Page 1

GROUTHOG

TILE AND GROUT MACHINE

Operating Instructions (ENG)

MODEL: GH3 (115V)

10050060

N

86038000 07/14/08

PRV NO. 98108

Read instructions before operating the machine.

Page 2

SAFETY

!

When using an electrical appliance, basic precaution

IMPORTANT SAFETY INSTRUCTIONS

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

WARNING:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer’s recommended components a nd attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water, return

it to an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is not suitable for picking up hazardous dust.

Machine can cause a fire when operating near flammable vapors or materials. Do not op erate this machine near

flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops

and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

During operation, attention shall be paid to other persons, especially children.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

Do not handle the plug or machine with wet hands.

Do not unplug machine by pulling on cord. To unplug, grasp the plug, not

Do not use with damaged cord or plug. Follow all instructions in this manual concerning grounding the ma chine.

Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp e dges or

corners.

Do not pull/run machine over cord. Keep cord away from heated surfaces.

Connect to a properly grounded outlet. See Grounding Instructions.

Do not allow to be used a s a toy. Close attention is necessary when used by or near children.

Do not use machine as a step.

Use extra caution when cleaning stairs.

Keep hair, loose clothing, fingers, and all parts of the body away from openings and moving parts.

Before opening cover, switch off machine. Wait until the fan/brush stops completely or dust and debris

may be ejected.

To reduce the risk of fire, electric shock, or injury:

the cord.

2

SAVE THESE INSTRUCTIONS

GROUTHOG 86038000 05/17/07

Page 3

INSPECTION

Please carefully unpack and inspect your

GROUTHOG for shipping damage. Each unit is

operated and thorougly inspected before shipment,

and any damaged is the responsibliltiy of the

delivering carrier who should be notified immediately.

ELECTRICAL

The Grouthog is designed to operate on a standard

15 amp, 115 volt, 60 hz, AC household current.

Check that the voltage shown on the serial number

plate is suitable for the supply available. Voltages

below 105 volts or above 125 volts could cause

damage to the motor.

* 230/250 volt 50 hz models are available.

NOTE: The GROUTHOG is equipped with a safety

relay switching system that prevents accidental motor

start-up. If the power cord is unplugged during use,

the machine will not start when reconnected, until the

the ‘ON’ switch is depressed.

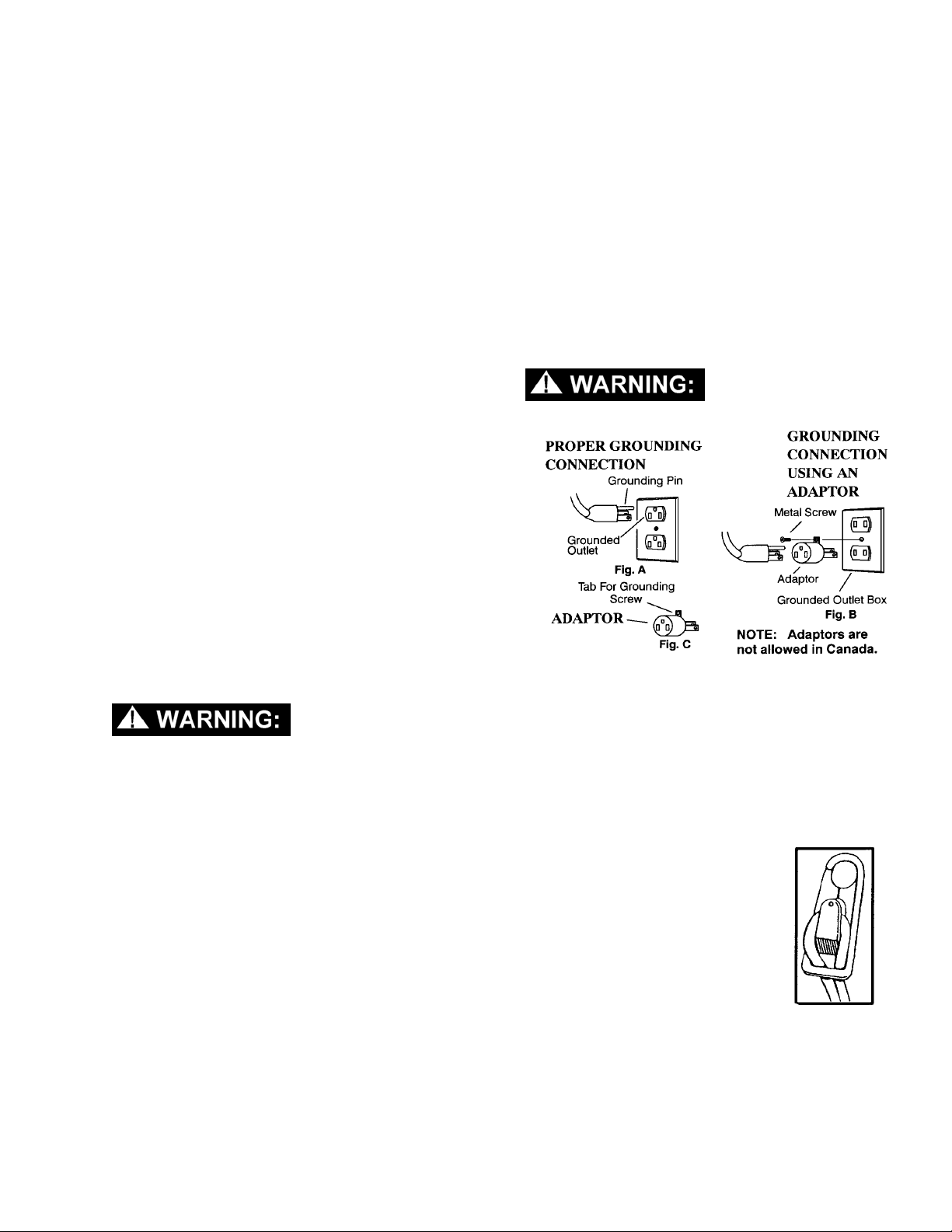

GROUNDING INSTRUCTIONS

This applicance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped

with a cord having an equipment-grounding

conductor and grounding plug. The plug must be

inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Improper connection of

the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified electrician

or service person if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the appliance. If it

will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAFETY

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like the

plug in “Fig. A” below. A temporary adaptor that

looks like the adaptor in “Fig. C” below may be used

to connect this plug to a 2-pole receptacle as shown

in “Fig. B” below, if properly grounded outlet is not

available. The temporay adaptor should be used

only until a properly grounded outlet (Fig. A) can be

installed by a qualified electrician. The green colored

rigid ear, lug, or the like extending from the adaptor

must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the

adaptor is used, it must be held in place by a metal

screw.

To avoid electrical

shock, use indoors only.

EXTENSION CORDS

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine and should be limited to 50 feet in length.

Extension cord must be three wire grounded. The

machine is equipped with a 18/3-40’ power cord.

EQUIPMENT SETUP

NOTE: Attach stain relief/cord retainer to the power

cord.

1. Make a loop in power cord

approximately 18” from main

housing.

2. Slide cord loop through slot in

retainer arm. Pull slack cord

back though slot to secure.

GROUTHOG 86038000 05/17/07

3

Page 4

OPERATION

SELECT THE RIGHT CHEMICAL FOR THE JOB:

1. For greasy or oily soil – Use a heavy-duty

degreaser.

2. For sealer or old wax - Use a heavy-duty

stripper.

3. For soap residue and lime build-up – Use a mild

acidic cleaner.

4. For routine maintenance – Use an all-purpose

cleaner.

Consult your Windsor

dealer for proper

chemicals. Always follow directions on the

container of the chemical being used.

SELECT THE RIGHT BRUSH FOR THE JOB:

1. For routine maintenance use the Universal

STANDARD Brush.

2. For cleaning groutlines use the Universal

AGRESSOR Brush.

CLEANING PROCEDURE

1. Remove trash receptacles, etc., from the area to

be cleaned.

2. Sweep or dust mop the floor.

3. Remove gum, labels or other debris from the

surface with a scraper.

4. Apply the pre-mixed solution generously with a

wet mop (or use optional tank) to a section of the

floor. Let solution stand for 5 to 10 minutes. Do

not allow solution to dry on the floor.

5. Plug the power cord of the machine into a

properly grounded outlet.

6. Adjust handle to a comfortable height.

7. Depress the “ON” switch to start machine.

(Depress the “OFF” switch to stop machine.)

The brush-drive motor is

thermally protected and

should an overload condition occur causing the

motor to stop, the machine will not start until the

“ON” switch is depressed.

8. Start cleaning at the farthest corner and work

toward the door. For best results, pull machine

backwards at a steady pace.

9. Keep the machine moving to avoid possible

damage to the grout.

10. Use a bristle hand brush to clean inside corners

and small areas not accessible by machine.

11. After scrubbing, rinse floor with clean water. Use

a wet vacuum to pick up loosened dirt an

solution.

12. Groutlines will appear dark at first, but will lighten

after they dry.

4

GROUTHOG 86038000 05/17/07

Page 5

DAILY MAINTENANCE

1. Before storing the machine, clean exterior.

Remove brush and rinse clean with hot water.

2. Periodically inspect electrical cable and

connections. Because the cable will lie on wet,

abrasive floors, the cable must be well insulated.

If the insulation is broken or frayed, repair or

replace immediately.

3. Remove wheels periodically and apply silicone

lubricant to the axle.

SERVICING THE GROUTHOG

Always disconnect the

power cord from electrical

source before making repairs or adjustments.

BRUSH REMOVAL

1. Place handle in upright position. Tilt machine

back with handle resting on floor.

2. Loosen Knob Assembly (item 20) holding the left

bearing block (item 29).

3. Remove bearing block from the frame and brush

core.

4. Remove brush (item 33) from the right bearing

block (item 38). When re-installing the brush,

make sure that the guide pins (item 30) on both

ends are properly aligned with the holes in the

brush core and the bearing block (items 29) is

correctly seated.

BELT REPLACEMENT

1. Remove main cover (item 73 held on by (4)

screws). Remove bottom belt guard (item 34

held on by (2) screws).

2. Using an allen wrench, remove the screw holding

the right bearing block (item 56).

3. Remove bearing block along with the old belt.

Replace belt and bearing block. Check belt for

proper tension and alignment (see Motor

Replacement for belt adjustment).

GROUTHOG 86038000 05/17/07

MAINTENANCE

BEARING REPLACEMENT

Using a small torch, heat the aluminum bearing block

just enough to allow the bearing and shaft (items 31

and 32, respectively) to be removed.

Use a bearing puller to remove old bearing. When

replacing bearing, use a socket or metal sleeve just

large enough to slip over the shaft and still contact

the inner bearing race. Use an arbor press or vise to

press new bearings on shaft. Re-heat aluminum

block just enough to allow re-assembly of bearing

and shaft.

Do not overheat block as

this will damage the bearing.

MOTOR REPLACEMENT

1. Remove motor cover (item 73 held on by (4)

screws).

2. Remove (4) screws holding motor (item 60).

Disconnect motor lead and remove motor.

3. When re-installing the motor use a straight edge

to realign pulleys. A screw driver can be used to

adjust tension.

4. NOTE: Belt should be adjusted to snug fit to

prevent slipping. DO NOT OVERTIGHTEN.

5

Page 6

WIRING DIAGRAM

886

115V GH3

BLACK 86268310

PRV NO. 88240

BLACK

86268150

PRV NO.

88165

BLACK 86268150

PRV NO. 88165

BLACK 86268600

PRV NO. 88421

BLACK 86268170

PRV NO.

BLACK 86268150

PRV NO. 88165

18

6

GROUTHOG 86038000 05/17/07

Page 7

THIS PAGE LEFT BLANK INTENTIONALLY

GROUTHOG 86038000 05/17/07

7

Page 8

GROUT HOG ASSEMBLY

62

81

61

68

39

59

58

57

39

40

31

35 34

54

41

38

63

60

56

55

37

30

43

66

28

64

42

63

52

53

42

30

67

65

33

17

18

44

AB

69

10

64

48

47

45

71

70

72

51

46

74

30

73

69

50

45

49

17

18

19

21

20

30

28

38

23

24

22

75

45

16

28

15

3

25

14

22

13

9

18

10

76

3

12

77

5

4

7

3

3

78

80

79

FRAME

4

1

2

6

8

35

32

31

GROUTHOG 86038000 07/14/08

29

27

23

26

11

10

6

FRAME

Page 9

GROUT HOG ASSEMBLY

REF PART NO. PRV NO. DESCRIPTION

1 86278140 70002 SHOULDER BOLT, 3/8 OD X 2.0 L

2 86259660 89038 WHEEL, GH 4" DIA.

3 86010680 87030 WASHER, 3/8 ID X 3/4 OD NYLON

4 86278910 87003 WASHER, 3/8 ID X 7/8 OD SS

5 86005750 57113 NUT, 5/16-18 HEX NYLOCK

6 86274050 70078 SCR, 5/16 X 3/8 PHSB PH SS DL

7 86091970 14222 BRKT ASM, GH HANDLE ADJ.

8 - OPEN -

9 86226780 73044 SPRING, EXT .44 D X 2.25 L X .054 W

10 86005720 57106 NUT, 1/4-20 HEX NYLOCK

11 76006490 70013 SCR, 8-32 X 3/4 PHMS SS

12 86273920 70049 SCR, 1/4-20 X 1.75 PHMS SS

13 86264220 6605 9 PLUG, GH HANDLE PIVOT

14 86005680 57047 NUT, 1/4-20 HEX NYLOCK

15 86273740 70010 SCR, 1/4-20 X 1.5 HHCS SS

16 86093390 66058 PIVOT, GH HANDLE

17 86010630 87013 WASHER, 1/4 ID X 5/8 OD SS

18 86010660 8702 5 WASHER, 1/4 LOCK EXT STAR SS

19 86273830 70020 SCR, 1/4-20 X 1/2 HHCS SS DL

20 86028070 48013 KNOB ASM, GH BEARING BLOCK

21 86028470 73183 SHIELD ASM, GH3 SPLASH

22 86010690 87068 WASHER, 1/8 RIVET BACKUP

23 86233060 20001 CLAMP, BAG SUPPORT

24 86086930 73157 SHIELD, GH SPLASH

25 86086340 67063 ROD, GH SPLASH SHLD HANGER

26 86086330 67062 ROD, GH SPLASH SHLD ROLLER

27 86264380 67061 ROLLER, SPLASH SHIELD

28 86273070 67005 RIVET, 1/8 OD WHT AL

29 86027310 14215 BLOCK ASM, GH LH BEARING

30 86272180 66060 PIN, ROLL 1/4" X 3/4" L

31 86228560 09021 BEARING, GH BRUSH SHAFT

32 86094050 7316 1 SHAFT/HUB ASM, GH DRIVEN

33A 86283940 12019 BRUSH, GH UNIVERSAL STANDARD

33B 86283950 14248 BRUSH, GH ALL PURPOSE AGGRESSOR

34 86064140 36045 GUARD, GH3 BELT

35 86006650 70177 SCR, 10-32 X 1/2 FHMS SS

36 - OPEN -

37 86094060 73163 SHAFT/HUB ASM, GH BRUSH DRIVE

38 86027320 14216 BLOCK ASM, GH RH BEARING

39 86277940 70126 SET SCR, 1/4-28 X 1/4 KCP

40 86250440 64029 PULLEY, GH BRUSH 20L050

41 86007670 73166 SNAP RING, EXTERNAL

42 86090230 87015 WASHER, 9/16 ID X 1.06 OD SS

43 86197300 1407 9 BUSHING, 1/8 FPT X 1/4 MPT HEX

44 86273780 70015 SCR, 1/4-20 X 3/4 HHCS SS

45 86226390 2721 8 CAP, GH FRAME TUBE

46 86273860 70025 SCR, 10-32 X 3/4 IHHMS UN SL SS

47 86273930 70051 SCR, 8-32 X 1/2 PPHMS

48 86005700 57104 NUT, 10-32 W/STAR WASHER PLTD

SERIAL NO.

FROM

NOTES:

GROUTHOG 86038000 05/17/07

9

Page 10

GROUT HOG ASSEMBLY

REF PART NO. PRV NO. DESCRIPTION

49 86092320 34111 FRAME, GH3 MAIN

50 86090390 89037 WEIGHT, GROUT HOG COUNTERBALANCE

51 86251350 67064 RELAY, 120V SPDT

52 86197560 40015 HOSEBARB, 1/4 FPT X 3/8

53 86237150 35065 GASKET, GH3 COVER

54 86076200 36051 GUSSET, GH3

55 86279090 87067 WASHER, 5/16 LOCK INT. STAR PLT

56 86277940 70126 SET SCR, 1/4-28 X 1/4 KCP DL

57 86229270 11011 BELT, GH3 DRIVE

58 86250430 64028 PULLEY, GH MOTOR 10L050

59 86271110 57123 NUT, 1/4-20 CAPTIVE (.074 W)

60 86247080 53113 MOTOR, 115V 1/3 HP W/T.O.

61 86274160 70110 SCR, 10-24 X 3/4 PHTC -F-

62 86244960 50211 LABEL, GROUTHOG MAIN

63 86256610 72015 SWITCH, SPDT 20A SNAP-ACTION

64 86279110 87075 WASHER, 3/8 ID INT. LOCK

65 86005670 57040 NUT, 1/2 NPT CONDUIT

66 86244990 50228 LABEL, GH WARNING

67 86244970 50212 LABEL, GROUTHOG ON

68 - OPEN -

69 86234710 27237 COVER, SWITCH PROTECTIVE

70 86245160 50399 LABEL, L1500 WARNING

71 86256200 73200 STRAIN RELIEF, 1/2 NPT FLEX

72 86244980 50213 LABEL, GROUTHOG OFF

73 86063380 27230 COVER, GH3 BLUE

74 86245260 50490 LABEL, 115V GH3 WIRING

75 86234100 23075 CORD ASM, 18/3 X 40 SJT, YL GH3

76 86006800 70361 SCR, 10-32 X 1/2 PHTR PLT

77 86076740 41144 HOOK, CORD

78 86256170 73169 STRAIN RELIEF, CORD HOOK

79 86092630 38079 HANDLE, GH MAIN

80 86232340 50352 CARD, GH3 INSTRUCTION

81 86245650 50776 LABEL, FOR SAFETY

SERIAL NO.

FROM

NOTES:

10

GROUTHOG 86038000 05/17/07

Loading...

Loading...