Windsor L175 Owner's Manual

Contents:

1

Warnings - Product Description

2

4

Wiring Diagrams

5

Motor, Frame, Driver Assembly

6

Cover Assembly

7

Handle Assembly

9

Trouble Shooting

10

Warranty

Operation

/

Maintenance / Service

Record model and serial number located on

data label. Refer to these numbers when calling

Windsor dealer for parts or service.

MODEL

:

SERIAL

NO.

:

PURCHASE

DATE

:

WARNING

OF

A

POTENTIAL INJURY:

This product contains moving parts. To

reduce the risk of injury unplug the

machine before servicing.

Whenever repairs are made ensure electrical

connections are correct and wiring matches

APPROPRIATE

diagram before plugging

machine into an electrical outlet.

CAUTION:

1

.)

See the Owner’s Guide for

complete operating instructions.

2.)

Maintenance

and

repairs must only

be done by qualified personnel.

3.)

Using non-Windsor parts to repair

this machine will void the warranty.

0

80110

USA

303-762-1800*FAX3

98116

Rev.1

512/94

INSPECTION

OPERATION

Please carefully unpack and inspect your machine

for shipping damage. Each unit is operated and thor

oughly inspected before shipment, and any damage is

the responsibility of the delivering carrier who should

be notified immediately.

ELECTRICAL

This rotary polisher is designed to operate on a standard

15

amp,

115

volt,

60

hz,

AC

household curtent. Check that the

voltage shown on the serial number plate is suitable for the

supply available. Voltages below

105

volts or above

125

volts

could cause damage to the motor.

NOTE: 230/250 volt

50

hz

models

are available.

,

GROUNDING INSTRUCTIONS

This appliance must be grounded.

If

it should malfunc

tion or break down, grounding provides a path of least

resistance for electric current to reduce the risk of elec

-

tric shock. This appliance is equipped with a cord hav

ing an equipment-grounding conductor and grounding

plug. The plug must be inserted into an appropriate out

let that is properly installed and grounded in accor

dance with all local codes and ordinances.

WARN

1

NG

:

Improper connection of the equipment-grounding

conductor can result in

a

risk of electric shock.

Check with a qualified electrician or service person

if

you are in doubt as

to

whether the outlet

is

prop

-

erly grounded.

Do

not modify the plug provided

with the appliance

-

if

it will not fit the outlet, have

a proper outlet installed by

a

qualified electrician.

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug in

“Fig.

A

below. A temporary adaptor that looks like the adap

-

tor

in

“Fig

.

C“

below

may

be used to connect this plug

to

a

2-pole receptacle as shown in “Fig. B below,

if

a

properly grounded outlet is not available. The tempo

rary adaptor should be used only until a properly

grounded outlet (Fig.

A)

can be installed by a qualified

electrician. The green colored rigid ear, lug,

or

the like

extending from the adaptor must be connected to a per

-

manent ground such as a properly grounded outlet box

cover. Whenever the adaptor

is

used, it must be held

in place by a metal screw.

PROPER GROUNDING CONNECTION

CONNECTION USING

AN

ADAPTOR

GROUNDING

Grounding Pin

\\

I

-

Metal

Screw

Grounded

Outlet

Rg.

A

/

Tab

For Groundina

-

Screw Grounded Outlet

Box

ADAPTOR

-

flg.

B

NOTE: Adaptors

are

not allowed In Canada.

‘6

Fig.

C

CAUTION: For indoor

Use

Only.

To

prevent possible damage to the floor

when using the Brush optlon, use water or other

approved

cleanlng solution while operating.

When using the pad optloln, always keep

the machine moving when In contact with the

floor.

WARNING:

HIGH STARTINQ

TORQUE.

HOLD MACHINE FIRMLY

WITH

BOTH

HANDS.

1

.)

Ensure that the pad driver

or

brush is installed correct

-

ly and in good shape. Install or change pad

if

necessary

(See Page 3

for

detall

of

Installation).

2.)

Plug the machine into a wall outlet

as

described in the

grounding instructions.

3.)

Lower the handle

by

unlocking the adjustment handle

and moving the handle into position.

Relock the handle

when it is in a comfortable position.

4.)

Check to be sure the pad driver or brush is installed

before starting.

5.)

With the switch lock@) rotated forward, squeeze

one

of the switch levers, turning the machine on. (These levers

can be operated independently

of

each other)

6.)

To

stop the machine, release the switch lever

and

switch lock.

NOTE

The machine is equipped with a circuit breaker

to

protect the motor in the event

an

overload condition

occurs. The circuit breaker is located

at

the bottom

of

the

switch housing. Push the reset button to restart the ma

-

chine.

If

the breaker trips again, correct the cause

of

over

-

loading before proceeding.

7.)

Do

not let machine rest on pad. When finished with the

machine for the day return handle to the storage position.

Be sure to leave machine in a

safe

place where there is no

risk

of

being tipped over.

CONTROLS

Page

2

R0v.l

y2/94

L175”

.. . .

I

1

NOTE:

In

the

following

instructions

all

letter

will

be

shown

in

the

up-

DAILY

MAINTENANCE:

(At

the

end

of

each

working

day):

1.

Inspect power cord for wear.

To

prevent

electrical

shock replace cords with frayed or cracked insulation

MAINTENANCE INSTRUCTIONS FOR THE

L175

SERIES

OF FLOOR SCRUBBERS

immediately.

Place machine

in

the storage position.

Check pad condition. Change

if

soiled or torn,

2.

3.

WARNING:

Remove machine power cord from electrical

source before making any adjustments or repairs to the

machine.

Only qualified maintenance personnel are

to

PADS:

perform repairs.

MOTOR

Only

standard

1/2

inch thick

pads

suitable for low

speed

burnishing

are recommended.

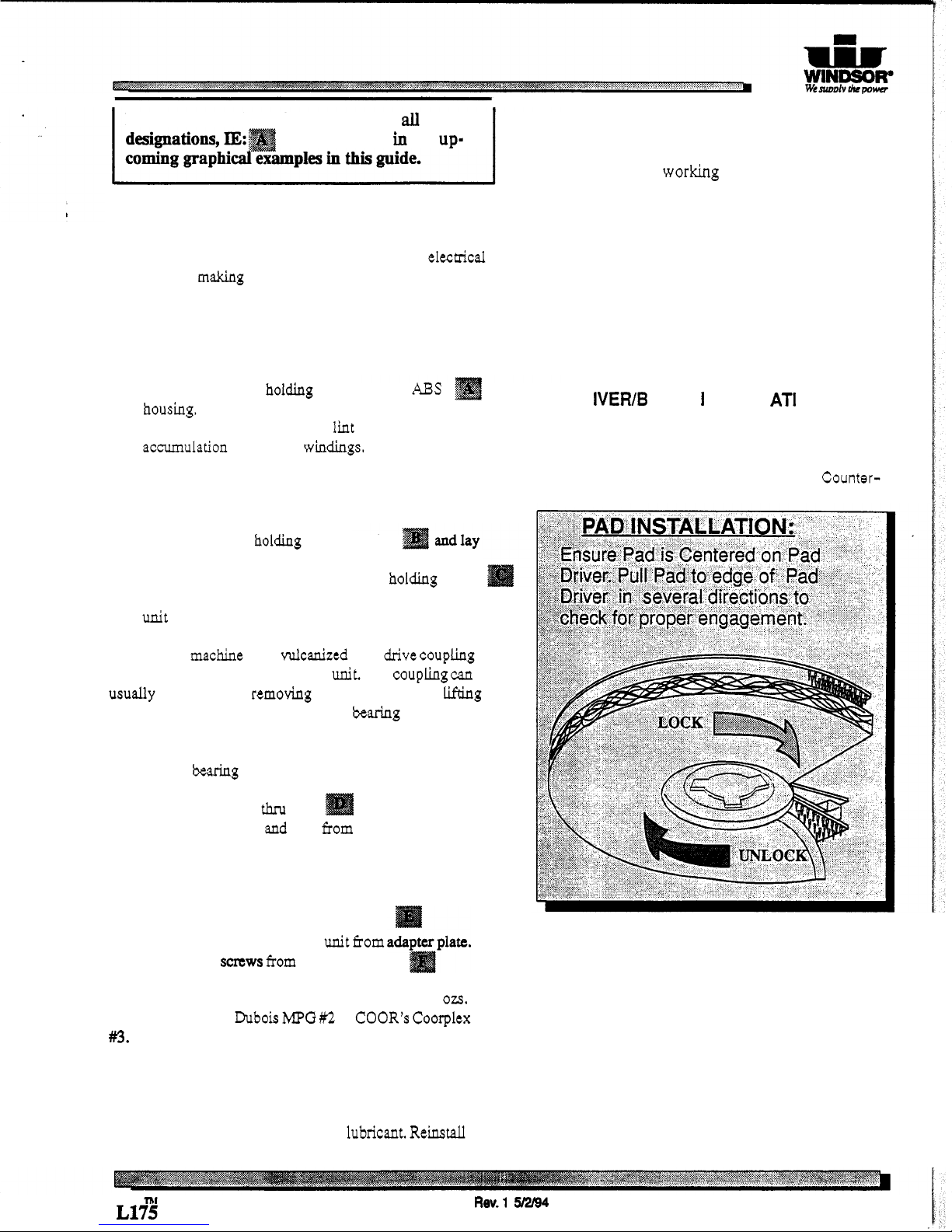

PAD

D

R

IV

ER/B

R

US

H I NSTA

LL

AT1 0 N

:

1.

2.

1.

2.

Remove

(4)

screws holding motor cover to

ABS

housing.

Use compressed

air

to remove lint

and

dust

accumulation from motor windings.

Lay

machine back on

the

ground, exposing

the

underside.

Place pad driver or

brush

on

the

motor lug and rotate

clockwise

until

engaged.

To

remove,

turn

Counter-

MOTOR-GEAR UNIT ASSEMBLY

1.

2.

Remove

(4)

bolts holding handle bracket

aside. Lift

off

plastic motor shroud.

Tip machine back

and

remove

(4)

bolts holding brush

cover and gear unit to

chassis.

Lift

out motor and gear

unit assembly.

NOTE:

The machine has a vulcanized steel drive coupling

located between

the

motor

and

gear

unit.

The coupling

can

usually be replaced by removing the motor cover and lifting

out the armature.

If

the

lower

armature

bearing

remains

in

gear unit adapter plate, it

will

have

to

be

removed from the

gear

box

to

access the bearing

for

removal.

3.

Remove

(4)

motor

thru

bolts and

lift

off

motor

cover. Remove armature

and

field from gear unit adapter

plate.

GEAR UNIT

1.

2.

3.

NOTE:

The

maximum

capacity

of

the

gear

unit

is

10

ozs.

Use

gearbox grease Dubois

MPG

#2

or COOR’s Coorplex

#3.

Remove

(6)

screws

from

adapter plate.

Use

pry bars to seperate gear unit fiom

Remove

(6)

saws

fnnn

gear unit cover.

Remove cover. Repair

as

needed.

WHEELS

1.

Remove wheels every 2 to 3 moths. Clean axle an

apply

a

small

amount

of

silicone lubricant. Reinstall

wheels.

clockwise.

NOTES:

L1%

Rev.1

5/2/94

3

Loading...

Loading...