Page 1

R

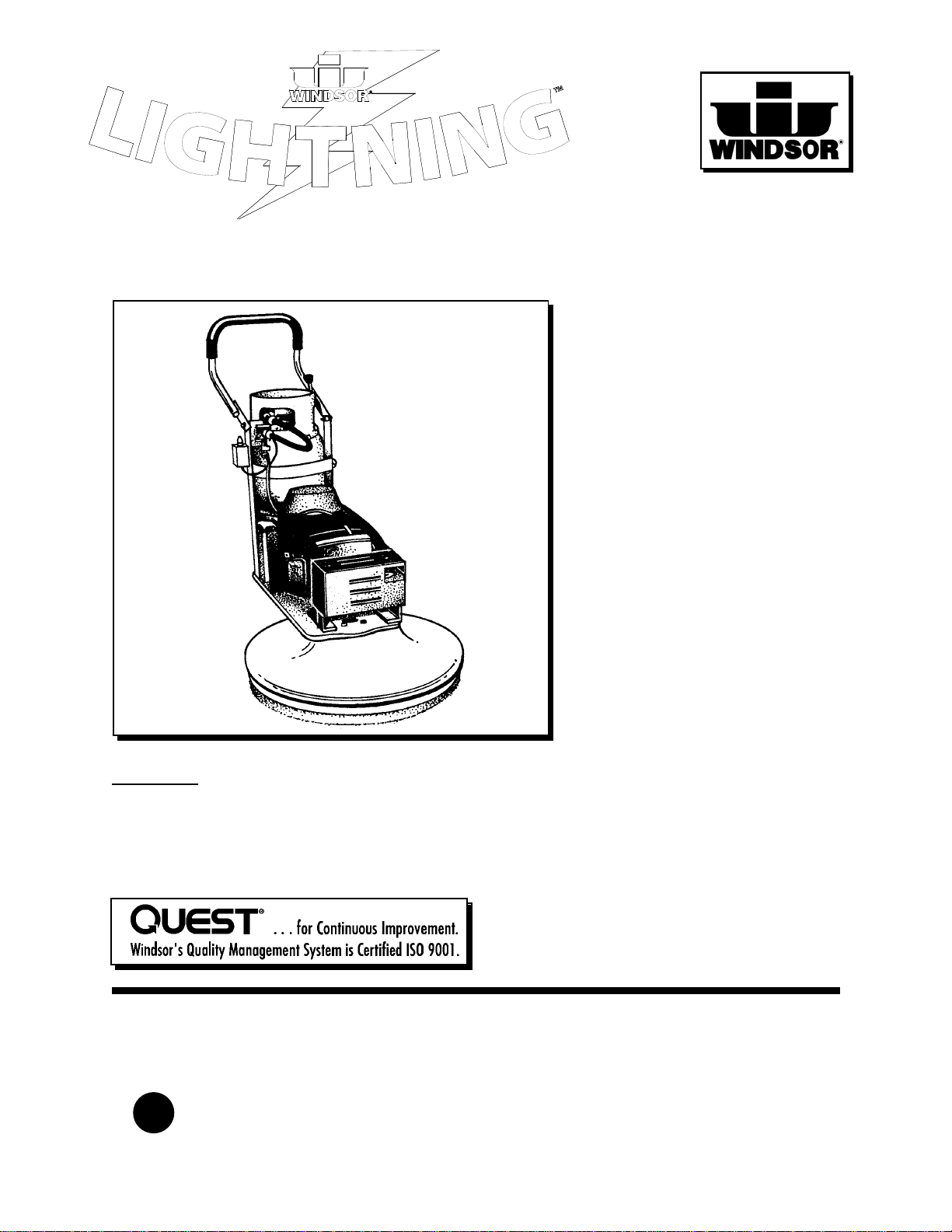

PROPANE POWERED HIGH SPEED

BURNISHER/STRIPPE

Operating Instructions

MODELS:

L21H13 10023000 LS30H13 10023110 L21K13 10023010

L24H13 10023040 L21K17 10023020 L24K17 10023060

L27H13 10023080 L24ER22 10023030 L27K17 10023090

LS30H13 10023110 L27ER22 10023070

C

86039180 05/23/07

Read these instructions before using the machine

Page 2

MACHINE DATA LOG/OVERVIEW

Name: __________________________________________________________________________________________________

Address: _______________________________________________________________________________________________

Phone Number: _________________________________________________________________________________________

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

DEALER NAME ________________________________

OPERATIONS GUIDE NUMBER ___________________

PUBLISHED

__________________________________________

Copyright 2002 Windsor Industries, Printed in USA

YOUR DEALER

For the name and address of your dealer contact: Windsor Industries

OVERVIEW

The Lightning is a propane powered, high speed, burnisher/stripper intended for commercial use.

The burnisher model buffs most hard floor surfaces with the use of special pads. The stripper

model applies stripping solution to the floor to remove any sealant, floor finishing, etc.

LIGHTNING 86039180 05/23/07

2

Page 3

Machine Data Log/Overview.........................2

Table of Contents..........................................3

HOW TO USE THIS MANUAL

How to use this Manual.................................1-1

SAFETY

Important Safety Instructions........................ 2-1

Hazard Intensity Level. .................................2-2

OPERATIONS

Machine Operation........................................3-1

Before Operating the Machine...................3-1

Emergency Stopping Procedure................3-2

Transporting/Storing Machine....................3-2

Propane Fuel System. ...............................3-3

Changing oil...............................................3-3

Adjusting Belt Tension...............................3-3

Refueling/Storing Cylinders. ......................3-3

MAINTENANCE

Service Schedule..........................................4-1

Installing or Removing Pad...........................4-2

Installing or Removing Pad Driver ................4-2

Machine Troubleshooting..............................4-3

TABLE OF CONTENTS

GROUP PARTS LIST

21” Deck Group. ...........................................5-1

24” Deck Group. ...........................................5-3

27” Deck Group. ...........................................5-5

30” Stripper Group........................................5-7

Kawasaki Fuel Block.....................................5-9

Kawasaki Wiring......................................... 5-10

Kawasaki Fuel System. .............................. 5-11

Honda Fuel System.................................... 5-12

Kill Switch ................................................... 5-13

Clutch and Switch.......................................5-14

Belt Chart/Notes ......................................... 5-15

Warranty..................................................... 5-16

LIGHTNING 86039180 05/23/07

3

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized Windsor

dealers.

When placing an order for parts, the

machine model and machine serial number are

important. Refer to the MACHINE DATA box which

is filled out during the installation of your machine.

The MACHINE DATA box is located on the inside of

the front cover of this manual.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

DEALER NAME ______________________________

OPERATIONS GUIDE NUMBER __________________

PUBLISHED ________________________________

Copyright 2002 Windsor Industries, Printed in USA

The model and serial number of your machine is on

the bottom back-end of the machine.

1-1

LIGHTNING 86039180 05/23/07

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition.

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- PRV NO. – reference number.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs. If

column has an asterisk (*), call

manufacturer for serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

!

When using a propane powered appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

WARNING:

To reduce the risk of fire, explosion, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Maintenance and repairs must be done by qualified personnel.

Only trained operators should be allowed to operate propane powered floor machines.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an authorized service center.

Check fuel cylinder for overfill before taking it into the building or placing it in storage.

Install fuel cylinder in a well ventilated place.

Be aware of possible leaks of propane gas if odor is present.

If the machine is stored inside a building, remove the fuel cylinder & store properly outside.

Secure fuel cylinders when being transported. If attached to the machine service valves should be

OFF.

Never store fuel cylinders in a vehicle, building, or area where they may exposed to high temperature

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

Machine can cause a fire when operating near open flames or sparks.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Remove fuel cylinder and disengage the starter before cleaning or servicing.

Before the machine is discarded, the fuel cylinder must be removed and properly disposed of.

During operation, attention shall be paid to other persons, especially children.

Before use all covers and doors shall be put in the positions specified in the instructions.

When leaving unattended, secure against unintentional movement.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

This appliance has been designed for use with the brushes specified by the manufacturer. The fitting

of other brushes may affect its safety.

SAVE THESE INSTRUCTIONS

LIGHTNING 860389180 05/23/07

2-1

Page 6

HAZARD INTENSITY LEVEL

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY . The level of hazard intensity is determined by the following definitions:

! WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To identify actions which must be followed for safe operation or equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

! WARNING

Fuel cylinders emit propane gas. Explosion or fire can result. Keep sparks and open flame away.

Do not smoke around fuel cylinders.

! WARNING

Remove fuel cylinder before working on machine. Only qualified personnel should work on

machine. Always wear eye protection and protective clothing when working on machine.

2-2

LIGHTNING 860389180 05/23/07

Page 7

Your machine is shipped ready for your operation,

with exception of fuel cylinder. For hazard and safety

issues, the cylinders are sent with no fuel. Prior to

operation have your cylinder filled at a reputable

propane dealer.

! CAUTION

The fuel cylinder supplied with this machine is a

DOT 4E240 propane cylinder. Cylinders not branded

with DOT 4E240 on the top collar should not be

used. Never use a cylinder from a barbecue, etc. on

this machine.

The capacity of the 4E240 cylinder is 20lbs., 80% of

the total water capacity. Never overfill the cylinder.

BEFORE OPERATING THE MACHINE:

1. Check fuel cylinders: Check for overfill before

taking them into the building.

To check a cylinder for overfill:

a. Take it to a safe area outside.

b. Open the fixed liquid level gauge.

(bleeder valve)

c. Observe the gas from the valve:

1. If White cloud – Overfilled

2. If Clear vapor – Safe

d. If overfilled, allow to vent until vapor is

Clear in color.

2. Check Oil level: Check level prior to starting

engine and daily before using machine. Use

specified oil if necessary to add. DO NOT OVER

FILL OIL LEVEL, to do so may cause damage to

the engine, thus voiding warranty.

When checking oil refer to the specific engine

manufacturers instruction manual, as some

engines differ in correct procedure.

Use 10W30 oil.

3. Check Air Filter: Be sure the carburetor air filter

is free of dust/oil, etc. NOTE: Dirty filters is the

most frequent cause of elevated toxic emissions.

Check and clean recoil dust filter if necessary.

(see specific engine owners manual)

4. Check Pad & Pad Driver.

5. Adjust handle height: Use a 9/16 wrench to

loosen and tighten pivot points. Most find it

necessary to adjust the handle to “belt height”

for optimum control.

6. Install Fuel Cylinder: Take machine to a well

ventilated area. Check cylinder for overfill. (see

step 1) Install cylinder on machine with tank

strap. Connect the fuel cylinder to the machine

using “Rego” connection. Tighten “hand-tight”.

NOTE: Careful not to cross thread the Rego

connection. Open the service valve slowly. Be

alert for propane leaks. To remove cylinder

reverse the procedure.

MACHINE OPERATIONS

STARTING PROCEDURES

Burnisher:

1. Tilt machine back on rear casters so pad is off

the floor.

2. Slowly open the service valve on the fuel

cylinder. NOTE: opening the service valve too

quickly may cause the excess flow valve to stop

the flow of propane. If this occurs, close the

service valve, wait a few seconds and re-open it

SLOWLY!

3. Push the throttle lever to the choke position and

engage the starter by using the start button.

(NOTE: If equipped with key switch, start by

turning the key) Do not engage starter for more

than 20 seconds at a time, allow 10-20 seconds

between attempts to start the engine.

4. When engine starts, ease the throttle ba ck to

running position.

! WARNING

DO NOT run engine with throttle in the choke

position. Excessive harmful emissions will be

produced putting you and others in harms way.

5. Increase throttle to about ¾ and carefully lower

the machine pad to the floor while walking

forward slowly.

Optional: Electric Clutch

If equipped with and optional clutch, move throttle to

slow and engage the clutch by squeezing the

“trigger switch” on the operation handle. Move the

throttle to ¾ speed, slowly lower pad to the floor

while walking forward slowly.

LIGHTNING 86039180 05/23/07

3-1

Page 8

MACHINE OPERATIONS

STARTING PROCEDURES

Stripper:

! CAUTION

This machine is only as fast as you allow it to be. It

is imperative that you keep the floor wet with

stripping solution while stripping and remove the

sludge quickly and completely. Rinsing thoroughly

before re-coating with sealer or floor finish.

1. Clear all areas of all displays. Remove any dust

and stickers from floor.

2. Prepare stripping solution according to

instructions on label.

3. Apply solution to the floor using a mop or other

method of application. KEEP FLOOR WET

WITH SOLUTION.

4. Allow 10 minutes or so for solution to penetrate

floor coating.

5. Using a “doodle bug” scrape the edg es clear of

floor finish.

6. Begin stripping with the machine. (one pass is

generally all that is needed).

7. Follow the machine with recovery of sludge and

damp mop. NOTE: rinse floor thoroughly.

Keep both models moving. Running the machine in

one place for more than a few seconds may damage

the floor.

! WARNING

Exhaust emissions contain harmful toxic gases. The

worst being carbon monoxide. Do not operate the

machine in confined areas for prolonged times.

Always make certain that adequate ventilation is

had.

! CAUTION

Never engage clutch in the fast run position or with

the pad on the floor, this may cause damage to the

clutch and the floor.

! WARNING

Be careful not to allow the machine to come in

contact with loose tiles or other obstruction on the

floor. The pad is turning at approximately 2000

RPM. If loose objects are hit by revolving pad they

could become dangerous missiles.

EMERGENCY STOPPING PROCEDURE

In case of an emergency, the machine can be

brought to an instant stop by:

1. Pull the throttle back to stop position or turn key

switch to OFF, if equipped.

2. Close service valve on the fuel cylinder.

3. If the machine is equipped with a “Kill Switch”,

activate the switch.

! CAUTION

The engine may backfire when stopped in this

manner.

STOPPING PROCEDURE

1. Close the service valve on the fuel cylinder while

the engine is running. This serves to “purge” the

fuel system of all flammable gas.

2. Tilt the machine back on it’s rear caster and

allow the engine to run until it stops.

3. Turn the key switch OFF if equipped.

Do not leave the machine unattended while the

engine is running for long periods of time. If

necessary to leave the machine for short periods to

move a display etc. move the throttle lever to idle

position and tip machine back on the rear caster.

It has been the accepted practice to start buffing

from the right side of the aisles. Most smaller

machines are offset to the right to allow buffing close

on that side.

TRANSPORTING/STORING MACHINE

When transporting the machine from one site to

another, secure the machine with the fuel cylinder

installed and the service valve OFF. Allow the

engine to cool down some before loading the

machine for transport.

When storing the machine, remove the propane

cylinder and store outside. (see pg. 3-3 for Storage

of Fuel Cylinders) Perform all daily maintenance

procedures. Store machine in a cool, dry, secure

area where it will not be damaged by other traffic.

Tilt the machine back on the rear caster with the pad

off of the floor.

3-2

LIGHTNING 86039180 05/23/07

Page 9

PROPANE FUEL SYSTEM

! WARNING

Adjustments and repairs to the propane fuel system

can only be made by properly trained and certified

Service Technicians.

! WARNING

Improper adjustments will cause increased toxic

emissions of carbon monoxide and may result in

carbon monoxide poisoning.

CHANGING OIL

The manufacturer recommends 10W30 oil.

1. Run engine for 5 minutes to warm the oil.

2. Make sure machine is on level surfa ce, pad on

the floor. Place container under drain and open

the oil drain valve. Allow oil to drain completely.

3. Close drain valve and add 1 qt. Of 10W30 motor

oil. Check level and add if necessary.

4. Replace oil-fill cap assembly. Hand tighten only.

! CAUTION

DO NOT over fill oil and never run engine with low

oil level, this could cause damage to the engine

voiding your warranty.

NOTE: When checking oil, remove dip stick, wipe

clean, then reinsert the dip stick into the engine. DO

NOT SCREW IN (check engine manufacturer

manual for recommended procedure). Remove dip

stick and observe oil level as indicated on dip stick.

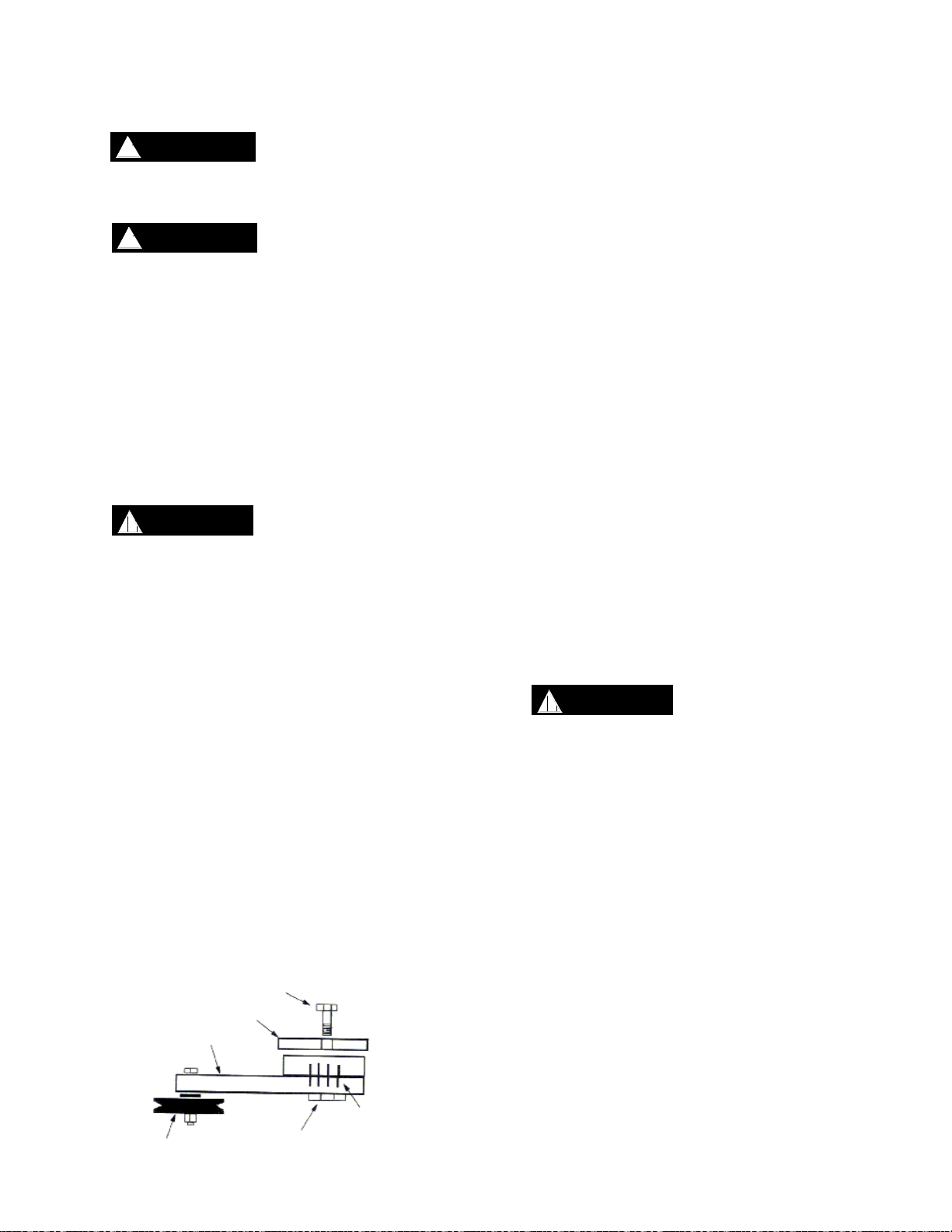

ADJUSTING BELT TENSION

Tools required for this procedure are:

- ¾” (19mm) open end wrench

1. Loosen mounting bolt on top side of machine

2. Rotate adjusting nut counter clockwise with

3. While holding the tension on the adjusting nut,

4. Check belt tension by pinching belt together.

- 15/16” (24mm) deep well socket

deck while holding adjusting nut on underside of

deck. NOTE: the mounting bolt must be

loosened before adjustment can be made.

socket to apply tension to belt.

tighten the mounting bolt on top of the deck.

Belt should depress only ½” (12mm)

Mounting Bolt

Machine Base

Tensioner

Tensioning Gauges

Idler Pulley

Adjusting Nut

LIGHTNING 86039180 05/23/07

MACHINE OPERATIONS

REFUELING/STORING CYLINDERS

The following information refers to regulations within

the United States of America and Canada. For other

countries, the owner must assure that the required

regulations are met.

National Fire Protection Association (NFPA) has

established standards for the storage and handling

of liquefied petroleum gasses. This standard is

NFPA 58.

Liquefied propane will expand 270 times into

flammable vapor, which is used as fuel for propane

engines. Proper training is recommended for those

operating propane powered machines in order to

limit the hazards related to the handling and storage

of propane fuel cylinders.

REFUELING

The capacity of the 4E240 cylinder is 20lbs., 80% of

the total water capacity. Never overfill the cylinder.

Have the cylinder filled at a reputable propane

dealer.

Do not attempt to repair a propane cylinder yourself.

Return the cylinder to your propane dealer for

authorized service.

STORING

Propane fuel cylinders whether full or empty should

be stored outside the building in a secure cylinder

storage cabinet in accordance with NFPA 58 5-4.2.1

! CAUTION

Vertical Propane fuel cylinders must always be

stored in a vertical position. This position assures

that the discharge from the pressure relief valve or

other items will be largely vapor and not liquid which

will expand to 270 times to flammable vapor.

The manufacturer reminds you that the fuel

cylinders should be removed from the machine

and placed in the proper storage cabinets

outside the building.

NOTE: Local authorities may have additional

requirements for storage of fuel cylinders. Always

check with the local authorities for these additional

requirements.

3-3

Page 10

MAINTENANCE

! WARNING

Before attempting any maintenance procedures on

the machine, close the service valve on the fuel tank

and stop the engine.

! CAUTION

Repairs and adjustments to the fuel system must be

made by an authorized, properly trained service

technician.

To keep the machine in good working condition,

simply follow the daily, weekly, and monthly

maintenance procedures.

Keeping the machine clean and free from

accumulated dust, lint, and oil allows free air flow

across the engine to cool the engine properly.

Always use clean recoil dust filters. These can be

cleaned by washing them in a flow of water and

shaking dry. Extra filters may be ordered from

customer service.

IMPORTANT: Preventative maintenance is the

responsibility of the operator.

DAILY MAINTENANCE

(every 4 hours of operation)

1. Check oil level (use 10W30 oil only).

2. Clean recoil filter.

3. Check & Clean carburetor air filter.

4. Check belt tension by pinching belt together.

Belt should deflect only ½” (13mm).

5. Make sure all components are secure an d tight.

(pad holder, fuel cylinder, etc.)

6. Check pad driver and pad, daily. (clean or

replace)

7. Clean machine, if compressed air is available

blow dust from machine and engine,

concentrating on the inside of engine shrouds.

Wash undercarriage.

WEEKLY MAINTENANCE

(every 20 hours of operation)

1. All checks made on a daily basis plus:

4-1

LIGHTNING 86039180 05/23/07

2. Change oil and oil filters at 50 hours of service.

Use 10W30 Motor Oil or other no ash motor oils

designed for use in propane engines. Use of

non-recommended oil may void the engine

warranty. (see engine manual supplied with

documentation).

3. Check for loose nuts and/or bolts on entire

machine.

4. Examine all propane fuel components for leaks

or wear. Replace if necessary.

5. Grease wheels. Use white lithium grease only

and no more than 1 pump of grease. More

grease than recommended will push the seals

and dust covers out, allowing dust and other

foreign materials to penetrate the bearing,

shortening the life of the bearings as well as

allowing grease to drop from the wheels to the

floor.

MONTHLY MAINTENANCE

(every 80 hours of operation)

1. Perform all daily and weekly services.

2. Torque head bolts.

3. Check valve clearance.

4. Torque valve cover bolts.

5. Inspect spark plug. Replace if necessary.

6. Remove engine shroud and clean cooling fins.

NOTE: Consult specific engine owner’s manual for

the above steps 2-6.

QUARTERLY MAINTENANCE

(every 250 hours of operation)

1. Perform all of the monthly maintenance items.

2. Have engine serviced by authorized service

center. Including emissions check.

Keep a log book of all maintenance and repairs

performed on your machine.

Page 11

INSTALLING OR REMOVING PAD

DRIVER OR PADS

Consult an authorized distributor to assist you in

selecting the correct pad for your specific needs.

Pad driver installation:

1. Tip machine on the right side (dip stick down).

2. Place pad driver on drive shaft and spin pad

driver clockwise to install.

Pad Removal & Installation:

1. Tilt machine back on rear caster or service

position.

2. Remove center-lock from pad driver.

3. Remove pad from pad holder.

4. Center new pad on pad driver & secure with

center-lock ring.

Pad driver removal:

1. Apply down pressure on bell of machine deck.

2. Use ¾” open end wrench on top of drive shaft

exposed on top of deck.

3. Strike wrench with rubber mallet to break loose

the shaft from the pad driver. (counter-clockwise)

4. Remove pad driver by spinning it off counterclockwise.

MAINTENANCE

LIGHTNING 86039180 05/23/07

4-2

Page 12

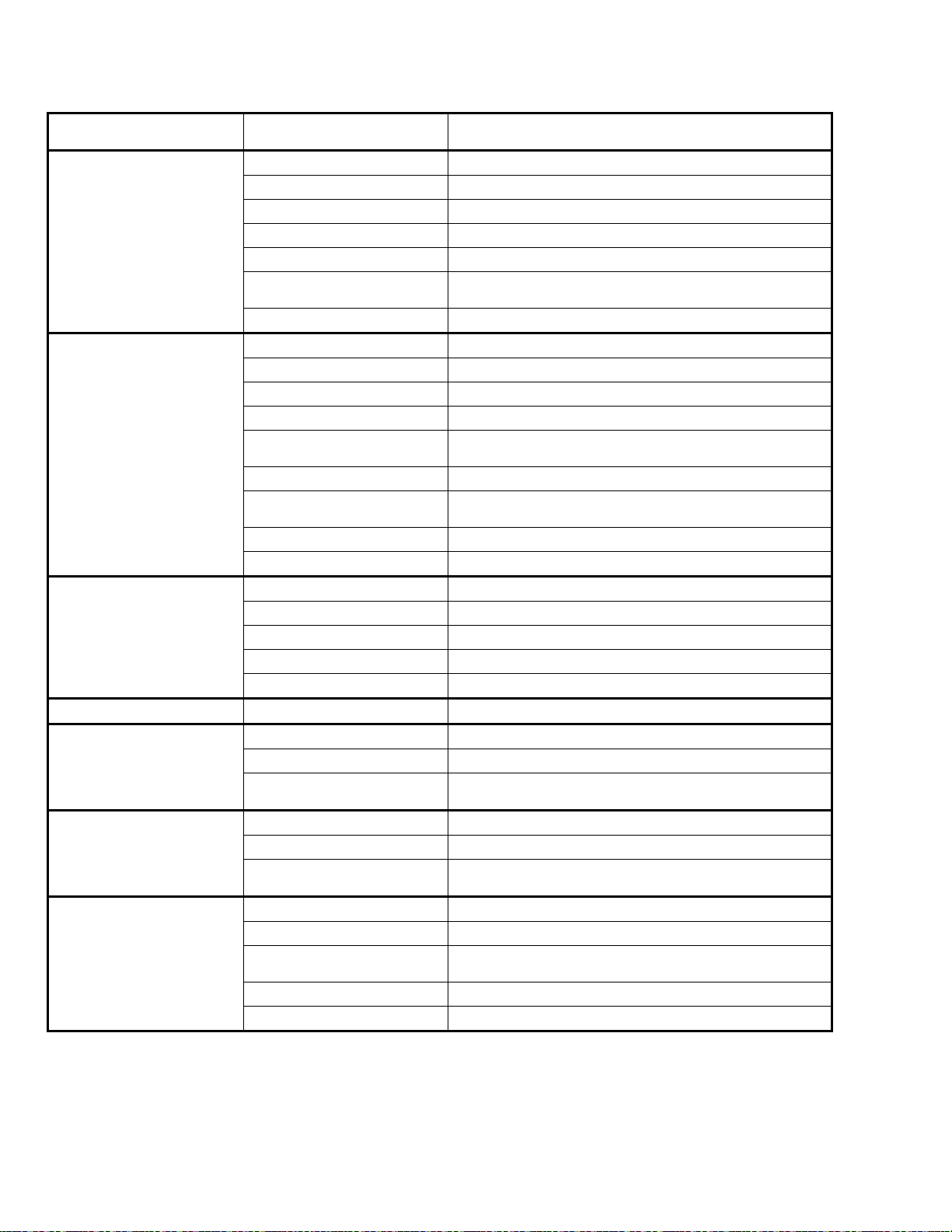

MACHINE TROUBLESHOOTING

PROBLEM.

Will not start No fuel or dirt in fuel line See engine owners manual for servicing.

Blown head gasket NOTE: ONLY properly trained service technicians

Dirty air cleaner

Faulty spark plug

Defective ignition coil

Hard to start No fuel or dirt in fuel line See engine owners manual for servicing.

Engine overload

Dirty air cleaner

Faulty spark plug

Blown head gasket

Regulator need adjustment

Insufficient vacuum

Lacks Power Improper valve clearance See engine owners manual for servicing.

Dirt in fuel line

Faulty spark plug

Improper oil level

Worn rings

Odor of burned rubber Belt out of adjustment See “Adjusting Belt Tension” pg. 3-3

Engine overheats Incorrect oil level See engine owners manual for servicing.

Engine overload

High fuel consumption Faulty spark plug See engine owners manual for servicing.

Dirty air cleaners

Machine stops suddenly Out of fuel Change fuel cylinders

Faulty spark plugs Clean adjust or replace spark plug

Incorrect pad size Replace with proper pad

Low oil Add oil (see pg. 3-3)

CAUSE SOLUTION

Engine overload Should adjust or repair fuel system.

Fuel system out of

adjustment

Spark plug or head bolts

loose

Timing, Coil or Valves

need adjustment

Build up of dirt inside

engine shroud

Improper fuel system

adjustment

Pad not centered on pad

driver

Center pad or pad driver

4-3

LIGHTNING 86039180 05/23/07

Page 13

MACHINE TROUBLESHOOTING

4

PROBLEM.

Excess vibration

CAUSE SOLUTION

Bolts loose on engine or

deck

Incorrect oil level Check and adjust oil level

Engine overload See engine owners manual for servicing.

Dirty filter See engine owners manual for servicing.

Faulty spark plug See engine owners manual for servicing.

Pad not centered or

damaged pad

Tighten all bolts

Center or replace pad

LIGHTNING 86039180 05/23/07

4-

Page 14

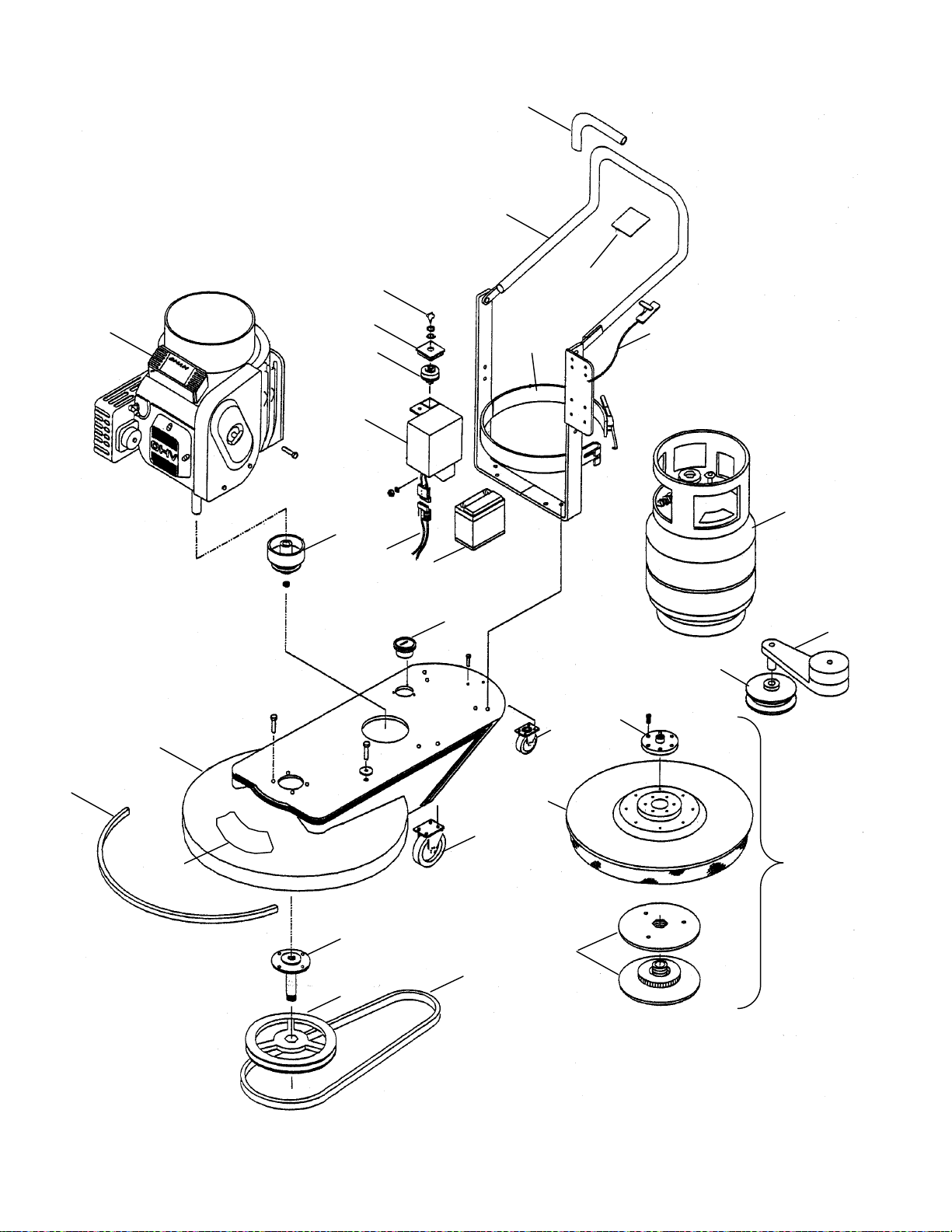

21” DECK GROUP

1

2

7A

7B

7C

12

6A

6B

8

5

(4)

9A

9B

4

10

11

26

21

3

27

25A

25B

24

23

22

13

5-1

14

20

19A

19B

28

15

18

17

16

LIGHTNING 86039180 05/23/07

Page 15

21” DECK PARTS LIST

2

REF PART NO. PRV NO. QTY DESCRIPTION

1 86262580 07093 1 FOAM HAND GRIPS

2 86262570 07083 1 FM HANDLE

3 N/A ref ENGINE OWNER’S MANUAL

4 86262830 07129 1 KEY SWITCH

5 86263140 07089 1 PLASTIC HOLDER

6A 86261970 07039 1 BATTERY BOX

6B 86261880 07068 1 6” KEY SWITCH BRACKET

7A 86262800 07086 1 KAWASAKI 17HP

7B 86262730 07123 ref HONDA 390 13HP

7C 86263030 07066 ref ONAN E124

8 86263200 07018 1 PULLEY 3.5

9A 86261980 07067 1 BATTERY CONNECTOR E124

9B 86262010 07116 ref BATTERY CONNECTOR KAWASAKI

10 86261960 07038 1 BATTERY 12VOLT

11 86262770 07017 1 HOUR METER

12 86262380 07001 1 DECK 21” BLUE

13 86262050 07150 1 BUMPER MOULDING

14 86243840 500664 1 LABEL, LIGHTNING PRPN WINDSOR

15 86262600 07022 1 FRONT BEARING ASSY. COMPLETE

16 86263210 07019 1 PULLEY 6.2

17 86262090 07027 1 BX40 BELT

18 86262300 07023 1 CENTER LOCK

19A 86263540 07014 2 WHEEL 6” W/BKT

19B 86263530 07013 ref WHEEL (ONLY) Service Only

20 86263100 07084 1 PAD DRIVER 21” FLEX

21 86262280 07015 2 CASTER 3”

22 86262560 07151 1 FLANGE

23 86262780 07016 1 IDLER PULLEY

24 86263460 07121 1 TENSIONER

25A 86262930 07063 1 LP TANK (ALUM)

25B 86262920 07025 ref LP TANK (STEEL)

26 86263520 07048 1 VELCRO TAPE

27 86263470 07002 1 THROTTLE CABLE

28 86263070 07079 1 PAD DRIVER 21” FLEX COMPLETE

29 86262330 07111 - CHOKE CABLE Not Shown

30 86262720 07024 - HONDA STARTER (110 VOLT) Not Shown

SERIAL NO.

FROM

Comes with

NOTES:

literature

NOTE: For engine information not listed in this standard manual parts list, refer to appropriate Engine

Owner’s Manual.

LIGHTNING 86039180 05/23/07

5-

Page 16

24” DECK GROUP

1

2

7A

7B

7C

7D

12

6A

6B

8

5

(4)

9A

9B

9C

4

10

11

26

21

3

27

25A

25B

24

23

22

13

5-3

14

16A

16B

16C

20

19A

19B

15

17A

17B

17C

LIGHTNING 86039180 05/23/07

28

18

Page 17

24” DECK PARTS LIST

4

REF PART NO. PRV NO. QTY DESCRIPTION

1 86262580 07093 1 FOAM HAND GRIPS

2 86262570 07083 1 FM HANDLE

3 N/A ref ENGINE OWNER’S MANUAL

4 86262830 07129 1 KEY SWITCH

5 86263140 07089 1 PLASTIC HOLDER

6A 86261970 07039 1 BATTERY BOX

6B 86261880 07068 1 6” KEY SWITCH BRACKET

7A 86262800 07086 1 KAWASAKI 17HP

7B 86262730 07123 ref HONDA 390 13HP

7C 86263040 07131 ref ONAN P248

7D 86263030 07066 ref ONAN E124

8 86263200 07018 1 PULLEY 3.5

9A 86261980 07067 1 BATTERY CONNECTOR E124

9B 86262010 07116 ref BATTERY CONNECTOR KAWASAKI

9C 86262000 07092 ref BATTERY CONNECTOR ONAN P248

10 86261960 07038 1 BATTERY 12VOLT

11 86262770 07017 1 HOUR METER

12 86262390 07032 1 DECK 24” BLUE

13 86262050 07150 1 BUMPER MOULDING

14 86243840 500664 1 LABEL, LIGHTNING PRPN WINDSOR

15 86262600 07022 1 FRONT BEARING ASSY. COMPLETE

16A 86263210 07019 1 PULLEY 6.2 Onan P248

16B 86263250 07090 ref PULLEY 8.5

16C 86263240 07055 ref PULLEY 7.0 Kawasaki

17A 86262110 07028 1 BX42 BELT Onan P248

17B 86262140 07031 ref BX45 BELT

17C 86262120 07069 ref BX43 BELT

18 86262300 07023 1 CENTER LOCK

19A 86263540 07014 2 WHEEL 6” W/BKT

19B 86263530 07013 ref WHEEL (ONLY) Service Only

20 86263120 07104 1 PAD DRIVER 24” FLEX

21 86262280 07015 2 CASTER 3”

22 86262560 07151 1 FLANGE

23 86262780 07016 1 IDLER PULLEY

24 86263460 07121 1 TENSIONER

25A 86262930 07063 1 LP TANK (ALUM)

25B 86262920 07025 ref LP TANK (STEEL)

26 86263520 07048 1 VELCRO TAPE

27 86263470 07002 1 THROTTLE CABLE

28 86263080 07080 1 PAD DRIVER 24” FLEX COMPLETE

29 86262330 07111 - CHOKE CABLE Not Shown

30 86262720 07024 - HONDA STARTER (110 VOLT) Not Shown

31 86261860 07109 - 20HP REGULATOR BRACKET Not Shown

32 86262340 07117 - CHOKE BRACKET Not Shown

SERIAL NO.

FROM

Comes with

Honda, Onan

NOTES:

literature

E124

NOTE: For engine information not listed in this standard manual parts list, refer to appropriate Engine

Owner’s Manual.

LIGHTNING 86039180 05/23/07

5-

Page 18

27” DECK GROUP

1

2

7A

7B

7C

7D

12

6A

6B

8

5

(4)

9A

9B

9C

4

10

11

26

21

3

27

25A

25B

24

23

22

13

5-5

14

16A

16B

20

19A

19B

28

15

18

17A

17B

LIGHTNING 86039180 05/23/07

Page 19

27” DECK PARTS LIST

6

REF PART NO. PRV NO. QTY DESCRIPTION

1 86262580 07093 1 FOAM HAND GRIPS

2 86262870 07083 1 FM HANDLE

3 N/A ref ENGINE OWNER’S MANUAL

4 86262830 07129 1 KEY SWITCH

5 86263140 07089 1 PLASTIC HOLDER

6A 86261970 07039 1 BATTERY BOX

6B 86261880 07068 1 6” KEY SWITCH BRACKET

7A 86262800 07086 1 KAWASAKI 17HP

7B 86262730 07123 ref HONDA 390 13HP

7C 86263040 07131 ref ONAN P248

7D 86263030 07066 ref ONAN E124

8 86263200 07018 1 PULLEY 3.5

9A 86261980 07067 1 BATTERY CONNECTOR E124

9B 86262010 07116 ref BATTERY CONNECTOR KAWASAKI

9C 86262000 07092 ref BATTERY CONNECTOR ONAN P248

10 86261960 07038 1 BATTERY 12VOLT

11 86262770 07017 1 HOUR METER

12 86262400 07033 1 DECK 27” BLUE

13 86262050 07150 1 BUMPER MOULDING

14 86243840 500664 1 LABEL, LIGHTNING PRPN WINDSOR

15 86262600 07022 1 FRONT BEARING ASSY. COMPLETE

16A 86263230 07034 1 PULLEY 9.4

16B 86263250 07090 ref PULLEY 8.5

17A 86262200 07054 1 BX51 BELT

17B 86262190 07035 ref BX50 BELT

18 86262300 07023 1 CENTER LOCK

19A 86263540 07014 2 WHEEL 6” W/BKT

19B 86263530 07013 ref WHEEL (ONLY) Service Only

20 86263110 07085 1 PAD DRIVER 27” FLEX

21 86262280 07015 2 CASTER 3”

22 86262560 07151 1 FLANGE

23 86262780 07016 1 IDLER PULLEY

24 86263460 07121 1 TENSIONER

25A 86262930 07063 1 LP TANK (ALUM)

25B 86262920 07025 ref LP TANK (STEEL)

26 86263520 07048 1 VELCRO TAPE

27 86263470 07002 1 THROTTLE CABLE

28 86263090 07081 1 PAD DRIVER 27” FLEX COMPLETE

29 86262330 07111 - CHOKE CABLE Not Shown

30 86262720 07024 - HONDA STARTER (110 VOLT) Not Shown

31 86261860 07109 - 20HP REGULATOR BRACKET Not Shown

32 86262340 07117 - CHOKE BRACKET Not Shown

SERIAL NO.

FROM

Comes with

Honda, Onan

Kawasaki,

Honda, Onan

Kawasaki,

NOTES:

literature

E124

Onan P248

E124

Onan P248

NOTE: For engine information not listed in this standard manual parts list, refer to appropriate Engine

Owner’s Manual.

LIGHTNING 86039180 05/23/07

5-

Page 20

30” STRIPPER GROUP

6A

6B

6C

4

1

2

36

3

37

34

10

9

12

38

11

17

15

7

14

8

5A

5B

13A

13B

16

33

32

29

31

35

14

30

29

5-7

24

18A

18B

21

23

22

19

20

26

25

LIGHTNING 86039180 05/23/07

27A

27B

28

Page 21

30” STRIPPER PARTS LIST

8

REF PART NO. PRV NO. QTY DESCRIPTION

1 86262580 07093 1 FOAM HAND GRIPS

2 86262570 07083 1 FM HANDLE

3 86233140 07089 1 PLASTIC HOLDER

4 86262830 07129 1 KEY SWITCH

5A 86261970 07039 1 BATTERY BOX

5B 86261880 07068 1 6” KEY SWITCH BRACKET

6A 86263030 07066 1 ONAN E124

6B 86262730 07123 ref HONDA 390 13HP

6C 86262800 07086 ref KAWASAKI 17HP

7 86262310 07046 1 CENTRIFUGAL SWITCH

8 86262180 07078 1 BX49 BELT

9 86262740 07112 1 HOOD ASSY. TWIN (ALUM) BLUE

10 86262500 07107 1 EXPANDED METAL PLATE 4.5 X 14

11 86262680 07120 2 GEAR BOX TWIN HEAD

12 86263260 07108 1 PULLEY 7.0 X 5/8

13A 86261980 07067 1 BATTERY CONNECTOR ONAN E124

13B 86262010 07116 1 BATTERY CONNECTOR KAWASAKI 17HP

14 86262690 07077 1 HANDLE GUSSETT

15 86262700 07105 1 HEAT SHIELD FOIL MATERIAL

16 86262770 07017 1 HOUR METER

17 86262710 07106 1 HEAT SHIELD SUPPORT PLATE

18A 86262040 07072 2 BRUSH PLATE CLAMP

18B 86263380 07071 2 SPRING CLIP

19 86263480 07170 1 TRANSPORT WHL – FRNT SPRT

20 86262840 07149 1 KEY STOCK ¼ X 3

21 86262970 07060 2 MOUNTING PLATE TWIN HEAD

22 86261920 07061 2 ALUMINUM HUB

23 86262320 07057 2 CENTRAL FLEX

24 86263410 07169 1 STRIP BRUSH (1 SET)

25 86262940 07075 6 LUGS L-800

26 86262280 07015 1 CASTER 3”

27A 86263460 07121 1 TENSIONSER

27B 86262780 07016 1 IDLER PULLEY

28 86263370 07110 1 SPLASH GUARD TRACKER

29 86262440 07070 2 DELRIN BEARING 1”

30 86263550 07040 2 WHEEL 10” AIR FILLED

31 86263560 07152 2 WHEEL SPACER ½”

32 86263490 07082 1 TWIN HEAD STRIP FRAME

33 86261960 07038 1 BATTERY 12VOLT

34 86263520 07048 2 VELCRO TAPE

35 86263470 07002 1 THROTTLE CABLE

36 86262920 07025 1 LP TANK (STEEL)

37 N/A ref Engine Owner’s Manual

38 86243840 500664 1 LABEL, LIGHTNING PRPN WINDSOR

39 86263430 07097 - SUPPORT Not Shown

40 86262340 07117 - CHOKE BRACKET Not Shown

41 86263220 07026 - PULLEY 3.0 Not Shown

SERIAL NO.

FROM

Comes with

NOTES:

Literature

NOTE: For engine information not listed in this standard manual parts list, refer to appropriate Engine

Owner’s Manual.

LIGHTNING 86039180 05/23/07

5-

Page 22

KAWASAKI FUEL LOAD BLOCK

REF PART NO. PRV NO. QTY DESCRIPTION

1 86262270 07134 1 CARBURETOR ASSEMBLY

2 86262620 07103 1 FUEL LOAD BLOCK

3 86263340 07156 1 RUBBER CAP ¼

4 86262790 07135 1 INSULATOR

5 86263510 07007 1 VACUUM TEE

6 86262650 07132 1 GASKET AIR FILTER

7 86263420 07155 1 STUD M-6 X 130

8 86262030 07100 1 BRASS PLUG 1/8

9 86261870 07101 1 3/8 HOSE X ¼ MP ELBOW

10 86262660 07133 1 GASKET AIR FILTER

SERIAL NO.

FROM

Note: For engine information not listed in the standard parts list, refer to the appropriate engine parts

manual.

5

3

NOTES:

7

10

10

2

1

4

6

1

8

9

5-9

LIGHTNING 86039180 05/23/07

Page 23

KAWASAKI WIRING DIAGRAM

0

M

-

12 V BATTERY

+

STARTER

BLUE

KEY SWITCH

-

-

ENGINE HARNESS

CONNECTOR

SWITCH

-

YELLOW

BLUE BLUE

-

-

-

BY-PASS DIODE

LOW OIL PRESSURE

CUTOFF SWITCH (NO)

HOUR METER

CHARGING SYSTEM

ALT

STATOR

FUEL LOCKOFF

YELLOW

BLUE FEMALE CONNECTOR

TO STARTER SOLENOID

BLUE

BLUE MALE CONNECTOR

TO ELECTRIC LOCK OFF

BLUE FEMALE

RED

BLUE FEMALE CONNECTOR

TO VOLTAGE REGUALTOR

YELLOW LOOP TO

STARTER SOLENOID

CONNECTOR

BLUE PIGGY BACK

CONNECTOR

BLUE FEMALE

CONNECTOR

LIGHTNING 86039180 05/23/07

LOW OIL PRESSURE

NOTE: RED WIRE CONNECTS

TO LEFT SIDE OF SWITCH. ALL

OTHER WIRES CONNECT TO

RIGHT SIDE OF SWITCH

SWITCH

5-1

Page 24

KAWASAKI FUEL SYSTEM

REF PART NO. PRV NO. QTY DESCRIPTION

1 86263270 07012 1 QUICK COUPLER

2 86262900 07006 1 LP HOSE TO TANK

3 86262530 07009 1 FITTING ¼ X 90 STREET ELBOW

4 86262760 07003 1 HOSE, VAC

5 86262610 07004 1 FUEL HOSE

6 86262540 07010 1 FITTING 3/8 BARB X 3/8 MP

7 86263320 07118 1 REGULATOR

8 86262630 07113 1 FUEL LOCK W/FILTER 12VOLT

9 86262550 07011 1 FITTING 1/4BARB X 1/4MP

SERIAL NO.

FROM

NOTE: For engine information not listed in this Standard Parts List, refer to the appropriate Engine

Parts Manual.

6

5

4

NOTES:

7

2

9

8

3

5-11

LIGHTNING 86039180 05/23/07

Page 25

HONDA FUEL SYSTEM

2

REF PART NO. PRV NO. QTY DESCRIPTION

1 86263270 07012 1 QUICK COUPLER

2 86262900 07006 1 LP HOSE TO TANK

3 86262530 07009 1 FITTING ¼ X 90 STREET ELBOW

4 86262760 07003 3 HOSE, VAC

5 86262610 07004 1 FUEL HOSE

6 86262540 07010 1 FITTING 3/8 BARB X 3/8 MP

7 86263310 07064 1 REGULATOR

8 86262880 07065 1 LOCKOFF

9 86262330 07011 2 FITTING 1/4BARB X 1/4MP

10 86262520 07008 1 FITTING 3/8 FLARE X 1/4MP

11 86263500 07042 1 VAC TEE

12 86262890 07005 1 LP HOSE REG TO LOCK

SERIAL NO.

FROM

NOTE: For engine information not listed in this Standard Parts List, refer to the appropriate Engine

Parts Manual.

NOTES:

1

2

4

3

4

4

11

5

6

7

9

10

9

12

8

LIGHTNING 86039180 05/23/07

5-1

Page 26

KILL SWITCH ASSEMBLY

REF PART NO. PRV NO. QTY DESCRIPTION

1 86261930 07056 1 ARM & SPRINGS (2 EACH)

2 86263450 07050 1 SWICTH MICRO (KILL)

SERIAL NO.

FROM

NOTE: For engine information not listed in this Standard Parts List, refer to the appropriate Engine

Parts Manual.

2

NOTES:

1

5-13

LIGHTNING 86039180 05/23/07

Page 27

CLUTCH AND SWITCH ASSEMBLY

4

REF PART NO. PRV NO. QTY DESCRIPTION

1 86261930 07056 1 ARM & SPRINGS (2 EACH)

2 86263440 07049 1 SWITCH (CLUTCH)

3 86262360 07047 1 CLUTCH SWITCH ASM. COMPLETE

4 86263350 07044 1 SPACER

5 86262460 07045 1 ELECTRIC CLUTCH

6 86262350 07043 1 CLUTCH ARM

SERIAL NO.

FROM

NOTE: For engine information not listed in this Standard Parts List, refer to the appropriate Engine

Parts Manual.

1

NOTES:

2

4

3

5 5

LIGHTNING 86039180 05/23/07

5-1

Page 28

BELT CHART/NOTES

PART NO. PRV NO. DESCRIPTION NOTES:

86262060 07052 BX34 BELT

86262070 07041 BX36 BELT

86262080 07020 BX38 BELT

86262090 07027 BX40 BELT

86262100 07021 BX41 BELT

86262110 07028 BX42 BELT

86262120 07069 BX43 BELT

86262130 07030 BX44 BELT

86262140 07031 BX45 BELT

86262150 07148 BX46 BELT

86262160 07091 BX47 BELT

86262170 07053 BX48 BELT

86262180 07078 BX49 BELT

86262190 07035 BX50 BELT

86262200 07054 BX51 BELT

86262210 07029 BX52 BELT

86262220 07037 BX53 BELT

86262230 07036 BX54 BELT

86262240 07073 BX55 BELT

86262250 07074 BX56 BELT

86262260 07087 BX58 BELT

MACHINE PRV MACHINE NO.

10023000 L21H13 86262090 07027 86262110 07028

10023020 L21K17 86262090 07027 86262110 07028

10023040 L24H13 86262140 07031 86262170 07053

10023030 L24ER22 86262110 07028 86262130 07030

10023060 L24K17 86262120 07069 86262150 07148

10023080 L27H13 86262200 07054 - 10023070 L27ER22 - N/A 86262260 07087

10023090 L27K17 86262190 07035 86262210 07029

10023110 LS30H13 86262180 07078 - N/A

10023110 LS30H13 86262180 07078 - N/A

STANDARD CLUTCH

BELT PART NO.

STANDARD CLUTCH

BELT PRV NO.

W/ELECTRIC CLUTCH

BELT PART NO.

W/ELECTRIC CLUTCH

BELT PRV NO.

5-15

LIGHTNING 86039180 05/23/07

Loading...

Loading...