Page 1

L22AF

(OBS)

Page

1

of

20

CONTENTS:

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

22

Safety Instructions

Battery Information

Control Panel

Layout

Drive Controls I Operation

Maintenance

Hood Assembly

Shroud Assembly

Service

I

Adjustments

Lvi

Linkage

Deck

Lift

Mechanism

Chassis

Drive Assembly

Drive Control Assembly

Electrical Controls

Wiring Diagram

(F22)

Wiring Diagram

(F22T)

Trouble Shooting

Warranty

-

MODELS:

F22,

F22T

~

981

77

Rev.

716194

FILTRON~C'

Page 2

-

IMPORTANT SAFETY INSTRUCTIONS

When using battery powered machines, basic precautions should always be followed, including

the

following:

READ ALL INSTRUCTIONS BEFORE USING MACHINE

Operate from the rear of the machine only.

Use caution when operating the machine on a ramp or incline.

Do

not turn the machine, or leave it unattended, on a ramp or incline.

~~ ~ ~~ ~~

Machine can cause an explosion when operated near flammable vapors

or materials.

Store machine inside. Keep the electrical components of the machine dry.

Lead acid batteries have a number of inherent dangers, carefully read the

instructions and warnings which accompany the batteries and battery charger.

REMEMBER:

The batteries generate gasses which can ignite. Always

charge in a well ventilated area. Keep sparks and flames away from the

batteries.

Do

not smoke around the batteries. Avoid skin contact with the acid

contained in the batteries. Always wear eye protection and protective clothing

when working on or near batteries. Never allow metal objects to lay across

battery tops.

~ ~~ ~~

All

maintenance and repairs must be done by qualified personnel only.

Maintain adjustments on machine as specified in service manual.

Make sure all warning and caution labels are legible and properly

attached to the machine.

SAVE

THESE

INSTRUCTIONS

Record the model and serial number on the blue data label located at the rear of the machine

.

These numbers are used when calling upon the Windsor dealer for parts and service.

MODEL SERIAL

NO.

PURCHASE

DATE

nv

damaaes

which

2

Rev.7

7/6/94

FILTRONIC

Page 3

L22AF

(OBS)

Page 3 of

20

Battery Maintenance:

When cleaning batteries use a solution

of

baking

soda and water.

(Do

not allow cleaning fluid to

enter inside battery cells.)

Keep a proper electrolyte level in battery cells.

Wipe down the battery tops at least once a

week.

If

a

cell

should accidently overflow, clean

immediately.

Test battery condition with a hydrometer at least

once a week.

Ensure that all connections are tight and that

all

corrosion

is

removed.

Every

4

to

6

months remove batteries from the

machine and clean the battery compartment.

Spare Parts and Accessories:

021

00

Hydrometer

02101

Battery

Post

Cleaner

02143

Battery,

12V

DC,

20

Amp,

185

Amp Hour

02104

Charger,

36V

DC 20 Amp, Auto Shut-Off

(115v)

02141

Charger,

36V

DC

20

Amp, Auto Shut-Off

(1

OOV

50/60

Hz)

02142

Charger,

36V

DC

20

Amp, Auto Shut-Off

(230V

60

Ht)

02155

Charger,

36V

DC

20

Amp, Auto Shut-Off

(250V

50

Hz)

021

63

Charger,

36V

DC

20 Amp, Auto Shut-Off

(230V

50

Hz)

231

25 Cable,

12

"

Red

78231

Battery Tray

FILTRON~

Rev.1

7W

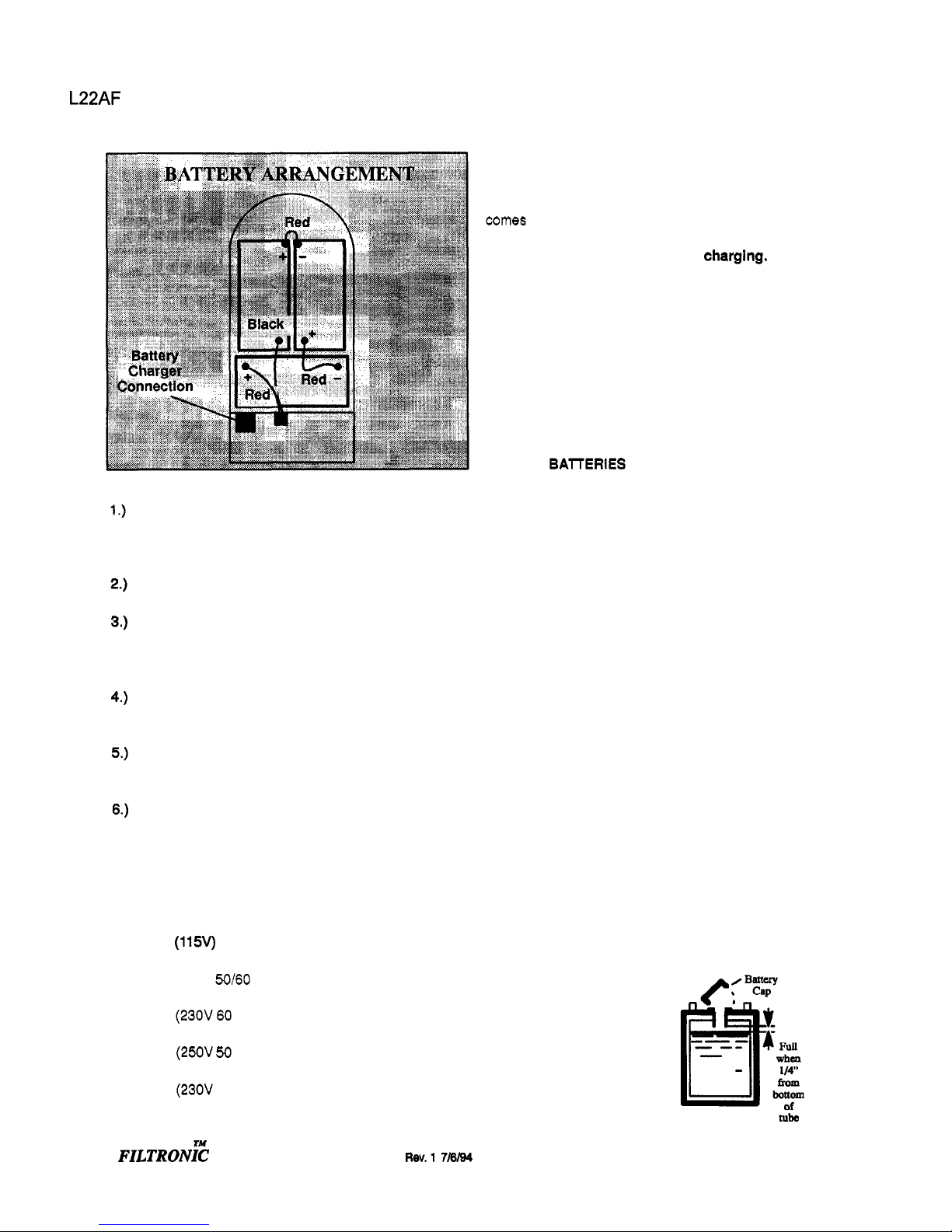

Battery Charging Procedure:

Charge the batteries once the amber charge

level

light

comes on.

The

amber light indicates that there is

about

20%

charge

left

in the batteries.

Do

not let the

batterles completely drain before

charglng.

Avoid

charging the batteries before the amber light comes

on.

The

machine will run for hours

on

fully charged,

well

maintained batteries.

DO NOT SMOKE, HAVE OPEN FLAMES,

OR

SPARKS NEAR BATTERIES

AT

ANY TIME.

WARNING:

WEAR EYE PROTECTION AND PROTECTIVE

CLOTHING WHEN WORKING

WITH

BATTERIES.

CHARGE

BAlTERlES IN A WELL VENTILATED

AREA WITH DECK DOWN AND COVER OPEN.

1

.)

Use

a

36

volt, 20 amp maximum output, D.C.

charger which turns itself

off,

when the batteries are

fully charged. The charger must have a connector

that matches the machines battery connection.

2.)

Read the instructions and warnings provided by

the battery charger manufacturer.

3.)

Set the charger

in a well

ventilated area on a lev

-

el

surface. Make sure cords will easily reach outlets

on both machine and wall.

4.)

Connect

charger to

D.C.

outlet on machine

first.

5.)

Connect the A.C. power cord to properly

grounded wall socket.

NEVER MAKE THE A.C.

CONNECTION FIRST, HAZARDOUS SPARKS MAY

RESULT.

6.)

After the batteries are completely charged discon

-

nect the charger from the A.C. wall socket.

7.)

Once the charger is disconnected from the A.C.

wall socket it is safe to disconnect the charger from

the machine.

8.)

When the batteries

are fully charged, check the

electrolyte level by removing

the caps on top of the

batteries.

If

necessary

fill

the

cells with distilled water as

shown in the diagram to the

-

-

right. Be careful not to overfill

cells.

Nbe

3

Page 4

L22AF

(OBS)

CONTROL

PANEL

I

I

n

IV

I

I

i

L.

70

Amp 3AmD r8AmD

Main power switch. Turns power on

and

off

to machine.

Deck lift switch. Tactile membrane

switch raises or lowers deck when

pressed.

Deck raised, amber indicator light.

Deck lowered, green indicator light.

Polisher running, green indicator

light. Light comes on when machine

is running and the pad is making

proper contact with floor.

[

1

J

I

Rev.$

71#’94

6.)

Battery charge drained, red light.

Operator has less than ten minutes to

return machine to charger. Once

batteries are completely drained the

red light flashes, polisher motor quits

running, and the deck automatically

raises.

7.)

Battery charge level low, amber

indicator light. Operator should return

machine

to

charger.

8.)

Battery charge level, green indicator

lights. Each light represents

1/4

charge, lights go out as the batteries

drain.

9.)

Danger, no pad, red flashing light.

If

someone tries to operate the machine

without the pad in place the deck will

automatically raise and the machine will

turn

off.

Turn main switch

off

and install

pad. Machine can be turned back on

once

pad

is

properly installed.

10.)

Brush wear, red indicator light.

Worn carbon motor brushes need to be

replaced before damage to motor

occurs.(See page

16

Item

20)

11

.)

Pad driver bar, starts pad driver when

squeezed to main handle, stops pad

driver when released.

12.)

Main handle.

13.)

Hour meter.

14.)

70

amp magnetic circuit breaker,

protects pad driver motor.

To

reset turn

to

“ON”

position.

15.)

3

amp thermal circuit breaker,

protects lift mechanism. Press to reset.

8

amp

F22T

Ty

FILTRONIC

Page 5

L22AF

(OBS)

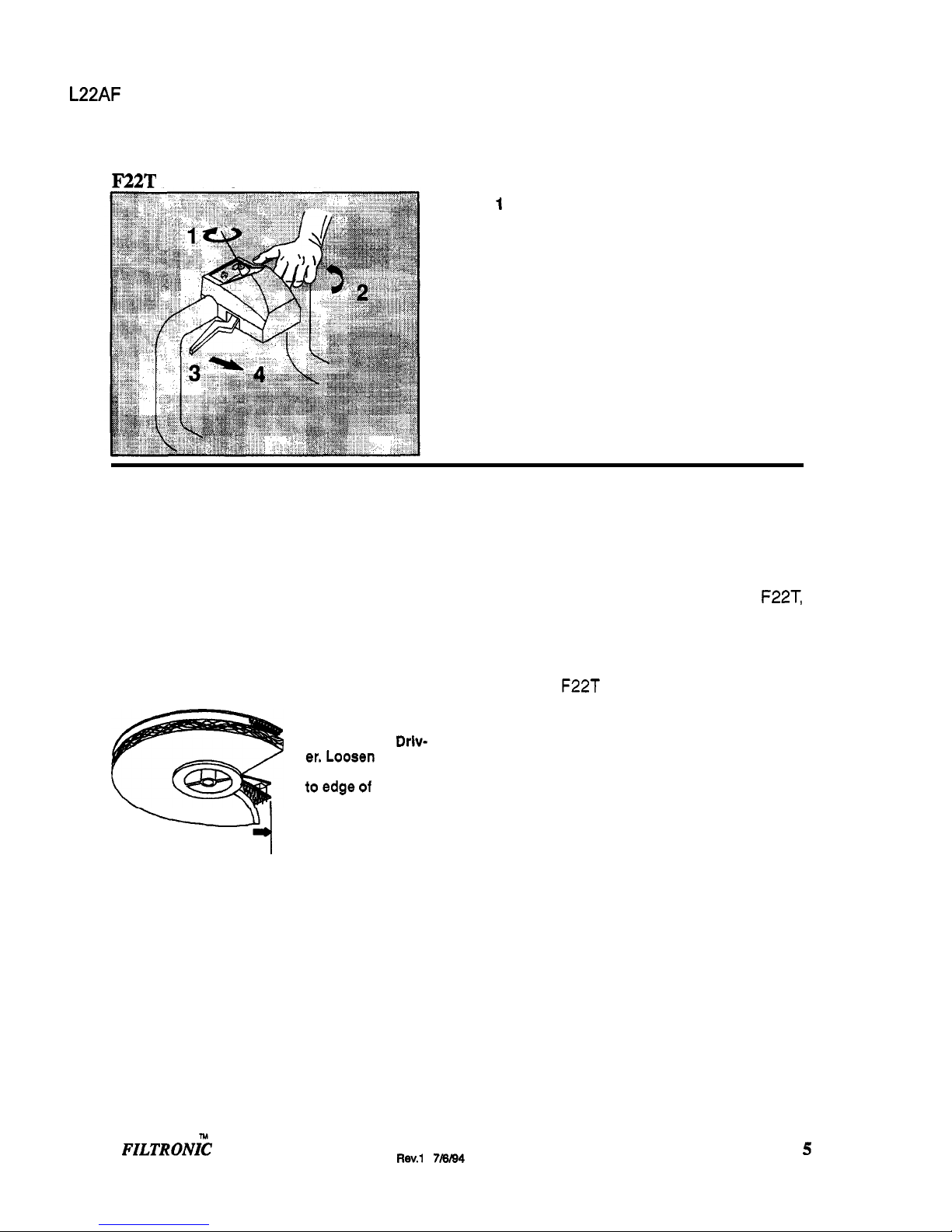

F22T

DRIVE

CONTROLS

Page

5

of

20

1

.)

The speed the machine will travel is

regulated by the knob located on the

controls which are found on the main

handle.

Turn

the knob

to

the

right

to

increase the speed

of

the machine.

2.)

Squeezing one or both

of

the control

levers will propel the machine forward

at the selected speed.

Releasing

both

control levers

will

stop

the machine.

3.)

4.)

Pressing forward on

the

levers moves

the machine backwards at the selected

speed.

Before starting the work period:

1

.)

2.)

Close the cover. is fully raised

4.)

Lower or raise deck by pressing deck

lift switch. On the

F22

models a green

light indicates position to begin

polishing. Amber light indicates deck

Disconnect the battery charger.

(See battery charging procedure)

3.)

Raise the deck. (Turn on the main

power switch and press the deck

lift switch.)

4.)

Turn or install a new buffing pad as

needed.

Ensure

Pad

is

Cen

-

tered

on

Pad

Drlv-

er.Loosen

Pad

Lock

and

pull

Pad

toedgeof

Pad

Driver

in

several

directions.

-i

5.)

Check wheels and other pivot points

for proper lubrication.

Operating the machine:

1

.)

If

using a machine which was already

set up, check to make sure the pad is

properly installed..

Adjust the operating control handle to

a comfortable position using the

handle lock lever.

2.)

3.)

FILTRONI?

Turn on the main power switch.

5.)

All

the machines, except for the F22T,

are controlled by squeezing the

thin pad driver bar and main handle

together.

The

F22T

drive controls are shown

above.

Caution:

To prevent possible

damage to the floor surface, always

keep the machine moving while the

pad is spinning.

The

F22

pad pressure will adjust automatically

to compensate for irregularities in the floor. pad

thickness, aggressiveness, and load. The

mo

-

tor amp draw is monitored causing the front

deck to be raised and lowered.

6.)

When the drive handle is released the

deck will automatically raise and the

motor will turn

off.

7.)

The operator can continue polishing

until all four green battery charge level

indicator lights

go

out.

Return the machine to the battery

charger when the amber charge level

light comes on.

5

8.)

Rev.1

7M4

Page 6

L22AF

(OBS)

Page 6 of

20

F22

MODELS

FILTER CARTRIDGE

The filter (part no. 3421 2)

is

accessed using

the latch at the front of the filter

cover.

Periodically wash the filter out.

BE

SURE

THE FILTER

HAS

COMPLETELY DRIED

BEFORE USING.

FELT DUST CONTROL SKIRT

Replace skirt (part no. 73520) when exces

sively soiled, worn, torn, or damaged in any

way that allows dust to escape.

Located inside the shroud the dust control

skirt is easily replaced. Each slot

on

the skirt

slips onto a tee nut inside the shroud.

ph

b150

ACTUATOR SPRING

To ensure pad pressure consistency, the dis

-

tance between the bottom of the cap spring

(p/n

27430)

and the flange on the actuator

pivot

(p/n 66150) should be 2.125 (see

above).

70424

\

pn

140032

LIFT LINKAGE

To ensure that the pad

is

at the proper height

when in the

“ready” position, the distance

between the edge of the safety switch brack

-

et (p/n 140032) and the end

of

the plunger

assembly

(see

above) must be 1.65”.

Weeklv

Maintenaace:

1.)

Use a hvdrometer to check the

conditioi of each battery cell.

Check battery cable clamps. Ensure

clamps are tight on battery terminals.

Clean tops of batteries with a wet

cloth and a solution of water and

baking soda. Wipe battery tops dry

after cleaning.

Check pad lock for looseness

or

damage.

Check filter and filter seals. Air flow

should be

unobstructed through filter.

Ensure that the chain, on the

F22T

model, and the pivot points and

casters, on all models, are properly

lubricated.

Tighten any loose screws or nuts.

At the end

of

each

work

period:

1

.)

Wipe down the exterior

of

the

machine.

2.) Vacuum out the filter cartridge.

3.)

Lower the deck.

4.)

Open the cover.

5.) Charge the batteries.

(See battery charging procedure

on page

3).

4to6Mo nth inten-

1

.)

Remove batteries - clean battery tray

-.

and battery compartment.

Clean battery cable clamps and

battery terminals.

Check the drive chain tension on the

F22T. Tighten, clean and lubricate

if necessary.

Check the carbon motor brushes in

the pad driver motor.

(#17 on page

12)

Use a vacuum to remove lint or dust

build

-

up from motor windings.

6

Rev.1

7/6/94

FILTRONI;

Page 7

L22AF

(OBS)

Lubrication;

The following symbols found throughout

the manual indicate items requiring

lubrication:

Apply grease

Use spray lubricant.

Use

anti-seize when repairing.

4

Permanent (Red) Thread Lock

reaker 3

Amp

471

Z

Wlrcuit 70

Am0

1491

7

4"

Polvurethane Swivel 18427

rx15 23izfi

23122

ntrol 34212

FlLTqpNlC Filter 35117

Flter.

Cartridae Dust

Co

I

Filter 35131

Holder. Centerlock

411a

Circuit Board. Contro

I

27035

Pad Driver 66182

671

66

Switch. Main

Rotary

72051

125VDC

SP

NC roller 72053

72088

72-

7-

8-

Cable

As-

27" 231

26

le

Asm..

4Ga

blk

x 37"

125VDC

SPST

N.O.

FILTRON~

NOTES:

Rev.1

7/8/94

7

Page 8

L22AF

(OBS)

HOOD

ASSEMBLY

F22, F22T

Page

8

of

20

12

*c

11

PARTS

LIST:

8

N

FILTRONIC

Page 9

L22AF

(OBS)

Page

9

of

20

2

4

See

page

12

inside

of

the

shroud

assembly

i

i

i

i

i

SHROUD

1

ASSEMBLY

1

.21

\

Hem

17

*NOTE:

Item

17

should

extend

3/8'

below

item

12.

N

FILTRONIC

Rev.1

7/8/94

9

Page 10

L22AF (OBS)

Page

10

of

20

ACTUATOR REMOVAL

1.)

Switch

on

main switch and lower buffing

head to floor. Switch

off

main switch.

2.)

Remove main cover and batteries.

3.)

Lay machine

on

left

side.

4.)

Remove actuator connecting

lift

link

##42

on

page

11.

5.)

Disconnect motor

leads.

,

6.)

Remove

(4)

bolts holding actuatorbracket

to frame and

lift

out actuator.

Testing Actuator

Barrel

’Iz.avel:

1.)

Donot allow the barrel

to

rotateorthe

1/2”-9/16” (1,25 to

1,4

cm) adjustment will

be

lost).

2.)

Connect white

wire

to

the

(+)

positive post and

the black

wire

to the

(-)

negative post of the

36VDC power supply to retract

the

barrel to the

lower limit.

3.)

Black

wire

to

the

(+)

positive post and the

white wire

to

the

(-)

negative

post

of the 36VDC

power supply

to

extend the barrel

to

the upper lim-

it.

4.)

Reverse the

wires

to

retract

the

barrel electrical

-

ly. the actuator

is

now ready for assembly and

installation.

LIMIT SWITCH

SETTINGS

Lower

Adjustment

1.)

Connect the white wire

to

the (-)negative

post

of

a 36VDC power supply and the black

wire

to the

(+)

positive post.

This

will

retract or

close the actuator barrel. Maintain the connection

until

the

limit switch shuts

the

power

off.

2.)

Disconnect both wires

from

the power supply.

Set

“A”

(barrel

to

frame

gap) at between

1/2

and

9/16

of

an

inch

(1,25

to

1,4

cm) rotating by

hand.

10

Rw.1

7m

Upper Adjustment

1.)

Hold Barrel

With

Hand

power supply, white wire to the

(+)

positive post

and the black wire

to

the

(-)

negative post.

This

will extend or open

the

actuator barrel.

Reverse the wire connections

to

the 36VDC

Do

not allow barrel to rotate.

2.)

Extend actuator barrel electrically

until

it

stops. Ensure

“A”

is

between 3 3/4 and 3

7/8

in

-

ches (95 to 9,9

cm)

on

all

models.

3.)

If

the

dimension is incorrect, disconnect from

the power supply and set the switch cam adjust

-

ment.

Switch

Cam Adjustment

1.)

Remove the two cam switch cover screws

(TOM

T15) and remove cam

switch

cover.

2.)

Loosen the two cam lock screws

(TORX

“20)

on

the cams.

CAUTION:

Do

not

allow

retract

cam

to

rotate.

3.)

If

the

“A”

dimension

is

incorrect, turning the

cam clockwise will INCREASE

“A,

counter-

clockwise

will

DECRBASE

“A”.

4.)

Tighten the two cam lock screws and cycle the

actuator.

Do

Not Allow The Barrel

To

Row.

Check the extended

“A”

dimension.

If

it is cor

-

rect,

replace

the cover with screws.

If

not repeat

3

above.

ru

FILTRONIC

Page 11

L22AF

(OBS)

Page

1 1

of

20

LIFT

LINKAGE

10

s/-

NOTE:

When the

actuator

continues

Wg

beyond

the

set

limits

use

page

10

to

adjust

or

replace

switches.

KEY

PART

NO.

DESCRIPTION

1

70015 Screw, 114-20 x 314 HHMS

2 70242 Screw, 4

-

40 x 114 PHMS

3 27457 Cord Assembly, Cover Pin

4 66092 Pin, Hair Spring Cotter

5

66149 Pivot, Cover

6 14725 Bushing, Cover Pivot

7 87025 Washer, 114 Star

8 70020 Screw,

114-20 x 112 HHMS

9 14704 Bracket, Deck Linkage

(Left)

10 87013 Washer, 114

ID

x 518

OD

Flat

11 66201 Pivot Asm,

F22T

12 14x8 Bushina. Flame 112 x 314 OD

13 14593 Bushina, Deck Linkaae

14

51147 Linkatre, Deck Lift

15 51151

Linkaae, Deck

Guide

Adi

lR

16 14705 Bracket, Deck Linkaae (Mid)

17

14706 Bracket, Scrub Deck Linkaae

(R)

18 57105 Nut, 1/4-20 Hex wl Star washer

19 571

63

Nut. 4-40 Hex wl Star washer

20

73456 Spacer, Plunaer Switch

21

70245

Screw. 4-40 x 314 PHMS

22 72053 Switch.

125VDC SPST NC

23 140032 Bracket,

Ext.

Microswitch Mntg. (Both:

24 67286 SnaD Rina, 5/16

11

FILTRONIC

Rev.1

7W

Page 12

L22AF

(OBS)

DECK

LIFT

MECHANISM

19-6

69-20

-l

I

Permanent

(Red)

Thread Loeking

adhive

2

For

the

Assemblies

see

pg.

9

Page

12

of

20

12

Rev.1

718/94

TM

FILTRONIC

Page 13

L22AF

(OBS)

F22T

See

Page

#

15

Page

13

of

20

CHASSIS

sea

page

14

of

thls

gulde.

'ARTS

LIST:

'./'

FILTRONI?

Rev.1

716194

13

Page 14

L22AF

(OBS)

DRIVE

ASSEMBLY

PARTS

LIST:

Page

14

of

20

Plate, Motor Spacer

Screw, 1/4

-

20 x 314

HHCS

Washer, 1/4 Lock

Ext

Star

SS

Washer 1/4

ID x 7/8 OD

SS

1”:”

Plate

,,D

Pro el Motor

I

70015

87025

870

13

14

Rev.1 7l6tW

lM

FILTRONIC

Page 15

L22AF

(OBS)

Page

15

of

20

F22T

DRIVE

CONTROL

ASSEMBLY

Adjustment

of

potentiometers

for

drive control

1.

2.

Turn the

speed

potentiometer

(U)

fully

clockwise.

(Max.

speed)

Loosen

the set

screw

(el)

and

adjust

the

direction

potentiometer

(T)

to center

of

travel.

Turn the

main

power

switch

on.

if the

machine

moves, adjust the direction potentiometer

until

movement

stops.

Tighten

the

set

screw

(#21)

3.

4.

5.

TM

15

FILTRONIC

Rev.1

7/6/04

Page 16

L22AF

(OBS)

Page

16

of

20

ELECTRICAL CONTROLS

NOTE:

This

Contrdler

needs

to

be

seperated

horn

the

frame

NOTE

When

wlrlng,

keep

wlnr

clear

of

shunt.

17

NOTE:

Apply

blue

lo*ite

to

internal

threads

of

item

62

on

bolh

end&

. _ .

. .

-

-

.. . . . .

__

5

24

'ARTS

LISF

.6

Rw.2

711

2/94

FILTRONI~

Page 17

WIRING

DIAGRAM

(F22)

CONTROL PANEL

0

000000

mp

88866

CHARGER

I

---

--

CONNECTION

88861

ASM

BLK

88665

n

’AD MOTOR

CIRCUIT

BREAKER

8868(

!ED

__

88670

BATTERIES

GROUND

POST

BLK 23127

CI

4

BLK

88678

1

4CTUATOR

BREAKER INDICATOR

BRUSH WEAR

n

BLK 88963

DEAD-MAN

SWITCH

ELK 88598

88594

ASM

MOLEX

I

BLK

FAsM

I

88958

88668

ELK

88957

ACTUATOR

I

MICRO

SWITCH

I

BL

K

88677

ELK 88859 88669

I-

h)

h)

R

n

0

m

cn

W

Page 18

L22AF

(OBS)

Page

18

of

20

I

FILTRONIC

Rev.

1

7/6rs4

Page 19

L22AF

(OBS)

Page

19

of

20

Troubleshooting

Chart

Condition Corrective

Action

No

Power

To

Mshb

Poor Cable Connection

Faulty micro switch

Faulty main power switch

Faulty

control board

Blown

fuse

Circuit breaker has tripped

Faulty drive handle

switch

Faulty relay

-

Carbon motor brushes

need to be replaced

-

lmhaslw

Circuit breaker has tripped

Loose

actuator conneotions

Faulty actuator

circuit

breaker

or actuator

Faulty control panel

Faulty control board

Deck stays on floor after motor after motor

stops

Deck height fluctuates excessively

FILTRONIC

Clean battery cable

clamps

of any corrosion and tighten test

voltage

at

points A

to

B

should

be

from

34

to

38

VDC.

Test

voltage

at

points C to B should

be

from

34

to

38

VDC.

If

there is no voltage check switch for continuity. Adjust or replace

as

needed

With

the main power switch turned on, test voltage at points B to

D

should be from

34

to

38

VDC.

If

there is no voltage remove

leads and check switch for

Continuity. Replace

if

necessary

Test

voltage at

L6

to

K7

should be from

34

to

38

VDC.

If

the

voltage is

good

at

L6

to

K7

but the machine still won't

respond,

all the tests

above

have been done, replace

the

control board.

Replace

fuse

Reset circuit breaker.

(N)

Unplug connector coming from main handle assembly. Squeeze

handle and test for continuity at handle end of connector

E.

Adjust or replace switch

as

needed

.

See

page

13

&

15

for

exploded

view of switch cover

(F22)

and drive control assemblies

F22T.

With main power on, pad

in

operating position

and

drive handle

squeezed:

Test

voltage

at

points

F

to

Q

and

F

to

B

should

be

from

34

to

38

VDC. When

the

relay

Is

working

it

should make a

clicking noise

as

the drive handle

is

squeezed. Replace relay

if

the

test

voltages measure properly and

the

pad

motor still does

not run.

If

the test voltages are not

34

to

38V DC, check wiring

and connections at

points F,

Q,

D and

B.

When the brush wear indicator light comes

on

it

is

necessary

to

put a new

set

of

carbon

motor brushes

in.

Caution:

Continuing

to

run the machine

until the brushes wear away completely

will cause motor damage.

Reset

circuit breaker

(M)

Check connections

J1L

J2

and

K3 & K4

on control board

along

with all other connections to actuator.

With

the

main power switch turned on

and

the

pad

upldown

switch depressed, test

voltage

at

K4

to

K3

should

be from

34

to

38

VDC.

If

the voltage is

good

at

K4

to W but the actuator

still

is not operating it will need to be repaired or replaced.

Unplug

the

connector at J on the control board. Test J (coming

from control panel) for continuity when pad switch is pressed.

Replace control panel

if

necessary.

Test voltage

at

L6

to

K7

should be from

34

to

38

VDC.

If

the

voltage

is

good

at

L6

to

K7

but

the

lift mechanism

still

won't

respond,

all

the

tests above have been done, replace the

control

board.

Check for worn out pad.

Check for worn

out

pad.

Rev.1

7m4

19

Page 20

L22AF

(OBS)

Page

20

of

20

Troubleshooting

Chart

(cont.)

Condition Corrective Actlon

-

-

Control board stuck in the

self check mode

When the main power is turned on within

3

seconds of the time

that the battery charger plug is removed the control board initiates

a self diagnostic program. To cancel the self diagnostic program

check, simply

turn

off

the main power

switch

for 3 seconds and

turn it back on.

If

the problem persists, turn

Ow

the main

switch

and

remove the 3 amp fuse for 5 seconds. Replace the fuse and turn

on the main switch.

-

Circuit Breaker tripped

Loose connections

Faulty micro switch

Faulty potentiometer

Faulty drive control board

Faulty motor

20

Reset

circuit breaker

(W).

Check

all

connections in propel motor drcuit especially

at

P,Q,R,

V and

X.

With the batteries disconnected, disconnect the wire leads to the

micro switch, at

V, and test for continuity. When the

control

levers

are squeezed the micro switch

is

engaged. There

should

be a

slight clicking sound when the switch is engaged.

Adjust

or

replace

as

necessary.

With the drive motor disconnected at

Q

or

X

test

the

output

voltage

to the drive motor. THe output voltage

at

Q

or X should vary

from

0

to

24

volts

as

the potentiometer U on the controls

is

adjusted and the control levers are squeezed. Resistance

of

the

potentiometen

can

be

tested at

the

green

and

black

leads

found

at

the molex connector at

R.

The resistance should vary from

0-

to

2.2

kilo ohms

as

the potentiometer U on the controls

is

adjusted

with the control levers

squeezed. If these fail, the potentiometers

will both

need

to

be

replaced.

Test

voltage at P should be from

34

to

38

VDC.

If

the voltage at

P

is

good

but

the propel motor won't respond, and all the tests

above have

boen done, replace the drive control

board.

Squeeze the control Ievem,

adjust

the potentiometer

U,

and test

the voltage at

X

or

Q.

When the output voltage at

X

or

Q

varies

from

0

to

24

volts but the motor does not respond, and all the tests

above have been done, replace the motor.

Rev.1

7/8/94

Loading...

Loading...