Page 1

A

LIGHTNING

BATTERY POWERED HIGH SPEED BURNISHER

MODEL: L20

10027100

L20T

10027110

Operating Instructions (ENG)

Bedienungsanleitung (GER)

86038450 - AV 10/20/08

PRV NO. 98753

Bitte lesen Sie diese

Read these instructions before operating the machine.

nleitungen, bevor Sie die Maschine in Gebrauch nehmen

Page 2

MACHINE DATA LOG

Name: __________________________________________________________________________________________________

Address: _______________________________________________________________________________________________

Phone Number: _________________________________________________________________________________________

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

Copyright 1995 Windsor Industries, Printed in USA

YOUR DEALER

2ENG

86038450 04/12/07

Page 3

G

Machine Data Log................................................2

Table of Contents.................................................3

HOW TO USE THIS MANUAL

How to use this Manual........................................1-1

SAFETY

Important Safety Instructions ...............................2-1

Hazard Intensity Level..........................................2-2

OPERATIONS

Components/Controls ..........................................3-1

Machine Operation...............................................3-2

Pre-Run Machine Inspection ............................3-2

Operating the Machine......................................3-2

Filter Bag...........................................................3-2

Dust Control Skirt..............................................3-2

MAINTENANCE

Battery Information...............................................4-1

Battery Connection...........................................4-1

Battery Maintenance........................................4-1

Battery Charging Procedure. ...........................4-1

Maintenance.........................................................4-2

Weekly Maintenance.........................................4-2

4 to 6 Month Maintenance................................4-2

Ending Work Periods........................................4-2

Shunt Adjustments............................................4-2

Shaft Adjustment...............................................4-2

Lubrication............................................................4-3

Service Schedule.................................................4-3

Machine Troubleshooting.....................................4-4

TABLE OF CONTENTS

GROUP PARTS LIST

Chassis/Drive Assembly Group. ..........................5-1

Deck Lift Mechanism............................................5-3

Electrical Controls Group .....................................5-5

Handle Assembly .................................................5-7

Hood Group..........................................................5-9

Lift Linkage Group..............................................5-11

Wiring Schematic (Non-traction). .......................5-13

Wiring Schematic (Traction)...............................5-15

Suggested Spare Parts......................................5-18

Notes..................................................................5-19

86038450 04/12/07

3EN

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized dealers.

When placing an order for parts, the machine model

and machine serial number are important. Refer to

the MACHINE DATA box which is filled out during

the installation of your machine. The MACHINE

DATA box is located on the inside of the front cover

of this manual.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

Copyright 1995 Windsor Industries, Printed in USA

The model and serial number of your machine is on

the bottom back-end of the machine.

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

- Batteries

- Maintenance

- Shunt Adjustments

- Shaft Adjustment

- Lubrication

- Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- PRV NO. - reference number.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The number on the lower left corner of the

front cover is the part number for this manual.

1-1ENG

86038450 04/12/07

Page 5

G

IMPORTANT SAFETY INSTRUCTIONS

When using an battery powered appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

This machine is not suitable for picking up hazardous dust.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

Disconnect battery before cleaning or servicing.

Before the machine is discarded, the batteries must be removed and properly disposed of.

Make sure all warning and caution labels are legible and properly attached to the machine.

During operation, attention shall be paid to other persons, especially children.

Before use all covers and doors shall be put in the positions specified in the instructions.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

Only chemicals recommended by the manufacturer shall be used.

This appliance has been designed for use with the brushes specified by the manufacturer. The fitting

of other brushes may affect its safety.

Do not use on surfaces having a gradient exceeding 2% unless the optional parking brake is installed

on the machine.

SAVE THESE INSTRUCTIONS

86038450 04/12/07

2-1EN

Page 6

HAZARD INTENSITY LEVEL

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

! WARNING

WARNING - Hazards or unsafe practices which COULD re sult in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practice s which could result in minor personal injury or product or property

damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the

equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on

the machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

! WARNING

Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep

solution tank in raised position when charging. Keep sparks and flames away from the batteries. Do not

smoke around batteries.

! WARNING

Disconnect batteries before working on machine. Only qualified personnel should work inside machine.

Always wear eye protection and protective clothing when working on or near batteries. Avoid skin contact

with the acid contained in the batteries.

! WARNING

Never allow metal to lie across battery tops.

2-2ENG

86038450 04/12/07

Page 7

COMPONENTS/CONTROLS

G

12

13

1. Hour Meter. Records machine use time.

2. Battery Condition Light. Indicates the charge condition of batteries.

3. Main Power Switch. Turns On and Off the machine.

4. Pad Pressure Meter. “Green Area” indicates correct pad pressure range.

5. Burnishing Head Switch. Raises and lowers burnishing head.

6. 3 Amp Circuit Breaker. Thermal circuit breaker protects lift mechanism. Press to reset.

7. Main Handle.

8. Handle Adjustment Lever.

9. Breaker. 60 amp magnetic circuit breaker, protects pad driver motor. Press to reset.

10. Pad Motor Switch Bar. Raising bar turns on pad driver motor.

11. Pad Adjustment Knob. Rotating knob adjusts pad pressure.

12. Reverse Button (Traction model only). Propel bar must be squeezed and button pushed for

reverse travel.

13. Speed Control (Traction model only). Knob rotated left to right for slow to fast speed.

14. 15 Amp Circuit Breaker (Traction model only). Protects transaxle.

86038450 04/12/07

3-1 EN

Page 8

MACHINE OPERATION

PRE-RUN MACHINE INSPECTION

1. Disconnect the battery charger. (See battery

charging procedure).

2. Close the cover.

3. To raise the deck: Turn on the main power

switch and press the burnishing head switch.

4. Turn or install a new burnishing pad as n eeded.

NOTE: Pad lock has left hand threads. To

loosen turn clockwise.

5. Check wheels and other pi vot points for proper

lubrication.

OPERATING THE MACHINE

1. If using a machine that is already set up, check

to make sure the pad is properly installed.

2. Adjust the operating control handle to a

comfortable position using the handle lock lever.

3. Turn on the main power switch.

4. Lower or raise deck by pressing burnishing head

switch.

5. The pad motor will only run when the burnishing

head is lowered to within 3 inches of the floor.

6. The drive controls are shown on page 3-1.

7. The pad pressure is adjusted using the knob at

center of panel. The operator monitors the amp

draw using the meter located on the control

panel and ensures that the needle remains in

the “green” operating

range. (See page 3-1, #4 & 11).

To prevent possible damage to the floor surface,

always keep the machine moving while the pad

is spinning.

8. When the pad motor switch bar is squeezed, the

pad motor runs.

9. Return the machine to the battery charger when

the battery light indicator light is amber. Do not

operate machine when indicator is flashing red.

FILTER BAG

The filter bag is accessed under the cover.

DUST CONTROL SKIRT

Replace skirt (86007290 – PRV NO. 730017) when

worn, torn, or damaged in any way that allows dust

to escape.

3-2ENG

86038450 04/12/07

Page 9

G

BATTERY MAINTENANCE

1. When cleaning batteries use a solution of baking

soda and water. (Do not allow cleaning fluid to

enter inside battery cells.)

2. Keep a proper electrolyte level in battery cells.

3. Wipe down the battery tops at least once a

week. If a cell should accidentally overflow,

clean immediately.

4. Test battery condition with a hydrometer at least

once a week.

5. Ensure that all connections are tight and that all

corrosion is removed.

6. Every 4 to 6 months remove batteries from the

machine and clean the battery compartment.

BATTERY CHARGING PROCEDURE

Charge the batteries once the amber charge level

light comes on. The amber light indicates that there

is about 20% charge left in the batteries. Do not let

the batteries completely drain before charging.

Avoid charging the batteries before the amber light

comes on. The machine will run for hours on fully

charged, well maintained batteries.

DO NOT SMOKE, HAVE OPEN FLAMES, OR

SPARKS NEAR BATTERIES AT ANY TIME.

WEAR EYE PROTECTION AND PROTECTIVE

CLOTHING WHEN WORKING WITH BATTERIES.

BATTERY INFORMATION

CHARGE BATTERIES IN A WELL-VENTILATED

AREA WITH DECK DOWN AND COVER OPEN.

1. Use a 36 volt, 20 amp maximum output, D.C.

charger that turns itself off, when batteries are

fully charged. The charger must have a

connector that matches the machine battery

connection.

2. Read the instructions and warnings p rovided by

the battery charger manufacturer.

3. Set the charger in a well-ventilated area on a

level surface. Make sure cords will easily reach

outlets on both machine and wall.

4. Connect charger to D.C. outlet on machine

first.

5. Connect the A.C. power cord to properly

grounded wall socket. NEVER MAKE THE A.C.

CONNECTION FIRST, HAZARDOUS SPARKS

MAY RESULT.

6. After the batteries are completely charged

disconnect the charger from the A.C. wall

socket.

7. Once the charger is disconnected from the A.C.

wall socket, it is safe to disconnect the charger

from the machine.

8. When the batteries are fully charged, check the

electrolyte level by removing, the caps on top of

the batteries. If necessary fill the cells with

distilled water as shown in the diagram below.

Be careful not to overfill cells.

86038450 04/12/07

4-1EN

Page 10

MAINTENANCE

WEEKLY MAINTENANCE

1. Use a hydrometer to check the condition of each

battery cell.

2. Check battery cable clamps. Ensure clamps are

tight on battery terminals.

3. Clean tops of batteries with a wet cloth and a

solution of water and baking soda. Wipe battery

tops dry after cleaning.

4. Check pad lock for looseness or da mage.

5. Check filter and filter seals. Airflow should be

unobstructed through filter.

6. Ensure that the pivot points and casters are

properly lubricated.

7. Tighten any loose screws or nuts.

4 TO 6 MONTH MAINTENANCE

1. Remove batteries-clean battery tray and battery

compartment.

2. Clean battery cable clamps and battery

terminals.

3. Check the carbon motor br ushes in the pad

driver motor.

4. Use a vacuum to remove lint or dust build-up

from motor windings.

5. Grease axles.

AT THE END OF EACH WORK PERIOD:

1. Wipe down the exterior of the machine.

2. Lower the deck.

3. Open the cover.

4. Charge the batteries. (See battery charging

procedure on page 4-1.)

SHUNT ADJUSTMENT

This pad pressure meter adjustment is factory set.

Over the course of time it may become necessary to

adjust this setting using the slotted connection on

the shunt.

SHUNT ADJUSTMENT (Cont.)

Check the amp range when nuisance tripping of the

circuit breaker indicates that the shunt may be out of

adjustment.

1. Connect a DC ampere meter to the positive

battery lead. Running the machine with a pad,

lower the pad to the floor until it is operating at

55-60 amps.

2. Moving the wire in the slot, adjust the pad

pressure meter until the needle sets at the line

between the green and red areas.

3. Check the other points indicated in the diagram

above. The high end should trip the circuit

breaker. Replace the pad pressure meter if the

approximate amp ranges shown cannot be set.

SHAFT ADJUSTMENT

If shaft is replaced make sure it is adjusted

correctly upon installation.

5/8"

4-2ENG

86038450 04/12/07

Page 11

LUBRICATION & SERVICE SCHEDULE

G

The following symbols found throughout the manual

indicate items requiring lubrication:

APPLY GREASE

USE SPRAY

LUBRICANT

USE ANTI-SEIZE WHEN

ANTISEIZE

AXLE GREASING:

1-2 STROKES OF MOBILTEMP©78 OR

COMPATIBLE CLAY-BASED OR CALCIUMBASED GREASE.

REPAIRING

PERMANENT (RED)

THREAD LOCK TIGHT

NOTES:

CAUTION: Do not use pressure washers to clean sealed gear boxes or bearings.

If it becomes necessary to clean under machine with a pressure washer; Ensure all items noted are relubricated

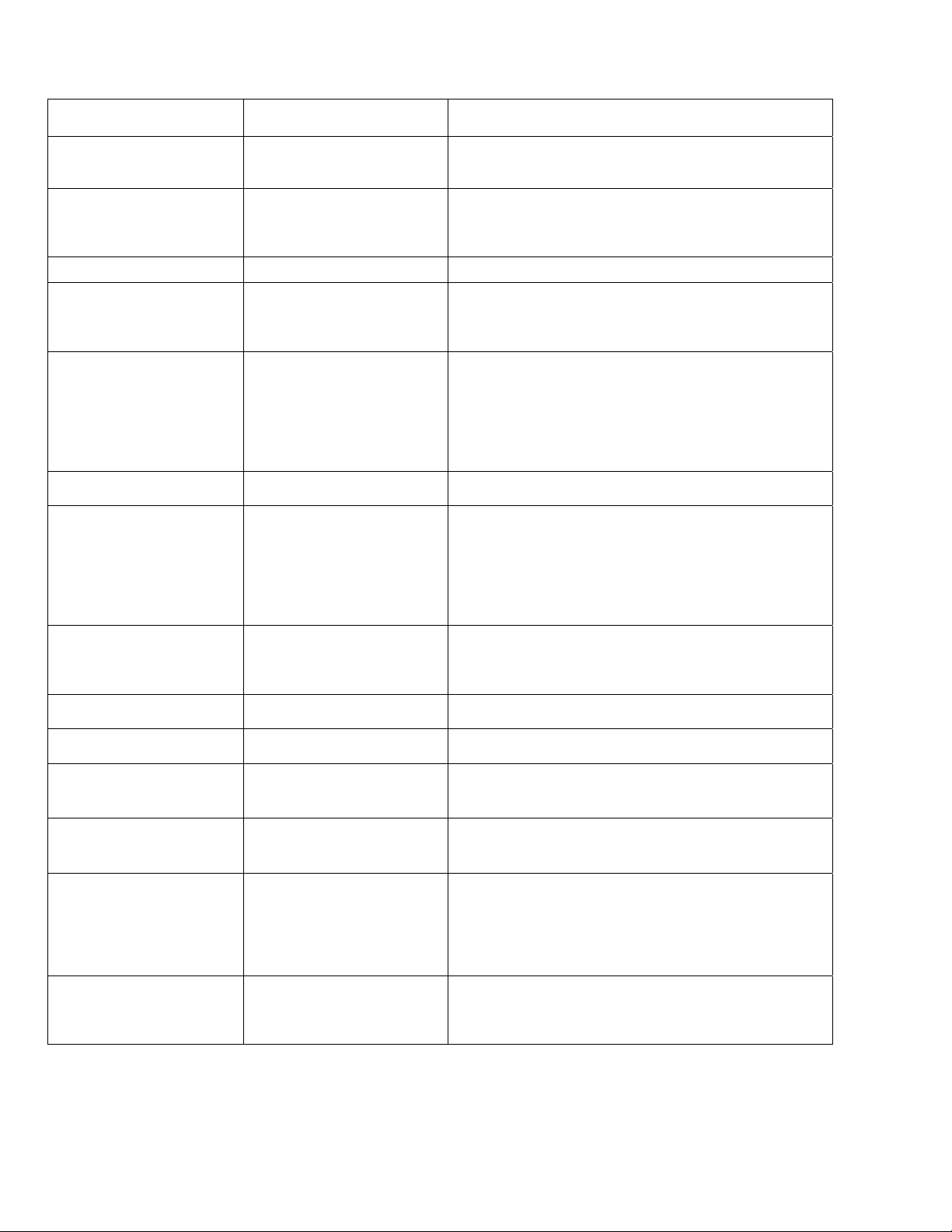

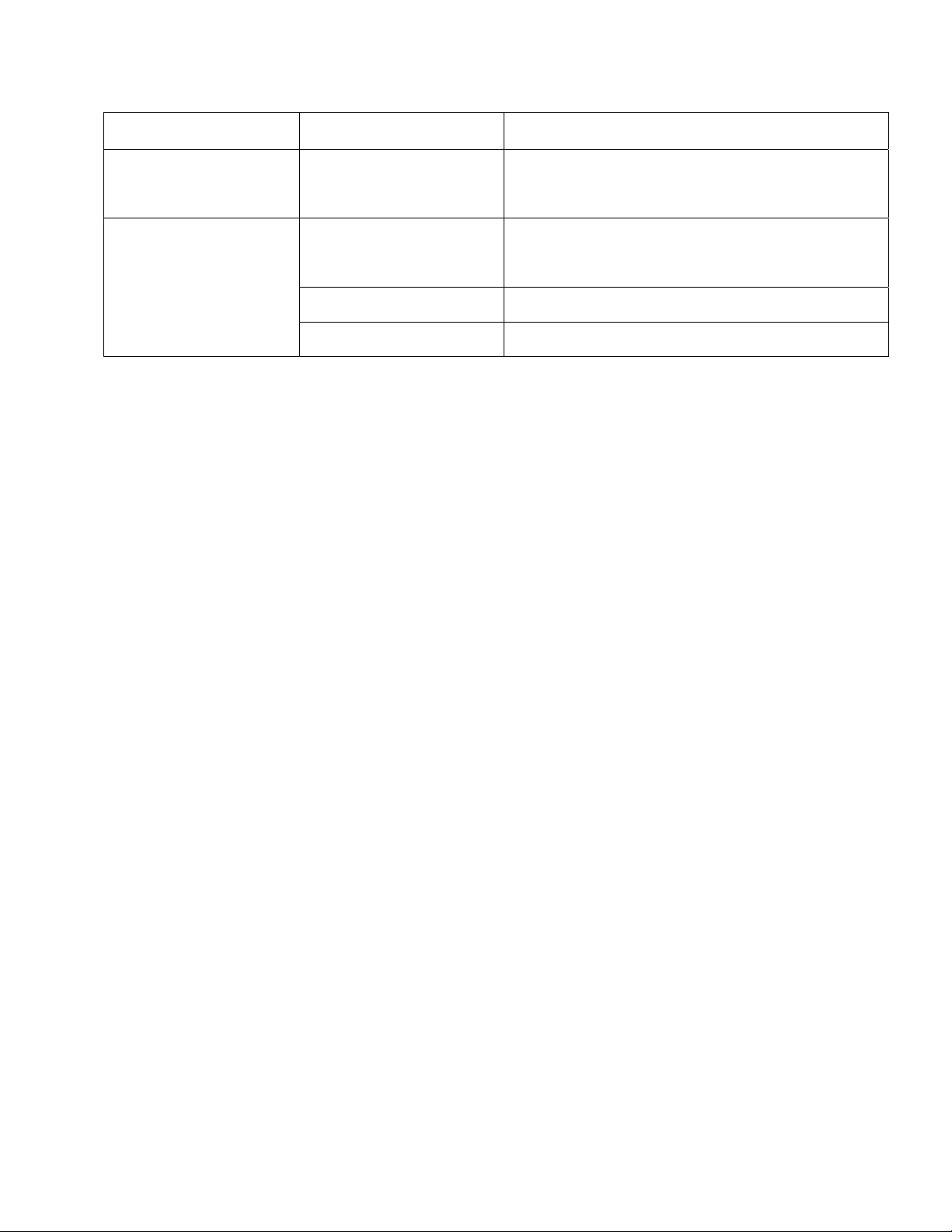

SERVICE SCHEDULE

MAINTENANCE DAILY MONTHLY

Check batteries after charging; add

water if necessary

Check pad wear to prevent buildup of

chemicals

Check pad driver system for damage

Check bag/filter

Check handles, switches, and knobs

for damage

Store with pad off the floor

Check batteries for corrosion, cracks

and evidence of overheating

Check all bearings for noise

Check skirt/bumpers for damage and

replace as necessary

Grease wheels and casters (if

appropriate)

Check potentiometer (speed control)

for adjustment

Check overall performance of machine

*

*

*

*

*

*

*

*

*

*

*

*

86038450 04/12/07

4-3EN

Page 12

MACHINE TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Clean battery cable clamps of any corrosion and

No power to machine

Faulty Main Power Switch

Pad motor won’t run

Actuator Safety Switch

Faulty Relay

Deck lift mechanism not

working

Deck switch not working

Deck actuator not

working

Handle switch not

working

Drive Controls

Poor Cable Connection

Circuit breaker has tripped Reset circuit breaker (H).

Circuit breaker has tripped Reset circuit breaker (J).

Circuit breaker has tripped.

Bad switch (es).

tighten. Test voltage at points G to B should be from 34

to 38 VDC.

With the main power switch turned on, test voltage at

points D to B should be from 34 to 38 VDC. If there is

no voltage remove leads and check switch for

continuity. Replace if necessary

With main power on, pad lowered to floor, switch bar

pulled up, test voltage at L (wire #2) to B (rear panel)

should be 34 to 38 VDC. If not, check and adjust or

replace safety switch as necessary.

With main power on, pad lowered to floor and drive

handle squeezed: Test voltage at points F to B and A to

B should be from 34 to 38 VDC. When the relay is

working it should make a clicking noise as the drive

handle is squeezed. Replace relay if the test voltage F

to B is OK. If test voltage F to B is not OK, check all

wiring to pad motor relay.

With main switch on, test voltage at C (5) to C (2)

should be 34 to 38 VDC. If not check circuit breaker (J)

and main power switch. If the test voltage at C (5) to C

(2) is 34 to 38 VDC, the voltage at deck switch C (3) to

C (6) should be 34 to 38 VDC when the deck switch is

pressed to raise/lower the pad. If not, replace deck

switch.

If the deck switch tested OK, but the deck lift actuator

still is not working, disconnect the white and black wires

to actuator (K) and apply 36 VDC directly to actuator. If

the actuator does not respond, replace actuator.

Check power from E (wire #1) to B. Check switch

continuity.

Check if power at wire #26. If yes, but breaker has no

power at wire 28 either reset breaker (Q) or replace.

Check continuity at handle switch for non-traction

model. Check continuity at propel switch or pad motor

switch for traction model. Replace as necessary.

4-4ENG

Loose connection.

Faulty potentiometer.

Faulty drive control board.

86038450 04/12/07

Check all connections of propel circuit especially at M,

N, P, R, S & T. Check transaxle connection at U.

With the drive motor disconnected at V, test the output

voltage to the drive motor. The output voltage at V

should vary from 0 to 36V at R & S as the control lever

is squeezed. Resistance of the potentiometer can be

tested at the leads 4 & 1 found at the potentiometer T.

The resistance should vary from 0-50K ohms.

Voltage at T1 (P) to T2 (N) should be from 34 to

38VDC. If the voltage at T1 is good but the propel

motor won't respond, and all the tests above have been

done, replace the drive control board.

Page 13

TROUBLESHOOTING.

G

PROBLEM CAUSE SOLUTION

Squeeze the control lever and test the voltage at U (wire

Drive controls cont.

Machine will not propel

Faulty motor.

Loose Connection.

Bad Relay.

Faulty Resistor.

#27 & 28). When the output voltage varies with the

control lever but the motor does not respond and all the

tests above have been done, replace the motor.

With main power on, test voltage at terminal 30 (X) on

Relay should be 34 to 38 VDC. With switch on, check

voltage to wire side of resistor (Y). Should be 34 to 38

VDC.

With main power on, test voltage at terminal 87 (Z)

should be 34 to 38 VDC.

With main power on, test voltage at terminal 85 (AA)

should be 22 to 26 VDC.

86038450 04/12/07

4-5EN

Loading...

Loading...