Page 1

m\

-In English and

Deutsch

CONTENTS:

1

2

3

4

5

4

7

8

9

10

11

12

13

14

Diagram

Safety Instructions (english)

Operation

Maintenance cont. (english)

Safety Instructions (deutsch)

Operation

Maintenance cont. (deutsch)

Control Panel

Vac motor I Frame Assembly

Tank Assemblies

Brush Drive Assembly

Vac Shoe Assembly

Plumbing Assemblies

Wiring Diagram

Model

Model1 PSP-I & PSP-IG

I

Maintenance (english)

I

Maintenance (deutsch)

I

Handle Assembly

98130

Rev. 1 5/2/94

PASSPOR

TLI

Page 2

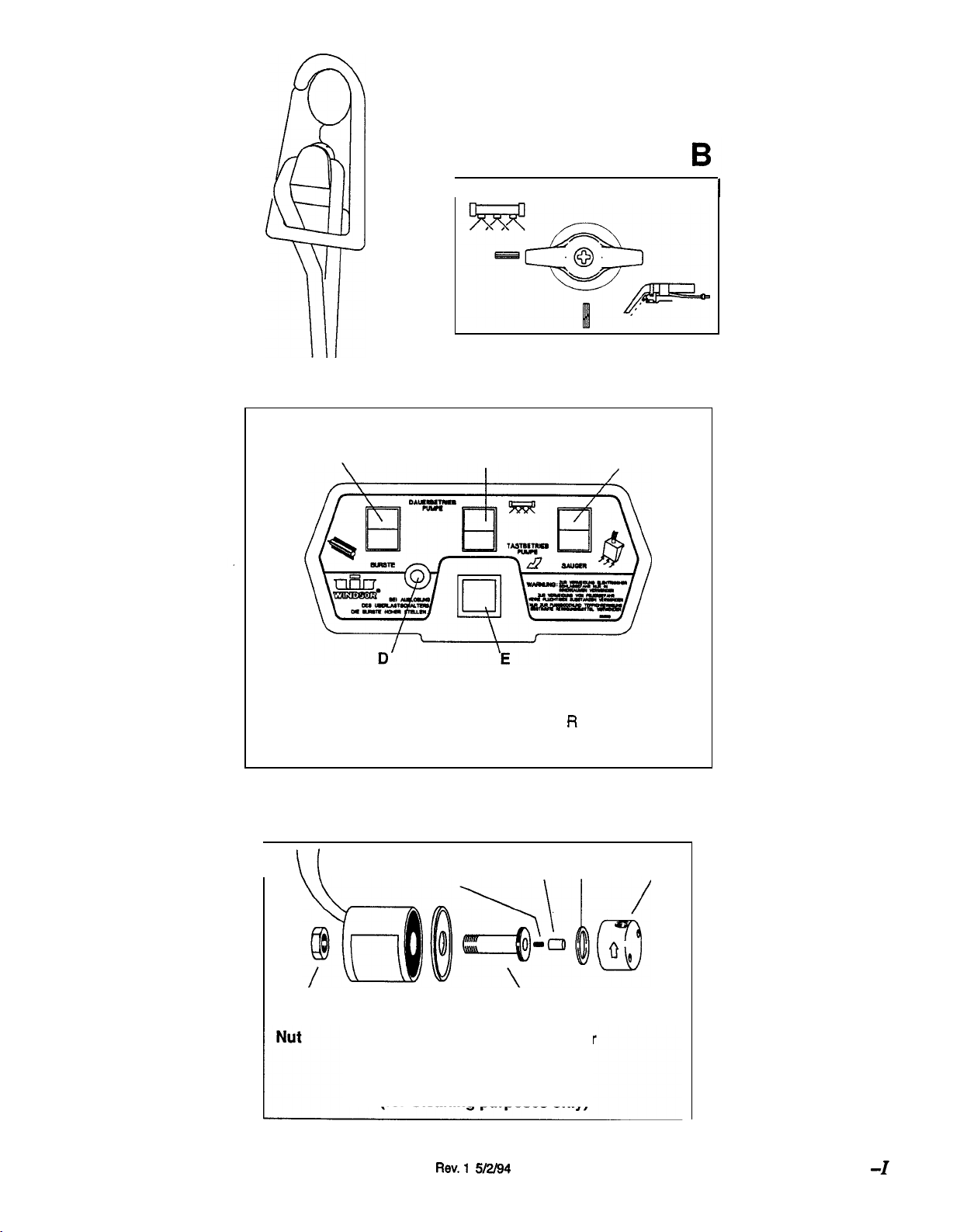

A

I

Switch Panel

50540

C

DIA GRAM

DIA

G

I

RA

MM

A

\

A- BRUSH A-BU RSTE

-

CONTINUOUS PUMP B-DAUERBETRIEB PUMPE

B

-

VACUUM C-SAUG

C

D-CI RCU

-

INTERMITTENT PUMP E-TASTBETRI

E

I

IT

BREAKER D-UBERLASTKNOPFES

\I

SPRING PLUNGER SEAL VALVE

B

E

R

EB

C

PUM

PE

D

BODY

1

\

Coil Washer Plunger

Solenoid Valve Assembly

(for Cleaning purposes only)

Rew.1

5/2/94

PASSPORT

-I

Page 3

ENGLISH

IMPORTANT SAFETY

INSTRUCTIONS

When

using

an

ptecautions

he

follcrruing:

-

Read

machine.

-

This

.

CAUTION:

designed

ht

health.

elecrrkal

must

all

instmctions before

machine

are

deemed

WARNING:

THE

ELECTRICAL SHOCK

OR

1,

Do

not

operate without filten

2.

Use only

Use

attachments.

3.

Use

Do

4.

Machines

near

not

fluids.

.

Do

materials

my

6.

00

smoking. such

hot

7.

Do

wet

8.

00

Unplug machine

use

9.

Turn

machine.

10.00

To

11.00

12.

If

has

outdoors.

to

13.

Do

handle.

around

14.00

cord away

15.

Do

attention is necessary

mar

16.

openings blocked.

I

7.

as

onty

manufacturers

indoors

not

expose

can

nammabie

operate

his

dust.

or

not

pick up

such

may

be

not

vaaum anythmg that

ashes.

not

handle

hands.

not

leave

and before servicing.

off

all

controls

not unplug machine

unplug.

grasp

not

use

with

the machine is not

been dropped.

or

an Authorized

not

carry

dose

sharp

cat

pulVrun

from

not allow

children.

Do

not

operate

deki

hat

may

~eep

hair.

loose

parpr

of

lhe

bcdy

PASSPORT^

appliance.

always

be

is

for

comd

7hi

machire

for

vacuuming

hazardous

RISK

OF

INJURY:

desaibed

onty.

present.

the

dropped into

by

to

in this

Do

not

to

rain.

cause

a

fire

vapors

01

machine

vapors.

fhmmabb

as

gasoline

as

cigarettes. matches,

he

plug

of

machine

from

outletwhen

before

by

the plug, not

damaged

warldng

damaged.

sewice

he

cord,

a

dbar

on

edges

cord.

a

men.

machiinewer

heated

surfaces.

be used

as

when

machi

Keep

reduce

aidlow.

cmmg,

away

from

basic

lolkwed,

using

is

not

dust

partides

to

your

TO

REDUCE

induding

this

W.

FIRE,

in

place.

manual.

recommended

use

outdoors.

when

operated

materials.

near

kumnable

or

combustible

or

use

where

Is

buming

machine

center.

use

with any

openings

wih

umtended.

not

unplugging

puling

on

the

cord.

ad

or

plug.

properly.

left

water,

return

cord

as

c#

pull

cord.

Keep

atoy.

Close

used

by

free

nng-.

and

ooenings

cord

Do

or

or

in

Ihe

card.

it

a

or

of

a11

and

18.

Vse

extra

caution

when

cleaning

stairs.

19.

Do

not

use

machine

20.

Maintenance and

by

qualified

personnel.

21.

when

cleaning

equipment

selec$ng

be

turned

elecMedl

22.

Duing use

outlee

devke

manufactuer

lineccnnecton

23.

When

arcuie

he

splash guard and mechanical

must

be

If

a

machine

persons,

damages

andlor

when

another

off.

Equipment

oudets

must

or

replacement

or

electrical fines-connections.

other

than

must

has

replaang

w

connections

ensured.

is

altered

connectors

Windsor

or

injuries

as

a

repairs

servicing

changing

lunclion,

be

mose

not

be

been

10

by

is

not

that

on

step.

must

be

clone

the

par&.

01

motor must

into

electrid

by

if

a

certain

to

elechi

equipment.

stability

when

Uw

plugged

unplugged.

of

prescribed

used

prescribed.

me

unauthorized

responsible

may occur.

any

the

for

SAVE THESE

INSTRUCTIONS

INSPECTION

Carefully

shipping damage. Each unit

thoroughly inspected before shipping, and

damage

should

unpack

and

Is

the responsibility

be

notified

immediately.

inspect your extactor

is

operated

of

the

-vier.

for

and

any

who

ELECTRICAL

This

extractor

AC circuit

240

Volts

torr.

panel

@

Make

specified

chine

operates

Voltages

could

Wring diagram

of

cause

machine.

WARNING:

sure

you

are

on

power

using the

nameplate

card

to

on

a standard

below

220

serious damage

is

mounted

correct

before

connecdng

outlet.

Volts

inside

230

or

above

to

control

voltage

Volt

me

as

ma

-

POWER SUPPLY CORDS

IMPORTANT

The

wires

in

cordance

the mains teads are cobured in

wim

the

Green-and-Yellow:

me:

Brown:

As

\he

mica

applicance may

markings

proceed

The wife

must

mat is

Eard\

and-YellOW.

ofthe

identifying

as

follows:

that

be connected

marked

symbol.

ronawing

wires

not

correspond

the

is

cdoured

wilh

or

cdwred

Rev.

code:

Earth

NWtrd

Live

in

he

meins

terminals

to

me

he

1

5/2/94

with

Grssmand-Yellow

terminal in the

letter

'F,

Qeen

in

lead

your

01

or

of

cobmd

plug,

by

the

Gteen-

ac

olis

dug

-

The

wire

that

is

nected

letter

The

wire

nected

kner

to

"N',

to

'C.

the

or

the

cx

coloured

coloured

ferminal that

coloured Black.

is

coloured

terminal that

Blue

Brown

Red.

is

marked

is

marked

must

must

be

wiih

be

with

con

rhe

con

the

CHEMICALS

-

WARNING:

Care

must

be

cals.

hedm

instructions

&

exercised

Chemicals are poisonous and

risk

Read and

regarding dangers and correct us

WARNING

se

flammable

CAUTION:

The

inter&

tor

chemicals.

attack

hydrocarbon sokents and chlorinated bleaches.

These

type

SUITABLE

Alkalis

Cbrox

Oefoaming

Detergene

Hydroxides

Oxygen Bleaches

Saps

Sla-Puf

Vinegar

White

'Registered Trademark

NON

Aldehydes

Aroma*

Buryis

Carbon fewchloride

Clorox'

Chlorinated Bleaches

Chlorinated Hydrocarbons

par^

are

suitable

for

But

from

some

noncompa~Me materials are

normally

used

CHEMICALS

I1

Bleach'

Agenrr

Fabric

Softener'

Monday Bleach'

COMPATISLE

Hydrocarbons

Lysol'

Methyls

(MEW

Perchlorethyhne

Phenols

Tnchlorethylene

D-LLnonene

FILLING

1.

Remove

he

2

Lift

upper

set

3.

Use a clean

hotwater.

for

propordons

CAUTION:

W

EXCEEOS

recovecy

aside.

budcet

Add

use

in

hot water extractors at

noted

NOT USE WATER TEMPERATURE THAT

5U"

in

rhe

use of

all

follow

can

the manufacturer's

:

materiafs.

of meyunp

use

they

are susceptible

deaning substances, such

for

(perc)

THE

dear

a nonfoaming concentrate

C.

(122'

used

most

carpet cleaning

in

!o

with

carpet deaning.

CHEMICALS

'

PASSPORT

dome

from

upper tank.

lank

from

machine

to

fill

solution rank with

on

he

F)

the

container.

the ex&-

not

chemi

pose

chemical

as

of

the

and

-

-

-

a

-

2

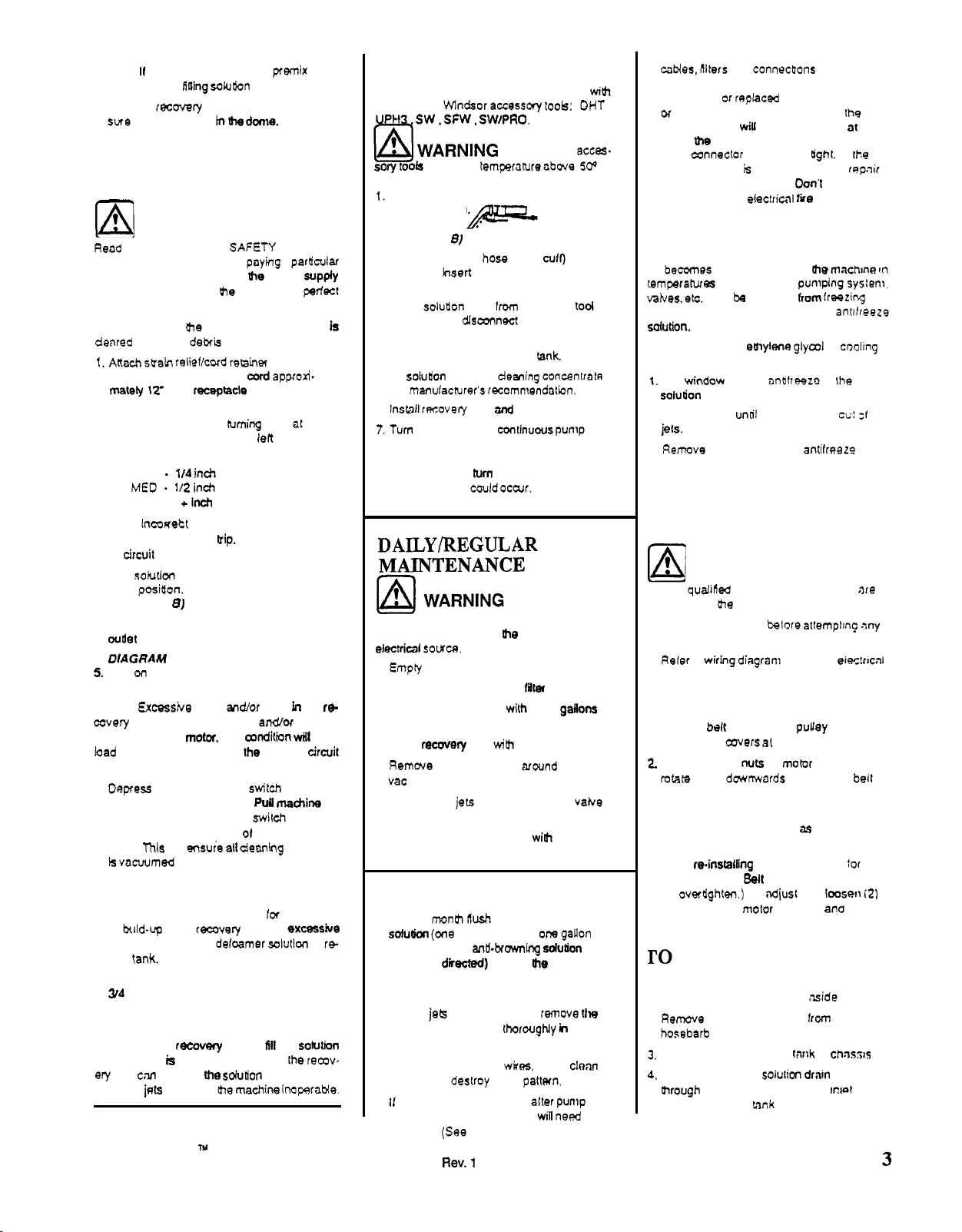

Page 4

NOTE:

If

hot

water before

A.

Reinstall

sure

powdered

hoses

fiOing salulion

recovery

are

snug

soap

is

used.

tank and dome.

h

he

donre.

OPERATING THE

PASSPORT

-

WARNING

Read the IMPORTANT

TIONS before

attention to

cord.

condition.

NOTE: Vacuum

dmred

I.

Attxh

cord. Make bop

matety

(DIAGRAM A.

2.

Adjust brush height by turning knob

front

indicates carpet

NOTE: lrPcouett move height

brush circuit breaker

reset circuit breaker.

3.

Turn

ING' position.

(DIAGRAM

4.

Plug power

outlet

DUGRAM

5.

Turn

switch.

NOTE:

cwery

enter

bad

breaker

6.

Depress

dispense

backwards.

12

pass.

k

care

Only

operate

of

surface

straln

relieflcotd

\

T

Prom

of

machine. Pointer

LOW

-

114

ME0

-

112inch

HIGH

-

1

+ih

sokrUon

valve

8)

cord

C:

on

he

vacuum switch and brush

Excessbe

tank may cause water andlor foam

the

vacuum

the

vacuum motor and

will

trip.

intermittent pump

cleaning

TMa

Release

before

will ensure

inches

vacuumed from carpet.

CAUTION:

While

operating machine, check

foam

buld-up

in

present,

recovery

use

me

jets

:

is

rendering

the

add

reeovwy tank to

CLEAN. Sediment

T-I

foam

is

covecy tank

7.

Empty

YA

full.

CAUTION

DO

not

tank. unless it

ery

tank cnn damage

he

spray

PASSPOR

SAFETY

operating,

and

che

debrk before cleaning.

in

recephcle

)

height.

inch

paying parfcular

use

of

the

if

the

cord

carpet

and make

n36ine1

power

ad

end.

on

to

kip.

Raise

to

'CARPET CLEAN

!%??

into

a

grounded wall

water

andlor

motw.

This

andition

the

switch

solution.

pump switch about

the end

ol

all

deanhg

recwecy

tank when approximately

TM

tank.

a defoamer solutlon

the

sobtion

dre

machine inoprable.

premix with

tank.

Make

INSTRUC

power supfly

is

in

perfect

sure

to

power

approxi-

at

left

side

may

cause

brush

and

loam h the

will

vacuum circuit

over

to

Puil

machine

each cleaning

solution

for

excessive

If

excessive

to

CII

the

sorution

in

the remv-

pump

and

it is

-

re

re-

dog

ACCESSORY TOOLS

The

-

PASSPORT

the

following

SW,

soty

took

1.

Turn

solution

TOOL

(DIAGRAM

2.

Remove

dome

accessory

3.

Attach

to

brass quick

side

of

4.

Remove

5.

Fill

soluljon

per

manu

6.

Install

7.

Turn

on

switches only.

CAUTION:

Damage

is

easily

Wlnhor

SFW,

WARNING

with

water temperaNre abwe

valve

-

position

6)

recovery

and

insert

vacuum hose

tool

in

sdulton

hose

dlsmnect fitting on

machine.

dome

and

tank with

facurer's recommendation.

rwovely

to

tank

vacuum and continuous pump

Do

not

Urn

carpel could ocwr.

adapted

access- took:

SWPRO.

Never

to

'ACCESSORY

hose (white

its place.

from

accessory

recovery

deaning

and

dome.

on

brush switch.

for

use

wich

DHT

operate acces-

509

C.

cull)

from

from

tod

left

bnk.

concentram

machine.

be

,

repaired

or

solution

electrical

times.

cable

cable

or

replace

chances

and connecuons

Frayed

or

pressure

cable

Ole

cable

connector

insulation

it

immediately.

with

an

or cracked

rsplaced

loss.

will

lie

must

screws

is

broken

electriGiI

PROTECT FROM

FREEZING

If

it

becomes

temperalures below

vabes.

a methyl hydrate (window washer) antifreeze

sofution.

NOTE:

system antifreeze.

1.

Add

solulon

2.

Turn

@S.

3.

Remove unused portion

from

necessary

eb.

must

be

protected

Do

not

use

eUiy{nne

window washer

tank.

on

pump

unol

tank

lo

4

"

C

nnofreero

solutionsprays

on

hoses

to

eliminate vacuum

Because

on

wet

carpet

be

well

insulated

kept Tght.

or

bayed. repair

Don1

take

rue

or

shock

store

dr@rnachine

the

pumping sys:eni,

horn

(rearing

glyml

or

to

of

antifreeze

your

should

thq

a1

If

the

cooling

the

cv:

and

in

with

zf

cables.

Rlters

MAINTENANCE

INSTRUCTIONS

DAILYREGULAR

w;*:zE

Before making

he

machine, disconnect

elec!riwl

1.

Emply

2.

Inspect and

3.

to

-

flush pumping

of

dean

4.

Rinse

5.

RemsJe

vac shoe.

6.

Check

if

required.

NOTE: Always

'store'

PERIODIC MAINTENANCE

1.

Twice a monm

salu(i0n

hot water)

(mixed

This

residue

2.

If

spray

spray tips, wash

vinegar

NOTE:

jets

as

3.

II

spray jets continue

turned

cleaning.

any

adjustments

sourco.

unused cleaning solution.

clean

hot

water.

recovery

any lint

spray

jets

store

position.

(me

quart

or

an

as

dwecred)

will

help

prevent

in

system.

je6

become clogged,

and

blow dry.

Do

not

use

this

will

destroy spray pattefn.

off.

the solenoid valve

(See

Rev.1

the

solution

system

with 1 to

lank

with

or

debris

and dean solenoid

machine

flush

a white vinegar

vinegar

anU-browning

through

build-up

them

thoroughly

pins, wires. etc. lo clnan

to

drip alter punip

MAINTENANCE

5/2/94

or

power

filter

dean

around

wih

to

one

the

of

remove

will

repairs

cord

from

screen.

2

gallons

water.

brush

vahre

brush

gallon

sdution

extractor.

alkaline

in

need

Instructions

to

and

in

of

the

is

-

1.

2.

3.

1.

2

3.

4.

ro

COMPONENTS

1.

2.

3.

4.

WARNING

Only

qualified maintenance personnel are

to

perform

che

following repairs.

Unplug

(he

repairs.

Reler

to

wirlng diagram

connections.

machine

belore

lor

proper ei%fric;II

attemptina

BRUSH ASSEMBLY

Remove belt guard, brush pulley guard

and bearing

Loosen

rotale

from

Remove

Replace brush

required.

When re.inslalng brush, check belt

proper tension.

not

hex

retighten

ACCESS

Lilt

Reme

hosebarb

Remove

Raise tank

through chassis.

torn

covers a1

(2)

hex

motor dawnwards and remove beit

motor pulley.

brush

overtighten.)

nuts,

rotate

nuts.

each

nuts

on

moor

assembly

or

bearings

&it

should

To

ndjust

molor

rearward anu

end

from

as

be

belt.

studs

.

taught

CHASSIS

off

recovery tank

solution-drain

(A)

and

rank and tay

and

set

.aside

hose

lrom

bolts holding lank to

pull soiulim

Remove

tmk

drain

pump

aside

of

brush

and

.

:or

lmseir

cn%x

hose

Inlot

.my

(Do

i2)

hose

3

Page 5

WARNING

The

internal

sdution

hoses

are

outer hose

in

lure. Replace

machine. paying panicular attention

outer hose

me

to

unlikely

is

protect

event

a solution hose

hoses as

not

damped.

the

ekPW

originally

encased

components

should

supp(i6d

to

CAUTION

Wlien replacing hosebarbs

NOT

OVERTIGHTEN

mke

and exhaust ports in pump head..

-

a~

on

pump head

his

Wld crack

BRUSH DRIVE MOTOR

When

My for

re-instalng

proper

motor

refer

to

belt tension adjusmenL

Brush

Assem

VAC MOTOR REMOVAL

1.

tilt

off

vac

motor

cooling

2.

Oisconnect

3.

Remove

4

Loosen

LOWER

5.

Remove

chassis and lift-out motor.

electrical

vac

hoses

strain reliel

handle

bolts.

screws holding

air intake

connections.

from

chassis oudet

nut

and remove

motor

plate

cover.

the

to

in

an

fup

In

lhe

which

DO

h

(2)

-

VAC MOTOR BRUSHES

To

inspect motor brushes,

assembly. Brushes

wn

to

318

inch

hours. After

mature

mmrnutalw

and concenlricity. Vac

but

such

motor

repair

second

repairs

shop.

or

should

remove

should

after

brush replacement

should

moton

be

hstr

be

replaced

about

7%

techedced

can

made

by

be

operaeing

for

repaired

a

qualified

VAC SHOE

When

re-imtalling

shoulder

low vac shoe

height adjusting screw.

grease

smth

bolB.

on

operation.

vac

shoe,

Leave

to

move

the adjusting screw

do

enough locseness b al

up and down with tho

A

light

not overdghfen

coat

of

will

hdder

when

the

ar

pitling

sillcon

ensure

-

-

4

Rev.1

5/2/94

Tu

PASSPORT-I

Page 6

DEUTSCH

WlCHTlGE

SlCH E RH ElTSH

Belm

Gebrauch eines elsklrischen

mi)ssen

immer grundsWiche

VorsichtsmaOnahmon bsachtet werden.

einschlieRlich der folgenden:

-

Die einschlagigen UnfalhrehUtungs-

Vorschriften

aHgernein

sicherheitstechnisschon,

arbeitsmedizvlischec,

einzuhalten.

-

Vor Gebrauch der Maschine

Betriebsanleitung

-

Diese Masdine

Beanspruchung bei gewerblicher

Verwendung en(wi&elt

VORSICHTDIW

die Absaugung gesundheilsgefahrdender

SUube geeignet

-

MWARNUNG: UM

FEUER; STROMSCHLAG

ODER

ZU

1.

Keine Benuaung ohm eingebauten

Filter.

2.

Benutrung

und rnit

Zu behdr.

3.

Nicht irn

Oberllilchen benutren.

4.

Maschinen

wenn sie

Gasen

werden. Also kein

von brennbaren

5.

Keine brennbaren

Materiallen wie

nicht

6.

Nlchts brennendes

Zigaretten. Streichhdlzer

Asche aufsaugen.

7. Maschine und

HBnden bedlenen.

8.

Maschine

Bei Stillstand und

ziehen.

9.

Bevor

ausschalten.

1O.Slecker nicht am

sondern

11

.Maschine nieht rnit beschadigtem Kabd

oder

12.Arbeitet die Maschine nicht einwandfrei,

ist

sie hingefalfen, beschadigt, hat sie

Freien gestanden oder ist

Beruhrung gekommen - Kontakt rnit

in

sowie

anerkannlen

BESCHADIGUNG

VERMEIDEN

nur

gemllR

dern

vorn

Freien

odw

Mnnen

in

der Nahe

odsr

Materialien

Stom

in

Stecker

Stecker

Benzin

deren

NBhe

Stedcer

nl&t

untaaublchtlgt

gerogen wird. Maschine

am

Stecker.

inbetriebnehmen.

IN

die

sonsthpn

Regeln

lesenf

ist

fcjl

erhdhte

Maschine

Betiebsanleitung

Hersteller

auf

naRen

Feuer

verumchen.

von

brennbaren

eingosetzt

Gebrauch

und

oder

enaOndbaren

aufsaugen und

arbeiten.

oder

qualmendes

oder

nicht

Wartung

KaM

Sleeker

herausriehen.

sie

W

EIS

Gerates

sind

ist

nicht

empfohlenen

in

der

Gasen.

heiRe

rnit naRen

Itlssen.

mil

Wasser

fur

Nahe

wie

irn

autorisierten Wartungsdienst

einem

au

fnehmen.

13.

Nicht

am

Kabel

E

Tragegriff benunen. nicht in der

einklemmen

und Kanten ziehen.

14.

Nlcht

mit der Maschine Uber das

fahren und Kabel von heinen FlBchen

femhalfen.

15.

Die

Maschine darf nicht als Spielzeug

benutzt werden. Besondere

Aulrnerksamkeit ist geboten, wenn die

Maschine

benunt

16.

Nicht

milder

irgendeine iiiftung blockiertjst.

Luttungsdffnungen frei von Uberresten

halten. welche die Luftzirkulation

behindern.

17. Haare.

anderen Kdrperteile von Olfnungen und

arbeitenden Teilen fernhalten.

18.

Besondere Vorsicht bei der

Treppenreinigung.

19.

Maschine nicfit als Treppenstufe

benutzen.

20.

Die

Wartung und lnstandsetzung

quaiifiziertem Personal durchtufUhren.

21.

Bern

Reinigen und

Maschine, beirn Auswechseln von Teilen

oder

bei der Urnstellung auf sine andere

Funktion, ist der

22.

Eei Vemendung oder Ersatz van

Netzanschlussleitungen darf nicht von

den

vorn

AusMhrungen abgewichen werden.

23.

Beim

Ersetzen

Netranschtuss-oder

Gehauseanschlussleinrngen

der

Spritzwasserschutr

rnechanische Festigkeit sichergestelt

bieiben.

ziehen,

oder

Uber scharfe Ecken

in

der

Nahe von Kindern

wid.

Maschine arbeiten wenn

lose

Kleidung. Finger und alle

Warten

Netzstecher

Hersteller

abgegebenen

van Kupplungen von

Egenmiichtige Veriinderungen

Maschine schlieOen

Herstellen

ScMden

fur daraus resultierende

aus.

eine

BEACHTEN SIE

H

IN W ElSE

I

NS P

E

KTI

0

N

Oas

Gerat

Transportschaden untersuchen. Alle

werden

untemtcht.

Schiiden zustandig istund solortknachrichtigt

werden muR.

ELEKTRISCHE ANGABEN

Dieses GerdtwirdstandardmBOig bei

Wechsdstrom betrieben. Spannung unter

V

Molorschaden Mhren.

vorsichtig auspacken und auf

vor

dern

Versand gepruff und grtindlich

sodanctielranspomirrnafilrjegliche

brw. uber

240

Volt

kann

€in

Schaltbild

Kabel

nicht

als

Ture

Kabel

ist

der

zu

ziehen.

milssem

und

die

an

Haftung des

DIESE

Gerate

230

zu

erheblichem

ist

an der

von

der

Volt

220

Steuertafel

aufmontiert.

des

Gedts innerhalb des Grilles

WARNUNG:

Vor

dern

sichergestellt

Typenschild angegebene richtige Spannung

vorhanden ist

AnschluR an das

werden.

Sttornnee

daO die auf

mu0

den1

CHEMIKALEN

WARNUNG:

Vorsicht ist geboten

kalien. Chemikalien sind gihig

Gesundheitshrko darsteilen. Lesenund

Sie den Hersteileranweisungen betuglic9

WARNUNG:

VORSICHT

Die

lnnenteile

Gebrauch

tel

cherniscbe Einwirkung einiger Aeinigungsm

tel.

chlorierte Bleichrnittei emplindlich.

vertriiglichen Slolfe werden normalerweise bei

der Teppichreinigung nicht vewendet.

der

geeignet

wie

2.

B.

GEEIGNETE

Alkali

Clorox

II

Bleach'

Bleach'

ff

bleich-

Schaumbrecher

Reinigungsmittel

Hydroxyde

Sauersto

mittel

Seilen

Sta-Puf Fabric

SOttener'

Essig

White Monday

'Schutzmafke

UNGEEIGNETE

Aldehyde

Aromatische Kohlenwasserstoffe

Bufyl Kohlenstofftetrachlorid

Clorox'

Chlorierte Bleichmittel

Chlorierte KohIewasserstofle

Lysol'

Methyle (MefhylAthylkelon)

Perchlorathylen

Phenol

Trichlorathy

D-Limonene

FULLEN

1.

Ole

durchsichtige Haube

Behdlter entfernen

2.

Den

oberen Auffangbehtllter vom Gerat

entfernen und

3.

Den

L6sungsbehiilter aus einem

beim

Gebrauch von Chemi-

und

kdnnen

tolgen

der

Wasserpumpe sind

meisten Teppichreinigungsmir-

jdoch

ist die Pumpe gegen

Kohlenwasserstomdsungen und

CHEMlKALlEN

CHEMlKALlEN

len

DES

PASSPORT

vorn

beiseitestellen.

fur

Oiese

obersn

ein

den

die

it.

un.

P

A

SSPO

R

Rev.

1

T

-

?

5/2/94

5

Page 7

sauberen Eimer niit heiOem Wasser

fullen. Ein

Heisswasserexlraktoren vorgesetienes,

nichlschiiuniendes Konrentrat unler

Beachlung der

angegebenen Proporlionen zugeben.

fur

den Gebrauch in

auf

dern BehBller

VORSICHT:

DARF

D1E

UBER

ANMERKUNO:

Seifenpulver

Ldsungsbehalters

aufgeldsl

4

BETRIEB

WASSERTEMPERATUR NlCHT

50'

C

sein.

Bei der Verwendung

muO

dieses

vor

in

werden.

Den

AuffganbehRller und die Kappe

aulsetzen. Ole SchlLuche

wieder

lest

in der Kappe sitzen.

helnem Wasser

DES

PASSPORT

von

dem FUllen des

rnilssen

WARNUNG:

Lasen

SlCHERHEiTSHlNWEiSE bevor Sie

bnlreiben. und achlen Sie besonders auf den

Zustand des Stromkables. Arbeilen Sie

einwandfreiem Stromkabel.

I

Oen

hallevorrichlung

anbringenh das Netzkabel

vom Ende eine Schlaufe machen.

(OIAGRAMM

2.

Die Biirstenhthe durch den an der Vor

derseite

einstellen.

raigt die Teppictiliohe

ANMERKUNG:

oingeslellle Hdhe kann den Bursten-

Uberlastknopf

Bursle heher einsteilen

eindrltcken.

3.

Den

REINIGUNG' Position stellen.

(DIAGRAMM

4.

Netzkabel anschiieflen.

OlAGRAMM

5.

Den

einsteilen.

ANMERKUNG:

in1 Auffangbehaller kann

gelangen. Dies wird densauger-Uberlastknopf

nuslbsen.

6

Den Schailer 'Tastbetrieb' drilcken.

wodurch Reinigungsidsung ausgelassen

wird.

sicherrustellen. daR die ReinigungS

Msung

aufgesogen wird. den

clrca

Reinigungsbnhn abslelien.

Sie

Oehnungsschug und die Kabel

dle WICHTIGEN

nrn

Netzkabel

ca.

A)

des

Gerdtes befindlichen Knopf

Der

Pfeil an der llnken Seile

an.

NIEDRIG

MITTEL

HOCH

L6sungshahn

Sauger- bzw. BUrstenxhaller

30

-

ca.

6mm

-

ca.

13

ca.

Eine

atif

rnrn

25

rnm

unsachgemLR

In

diesem

und

den

'TEPPICH-

oder hdher

-

awldsen.

6)

C:

Zwiel

Wasser

brw. Schaurn

in

den Saugrnolor

Das

Gerlt rilckwdrts ziehen. Urn

voilkommnn vom Teppich

cm

vor dern

Pumpmnschaller

Ende

jder

Knopf

rn

30

nur

-

cm

Fall

wiedec

niil

die

6

VORSICHT:

WShrend der Arbeit

AuflangbehQter achten. Wenn sich Schaum

bildet- Anllschaummillel in den Auffangbehllter

geben.

7.

Der Auffangbehiiller

wenn

er

ungefiihr

aul

Schaumbildung im

mu0

geieert warden,

314

volt ist.

VORSICHT:

Der &(fangbehalter

des

LOsungsbeh~llersgebrruchlwerden.

er SAUBER

fangbehglter

beschadigen und die Spruhdllsen verstopferi.

wodurch das

darf

nur

is!.

Ablagerungen

kdnnen

GerLl

die Lbsungspumpe

betriebsunf3hig wird.

dann zum

Im

Fallen

wenn

Auf-

ZU'BEHORTEILE

Der

PASSPORT

Zubehijrleiien

rich(

einsetzbar.

El

vermeidm

TAG

WARNUNG:

Zuberhdrteile nie mil einer Wassertemperalur

iJber

50

"

C

belreiben.

I.

Den LBsunqshahn aul

stellen.

(DIAGRAMM

2.

Den Auffangsclilauch (weisse

schelle) von der Kappe entfernen und an

seiner

Stelte

tubehdlleil einslecken.

3.

Den

Lllsungsschlauch des Zubehdrteils

der links am GerLt befindlichen Schnelhrer

bindungsfassung

4.

Kappe

und

5.

Den Ldsungstank enlsprechend den

Anweisungen des

nigungsmittel fullen.

6.

Auffangbeh4iler und Kappe wiader

aukelten.

7.

Nur die Sauger.

schalter einstellen.

Urn

eine Besch#digung

den

LICHEIREG

ist

OHT.

den Saugschlauch

AulfangbehOIter abnehmen.

0urstenschal!er nicht einstelllen!

mil den Windsor

UPH3. SW. SWF,

'ZUEEHORTEIL'

8)

aus

Messing befeslgen.

Herstellers

und

Dauerbelrlabs-

des

ELMA

Man

for

das

mit Rei.

Teppichs

OIG

SW/

E

WARTUNG

Vor

Anderungen und Reparaturen inirner

Netzslecker ziehen.

1.

Den

Rest

W

LBsungsbehBlter nntlernen.

2.

Den Filtereinsatz irn Ldsungsbehalter

inspiriaren und reinigen.

3.

Das

Pumpensyslern mil

sauberem. heiflem Wasser durchspulen.

4.

Den Auffangbsfiliter

saubnrom Wasser spulen.

5.

Oas Spruhsctierna der Diisen :Iglich

ilberprufen.

Reinlgungdllsung aus dern

ca.

4

bis 8 Liter

entleeren

Rev.

1

5/2/94

und

mit

in

zu

6. Vom

Vakuurngleitschuh evil. abgdsgerte

Fasern

bm.

SchmuUteile entfernen.

7.

Abgelagerte Fasern und Schmulrleile von

der

BUrste und

entlernen.

von

dern Geh5use

PERIODISCHE WARTUNG

1.

Zwelrnal monatlich das

Ldsung aus weinern Essig

Essig auf ca. 4 Liter Wasser)

Antibraunungsldsung

Gebrauchsanwekung) durchspulen.

Dadurch wird die Anlagerung von Alkali

resten in dern Syslem verhindert.

2

Bei

einer Verstopfung

dleselben entfernen. grdndlich in Essig

waschen und

ANMERKUNG:

benutzen. Dies beschadigt die Dusen.

3.

Tropfen die Sprdhdusen

der Pumpe.

gereinigt werden. (siehe

Answeisungen).

4.

Alle Schlluche. eleklrischen Kabel.

und Maschinenansch1i)sse mussen in

regelmBOigen Absllnden lmpiriert

wmrden. Zerschlissene oder rissige

Schlache

werden, um

oder

eleklrische Kabel zeilweise

feuchten Teppich

sein und die

miJssen lest sitzen.

Kabellsoliiung terrissen oder

verschlissm ist.

oder

ersekt werden. Sie vermeiden

Feuer und Slronischlagl

trockenblasen.

Keine Nadeln. OrBhfe. wc.

mufl

miissen

einen

L6sungsdrudc

Kabelverbindungsschrauben

Gerer

mil einer

(GI.

1

oder

(enlsprechend

der

Spruhdilsen

nach

das Soienoidventil

repariert oder

Vetlust

zu

liegt.

Wenn

muO

Abslellen

auch

Wartung

van Vakuurn

verhuten

aul

einem

rnuR es gut isoliert

die

sie sofort repariert

Liter

einer

der

Filler

ersetzt

Da

das

so

-

FROSTSCH UTZ

Wlrd

es

notwendig die Maschine unler

lagem. milssen Pumpensystem. Schli3uche.

Venlile durch

iUel

(Waschmittel

Gefrieren

ANMERKUNG:

Kuhlsystern-Frostschutrmillel

I,

Froslschultmittel (Waschmittel

Windschulzscheiben)

L6sungsbehtliter

2. Die

Diken sprdhl.

3.

Den

dem

ein

Me~yihydral-Frostschutzm-

Nr

geschiilzt werden.

Purnpe belreiben.

Rest des Fmstschu~rnittels aus

Behsller entlernen.

Windschu(zscheiben)vor

Keine hhylenglykoi

in

den

Klllen.

bis

Ltkung

vewen&-

for

nus

4

C

zu

den

WARTUNG ANWEISUNGEN

@

WARNUNG:

te

o

I.

2.

3

genden Reparaturen dilrfen nur

van quoiifldertem Pflegepersonal

ausgefuhrl werden.

Vor

Aeparnturnn immar NeUstecker

tietien.

Filr

die richligen eiektrishcen Ver

bmdungen beriehm

Schalldiagramm.

Sin

P

sich

A

S

bitre

S

P

auf das

O

R

T

-

.

?!

Page 8

BURSTENMONTAGE

1,

Den

TreibriemenschuQ.

schuu und die an beiden

BUrste

befindlichen

entfernen.

2. (2)

Sechskantschrauben am

gehluse ldsen und den

herausdrehen und den freibriemen

Motorblock abrollen.

3.

Die Biirstenmontage

entfernen.

llch

4.

Beim Wiedereinsetzen der

Spannung

Er

rnAOlg amiehen). Zwecks Anderungen

der Treibriemenspannung die

Sechskantmunern

rijdrwarts

anziehen.

BOrste

ersetzen.

des Treibriemens Oberprilfen.

sollte

angespannt sein (nicht ilber-

rotieren und die Muttern wieder

Biintenroller

Enden

Lagerkappen

Motor

vom

Gehause

oder

Lager

I(isen,

den

Motor

nach

wie

Burste

(2)

Motor

der

unten

vom

erforder

die

BURSTEN

Bei Weideroinsetren des

BURSTENMONTAGE

Spannungseinstellung des Treibriernens

beachten.

ANTRIEBSMOTOR

Motors

filr

die richtige

bitte

AUSBAU DES

VAKUUMMOTORS

1.

Den

Deckel

des Vakuummotors abnehmen.

2.

Schallpult abnehmen und elektrische

Anschlusse.

3. Den

lausgang

4.

Die Dehnungsschutzschraube

die

(2)

5.

Die Schrauben

Motorplatte

und den

des LuftkBhlungseinlasses

Vakuumschlauch

endernen.

untaren Griffbolzen

enlfernen

am

Fahrgestell befestigt

Motor

herausheben.

vom

Fahrgeslel

entfetnen.

mi1 der die

ldsen

und

1st.

ZUZANG ZU DEN

MOTOREN

1,

Auffangbehalter abheben und

beiseitestellen.

2.

L6sungsablaufschlauch

3.

Ole

(4)

Muttern.

am Fahrgestell befestigt ist. entfernen.

4.

Den

Behalter hochheben und den

LClsungsablaufschlauch am Fahrgestell

Wsen.

Einlaufsctrlauch der Pumpe

Behater entfernen und Behalter beiseite-

legen.

WARNUNG:

Filr

den unwahrscheinlichen Fall eines

Ldsungsschlauchrisses sind die inneren

UsungsschlBuche

chen

Komponenten

Schlauch umgeben. Die SchlBuche

genau wie ursprtlnglich geliefert wieder

eingeseat werden. Vorsicht: Schla uche

einklemmen.

VO

RS

ICHT:

Beim Wiedereinsetzen

einrasthaken au dem Pumpenkopf NICHT

FEST ANZIEHEN. da dadwch

Ansaug

Pumpenkopfes

-

bzw. AuslaBUffnungen des

entstehen konnten.

entfernen.

mit denen der Behater

vom

zum

SchuQ der elektris-

von

einem

auneren

massen

der

Schlauch

RQse

in den

nicht

ZU

VAKUUMBURSTENMOTOR

Zur lnspektion der Motorbursten die

Bilrstenhalterung

bei einer Abnutzung

Betrlebsstunden

zweiten Austausch der

Armalurenkommutator aUf VerschleiB und

Kontentritirat ijberpruft werden.

Vakuummotoren kdnnenrepariertwerden, doch

soltten

die Reparaturen durch qualifiriertes

Motorreparaturpersonai ausgeNhrt werden.

entfernen.

auf

a.

ersetzt

werden.

Die BOrsten sollten

1

an

oder nach

BUrsten

VAKUUMGLEITSCHUH

Vakuumgleitschuhs dfirfen

nicht ru strengangezogen werden.

lose

genug

sein,

damit sich der Gleitschuh

kann.

-

der

H(lhenmnsteilsdrrau~nechobenundun1en

bewegen

die

Auflagebolten

Nach

soilte der

Sie

miissen

750

dem

mil

P

A

SSPO

R

T

-

?

Rev.

1

5/2/94

Page 9

HANDLE/PANEL ASSEMBLY

~~

8

Rev.

1

512194

P

A

SS

POR

T

-

?

Page 10

VAC

MOTORBRAME ASSEMBLY

'ARTS

LIST:

PASSPORT-Y

Rev.

1

5/2/94

9

Page 11

TANK

ASSEMBLIES

21

PARTS

10

LIST:

31 14042 Bushinn, 1.63

32 98130 Manual,

Rev.1

5/2/94

ID

PSP-IG

Snap

I

TM

PASSPORT-I

Page 12

DRIVE ASSEMBLY

,

PARTS

I

KEY

LIST

PART

03069

12005

24 70020

25 87025

26 41114

27

57030

NO.

DESCRIPTION

Axle, Brush

Brush

Scr,

1/4-20 x 112

Washer,

Housing,

Nut,

114

Brush

10-32

Lock

HHMS

Star

PASSPORT^

Rev.1

5/2/94

11

Page 13

VAC SHOE ASSEMBLY

16

PARTS LIST

I

KEY

PART NO. DESCRIPTION

I

12

Rev.

1

5/2/94

P

A

SS

P

O

R

T

-

?

Page 14

PLUMBING ASSEMBLIES

PARTS

LIST:

I

4-5

PUMP ASSEMBLY 651151

I-

PUMP REPAIR KIT 47176

-1

PASSPOR

HOUSiNG 41 226

TM

T-I

COVER 27057

Rew.1

5/2/94

\

230V MOTOR 5301 7

13

Page 15

WIRING DIAGRAM

93218

230V

VACUVM

MOTOR

GRNIYLW

-

rn

2

CIRCUIT

BREAKER

14

Rev.1

5/2/94

PASSPORT^

Page 16

w

WINDSOR"

Wesupply

thepower

15

Rev.1

TM

PASSPORT-I

5l2l94

Loading...

Loading...