Page 1

Page 2

Operator Safety Instructions

Read the instruction manual before operating this

mac h i ne.

Operate this machine only from the rear of machine.

~ ~~~~ ~~~

Use caution when operating the machine on a ramp

or

incline.

on a ramp or incline.

Machine can cause an explosion when operated near

flammable vapors and materials.

Do

not turn

or

leave this machine unattended

~

'

~ ~~

Store machine inside. Keep the electrical components

of the machine dry.

~ ~ ~~

Lead acid batteries generate gases which can cause

an explosion. Keep sparks and flames away from the

batteries. Charge the batteries only in a well ventilated

area.

~ ~ ~~ ~~ ~

Wear eye protection when working near batteries.

Do

not put any type of metal objects across the battery

or

terminals

on top of the batteries.

Maintenance and repairs must be done by qualified

personnel only. Maintain adjustments on machine

as per specifications noted in the service manual.

Make sure all warning and caution labels are legible

and properly attached to the machine.

2

Page 3

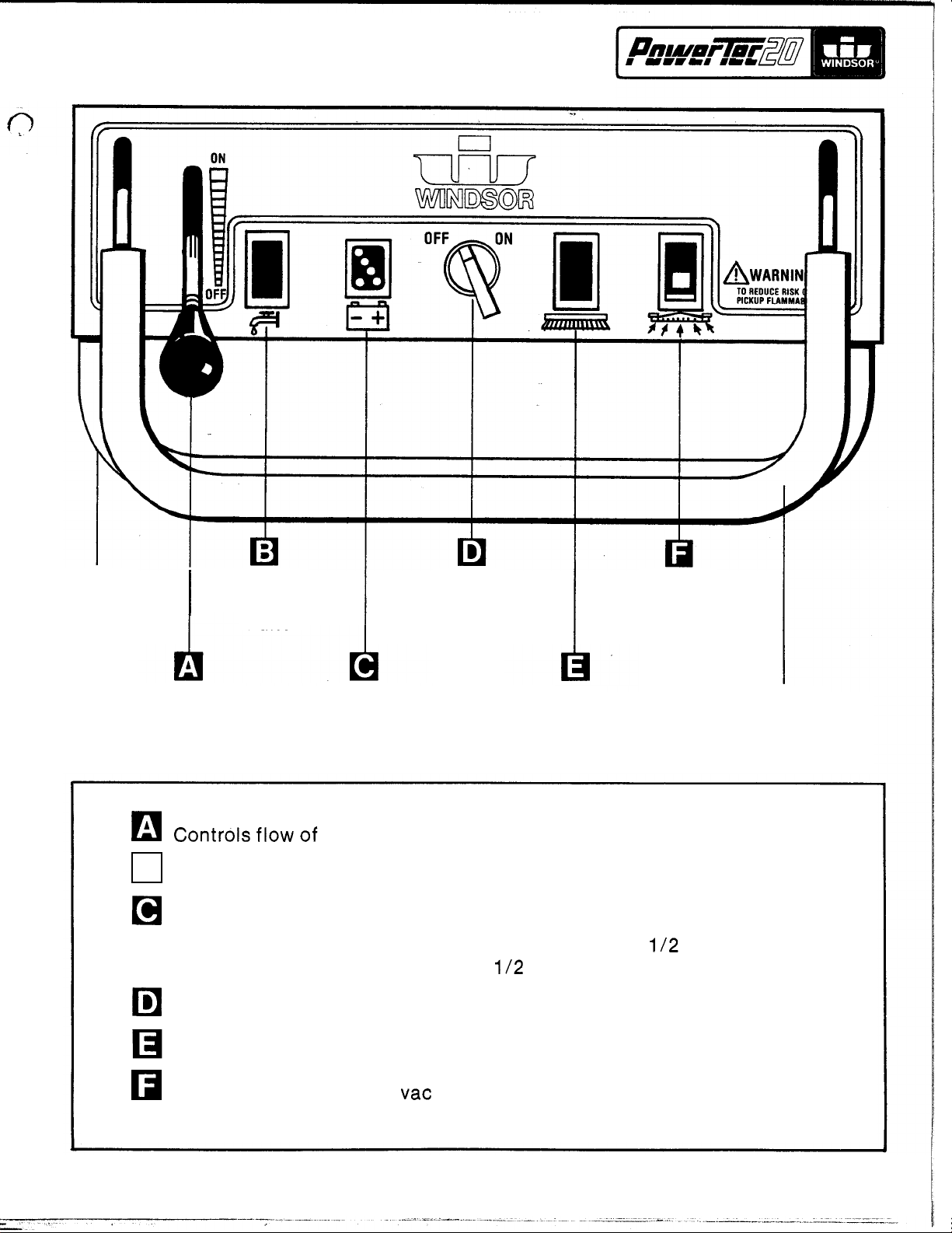

CONTROL

HANDLE

SOLUTION

“ON”

I

LIGHT

MAIN

SWITCH

LIGHTED

VACUUM

SWITCH

SOLUTION

CONTROL

LEVER

Controls flow of cleaning solution to floor.

Light

Indicates charge condition of batteries

Switches on main drive motor and brush.

Light

Lighted switch indicates vac motor is on.

“ON”

4

green lights - full charge - approximately

1

green light - approximately

“ON”

BATTERY

CONDITION

LIGHTS

indicates solution valve is open.

indicates brush is turning.

BRUSH

“ON”

LIGHT

-

112

hour run time left.

4

TRAVERSE

112

hours run time.

CONTROL

HANDLE

3

Page 4

,

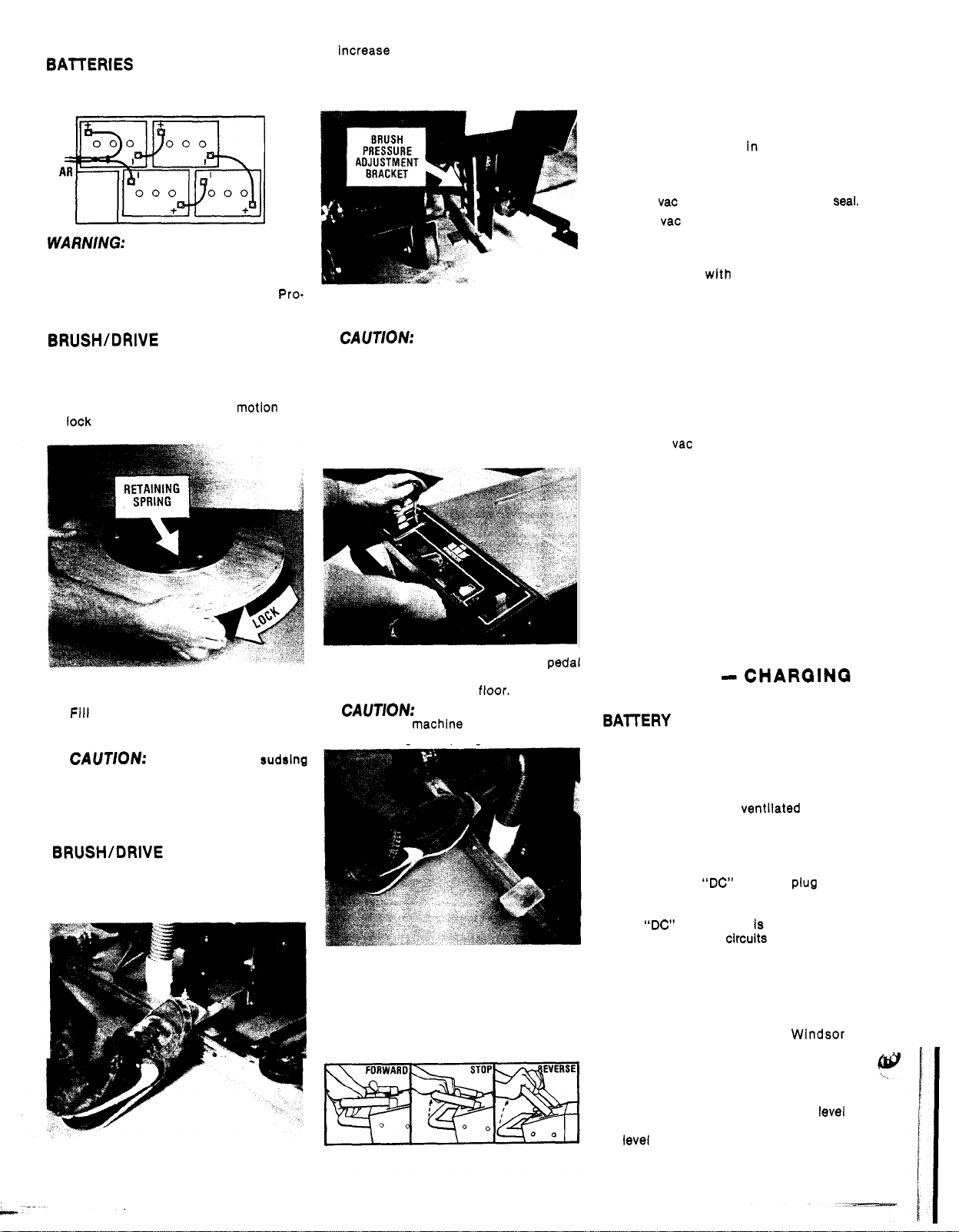

MACHINE PREPARATION

BAITERIES

1.

Install batteries and connect battery

cables as shown.

RE

MfARN/NG:

leave cover open when charging batteries.

2.

Charge the batteries before using the

machine. (See Battery Charging

ced u re)

Provide proper ventilation and

BRUSH/DRIVE PAD ASSEMBLY

1.

Remove brush cover.

2.

Position brush under drive plate and lift

brush to engage drive lugs in recesses

in plate.

lock brush to drive plate.

A

quick clockwise motion will

FRONT

Pro-

NOTE

This pedal can also be used to

Increase brush pressure to the floor.

This can be done by pulling up on the

pedal and locking it in one of the posi

tions on the brush adjustment bracket.

2.

Switch on brush motor by turning the

main switch clockwise.

CAUTION:

on floor while machine is stationary.

3.

Switch on vacuum switch.

4.

Push solution lever forward.

amount of solution can be regulated

during operation depending on the type

of floor and the traverse speed of the

machine.

Do

not leave brush running

NOTE:

REGULAR MAINTENANCE

BEFORE STARTING

-

1.

Disconnect battery charger.

connect the “AC” power cord from the

wall receptacle before removing the

“DC” charger plug from machine.

2.

Check water level In batteries. Add

distilled water as needed.

3.

Attach brush

4.

Check vac motor and float for proper seal.

5.

Check vac hose connection at squeegee

shoe.

8.

Check squeegee blades for wear.

7.

Fill machine with hot water and add

cleaning chemical at the proportions

noted on the container.

sudsing cleaner designed for use in

automatic hard surface floor scrubbers.

BEFORE STORING MACHINE AT

The

THE END

1.

Drain both solution and recovery tanks

and rinse clean.

2.

Lift out vac motor and float assembly

to allow recovery tank to air dry.

3.

Remove brush or drive pad from drive

plate and store upside down or hang on

wall.

4.

Wipe down exterior of machine with

damp cloth.

5.

Raise squeegee assembly to “store”

position.

8.

Charge batteries. (See Battery Charging

Procedure)

OF

WORK

or

drive pad to drive plate.

WORK

PERIOD

NOTE

NOTE

Use a low

PERIOD:

Dis

-

CLEANING SOLUTION

1.

Fill machine with hot water and add

cleaning chemical at the proportion

noted on the container.

CAUTION:

cleaning chemical designed for use in

automatic hard surface floor scrubbers.

OPERATINO

Always use a

THE

MACHINE

low

rudsing

BRUSH/DRIVE PAD CONTROL

1.

Push down and slightly to the left on

brush lift arm to lower brush to floor

(right hand pedal).

4

5.

Push down on front of squeegee pedal

to release the latch arm and lower

squeegee assembly to

CAUTION:

moving the machlne in

vent damage to squeegee blades.

8.

To

go

traverse handle.

STOP

To

pull back on the control handle.

To

REVERSE

handle.

Always lift squeegee before

FORWARD

release the traverse handle and

machine lift up on traverse

floor.

REVERSE

press down on the

to pre

BATTERIES - CHAROINQ

AND MAINTENANCE

BAITERY CHARGING PROCEDURE

-

WARNING:

gases which can cause an explosion. Keep

sparks and flames away from batteries.

SMOKING.

when working near batteries. Charge the

batteries only in a well

1.

Set the charger on a flat level surface.

2.

Lift

cover up during charging cycle.

3.

Connect the “DC” charger plug to the

connector on the machine.

safety override switch is activated when

the

prevents all panel circuits on the machine

from accidentally being switched on

during charging cycle.

4.

Connect charger “AC” plug to properly

grounded outlet that has correct voltage

for the charger.

5.

The charger supplied by Windsor is

totally automatic and shuts

batteries are fully charged.

NOTE:

detailed charging information.

8.

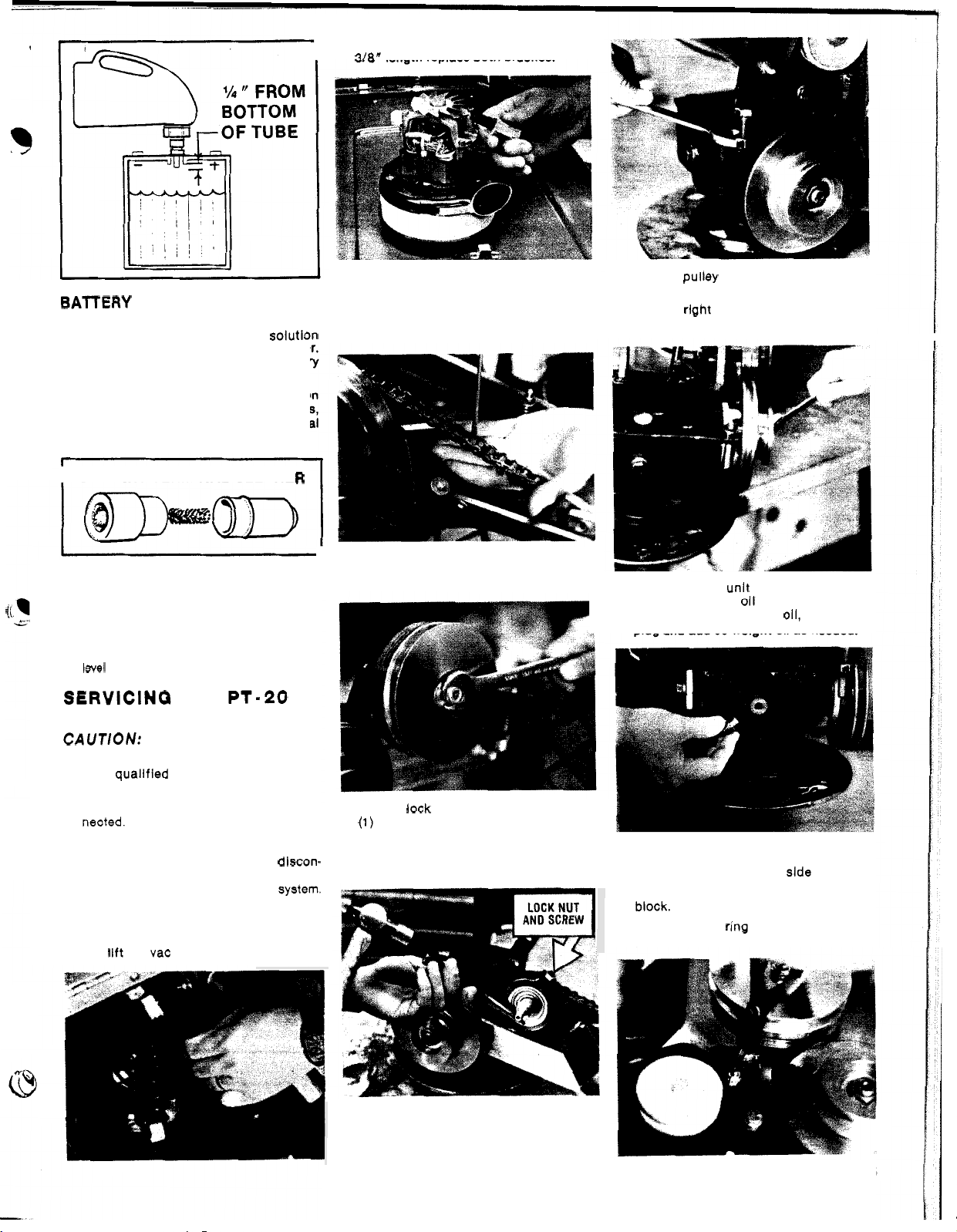

After charging check electrolyte level

the batteries. Add distilled water to the

level as shown in dlagram. (upper right)

Lead acid batteries generate

Always wear eye protection

ventilated area.

up battery compartment cover. Leave

NOTE

“DC’

charge plug Is connected. This

off

when the

Refer to the charger manual for

NO

A

Of

Page 5

BATTERY MAINTENANCE

1.

Keep tops of batteries clean and dry.

Use a damp cloth with a weak

of baking soda or ammonia and water.

Use a clean dry cloth to wipe battery

tops dry after cleaning.

2.

If

corrosion (white deposits) appears on

the battery terminals and cable clamps,

remove and clean. Use a battery terminal

and connector cleaning tool.

SOlutlOn

2.

Check motor brushes - when worn to

318"

length replace both brushes.

DRIVE CHAIN

1.

Remove left side skirt and side panel.

2. To

remove chain, remove retaining clip

and pull out master link.

2.

Remove pulley to allow removal of left

hand lift arm.

3.

Remove right hand pivot bolt, bushing

and lift arm.

BATTERY TERM

3.

Keep the battery electrolyte at the

correct level

bottom of filler tube of each cell. Dis

tilled

water should be added, as needed,

AFTER

charging cycle.

WARNING:

level to drop below the tops of the plates.

SERVlClNQ

I

N

AL CLEAN E

-

approximately

Do not allow electrolyte

THE

114

PT-20

SCRUBBER

CAUTION:

ments or repairs to the machine..

1.

Only qualified maintenance personnel

are to perform repairs.

2.

Make sure battery charger is dlscon

nected.

3.

Make sure all switches are

4.

Remove batteries as required or dlscon-

nect main battery leads from batteries

when making repairs to electrical

VACUUM

1.

Disconnect motor leads from connector

and

Before making any adjust

MOTOR

lift out vac motor.

"

.

OFF

R

"

below

"

system.

3.

To

adjust chain tension

A.

Remove traverse drive pulley.

-

-

B.

Loosen lock nut and back out screw

-

(I)

turn.

C.

Use a hammer and punch to rotate

the eccentric bushing to tighten or

loosen the drive chain.

. . .

4.

To

check gear unit oil level - remove

Inspection plug;

bottom of hole.

plug and add

TRAVERSE DRIVE

1.

Remove lower right hand side skirt.

2.

Disconnect motor leads from terminal

block.

3.

Remove snap ring from end of motor

pivot shaft.

oil should be at the

To

add

011,

90

welght oil as needed.

remove

MOTOR

fill

QEAR

1.

UNIT

Loosen belt tension screw and remove

belts.

5

Page 6

4.

Lift out motor - check motor brushes.

When worn to

318"

replace brushes.

3.

Remove axle hub clamps. Lift

bly and lay on bench to service.

off

assem

-

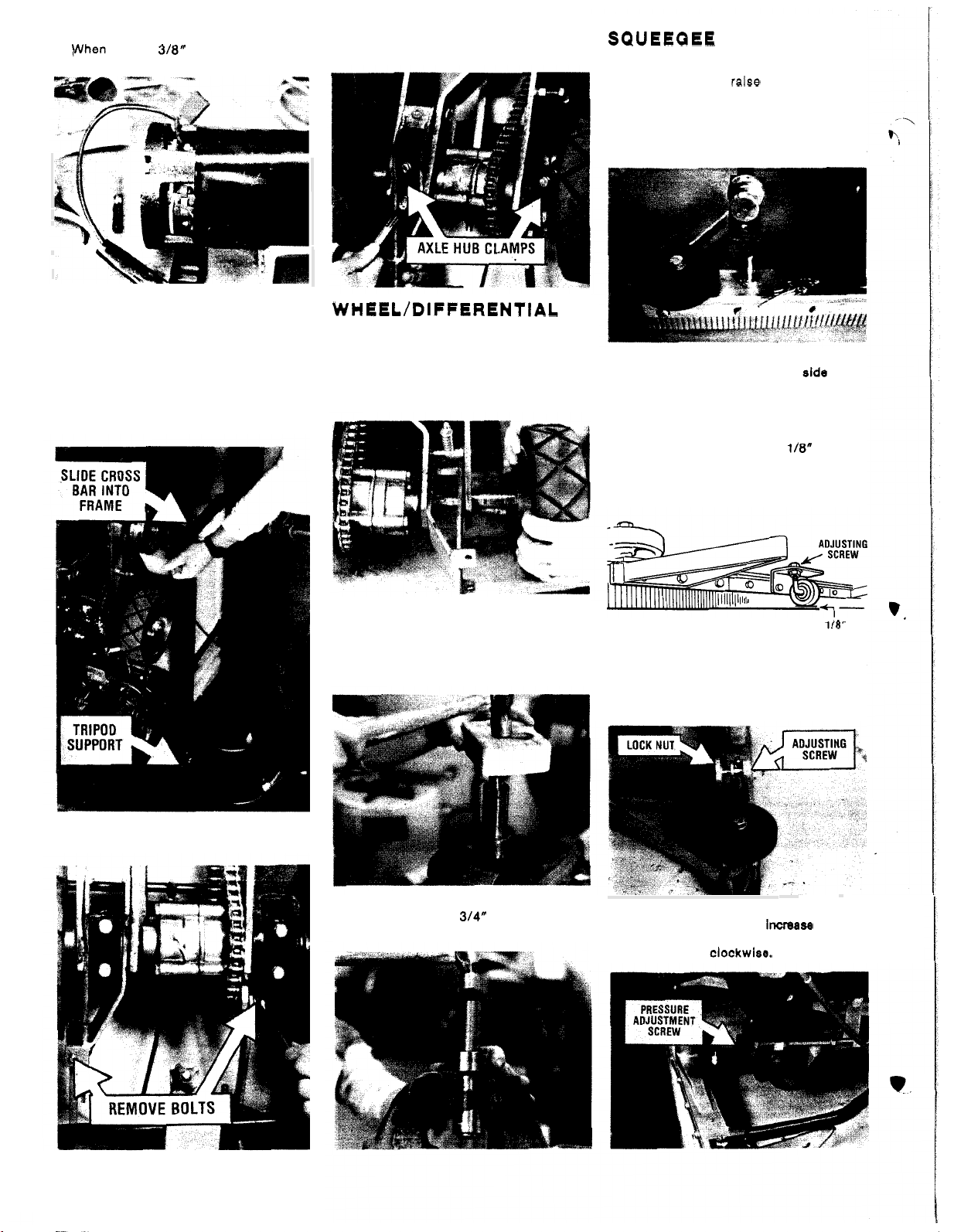

SQUEEQEE ASSEMBLY

To

remove squeegee assembly.. .

1.

Depress pedal to raise squeegee.

2. Pull retaining pin from locator stud.

3.

Push down on squeegee to remove from

drag arm and slide squeegee to the right

to disengage right hand stud from arm.

DIFFERENTIAL ASSEMBLY

NOTE:

The differential assembly, traverse

drive motor and brush gear unit can be

removed as a total unit for servicing, if

required.

1.

Lay machine on side or build tripod

supports for each side of machine to

hold unit upright as shown.

WHEEL/DIFFERENTIAL

AXLE ASSEMBLY

1.

Remove bolt holding wheel to axle.

2.

Remove wheel from axle. Use wheel

if

puller,

damage threads in center hole of axle.

3.

To

A.

B.

needed, being careful not to

remove axle and bearings from hub ...

Remove snap ring from hub.

Use an arbor press or hammer and

block of wood to remove bearing and

axle.

4.

When installing or replacing squeegee

blades make sure the smooth

blade is next to the squeegee casting.

5.

Squeegee support caster - with

squeegee assembly setting perpendicular

to the floor surface, adjust caster to a

clearance of approximately

bottom of caster and the floor.

squeegee blades wear, adjust caster to

maintain this dimension.

6. The angle of the squeegee can be

changed with the adjusting screw. Turn

screw clockwise to tilt squeegee forward

and counterclockwise to tilt rearward.

Tighten lock nut after making adjustment.

1/8"

slde

between

As

1/0"

of the

the

2. Remove boits from brush lift arm bracket

and traverse drive connecting arm.

6

C.

To

remove roiler bearing from hub,

use a piece of

out bearing.

314"

dia. tube to drive

7.

Squeegee pressure can be changed with

the adjusting screw.

turn counterclockwise, to decrease

pressure turn

To

clockwise.

Increase

pressure

Page 7

CAUTION:

excessive pressure on the squeegee will

cause abnormal wear on the squeegee

blades.

BRUSH DRIVE BELT

‘\

1.

Remove traverse drive belt by rolling belt

off pulley.

2.

Loosen belt tension adjusting screw and

remove brush drive belt. After readjust

ing belt tension, make sure lock nut on

adjusting screw Is tight.

Operating the machine with

TRAVERSE DRIVE BELT

1.

With operating handle in neutral position,

roll belt off pulley. Replace as required.

2.

After installing new belt check for clear

ance between traverse pulley and brush

drive belt. The pulley should not be in

contact

handle is in the neutral position.

To

A.

B.

-

with the belt when the traverse

adjust clearance:

Remove left side panel.

Loosen lock nuts on link rod. Adjust

bracket on link rod

contact belt. Retighten lock nuts on pletely on the floor.

link rod.

so

pulley does not Springs will allow the brush to rest com

BRUSH ANGLE

-

ADJUSTMENT

- -- - -

1.

2.

3.

4.

-

~ ~

Start

the

brush

motor

brush slowly to the floor. When the rear

of the brush

front of the brush

3/16”

BY releasing the foot lift pedal the

A.

If

the brush vibrates while in opera-

tlon

B.

If

the machine pulls to the left during

operation

The springs

to maintain the distances

To

change brush inclination, IOOSen nut

(D)

and turn tie-rod

angle

“A”

from the floor.

Increase dirtanu

decrease dlrtanu

(C)

should be adjusted

Is reached.

and

touches the floor, the

“8”

should be about

(E)

until the correct

A

“B”.

as

lower

“B”.

shown.

so

the

-

as

Page 8

'

VAC,

BATTERY,

TANK

REV

VAC,

PARTNO.

BATTERY,

mnitvion

TANK

7

/

32

9

70280

Stud,

1/4 Turn Fastener

Scr,

10 70076

11 51074 Lug,

12 48012 Knob, 5/16

10-32 x 1 FHMS

Shroud

Mounting

-

18

8

Page 9

17

A

I

16

9

Page 10

'

MAINFRAME

WITANKS

34

38

37

36

35

I

41'

io

13

14,

"1

/

39

46

Page 11

SQUEEGEE

w/ARM

59

69

-

21

-

-

1

I

11

.

.

~

__

.

.

.

.- .- .

.

, . ,

.

.

.

-

.

..

Page 12

~ONTROLS

KEY PART NO. DESCRIPTION

1 05029 Arm. Drive Linkage Adj

2 70015 Scr. 1/4-20 x 314 HHMS

3 87090 Washer, 1/4 ID x 3/4

4 14492 Bushing, .25

5 70270 Scr, 1/4

6 05030 Arm, Drive Linkage

7

70260 Scr., M6 x 16 HHMS

8

87087 Washer, M6 x 25

9 14493 Bushing,

10 57105 Nut, 1/4-20 Hex w/Star Washer

11 05033 Arm, Linkage Transfer

12 14491 Bushing, .25

13 70265 Scr, 1/4

14 73268 Spring, Drive Linkage

15 57117 Nut. 5/16

16 67114 Rod, Drive Linkage

17 87096 Washer, 5/16

18 27277 Clevis, 5/16

19 66116

20 66121 Pin, 3/32 x 112 Cotter

21 70273 Shoulder Bolt, 318 x 1

22 87003 Washer, 318

23 90002 Yoke, PT-20 Drive Linkage

24 57112 Nut, 5/16

25 57104 Nut. 10

26 67122 Rod, Drive Linkage

27 14509 Bracket, RH Drive Handle Mtg

28 62190 Plate, PT

29 62211 Plate, Drive Handle Arm

30 70085 Scr, 1/4

31 57047 Nut, 1/4-20 Lock

32 61 102 Panel, PT

33 70054 Scr, 8

34 38131 Handle, PT

35 36084 Grip, PT

36 48030 Knob, PT

37 38133 Handle, PT

.

38 70057 Scr, 1/4-20 x 1

(

MECHANICAL

ID

x

-

20 x 3/4 HHCS

-

20 x 314

Pin Clevis, 114 x 314

-

32 w/Star Washer

-

-

20 x 112 PHMS

-

32 x 3/8 FHMS

-

20 Drive

-

.37

.25

ID

x .37

ID

x .62

SHCS

-

24 Hex

Int Lock-Lite

-

24 UNF Rod

ID

x 718

-

18 Flange

20 Support

-

20 Control

-

20 Drive

20 Solution Lever

-

20 Main

.OO

OD

OD

OD

OD

.OO

OD

RHMS

x .25

)

CONTROLS (MECHANICAL)

/

28

\

‘25

-\

l5

\

48

\

\

47

12

7

49

Controls (Mechanical) continued

I

KEY PARTNO. DESCRIPTION

45 70245 Scr, 4-40 x 314 PHMS

46 72053 Switch, 125 VDC SPST No Lever

47 57100 Nut, 4

48 14519 Bracket, Solution Cable Mtg

49 27289 Cable,

50 70085 1/4

5

51 70024 Scr,

52

70279

53

87029 Washer, 5/16

-

40 Hex

PT-20

Solution

-

20 x 112 PHMS

#8

x

112 Sheet Metal

Scr, MOB Sheet Metal PH

ID

x 3/4

O

I

D

Page 13

48

49

50

Page 14

‘IAL

-

39

14 21

Page 15

PT.20

PART NO. DESCRIPTION LOCATION

I

50378

Instruction Card

I

9387

Maintenance Under hood

LABELS

inside cover

On

handle

15

I

I

I

Page 16

-;:"BRUSH

I.

DRIVE

BRUSH

DRIVE

74

-

Reduction

KEY

PART

NO.

DESCRIPTION

53 671 12 Rod, Turnbuckle Sliding

54 57022 Nut, 3/8-16

55

66105 Pin, Turnbuckle

56 67104 Ring,

57 70260 Scr, M6x 16

58 87056 Washer, M6

59 20068 Clamp, PT-20 Brush

60 73317 Shim,

61 73318 Shim, 15mm Dia.

62 73319 Spring, PT-20 Brush Lock

63A 02095 Brush, PT-20 Nylon

638 02096 Brush, PT

63C 02097 Brush, PT-20 Extra Aggressive

630 02098 Pad Driver, PT-20

64 59020 0-Ring, 4125

65 57133 Nut, M24 x 2 Lock

66 73320 Shim, M47 x 0.3

67 67144 Ring, M47 Int Snap

68 73313 Seal, M30

69 36090 Gear, Reduction Pinion

70 67143 Ring, M60

71 62202 Plate, PT-20 Brush Holder

72 70304 Scr, 1/4-20 x 1.25

73 51076 Lug, Brush Mounting

74 36076 Gearbox Asm, PT-20 Reduction

Lock

518

Ext

Snap

12mm Dia.

-

20 Polypro

x

47 x

Ext Snap

Gearbox

H-D

7

Oil

FHWS

Assembly

,

1

t

16

Page 17

I'

"

Product

Modification

Pi-20

Beginning

were made

in

the .service manual. Retain

manual

BATTERY

with

for

to

Serial

the

#I700

brush

reference when ordering replacement

parts.

1.

Key

#44

-

Changed

replacing the snap

2.

Keys

drive plate,

#1-2-3-4-6-35-72-73-74-75-76-77

brush

to

rings.

drive lock, and new gear

assembly.

43

SC

the

drive as

this

rod

with

42

41

40

RU

B

B

ER

following changes

shown

lock

on

notice

nuts,

-

Page

in

16

your

Changed

unit

39

38

37

I

18

(Rev.

3/91)

b-

I

Page 18

PROBLEM

No

power.

Vacuum motor

does not run.

Brush motor

does

not

run.

Solution light

does

not work.

Battery charge

level Indicator

lights.

PROBABLE CAUSE

Circuit breaker tripped.

Battery cables corroded

at battery terminals.

Faulty main switch.

Faulty safety override

micro switch.

Faulty solenoid.

Circuit breaker tripped.

Loose connections.

Faulty

vac circuit

breaker.

vac switch.

Faulty

Motor brushes worn.

Circuit breaker tripped.

Loose connection.

Faulty solenoid.

Faulty drive motor.

Faulty circuit breaker.

Loose connections.

Faulty solution light.

Light stay on with

solution lever in

“OFF” position.

No

light are on with

main switch on.

Loose connections.

I

7

J.

CORRECTIVE ACTION

Reset brush motor circuit breaker

1. Clean battery cable clamps and battery terminals.

2. Check voltage at points A and

1.

Check voltage at points A and C. Voltage should be 22/26 VDC.

2. Turn main switch on and check voltage at points A and D. Voltage should be

22/26 VDC.

With main switch

be 22/26 VDC.

continuity. Should be continuity

lever is activated.

With main switch on (solenoid energized) check voltage at points

should be 22/26 VDC.

vac motor circuit breaker.

Reset

Check motor lead connections at terminal block and

motor. Keep all connections tight.

With main switch on check voltage at points A and H and A and

check continuity of circuit breaker. Replace as needed.

Remove leads and check switch for continuity. Replace as needed.

Check motor brushes. Replace when worn to

motor and applying

15

amp.

Reset

(50

Check motor leads at terminal block connection (located under right hand lower

side panel) tighten set screws as needed.

With main switch on check ouput voltage at points A and

22/26 VDC.

Check motor brushes

and motor secured, apply battery voltage direct to motor.

should be 12 to 13 amps.

Reset (6 amp) battery circuit breaker.

Check for loose electrical connections at terminal block, solution switch, and

solution light.

Remove light and apply direct battery voltage (24 VDC)

Adjust solution light switch.

Check (6 amp) battery circuit breaker. Reset

1.

Check electrical connections at circuit breaker.

2. Check voltage at inline connector at PC Board. Should be 22/26 VDC.

If

no voltage remove leads and check switch for continuity,

“ON”

If

check voltage at points A and E and A and F. Voltage should

no voltage at A and F remove leads and check micro switch for

If

24

VDC

amp) brush motor circuit breaker.

-

(50

amp).

B.

Voltage should be 22/26 VDC.

in

normal position and no continuity when switch

A

and

G

-

no voltage replace solenoid.

inline connector near vac

I.

W8“.

to

motor leads.

replace when worn to 3/8“. With batteries fully charged

No

if

Check vac motor by securing

load amp draw of motor should be

G.

Voltage should be

No

load amp draw

to

light. Replace light as needed.

tripped.

voltage

If

no voltage,

of

motor

17

Loading...

Loading...