Page 1

SUPREME

ULTRA

HIGH

SPEED

SERVICE

INSPECTION

Carefully unpack and inspect your ma

chine for shipping damage. Each unit is

operated and thoroughly inspected before

shipment, and any damage is the re

sponsibility of the delivering carrier who

should be notified immediately.

ELECTRICAL

This rotary polisher is designed

ate on a standard

AC household current. Check that the

voltage shown on the serial number plate

is suitable for the supply available. Volt

ages below

could cause damage

WARNING:

not expose to rain. Store indoors.

15

amp,

105

volts or above

to

the motor.

To avoid electric shock do

GROUNDING INSTRUCTIONS

To protect the operator from electrical

shock, this machine must be grounded

while in use. The machine is equipped

with an approved, three

power cord and three

type plug

type receptacle. The

ped with a

to

fit the proper grounding

14-3,80

-

prong grounding

P1700-20

foot power cord.

OPERATION

1.

Plug machine into the power supply

and check that the red indicator light

(located on top of switch housing)

on.

2

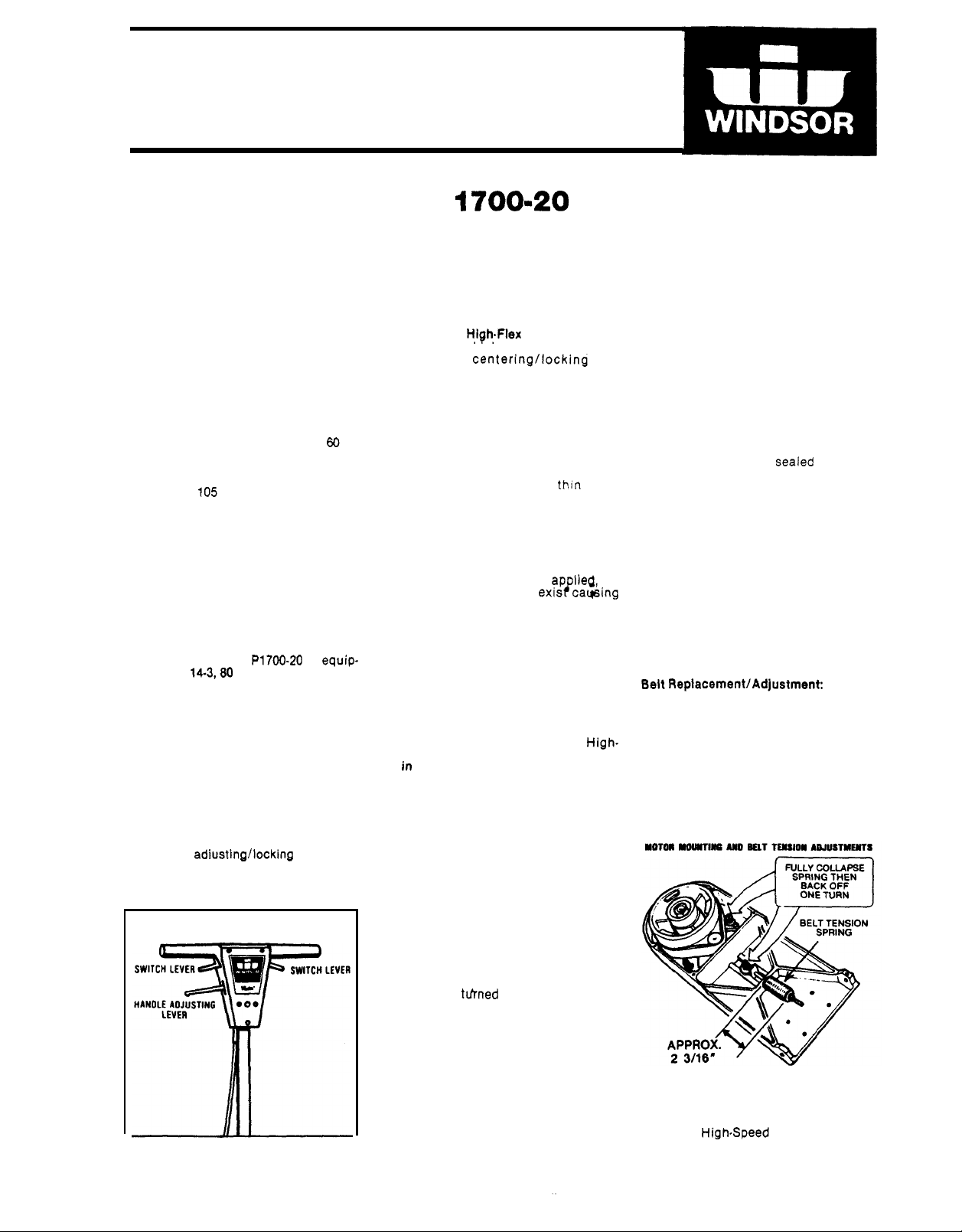

You will notice three control levers

located at the top of the handle. The

two smaller ones directly beneath

the handle grips control the onloff

switches. From the operator's posi

tion, the longer lever on the right is

used for

in position.'

adiustina/lockina the handle

"

to

115

volt,

125

-

conductor

is equip

-

oper

60

volts

hz,

BURNISHER

MANUAL

3.

With the handle locked in the upright

position, tilt the machine back until

-

the handle is resting on the floor ex

posing the

the proper high speed buffing pad

-

using the

holder

4.

With the pad properly installed, return

machine

CAUTION:

age to the pad or pad driver, remove

buffing pad from machine when not

in use.

-

5.

Adjust front caster: For

turn caster adjusting knob counter

clockwise to lower machine. For

thick pads turn clockwise to raise

machine.

NOTE:

set, the machine will start instantly.

It too much pressure is

overload of motor will exisf cawing

circuit breaker

6.

Pull up on the adjusting lever and

lower the handle to a comfortable

working height. Release adjusting

lever

NOTE:

the handle

run until handle is lowered

operating position.

is

-

For best results, the Supreme

Speed Burnisher should be operated

in a straight line - forward and re

verse

a

low speed polisher.

The floor polisher is equipped with a

circuit breaker. The action of the cir

cuit breaker is entirely dependent

upon the loading

motor and will only trip under exces

sive overload conditions. If the circuit

breaker should trip, it can be reset

after

set button on the right hand side of

the motor housing.

NOTE:

the cause

ceeding. The most common cause is

an excessively soiled pad which

should be

placed.

P

1

700120

AND

Hi$h-Flex

centering/locking pad

to

retain pad.

to

the upright position.

To prevent possible dam

When pad pressure is properly

to

lock

handle

A

safety switch mounted

will

-

not side

20

seconds by pressing the re

The operator should correct

of

overloading before pro

tu'rned over, cleaned

drive-pad. Install

to

trip.

in

place.

not allow machine

to

side as you would

of

the brush drive

PARTS

thln

pads

applied, an

to

High-

or

LIST

SERVICING

A

full service inspection involves the

spection and testing of all items which

affect operator safety, items which may

require adjustment from time

and items subject to wear which may

require replacement in order

a

breakdown.

Motor:

-

All

enough lubricant for the life of the

machine.

Remove motor cover occasionally and

blow dust and lint from motor housing.

Wheels: Periodically remove wheels and

add silicone lubricant

Motor

1.

2.

3.

4.

in

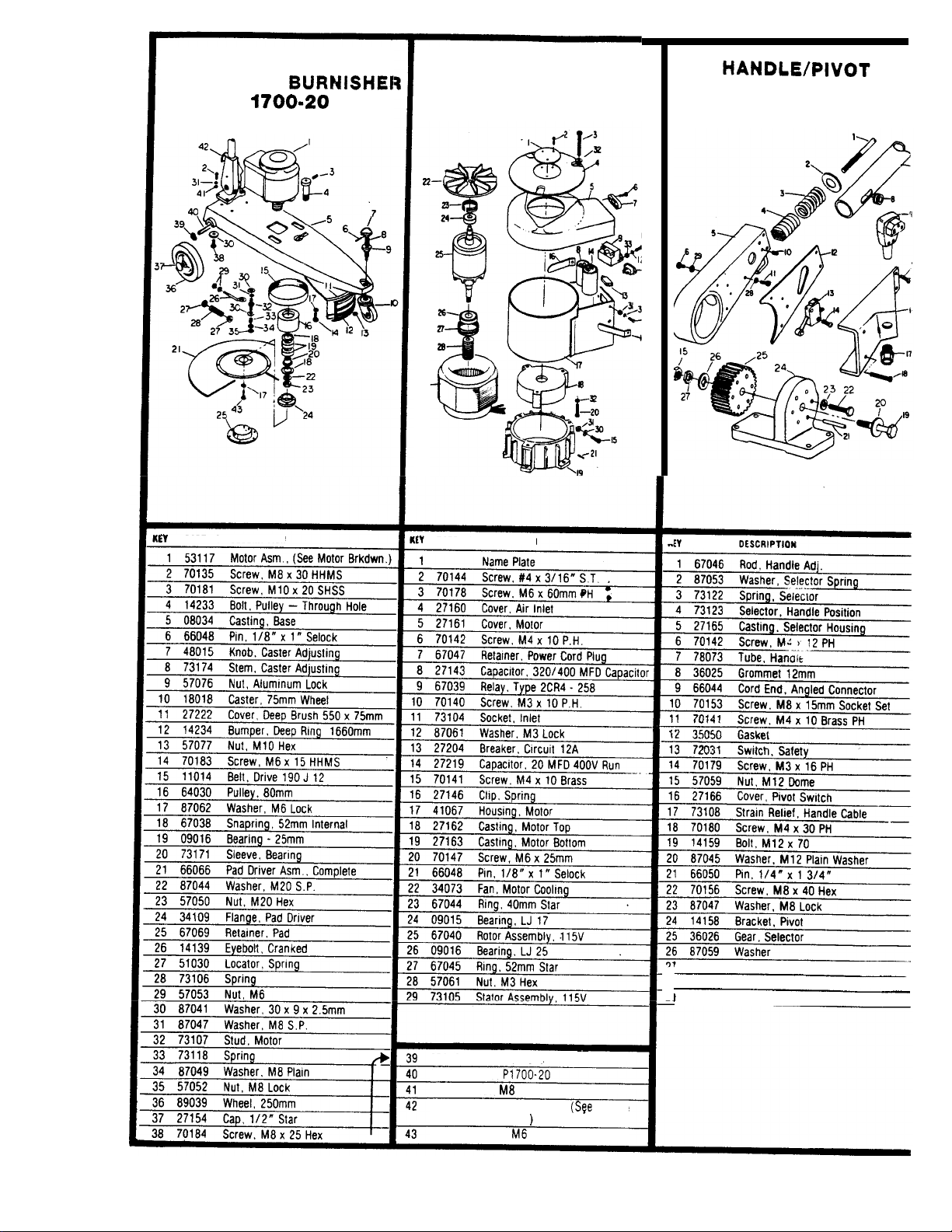

Belt Replacement/Adjustment:

to

1.

the

2.

3.

-

4.

5.

-

-

-

-

re

-

The motor is totally enclosed,

capacitor start, capacitor run with circuit

breaker protection.

ball bearings are sealed and have

to

Removal:

Remove high-flex drive pad

Remove brush cover

Release tension on belt tension spring.

Remove motor mounting bolts

Remove high-flex drive pad.

Remove brush cover.

Release tension on

Loosen nuts on motor mounting studs

-

4

or 5 turns.

Install new belt and readjust belt

tension as shown:

(6)

belt

to

time,

to

prevent

axle.

(4)

screws.

screws.

(3).

tension spring.

in

-

The trouble shooting guides on inside

and back cover have been categorized

to

assist you

problems that could occur during the

life of the

in

locating and servicing

High-speed Burnisher.

Page 2

SUPREME ULTRA

-

HIGH

SPEED BURNISHE1

P

d

700-20

MOTOR

29

ASSEMBLY

1

700-20

P

HANDLEIPIVOT

ASSEMBLY

:Y

PART NO. DESCRIPTION

iY

PART NO. DESCRIPTION

IY

PART

NO.

OESCRIPTION

'

57060

I

I

Nut.

87058 Washer.

87057 Washer,

Half Hex

M4

M4

Flat

Shakeproof

-

87046

Washer, Wave

03025 Axle.

57054

66067

70185 Screw,

P1700-20

Nut.

M8

Handle Pivot

Breakdown

~~

Asm..

(See Handle

)

M6 x 30 PHMS

Page 3

Page 4

Red

ligM will not

or

goes

start

breaker

fuses

to

out

start

come on

when trying

Red

light on

will not

Poor

starl/run

trips circuit

or

blows

Machine “wobbles”

in

use

GENERAL

Usor

sorvltoablo

C

AULT

Not

plugged

in.

switched on

Faulty plug connections

fuse blown or wrong

not

fuse fitted

Faulty supply cable

Wrong supply voltage

Handle not

in

operating

position

Handle assembly

plugged

into

motor

not

Circuit breaker tripped

motor overloaded

Wrong supply voltage.

Floor pad

wornlnot

centered.

faults

REMEDY

Plug in and switch on

Open plug and inspect

connections

straint - fit a new fuse

Check by substitution

Check name plate.

Lower handle

Plug handle assembly

into motor

Press red button

circuit breaker

or replace floor pad.

Check name Plate

Check floor pad for uneven

wear

drive plate.

-

&

center

cable re

to

reset

-

wash

on

the

-

WINDSOR

WINDSOR

year from date of purchase that this Rotary

from defects in

service. and when operated and maintained in accordance with

Windsor’s service and operating instructions This warranty does

not

capacitors. rubber parts and switches During this one year period

Windsor will replace

ranty when the machine

Colorado

Costs are

EXTENDED

In

This warranty is in lieu of all other warranties. expressed

and releases WINDSOR from all other obligations and liabilities

is applicable

to

WINDSOR is

other persons unless they have been specifically authorized in

advance and in writing by WINDSOR This warranty

to

misuse

or

warrants

apply

to

or

to

addition

to

1

In

the event of failure from normal usage during the useful life

Of

the machine of the main

chine handle switch housing. WINDSOR will replace or repair

such switch free of cost except for labor and transportation

charges which

2

For a period

out charge replace

defects during normal service and usage except for normal

wear items as described above and for transportation charges

to

and from the Windsor factory which must be prepaid by the

original purchaser

the original user purchaser of this product

damage from transportation alterations by unauthorized persons

or

abuse of the equipment use of noncampatible chemicals

damage or

LIMITED

to

the original purchaserluser

workmanship and materials, under normal use and

normal wear items such as electrical cable relays

or

repair defective parts covered b this war

IS

to

an Authorized Windsor Service Center ?ransportation

be prepald by the original purchaserluser

WARRANTY

the above warranty, the following

only

not

loss

delivered either to the fact0 $n;lglewm

must

be borne by the original purchaser

of

three years after purchase WINDSOR will. with

or

repair any motor that fails as a result of

in

the U S A and Canada, and

responsible for costs

of income due to malfunctioning of the product

WARRANTY

for

a

period

Floor

Machine

will

apply

onloff’ switch located in the ma

or

implied.

IS

extended only

for

repairs performed by

does

not apply

of

one

IS

free

-

It

MDtor

runs,

nalpoor

start.

promaturo

Belt

runs

High

amps,

blows

fuses

or

Noisy

drivo

pulley

SYMPTOM

bolt

slip,

drivo,

squeak on

bolt

OH

tripping.

“clicking”

TROUBLE

Belt too slack

woar

Belt worn or broken

Motor

Polished/greasy drive pulley

Pulleys out

belt tension too high

Seized or stiff pulley

bearings

Bearings or housings worn.

SHOOTING

CAULT

slide

seized

of

alignment

BELT

DRIVE

TEST

Stall test machine with

drive board glued or screwed

to floor

lnsoection

Remove belt slacken

mounting spring check for

free movement.

Inspection

-

Check pulley alignment

Turn drive by hand

motor with belt removed.

InSpectlOn

TRAIN

-

run

REMEDY

Adjust

belt tension correctly.

Check pulley alignment

before fitting new belt.

Ensure free movement in

guide

slots

over

lull

length.

Remove grease with solvent

-

emery pulley surface.

Realign pulleys. refit drive

belt.do not over tension.

Replace bearings.

Replace

-

The bearings are shrink

fitted. heat the pulley before

reassembly.

CAUTION

I

w

WINDSOR

INDUSTRIES,

INC.,

135

W.

Stanford

Ave.,

Englewood,

CO

80110

USA

3031762-1800

TWX

!

910.931-0565

2af

Loading...

Loading...