Page 1

p

(4 Gallon)

Mi ni Car

et Extractor

Operating instructions (ENG)

MODELS: MPRO

10080390

MPROEU

10080400

MPROGB

10080410

MPROAU

10080420

86037780-AF

08/15/11

Read these instructions before using the machine.

Page 2

Machine Data Log & Overview

Warr an ty Regis t ra tion

Thank you for ch oosing our product. Warranty registration is quick and easy.

Y

our registration will allow us to serve you better over the lifetime of the product.

To register your prod uct go to:

http://warranty.k archerna.com/warrantyregistration.aspx

OVERVIEW

The carpet extractor is a mains powered, portable extractor intended for commercial use. The appliance sprays a

cleaning solution onto the carpet, agitates the wet carpet, and then extracts the soiled solution back into the unit’s

recovery tank. The appliance can be fitted with an accessory tool for cleaning upholstery and stairs.

2 86037780 MINI EXTRACTOR

Page 3

Table of contents

Machine Data Log & Overview . . . . . . . . . . . . . . . . .2

Table of contents. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . .4

Safety

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . .5

HAZARD INTENSITY LEVEL. . . . . . . . . . . . . . . . . .7

GROUNDING INSTRUCTIONS . . . . . . . . . . . . . . . .9

Safety Label Location . . . . . . . . . . . . . . . . . . . . . . .10

Operation

Technical Specifications . . . . . . . . . . . . . . . . . . . . .11

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Controls & Components . . . . . . . . . . . . . . . . . . . . .13

Filling The Solution Tank . . . . . . . . . . . . . . . . . . . .14

Operating the Machine . . . . . . . . . . . . . . . . . . . . . .15

Operating Machine With Accessory Tools . . . . . . .16

Maintenance

Protect From Freezing . . . . . . . . . . . . . . . . . . . . . .17

Daily Regular Maintenance. . . . . . . . . . . . . . . . . . .17

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . .17

Maintenance Instructions . . . . . . . . . . . . . . . . . . . .18

Brush Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Spray Jet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Brush Motor Removal. . . . . . . . . . . . . . . . . . . . . . .19

Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Vacuum Motor Removal . . . . . . . . . . . . . . . . . . . . .20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .21

PARTS

Brush Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Decal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame & Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tank & Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Wiring Diagram - Main 230V. . . . . . . . . . . . . . . . . 42

Wiring Diagram-Control Panel 115V. . . . . . . . . . . 44

Wiring Diagram-Vacuum, Brush

Motor & Pump 115V . . . . . . . . . . . . . . . . . . . . . . . 46

Wiring Diagram-Control Panel 230V. . . . . . . . . . . 48

Wiring Diagram-Vacuum, Brush

Motor & Pump 230V . . . . . . . . . . . . . . . . . . . . . . . 50

Hose Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

86037780 MINI EXTRACTOR 3

Page 4

How to Use This Manual

This manual contains the following sections:

• HOW TO USE THIS MANUAL

• SAFETY

•OPERATIONS

• MAINTENANCE

• PARTS LIST

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine model and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The model and serial number of your machine is

located on the lower back panel.

The SAFETY section contains important information

regarding hazardous or unsafe practices of the

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

The OPERAT IONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in

good working condition. They are listed in this general

order:

•Periodic

• Daily/Regular

• Troubleshooting

The PARTS LIST section contains assembled part s

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

• REF - column refers to the reference number on

the parts illustration.

• P ART NO. - column list s the part number fo r the

part.

• PRV NO. - Reference number.

• QTY - column lists the quantity of the part used

in that area of the machine.

• DESCRIPTION - column is a brief description of

the part.

• SERIAL NO. FROM - column indicates the first

machine the part number is applicable to. When

the machine design has changed, this column

will indicate serial number of applicable

machine. The main illustration shows the most

current design of the machine. The boxed illustrations show older designs. If column has an

asterisk (*), call manufacturer for serial number.

• NOTES - column for information not noted by

the other columns.

4 86037780 MINI EXTRACTOR

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

NOTE: The manual part number is located on the

lower left corner of the front cover.

Page 5

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution must always be followed,

including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

To reduce the risk of fire, electric shock, or injury:

Connect to a properly grounded outlet. See Gr ou nd in g Ins tr uct ion s.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before maintenance or

service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near children.

Use only as described in this manual. Use only manufacturer's recommended components and attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding the

machine. If the machine is not working properly, has been dropp ed, damaged , lef t o ut doors, or d ropped in to water,

return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord around sharp

edges or corners.

Do not run machine over cord. Keep cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug , not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine near

flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offices

for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

SAVE THESE INSTRUCTIONS

86037780 MINI EXTRACTOR 5

Page 6

Safety

CONSIGNES IMPORTANTES DE SÉCURITÉ

Lors de l'utilisation d'un appareil électrique, il faut toujours observer des précau-

tions élémentaires,qui comprennent parmi celles-ci :

LISEZ BIEN L'ENSEMBLE DES CONSIGNES AVANT D'UTILISER CET APPAREIL.

Cette machine est pour l’utilisation commerciale.

Pour réduire les risques d'incendie, d'électrocution ou de blessure :

Raccordez l'appareil à une prise adéquatement reliée à la terre. Voir les Consignes de mise à la terre.

Ne laissez pas l'appareil sans surveillance lorsqu'il est branché. Débranchez l'appareil lorsqu'il n'est pas utilisé et

avant tout entretien.

Utilisez-le exclusivement dans des endroits fermés. Ne l'utilisez pas en plein air et ne le laissez pas sous la pluie.

Ne pas permettre aux enfants dejouer avec l'appareil. Durant la manoeuvre de la machine, prendre garde aux

personnes environnantes et notamment aux enfants.

Utilisez-le exclusivement de la manière décrite dans ce manuel. Utilisez exclusivement les composants et les

fixations recommandés par le fabricant.

N'utilisez pas l'appareil si le cordon ou la fiche est endommagé(e). Observez toutes les consignes figurant dans ce

manuel au sujet de la mise à la terre de l'appareil. Si l'appareil ne fonctionne pas correctement, s'il est tombé par

terre, s'il est endommagé, s'il a été laissé dehors ou s'il a été plongé dans l'eau, veuillez le renvoyer à un centre

d'entretien agréé.

Ne tirez pas sur le cordon, ne portez pas l'appareil par le cordon, n'utilisez pas le cordon comme poignée, ne

fermez pas une porte sur le cordon, ne tirez pas sur le cordon dans des angles ou des coins pointus.

Ne faites pas passer l'appareil par-dessus le cordon. Maintenez le cordon à l'écart de surfaces chauffées..

Ne débranchez pas l'appareil en tirant sur le cordon. Pour le débrancher, empoignez la fiche, non pas le cordon.

Ne manipulez pas la fiche ou l'appareil les mains mouillées.

Ne faites pas fonctionner l'appareil si des ouvertures sont bouchées. Dégagez des ouvertures tous débris suscep-

tibles d'entraver le passage de l'air.

Cette machine est destinée pour nettoyer le tapis seulement.

Ne pas ramasser quelque chose qui brûle ou fume, comme des cigarettes, des allumettes ou des cendres

chaudes.

Cet appareil n'est pas conçu pour aspirer des poussières dangereuses.

Arrêtez toutes les commandes avant le débranchement.

L'appareil peut déclencher un incendie s'il se trouve à proximité de vapeurs ou de matériaux inflammables. Ne

faites pas fonctionner cet appareil à proximité de fluides, de poussières ou de vapeurs in flammables.

Cet appareil est adapté à un usage commercial : par exemple dans les hôtels, les établissements scolaires, les

hôpitaux, les usines, les magasins et les bureaux, à des fins plus étendues qu'un simple entretien de la maison.

Les travaux de maintenance et de réparation doivent absolument être effectués par du personnel qualifié.

Si de la mousse ou du liquide s'échappe de la machine, éteignez-la immédiatement.

CONSERVEZ CES CONSIGNESS

6 86037780 MINI EXTRACTOR

Page 7

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or

property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully . Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use only manufacturer approved replacement parts.

86037780 MINI EXTRACTOR

7

Page 8

Safety

Les symboles ci-dessous sont utilisés à travers ce manuel comme illustré dans leurs descriptions :

DEGRÉS DE RISQUES EN CAS DE DANGER

Il existe trois degrés de risques identifiés par les termes signalétiques -AVERTISSEMENT et

ATTENTION et POUR VOTRE SÉCURITÉ. Le degré de risque est défini de la manière suivante :

AVERTISSEMENT - Dangers ou méthodes dangereuses qui POURRAIENT provoquer de graves

blessures ou entraîner la mort.

ATTENTION - Dangers ou méthodes dangereuses qui pourraient provoquer des blessures légères ou

une détérioration du produit ou des biens immobiliers.

POUR VOTRE SÉCURITÉ : ce signe permet d'identifier les mesures de précaution à prendre pour

assurer un bon fonctionnement du matériel.

Rendre compte immédiatement d'une défaillance ou d'une détérioration de la machine. Ne pas utiliser la

machine si celle-ci ne fonctionne pas correctement. Lire soigneusement les informations ci-dessous

signalant certains dangers potentiels pour l'opérateur de la machine. L'o pérateur doit être absolument au

courant de ces dangers potentiels. Localiser tous les dispositifs de sécurité sur la machine. Il est

conseillé de prendre les mesures nécessaires pour former le personnel opérateur.

POUR VOTRE SÉCURITÉ :

NE PAS MANOEUVRER LA MACHINE :

Lorsqu'on n'est pas expérimenté ou qualifié.

Lorsque le guide d'utilisation n'est pas été lu ou compris.

Dans des zones inflammables ou explosives.

Dans des zones où des objets peuvent tomber.

LORS DE L'ENTRETIEN DE LA MACHINE :

Éviter les parties amovibles. Ne pas porter de vêtements amples, tels que des vestes, des

chemises ou des vêtements avec manches lors de l'utilisation de la machine. Utiliser les pièces

détachées Windsor homologuées.

8

86037780 MINI EXTRACTOR

Page 9

Safety

GROUNDING

PIN

GROUNDED

OUTLET

ADAPTER

METAL SCREW

TAB FOR

GROUNDING SCREW

GROUNDED

OUTLET BOX

(A) (B)

(C)

THIS PRODUCT IS FOR COMMERCIAL

USE ONLY.

ELECTRICAL

In the USA this machine operates on a standard 15

amp 120V, 60 hz, A.C. power circuit. The amp, hertz,

and voltage are listed on the data label found on each

machine. Using voltages above or below those

indicated on the data label will cause serious damage

to the motors.

EXTENSION CORDS

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine, and must be limited to 50 feet (15.5m) in

length.

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or break down, grounding provides a path of least

resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and

grounding plug. The plug must be inserted into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

120 VOLT MODELS

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug in "Fig.

A". A temporary adaptor that looks like the adaptor in

"Fig. C" may be used to connect this plug to a 2-pole

receptacle as shown in "Fig. B", if a properly grounded

outlet is not available. The temporary adaptor should

be used only until a properly grounded outlet (Fig. A)

can be installed by a qualified electrician. The green

colored rigid ear, lug, or wire extending from the

adaptor must be connected to a permanent ground

such as a properly grounded outlet box cover.

Whenever the adaptor is used, it must be held in place

by a metal screw.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check

with a qualified electrician or service person if you are

in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the appliance - if it

will not fit the outlet, have a proper outlet installed by a

qualified electrician.

Le raccordement incorrect du conducteur de terre

d'équipement peut entraîner des risques d'électrocution. Vérifiez auprès d'un électricien qualifié ou d'un

responsable de l'entretien si vous avez quelque doute

que ce soit quant au raccordement à la terre de votre

prise murale. Ne modifiez pas la fiche fournie avec

l'appareil : si elle ne correspond pas à la prise murale,

faites installer une prise adéquate par un élec tricien

qualifié.

86037780 MINI EXTRACTOR

9

Page 10

Safety

WARNING LABEL

PART NUMBER 86220140

PRV 500895

Safety Label Location

The following WARNING LABEL(S) are found on yo ur cleaning unit. These labels point out impor tant W arnings and

Cautions which should be followed at all times. Failure to follow warnings and cautions could result in fatality,

personal injury to yourself and/or others, or property damage. Follow these instructions carefully! DO NOT remove

these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

Les ÉTIQUETTES D'AVERTISSEMENT suivantes se trouvent sur votre unité de nettoyage. Ces étiquettes

signalent les avertissements et mises en garde importantes qui doivent être suivis en tout temps. Le non respect

des avertissements et mises en garde pourr ait entraîner d es dommages matériels, de s blessures graves ou même

la mort. Suivez attentivement ces instructions ! NE PAS retirer ces étiquettes.

REMARQUE : Si, à tout moment, les étiquettes deviennent illisibles, remplacez-les rapidement.

10 86037780 MINI EXTRACTOR

Page 11

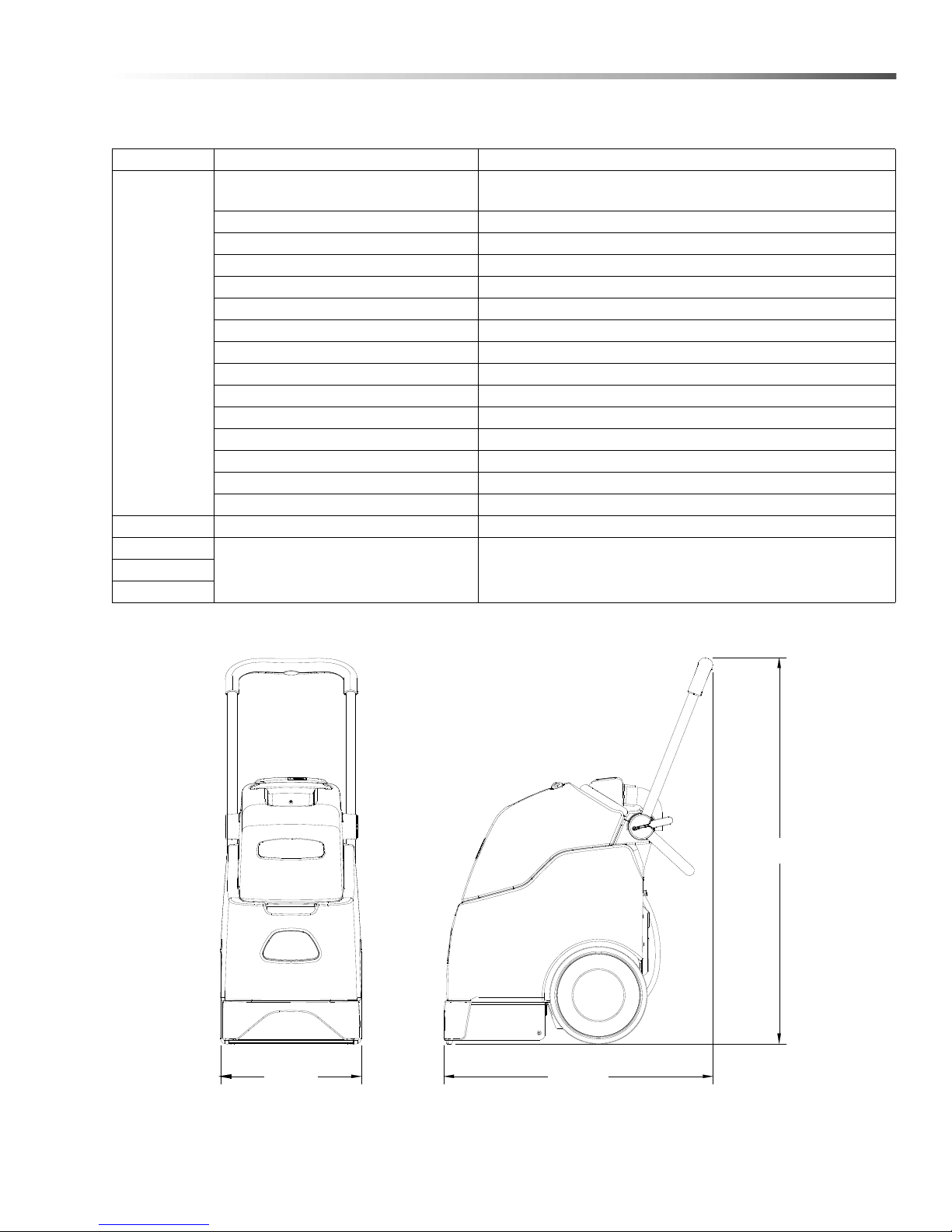

Technical Specifications

Width

Length

Height

MODEL ITEM MEASURE

Vacuum Motor

Floating Brush 10” (25.4cm)

Main Jet Solution Pump Solenoid Style

Accessory Solution Pump Solenoid Style

Solution Capacity 4.6 Gal (17.3L)

Recovery Capacity 3.9 Gal (14.7L)

ALL

10080390 Electrical 115V, 15A, 60Hz

10080400

10080420

Brush Speed 1160 rpm

Wheels (2) 10” dia. (25cm) by 2” (5cm)

Vacuum Shoe 12” (30.48cm) cast aluminum

Solution Spray 1 quick change jet

Power cord 25’ (7.6m) (14 gauge)

Height 39 inches (100cm) (Handle adjusted to highest position)

Length 27 inches (69cm) (Handle adjusted to highest position)

Width 14 inches (36cm)

Weight 75 lbs. (34kg)

Electrical 230 V, 5A, 50Hz10080410

(1) 3 stage, 1.5hp 100 cfm (2.8cubic meters/min.)

Waterlift - 120” (305cm)

Operation

86037780 MINI EXTRACTOR 11

Page 12

Operation

To avoid electric shock use indoors only.To reduce risk

of fire, do not use volatile substances. Use only

cleaners intended for carpet application.

Chemicals

Use only the suitable chemicals listed below. Using

incompatible chemicals will damage the machine.

Damages of this type are not covered under warranty.

Carefully read ingredients on manufacturer's label

before using any product in this machine.

Pour éviter une électrocution, utilisez la machine à

l'intérieur seulement. Pour réduire les risques

d'incendie, n'utilisez pas de substances volatiles.

Utilisez seulement des nettoyants destinés à être

appliqués sur les tapis.

Inspection

Carefully unpack and inspect your extractor for

shipping damage. Each unit is operated and thoroughly inspected before shipping, and any damage is

the responsibility of the carrier, who should be notified

immediately.

To avoid possible distortion of polyethylene solution/

recovery tanks, DO NOT USE WATER TEMPERATURE THA T EXCEEDS 140°F (60° C).

Pour éviter toute distorsion possible aux réservoirs de

récupération /de la solution de polyéthylène ,

N’UTILISEZ PAS D'EAU DONT LA TEMPÉRATURE

DÉPASSE 60° C (140° F).

Suitable Chemicals Incompatible Chemicals

Alkalis Aldehydes; Butyls

Defoaming Agents Carbon Tetrachloride

Detergents Chlorinated Bleaches

Soaps Chlorinated Hydrocarbons

Vinegar Trichlorethylene

Hydroxides Phenols; Methyls (MEK)

Perchlorethylene (perc)

Aromatic Hydrocarbons

D-Limonene

12 86037780 MINI EXTRACTOR

Page 13

Operation

2

1

9

3

8

5

4

6

7

10

11

12

13

Controls & Components

1. Power and Operation Mode Switch

Turns accessory tool on or machine on.

2. Main Handle

3. Solution Button

Sprays solution on floor when pressed.

4. Brush Motor Circuit Breaker

Protects brush motor from overheating.

5. Vac Motor Circuit Breaker

7. Solution Tank Drain Hose

8. Accessory Tool Connection

Solution connection for accessory tools.

9. Accessory Hose Connection

Hose connection for accessory tool.

10. Dome Clamp

11. Dome

12. Recovery Tank

13. Solution Tank

Protects the vac motor from overheating

6. Handle Adjustment Lever

Adjusts handle position.

86037780 MINI EXTRACTOR 13

Page 14

Operation

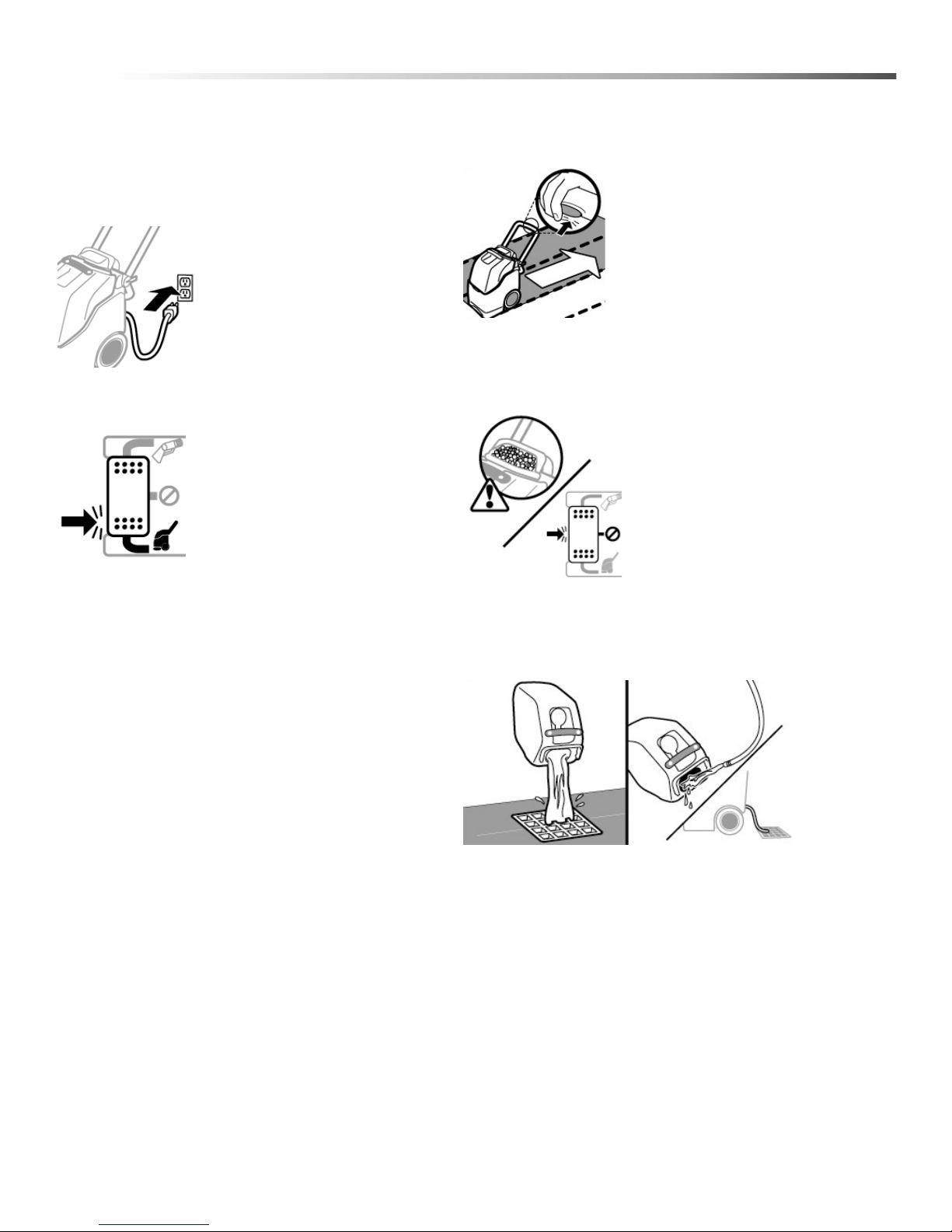

Filling The Solution Tank

1. Release dome clamp.

2. Lift upper recovery tank from machine and set

aside.

3. Use a clean bucket, recovery tank or hose to fill

solution tank with hot water. The solution tank

holds 4 gallons (15.2 liters) of cleaning solution.

Add a non-foaming concentrate for use in hot water

extractors at the proportions noted on the

container.

4. Place recovery tank back on machine.

Place dome on recovery tank. Make sure dome is

seated correctly to ensure proper vacuum seal.

Clamp dome securely to recovery tank.

Use only the suitable chemicals listed in the Chemical

Section. Using incompatible chemicals will damage the

machine. Carefully read ingredients on manufacturer's

label before using any product in this machine.

SPECIAL NOTES:

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance b y a person

responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.

The sound pressure level at the operator's ear was

measured to be 73.7 dBA. This was a nearfield, broadband measurement taken in a typical industria l environment on a tile floor. This appliance contains no

possible source of impact noise. The instantaneous

sound pressure level is below 63 Pa.

NOTE: Periodically operate the extractor with only

hot water to remove chemical residue in carpet.

To avoid possible distortion of the polyethyleneso lution/

recovery tanks, DO NOT USE WATER WITH A

TEMPERATURE THAT EXCEEDS 140°F(60°C).

14 86037780 MINI EXTRACTOR

The weighted root mean square acceleration at the

operator's arms was measured to be below 2.5m/s2.

This was a tri-axial, third-octave-band measurement

made during normal operation on a composite tile floor .

The measurement and related calculations were made

in accordance with ISO 5349-1.

Page 15

Operating the Machine

Operation

1. Vacuum the carpet and make sure it is cleared of

surface debris before cleaning.

2. Plug power cord into a grounded wall outlet.

NOTE: Defeating the grounding pin on th e po we r

cord can result in a severe electrical shock.

3. Turn on the machine by pressing the switch in the

normal operation mode.

4. To operate the machine, pull straight back without

pushing down on handle. Press the solution spray

button to apply cleaning solution.

5. While operating machine, check for excessive

foam buildup in the recovery tank. If excessive

foam is present, add a defoamer solution to

recovery tank, or empty tank.

NOTE: The vacuum and the brush are protected by

circuit breakers located on the control panel, to the

right of the switch.

NOTE: If either motor does not respond to being

switched on, reset the circuit breakers by pressing

them in, and attempt to switch the machine on again.

NOTE: If solution does not dispense in an even

pattern across the width of the machine, the spray jet

may be clogged. Tilt the machine back, check for

debris and clean surface of jet.

NOTE: Do not use pins, wire, etc. to clean spray jet

nozzle as this will deform the jet and destroy the

spray pattern.

6. Empty recovery tank when approximately 3/4 full. If

the recovery tank is overfilled, the water will drain

back onto the carpet when the vacuum is switched

off.

7. Ventilate area after carpet has been cleaned.

Keep children and pets away and do not walk on carpet

until it is dry.

A Windblower™ fan can be used to reduce drying time.

86037780 MINI EXTRACTOR 15

Page 16

Operation

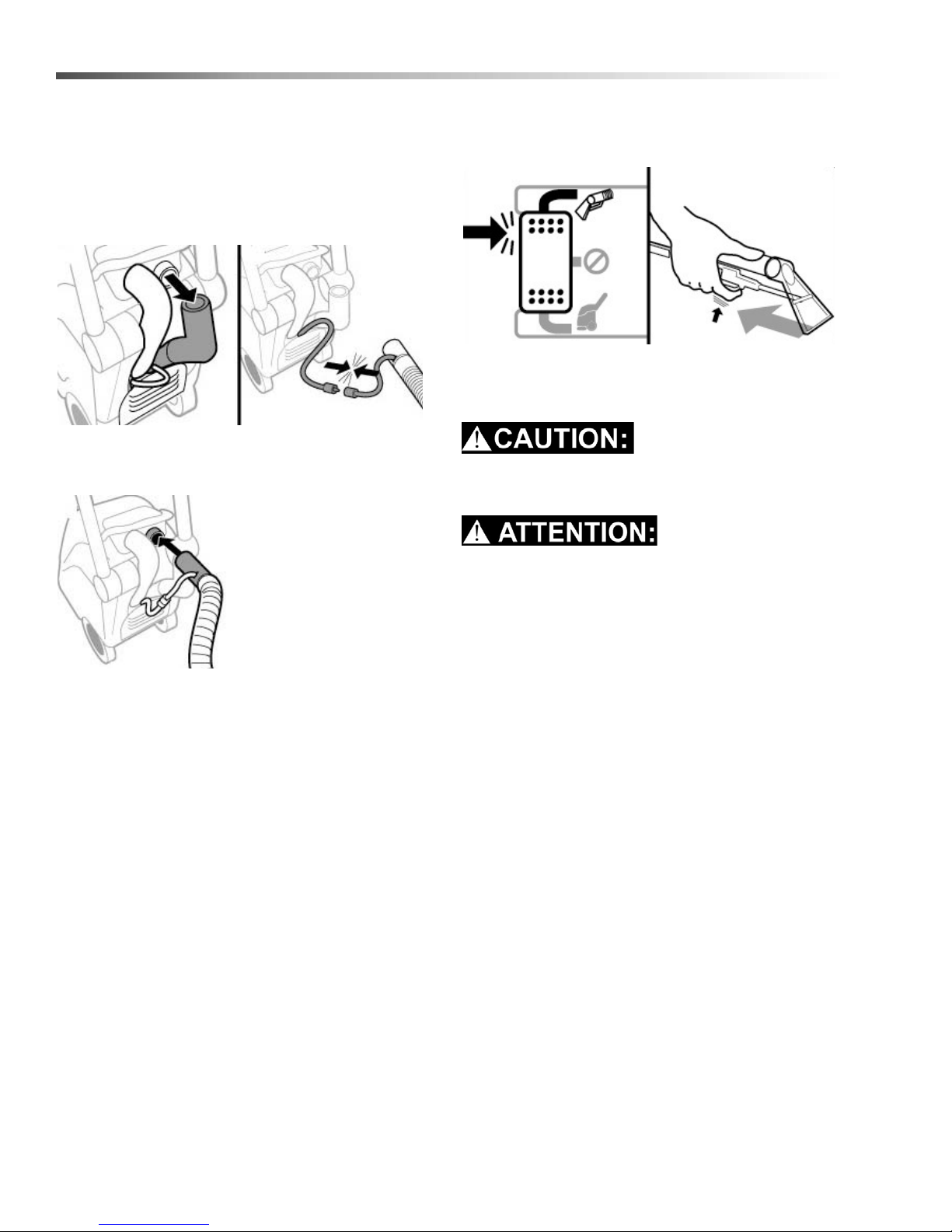

Operating Machine With Accessory Tools

This extractor is easily adapted for use with Windsor

accessory tools: Contact Customer Service for details.

1. Disconnect vacuum hose at dome, insert hose cuff

into the dome, ensuring that there is a tight fit.

Dome must be clamped to recovery tank.

2. Attach the solution hose from accessory tool to the

brass solution fitting on the back of machine.

3. Turn on the switch in the accessory position. The

application of cleaning solution is now controlled by

the lever on the accessory tool.

NOTE: The solution pump is not intended to run dry.

When using the extractor for vacuum pick-up only. Do

not press the solution spray button.

This appliance is not suitable for picking up

hazardous dust.

Cet appareil n'est pas conçu pour aspirer de s poussières dangereuses.

16 86037780 MINI EXTRACTOR

Page 17

Maintenance

Protect From Freezing

If it becomes necessary to store in temperatures that

could drop below 40°F, the pumping system , hoses and

valves must be protected from freezing with a methyl

hydrate window washer antifreeze solutio n.

NOTE: Do not use ethylene glycol or cooling system

antifreezes.

1. Add one gallon of window washer antifreeze to the

supply tank.

2. Turn on pump switch and sp ray until the anti-freeze

solution fills the solution lines.

3. Drain the leftover antifreeze from the supply tank.

Always allow the unit to reach room temperature

before filling with hot water or operating.

4. Before operation be sure to flush system

completely. Failure to do so after winterizing

machine will damage carpet.

Daily Regular Maintenance

Before making any adjustments or repairs to the

machine, disconnect the power cord from the electrical source.

1. Empty unused cleaning solution from the solution

tank.

Periodic Maintenance

1. After every 25 hours of operation, flush a white

vinegar solution (ONE quart vinegar to two gallons

of water) or anti-browning solution (mixed as

directed) through the extractor. This will prevent

build-up of alkaline residue in the system.

2. If the spray jet becomes clogged, check for debris

and clean surface of jet.

NOTE: Do not use pins, wire, etc. to clean spray jet

nozzle as this will deform the jet and destroy the

spray pattern.

3. Periodically inspect all hoses, electrical cables,

filters, gaskets and connections on your machine.

Frayed or cracked hoses should be repaired or

replaced to eliminate vacuum or solution pressure

loss.

4. The electrical cable must be well insulated, if the

cable insulation is broken or frayed, repair or

replace it immediately. Don't take chances with

electrical fire or shock.

5. The filter in the bottom of the solution tank and at

the fill port must be clean to allow free flow of

cleaning solution. The screen filter on the vacuum

intake in the dome must be free of lint buildup to

ensure full vacuum strength.

2. Inspect and clean filter at solution tank fill port and

at the vacuum intake port in the dome.

3. Flush pumping system with 1 to 2 gallons of clean,

hot water.

4. Check spray jet for full spray pattern.

5. Empty the recovery tank and rinse with clean

water.

6. Check for and remove any lint or debris around

brush and vac shoe.

7. Clean float screen and check float valve to make

sure it moves freely.

6. The dome gasket must be properly seated and fre e

of damage to create the air seal needed to extract

water.

86037780 MINI EXTRACTOR 17

Page 18

Maintenance

Maintenance Instructions

Remove machine power cord from electrical

source before making any adjustments or repairs

to the machine.

Retirez le cordon d'alimentation d e la machine de la

source électrique avant de procéder à des réparations ou des ajustements de la machine.

Only qualified maintenance personnel are to

perform repairs.

Only use the brushes provided with the appliance

or those specified in the instruction manual. The

use of other brushes may impair safety.

N'utilisez que les brosses fournies avec l'appareil

ou celles qui sont spécifiées dans le manuel

d'instructions. L'utilisation d'autres brosses peut

nuire à la sécurité.

Spray Jet

NOTE: To prevent a clogged jet due to alkali build-

up, the spray system should be flushed with 1 to 2

gallons of clean hot water at the end of each day.

1. Turn off switch and unplug machine.

Seul le personnel d'entretien qualifié peut effectuer

des réparations.

Brush Assembly

1. Turn off switch and unplug machine.

2. Position the machine to have access to the bottom.

Remove screws (2) at the sides of the machine

holding the brush deck pivot axle.

3. Remove screw mounting belt cover and remove

belt cover.

4. Loosen the nuts (2) at brush motor and slide motor

forward to reduce belt tension. Remove belt.

5. Loosen set screw on brush pulley. Remove pulley.

6. Remove screws (4) mounting brush bearings to

frame. Slide bearing off brush axle.

7. Remove brush by lifting drive end out of frame and

sliding other end out of bearings mounted to frame.

8. Inspect/replace brush and bea rin gs as required.

The brush is equipped with yellow wear indicator

bristles. Replace the brush when it wears down to

the height of the yellow bristles.

2. Position the machine to have access to the bottom.

Remove screws (2) at the sides of the machine

holding the brush deck pivot axle.

3. Position the machine to have access to the bottom.

4. Pull off the clip mounting the jet to the frame. Push

the jet and hose out of the mounting hole in the

frame.

5. Loosen the hose clamp and pull the jet out of the

hose.

6. Reverse the process to reinstall the jet. Be sure to

have jet rotated correctly before installing clip. Clip

tab must face back of machine.

NOTE: Do not use pins or wire to remove obstructio n

if clogged, this may damage jet and alter spray

pattern.

9. Reverse the process to reinstall the brush and

bearings. Check belt for proper belt tension.

18 86037780 MINI EXTRACTOR

Page 19

Maintenance

Brush Motor Removal

1. Turn off switch and unplug machine.

2. Set the machine in its upright position. Remove the

screws (2) in the back metal cover. Rotate the

cover down and slide back releasing the tab under

the machine from the main frame.

3. Remove the pump box cover. Remove screws (4)

at each leg of the cover.

4. To remove brush motor, position the machine to

have access to the bottom. Remove screws (2) at

the sides of the machine holding the brush de ck

pivot axle.

5. Remove screw mounting belt cover and remove

belt cover.

6. Remove the nuts and washers (2) at brush motor

and slide motor forward to reduce belt tension.

Remove belt.

7. Remove pulley by loosening set screw and pull off

shaft.

8. Unplug the brush motor wires from the rectifier

located in the pump mount housing. Also, remove

the ground lug from the stud on the main frame by

removing the nut on the stud.

Pump Removal

1. Turn off switch and unplug machine.

2. Set the machine in its upright position. Remove the

screws (2) in the back metal cover. Rotate the

cover down and slide back releasing the tab under

the machine from the main frame.

3. Remove the pump box cover. Remove screws (4)

at each leg of the cover.

4. T o remo ve either pump, loosen the hose clamp and

remove the hose from both ends of the pump.

5. Remove screws and washers (4) that mount pump

housing.

6. Unscrew the hose fittings from each end of the

pump.

7. Flex the pump mounting housing to remove the

pump.

8. Remove the screw attaching the ground wire to the

pump. Remove the other two wire connecto rs

attached to the pump.

9. Reverse the process to reinstall

9. Reverse the process to reinstall the motor. Align

motor pulley with brush pulley. Check belt for

proper belt tension.

86037780 MINI EXTRACTOR 19

Page 20

Maintenance

3

8

[9.5mm]

Vacuum Motor Carbon Brushes

Carbon

Brushes

End Cap

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a

qualified service center.

Inportant:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage

motor if brushes are allowed to wear away completely.

Periodically check the length of the carbon brushes. Replace

both carbon brushes when either is less tan 3/8" (9.5mm)

long.

Vacuum Motor Removal

1. Turn off switch and unplug machine.

2. Set the machine in its upright position. Remove

the screws (2) in the back metal cover. Rotate the

cover down and slide back releasing the ta b under

the machine from the main frame.

3. Remove the pump box cover. Remove screws (4)

at each leg of the cover.

4. Remove vacuum hose, loosen hose clamp and pull

hose from bottom of vacuum motor.

5. Unplug wires (2) from main harness located in

pump mount housing. Remove ground from stud

on main frame.

6. To remove the vacuum motor, remove the screws

(2) in the back of the machine that mount the

plastic cover to the solution tank.

7. Remove the screws (3) that mount the vacuum

motor to the plastic cover. Pull the cover off the

vacuum motor.

8. Unscrew the ground wire from the vacuum motor.

9. Reverse the process to reinstall the vacuum motor.

NOTE: Make sure the excess wire lengths do n ot get

pinched between the vacuum motor and plastic

cover.

NOTE: The vac motor is protected by a circuit

breaker located in the switch panel. The breaker will

only trip under conditions of abuse.

20 86037780 MINI EXTRACTOR

Page 21

Maintenance

Troubleshooting

PROBLEM CAUSE SOLUTION

No power, nothing runs. Is the cord plugged in. Plug in cord.

Circuit breaker tripped in building. Reset breaker.

Faulty switch. Call for service.

Faulty power cord or pigtail. Call for service.

Vacuum motor will not run. Vacuum circuit breaker tripped. Reset breaker.

Faulty main switch. Call for service.

Loose wiring. Call for service.

Faulty vac motor. Call for service.

Vacuum motor runs but

suction is poor.

Poor or no water flow.

(carpet is streaky)

Brush does not spin. Switch in accessory mode. Turn to deep clean position.

Accessory tool fitting difficult

to connect

Debris lodged in vac shoe. Remove debris from vac shoe.

Dome gasket defective or missing. Replace as necessary.

Vacuum hose cracked or hose cuff loose Replace or repair as necessary.

Recovery tank full.

Switch to accessory mode. Turn to deep clean position.

Jets clogged or missing. Jets clogged or missing.

Solution filter clogged.

Faulty solution pump. Call for service.

Brush circuit breaker tripped. Reset circuit breaker.

Brush belt broken. Replace as necessary.

Faulty brush motor. Call for service.

Corrosion on fitting.

Turn off vac motor. Drain and rinserecovery tank.

Drain solution tank and clean solutionfilter.

Clean with steel wool. Remove and soak

in acetic acid (white vinegar). Lubricate

lightly with silicone base lubricant.

86037780 MINI EXTRACTOR 21

Page 22

Maintenance

Troubleshooting

Problem Cause Solution

Worn brush bearings

Carpet not getting clean Severe soil conditions

Carpet too wet Worn spray jet Replace spray jet which is producing a fine mist.

Carpet not getting wet

Squealing or grinding sound in

brush housing.

Solution filter screen clogged.

Spray jet clogged.

Pump not running.

Faulty solution switch. Replace switch in handle.

Replace bearings.

Make several passes at right angles to ea ch other .

Use a pre-spray.

Clean solution filter screen located inside lower

tank.

Clean or replace jet. Do not use a wire to clean

jet. Damaged jet will cause over-saturation.

Check for and correct any loose wires. Repair or

replace.

22

86037780 MINI ETRACTOR

Page 23

PARTS

86037780 MINI EXTRACTOR

Page 24

Brush Deck

6

16

1

7

1

2

3

4

5

1

7

8

9

10

11

12

13

14

15

17

24 86037780 MINI EXTRACTOR

Page 25

Brush Deck

REF PART NO. PRV NO. QTY DESCRIPTION

1 86173020 70916 5 SCR, M5 X 10, PHMS, ISO7045, SS

2 86217390 270146 1 COVER, PULLEY, BRUSH DECK

3 86215260 11051 1 BELT, HTD 5MM 69T 9 WIDE

4 86223780 70896 2 SET SCR, M4 X 6LG, CP BLK

5 86223300 64115 1 PULLEY, BRUSH

6 86214970 03124 1 AXLE, PIVOT, BRUSH DECK

7 86229020 09163 2 BEARING, BRUSH PLASTIC

8 86005640 57030 2 NUT, 10-32 HEX NYLOCK

9 86173330 87513 2 WASHER, M5, FLAT, ISO7093, SS

10A 86247110 53146 1 M OTOR, 115V BRUSH DRIVE 115V ONLY

10B 86306720 - 1 MOTOR ASM, 230V DC PM 230V ONLY

11 86217920 140893 1 BRKT, FLOATING BRUSH, 10 IN

12 86223490 67468 2 RING, 10MM EXT SNAP, DIN 471

13 86216430 140912 2 BUSHING, BRUSH PRESSURE

14 86216040 02506 1 BRUSH, CHEVRON, 10 IN

15 86173220 7095 4 2 SCR, M6X12 PHCS, 12.5MM HD,SS

16 86223350 64125 1 PULLEY, MOTOR

17 86010680 87030 1 WASHER, 3/8 ID X 3/4 OD NYLON

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 25

Page 26

Control Panel

10

9

11

1

2

3

4

6

5

7

8

12

26 86037780 MINI EXTRACTOR

Page 27

Control Panel

REF PART NO. PRV NO. QTY DESCRIPTION

1 86007200 72162 1 SWITCH, DPDT 3-POSITION ROCKER

2 86002010 14942 2 BOOT, 3/8 CIRCUIT BREAKER

3 86173140 70945 2 SCR, KA40X16, PT OV AL, WN1412, PL

4 86217410 270152 1 COVER, CONTROLS TOP

5A 86230140 14622 1 BREAKER, 1.5A CIRCUIT 115V ONLY

5B 86001780 14308 1 BREAKER, 0.8A CIRCUIT 230V ONLY

6A 86291460 - 1 BREAKER, 11A VDE CIRCUIT 115V ONLY

6B 86198130 141047 1 BREAKER, 6A VDE CIRCUIT 230V ONLY

7 86223420 67622 1 RELAY, 10A 230VAC SPDT 230V ONLY

8 86302680 - 1 EMI FILTER MAIN 230V ONLY

9 86292300 - 2 SCR, M4X20 SBHCS, BLK EDP

10 86173350 87515 2 WASHER, M5, FLAT, ISO7089, SS

11 86216300 140956 2 BUMPER, CONSOLE

SEE WIRING DIAGRAM FOR WIRE CONNECTIONS.

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 27

Page 28

Decal

2

1

3

28 86037780 MINI EXTRACTOR

Page 29

Decal

REF PART NO. PRV NO. QTY DESCRIPTION

1 86221090 501128 1 LABEL, CONTROL PANEL

2 86221470 501208 1 LABEL, DOME ACCESSORY

3 86013720 - 1 LABEL, MINI EXT.INSTRUCTION

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 29

Page 30

Frame & Wheels

11

13

10

8

9

12

7

6

5

4

3

2

1

30 86037780 MINI EXTRACTOR

Page 31

Frame & Wheels

REF PART NO. PRV NO. QTY DESCRIPTION

1 86215830 140897 1 BRKT, BRUSH HOUSING, 10 IN

2 86173010 70915 6 SCR, M4 X 16, SHCS, ISO4762, SS

3 86216290 140895 1 BUMPER, EXTRACTOR, FRONT

4 86218090 35360 1 GASKET, VAC SHOE

5 86225530 85086 1 VAC SHOE, 12 IN

6 86172630 57314 6 NUT, M4, LOCK, ISO7040, SS

7 86173220 70954 6 SCR, M6X12 PHCS, 12.5MM HD, SS

8 86226050 89279 2 WHEEL, 10IN

9 86011880 - 2 WASHER, 16.2 X 23 X 0.6MM, PLT

10 86214980 03125 1 AXLE, WHEELS, 5/8 DIA

11 86272750 67010 2 RING, 5/8 EXTERNAL SNAP

12 86219480 4156 7 2 HUBCAP, 9.75" WHEEL

13 86291130 - 1 BUMPER, BRUSH DECK

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 31

Page 32

Handle

27

8

41

42

43

13

19

20

21

22

23

26

28

7

6

5

47

48

46

49

18

17

44

13

29

30

31

36

34

33

32

25

24

35

37

38

45

40

9

10

11

12

14

16

15

4

3

2

1

24

37

36

31

39

32 86037780 MINI EXTRACTOR

Page 33

Handle

REF PARTNO. PRV NO. QTY DESCRIPTION

1 86012660 - 3 SCR, KA40X25, PT OHCS,WN1452,PL

2 86218570 38342 1 HANDLE, GRIP BOTTOM

3 86225910 38343 1 WELDMENT, HANDLE TUBE

4 86218560 38341 1 HANDLE, GRIP TOP

5 86225140 72204 1 SWITCH, MICRO

6 86224650 730392 1 SPRING, LEVER

7 86216470 140922 1 BUTTON, SPRAY HANDLE

8 86219460 41553 1 HUB, SPLINE HANDLE

9 86216440 140934 1 BUSHING, SHAFT HANDLE

10 86219660 48113 1 KEY, HANDLE CAM, 4X24MM

11 86221790 51548 1 LEVER CAM HANDLE

12 86217360 270138 1 COVER, TUBE HUB LEFT

13 86277600 70882 3 SCR, M4 X 20, PHMS, ISO7045, SET

14 86008650 80604 1 COTTER, 1/4" RING

15 86222600 66887 1 PIN, CLEVIS 5MM

16 86224150 730405 1 SHAFT, HANDLE CAM

17 86222340 57512 1 NUT, M12, LOCK. ISO 7040, SST

18 86259430 87485 1 WASHER, M12 FLAT

19 86173220 70954 4 SCR, M6X12 PHCS, 12.5MM HD, SS

20 86224930 730012 1 STRAIN RELIEF, 14/3 STRAIGHT

21 86224460 730406 1 SPACER, SHAFT HANDLE

22 86224140 730404 1 SHAFT, HANDLE

23 86217380 270144 1 COVER, TUBE HUB RIGHT

24 86010640 87016 2 WASHER, #10 LOCK EXT STAR

25 86270800 57014 1 NUT, 10-32 HEX SS

26 86217350 270135 1 COVER, CONTROLS, BOTTOM

27 86172870 70898 4 SCR, M4X14 PHMS, DIN7985 SST

28 86215520 140921 1 BRACKET, HANDLE AXLE

29 86233170 20054 1 CLAMP, 3/8 NYLON UL/CSA

30A 86217140 23732 1 CORD ASM, 14X3 SJTX25' 115V ONLY

30B 86288380 23706 1 CORD ASM, AB EURO 230V ONLY

30C 86217030 23710 1 CORD ASM, AUST AB 230V ONLY

31 86173030 70917 3 SCR, M4 X 6, PHMS, ISO7045, PL

32 86005640 57030 1 NUT, 10-32 HEX NYLOCK

33 86218230 35376 1 GASKET, CONTROL BOX RIGHT

34 86218220 35375 1 GASKET, CONTROL BOX LEFT

35 86013730 - 1 SHEILD, MICROSWITCH

36 86173320 87510 3 WASHER, FLAT M4 DIN125 SST

37 86006770 70323 2 SCR, 10-32 X 1/4 PH PLTD

38 86288680 87230 4 WASHER, M5 RIVET BACKUP

39 86266080 76040 1 TERM, 18G .25 FEMALE COUPLER

40 86296620 -

41 86292550 - 1 BUSHING, HANDLE LOCK *(2)

42 86296610 - 1 LEVER, CAM HANDLE *(2)

43 86296600 - 1 COVER, HUB TUBE LEFT *(2)

44 86292560 - 1 SHAFT, HANDLE LOCK *(2)

45 86266630 - 1 PIN, DOWEL 5 X 25MM, PLTD *(2)

46 86297150 - 1 HANDLE, GRIP TOP *(1)

47 86297160 - 1 HANDLE, GRIP BOTTOM *(1)

48 86298790 - 1 WELDMENT, HANDLE TUBE *(1)

49 86173140 70945 4 SCR, KA40 X 16, PT OHCS, WN1452PL *(1)

AS

REQ’D

WASHER, 0.2X19.8C25.0MM PLTD *(2)

SERIAL

NO.FROM

NOTES

86037780 MINI EXTRACTOR 33

Page 34

Solution

34 86037780 MINI EXTRACTOR

Page 35

Solution

REF PART NO. PRV NO. QTY DESCRIPTION

1A 86201110 250-78 2 PUMP, 110/120 60HZ FLOJET 115V ONLY

1B 86201120 250-78A 2 PUMP, 220/240V 50HZ FLOJET 230V ONLY

2 86240520 40097 4 HOSEBARB, 1/8MPT X 1/4 90D

3 86010640 87016 2 WASHER, #10 LOCK EXT STAR

4 86006770 70323 2 SCR, 10-32 X 1/4 PHTR PLTD

5 86215450 140930 1 BOX, PUMP MOUNT

6 86304750 - 1 SHEILD, PUMP ENCLOSURE *(1)

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 35

Page 36

Solution

36 86037780 MINI EXTRACTOR

Page 37

REF PART NO. PRV NO. QTY DESCRIPTION

1 86219580 44106 1 JET, RT ANG, 1/4 BARB

2 86216810 270131 1 CLIP, SHAFT, 9-12MM

3 86219200 40114 1 HOSEBARB, 3/8MPT, 2 X 1/4. 1 X 3/8

4 86172950 70909 4 SCR, M5X12, SHCS, ISO4762, SS

5 86233150 20042 3 CLAMP, 3/8 HOSE (D-SLOT)

6 86219090 39728 1 HOSE, 3/8" X 432MM CLEAR

7 86200820 270-11A 1 NIPPLE, 1/8FPT QD MALE BRASS

8 86219070 39726 1

HOSE ASM, 6MM X 610MM

NYLOBRAID

9 86219080 39727 1 HOSE, 6MM X 245 MM NY LO BRAI D

10 8623309 0 20016 7 CLAMP, 1/4 ID HOSE

11 86289330 40062 1 HOSEBARB, TEE 3/8 X 3/8 X 1/4

12 86219050 39724 1 HOSE, 6MM X 390MM NYLOBRAID

13 86240430 40083 1 HOSEBARB, 3/8 MPT X 3/8 NYLON

14 86012680 - 1 HOSE, 3/8ID X 60MM NYLOBRAID

15 86005640 57030 1 NUT, 10-32 NYLOCK

16 86010640 87016 1 WASHER, #10 LOCK EXT STAR SS

17 86219060 39725 1 HOSE, 6MM X 420MM NYLOBRAID

18 8629167 0 - 1 COVER, PUMP BOX

SERIAL NO.

FROM

NOTES

SEE HOSE DIAGRAM FOR HOSE ROUTING.

86037780 MINI EXTRACTOR 37

Page 38

Tank & Dome

38 86037780 MINI EXTRACTOR

Page 39

Tank & Dome

REF PART NO. PRV NO. QTY DESCRIPTION

1 86225240 75471 1 TANK, SOLUTION, EXTRACTOR

2 86002390 20063 2 CLAMP, 1.75" WORM GEAR X .312

3 86011910 - 2 HOSE ASM, 1.5X34" VAC W/ELBOW

4 86291230 - 1 GASKET, DOME, MINI PRO

5 86217700 28070 1 DOME

6 86291170 - 1 DOME, PLATE INTERIOR

7 86291190 - 1 SCREEN, VACUUM INTAKE

8 86007970 73864 1 STRAINER, 3/8 IN. NPT 60 MESH

9 86172940 70908 6 SCR, KA40X10,PT OVAL, WN1412,PL

10 86224960 730373 1 STRAINER, BASKET

11 86172990 70913 4 SCR, M6X12 BHCS, ISO7380, SS

12 86218530 38338 1 HANDLE, RECOVERY TANK

13 86225260 75472 1 TANK, RECOVERY, EXTRACTOR

14 86216770 22113 1 CLAMP, DOME

15 86215970 141049 2 BRKT, DOME CLAMP

16 86173350 87515 4 WASHER, M5, FLAT, ISO7089, SS

17 86291180 - 1 DUCT, VACUUM INTAKE

18 86291210 - 1 O-RING, 26MM ID X 2MM THICK

19 86173000 7091 4 2 SCR, KA40X20, PT OV AL, WN1412,PL

20 86291220 - 2 SCR, KA40X16, PT, WN1413, SS

21 86292450 - 1 GASKET, DUCT

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 39

Page 40

Vacuum

6

1

7

(GROUND

WIRE)

8

3

5

3

4

2

40 86037780 MINI EXTRACTOR

Page 41

Vacuum

REF PART NO. PRV NO. QTY DESCRIPTION

1 86173000 70914 3

2A 86225480 53272 1 VAC MOTOR, 120V 5.7 3ST W/TUBE 115V ONLY

2B 86308980 - 1 VAC MOTOR ASM, 230V MINIPRO 230V ONLY

3 86173220 70954 4 SCR, M6X12 PHCS, 12.5MM HD, SS

4 86217420 270703 1 COVER, VAC MOTOR

5 86217370 270140 1 COVER, LOWER BACK

6 86006770 70323 1 SCR, 10-32 X 1/4 PHTR PLTD

7 86010640 87016 1 WASHER, #10 LOCK EXT STAR

8 86291680 - 1 GASKET, VAC MOTOR

SCR, KA40x20, PT OHS, WN1412,

PLTD

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 41

Page 42

Wiring Diagram - Main 230V

gews

ge

rt

bn

ws

or

sw

ws

ws

A

1.5

A

1.2

L

N

G

OFF

OFF

230V/50Hz

Z4

102 102

25A

6A8A

Z3

Z5

4

2

3

1

bl sw bn rt ws

ge

153/1.4

264/1.3

7

8

-K1

rt

rt

bn

sw

swbl

rt

bl

ws

bn

ge

1~M1~M1~

M

12

-M2

1~M1~M1~

M

12

-M3

1~M1~M1~

M

12

-M4

5

4 6

-S1

2

1 3

ws

ws

bl

bn

bl

sw bn

bn rt

ge

wssw

ge ge

ge

bl

bn

sw

ws ws

rt

12

-F1

1

5

3

-K1

/1.5

2

6

4

-K1

/1.5

1

2

-F2

1

2

-F3

NC

C

NO

-S2

-

˜

˜

+

-V1

M

12

-M1

-Z1

-U1

-Z2

ws

sw

42 86037780 MINI EXTRACTOR

Page 43

Wiring Diagram - Main 230V

REFERENCE DESCRIPTION

F1 25 AMP FUSE

F2 8 AMP CIRCUIT BREAKER

F3 6 AMP CIRCUIT BREAKER

K1 MAIN RELAY

S1 MAIN SWITCH LINE ON/OFF/ACCESSARY

S2 SWITCH

X* SEE SCHEMATIC

Z1 FILTER

Z2 FILTER

Z3 FERRITE BEAD

Z4 FERRITE BEAD

Z5 FERRITE BEAD

V1 RECTIFIER

M1 BRUSH MOTOR

M2 VACUUM MOTOR

M3 PUMP MOTOR

M4 PUMP MOTOR

U1 6 CONDUCTOR CABLE

86037780 MINI EXTRACTOR 43

Page 44

Wiring Diagram-Control Panel 115V

BLK

PEM

STUD

MODE

SWITCH

HANDLE

MICRO SWITCH

C

NC

NO

BLK

BLU

1.5A BREAKER

BRUSH MOTOR

11A BREAKER

VAC MOTOR

BLKBLK

3 CONDUCTOR

18 GUAGE

BLACK SHEATH

6 CONDUCTOR

14/16 GUAGE

BLACK SHEATH

FORWARD = ACCESSORY TOOL

CENTER = OFF

BACK = EXTRACT

GRN

YEL

RED

GRN

WHT

TOP OF

MACHINE

GROUND

SCREW

"BACK

POSTION"

"FORWARD

POSITION"

BLK

321

456

BLK

P/N 880464

BLK

RED

RED

BRN

GRN

WHT

BLK

BLU

3 CONDUCTOR

12 GUAGE

YELLOW SHEATH

YEL

RED

YEL

FRONT OF CONSOLE

GRN

CONNECTOR

MODE SWITCH

1

2

3

4

44 86037780 MINI EXTRACTOR

Page 45

Wiring Diagram-Control Panel 115V

REF PARTNO. PRV NO. QTY DESCRIPTION

1 86218840 41573 1 HARNESS, MAIN

2 86226230 880464 1

3 86218830 41572 1 HARNESS, HANDLE

4 86226250 880466 1 WIRE, 14" BLACK/14 76010

WIRE ASM, CONTROL PANEL

JUMPER

SERIAL

NO.FROM

NOTES

86037780 MINI EXTRACTOR 45

Page 46

Wiring Diagram-Vacuum, Brush Motor & Pump 115V

BLK

WHT

GRN

BRN

RED

WHT

BLU

BLK

GRN

GRN

GRN

CONNECTOR

G

R

N

GRN

G

R

N

GRN

GRN

DASH LINE = PUMP BOX OUTLINE

PUMP

ACC

PUMP

MAIN

GRN

GRN

GRN

BACK COVER

VAC

MOTOR

BRUSH

MOTOR

1

1

4

3

2

WHT

WHT

BLK

WHT

BRN

WHT

RED

BLK

WHT

FULL

BRIDGE

RECT

PEM

STUD

BOTTOM OF

MACHINE

BLU

46 86037780 MINI EXTRACTOR

Page 47

Wiring Diagram-Vacuum, Brush Motor & Pump 115V

REF PART NO. PRV NO. QTY DESCRIPTION

1 86226250 88884 3 WIRE, 14" GRN/14 76008 X 76008

2 86223460 67499 1 RECTIFIER, 50A 1000V BRIDGE

3 86303670 - 1 WIRE ASM, 18 GA GRN 76008/76040

4 86303680 - 1 WIRE ASM, 18 GA GRN 76008/76042

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 47

Page 48

Wiring Diagram-Control Panel 230V

BLKBLK

FORWARD = ACCESSORY TOOL

CENTER = OFF

BACK = EXTRACT

GRN

YEL

RED

TOP OF

MACHINE

GROUND

SCREW

"BACK

POSTION"

"FORWARD

POSITION"

321

456

R

E

D

RED

BRN

GRN

WHT

BLK

BLU

3 CONDUCTOR

12 GUAGE

YELLOW SHEATH

YEL

RED

YEL

FRONT OF CONSOLE

GRN

GRN

W

H

T

EMI

FILTER

GRN

B

L

U

B

R

N

B

R

N

B

L

U

BLK

1 2

4

3

56

87

RED

R

E

D

BLK

W

H

T

O

R

G

W

H

T

B

L

K

W

H

T

WHT

WHT

FUSE

25A

P/N

86305240

RELAY

3 CONDUCTOR

18 GUAGE

BLACK SHEATH

.8A BREAKER

BRUSH MOTOR

6A BREAKER

VAC. MOTOR

1

2

3

4

5

6

7

8

9

6 CONDUCTOR

14/16 GUAGE

BLACK SHEATH

PEM

STUD

MODE

SWITCH

MICRO

SWITCH

C

NC

NO

BLU

48 86037780 MINI EXTRACTOR

Page 49

Wiring Diagram-Control Panel 230V

REF PART NO. PRV NO. QTY DESCRIPTION

1 86218840 41573 1 HARNESS, MAIN

2 86218830 41572 1 HARNESS, HANDLE

3 86012400 - 1 WIRE ASM, 18GA 4" BLK

4 86012420 - 1 WIRE ASM, 18GA RED

5 86226250 880466 1 WIRE, 14" BLACK/14 76010

6 86012430 - 1 WIRE ASM, 18GA WHT

7 86012410 - 1 WIRE ASM, 18GA 4" ORG

8 86302680 - 1 ASM, FILTER EMI MAIN

9 86223420 67622 1 RELAY, 10A 230VAC SPDT

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 49

Page 50

Wiring Diagram-Vacuum, Brush Motor & Pump 230V

PUMP

MAIN

PUMP

ACC

VAC

MOTOR

FULL

BRIDGE

RECT

BACK COVER

BOTTOM OF

MACHINE

BLU

BLK

WHT

GRN

BRN

RED

DASH LINE = PUMP BOX OUTLINE

EMI FILTER

FERRITE

RED

GRN

GRN

GRN

GRN

GRN

GRN

GRN

GRN

GRN

GRN

GRN

WHT

WHT

WHT

WHT

WHT

WHT

WHT

W

H

T

BLK

BLK

BLK

B

L

K

BLK

BRN

BRN

BLU

BLU

BLU

BRN

GRN

GRN

B

L

K

W

H

T

GRN

GRN

3

2

7

1

1

4

5

FERRITE

BRUSH

MOTOR

FERRITE

8

8

6

50 86037780 MINI EXTRACTOR

Page 51

Wiring Diagram-Vacuum, Brush Motor & Pump 230V

REF PART NO. PRV NO. QTY DESCRIPTION

1 86226310 88884 2 WIRE, 14" GRN/18 76008 X 76008

2 86308960 - 1 ASM, FILTER EMI BRUSH

3 86223390 67488 1 RECTIFIER, 50A 600V BRIDGE

4 86303680 - 1 WIRE ASM, 18 GA GRN 76008/76042

5 86303670 - 1 WIRE ASM, 18 GA GRN 76008/76040

6 86302670 - 1 FERRITE, AXIAL LCR 3.007.1943

7 86309300 - 1 WIRE, 30.5" GRN/18 76008 X 76008

8 86311030 - 2 FERRITE, WURTH 74270115

SERIAL NO.

FROM

NOTES

86037780 MINI EXTRACTOR 51

Page 52

Hose Diagram

(86240430)

(86219050) (PRV 39724)

(86219090) (PRV 39728)

(PRV 40114)

(86012680)

(86219090) (PRV 39725)

(86219080) (PRV 39727)

(86219070)

TO SOLUTION TANK

ACCESSORY PUMP

MAIN PUMP

ACCESSORY TOOL

JET

TO SOLUITON

TANK

(PRV 44106)

(86240520)

(PRV 40062)

(PRV 40083)

(PRV 40097)

4X

(86200820)

(PRV 270-11A)

(PRV 39726)

(86219580)

(86289330)

(86219200)

52 86037780 MINI EXTRACTOR

Page 53

Spare Parts

PART NO. PRV NO. DESCRIPTION

86216430 140912 BUSHING, BRUSH PRESSURE

86229010 09163 BEARING, BRUSH

86216040 02506 BRUSH, CHEVRON, 10 IN

86223350 64125 PULLEY, MOTOR

86223300 64115 PULLEY, BRUSH

86215260 11051 BELT, HTD 5MM 69T 9 WIDE

86247110 53146 MOTOR, 115V BRUSH DRIVE 115V ONLY

86306720 - MOTOR, 230V DC PM 230V ONLY

86217390 270146 COVER, BELT GUARD

86218090 35360 GASKET, VAC SHOE

86219580 44106 JET, RT ANG, 1/4 BARB

86201110 250-78 PUMP, 110/120 60HZ FLOJET 115V ONLY

86201120 250-78A PUMP, 220/240V 50HZ FLOJET 230V ONLY

86224960 730373 STRAINER, RECT, 80 MESH SS

86225480 53272 VAC MOTOR, 120V 5.7 3ST W/TUBE 115V ONLY

86308980 - VAC MOTOR ASM, MINIPRO 230V 230V ONLY

86135320 140687 BRUSH SET, 120V VAC 115V ONLY

86135330 140688 BRUSH SET, 230V VAC MTR 230V ONLY

86291230 - GASKET, DOME

86291190 - SCREEN, DOME VAC INTAKE

86291460 - BREAKER, 11A VDE CIRCUIT 115V ONLY

86230140 14622 BREAKER, 1.5A CIRCUIT 115V ONLY

86215720 141047 BREAKER, 6A VDE CIRCUIT 230V ONLY

86001780 14308 BREAKER, 0.8A CIRCUIT 230V ONLY

86002010 14942 BOOT, 3/8 CIRCUIT BREAKER

86007200 72162 SWITCH, DPDT3-POSITION ROCKER

86349430 - CHECK VALVE KIT

SERIAL

NO. FROM

NOTES

PART NO. PRV NO. DESCRIPTION

86218790 HTO HANDTOOL W/1/8 FEM QD (INCLUDES HOSE ASM)

86290360 - HANDTOOL KIT (INCLUDES HOSE ASM AND CARRY BAG)

Accessories

86037780 MINI EXTRACTOR 53

Page 54

Serial Numbers

REF. NO MODEL: SERIAL #

1 MPRO, MPROEU, MPROGB, MPROAU:1008039000126

2 MPRO, MPROEU, MPROGB, MPROAU:1008039000001

54

86037780 MINI ETRACTOR

Loading...

Loading...