Page 1

CARPET EXTRACTOR

MODEL POWER SOURCE

EXP 115V ELECTRIC

EXPJ 100V ELECTRIC

U

Read these instructions before using the machine

98363 10/19/02

Page 2

MACHINE DATALOG

y

TABLE OF CONTENTS

MODEL-

DATE OF PURCHASE-

SERIAL NUMBER-

SALES REPERESENTIVE-

DISTRIBUTOR NAME-

OPERATIONS GUIDE NUMBER – 98363

©Copyright 1996 Windsor Industries, Printed in U.S.A.

Cover Sheet......................................................... 1

Data Log / Table of Contents............................... 2

Information in this guide ...................................... 3

Safety................................................................... 4

Hazard Intensity Level ......................................... 5

Operations ........................................................... 6

Option Controls.................................................... 7

Operating Instructions ......................................... 8

Maintenance ........................................................ 9

Maintenance Cont................................................ 10

Troubleshooting ................................................... 11

Wiring Diagram .................................................... 12

Service Schedule................................................. 13

Vac, Solution Tank, Control Panel Assembl

...... 14

Vac, Solution Tank, Control Panel Parts List .......15

Brush, Brush Motor, Frame Assembly .................16

Brush, Brush Motor, Frame Assembly

Parts List ..............................................................17

Pump Assembly ...................................................18

Pump Assembly Parts List ...................................19

Solution Lever, Main Handle Assembly ...............20

Solution Lever, Main Handle Assembly

Parts List ..............................................................21

Recovery Tank Assembly.....................................22

Recovery Tank Assembly Parts List ....................23

Solution Plumbing Spray Jet Assembly ...............24

Solution Plumbing Spray Jet Assembly

Parts List ..............................................................25

Spare Parts and Accessories ...............................26

Warranty...............................................................27

2

EXP 98363 10/19/02

Page 3

INFORMATION IN THIS GUIDE

This Owner’s Guide contains valuable information

about the operation, maintenance, service and part

numbers for repairs of your Windsor machine.

Please read this introductory page thoroughly to

become familiar with the contents of the owner’s

guide, making the information you are looking for

easier to locate.

The owner’s guide consists of multiple sections of

reference information, and the remainder contains

part information for ordering parts for the machine.

At the top of each page is the name of the particular

section. This way you can quickly locate each

section more easily.

REFERENCE SECTIONS

The reference information sections of this guide are

as follows; General Information, Operation,

Maintenance.

GENERAL INFORMATION

This section of the guide contains safety

precautions. The Safety Precau tio ns are an

overview of the safety measures to be observed

when operating and maintaining the machine.

PART SECTIONS

To easily locate the part needed, please refer to The

Table of Contents for component locations to find

the general area where the part is located. Use the

information to quickly locate the correct component.

The remaining sections of the guide contain part

number information for ordering repair parts for the

machine. The guide contains part number

information on every machine model available.

Therefore there will be part num ber inf orm ation in

your guide which you will not need to refer to when

placing an order.

ORDERING REPAIR PARTS

If you are in need of technical assistance contact

your WINDSOR Distributor or Service Center for

further assistance. Once you have located a part to

order, call your local WINDSOR distributor. Make

sure to have the machine’s serial number and your

Owner’s Guide with you to aid in ordering the correct

component(s).

NOTES:

OPERATION

The Operation section of the guide contains the

information needed to operate the machine. There is

a complete list of instruments and controls on the

machine, an overview of mac hine oper at io n, and

information on how to transport and store the

machine.

MAINTENANCE

The Maintenance section contains the information

on the suggested maintenance procedures and

adjustments to keeping the machine in top operating

condition. The section includes a maintenance

schedule and the areas of the machine to be

addressed. Each subject of maintenance is covered

in more detail in such areas as Lubrication, Motors

and Electrical System .

EXP 98363 7/1/96

3

Page 4

SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

To reduce the risk of fire, electric shock, or injury:

Connect to a properly grounded outlet. See Grounding Instructions.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before

maintenance or service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near

children.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding

the machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or

dropped into water, return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord

around sharp edges or corners.

Do not run machine over cord. Keep cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liqui d comes out of machine, swi tch off immedi ately.

SAVE THESE INSTRUCTIONS

4

EXP 98363 03/24/00

Page 5

HAZARD INTENSITY LEVEL

The following symbols are us ed t hroughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of haz ard int ensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following defin itions:

! WARNING

WARNING - Haz ards or unsafe practices which COULD res ult i n severe personal injury or death

! CAUTION

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To Id entify actions which mu st be followed for safe oper at i on of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Aut horized.

Unless Operation Guide i s Read and understood.

In Flammable or Explosive are as.

In areas with possible falling objects.

.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not we ar loose clothing; jackets, shirts, or sl eeves when working on the

machine. Use Windsor ap proved replacement parts.

.

EXP 98363 03/24/00

5

Page 6

OPERATIONS

HOW IT OPERATES:

This machine is a portable, easy to use carpet extractor

designed for use indoors, in a household or light

industrial environment.

When operating as a carpet extractor, cleaning solution

is dispensed onto the carpet and agitated by a rotating

brush. The solution is then extracted from the carpet by

a vacuum. The head on the brush is floating, allowing it

to automatically adjust to various carpet depths while

applying an effective brush pressure.

1. To avoid electric shock use indoors only.

2. To reduce risk of fire, do not use volatile

substances.

3. Use only cleaners intended for carpet

application.

INSPECTION:

Carefully unpack and inspect your extractor for shipping

damage. Each unit is operated and thoroughly

inspected before shipping, and any damage is the

responsibility of the carrier, who should be notified

immediately.

ELECTRICAL:

This extractor operates on a standard 15 amp 120 volt

AC circuit. This is the typical wall receptacle found in

household and light industrial environments. Voltages

below 105 volts or above 125 volts could cause serious

damage to motors. *Special voltage models available. A

wiring diagram is mounted inside the rear control panel

of machine. A copy of the wiring diagram is included in

this Owner’s Guide.

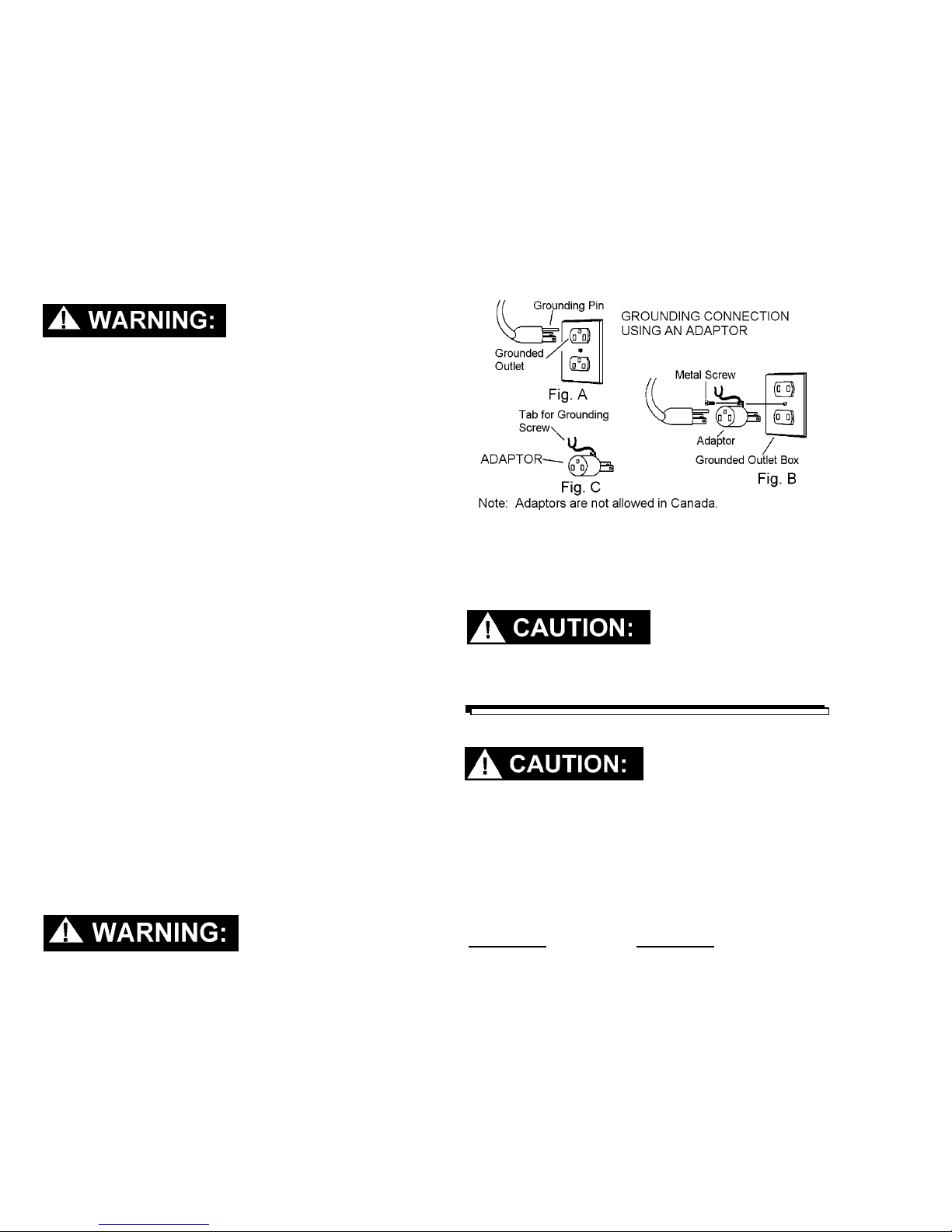

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a path of

least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and

grounding plug. The plug must be inserted into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

“Fig . C” may be used to connect this plug to a 2-pole

receptacle as shown in “Fig. B”, if a properly grounded

outlet is not available. The temporary adaptor should be

used only until a properly grounded outlet (Fig. A) can

be installed by a qualified electrician. The green colored

rigid ear, lug, or wire extending from the adaptor must

be

connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adaptor is

used, it must be held in place by a metal screw.

EXTENSION CORDS:

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine: This extractor is equipped with a 25 ft. 16/3

power cord.

To avoid possible distortion of polyethylene

solution/recovery tanks, DO NOT USE WATER

TEMPERATURE THAT EXCEEDS 140 F (60 C).

CHEMICALS

Use only the suitable chemicals listed below.

Using incompatible chemicals will damage the

machine. Damages of this type are not covered

under warranty. Carefully read ingredients on

manufacturer’s label before using any product in

this machine.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock.

Check with a qualified electrician or service

person if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug

provided with the appliance – I is will no fit the

outlet, have a proper outlet installed by a qualified

electrician.

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug in “Fig.

A”. A temporary adaptor that looks like the adaptor in

6

Suitable Incompatible

Chemicals Chemicals

Alkalis Aldehydes; Butyls

Defoaming Agents Carbon Tetrachloride

Detergents Chlorinated Bleaches

Soaps Chlorina ted H ydroc ar bo ns

Vinegar Trichlorethylene

Hydroxides Phenols; Methyls (MEK)

Perchlorethylene (perc)

Aromatic Hydrocarbons

D-Limonene

EXP 98363 7/1/96

Page 7

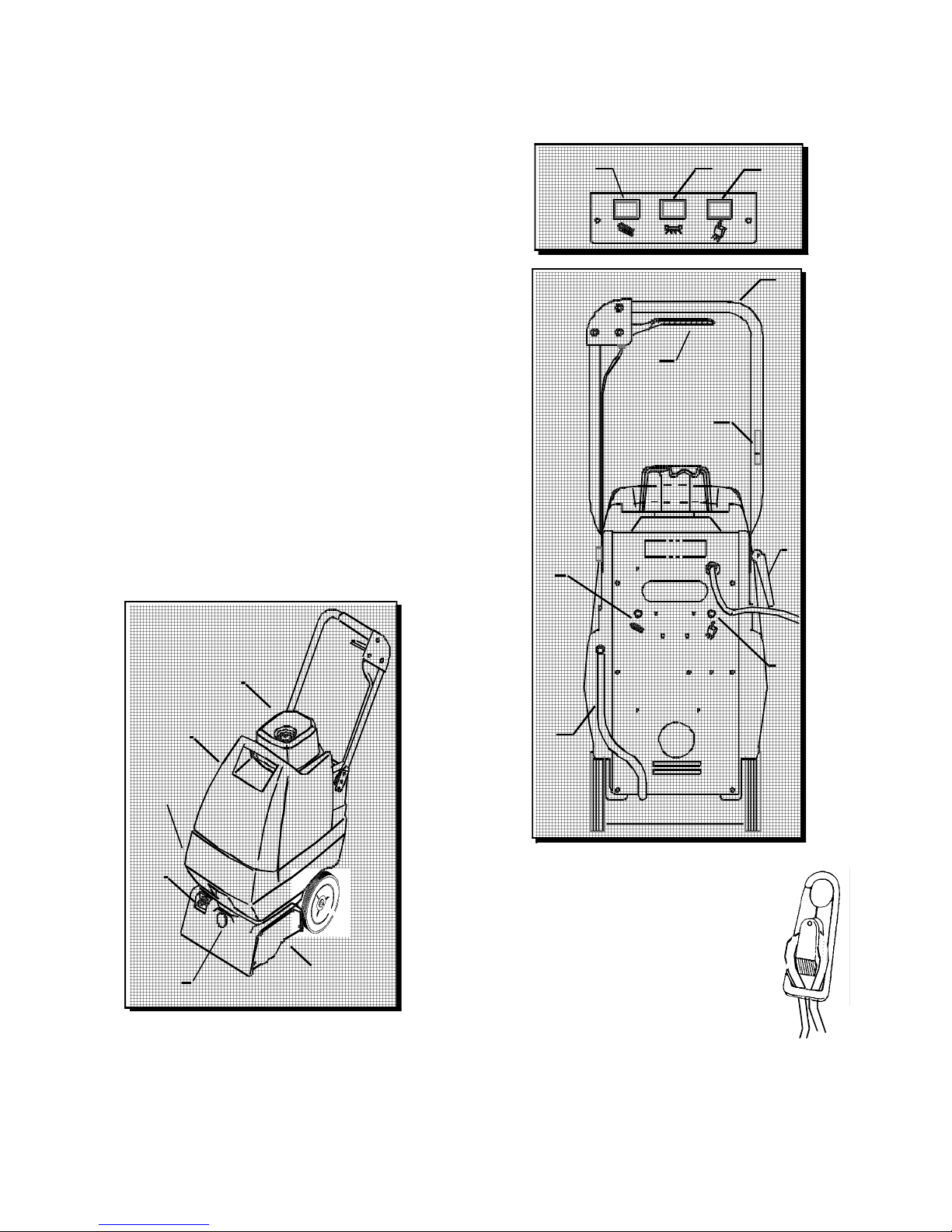

OPTION CONTROL

1 Brush Switch On/Off.

2 So lut io n Switc h On/O f f.

3 Vac Sw itch On/Off

4Main Handle.

5Solution Lever.

flow of solution to the floor .

6 Brush Motor Circuit Breaker.

Protects brush motor from overheating.

7 Vac Motor Circui t Breaker.

vac motor from overheating.

8 Ha n d l e Adj ustme nt L eve r.

Adjusts the ma in handl es angle.

9. Solution T ank Drain Hose.

10. Accessory T ool Connection.

ac ces s ory t o ol s.

1 1. Access ory Hose Connection.

conne ction for accessory tool.

12. Cord Hook.

Turns brush motor on and off.

T urns solution pump on a n d off.

. Tur ns va cuum mot or on a nd off .

Controls the amou nt of

Protects t h e

Solution connection f or

Hose

VIEW : TOP of CONTROL

1

VIEW: REAR of MACHIN E

5

6

23

4

12

8

VIEW: FR ON T of MA CHIN E

Dome

Recovery

Tank

Solution

Tank

10

11

Vacuum

Shoe / Brush

Housing

9

NOTE: Attach strain relief/cord

retainer to the pow er cord.

Make a loop in power cord appr oxim atel y

1.

12” from strain re li ef on machine .

Slide cord loop through slot

2.

in retainer arm. Pull slack

cord back through slot to

secure. Attach ret ainer t o

handle.

7

EXP 98363 03/24/00

7

Page 8

OPERATIONS

I

I

s

t

d

s

-

-

n

e

OPERATING INSTRUCTIONS

A. FI LL ING T HE S O LU TION TA NK:

Remove clear dome from recovery tank .

1.

Lif t upper recovery tank from machine and set

2.

aside.

Use a clean bucket or hose to fill so lution tank with

3.

hot wat er. The solution tank holds 4 gallons (15.2

liters) of cleaning solution.

Do not use the recovery tank to fi ll the solution tank. Sediment i n the recovery t ank can damage the solution pump

and clog the spray j ets, rendering the machine inoperable.

Add a non-foam ing c oncentrate for use in hot

4.

water extractors at the proportions noted on the

container.

Note: Periodically operate ext ractor with only hot water to remove chemical residue in carpet.

To avoid possible distortion o f polyethylene solution /recovery tan ks, DO NOT USE WATER WITH A TEMPERATURE TH AT EXCE EDS 140° F (60° C ).

Place recovery tank back on m achine.

5.

Place dome on rec overy tank. Make sure dome is

6.

seated c orrectly to ensure proper vacuum seal.

NOTE: If solut i on does not dispense in an even patt ern acros

the width of the machine, the spray jet may be clogged. Til

the machine back and remove the spray tip by pushing in an

tur ning i t one quarter t urn. Was h i t t horoughly, and blow dry.

NOTE: Do not use pins, wire, etc . to clean spray jet nozzle a

this will deform the jet and destroy the spray p att er n.

Begin with t he machine at the edge of the carpet.

6.

While operat ing machine, check for excessi ve fo am buil d

up in the recovery tank. If excessive foam is present, add

a d efoamer solution to reco very tan k, or empty tank.

7.

8.

Actuate the solut ion lev er while pulling the machine

backwards. Release solution lever at least 12

inc hes before the end of each cleaning p ass . This

will ensure all dispensed cleaning solution is

extrac ted from carpet.

Empty recovery tank when approximately 3/4 full.

If the recovery tank is overfilled , the water will drain

back ont o the carpet when the vacuum is sw itched

off.

Ven tilate area after carpet has bee n cleaned.

Ke ep childr en and pets aw ay and do not w alk

on carpet until it is dry.

Use only the suitable chemicals listed above. Using incomp atible ch emicals will damage the machine. Caref ully

read ingredients on man ufacturer’s label b efore usin g any

pr od uc t in this m a c hi ne .

I

OPERATING THE MACHINE

Vacuum the carpet and make sure it is cleared of

1.

surface debris before cleaning.

Plug power cord into a grounded wall outlet.

2.

Defeatin g the grounding pin on the power cord can result

in a severe electrical shoc

Turn on the pump, brush and v acuum

3.

swit ches, listeni ng for each motor to turn on.

NOTE: The vacuum and the brush are protected by circuit

breakers located on the back panel, below their respective

switch.

NOTE: If either of these motors does not respond to being

swit ched on, res et the circ uit breakers by pressing them in, and

attempt to switch the machine on again.

k.

A Windbloweräfan can be used to reduce drying time.

III

OPERATING MACHINE WITH

ACCESSORY TOOLS

This extractor is easil y adapted for use the following

Windsor accessory tools: DHT-UPH3-SW-SFW-SW/PRO

DDH-SPW

1.

2.

3.

Do not switch on brush when operating the machine

w ith acce ssory too l s. C arp et damage may occur.

NOTE: The s olution pump is not intended to run dry. W he

using the extractor for vacuum pick-up only, insure that th

pump swit ch is turned off.

Lift flap on the front of vac shoe and insert hose cuff

into the vac shoe, ensuring that there is a tight fit.

Attac h the solution hose from accessor y tool to the

brass soluti on fitti ng on the front of machi ne.

Switch on the pum p and the vacuum. The applic ation of cleaning solution is now controlled by

the lever on the accessor y tool.

OPERATING THE MACHINE

cont..

8

EXP 98363 03/24/00

Page 9

PROTECT FROM FREEZING

E

If it becomes necessary to store in tem peratures t hat could

drop below 40° F, the pumping sy stem, hos es and valves must

be protected from freezing with a methyl hy drate window wash-

er antifreeze solution

NOTE:Do not use ethylene glycol or cooling system

antifreezes.

Add on a gallon of window washer antifreeze

1.

.

to the sup ply tank.

Tu rn on pump switch and spray unti l the

2.

antifreeze so lu tion fi lls the solution lines.

Drain ou t the leftover antifreeze from the

3.

supply tank. Always allow the unit to reach

room temperatures before filling with h ot

water or op erati ng.

DA ILY /R E GU L A R M AI NT E NA N CE

! WARNING

Before making any adjustments or repairs to th e

machi n e, d i scon ne ct the power co r d for m e lect r i cal

source.

Empty unused cleaning solution f rom the

1.

s o lutio n ta nk.

Inspect and clean fil ter screens in solution tank, and

2.

on top of tube in recovery tank.

Flush pumping system wit h 1 or 2 gallons of

3.

cl ean, hot water.

MAINTENANCE

Periodic ally inspect all hoses, electrical cables, fil ters,

3.

gaskets and connections on your machine.Frayed or

cracked hoses should be repaired or replac ed to

elimi nate vacuum or solution pressure loss.

The electric al cable must be well insulat ed, if the cable

4.

ins ulation is broken or f rayed, re pair or replace it

im mediately. D on’t t ake chances with elec trical f ire or

shock.

The filt er in the bottom of the solution tank must be

5.

clean to allow free flow of cleaning solution. The screen

f ilter on the vacuum tube in the recov ery tank mus t be

f ree of lint buildup to ensure fu ll vacuum strength.

The dome gask et must be properly s eated and free of

6.

damage to creat e the air seal needed t o extract water.

MAINTENANCE INSTRUCTIONS

! WARNING

Remove machine power cord from electrical source

befor e makin g an y ad justm en ts o r r ep air s to the m a-

chine.

! WARNING

Only qualified maintenance p ersonnel a re to perform repairs.

BRUSH ASSEMBLY

Situate machine in order to access bottom cover. Remove

1.

screws (6) and bottom cover. Remove screws (3) and

belt cover.

C h e ck spra y j e t fo r fu l l spray p a tter n .

4.

Empty th e recovery tank and rins e with clean

5.

w a te r.

Check fo r and rem ove any lint or debris around

6.

brush and v ac shoe .

PE RIODIC MAINTENANCE

After every 25 hours of operation, flush a white

1.

vi negar solution (ONE quart vinegar to two

gallons of water) or anti-browning solution

(mixed as directed) through t he extractor. T his

will prevent build-up of alka line residue in t he

system.

If the spray jet becomes clogged, remove the

2.

spray tip, wash it thoroughly, and blow dry.

NOTE: Do not use pins, wire, etc. t o clean spray jet nozzle as

thi s will deform the jet and destroy the spray p atter n.

PERIODIC MAINTENANC

cont..

EXP 98363 03/24/00

Loosen nuts at brush motor and slid e motor forward

2.

to reduce belt tension. R emove belt.

Remove lower brush st op on belt side (closest to you with

3.

machine upside down) and rotate b lack plastic finger

guard tow ard rear of machine.

Remove one s crew holding each brush bearing t o

4.

brus h bracket .

With the blade of a screw drive, bend bearings

5.

inward enough to disengage locating tabs .

Slide brush, axle, and bearing out of brush bracket.

6.

Ins pect/replace brush and bearings as required.

7.

The brush is equipped with yellow wear indicator

bris tles. The brush should be replac ed when it

wears down to the height of the yellow bristles .

When reinstalling brus h, chec k belt for proper

8.

tens ion.

9

Page 10

MAINTENANCE

TO ACCESS PUMP AND BRUSH MOTOR

1. Situate machine in order to access bottom

cover. Remove screws (6) and bottom cover.

2. To remove brush motor, loosen nuts at brush

motor and slide motor forward to reduce belt

tension. Remove belt. Continue loosening nuts at

brush motor until free from brush bracket.

Disconnect wires.

3. To remove pump, loosen screws holding pump

mounting bracket to casting and remove as one unit.

Lift pump and mounting bracket up to gain access to

all hose clamps which need to be removed before

pump is free from machine. Disconnect wires.

TO ACCESS VAC MOTOR

Lift off recovery tank.

1.

2. Remove screws (5) and lift off vac motor

cover.

3. Vac motor can be lifted out and electrically

disconnected.

NOTE: The vac motor is protected by a circuit breaker

located in the switch panel. The breaker will only trip

under conditions of abuse.

SOLUTION VALVE CABLE ADJUSTMENT

The solution valve cable has been factory set so that

action of the solution lever moves the valve from fully

closed to fully open. As the machine operates the cable

will stretch and the lever will not be able to fully open the

valve. The play in the solution lever should be checked

periodically and adjusted when needed as described

below.

1. Loosen the lock nut at the point where the cable

enters the lever housing on the machine handle.

2. Turn the threaded end of the cable sleeve to

adjust. Threading the end further into the

housing will slacken the cable, increasing the

play in the lever. Threading the end out of the

housing will tighten the cable, decreasing the

play in the lever.

4. When replacing the vac motor, make sure

the excess wire lengths do not get pinched

in the gaskets which seal the vac motor. If

need be, remove the rear control panel and

pull excess lead length out of the vac motor

compartment.

VAC MOTOR BRUSHES

1. To inspect motor brushes, remove vac

motor from tank by disconnecting wires.

Then remove black vac motor fan housing

and brush holder assembly.

be replaced when worn to 3/8 inch or after about

750 operating hours. After second brush

replacement, the armature commutator should

be checked for pitting and concentricity. Vac

motors can be repaired, but such repairs should

be made by a qualified motor repair shop.

VAC MOTOR

location

of brushes

en d cap

ground

Brushes should

3. Tighten the locking nut against the housing after

adjusting the play as required.

4. If there is not enough thread adjustment

available, the cable length can be adjusted

directly at its connection to the solution valve.

This is accessed by removing the back control

panel.

SPRAY JET

Note: To prevent a clogged jet due to alkali build-up,

the spray system should be flushed with 1 to 2 gallons

of clean hot water at the end of each day.

1. Situate machine in order to access bottom cover.

2. The machine is equipped with a ”Quick Change”

jet that can be easily removed for cleaning. To

remove- push jet in and rotate 1/4 turn.

3. Wash jet and blow dry. Do not use pins or wire

to remove obstruction as this will change spray

pattern.

3/8

VAC MOTOR BRUSHES cont..

NOTE: When replacing electrical component parts refer

to Wiring Diagram for proper connection.

10

EXP 98363 03/24/00

Page 11

TROUBLESHOOTING CHART

A

No Pow er To Machine:

Dead electrical circuit breaker in fuse box

Fau lt y po wer cord

Power sw itc h f ailure

Faulty circuit breaker

Internal wiring problem

El ect rical Sho c k:

Equipment not grounding

Receptacle not grounded

I nternal ele ct rical p robl em

N uisance Tripping of Circuit Breaker:

Faulty circuit breaker

Mechanical problem

Va c u u m M o t o r S p e ed

Varies or Doesn’ t Run:

Worn motor brus he s

Motor worn out

Fau lt y sw itc h

Faulty circuit breaker

Internal wiring problem

Loss Of V acuum:

Loose vac dom e

Incorre ct se ating of recove ry tank.

Crack in dome or poor joint

Damaged dome gasket

Lint or dirt clogging vacuum intake screen

ccessory tool clogged

I nternal ele ct rical p robl em

Accessory Tool Fitting Diff icult to Connect:

Cor rosion on fitting

Brush Not Turning:

Belt broken

Fau lt y sw itc h

Faulty circuit breaker

Faulty brush motor

Worn Bearings:

Squealing or grinding sound in brush housing

Carpet Not Getting Clean:

Severe soil condit ion s

Car pe t Too Wet:

Worn spray jet (s)

Carpet Not Getting Wet:

Solution filter s creen clogged

Spray jet(s) clogged

Pump not running

Fau lt y pu mp

Solution valve adjustm ent

Incorrect jet orientation

Corre ctive Action:

Che ck buil din g circ ui t breaker.

Replace power switch f ailureTest switch for continuity/Replace if necessary.

Test circuit breaker for continuity. Replace if necessary. With the m achine

unplugged, check for, and correct, any loose wire

connections inside the machine at the switches and t erminal block.

Fol l ow ground i ng instructions exact l y.

Have an electrician inspect the building’s wiring.

Ensure that the mac hi ne’s wiring matches the appropriate wiring diagram.

Check for and co rrect any loos e w ire c on nections. Replace any wires o r

component s whic h are short circuiting.

Turn brush motor and pump switches on wi th machine til ted rearward (brush

off f loor). Lower mach ine back to carpet slowly.

Test circuit breaker for continuity/Replace if necessary.

Higher amp draws may indicate a mechanical problem. Find parts which are

not moving freely and repair or replace.

Replace

Replace

Replace

Replace

Check f or and correct any loose wire connec tions,

Seat dome squarely over tank opening.

. Remove recovery tank , clean of f seals on top of solution t ank, and reseal

recove ry tank .

Repl ace or repair using acrylic plastic c ement only.

Repl ace gasket.

With pow er off clean v ac intake screen found in dom e.

Clean out tool, ensure free air flow.

Have a trained service tec hnician inspect and repair the machine.

Clean with steel wool.

Remove and soak in acetic acid (white vinegar).

Lubr icate light ly with s ilicone ba se lubrican t .

Remove belt cover on right side of machine.

Inspect belt Replace if necessary.

Replace.

Replace.

If t he belt, circuit breaker, and switch have been tested and found to be in

good w orking order, the brush motor may need to be replaced.

Repl ace beari ngs.

Make s everal passes at right angles to each other.

Use a pre-spray.

Replace spray jets which are producing more than a fine mist.

C lean s olution filter sc reen loc ated inside lower tan k near the front.

Clean or replace jets.

Damaged jets will cause over-saturation.

Check for and correct any loose wires

R epa ir or replac e

Adjust solution valve cable unt il valve operates wh en handle is pulled.

Align slit in jet par allel wit h cen ter line of brush .

Do not use a wire to clean jet.

EXP 98363 03/24/00

11

Page 12

WIRING DIAGRAM

115V EXPERT

ORG

BLK

15

12

EXP 98363 03/24/00

Page 13

3

SERVICE SCHEDULE

MAINTENANCE DAILY WEEKLY QUARTERLY

Check machine for cord damage

Check recovery dome and gasket for

damage and cleanliness

Check brush – should be clean with no

lint or strings attached

Inspect vac shoe for blockage; remove

fibers with coat hanger, etc.

Check hoses for wear, blockages, or

damage

Check handles, switches, and knobs

for damage

Check vac motor intake filter and clean

Run one gallon of water through

system

Clean out recovery tank and check

float valve to make sure it moves freely

Clean out solution tank and remove

and clean vacuum intake screen

Clean outside of all tanks and check for

damage

Run vac motor for at least one minute

to allow motor to dry

Store with dome off tank to allow the

tank to dry

Check all bearings for noise

Check all gaskets for wear and leakage

Check vacuum intake screen for

damage; replace if necessary

Check pump pressure; observe spray

pattern and check with gauge if

necessary

Check and clean solution screen

Check belts for wear and replace as

necessary

Check brush for wear; ensure bristles

are not damaged

Check cables for fraying

Check the spray bar (manifold) for

damage; replace if broken or bent

Check condition of vac shoe and frame

for damage

Check overall performance of machine

Check vac motor carbon brushes

MAINTENANCE

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

EXP 98363 10/19/02

1

Page 14

VAC/SOLUTION TANK/CONTROL PANEL

1

44(5)

2

4

5

8A

10

45(5)

24

41

43

12(2)

45(2)

16

25(3)

33

17

32(2)

31

23

19

9

20

14

6

7

30

12

48(2)

27

44(6)

13(2)

37

38

11

26(4)

35(4)

46

3(4)

40(2)

49

31

39(4)

42

36

18

31(2)

34

47(2)

29

28

15

44 REF

45(6)

21(2)

22(2)

14

EXP 98363 10/22/01

Page 15

VAC/SOLUTION TANK/CONTROL PANEL PARTS LIST

REF PART NO. QTY DESCRIPTION

1 35175 2 GASKET, TANK TO VAC COVER

2 27631 1 COVER, VAC MOTOR

3 70627 4 SCR, 1/4 X 1/2 PPHST HI-LO 443236

4 27759 1 CUFF, 1.5” BLACK HOSE

5 39276 1 HOSE, 1.5” X 14” VAC

6 57208 1 NUT PG11 METAL, 1.024 OD X 0.73 ID

7 70211 1 SCR, 10-32 X 3/4 PH. BLK NYLON

8A 53771 1 VAC MOTOR ASM, 115V EXP.

8B 53780 1 VAC MOTOR ASM, 100V EXP.

9 500551 1 LABEL, CONTROL PANEL MAIN

10 27632 1 CAP, VAC MOTOR

11 34331 1 FRAME/SOL EXP II

12 70532 3 SCREW, 10-32 X 1/2 PHMS BLK

13 14942 2 COVER, CIRCUIT BREAKER

14 72151 3 SWITCH, 125V SPST

15 14622 1 BREAKER, 1.5A CIRCUIT

16 27787 1 COVER, REAR (CONTROL PANEL)

17 14700 1 BREAKER, 15A 250 VAC 50 VDC 1000001018

18 03102 1 AXLE, WHEEL

19 23664 1 CORD ASM, 115V

20 73710 1 STRAIN RELIEF, PG11 METRIC TRUMPET

21 89048 2 WHEEL, 8” NON-MARKING

22 57196 2 HUBCAP, 1/2” DIA

23 14020 1 TERMINAL BLOCK

24 35169 1 GASKET, VAC COVER

25 27376 3 CLIP, SWITCH RETAINING

26 70393 4 SET SCR, 1/4-20 X 1.25L

27 70595 1 SCREW, 10-32 X 1 PHMS GRN

28 880041 1 WIRE ASM, PANEL TO BASE

29 20086 1 CLAMP, CORD

30 70547 1 SCREW, #10-32 X 1 PPHMS BLK

31 57104 4 NUT, #10-32 KEPS

32 57116 2 NUT, #6-32 KEPS

33 87100 1 WASHER, 3/8 INT. LOCK THIN

34 35222 1 GASKET, 2 ID X 2.75 X 3/8 THK PORON

35 35182 4 GASKET, FRAME

36 73864 1 STRAINER, 3/8” NPT 60 MESH

37 500226 1 LABEL, CIRCUIT BREAKER BRUSH

38 500225 1 LABEL, CIRCUIT BREAKER VAC

39 70517 4 SCREW, 8-32 X 1/2 FHMS SS

40 51254 2 LOCK, HANDLE EXPERT TANK

41 35193 1 GASKET, REAR COVER

42 67029 1 RECTIFIER, BRIDGE

43 50776 1 LABEL, FOR SAFETY

44 70626 11 SCR, 10-3/4 PPHST TYPE B BLK

45 87189 13 WASHER, .2 ID X .5 OD BLK SS

46 62717 2 PLATE, AXLE EXP

47 87146 2 WASHER, 1/2 ID X 1” OD X .08” NYLON

48 70235 2 SCREW, 6-32 X 1.0 PH BLK NYLON

49 20035 1 CLAMP, 7/16 DIA. NYLON UL 1000028686

SERIAL NO.

FROM

NOTES:

EXP 98363 10/22/01

15

Page 16

BRUSH/BRUSH MOTOR/FRAME

Vac H ose

REF.( 39276)

REF

12

29

28

Part of

item 28

42

2

27

39468

33

Brush brkt

5

4

1

outside

of

machine

Housing

13

32

Diagram A

30

18

20

See

Dia gram B

14

34

13(2)

42

19

See

Diagram C

37

23

17

21

See

Diagram A

16

13(2)

6

10(3)

15

24

8(2)

22

11

36

30

Brush brkt

Housing

13

32

Diagram B

7(2)

35(2)

39

Wiring Asm.

REF. (88004)

40

Inside rear wall of housing

37

8(4)

Housing

outside

of

machine

33

10(5)

26

16

44

43

EXP 98363 10/17/01

41(4)

9(4)

*-left side only

Diagram C

Page 17

BRUSH/BRUSH MOTOR/FRAME PARTS LIST

REF PART NO. QTY DESCRIPTION

1 41279 1 HOUSING, BRUSH W/VAC SHOE

2 27674 1 COVER, ACCESS PORT

3 - - OPEN

4 35195 1 GASKET, .25 X .75 X 2.00 L

5 27759 1 CUFF, 1.5” BLACK HOSE

6 67138 1 RING, 3/8 EXTERNAL SNAP

7 57104 2 NUT, 10-32 W/STAR WASHER SHOE

8 57030 6 NUT, 10-32 NYLOCK

9 70557 4 SCR, 10-32 X 1” FHMS BLK

10 70532 5 SCR, 10-32 X 1/2 PPHMS BLACK

11 27636 1 COVER, BELT

12 20016 1 CLAMP, 1/4 ID HOSE

13 87139 4 WASHER, 3/16 FLAT

14 09113 1 BEARING, RIGH T

15 70740 3 SCR, 10-32 X 1/2 PTHMS BLK

16 64085 1 PULLEY, MOTOR

17 53608 1 MOTOR ASM, BRUSH DRIVE

18 140036 1 BRACKET ASM, BRUSH MOTOR

19 09114 1 BEARING, LEF T

20 140040 1 BRUSH

21 64086 1 PULLEY, BRUS H

22 11039 1 BELT, BRUSH DRIVE

23 03084 1 AXLE, BRU SH

24 35176 1 GASKET, BOTTOM COVER

25 - - OPEN

26 27639 1 COVER, BOTTOM

27 35171 1 GASKET, ACCESS PORT COVER

28 140087 1 BULKHEAD, 1/4 MPT X 1/4 BARB

29 56012 1 NIPPLE, 1/4 FPT QD

30 70303 2 SHOULDER BOLT, 1/4 OD X 5/8 L

31 - - OPEN

32 09117 2 BEARING, BRUSH BRACKET

33 57018 2 NUT, 10-24 HEX LOCK

34 70578 2 SCREW, 8-32 X 1” FHMS SS

35 70031 2 SCR, 10-32 X 1/4 PPHMS

36 87003 1 WASHER, 3/8 ID X 7/8 OD SS

37 62556 1 PLATE, GUARD ON LEFT SIDE ONLY

38 - - OPEN

39 70595 1 SCR, 10-32 X 1.0 PHMS GRN

40 20086 1 CLAMP, CORD

41 73781 4 HOSE, 5/16 X 3/16 ID CLR VINYL

42 70351 4 SCR, 10-32 X 3/8 HHTR W/STAR

43 70604 1 SCR, 10-32 X 5/8 PHMS BL K

44 87189 1 WASHER, .2 ID X .5 OD BLK SS

SERIAL NO.

FROM

NOTES:

NOTE: The left and right sides of the machine are

assigned as if standing behind the machine in the

operator’s position.

EXP 98363 10/17/01

17

Page 18

PUMP ASSEMBLY

10

13

9

12

Valve

5(2)

6(2)

8

11(2)

4

1(2)

7

So lut ion Ta nk

2

14

18

1

3

Accessory Port

EXP 98363 03/27/00

NOTE: Head of screw on this

hose clamp shall point towards

center of pump head as shown.

Page 19

PUMP ASSEMBLY PARTS LIST

REF PART NO. QTY DESCRIPTION

1 20016 2 CLAMP, 1/4 ID HOSE

2 39510 1 HOSE, 3/8 WIREBOUND X 3”

3 39468 1 HOSE, 1/4 NYLOBRAID X 11.5”

4 39508 1 HOSE, 1/4 NYLOBRAID X 15”

5 70484 2 SCR, 10-32 X 5/8 PPHMS SS

6 87016 2 WASHER, #10 LOCK EXT. ST AR

7 140034 1 BRACKET, PUMP

8 40009 1 HOSEBARB, 1/4 MPT X 1/4

9 40065 1

10 65164 1 PUMP ASM, EX PERT

11 70581 2 SCR, 10-32 X 3/8 HHTFW/WASH

12 78024 1 TEE, 1/4 BRANCH

13 40033 1

14 20042 1 CLAMP, 3/8 (D-SLO T )

HOSEBARB, 1/4 MPT X 1/4 X 90°

HOSEBARB, 1/4 MPT X 3/8 90°

SERIAL NO.

FROM

NOTES:

EXP 98363 03/27/00

19

Page 20

SOLUTION LEVER/MAIN HANDLE

S ol ution Lever

5

4(3)

3

16

1(3)

34331

REF

3

41 REF

2

12

9

8

42(2)

38

7

6

VIEW A-A

31

T

E

R

X

P

32

E

17

11

15

14

13(2)

28

33

12(2)

18

20

29(2)

A

A

B

30A

30B

34(4)

19

10

21

See Rear View

B

35

27

22

41

39(2)

36

42

A

40

26

23(2)

Rear View

A

43

37

20

EXP 98363 03/27/00

Page 21

SOLUTION LEVER/MAIN HANDLE PARTS LIST

REF PART NO. QTY DESCRIPTION

1 57238 3 NUT, 10-24 JOINT CONNECTOR BLK

2 51251 1 LEVER, SOLUTION

3 41302 2 HOUSING, SOLUTION LEVER

4 70537 3 SCR, 10-24 TRUSS HEAD BLK

5 36046 1 GRIP, HANDLE X 13”

6 38247 1 HANDLE

7 27785 1 CABLE, VALVE SOLUTION 27-1/2 LG

8 87029 1 WASHER, 5/16 FLAT SAE 441847 WAS 57138 (QTY 1)

9 57234 1 NUT, 3/8-16 SQUARE

10 57022 1 NUT, 3/8-16 HEX NYLOCK

11 87080 1 WASHER, .52 1.25 FLAT PLTD

12 87016 3 WASHER, #10 LOCK

13 87139 2 WASHER, 3/16 FLAT USS 441847 (QTY WAS 3)

14 67397 1 ROD, HANDLE ADJUSTMENT EXP II

15 80604 1 RING, RUE COTTER 1/4”

16 51142 1 LEVER, HANDLE LOCK

17 66133 1 PIN, CLEVIS

18 51184 2 LOCK, HANDLE ADJUSTMENT

19 62716 1 PLATE, STOP EXPT

20 73735 1 SPACER, 1.0 OD X .26 ID X 1 BLK NYL

21 70556 1 SCREW, 1/4-20 X 1.5 SS

22 84153 1 VALVE, KING STEN

23 40065 2

24 - - OPEN

25 - - OPEN

26 57018 1 NUT, 10-24 LOCK

27 89144 1 WELDMENT, LEVER VALVE EXP

28 41144 1 HOOK, CORD

29 70361 2 SCR, #10-32 X 1/2 PHTR

30A 50729 1 CARD, INSTRUCTION

30B 50765 1 CARD INSTRUCTION EXP J

31 27417 1 CORD, 1/8 X 12”

32 73169 1 STRAIN RELIEF, CORD HOOK

33 99620 7” HEAT SHRINK, 3/8 ID UL/CSA

34 70031 4 SCR, 10-32 X 1/4 PPHMS PLTD

35 40043 1

36 39508 1 HOSE, 1/4 NYLO BR AID 15”

37 39507 1 HOSE, 1/4 NYLO BR AID 17”

38 88551 1 WIRE ASM, 19” GRN/18 78008 X 78008

39 20016 2 CLAMP, 1/4 ID HOSE

40 73866 1 SPACER, 1/2 OD X .219 ID X 1/2 NYLON

41 140308 1 BRACKET, VALVE EXPERT

42 70626 3 SCR, 10-3/4 PPHST TYPE B BLK

43 66086 1 PIN, ROLL 3/16 X 5/8

HOSEBARB, 1/4 MPT X 1/4 90°

HOSEBARB, 3/8 MPT X 3/8 90° NYLON BLK

SERIAL

NO.

NOTES:

EXP 98363 03/27/00

21

Page 22

RECOVERY TANK

8

5

4(3)

9

TO REAR

COVER

1

7

10

3

2

6

11

22

EXP 98363 03/27/00

Page 23

RECOVERY TANK PARTS LIST

REF PART NO. QTY DESCRIPTION

1 28050 1 DOME

2 35178 1 GASKET, DOME

3 62465 1 PLATE, COVER

4 70114 3 SCR, 10-32 X 3/4 POLYFAST

5 35167 1 GASKET, COVER

6 75212 1 TANK, RECOVERY

7 34140 1 FILTER, VAC INTAKE

8 78162 1 TUBE, 1.5 PVC X 4.88”

9 27417 1 CORD, 1/8 X 1/2”

10 500009 1 LABEL, WARNING

11 500016 1 LABEL, EXPERT

SERIAL NO.

FROM

NOTES:

EXP 98363 10/22/01

23

Page 24

SOLUTION PLUMBING/SPRAY JET

5

1

2

39507

REF

7

12

10

9

4

TO

PUMP

3

2

24

EXP 98363 03/27/00

Page 25

SOLUTION PLUMBING/SPRAY JET PARTS LIST

REF PART NO. QTY DESCRIPTION

1 40069 1 HOSEBARB, 3/8 NPT X 3/8 TEE

2 20016 2 CLAMP, 1/4 ID HOSE

3 20042 1 CLAMP, 3/8 HOSE

4 31028 1

5 39509 1 HOSE, 3/8” CLEAR X 15.5”

6 62800 1 PLATE, GUARD EXPERT

7 40064 1 HOSE BARB, 1/8” FPT X 1/4”

8 - - OPEN

9 44066 1 JET, BRASS MINI-QUICK

10 44052 1 JET BODY, MINI-QUICK W/SEAL

11 - - OPEN

12 87185 1 WASHER, 3/8 SEALING X 3/4 OD

ELBOW, 1/8 45° STREET

SERIAL NO.

FROM

NOTES:

EXP 98363 03/27/00

25

Page 26

SPARE PARTS AND ACCESSORIES

PART NO. DESCRIPTION

11039 BELT, BRUSH DRIVE

35178 GASKET, DOME

35171 GASKET, ACCESSORY PORT

140040 BRUSH, EXP

44066 JET, 11004 BRASS MINI-QUICK

44051 JET SEAL, MINI-QUICK

44052 JET BODY, MINI-QUICK W/SEAL

35175 GASKET, TANK TO VAC COVER

50729 INSTRUCTION CARD

09114 BEARING, LEFT

09113 BEARING, RIGHT

64085 BRUSH MOTOR PULLEY

64086 BRUSH PULLEY

35176 GASKET, BOTTOM COVER

73169 STRAIN RELIEF, CORD HOOK

34140 FILTER, VAC INTAKE

ACCESSORIES

SW – STANDARD WAND

SPW – STANDARD WAND PROFESSIONAL

DHT – DELUXE HAND TOOL

DHTK – DELUXE HAND TOOL KIT

DDH – DOUBLE DRY HAND

26

EXP 98363 03/27/00

Page 27

WINDSOR INDUSTRIES

New Machine Warranty

Limited Warranty

Windsor Industries, Inc. warrants new machines against defects in material and workmanship under normal use and service to the

original purchaser. Any statutory implied warranties, including any warranty of merchantability or fitness for a particular purpose, are

expressly limited to the duration of this written warranty. Windsor will not be liable for any other damages, including but not limited

to indirect or special consequential damages arising out of or in connection with the furnishing, performance, use or inability to use

the machine. This remedy shall be the exclusive remedy of the buyer. The warranty period is subject to the conditions stated below.

6 / 3 / 1 Warranty: 6 Years Polyethylene (PE) Housings, 3 Years Parts, and 1 Year Service Labor

Subject to conditions outlined below, Windsor Industries warrants rotationally molded PE housings and parts on all of its machines to

be free from defects in material and workmanship, under normal use and service for six (6) years to the original owner.

Under this warranty we guarantee the performance of non-polyethylene parts and components to be free from defects and for up to

three (3) years to the original end user. Parts replaced or repaired under this warranty are guaranteed for the remainder of the original

warranty period. (See table below)

Service labor charges are covered for up to one (1) year from the date of purchase through authorized Windsor service provider. No

travel coverage is extended for cord-electric models. See table below for each general product model warranty coverage.

Product PE Housing & Parts Non- PE Parts Service Labor Travel

Rider Scrubbers 6 years 3 years 1 years 6 Months

Rider Sweepers 6 years 1 year 1 years 6 Months

Walk Behind Scrubbers 6 years 3 years 1 years 6 Months

Walk Behind Sweepers 6 years 1 year 1 years 6 Months

Extractors 6 years 3 years 1 years Polishers / Elec. Burnishers / GH 6 years 3 years 1 years Wide Areas Vacuums 6 years 3 years 1 years VacPak Vacuums 6 years 1 year 1 year Air Movers / Dri-matic / TITANä

Propane Burnishers / Strippers - 2 year 1 year Tracer/Flex Sweepers/Scrubbers 6 years 2 year 6 months 90 days

1 year 1 year 1 year -

VERSAMATICÒ

SENSORÒ

Product exceptions and Exclusions:

· Extractor brush motors, pump motors, ALL PC boards and electronics, ALL Vacuum motors (other than VERSAMATICÒ and

SENSORÒ), ALL pumps, and FLEXSOLä diaphragms carry a one (1) year parts and service labor warranty.

· The OnanÒ engines have three (3) year manufacturer’s warranty. The HondaÒ and KawasakiÒ engines have two (2) year

manufacturer’s warranty. NOTE: The engine warranty is administered through the engine manufacturer and must be repaired at

an authorized service center.

Normal wear items and accessories including, but not limited to, belts, brushes, capacitors, carbon brushes, casters, clutches, cords,

filters, finishes, gaskets, hoses, light bulbs, rectifiers, switches, squeegees, bearings, pulleys, relays, actuating cables, wheels, tires,

propane tanks, and batteries will be warranted for manufacturing defects for 90-days from the purchase date.

The warranty commences on the purchase date by the original end user from an authorized Windsor agent, subject to proof of

purchase. The Machine Registration Card must be completed and returned immediately at the time of purchase. If proof of purchase

cannot be identified, the warranty start date is 90 days after the date of sale to an authorized Windsor distributor. Parts replaced or

repaired under warranty are guaranteed for the remainder of the original warranty period.

Windsor Industries reserves the right to change its warranty policy without notice – Rev2 10/16/02 1

Windsor Industries, Inc. ● a Castle Rock Industries company ● 1351 W. Stanford Ave. ● (303) 762-1800 ● 800-444-7654 ● FAX (303) 865-2800

Brush motor, Vacuum motor, Belts – 3 years All other parts – 1 year

Vacuum motor, Belts – 2 years All other parts – 1 year

Page 28

WINDSOR INDUSTRIES

New Machine Warranty

90 Day Warranty Extension Available

Upon receipt of the Machine Registration Card, Windsor will extend by 90 days, from the date of purchase, all items included under

the one-year provision. This applies only to one-year items and does not include 90-day wear items.

This Warranty Shall Not Apply To:

1. Any product that has been subject to abuse, misuse, neglect or unauthorized alteration (including the use of incompatible or

corrosive chemicals or overloading of capacity).

2. Products that have experienced shipping or freight damage.

3. Repairs necessary to correct any failure due to improper pre-delivery service and inspection by the selling dealer.

4. Excessive time for cleaning units in preparation for repair.

5. Any repairs resulting from poor initial service work or improper diagnosis.

6. Tune-up parts such as plugs, plug wires and condensers.

7. Any design alterations performed by an organization not authorized or specified by Windsor.

8. Battery and charger warranties are handled directly with the manufacturer (TrojanÒ batteries and LesterÒ chargers).

9. High-pressure washing.

10. Electrical components exposed to moisture.

If difficulty develops during the warranty period, contact the authorized Windsor agent from whom the product was purchased.

Windsor Industries, Inc. may elect to require the return of components to validate a claim. Any defective part to be returned must be

shipped freight prepaid to an authorized Windsor Distributor/Service Center or to the Windsor factory.

Use Of Parts Not Approved By Windsor Industries, Inc. Will Void All Warranties

This warranty is valid only for all products sold after July 1, 1995. A product sold before that date shall be covered by the limited

warranty in effect at the date of sale to the original purchaser.

Windsor Industries reserves the right to change its warranty policy without notice – Rev2 10/16/02 2

Windsor Industries, Inc. ● a Castle Rock Industries company ● 1351 W. Stanford Ave. ● (303) 762-1800 ● 800-444-7654 ● FAX (303) 865-2800

Loading...

Loading...