foundation Pressure (at recommended tire psi) 35 lbs/in.²

Maximum Speed 3.7 miles/hour (5.95 km/hour)

Coverage 46,200 ft² /hour @ 3.5 mph with 2 in. overlap

Frame construction Welded cold rolled steel and steel plated

Brakes Self centering mechanical 8 in. (20.3 cm) disc with hand lock

Minimum aisle u-turn width 66 in (168 cm)

Steering Rack and Pinon

Ramp climbing 7.5 degrees

Height 53 in. (135 cm)

Length 61 in.(155 cm) without counterweighed bumper

Length 64 in. (163 cm) with counterweighted bumper

Width without squeegee 37.75 (96 cm)

Width with squeegee 41 in (104 cm)

Width of scrub path 32 in. (81 cm)

12 in. (30.5 cm) pneumatic non-marking standard

12 in. (30.5 cm) Black Knobby Foam Fill

parking brake.

LENGTH

The sound pressure level at the operators ear

was measured to be 73 dBA. This was a

nearfield, broad-band measurement taken in a

typical commercial environment on a tile floor .

This appliance contains no possible source of

impact noise. The instantaneous sound

pressure level is below 63 Pa.

3-1

HEIGHT

WIDTH

The weighted root mean square acceleration at

the operator’s arms was measured to be below

2.5 m/s² . This was a tri-axial, third-octive band

measurement made during normal operation on

a composite tile floor. The measurement and

related calculations were made in accordance

with ANSI S3.34-1986.

QUICK 98560 03/17/01

Page 6

PREPARING FOR OPERATION

The machine has been delivered to you by your

dealer serviced and ready for operation. Should any

discrepancies exist contact your dealer immediately.

BEFORE OPERATING THE QUICK©

1. Before operating check the machine for any

shipping damage. Report any damage to your

dealer.

2. Complete the machine data sheet on page 2.

3. Read this manual carefully before operating or

servicing the machine.

! CAUTION

Do not operate machine unless operation manual is

read and understood.

! CAUTION

Wear safety glasses when servicing the

batteries. Avoid contact with battery acid.

4. Check the electrolyte level of the batteries. See

“Batteries” in the Maintenance section.

5. Check the specific gravity of the batteries to

determine the charge for the batteries. See

“Batteries” in the Maintenance section.

6. Check for proper connection of the

batteries/battery to machine.

7. Check squeegee wheels for free movement.

8. Check the squeegee for proper adjustment.

9. Check for proper brush installation.

10. Check the scrub head side squeegee for proper

installation and adjustment.

11. Check tires for damage and proper inflation.

QUICK 98560 09/20/99

3-2

Page 7

CONTROLS

Q

X

K

S

R

P

F

G

A

A. Key Operated Switch

B. Directional Control Pedal

C. Brake Pedal

D. Parking Brake

E. Comfort Zone Operators Seat

F. Brush Motor/Lift Switch

G. Squeegee/Vacuum Motor Switch

H. Solution Control

I. Emergency Stop Button

J. Hour Meter

K. Battery Condition Indicator

L. Steering Wheel

M

CONTROL PANEL QUICK

M. Horn Button

N. Circuit Breakers

O. Fuses

P. Bru sh Pre ssu r e Swit ch

Q. Optional Pump Switch

R. Brush Circuit Breaker Monitor

S. Full Recovery Tank Indicator

T. Solution Tank Cover

U. Recovery Tank Drain Hose

V. Lid

W. Solution Tank Drain Hose

X. Recycle Option Switch

3-3

QUICK 98560 09/20/99

Page 8

CONTROLS

T

Q

R

O

X

H

N

B

L

V

E

W

I

D

J

U

C

QUICK 98560 09/20/99

3-4

Page 9

CONTROLS

A. KEY OPERATED SWITCH

The key switch controls the power for machine

functions. All touch panel switches are controlled by

the key switch. To operate the machine, turn the

key clockwise. To turn off the machine, turn the key

counter-clockwise. Turning off the key switch will

immediately stop the brushes, vac u um motors,

optional recycle pump, and also stop the actuators

for the deck and squeegee.

NOTE: Turning the key switch off during normal

running operation will stop all motors and actuators.

When the key is turned back on the system will

assume they are in the normal parked mode (s cr ub

deck up, squeegee up, and motors off). Any touch

panel command will send the selected system to the

working position regardless of the position it was in

when the key switch was turned off. This is normal

and will not damage machine.

FOR SAFETY: Always remove the key when

machine is unattended or during service to

prevent unauthorized movement.

B. DIRECTIONAL CONTROL PEDAL

This pedal controls the direction of travel and the

speed of the vehicle.

D. PARKING BRAKE

The parking brake lever is located on the left side of

the steering pedestal. With the service brakes fully

applied pulling the lever toward the operator then

releasing the brake pedal sets the parking brake. To

release the parking brake simply tap the brake

pedal.

FOR SAFETY: Always park on a level surface,

turn the machine off, and set the parking brake

before leaving the machine of before servicing

the machine.

E. COMFORT ZONE OPERATOR SEAT

F. BRUSH MOTOR/LIFT SWITCH

One touch on the control panel “brush” switch

automatically lowers the scrub head to the “light

Scrub” position, turns on both brush drive motors,

turns on the vacuum motor, and lowers the

squeegee. Three sets of LED’s will light on the

touch panel. The first, indicates the brush pressure

setting. The second, shows that the brush motors is

lowering. The third lights to show the vacuum motor

has been activated as well as the squeegee.

Touching the switch again turns off the brushes and

returns the scrub deck to the up position. The two

LED indicators are turned off. Also the squeegee

will raise after a delay of 15 seconds and in an

additional 15 seconds the vacuum motor will turn off.

If the scrub deck is lowered without brushes installed

the brush motors will stop, the deck will raise and all

four of the brush pressure LED’s will flash

continuously until the brush s witc h has been

pressed once again.

Slowly pressing the front of the pedal causes the

machine to travel forward. Pressing the rear of the

pedal causes the vehicle to travel in reverse. The

vehicle speed can be controlled by varying the

pressure on the front of the pedal.

FOR SAFETY: the vehicle can coast for a short

distance after releasing the directional pedal.

Remove food from pedal and use brakes to slow

or stop the machine.

C. BRAKE PEDAL

The brake pedal is located on the floor to the left

side of the steering column. This pedal operates the

disc brake on the two front wheels. To slow or stop

the vehicle, apply pressure to the brake pedal.

3-5

QUICK 98560 09/20/99

G. SQUEEGEE/VACUUM MOTOR SWITCH

A touch panel switch (with LED indicator) lowers the

squeegee and turns on the vacuum motors. This

switch will also shut off the vacuum motor/motors

and raise the squeegee if double scrubbing is

required. The LED will light when the squeegee is in

the down position. Pressing the switch again raises

the squeegee fully and turns off the vacuum motors

after approximately 15 seconds.

H. SOLUTION CONTROL

The slide lever mounted to the electric panel

controls the solution flow to the scrub deck. Pushing

the lever toward the down position allows full flow to

the floor. Pulling the lever to the up position

gradually reduces flow to full off. If the brush motors

are turned off a secondary valve automatically

interrupts the flow until the motors are turned on

again. This feature aides in preventing an

unintentional draining of the solution tank and allow

the operator to adjust the amount of solution to the

floor without resetting each time the scrubbing

operation is interrupted.

Page 10

I. EMERGENCY STOP BUTTON

The emergency stop switch controls all battery power

to the machine. In an emergency that requires quick

disconnection of the batteries, push down firmly on

the red knob.

NOTE: The emergency disconnect should only be

used for emergencies and service. Repeated nonessential use well shorten the life of the connector.

Also, when all power is removed from the machine

the battery condition meter resets to a less than

accurate full charge position when power to restored.

CONTROLS

L. STEERING WHEEL

The steering wheel turns the front wheels of the

machine causing the machine to turn.

M. HORN BUTTON

The horn button is located at the bottom of the touch

panel. The horn is activated by pressing the horn

button.

J. HOUR METER

The hour meter located at the rear of the touch panel

records the number of hours the machine has been in

operation with the scrub brushes running. This

information is useful in determining when to service

the machine

K. BATTERY CONDITION INDICATOR

The battery condition 6 LED’s indicated the present

charge of the battery. When only the LED near the

left side of the gauge is on, the batteries should be

recharged. Further operation of the machine could

damage the machine or batteries. The LED second

from left indicates 80% discharge signaling ideal time

to recharge batteries. The remaining 4 LED’s

indicate the approxim ate charge le ve l of the batteries .

When the machine is left overnight with less than a

full charge, the display may initially indicate a full

charge. It will also indicate a full charge if the

batteries are disconnected, than reconnected. After

a few minutes of operation the gauge will give the

correct charge level.

NOTE: See “Batteries” in maintenance section for

more information on battery maintenance.

N. CIRCUIT BREAKERS

The circuit breakers are circuit protection devices

designed to interrupt the flow of current in the event

of an electrical overload. When tripped, the circuit

breaker must be reset by pressing the exposed

button on the face of the affected circuit breaker. All

circuit breakers are located on the right side of the

electrical panel. If the circuit breaker continues to

trip, the cause of the electrical overload should be

found and corrected.

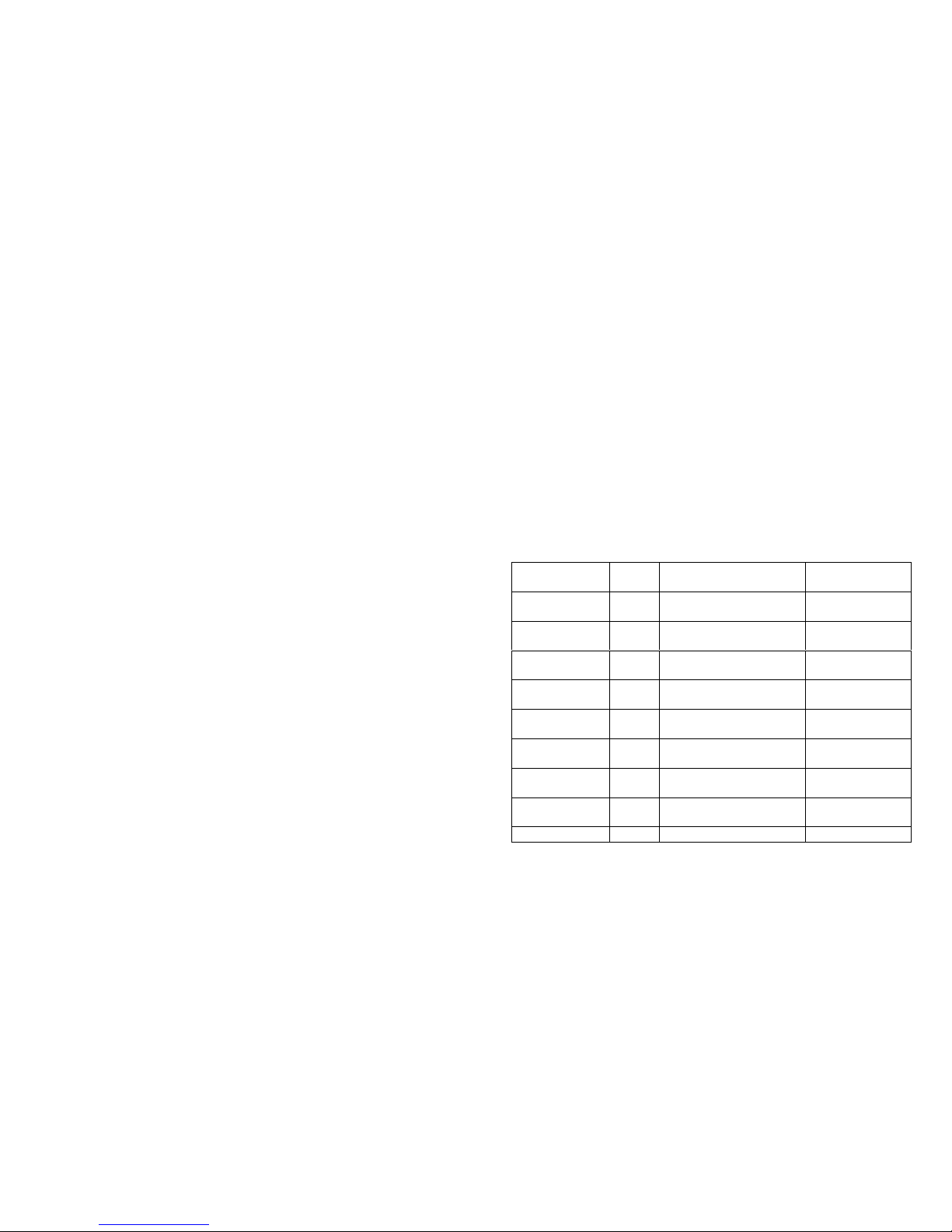

The following chart shows the circuit breakers and

fuses with the components they protect:

DEVICE RATINGCOMPONENT

1 Circuit

breaker

2 Circuit

breaker

3 Circuit

breaker

4 Circuit

Breaker

6 Circuit

breaker

7 Circuit

breaker

8 Circuit

breaker

Fuse 8a Touch pad Right of

Fuse 200 Drive System Electrical panel

PROTECTED

25 Rear vacuum motor Right of

25 Optional front vacuum

motor

35 Left side scrub brush Right of

35 Right side scrub brush Right of

5 Squeegee actuator Right of

5 Brush actuator Right of

10 Ignition, horn, battery

and hour meter

LOCATION

steering column

Right of

steering column

steering column

steering column

steering column

steering column

Right of

steering column

steering column

QUICK 98560 09/20/99

3-6

Page 11

CONTROLS

O. FUSE

The fuses are a one-time circuit protection device

designed to stop the flow of electrical current in the

event of an electrical overload. If a fuse is blown, it

must be replace. The knife fuse located in the

electrical panel housing protects the drive system.

The touch pad is protected by a fuse on the circuit

breaker panel.

P. BRUSH PRES SUR E SW ITCH

The brush pressure switch selects the down pressure

on the scrub deck. One touch sets the brush

pressure to light scrub. Each succeeding touch

increases the pressure one step. After four touches

the pressure returns to the lightest position to begin

the cycle again. LED’s corresponding to the pressure

position are activated on the panel above the switch.

If the scrub deck is lowered without brushes installed

the brush motors will stop, the deck will raise and all

four of the LED’s will flash continuously until the

brush switch has been pressed once again.

Q. OPTION PUMP SWITCH

Activating this switch turns on the options pump to

operate a scrub wand.

R. BRUSH CIRCUIT BREAKER MONITOR

The LED will light when either of the two brush motor

circuit breakers has tripped.

S. FULL RECOVERY TANK INDICATOR

This LED will light when th float senses a full

recovery tank. The LED will light intermittently

When the tank approaches full. When the LED is on

constantly for 70 seconds, the squeegee will raise

and the vacuum motors will turn off. The vacuum

motor cannot be activated until the recovery tank is

emptied. However the squeegee lift mechanism will

continue to function.

T. SOLUTION TANK COVER

Located on top of solution tank. Remove to fill

solution tank.

U. RECOVERY TANK DRAIN HOSE

Located at left rear of machine. Secured by clip and

closed by expandable plug.

V. RECOVERY TANK LID

Rectangular cover located on top, right side lower

tank. Cover secured by knobs.

W. SOLUTION TANK DRAIN HOSE

Locate at left rear of machine. Secured by clip and

closed by expandable plug.

X. RECYCLE OPTION SWITCH

3-7

QUICK 98560 09/20/99

Page 12

MACHINE OPERATION

PRE-RUN MACHINE INSPECTION

Do a pre-run inspection to find problems that could

cause poor performance or lost time from breakdown.

Follow the same procedure each time to avoid

missing steps.

NOTE: See maintenance section for pre-run machine

inspection checklist items.

STARTING MACHINE

NOTE: Perform pre-run machine insp ec tio n before

operating machine.

FOR SAFETY: Before starting machine, make

sure that all safety devices are in place and

operating properly.

1. The operator should be in the seat with the left

foot on the brake pedal or with the parking brake

on. The directional pedal must be in the neutral

position to avoid unintentional movement. There

is a built in safety to disable the drive system if

the key is turned on with the directional pedal

engaged. The directional pedal must go back to

neutral before the machine will move.

NOTE: The operator must be in position on the seat

in order to activate any machine functions.

2. Turn the key switch clockwise to the “ON”

position.

3. Release the brake, then press lightly on the

directional pedal in the desired direction and

drive to the filling area.

EMERGENCY STOP PROCEDURE

1. Turn key to off position. If an electrical problem

is suspected push in emergency stop button to

remove all power from machine.

2. Release pressure on direction al ped al.

3. Apply brakes.

NOTE: Turning the key switch off during normal

running operation will stop all motors and lift

actuators. When the key is turned back on the

systems will assume they are in the normal parked

mode (scrub deck up, squeegee up, and motors off).

Any switch command will send the selected system

to the working position regardless of the position it

was in when the key switch was turned off. Two

touches of the respective switch are required to raise

the scrub deck and squeegee and turn off motors.

This is normal. No damage to the machine will result.

FILLING THE QUICK©

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking brake,

turn off machine and remove key.

1. Set squeegee and scrub deck to up position, set

parking brake, and turn off key switch.

2. Remove solution tank cover.

Flammable materials can

! WARNING

Do not use flammable materials in the tanks.

3. Fill the solution tank with clean water, 5” from the

bottom of the fill inlet. At this level the solution

tank contains 25 gallons (97.5 liters). The water

must not be hotter than 140ºF (60ºC) to prevent

damage to the tank.

4. Measure the required amount of chemical into

the solution tank. Liquid chemicals should be

added to the solution tank after filling with water.

Dry chemicals should be thoroughly mixed before

being added into solution tank. Commercially

available, high alkaline cleaners, specifically

manufactured for floor cleaning are suitable for

use in the QUICK© solution system.

NOTE: Read the chemical manufacturers

recommended proportions instructions and

application instructions.

5. Inspect solution tank cover vent for obstructions.

A blocked vent will prevent proper flow of solution

form reaching the scrub deck.

6. Replace solution tank cover.

cause an explosion or fire.

QUICK 98560 09/20/99

3-8

Page 13

MACHINE OPERATION

SCRUBBING WITH THE QUICK©

Plan the scrubbing pattern in advance. The longest

track is around the perimeter of the area to be

cleaned. For efficient operation, the runs should be

the longest possible without turning, stopping, or

raising and lowering scrub deck/squeegee. Overlap

the bush paths and avoid transporting over

previously cleaned areas.

The QUICK© will automatically raise the squeegee

slightly when reverse travel is selected. If the

machine is allowed to stand in neutral with the scrub

head down for more than 2 seconds, brush motors

stop, solution flow stops, and the scrub deck will

raise slightly. If either forward or reverse travel is

selected, the scrub head will lower to the preset

position and solution flow will continue in the same

settings once movement begins.

NOTE: In order to achieve the best possible results,

the area which is to be cleaned should be swept

before scrubbing. Large debris, strings, wire must

be removed to prevent being caught in brushes or

squeegee.

TO BEGIN SCRUBBING

The QUICK© uses a one touch system for turning

on the brushes and vacuum motor and lowering both

to the operating position.

! CAUTION

When operating the machine around people, pay

close attention for unexpected movement. Use

extra caution around children.

! WARNING

Flammable liquids and/or reactive metals can

cause explosions or fire! Do not pick up.

1. Place left foot on brake pedal or make sure

parking brake has been set.

2. With directional pedal in neutral turn key switch

to “ON”.

3. Release brake.

4. Press directional pedal to travel in the desired

direction and steer to the start of the scrub

pattern.

5. Press the brush switch (#1) on the console

touch pad. The vacuum motors will switch on,

the LED will light, and the squeegee will lower to

the floor. The brush motors will start, the scrub

deck will lower to the light scrub position, and

the solution will begin. Three set of LED’s (one

set of four lights indicating amount of brush

pressure, one light for brush motor on, and one

light for vacuum motor on/squeegee down will all

light. The brush light will blink until the selected

pressure is attained.

NOTE: Shut machine off immediately if water or

foam is expelled from the machine.

6. To double scrub touch the squeegee switch and

the squeegee will raise.

7. Adjust the brush pressure by touching switch on

the touch pad.

8. Adjust the solution valve with lever . Solut io n wi ll

not flow to the floor until the scrub deck is

activated.

9. Adjust ground speed and solution flow to suit

cleaning conditions.

NOTE: Once solution flow rate is set it is not

necessary to shut off solution when stopping

scrubbing. Solution flow is automatically shut off

when brush motors stop. When bush motors are

turned on, flow automatically res umes.

3-9

QUICK 98560 09/20/99

Page 14

MACHINE OPERATION

TO STOP SCRUBBING

1. Press the brush motor switch (#1) on the console

touch pad. The motors will stop and the scrub

deck will raise to the park position. Nothing

further needs to be done. After 15 seconds the

squeegee will lift and the vacuum motor will run

an additional 15 seconds. These delays are

programmed to avoid leaving water between the

location the brush lifted and the sque ege e lifted,

and to clean the recovery hose.

2. Apply brake to stop machine.

3. Turn key switch off.

4. Set parking brake.

DOUBLE SCRUB

Floors which are heavily soiled or have thick

accumulations of floor finish may not clean

sufficiently with one pass. In these cases it will be

necessary to double scrub.

To double scrub, make the first pass over the surface

being cleaned with the squeegee up, the solution on,

and brushes down. This allows the solution to stay in

contact with the soil while loosening the sur f ac e

accumulation with the brushes. Allow time for the

first application to stay in contact with the floor.

Length of time between the first and second pass

depends on amount of accumulation and type of

chemical being used. A second scrubbing with the

squeegee down again the solution and brushes on

will further loosen the soil. The additional application

of solution will further assist the difficult cleaning job.

If desired the side squeegee may be locked in the up

position by raising squeegee and rotating latch.

EMPTYING AND CLEANING TANKS

RECOVERY TANK

1. Pull the solution lever all the way up to stop

solution flow if scrubbing is complete. Otherwise

raising the scrub deck will stop solution flow.

2. Touch the scrub brush switch to raise the scrub

deck, stop the brush motors, raise the squeegee

and stop the vacuum.

3. Park the QUICK© next to a floor drain.

4. Turn off the key switch and set the machine

parking brakes.

5. Unhook the drain hose from retainer. Unscrew Thandle on plug enough to loosen plug and lower

hose in direction of drain. Stand behind end of

hose. Recovered solution will come out with

force. Slowly remove plug from drain hose.

6. Recovery tank should be flushed out with clean

water on a daily basis. Do not use water hotter

than 140°F (60°C) to clean tank. Damage to tank

may occur.

7. Clean around float shut off device and check for

free movement of float.

8. Large debris or compacted dirt may be removed

by clean out cap located on left side at rear.

9. Replace plug and secure drain hose in bracket.

10. If machine is to be stored, leave recovery tank

cover open and drain cap off.

SOLUTION TANK

1. Drain solution tank by lowering clear vinyl tube

from hanging bracket. Unscrew T-handle and

remove plug.

2. Flush tank of all chemical solution.

3. Run several gallons of clean water through

system.

NOTE: Never allow solution to remain in tank.

Damage to tank, seals and valves could occur.

QUICK 98560 09/22/99

3-10

Page 15

TRANSPORTING MACHINE

TOWING OR PUSHING MACHINE

The QUICK© may be towed for short distances at

speeds not to exceed 5 mph. Be careful to avoid

damaging machine. Attach towing device at tie

down point. The machine may be pushed by hand

from the rear.

NOTE: To avoid damage caused by regenerative

voltage, unplug traction motor before towing or

pushing machine.

MACHINE TIE-DOWNS

There are two tie points located at the rear, side of

the machine frame and one on the steering fork

above front tires. Tie-down devices must be of the

proper type and strength. The combined strength of

all tie-downs must be strong enough to lift tow times

the weight of the machine. Tie-downs must be

positioned to prevent the machine from moving

forward, backward, or either side to side. Use all

four corners of the machine with the tie-downs

running out opposite directions . Tie- d o wns m ust be

attached to the transporting vehicle securely.

PREPARATION FOR TRANSPORTING

Remove squeegee tool to eliminate interference with

tie-downs.

Scrub head must be in the up position before

loading.

NOTE: When transporting the machine on a trailer or

in a truck, in addition to using tie-downs, be sure to

set the parking brake, and block the tires to prevent

the machine from rolling.

MACHINE JACKING

The machine may be jacked up for service or

inspection by using the specified jack locations.

Always block the tires when jacking up the machine.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

The rear jack points are the frame just behind the

rear wheels. Remove the squeegee tool before

jacking.

NOTE: See Squeegee Tool Removal in

Maintenance Section.

The front jacking point is the steering fork just above

the front tires.

3-11

QUICK 98560 09/20/99

Page 16

JACKING MACHINE

TO JACK UP MACHINE

1. Empty the recovery and solution tank.

2. Turn the key switch off and set the parking brake.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

3. Block the tires that are not being raised to

prevent the machine from rolling.

FOR SAFETY: When servicing machine, block

machine tires before raising machine.

4. Using a jack of adequate capacity. Raise the

machine using the designated jack points.

FOR SAFETY: When servicing machine, use hoist

or jack of adequate capacity, jack machine at

designated jack locations only. Block machine

with jack stands when raised.

5. When machine is raised, use jack stands at the

designated jack locations.

FOR SAFETY: Block machine at designated jack

locations with jack stands when raised.

MACHINE STORAGE

If the machine is to be stored for extended periods of

time, the following steps must be taken to minimize

the chance of corrosion or deposits forming.

1. Drain both solution and recovery tanks. Clean

soil and chemical build up from tank. Flush with

clean water including the solutio n del iv er y

system. Leave solution tank lid and recovery

cover open.

2. Raise the rear squeegee assembly and the scrub

deck.

3. Remove brushes and rinse with clean water. Dry

thoroughly.

4. Wash squeegee blades with clean water.

5. Park the machine in a cool, dry area.

6. Check the charge level of the batteries monthly.

Recharge when batteries drop below 25%

charge.

If suitable space exists to store batteries from

machine, remove from machine.

7. Perform next lubrication interval.

6. Slowly lower the machine onto the jack stands.

7. Be sure that the machine is secure.

8. Service or inspect the machine as required.

9. When finished working on the machine, raise the

machine off the jack stands.

10. Remove the jack stands.

11. Lower the machine to the floor. Block wheels as

they are lowered.

12. Remove wheel block after machine has been

completely lowered .

QUICK 98560 09/20/99

3-12

Page 17

MAINTENANCE

GENERAL

The QUICK© has been designed with many

maintenance free features. Except as noted, all

bearings are permanently lubricated and sealed. All

friction points use bushings which do not require

lubrication. Keeping the equipment clean is the

primary preventative maintenance. With the

exception of the brush motors, vacuum motors, and

the main drive motor all exposed areas may be

washed without damage to the machine. A few steps

can be taken by the user in order to provide trouble

free service. The following explanations are

guidelines to follow for user service.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

DIRECTIONAL CONTROL SYSTEM

(Refer to the “Electrical Component Group” in the parts manual)

The directional control system controls the direction

and speed of the machine. The system is made up

of the directional pedal, the electronic throttle, the

controller and the traction motor. The controller,

located in the electrical compartment, can only be

serviced by trained personnel.

brushes to follow irregularities and changes in floor

without losing contact with floor.

NOTE: Do not use a pressure washer to clean the

Scrub Head. Use tap pressure only. Care must be

taken so that water is not directed in brush motor air

intakes.

SCRUB BRUSHES

NOTE: All original equipment brushes are equipped

with “Perform Alert©”. This feature will tell the

operator when it is time to replace the scrub

brushes. “Perform Alert©” brushes have pre-trimmed

bright yellow tufts. When the tufts in the scrub brush

wear to a length equal to the yellow tufts, the scrub

brushes should be replaces.

There are five different types of brushes available to

cover applications from cleaning heavily soiled floors

to polishing. A pad driver is also available to take

advantage of the many cleaning pads on the market

and further add to the flexibility of the QUICK©.

Please refer to the following to assist in selecting the

proper brush or pad for the work at hand.

DIRECTIONAL CONTROL PEDAL ADJUSTMENT

(Refer to the “Pedal Group” in the parts manual)

The directional pedal is designed to prevent driver

fatigue. The pedal should require little effort to

operate. The complete assembly can be mounted in

two different positions to suit the individual. If a

different pedal position is preferred follow the

directions below.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

1. Disconnect batteries from machine.

2. Locate the two bolts securing the pedal mount to

the floor plate.

3. Loosen the rear bolt and remove the front bolt.

4. Move assembly to alternate position.

5. Reinstall and tighten bolts.

SCRUB HEAD

(Refer to the “Scrub Head Group” in the parts manual)

The scrub head consists of two rotary type scrub

brushes, drive motors, self-adjusting side squeegee,

and splash skirt. The scrub head is factory adjusted

and has machine controlled down pressure

adjustment. The operator can select one of four

different down pressure settings on the touch control

panel. There are no mechanical adjustments to be

made by the operator. The hex drive hub allows

4-1

QUICK 98560 09/20/99

Page 18

MAINTENANCE

UNCOATED FLOORS

Aggressive Grit is nylon fiber impregnated with

silicone carbide grit. It grinds away stain, soil and

removes surface material.

Mild Grit is a less aggressive silicone carbide grit

suitable for cleaning medium soil conditions.

Advantages are faster ground speed than nylon

bristles on light solid applications.

Nylon is a general-purpose scrub brush with stiff

bristles. Polypropylene works well for maintaining

concrete, wood, and tile floors.

FINISHED FLOORS

Nylon Polish is the softest brush. It will gently clean

finished tile or terrazzo floors without removing floor

finish for floor material. Used for washing highly

polished or burnished floors.

Nylon bristles are used in a variety of applicat io ns on

coated or uncoated floors.

White Pads (Polishing) are used for dry polishing to

achieve a high-gloss appearance, or surface washing

on highly polished or burnished floors.

REPLACING OR INSTALLING SCRUB BRUSHES

1. With the scrub deck up, turn “OFF” the machine

and set the parking brake.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

2. Locate release lever on top of brush or pad

driver. Rotate release lever counter-clockwise

and the brush/pad driver will release and drop

down.

3. To reinstall, center the brush diver under the

brush drive hub. Raise until it contacts brush

driver assembly. Turn clockwise until release

lever plate locks into position.

NOTE: Check that release plate is completely closed

and pad/brush is securely attached. Damage to

driver or brush could occur.

4. Repeat the procedure for the opposite side of the

machine.

Red Pads (Buffing) are used for light-duty scrubbing.

When used with a mild detergent they will provide

surface cleaning without removing the finish.

Blue Pads (Scrubbing) are used for heavy-duty

scrubbing and light stripping. The blue pads remove

less finish than brown stripping pads, yet will remove

black marks, stains, and dirt.

Brown Pads (Stripping) are used for easy and

complete removal of old floor waxes/finishes. They

will quickly remove ground in dirt, black heel marks,

and spills. When used with the proper stripper, this

pad leaves the floor clean and ready for finishing.

The scrub brushes should be checked before each

days work for wire, wear, or damage. The scrub

brushes should be replaced if brush bristles are

missing or if yellow Perform Alert© indicate minimum

brush length.

NOTE: For uniform scrubbing, scrub brushes must be

replace as a set.

QUICK 98560 09/20/99

4-2

Page 19

MAINTENANCE

SCRUB DECK REMOVAL

(Refer to the “Scrub Head Group” in the parts manual)

1. Lower deck to floor.

2. Disconnect horn.

3. Remove right skirt.

4. Remove solution line.

5. Disconnect scrub motors from wiring harness.

6. Disconnect actuator barrel from wiring harness.

7. Disconnect actuator wires.

8. Remove actuator from top.

9. Remove two bolts (KEY 16 SCRUB HEAD LIFT

GROUP) to frame.

10. Remove ball joint linkage from front of scrub

deck lift brackets.

11. Jack machine up at front.

12. Slide deck out.

NOTE: When installing the scrub deck it is important

to adjust actuator properly. To provide maximum

clearance for removing/installing brushes without

binding or bottoming out actuator, adjust actuator

such that in raised position there is 1/8” to 1/4” (3mm

to 6mm) clearance from top of scrub head mounts to

bottom of frame.

SQUEEGEE ASSEMBLY

(Refer to the “Squeegee Group” in the parts manual)

The QUICK© steering geometry and the design of

the squeegee assembly allows the squeegee

assembly to follow the track of the scrub of the scrub

head even in hard turns.

The assembly rides on the floor supported by two

wheels which follows changing levels in the floor.

Down pressure and squeegee flair is constant in

relation to the floor. Spring pressure is applied to

squeegee to maintain good contact with the floor.

(Refer to “Adjusting Squeegee”)

Rollers are mounted on each end of the squeegee

assembly to assist in rolling by obstacles.

The squeegee assembly is easily removed from lift

mechanism for service and transport.

SCRUB DECK SKIRT AND SIDE SQUEEGEE

(Refer to the “Scrub Head Group” in the parts manual)

The design requires the use of a side squeegee to

direct scrub solution to the main squeegee. The

side squeegee is spring loaded allowing constant

contact with the floor. The deflection of the side

squeegee is controlled at front by a guide that

contacts the floor and at rear by an adjustment knob.

Check the blade and guide for damage and wear.

The QUICK© uses a scrub deck skirt to contain the

solution around the scrub brushes. The scrub deck

shirt is self-adjusting by means of its accordion

design. As the brushes wear the skirt assembly will

automatically remain in contact with the floor.

The skirts should be inspected weekly for wear and

damage. Replace the skirts when it becomes

cracked, torn or brittle. The skirt may be removed by

loosening the nut on retaining band at center rear of

scrub head.

4-3

QUICK 98560 09/20/99

Page 20

MAINTENANCE

SQUEEGEE BLADES

There are four sets of squeegee blades available for

the QUICK©. Sets include front, rear and scrub deck

side squeegee blades. There are three different

notch patterns and three different colors for varying

floor conditions. Linatex squeegees are for industrial

settings. See squeegee parts list for part numbers.

The front squeegee blade allows solution to pass

through channels in the blade into the squeegee tool

while maintaining vacuum to provide lift. The front

blade has four wear surfaces and can be rotated for

extended life. The red blade has less notches and is

for rougher or tiled surfaces. The green blade has no

notches and is for very rough floors such as knobby

tile or uneven tile. The front blade should not require

regular replacement under normal use.

The rear blade wipes the floor to a near dry condition.

It is important the rear blade be in good condition to

properly do its job. Each squeegee blade has four

wear surfaces for extended service.

Check both the front and rear squeegee blades for

damage, wear, and adjustment each day in the prerun check. Change the front blade if it is torn or has

an uneven edge. Change the rear blade if it is less

than 1/2 the original thicknes s .

3. Unlock and pull open latch on right rear side of

tool.

4. Remove blade retainer strap from squeegee tool.

5. Remove squeegee blade from locating pins on

squeegee tool and rotate to new position or

replace as required.

6. Install blade on locating pins of squeegee tool.

7. Install squeegee retainer strap on left side of

squeegee tool. Install short retainer strap on

right side of squeegee tool.

8. Fasten and lock latch. Latch is adjustable.

Adjust latch only tight enough to take up slack in

retaining strap.

NOTE: Changing of squeegee blades does not

always necessitate a readjustment. Refer to section

on adjusting squeegee.

NOTE: An optional rear urethane blade is

available for industrial settings that have oil or

chemical based products.

TO REPLACE OR ROTATE REAR

SQUEEGEE BLADES

1. Touch squeegee switch on touch panel to raise

squeegee.

2. Turn off the key switch and set the machine

parking brake.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

TO REMOVE SQUEEGEE TOOL

1. Raise squeegee tool.

2. Disconnect vacuum hose from tank and loosen

the two knobs.

3. Pull squeegee tool assembly rearward from the

lifting carrier.

4. With squeegee tool assembly on bench inspect

or repair as necessary.

5. To reinstall, align squeegee tool to lift carrier.

Push forward while keeping squeegee level.

6. Tighten knobs.

7. Attach vacuum hose.

TO REPLACE FRONT SQUEEGEE BLADES

1. With squeegee tool assembly on bench, release

latch securing retainer strap.

2. Remove front retainer strap.

3. Remove squeegee blade from locating pins on

squeegee tool and rotate to new position or

replaces required.

4. Install blade on locating pins of squeegee tool.

5. Replace front retainer strap.

6. Secure strap by locking latch.

NOTE: Changing of squeegee blades does not

always necessitate a readjustment. Refer to section

on adjusting squeegee.

QUICK 98560 04/05/01

4-4

Page 21

MAINTENANCE

ADJUSTING SQUEEGEE

Adjusting the squeegee is a two part process. First,

the squeegee tool must have correct pitch in order

for the squeegee blade to have the same deflection

at each tip as well as the center. The pitch

adjustment on the QUICK© is facili tated by the use

of a spirit level mounted on the squeegee tool. The

second adjustment is the amount of deflection or

down pressure on the squeegee. The ideal

deflection is conveniently marked by colors on the

squeegee tool according to the type of floor and

squeegee blade emplo yed.

TO ADJUST REAR SQUEEGEE PITCH

1. Choose a smooth, level surface, turn on the key

switch release the machine parking brake lower

the squeegee and drive forward at least 2 feet

(60 cm).

2. With the squeegee down, stop the machine with

the brake and set the parking brake. Do not

allow the machine to roll back.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

3. Determine the differences, if any, in deflection of

the squeegee blade between each end and the

middle. Proper adjustment is obtained when

deflection is equal all the way across tool. This

should correspond to the bubble being in the

middle position of the spirit level.

4. To decrease the deflection of the squeegee

blade at the ends, loosen plastic knob on

squeegee railing arm. To increase the

deflection at the ends of the squeegee

assembly, tighten plastic knob on trailing arm.

5. Again check the deflection of the squeegee

blades. Repeat steps 1 through 4 until the

deflection is equal across the entire rear

squeegee blade.

TO ADJUST REAR SQUEEGEE DEFLECTION

1. Choose a smooth, level surface. Lower the

squeegee and drive forward at least 2 feet.

2. With the squeegee down, stop the machine and

set the parking brake. Do not allow the machine

to roll back.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

3. Observe the amount of squeegee deflection. It

should deflect 3/8 in (9.5 mm) across the entire

width of the squeegee.

4. To adjust the squeegee deflection. Loosen knob

on the squeegee slide bar.

5. Sliding bar to left increases deflection. Sliding

bar to right decreases deflection.

6. Tighten knob on squeegee slide bar.

7. Turn the key switch, release the machine

parking brake. Raise, then lower squeegee

assembly by pressing the vacuum switch. Drive

forward at least 2 feet.

8. Repeat steps 2 through 7 until deflection of 3/8

in. (9.5 mm) is reached.

4-5

QUICK 98560 09/20/99

Page 22

MAINTENANCE

DRIVE WHEEL CHAIN

(Refer to the “Front Wheel Group” in the parts listing)

The drive wheel chain transfers power from the motor

to the drive wheels. Check the chain condition and

tension every 200 hours or operation. The chain

should deflect 1/2 in (13 mm). Lubrication of drive

chain is not recommended. Clean dirt and grease

build up from chain to eliminate the abrasive effects.

ADJUSTING THE DRIVE WHEEL CHAINS

1. Turn off machine with key switch and set parking

brake.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

2. Loosen the bolts on the drive motor.

3. Slide the motor to adjust tension.

4. Tighten motor mounting bolts.

BRAKES

(Refer to the “Brake Group” in the parts listing)

The brake pedal and the parking brake operate the

self-centering front wheel disc brake. With the

parking brake set, the brake should hold machine

from moving with full throttle in either forward or

reverse. This brake check should be preformed in

the pre-run check before each days operation. The

disc and caliper should be inspected every 200 hours

of operation. The brake should be adjusted so that

the disc pads are as close to the disc as possible,

without causing brake to drag.

TIRES AND WHEEL

Inspect tires for proper inflation, cuts, and abrasion.

Check lug nuts for tightness. Lug nuts should be

tightened to 50-55 foot pounds (6.7-7.6 kg-meters).

Wheels should be checked for cracked or bent rims.

VACUUM MOTOR

(Refer to the “Vacuum Group” in the parts manual)

Do not use a pressure washer to clean around the

vacuum motors. Use tap pressure only. Care must

be taken so the water is not directed into vacuum

motor air intakes.

CHANGING VACUUM MOTORS

1. Disconnect vacuum motors.

2. Loosen bolts securing mounting brackets to

vacuum motor and remove motors.

3. Disengage mounting bracket from vacuum motor

and remove motor.

4. Reverse steps to install.

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

1. Jack up front of machine and support on jack

stands.

(Refer to section on JACKING MACHINE)

2. Once machine is secure on jack stands, release

parking brake.

3. Remove brake cover.

4. Locate the brake adjustment screws on the brake

caliper.

5. Turn the adjusting screw so that the disc pads

are as close to the disc as possible, without

causing brake to drag.

6. Reinstall brake cover.

7. Lower machine.

QUICK 98560 09/20/99

4-6

Page 23

BATTERIES

The batteries provide the power to operate the

machine. The batteries require regular maintenance

to keep them operating at peak efficiency.

The machine batteries will hold their charge for long

periods of time, but they can only be charged a

certain number of times. To get the greatest life

from the batteries, charge then when their level

reaches 25% of its full charge. Use a hydrometer to

check charge level.

Do not allow the batteries to remain in a discharged

condition for any length of time. Never expose a

discharged battery to temperatures below freezing.

Discharged batteries will freeze casing cracked

cases. Do not operate the machine if the batteries

are in poor condition or if they have a charge level

below 25%, specific gravity below 1.177.

Keep all metallic objects off the top of the batteries,

as they may cause a short circuit. Replace worn or

damaged cables and terminals.

Check the electrolyte level in each battery cell

before and after charging the batteries. Never add

acid to the batteries, use water. Do not allow water

level to fall below the battery plates. Portions of

plates exposed to air will be destroyed. Do not

overfill. Keep plugs firmly in place at all times.

! CAUTION

When servicing machine, avoid contact with

battery acid.

! WARNING

Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away.

Keep covers open when charging.

! WARNING

Wear eye protection and protective clothing

when working with batteries.

! WARNING

Charge batteries in a well ventilated area. Leave

solution tank raised.

BATTERY MAINTENANCE

1. When cleaning the batteries, use a solution of

baking soda and water. Do not allow the

cleaning fluid to enter the battery cells.

Electrolyte will be neutralized.

2. Maintain the proper electrolyte level in each

battery cell. If a cell should accidentally

overflow, clean immediately.

3. Do not add water until the battery is fully

charged.

4. Wipe off the top of the batteries at least once a

week.

5. Test battery condition with a hydrometer at least

once a week.

6. Ensure that all connections are tight and all

corrosion removed.

7. Every 4 to 6 months, remove the batteries from

the machine and clean the battery cases and

battery compartment.

CHECKING BATTERY SPECIFIC GRAVITY

Use a hydrometer to check the battery specific

gravity.

CHECKING GRAVITY

A. Hydrometer

B. battery

NOTE: Do not take readings immediately after

adding water, if the water and acid are not

thoroughly mixed, the reading may not be accurate.

Check the hydrometer readings against this chart.

SPECIFIC GRAVITY @80°F (27º C) BATTERY CONDITION

1.265

1.225

1.190

1.155

1.120

NOTE: If readings are taken when the battery

electrolyte is any temperature other than 80ºF

(27ºC), the reading must be temperature corrected.

To find the corrected specific gravity reading when

the temperature of the battery electrolyte is other

than 80º F (27º C); Add (+) to the specific gravity

reading 0.004 (4 points), for each:

10º F (6º C) above 80º F (27º C)

Subtract (-) from the specific reading 0.004

(4 points), for each 10º F (6º C) below 80º F (27º C).

100% charged

75% charged

50% charged

25% charged

Discharged

4-7

QUICK 98560 09/20/99

Page 24

BATTERIES

8

TO CHA RGE BATTERIES

! CAUTION

When servicing machine, avoid contact with

battery acid.

! WARNING

Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away.

Keep covers open when charging.

! WARNING

Wear eye protection and protective clothing

when working with batteries.

! WARNING

Charge batteries in a well ventilated area. Leave

solution tank raised.

Use a 24 volt, 25 amp maximum output, DC charger

which will automatically shut off when the batteries

are fully charged.

1. Stop the machine in a clean, well ventilated area

next to the charger.

2. Turn off machine and set parking brake.

For Safety: Before leaving or servicing machine;

Stop on level surface, set parking brake, turn off

machine and remove key.

Drain solution tank and raise the solution tank and

lock the support arm. Make sure the support arm is

fully engaged.

! WARNING

Batteries emit hydrogen gas. Explosion or fire

can result. Keep sparks and open flame away.

Keep covers open when charging.

For Safety: When charging, connect the charger

to the batteries before connecting the charger to

the AC wall outlet. Never connect the charger to

the AC wall outlet first. Hazardous sparks may

result.

7. Plug the charger into the battery connector.

Connect the charger AC plug to a wall outlet.

The charger gauge should indicate that the

batteries are charging.

8. When the batteries are fully charged, disconnect

the charger from the AC wall outlet, then

disconnect the charger from the batteries.

9. Connect the batteries to the machine connector.

10. Check the electrolyte level. It should be up to

the indicator ring. If necessary add distilled

water.

11. Lower the solution tank.

TO INSTALL BATTERIES

(Refer to diagram in “Battery Group”)

For Safety: Before leaving or servicing machine;

Stop on level surface, set parking brake, turn off

machine and remove key.

1. Drain solution tank and raise the solution tank

and lock the support arm. Make sure the

support arm is fully engaged.

2. Place batteries in battery compartment as

shown on diagram.

3. Connect all jumper cables positive to negative to

the four batteries.

4. Connect positive cable to battery in the position

shown.

5. Connect negative cable to battery in the position

shown.

6. Lower solution tank.

4. Check the electrolyte level in each battery cell.

Before charging, add just enough water to cover

the plates. After charging has completed, add

just enough water to bring the level to the

indicator ring. If the water level is too high

before charging normal expansion of the

electrolyte may cause an overflow, resulting in

loss of battery acid balance and damage to the

machine.

5. Replace the battery caps, and leave them in

place while charging.

6. Unplug the battery connector from the machine.

QUICK 98560 09/20/99

4-

Page 25

BATTERIES

TO REMOVE BATTERIES

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

1. Drain solution tank and raise the solution tank

and lock the support arm. Make sure the

support arm is fully engaged.

2. Disconnect battery pack from mac hine.

3. Use the proper size open end wrench to

disconnect main ground wire first and secure

cable terminal away from batteries.

4. Disconnect main positive lead and secure cable

terminal away from battery/batteries.

5. Loosen both terminals on each jumper cable

and remove one at a time.

6. Prepare a suitable site to place the batteries.

7. Attach suitable battery lifting device and lift

batteries from the machine.

! WARNING

Batteries are a potential environmental hazard.

Consult your battery supplier for safe disposal

methods.

FUSE LINK

(Refer to the “electrical Component Group”)

The fusible link protects the main contactors from

overload, and is located on electrical panel.

TO REPLACE FUSE LINK

FOR SAFETY: Before leaving or servicing

machine; Stop on level surface, set parking

brake, turn off machine and remove key.

FOR SAFETY: Disconnect all power to machine

by disconnecting battery pack from machine.

1. Remove plastic front cover from electrical panel.

2. Loosen nuts on burnt fuse.

3. Remove fuse by rotating and pulling up.

4. Replace fuse.

5. Tighten nuts.

6. Reinstall front cover.

4-9

QUICK 98560 09/20/99

Page 26

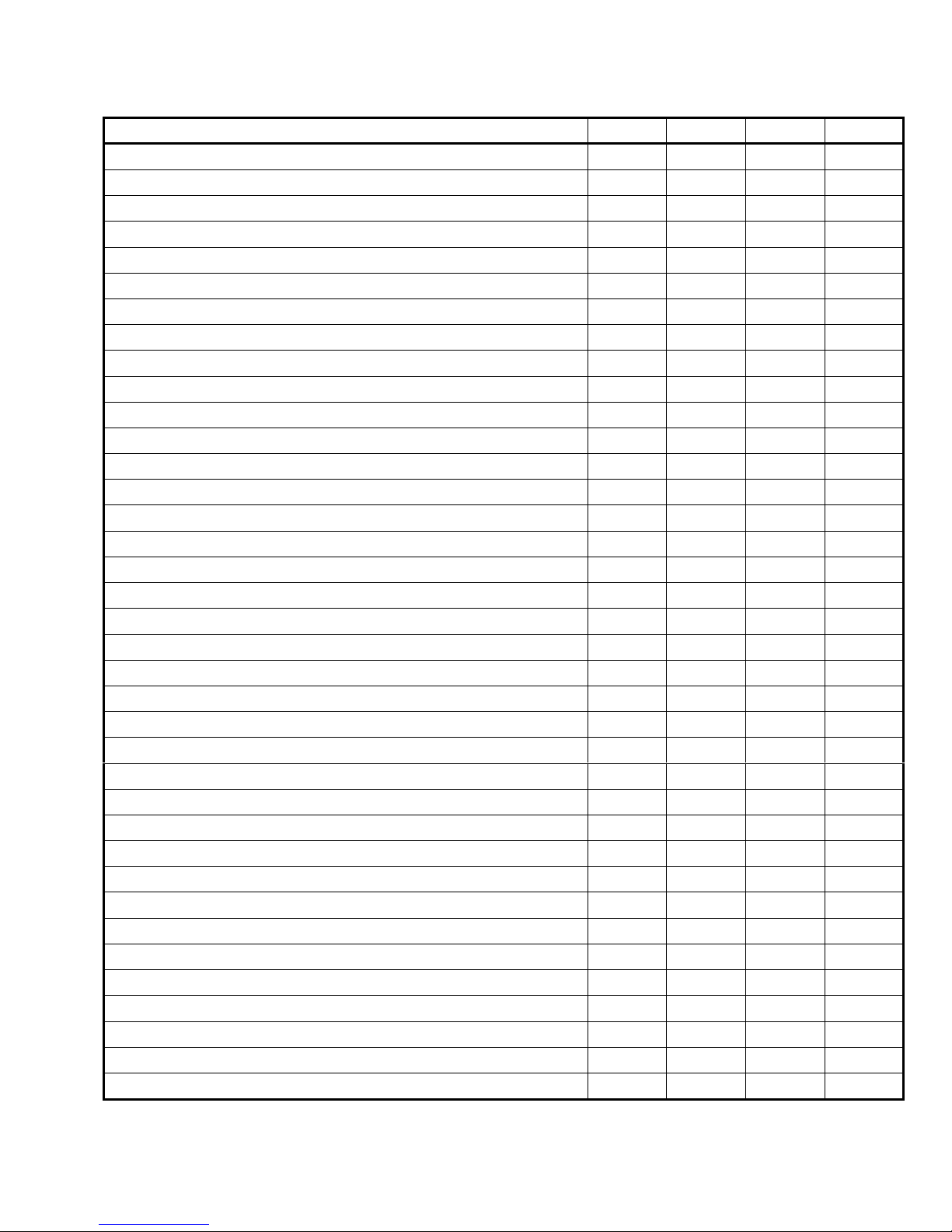

Maintenance Item Daily 50hrs 100hrs 200hrs

Before Starting The Work Period:

Check water level of batteries after charging.

Check that recovery tank cover seals tightly.

Visually check for low or worn tires.

Check brushes or pads for proper installation.

Check vacuum hose connections.

Check that squeegee is securely attached and properly adjusted.

Check for securely attached drain hose, plug and caps.

Check batteries and steering for proper operation.

End Of Work Period Before Storing:

Clean out solution tank and filter, check flow.

Run vacuum motors to dry.

Clean brushes or pad and check wear.

Clean squeegee blades and check wear.

Clean out recovery tank and vacuum filter.

Clean and inspect float shut-off.

Clean outside of tanks, check for damage.

Store with covers off tanks.

SERVICE SCHEDULE

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Check side squeegee guide for wear.

Check air pressure in tires.

Clean off top of batteries.

Check battery condition with hydrometer.

Inspect scrub deck skirt.

Tighten wheel nuts.

Clean and check drive chain for wear and tension.

Check battery connections are tight.

Clean battery cases and battery compartment.

Check parking brake adjustment and cable for wear.

Clean pivot points on squeegee and scrub deck.

Check squeegee lift and solution cables for wear and damage.

Blow out dust form motors.

Check all motors for carbon brush wear.

Check motor commutators.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

QUICK 98560 09/20/99

4-10

Page 27

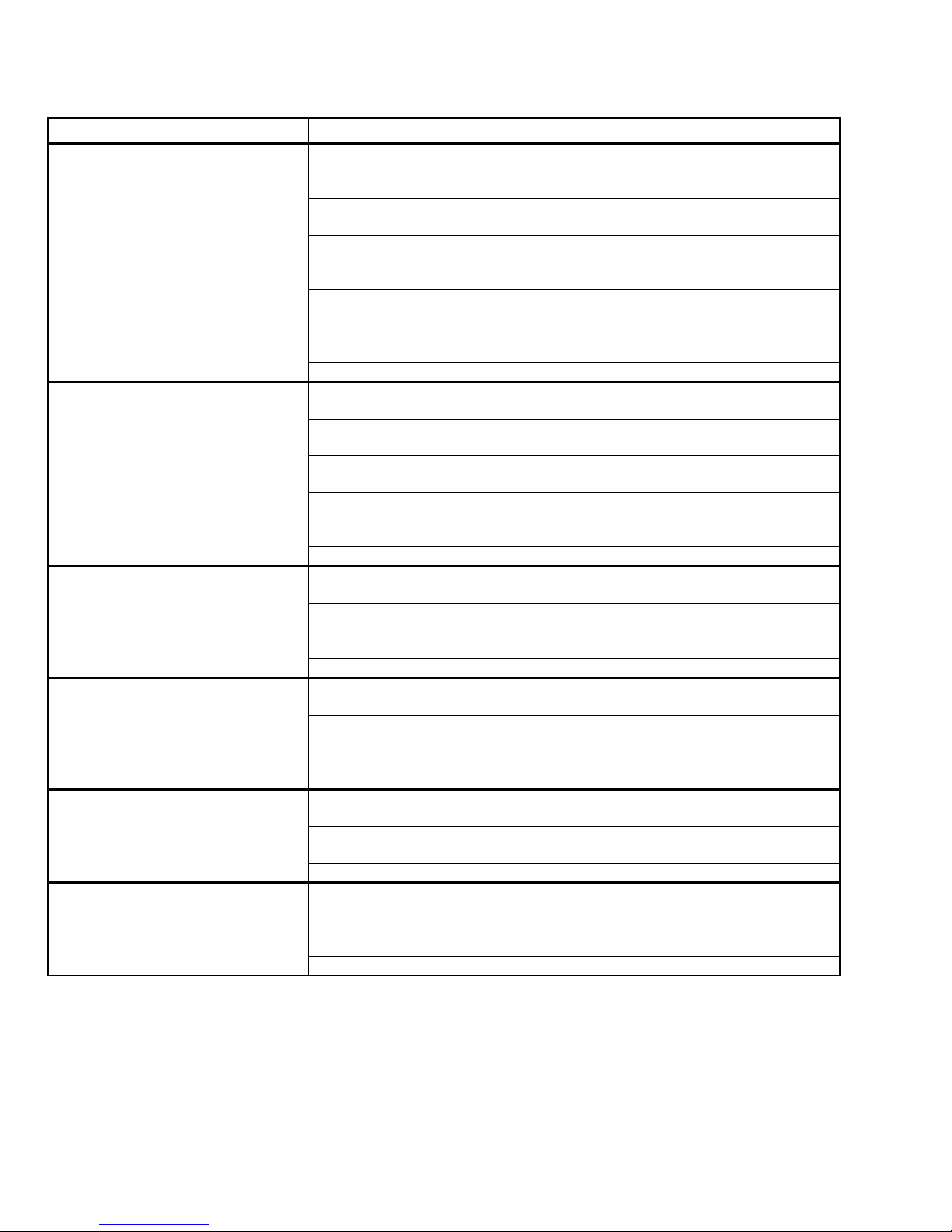

MACHINE TROUBLESHOOTING

Problem Cause Solution

Cable disconnected Check connections of all battery

Emergency shut-off activated Reconnect

Battery cables corroded Clean battery cable clamps and

No power to machine

Blown fuse link Replace fuse link

Main connector failure Inspect/replace main connector

Key operated on/off switch failure Inspect/replace on/off switch

Circuit breakers tripped Reset breaker

Loose connection Check motor wires and connections

cables

terminals. Check voltage

Vacuum motor/s do not run or

speed varies

Squeegee will not go down/up

Scrub deck will not go down/up

Worn motor brushes Replace, check commutators

Recovery tank full Check recovery tank full LED. Drain

recovery tank.

Faulty contactor Replace contactor

Circuit breaker tripped Reset breaker

Loose connection Check motor wires and connections

Faulty actuator Repair/replace actuator

Broken lift cable Replace cable

Actuator circuit breaker tripped Reset breaker

Loose connection Check motor wires and connections

Faulty actuator Repair/replace actuator

Circuit breaker tripped Reset breaker

Loose connection Check motor wires and connectionsBrush motors do not run

Faulty contactor Replace contactor

Solution tank empty Fill solution tank

Vent hole in solution tank lid

obstructed

Solution strainer lines obstructed Clear blocked solution lines.

4-11

Clean vent holeNo solution or slow solution flow

QUICK 98560 09/20/99

Page 28

MACHINE TROUBLESHOOTING

2

Problem Cause Solution

Low battery charge Charge batteries

Controller overheated Allow cool down period. Check cooling

fan.

No propel

Full speed only

Machine will not reach full speed

Little power, high pitched whis tle

Forward speed only

Reverse speed only

Sporadic operation

Chain failure Repair/replace

Faulty motor Repair/replace motor

Machine turned on with pedal not in

neutral position

Damaged wires, short circuits crossed

wires.

Batteries run down Charge batteries

Controller overheated Allow controller to cool. Check cooling

Faulty throttle Check throttle

Faulty controller Check controller

Faulty throttle Check throttle. Check controller

Low battery charge Charge batteries

Allow pedal to return to neutral position

Check visually for damage. Check

controller for dirt or metal chips

causing short circuit.

fan.

QUICK 98560 09/20/99

4-1

Page 29

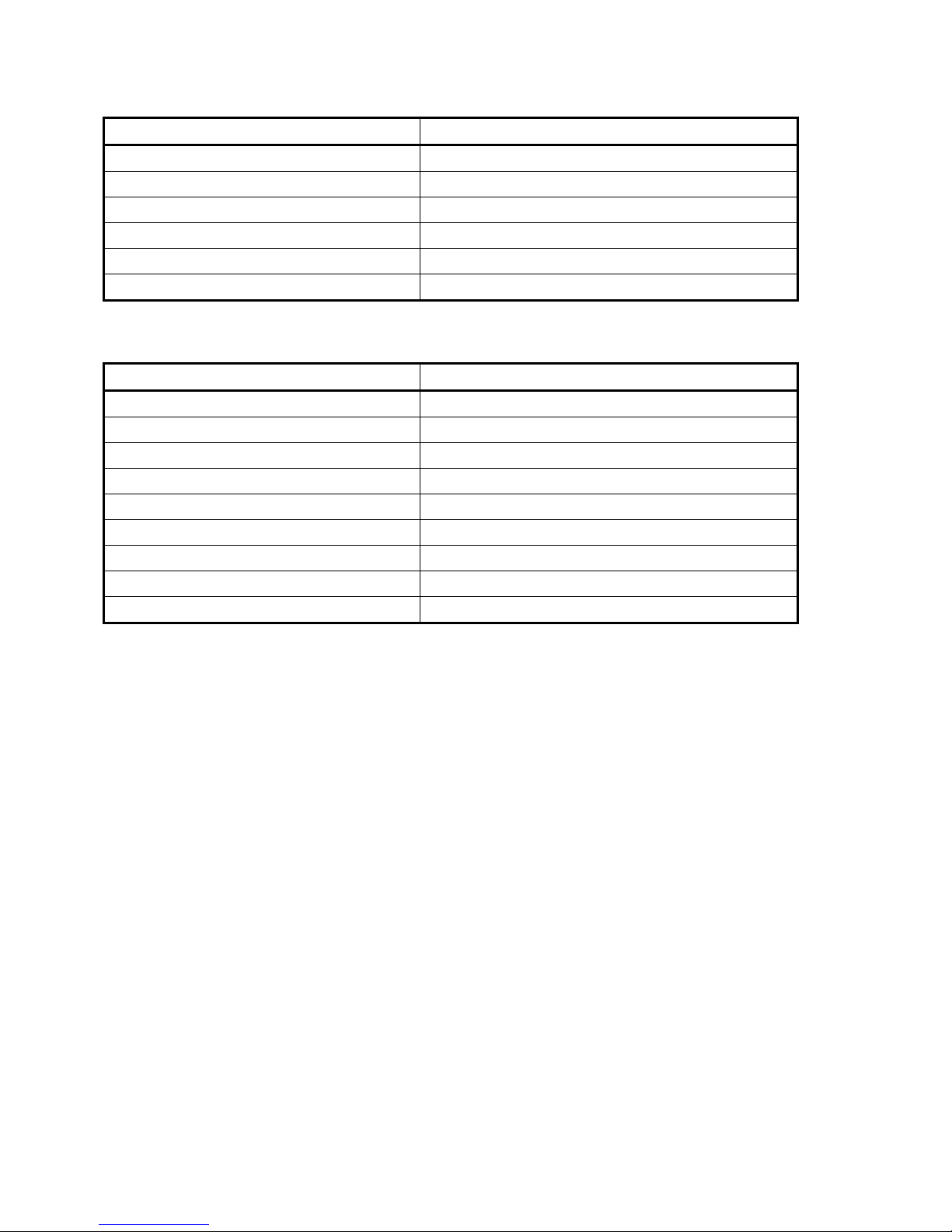

END USER STOCKING LIST QUICK

Part Number Description

830060 Scrub deck skirt

82616 Side squeegee guide

34345 Fuse 200A

81404 Fuse 8A

66227 Drain plug

81535 Knob

SQUEEGEE BLADE OPTIONS:

Part Number Description

82528 Squeegee blade, front red linatex (standard)

82529 Squeegee blade, rear red linatex (standard)

82652 Squeegee blade, side red linatex (standard)

82637 Squeegee blade, front blue tile

82638 Squeegee blade, rear blue tile

82650 Squeegee blade, side blue tile

82640 Squeegee blade, front green buttons

82641 Squeegee blade, rear green buttons

82651 Squeegee blade, side green buttons

4-13

QUICK 98560 09/20/99

Page 30

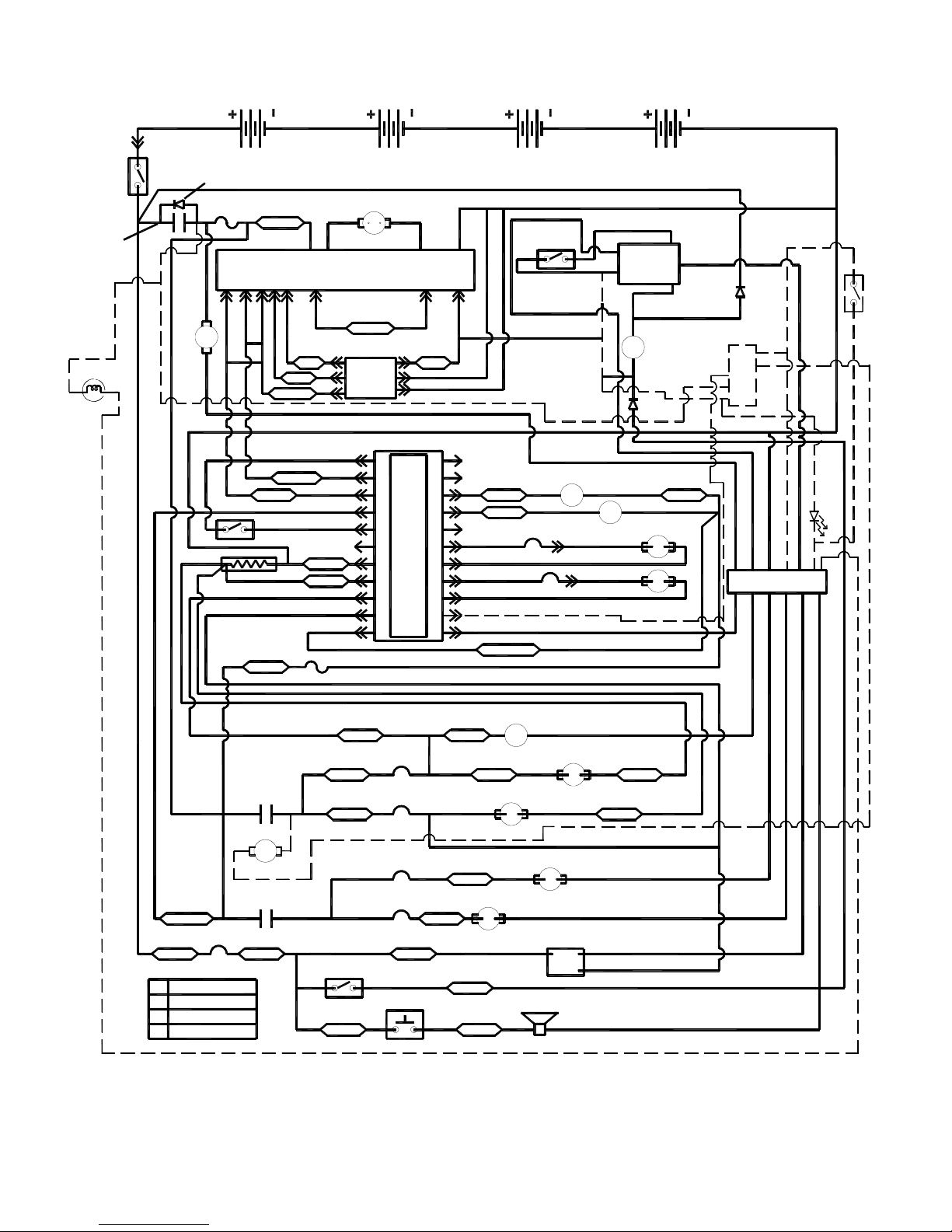

WIRING GROUP-SCHEMATIC

MAIN

CONTACTOR

RED 1

(OPT)

LIGHT

BLK 2

RED

EMERGENCY

SWITCH

M1

DIODE 29215

FUSE

200A

FAN

WHT 29

FWDREV 12 13 2 1

BLK 6

WHT 4

WHT/BLK

WHT/BLK 2

RED 3

FLOAT SWITCH

BLK

SHUNT

YLW

WHT 28

8A

M2

FWD

REV

GRAY

WHT/RED

GRAY

BRN 7

TAN 8

GRAY

WHT/TAN

FUSE

TRACTION

MOTOR

PM

CONTROLLER

TAN 23

THROTTLE

MODULE

P1 TOUCH PAD

112 1

6

71887

819

920109

10

11

M1

4

RED 4A

12

2132

13

14

1433

4154

15

165

5

16

6

17

17

18

19

20

21

21

22 11

22

B-

15

WHT/ORG

WHT/BLK

WHT/YLW

BLU 14

PUR 15

LT BLU

GRN

BLK

WHT/TAN 11A

SEAT

SWITCH

WHT/GRAY 16

BLK 32

RED

CONT COIL

BRUSH

CONT COIL

CB 7

15A

CB 6

15A

BLU 8

M2

VAC

GRN 7

RED

880206

WHT/TAN

WHT/GRAY 33

2

TIMER

1

NC

M2

ORG 6

M3

SCRUB BRUSH

ACTUATOR

PM

PM

SQUEEGEE

ACTUATOR

6

NO

C

WHT 880204

MAIN

CONT COIL

BRN 24

BLK 880093

RECYCLE BOARD

(OPT)

NEG

PMCTL

PM+

PWR

RED 5

BLK

TERMINAL

BLOCK

RED 82687

BLK 4

(OPT)

LED

(OPT)

REC

FLT

B

L

K

3

WHT/RED 4

PNK 27

LEGEND

CB

CIRCUIT BREAKER

PM

PERMENANT MAGNET

RELAY (CONTACTOR)

M

ARM

ARMATURE

SCRUB BRUSH

CONTACTOR

VACUUM MOTOR

CONTACTOR

CB 8

3A

M2

PUMP (OPT)

M3

BLU 23B

RED 1

GRN 880205

YLW 9

PUR 26

PUR 25

WHT 2

GRN 880206

KEY

SWITCH

BLU 23A

CB 4

35A

CB 3

35A

CB 1

25A

CB 2

25A

BLU 23

HORN

SWITCH

GRAY

RED 12

YLW 13

BLU 15

FRONT VACUUM

MOTOR

RED 24

ORG 25

NOTE: OPTIONAL ITEMS SHOWN IN HIDDEN LINES.

SOLUTION VALVE

SOLENOID

M4

YLW 19

RIGHT SCRUB

BRUSH MOTOR

PM

REAR VACUUM

MOTOR

PM

HORN

LEFT SCRUB

BRUSH MOTOR

PM

PM

HOUR

METER

12

3

BLK

BRN 20

BRN 22

GRAY

BLK

BLK

BLK

GRAY

BLK

QUICK 98560 09/29/00

4-14

Loading...

Loading...