Page 1

OPE~UIION

WIN-

INDUSTRIES, INC., 1351

W.

Stanford Ave., Englewood,

CO

Floor Scrubber

80110

1

USA 303/762-1800 FAX 303/762-0817

Page 2

Operator Safety Instructions

Read the instruction manual before operating this

machine.

Operate this machine only from the rear of machine.

Use caution when operating the machine on a ramp

or incline.

on a ramp or incline.

Machine can cause an explosion when operated near

flammable vapors and materials.

Do

not turn or leave this machine unattended

Store machine inside. Keep the electrical components

of the machine dry.

Lead acid batteries generate gases which can cause

an explosion. Keep sparks and flames away from the

batteries. Charge the batteries only in a well ventilated

area.

Wear eye protection when working near batteries.

not put any type of metal objects across the battery

or

terminals

Maintenance and repairs must be done by qualified

personnel only. Maintain adjustments on machine

as per specifications noted in the service manual.

Make sure all warning and caution labels are legible

and properly attached to the machine.

on top of the batteries.

Do

Page 3

‘I

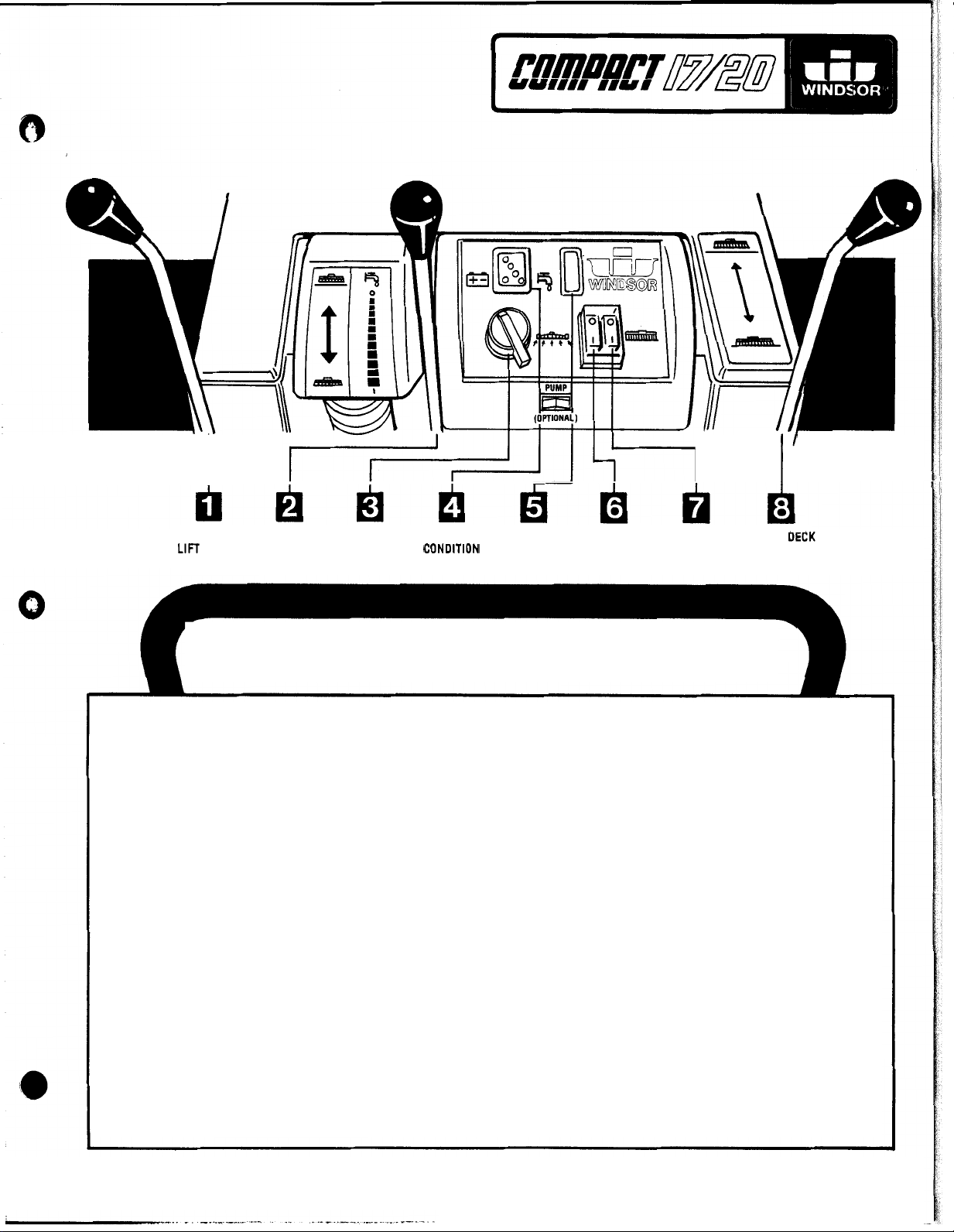

SQUEEGEE SOLUTION MAIN BATTERY SOLUTION VACUUM BRUSH SCRUB DECK

LIFT LEVER CONTROL SWITCH CONOlTlON “ON” “ON” LIGHTED “ON” LIGHTED LIFT LEVER

1.

2.

3.

4.

LEVER LIGHT LIGHT SWITCH SWITCH

OPERATOR CONTROL HANDLE

Raises and lowers squeegee assembly.

Controls flow of cleaning solution to floor.

Controls electric power to all switched components.

Indicates charge condition of batteries.

I‘

5.

Light

6.

Switches on vacuum motor.

7.

Switches on brush drive motor.

8.

Raises and lowers scrub deck assembly.

“ON”

indicates solution valve is open.

3

.

Page 4

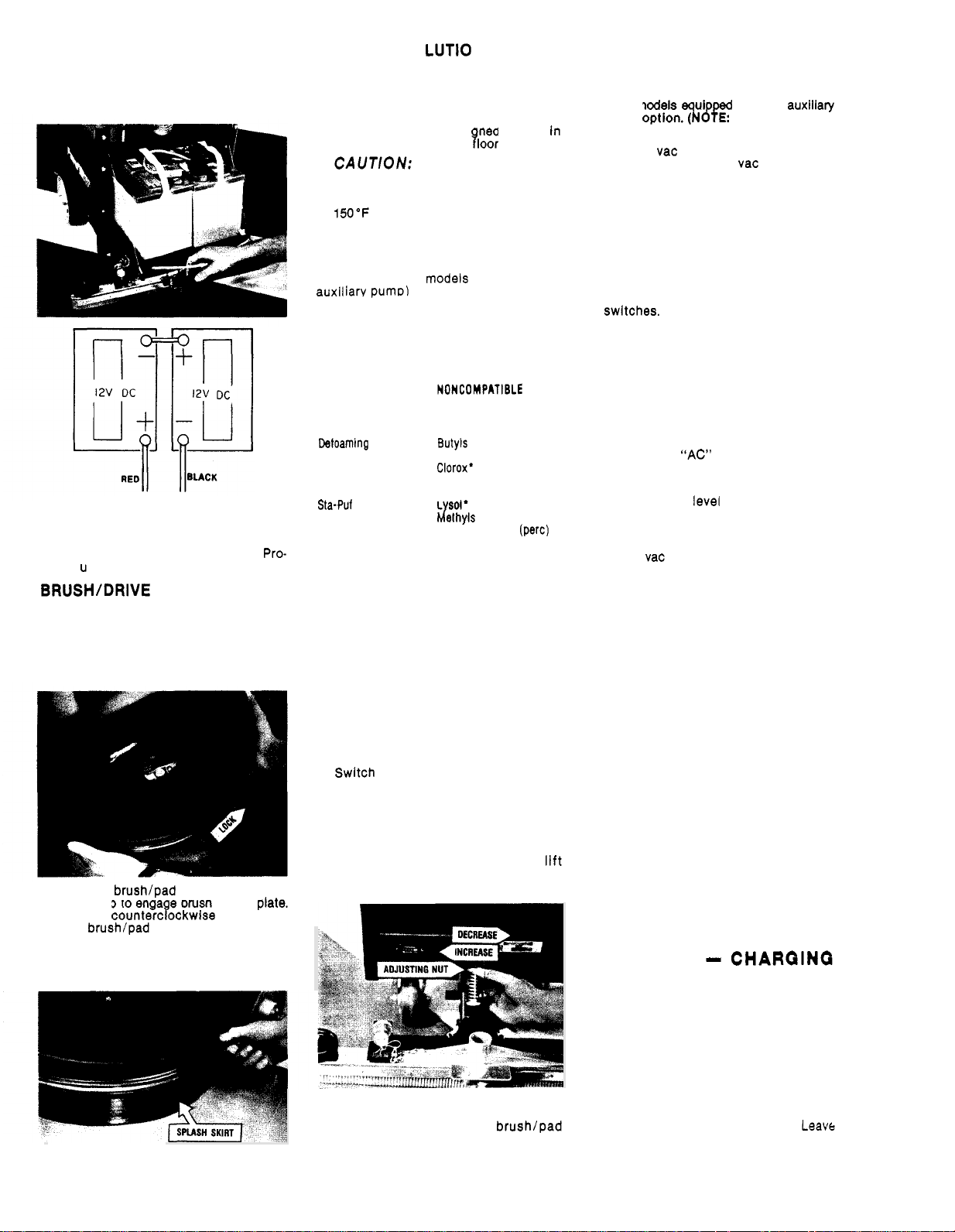

MACHINE PREPARATION

BATTERIES

1.

Install batteries and connect battery

cables as shown.

WARNING:

leave door open when charging batteries.

2.

Charge the batteries before using the

machine. (See Battery Charging

ced u re)

BRUSH/DRIVE PAD ASSEMBLY

1.

Raise scrub deck assembly by raising

control lever to store position.

2.

Reach under scrub deck and rotate drive

plate until a lug hole is visible through

scrub deck sight hole.

3.

Positlon brush/pad driver under plate

and lift up to enga e brush lugs in

A

quick countercyockwise motion will

lock

4.

Lower scrub deck by pulling control

lever rearward. Adjust splash skirt to

floor.

Provide proper ventilation,

Pro-

plate.

brush/pad driver in position.

CLEAN I N G

1.

Fill machine with hot water and add

cleaning chemical at the proportion

noted on the container.

CAUTION:

cleaning chemical desi ned for use In

automatic hard surface ?loor scrubbers.

CAUTION:

tortion of polyethylene solution/

recovery tanks. DO NOT USE WATER

TEMPERATURE THAT EXCEEDS

150’F

(65°C).

SO

LUTlO N

Always use a

To avoid possible dis

low

sudslng

CHEMICALS

The internal parts of the pump used in

the scrubber (on

auxiliarv pumo) are suitable for use with

most cleaning chemicals. But it is

ceptible to chemical attach from some

cleaning substances, such as hydro

carbon solvents and chlorinated bleaches.

These noncompatible materials are not

of the type normally used for cleaning.

SUITABLE

CHEMICALS CHEMICALS

Alkalis

Clorox

ii

Bleach’

Detoarning

Detergents Carbon Tetrachloride

Hydroxides

Oxygen Bleaches

Soaps

Sta-Puf

Vinegar

White Monday Bleach’ Perchlorethylene (perc)

*Registered Trademark

Agents

Fabric Softener’

OPERATING

1.

Adjust the operator control handle to

a comfortable position.

2.

Switch on main power switch.

3.

Release solution. Pull solution control

lever rearward.

solution can be regulated during oper

ation depending on the type of floor

and the traverse speed of the machine.

4.

Switch on brush drive motor.

5.

Switch on vacuum motor.

6.

Lower scrub deck. Pull deck lift lever

rearward.

CAUTION:

on floor while machine is stationary.

7.

Lower squeegee. Pull squeegee lift

lever rearward.

knob to change pressure on squeegee.

8.

Push machine forward to begin clean

ing. Forward motion is assisted by the

scrubbing action of the

driver.

models equipped with

NONCOMPATIBLE

Aldehydes

Aromatic Hydrocarbons

Butyts

Clorox’

Chlorinated Bleaches

Chlorinated Hydrocarbons

L

soi.

dethyls

(MEK)

Phenols

Trichlorethylene

D-Limonene

THE

MACHINE

NOTE

The amount of

DO

not leave brush running

NOTE

Use adjusting

brushlpad

sus

OPERATING MACHINE

WITH ACCESSORY

The

HFT

used

pump kit optionTPed E Factory installed

option only.)

1.

-

2.

3.

4.

5.

-

-

floor tool for wet pick-up can be

on models with the

Remove vac hose from squeegee and

connect to accessory

metal hose coupler.

Connect solution hose from accessory

tool to solution outlet nipple located at

lower right hand corner of rear panel.

Check solution tank for cleaning solu

tion and make sure dome is in place.

Switch on main power switch.

Switch on auxiliary pump and vacuum

switches.

WARNING:

motor when operating machine with

accessory tools.

vac hose, using

Do not switch on brush

REGULAR MAINTENANCE

BEFORE STARTING

1.

Disconnect battery charger.

connect the “AC” power cord from the

wall receptacle before removing the

“DC” charger plug from machine.

2.

Check water level in batteries. Add

distilled water as needed.

3.

Attach brush or drive pad to drive plate.

4.

Check vac hose connection at squeegee

shoe.

5.

Check squeegee blades for wear.

6.

Fill machine with hot water and add

cleaning chemical at the proportions

noted on the container.

low

sudsing cleaner designed for use in

automatic hard surface floor scrubbers.

BEFORE STORING MACHINE AT

THE END

-

1.

2.

3.

4.

5.

6.

Drain both solution and recovery tanks

and rinse clean.

Remove dome, lift out float assembly

to allow recovery tank to air dry.

Remove brush or drive pad from drive

plate and store upside down or hang

on wall.

Wipe down exterior of machine with

damp cloth.

Raise squeegee assembly to “store”

position.

Charge batteries. (See Battery Charging

Procedure)

OF

WORK

WORK

NOTE

PERIOD:

BATTERIES - CHARQINQ

AND MAINTENANCE

BATTERY CHARGING PROCEDURE

WARNING:

gases which can cause an explosion. Keep

sparks and flames away from batteries.

NO

SMOKING.

when working near batteries. Charge the

batteries only in a well ventilated area.

-

1.

Set the charger on a flat level surface.

2.

Open bettery compartment door.

door open during charging cycle.

Lead acid batteries generate

Always wear eye protection

TOOL

auxiliary

PERIOD

NOTE

Dis

Use a

Leave

-

-

4

Page 5

’

3.

Connect the “DC” charger plug to the

connector on the machine.

safety override switch is activated

when the “DC charge plug is connected.

This prevents all panel circuits on the

machine from accidentally being

switched on during charging cycle.

4.

Connect charger “AC” plug to properly

rounded outlet that has correct voltage

B

or the charger.

5.

The charger suppled by Wlndsor is

totally automatic and shuts off when

the batteries are fully charged.

NOTE

Refer to the charger manual for

detailed charging information.

6.

After charging check electrolyte level

of the batteries. Add distilled water to

the level as shown in diagram.

NOTE

’/4

”

FROM

BOTTOM

OF TUBE

3.

Keep the battery electrolyte at th$

correct level - approximately

below bottom of filler tube of each cell.

Distilled water should be added, as

needed,

WARNING:

level to drop below the tops of the plates.

AFTER

charging cycle.

Do not allow electrolyte

SERVICING THE

COMPACT SCRUBBER

CAUTION:

ments or repairs to the machine.

A

1.

Only qualified maintenance personnel

are

2.

Make sure battery charger is discon

nected.

3.

Make sure all switches are “OFF”.

4.

Remove batteries as required or discon

nect main battery leads from batteries

when making repairs to electrical system.

5.

Refer to wiring diagram when replacing

electrical parts or repairing electrical

system.

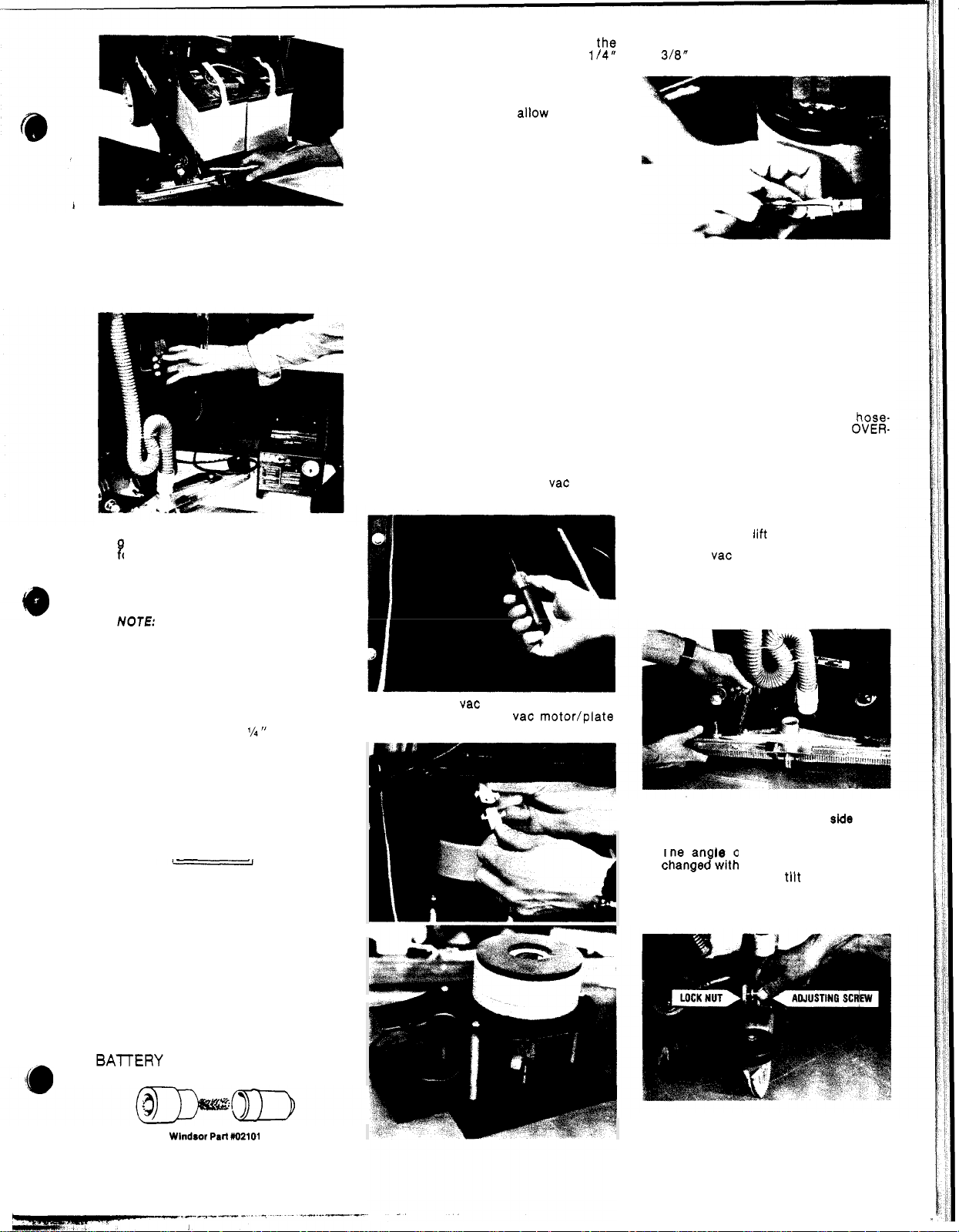

VACUUM

1.

Disconnect battery leads and remove

batteries from compartment.

2.

Remove

plate assembly to recovery tank.

3.

Disconnect vac motor lead from con

nector and lift out vac motor/plate

assembly.

Before making any adjust

to

perform repairs.

MOTOR

(6)

screws holding vac motor/

4.

114

-

.

.

-

-

Check motor brushes. When worn to

318”

replace both brushes.

PUMP

(On models equipped with auxiliary pump)

1.

2.

ASSEMBLY

Remove batteries and squeegee as

sembly. Lay machine on side.

Disconnect pump motor leads. Re

move

(4)

chassis. Disconnect solution hoses

from pump head and lift out pump.

Refer to pump drawing for replace

ment parts.

CAUTION:

barbs on pump head-DO NOT OVER-

TIGHTEN-as this could crack intake

and exhaust ports in pump head.

screws holding pump to

When replacing hose-

-

-

-

SQUEEGEE ASSEMBLY

To remove squeegee assembly.

1.

Raise squeegee lift arm to store position.

2.

Remove vac hose from squeegee.

3.

Pull retaining pin from locator stud.

Push down and slide squeegee to the

right to disengage right hand stud from

drag arm.

-

.

BATTERY MAINTENANCE

1.

Keep tops of batteries clean and dry.

Use a damp cloth with a weak solution

of baking soda or ammonia and water.

Use a clean dry cloth to wipe battery

tops dry after cleaning.

2.

If corrosion (white deposits) appears

on the battery terminals and cable

clamps, remove and clean. Use a battery

terminal and connector cleaning tool.

BAlTERY TERMINAL CLEANER

Wlndsor

Pall

M2101

4.

When installing or replacing squeegee

blades make sure the

blade is next to the squeegee casting.

5.

The an

changejwith the adjusting screw. Turn

screw clockwise to

ward and counterclockwise to tilt rear

ward. Tighten lock nut after making

adjustment.

6.

Down pressure can be increased or

decreased with the adjusting nut.

18

of the squeegee can be

smooth

side

tiit squeegee for

of the

-

-

5

Page 6

7.

Squeegee tracking can be controlled

by adjustin tension of squeegee

springs.

as shown before making adjustments.

NOT%

:

Position

recovery

hose

SCRUB DECK/BRUSH

MOTOR

1.

Remove

shroud.

(4)

screws holding motor

4.

Disconnect motor leads from terminal

block.

5.

Remove

to scrub deck.

(4)

screws holding brush motor

WHEELS/CASTERS

1.

Use allen wrench to remove wheel

retaining screw.

Use arbor press to replace bearings as

2.

required. Use grease gun to lubricate

bearings through zerk fitting on wheel

hub and caster axle.

2.

Remove batteries and squeegee as

sembly. Lay machine on side.

3.

Remove center screw holding drive

plate. Slide drive plate off motor shaft.

Limited

Warranty:

Windsor machine covered

defects in workmanship and

Brush

-

6.

Windsor Industries warrants that the

Motor

Remove

end bell. Replace brushes when worn

to

(2)

motor thru-bolts and lift off

310

inch.

by

this warranty is free from

materiqls under the following

terms:

6

YEARS

3

YEARS

Chassis and Metal Frames.

1

YEAR:

year

On Rotationally Molded Polyethylene Tanks.

On Traverse Drive Motors, Gear Units, AC Induction Polisher Motors, all Metal

On all other parts which are not specifically referenced herein, plus an extra

(2

years total) on Rectified DC Polisher Motors and Scrubber Brush Motors.

SOLUTION STRAINER

1.

An inline solution strainer is located

under chassis behind left wheel. Re

move sediment bowl and screen period

ically and rinse clean with hot water.

6

The warranty period shall commence at the date of FIRST PURCHASE BY THE END USER

FROM AN AUTHORIZED

to failure caused by abuse or normal wear.

Windsor will, at its option, repair or replace without charge, except for normal transportation

costs, parts that fail under normal use and service when operated and maintained in accord

ance with the Owners Instruction Manual and the Preventive

applicable. This warranty shall apply to defects in material and workmanship only and

-

does not apply to:

-

c) misuse or abuse (including use of incompatible or corrosive chemicals or overloading of

capacity), d) failure caused by lack of proper maintenance and cleaning,

chargers which are warranted by the original manufacturer for one year, and

wear on items such as belts, brushes, bearings, capacitors, carbon brushes, clutches,

cords, filters, finishes, gaskets, hoses, pulleys, relays, rectifiers, and switches.

The warranty is in lieu of all warranties, expressed or Implied, and releases Windsor from all

other obligations and liabilities. It is applicable only in the U.S.A., Canada, Australia, and

Zealand. Windsor Industries is not responsible for costs of repairs performed by

New

persons other than those specifically authorized by Windsor. This warranty does not apply

to damage or

APPROVED BY

If

a difficulty develops with this machine, contact either the Dealer from whom you

purchased the product or write to:

loss

WINDSOR

WINDSOR DISTRIBUTOR and applies to defective parts only, not

Maintenance Guide where

a) transportation damages, b) alterations by unauthorized persons,

e) batteries and

of income due to malfunctloning of the machine. USE

WILL

VOID WARRANTY.

OF

PARTS NOT

-

f) normal

Page 7

TANKS,

'

27

VAC & FRAME

39

KEY

PART

NO.

DESCRIPTION

1 70020 Scr, 1/4-20 x 112 HHMS

2 61181 Panel, Rear

3 87090 Washer, 1/4 Flat

4 70010 Scr, 1/4

5

34188 Frame, Main

6 57119 Nut, 3/8

-

20 x 1.5 HHCS

-

16 Lock

7 18027 Caster

8 70266 Scr,

9 70327 Scr, 1/4

318-16x 1 HHCS

-

20 x 3/8 THMS

10 27266 Cap, Wheel Hub

11 09010 Bearing, Caged Cup Needle

12 89068 Wheel (With

13 73437 Spacer, Wheel

14 27408 Collar,

Item 11)

Axle

Axle

15 70119 Set Scr, 1/4-20 x 3/8 KCP

16 03058

Axle,

Wheel

17 75152 Tank, Solution

18 50363 Label, Solution Warning

19 27416 Cord, Solution Lid

20 51138 Lid, Solution Tank

21 75153 Tank, Recovery

TANKS,

KEY PART

VAC

NO.

DESCRIPTION

6

FRAME

22 57047 Nut, 1/4-20 Ny-Lock

23 73427

Float

-

24 67227 Rod, Vac Float

25 73423 Screen, Float

26 27142 Cap Nut,

27 34190 Float

114"

Asm,

Vac Shut-Off

28 35060 Gasket, Dome

29 28040 Lid, Recovery Tank

30 27417 Cord,

1/8x 12

"

31 29154 Deflector, Vac Intake

32 70233 Scr,

#lo X 318

PH Hi-

33 20046 Clamp, 2.25 Hose

34 27188 Cord, Drain Hose Plug

35 66051 Plug, Drain Hose

36 40019 Hosebarb, 1.5 Double

37 20002 Clamp, 2" Nylon

"

38 39037 Hose, 1.5 x 24

39 39383 Hose

40

27282 Cuff, 1.5 Slip x 1.5 Hose

-

41 70085 Scr, 1/4

Asm,

-

42 87025 Washer,

Drain

Vac

20 x 1/2 PHMS

114 Star

LO

KEY

PART

NO.

DESCRIPTIOM

12

It

7

Page 8

SCRUB

DECK

0

‘74

\

//

24

A0

8

8

Page 9

I

KEY

PARTNO. DESCRIPTION

1A 73425 Strap Asm, PTC17 Bumper

1B 73465 Strap Asm, PTC20 Bumper

1/4

ID

x

2 87090 Washer,

3

48012 Knob, Adjustment

t

4A 14676 Bumper, PTC17 Brush Shroud

48 14571

I

5A 02162

58 02156

I

5C

02098 Pad Driver,

5D

02169 Pad Driver Asm, 18" Weighted

I

6 70304 Scr, W14x 1.25 FHWS

7

51076 Lug, Brush Mtg

8

41200 Synthetic Pad Lock

9 70233 Scr,

10A

02115 Brush Asm, 16" Nylon

Bumper,

Pad Driver, 16

Pad Driver

W10 x 3/8 PH Hi-Lo

3/4

PTC20 Brush Shroud

"

Ylw

Pad Lock

Asm. 16" Weighted

18

"

Blk Pad Lock

Flat

KEV

PUTNO.

SCRUB

DECK

DESCRIPTION

I

KEY

PARTNO.

DESCRIPTION

I

I

BATTERY COMPARTMENT

KEY

PARTNO. DESCRIPTION

BATTERY COMPARTMENT

9

Page 10

ELECTRICAL

CONTROLS

,

26

27

28

29

14

13

10

Page 11

MECHANICAL CONTROLS

I'

14

28

I

/"

30

34

I

-@--

13

41

12

1

37

LJ

'\

24

I.

t

A

-

-3

3

1/36

22

1-

32

I

8'

I(EI

PART

NO.

1

29151

2 66068

3 67226

4 73236

5

27413

6 66121

7 661 16

8

70020

9 27401

10 70025

11

57030

12 51125

13 67138

14 48030

DESCRIPTION

Door. Battery Compartment

Pin,

118

x

5/8

Roll

Rod, Battery Door Lock

Spring,

1.12

Cable, Battery Compartment Door

Pin,

Pin,

Scr,

Cable, Solution

Scr,

Nut,

Lever, Solution

Ring,

Knob, Handle

Compression

3/32 x 1/2

1/4 x 3/4

1/4-20 x 112

10-32 x 3/4

10-32

318

Clevis

Ny-Lock

Ext

Snap

Cotter

HHMS

HHMS

MECHANICAL CONTROLS

KEV

PARTNO. DESCRIPTION

15

27460

16 70298

17 87029

19 87030

20 66144

21 57006

22 70119

23 67221

24 14679

25 50473

26 57032

27 87080

28 78220

29 38169

Cable, Squeegee

Shoulder Bolt,

Washer,

Washer,

Pivot, Cable

Nut,

1/4-20

Set Scr,

Rod, Main Lever

Bushing, Lever Pivot

Card, Instruction

Nut,

3/8-16

Washer,

Tube, Handle Adj

Handle, w/Foam Grip

5/16

5/16

Flat

3/8 x 3/4

1/4-20 x 318

1/2"

Nylon

Hex

Serrated Flange

Flat

OD

KCP

x

318

L

-

KEV

PARTNO. DESCRIPTION

30 67224

31 51142

32 27459

33 67228

34 66133

35 87018

36 66073

37 50477

38 61181

39 57105

40 70018

41 87003

42 36059

Rod, Handle Adjust

Lever, Handle Clamp

Cable, Scrub Deck

Rod, Scrub Deck Lift

Pin,

3/16

x

.88

#lo

Flat

Dla

x

Hex w/Star

x 1 HHCS

5/16

Flat

Handle

L Clevis

3/4

L

Washer,

Pin,

1/16

Label, Charger Warning

Panel, Rear

Nut,

1/4-20

Scr,

1/4-20

Washer,

Grip,

MX

Cotter

11

Page 12

SQUEEGEE

EL

SQUEEOEE

LIFT

MECHANISM

r

I

4?

-I

-

Frame

Frame

KEY PART

1

2

3 89058 Wheel, Squeegee Roller

4 66108

5

6 14482 Brkt, Squeegee Wheel

7 70011 Scr, 1/4

8 87025 Washer,

9

10

11A

116 02165 Squeegee Blade, Urethane

12 73428 Squeegee Shoe

13A 73415 Squeegee Blade, Front

138

14 57085 Nut, 3/8

15

16 66092 Pin, Hair Spring Cotter

17 70098 Scr, 8

NO.

OESCRIPTION

67103 Ring, 5/16

87029 Washer, 5/16 Flat

Pin, Squeegee

57112

70020 Scr, 1/4-20 x 1/2 HHMS

67217 Retainer, Squeegee

73416 Squeegee Blade, Rear

02165 Squeegee Blade, Urethane

14483 Bolt, Squeegee Stud

Nut, 5/16-18 Flange

Ext

Snap

Wheel

-

20 x 5/8 HHMS

114 Star

-

16 Hex Jam

-

32 x 318 PHST

SQUEEGEE & SQUEEGEE

KEY

PART

NO. OESCRIPTION

36 27382 Collar, Squeegee

LIFT

MECHANISM

I

I

KEY PART

NO.

OESCRIPTION

I

4

12

Page 13

AUXILIARY

3

20

PUMP

MODEL

PLUMBING

28

27

Note:

i

I

lus trated with

machine laying

on right side.

STANDARD MODEL

Plumbing

6

I

13

Page 14

TROUBLE-SHOOTING

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

I

No

power.

Vacuum motor

Battery cables corroded

at battery terminals.

Faulty main switch.

Faulty safety override

switch.

Circuit breaker tripped.

GUIDE

1. Clean battery cable clamps and battery terminals.

2.

Check voltage at points A and B. Voltage should be

1. Check voltage at points

2.

Turn main switch on and check voltage at points B and D. Voltage should be

22/26

VDC.

If

no voltage remove leads and check switch for continuity.

With main switch

at B and

tinuity in normal position and no continuity when switch is activated.

Reset

H

vac motor circuit breaker

“ON” check voltage at points B and

remove leads and check micro-switch for continuity. Should have con

does not run.

Loose connection.

vac switch.

Faulty

vac relay.

Faulty

vac circuit

Faulty

breaker.

Motor brushes worn.

Check motor lead connections at terminals.

Remove leads and check switch for continuity. Replace as needed.

With main switch

Voltage should be

With main switch

Voltage should be

Check motor brushes.

and motor secured

motor should be

“ON”

22/26

“ON”

22/26

,

6.2

22/26

VDC.

B

and C. Voltage should be

(20

amp).

and vac switch “ON” check voltage at points B and

VDC.

and vac switch

VDC.

ReDlace when worn

apply ’battery voltage directly

amps.

“ON”

to

318”.

22/26

VDC.

G,

and B and

check voltage at points B and

With batteries fullv charaed

to

motor.

H.

No

load amp draw of

If

no voltage

-

I.

J.

Brush motor

does not run.

Solution

light

does not work.

Battery charge

level lndlcator

does not light.

Circuit breaker tripped.

Loose connections.

Faulty brush switch.

Faulty brush relay.

Faulty brush circuit

breaker.

Motor brushes worn.

Loose connections.

Faulty solution light.

Light stays on with

solution lever in

“OFF” position.

Loose connections.

Faulty PC Board or

faulty light.

Reset circuit breaker.

Check motor leads at terminal block connections (located on inside front of frame).

Tighten screws as needed.

Remove leads and check switch for continuity. Replace as needed.

“ON”

With main switch

Voltage should be

With main switch

Voltage should be

Check motor brushes. Replace when worn

and motor secured, apply battery voltage directly

motor should be

Check for loose connections at solution light, solution switch and at

ground.

Remove light and apply direct voltage

Adjust solution light switch.

Check connections at battery card, micro

ground connection at

Check voltage into PC Board (point

across first pin (from right) and eighth pin (from right) point

8/10

VDC. If voltage is 8/10 VDC replace battery charge level indicator light. If

there is no voltage replace PC Board.

6

and brush switch

22/26

VDC.

“ON”

and brush switch

22/26

VDC.

to

8 amps.

vac motor relay.

T).

“ON”

check voltage at points B and

“ON”

check voltage at points B and L.

to

3/8”. With batteries fully charged

to

motor.

No

load amp draw of

(24

VDC)

to

light. Replace light as needed.

-

switch at charger Connection, and

Voltage should be

22/26

VDC. Check voltage

U.

Voltage should be

K.

vac fan relay

14

Page 15

POWER

SWITCH SWITCH LIGHT

e

[

\

SOLUTION SOLUTION LIGHT BATTERY LEVEL

VACWM/BRUSH

SWITCH

WIRING

DIAGRAM

VACUUM

MOTOR

PUMP SWITCH

IOPTIONAL)

CHARGER

CONNECTION

I

i

al:

PUMP MOTOR

(OPTIONAL)

I

Plug

66017

Housing

41010

Pump

I

I

0

Assembly

Pump Repair

Cover

27057

65019

Kit

62053

47020

Base

I

ra

I

-

Pump

I

Motor

PUMP

53188

15

Loading...

Loading...