Page 1

CARPET EXTRACTOR

MODEL POWER SOURCE

EXP 115V ELECTRIC

AB

98363 08/14/07

Read these instructions before using the machine

Page 2

MACHINE DATA LOG/OVERVIEW

Name: __________________________________________________________________________________________________

Address: _______________________________________________________________________________________________

Phone Number: _________________________________________________________________________________________

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

DEALER NAME ________________________________

OPERATIONS GUIDE NUMBER ___________________

PUBLISHED

__________________________________________

YOUR DEALER

For the name and address of your dealer contact: Windsor Industries

1

EXP 98363 08/25/04

Page 3

Machine Data Log/Overview.........................1

Table of Contents..........................................2

HOW TO USE THIS MANUAL

How to use this Manual.................................1-1

SAFETY

Important Safety Instructions........................2-1

Hazard Intensity Level ..................................2-2

Grounding Instructions..................................2-3

OPERATIONS

How It Operates............................................3-1

Controls.........................................................3-2

Operating Instructions...................................3-3

MAINTENANCE

Protect From Freezing..................................4-1

Daily/ Regular Maintenance..........................4-1

Periodic Maintenance. ..................................4-1

Brush Assembly............................................4-1

Service Schedule..........................................4-2

To Access Pump & Brush Motor ..................4-3

Solution Valve Cable Adjustment .................4-3

Spray Jet ......................................................4-3

Vac Motor Brushes ......................................4-4

Vacuum Motor Replacement. .......................4-4

Wiring Diagram.............................................4-5

Troubleshooting Chart ..................................4-6

GROUP PARTS LIST

Vac/Solution Tank/Control Panel................5-1

Brush/Brush Motor/Frame........................... 5-3

Pump Assembly..........................................5-5

Solution Lever/Main Handle........................5-7

Recovery Tank............................................5-9

Solution Plumbing/Spray Jet.......................5-11

Suggested Spare Parts/Accessories .......... 5-13

Warranty ...........................................…...…5-14

TABLE OF CONTENTS

EXP 98363 08/25/04

2

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized dealers.

When placing an order for parts, the machine model

and machine serial number are important. Refer to

the MACHINE DATA box which is filled out during

the installation of your machine. The MACHINE

DATA box is located on the inside of the front cover

of this manual.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

DEALER NAME ______________________________

OPERATIONS GUIDE NUMBER __________________

PUBLISHED ________________________________

The model and serial number of your machine is

located on the lower left back panel.

1-1

EXP 98363 08/25/04

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

- Periodic

- Daily/Regular

- Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs.

If column has an asterisk (*), call

manufacturer for serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The 98# on the lower left corner of the front

cover is the part number for this manual.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

!

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

To reduce the risk of fire, electric shock, or injury:

WARNING:

Connect to a properly grounded outlet. See Grounding Instructions.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before maintenance or

service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near children.

Use only as described in this manual. Use only manufacturer’s recommended components and attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding the

machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord around sharp

edges or corners.

Do not run machine over cord. Keep cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine near

flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops

and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

SAVE THESE INSTRUCTIONS

EXP 98363 08/25/04

2-1

Page 6

HAZARD INTENSITY LEVEL

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

!

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

.

2-2

EXP 98363 08/25/04

Page 7

GROUNDING INSTRUCTIONS

3

!

t

p

A

A

THIS PRODUCT IS FOR COMMERCIAL USE ONLY.

ELECTRICAL:

In the USA this machine operates on a standard 15 amp

115V, 60 hz, A.C. power circuit . The amp, hertz, and

voltage are listed on the data label found on each

machine. Using voltages above or below those

indicated on the data label will cause serious damage to

the motors.

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a path of

least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and

grounding plug. The plug must be inserted into an

appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

This appliance is for use on a nominal 115-volt circuit,

and has a grounded plug that

looks like the plug in “Fig. A”. A temporary adaptor that

looks like the adaptor in “Fig . C” may be used to

connect this plug to a 2-pole receptacle as shown in

“Fig. B”, if a properly grounded outlet is not available.

The temporary adaptor should be used only until a

properly grounded outlet (Fig. A) can be installed by a

qualified electrician. The green colored rigid ear, lug, or

the like extending from the adaptor must be connected

to a permanent ground such as a properly grounded

outlet box cover. Whenever the adaptor is used, it must

be held in place by a metal screw.

WARNING:

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check

with a qualified electrician or service person if you are in

doubt as to whether the outlet is properly grounded. Do

not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a

qualified electrician.

PROPER GROUNDING

Grounding Pin

Grounded

Outlet

Fig. A

Tab For Grounding Screw

daptor

NOTE: In Canada, the us e of a tem p or a ry ada p tor is no

ermitted by the Canadian Electrical Code

Metal Screw

daptor

Grounded Outlet Box

Fig. B

Fig. C

EXP 98363 08/25/04

2-

Page 8

OPERATIONS

HOW IT OPERATES:

This machine is a portable, easy to use carpet extractor

designed for use indoors, in a household or light

industrial environment.

When operating as a carpet extractor, cleaning solution

is dispensed onto the carpet and agitated by a rotating

brush. The solution is then extracted from the carpet by

a vacuum. The head on the brush is floating, allowing it

to automatically adjust to various carpet depths while

applying an effective brush pressure.

1. To avoid electric shock use indoors only.

2. To reduce risk of fire, do not use volatile

substances.

3. Use only cleaners intended for carpe t

application.

INSPECTION:

Carefully unpack and inspect your extractor for shipping

damage. Each unit is operated and thoroughly

inspected before shipping, and any damage is the

responsibility of the carrier, who should be notified

immediately.

CHEMICALS

Use only the suitable chemicals listed below.

Using incompatible chemicals will damage the

machine. Damages of this type are not covered

under warranty. Carefully read ingredients on

manufacturer’s label before using any product in

this machine.

Suitable Incompatible

Chemicals

Alkalis Aldehydes; Butyls

Defoaming Agents Carbon Tetrachloride

Detergents Chlorinated Bleaches

Soaps Chlorinated Hydrocarbons

Vinegar Trichlorethylene

Hydroxides Phenols; Methyls (MEK)

Perchlorethylene (perc)

Aromatic Hydrocarbons

D-Limonene

Chemicals

ELECTRICAL:

This extractor operates on a standard 15 amp 120 volt

AC circuit. This is the typical wall receptacle found in

household and light industrial environments. Voltages

below 105 volts or above 125 volts could cause serious

damage to motors. *Special voltage models available. A

wiring diagram is mounted inside the rear control panel

of machine. A copy of the wiring diagram is included in

this Owner’s Guide.

EXTENSION CORDS:

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine: This extractor is equipped with a 25 ft. 16/3

power cord.

To avoid possible distortion of polyethylene

solution/recovery tanks, DO NOT USE WATER

TEMPERATURE THAT EXCEEDS 140 F (60 C).

3-1

EXP 98363 08/25/04

Page 9

A

1 Brush Switch On/Off.

2 S o l ution Switch On/ O f f.

Turns brush motor on and off.

Tur ns solution pump on and off.

VIE W: TOP of CONTR OL

1

CONTROLS

23

3 Vac Switc h On/O f f

4Main Handle.

5 S o l ution L ever .

flow of solution to the floor.

6 Brush Motor Circuit Breaker.

Prot ects brush motor from overheating.

7 Vac Motor Circuit Breaker.

vac motor from overheating.

8 Han dle Ad j ustm ent L ever.

Adjusts the main handles angle.

9. Solution T ank Dr ain Hose.

10. A ccessory T ool Connection.

ac ces s o ry to o l s.

11. A ccessory Ho s e Co nnec ti o n.

connection for accessory tool.

12. Cord Hook.

VI EW: FRON T of MACHIN E

. Turns vacuum motor on and off.

Controls the amount of

Protects the

Solut ion connection for

Hose

VIEW: REAR of MACHINE

5

6

4

12

8

Recovery

Tank

Solution

Tank

10

11

Dome

Vacuum

Shoe / Brush

Housing

9

NOTE: Attach strain relief/cord

TTACH STRAIN RELIEF/CORD RETAINER TO

retainer to the power cord.

THE POWER CORD.

Make a loop in power cord approximately

1.

12” from strain relief on machine.

Slide cord loop through slot

2.

in retainer arm. Pull slack

cord back through slot to

secure. Attach retainer to

handle.

7

EXP 98363 08/25/04

3-2

Page 10

OPERATIONS

OPERATING INSTRUCTIONS

A. FILLING THE SOLUTION TANK:

1. Remove clea r dome from recovery tank.

2. Lift upper recovery tank from machine and

set aside.

3. Use a clean bucket or hose to fill solution

tank with hot water. The solution tank holds

4 gallons (15.2 liters) of cleaning solution.

Do not use the recovery tank to fill the solution

tank. Sediment in the recovery tank can damage

the solution pump and clog the spray jets,

rendering the machine inoperable.

4. Add a non-fo aming concentrate for use in

hot water extractors at the proportions noted

on the container.

Note: Periodically operate the extractor with only hot

water to remove chemical residue in carpet.

To avoid possible distortion of the polyethylene

solution/recovery tanks, DO NOT USE WATER

WITH A TEMPERATURE THAT EXCEEDS 140°F

(60°C).

5. Place recovery tank back on machine.

6. Place dome on recovery ta nk. Make sure

dome is seated correctly to ensure proper

vacuum seal.

Use only the suitable chemicals listed in the

Chemical Section. Using incompatible

chemicals will damage the machine. Carefully

read ingredients on manufacturer’s label before

using any product in this machine.

OPERATING THE MACHINE

1. Vacuum the carpet and make sure it is cleared

of surface debris before cleaning.

2. Plug power cord into a grounded wall outlet.

Defeating the grounding pin on the power cord

can result in a severe electrical shock.

3. Turn on the pump, brush and vacuum switches,

listening for each motor to turn on.

NOTE: The vacuum and the brush are protected by

circuit breakers located on the back panel, below

their respective switch.

NOTE: If either of these motors does not respond to

being switched on, reset the circuit breakers by

pressing them in, and attempt to switch the machine

on again.

NOTE: If solution does not dispense in an even

pattern across the width of the machine, the spray

jet may be clogged. Tilt the machine back and

remove the spray tip by pushing in and turning it

one quarter turn. Wash it thoroughly, and blow dry.

NOTE: Do not use pins, wire, etc. to clean spray jet

nozzle as this will deform the jet and destroy the

spray pattern.

6. Begin with the machine at the edge of the

carpet. Actuate the solution lever while pulling

the machine backwards. Release solution lever

at least 12 inches before the end of each

cleaning pass. This will ensure all dispensed

cleaning solution is extracted from carpet.

While operating machine, check for excessive

foam buildup in the recovery tank. If excessive

foam is present, add a defoamer solution to

recovery tank, or empty tank.

7. Empty recovery tank when approximately 3/4

full. If the recovery tank is overfilled, the water

will drain back onto the carpet when the vacuum

is switched off.

8. Ventilate area after carpet has been cleaned.

Keep children and pets away and do not walk

on carpet until it is dry.

A Windblower™ fan can be used to reduce drying time.

OPERATING MACHINE WITH

ACCESSORY TOOLS

This extractor is easily adapted for use with Windsor

accessory tools: Contact Customer Service for details.

1. Lift flap on the front of the vac shoe and insert

hose cuff into the vac shoe, ensuring that there is

a tight fit.

2. Attach the solution hose from accessory tool to the

brass solution fitting on the front of machine.

3. Switch on the pump and the vacuum. The

application of cleaning solution is now controlled

by the lever on the accessory tool.

Do not switch on brush when operating the

machine with accessory tools. Carpet damage

may occur.

NOTE: The solution pump is not intended to run dry.

When using the extractor for vacuum pick-up only,

insure that the pump switch is turned off.

3-3

EXP 98363 08/25/04

Page 11

PROTECT FROM FREEZING

If it becomes necessary to store in temperatures that

could drop below 40°F, the pumping system, hoses

and valves must be protected from freezing with a

methyl hydrate window washer antifreeze solution.

NOTE: Do not use ethylene glycol or cooling system

antifreezes.

1. Add one gallon of window washer antifreeze to

the supply tank.

2. Turn on pump switch and spray until the

antifreeze solution fills the solution lines.

3. Drain the leftover antifreeze from the supply tank.

Always allow the unit to reach room temperature

before filling with hot water or operating.

4. Before operation be sure to flush system

completely. Failure to do so after winterizing

machine will damage carpet.

DAILY/REGULAR MAINTENANCE

! WARNING

Before making any adjustments or repairs to the

machine, disconnect the power cord from the

electrical source.

1. Empty unused cleaning solution from the

solution tank.

2. Inspect and clean filter screens in solution tank,

and on top of tube in recovery tank.

3. Flush pumping system with 1 or 2 gallons of

clean, hot water.

4. Check spray jet for full spray pattern.

5. Empty the recovery tank and rinse with clean water.

6. Check for and remove any lint or debris around

brush and vac shoe.

PERIODIC MAINTENANCE

1. After every 25 hours of operation, flush a white

vinegar solution (ONE quart vinegar to two

gallons of water) or anti-browning solution (mixed

as directed) through the extractor. This will

prevent build-up of alkaline residue in the system.

2. If the spray jet becomes clogged, remove the

spray tip, wash it thoroughly, and blow dry.

NOTE: Do not use pins, wire, etc. to clean spray jet

nozzle as this will deform the jet and destroy the spray

pattern.

MAINTENANCE

3. Periodically inspect all hoses, electrical cables, filters,

gaskets and connections on your machine. Frayed

or cracked hoses should be repaired or replaced to

eliminate vacuum or solution pressure loss.

4. The electrical cable must be well insulated, if the

cable insulation is broken or frayed, repair or

replace it immediately. Don't take chances with

electrical fire or shock.

5. The filter in the bottom of the solution tank must

be clean to allow free flow of cleaning solution.

The screen filter on the vacuum tube in the

recovery tank must be free of lint buildup to

ensure full vacuum strength.

6. The dome gasket must be properly seated and

free of damage to create the air seal needed to

extract water.

MAINTENANCE INSTRUCTIONS

! WARNING

Remove machine power cord from electrical

source before making any adjustments or repairs

to the machine.

! WARNING

Only qualified maintenance personnel are to

perform repairs.

BRUSH ASSEMBLY

1. Situate machine in order to access bottom cover.

Remove screws (6) and bottom cover. Remov e

screws (3) and belt cover.

2. Loosen nuts at brush motor and slide motor

forward to reduce belt tension. Remove belt.

3. Remove lower brush stop on belt side (closest to

you with machine upside down) and rotate black

plastic finger guard toward rear of machine.

4. Remove one screw holding each brush bearing

to brush bracket.

5. With the blade of a screw driver, bend bearings

inward enough to disengage locating tabs.

6. Slide brush, axle, and bearing out of brush bracket.

7. Inspect/replace brush and bearings as required.

The brush is equipped with yellow wear indicator

Bristles. The brush should be replaced when it

wears down to the height of the yellow bristles.

8. When reinstalling brush, check belt for proper tension.

EXP 98363 08/25/04

4-1

Page 12

MAINTENANCE

2

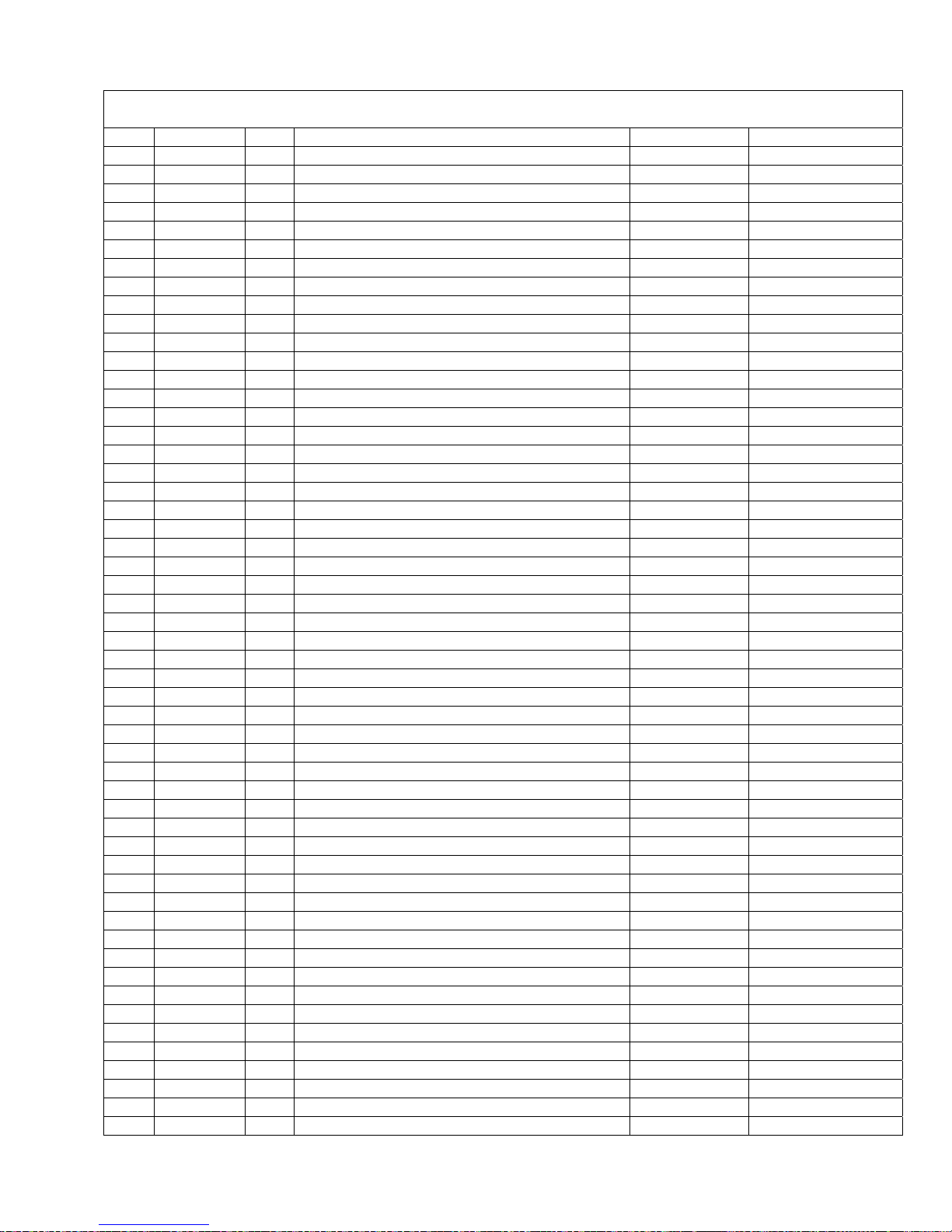

SERVICE SCHEDULE

Check machine for cord damage

Check recovery dome and gasket for

damage and cleanliness

Check brush – should be clean with no

lint or strings attached

Inspect vac shoe for blockage; remove

fibers with coat hanger, etc.

Check hoses for wear, blockages, or

damage

Check handles, switches, and knobs

for damage

Check vac motor intake filter and clean

Run one gallon of water through

system

Clean out recovery tank and check

float valve to make sure it moves freely

Clean out solution tank and remove

and clean vacuum intake screen

Clean outside of all tanks and check for

damage

Run vac motor for at least one minute

to allow motor to dry

Store with dome off tank to allow the

tank to dry

Check all bearings for noise

Check all gaskets for wear and leakage

Check vacuum intake screen for

damage; replace if necessary

Check pump pressure; observe spray

pattern and check with gauge if

necessary

Check and clean solution screen

Check belts for wear and replace as

necessary

Check brush for wear; ensure bristles

are not damaged

Check cables for fraying

Check the spray bar (manifold) for

damage; replace if broken or bent

Check condition of vac shoe and frame

for damage

Check overall performance of machine

Check vac motor carbon brushe s

MAINTENANCE DAILY WEEKLY QUARTERLY

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

4-

EXP 98363 08/25/04

Page 13

TO ACCESS PUMP AND BRUSH MOTOR

1. Situate machine in order to access bottom

cover. Remove screws (6) and bottom cover.

2. To remove brush motor, loosen nuts at brush

motor and slide motor forward to reduce belt

tension. Remove belt. Continue loosening nuts

at brush motor until free from brush bracket.

Disconnect wires.

3. To remove pump, loosen screws holding pump

mounting bracket to casting and remove as one

unit. Lift pump and mounting bracket up to

gain access to all hose clamps which need to

be removed before pump is free from machine.

Disconnect wires.

SOLUTION VALVE CABLE ADJUSTMENT

The solution valve cable has been factory set so that

action of the solution lever moves the valve from

fully closed to fully open. As the machine operates

the cable will stretch and the lever will not be able to

fully open the valve. The play in the solution lever

should be checked periodically and adjusted when

needed as described below.

1. Loosen the lock nut at the point where the

cable enters the lever housing on the

machine handle.

2. Turn the threaded end of the cable sleeve

to adjust. Threading the end further into the

housing will slacken the cable, increasing

the play in the lever. Threading the end out

of the housing will tighten the cable,

decreasing the play in the lever.

3. Tighten the locking nut against the housing

after adjusting the play as required.

4. If there is not enough thread adjustment

available, the cable length can be adjusted

directly at its connection to the solution

valve. This is accessed by removing the

back control panel.

MAINTENANCE

SPRAY JET

Note: To prevent a clogged jet due to alkali build-up,

the spray system should be flushed with 1 to 2

gallons of clean hot water at the end of each day.

1. Situate machine in order to access bottom

cover.

2. The machine is equipped with a ”Quick

Change” jet that can be easily removed for

cleaning. To remove- push jet in and rotate

1/4 turn.

3. Wash jet and blow dry. Do not use pins or

wire to remove obstruction as this will change

spray pattern.

EXP 98363 08-25-04

4-3

Page 14

MAINTENANCE

4

ONLY QUALIFIED MAINTENANCE PERSONNEL

ARE TO PERFORM THE FOLLOWING REPAIRS.

VACUUM MOTOR REPLACEMENT

1. Turn off all switches and unplug machine.

2. Remove recovery tank.

3. Remove the 5 screws holding the vacuum motor

cover to the solution tank.

4. Locate the vacuum motor wires an d disconnect

at the connector.

5. Remove the vacuum motor.

6. Reverse process to install.

Make sure the excess wire lengths do not get

pinched in the gaskets which seal the vac motor.

If need be, remove the rear control panel and pull

excess lead length out of the vac motor

compartment.

The vac motor is protected by a circuit breaker

located in the switch panel. The breaker will only

trip under conditions of abuse.

Vacuum Motor Carbon Brushes Replacement (Windsor)

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a

qualified service center.

Important:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will dama ge

motor if brushes are allowed to wear away completely.

Periodically check the length of the carbon brushes. Replace

both carbon brushes when either is less than 3/8" (9.5mm)

long.

End Cap

WARNING: The green

ground wire must be

attached for safe operation.

See wiring diagram.

3

[9.5mm]

8

Vacuum Motor Carbon Brushes Replacement (Ametek)

End Cap

Carbon

Brushes

Note: When replacing carbon brushes loosen wire terminal

BEFORE removing screws on bracket.

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a

qualified service center.

Important:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will dama ge

motor if brushes are allowed to wear away completely.

WARNING: The green

ground wire must be

attached for safe operation.

See wiring diagram.

Wire

Terminal

Note:

Place

stop in

groove.

Wire Terminal

3/8 (9.5mm)

Periodically check the length of the carbon brushes. Replace

both carbon brushes when either is less than 3/8" (9.5mm)

long.

4-

EXP 980363 08/25/04

Page 15

WIRING DIAGRAM

115V EXPERT

ORG

BLK

15

EXP 98363 08/25/04

4-5

Page 16

TROUBLESHOOTING CHART

PROBLEM CAUSE SOLUTION

No Power, Nothing

Runs

Vacuum Motor Will Not

Run

Vacuum Motor Runs

But Suction Is Poor

Poor Or No Water Flow

(Carpet Is Streaky)

Brush Does Not Spin

Accessory Tool Fitting

Difficult to Connect

Is the cord plugged in. Plug in cord.

Circuit breaker tripped in building. Reset breaker

Faulty switch. Call for service.

Faulty power cord or pigtail. Call for service.

Vacuum circuit breaker tripped. Reset breaker

Faulty main vacuum switch. Call for service.

Loose wiring. Call for service.

Faulty vac motor. Call for service.

Debris lodged in vac shoe. Remove debris from vac shoe.

Dome gasket defective or missing. Replace as necessary.

Vacuum hose cracked or hose cuff loose. Replace or repair as necessary.

Recovery tank full / float ball stuck in the

up position.

Main pump switch off. Turn on.

Jets clogged or missing. Clean using a vinegar /water solution or

Solution filter clogged. Drain solution tank and clean solution

Faulty solenoid. Call for service.

Brush switch off. Turn on brush switch.

Brush circuit breaker tripped. Reset circuit breaker.

Brush belt broken. Replace as necessary.

Faulty brush motor. Call for service.

Corrosion on fitting.

Turn off vac motor. Drain and rinse

recovery tank.

replace.

filter.

Clean with steel wool.

Remove and soak in acetic acid (white

vinegar).

Lubricate lightly with silicone base

lubricant.

4-6

EXP 98363 08/25/04

Page 17

TROUBLESHOOTING CHART

PROBLEM CAUSE SOLUTION

Belt broken.

Brush Not Turning

Worn Bearings

Carpet Not Getting

Clean

Carpet Too Wet

Carpet Not Getting Wet

Faulty switch. Replace.

Faulty circuit breaker. Replace

Faulty brush motor.

Squealing or grinding sound in brush

housing.

Severe soil conditions

Worn spray jet(s)

Solution filter screen clogged.

Spray jet(s) clogged.

Pump not running.

Solution valve adjustment.

Remove belt cover on right side of

machine.

Inspect belt.

Replace if necessary.

If the belt, circuit breaker, and switch

have been tested and found to be in

good working order, the brush motor

may need to be replaced.

Replace bearings.

Make several passes at right angles to

each other.

Use a pre-spray.

Replace spray jets which are producing

more than a fine mist.

Clean solution filter screen located

inside lower tank near the front.

Clean or replace jets. Do not use a

wire to clean jet. Damaged jets will

cause over-saturation.

Check for and correct any loose wires.

Repair or replace.

Adjust solution valve cable until valve

operates when handle is pulled.

Align slit in jet parallel with center line

of brush.

EXP 98363 08/25/04

4-7

Page 18

VAC/SOLUTION TANK/CONTROL PANEL

“-“ IN LOWER CORNER

9

8

7

6

10

11

44

47

46

50

43

26

25 49

48

45

51

1

*

2

1

52

21

22

23

1

40

39

4

3

25

19

5

16

24

17

20

18

14

15

19

13

12

42

41

29

28

5-1

32

31

30

98363 12/04/04

33

36

34

38

35

37

27

25

26

Page 19

REF PART NO. QTY DESCRIPTION

1 57104 4 NUT, #10-32 KEPS

2 67029 1 RECTIFIER, BRIDGE

3 14622 1 BREAKER, 1.5A CIRCUIT 10000443236

4 14020 1 TERMINAL BLOCK

5 57116 2 NUT, #6-32 KEPS

6 14700 1 BREAKER, 15A 250 VAC 50 VDC 1000001018

7 87100 1 WASHER, 3/8 INT. LOCK THIN

8 500225 1 LABEL, CIRCUIT BREAKER VAC

9 14942 2 COVER, CIRCUIT BREAKER

10 70595 1 SCREW, 10-32 X 1 PHMS GRN

11 70211 1 SCR, 10-32 X 3/4 PH. BLK NYLON

12 70235 2 SCREW, 6-32 X 1.0 PH BLK NYLON

13 500226 1 LABEL, CIRCUIT BREAKER BRUSH

14 23664 1 CORD ASM, 115V

15 73710 1 STRAIN RELIEF, PG11 METRIC TRUMPET

16 72069 3 SWITCH, 125V DPDT

17 27417 1 CORD, 1/8” X 12”

18 70547 1 SCREW, #10-32 X 1 PPHMS BLK

19 70532 3 SCREW, 10-32 X 1/2 PHMS BLK

20 57208 1 NUT PG11 METAL, 1.024 OD X 0.73 ID

21 27376 3 CLIP, SWITCH RETAINING

22 880041 1 WIRE ASM, PANEL TO BASE

23 20086 1 CLAMP, CORD

24 70222 2 SCR, #8 X ½ PPHST BLK

25 87189 13 WASHER, .2 ID X .5 OD BLK SS

26 70745 11 SCR, #10-5/8 PPHST HI LO BLK

27 27787 1 COVER, REAR (CONTROL PANEL)

28 35182 4 GASKET, FRAME

29 70393 4 SET SCR, 1/4-20 X 1.25L

30 70627 4 SCR, 1/4 X 1/2 PPHST HI-LO

31 20035 1 CLAMP, 7/16 DIA. NYLON UL 1000028686

32 62717 2 PLATE, AXLE EXP

33 34331 1 FRAME/SOL EXP II

34 73864 1 STRAINER, 3/8” NPT 60 MESH

35 35222 1 GASKET, 2 ID X 2.75 X 3/8 THK PORON

36 50746 1 LABEL, WIRING DIAGRAM

37 70517 4 SCREW, 8-32 X 1/2 FHMS SS

38 51254 2 LOCK, HANDLE EXPERT TANK

39 50776 1 LABEL, FOR SAFETY

40 35193 1 GASKET, REAR COVER

41 03102 1 AXLE, WHEEL

42 87146 2 WASHER, 1/2 ID X 1” OD X .08” NYLON

43 89507 2 WHEEL, 8” GREY (HOOSIER)

44 57196 2 HUBCAP, 1/2” DIA

45 53771 1 VAC MOTOR ASM, 115V EXP.

45A 41258 - BRUSH SET, 120V 5.7 VAC, AMETEK SERVICE ONLY

45B 140687 - BRUSH SET, 120V VAC, WINDSOR 1000121568 SERVICE ONLY

46 39276 1 HOSE, 1.5” X 14” VAC

47 27759 1 CUFF, 1.5” BLACK HOSE

48 35169 1 GASKET, VAC COVER

49 27631 1 COVER, VAC MOTOR

50 35175 2 GASKET, TANK TO VAC COVER

51 27632 1 CAP, VAC MOTOR

52 500551 1 LABEL, CONTROL PANEL MAIN

VAC/SOLUTION TANK/CONTROL PANEL PARTS LIST

SERIAL NO.

FROM

98363 08/14/07

NOTES:

5-2

Page 20

BRUSH/BRUSH MOTOR/FRAME

5-3

EXP 98363 08/25/04

Page 21

BRUSH/BRUSH MOTOR/FRAME PARTS LIST

REF PART NO. QTY DESCRIPTION

1 41279 1 HOUSING, BRUSH W/VAC SHOE

2 27674 1 COVER, ACCESS PORT

3 39276 REF HOSE, 1.5 BLK VAC X 14”

4 35195 1 GASKET, .25 X .75 X 2.00 L

5 27759 1 CUFF, 1.5” BLACK HOSE

6 67138 1 RING, 3/8 EXTERNAL SNAP

7 57104 2 NUT, 10-32 W/STAR WASHER SHOE

8 57030 6 NUT, 10-32 NYLOCK

9 70557 4 SCR, 10-32 X 1” FHMS BLK

10 70532 5 SCR, 10-32 X 1/2 PPHMS BLACK

11 27636 1 COVER, BELT

12 20016 1 CLAMP, 1/4 ID HOSE

13 87139 4 WASHER, 3/16 FLAT

14 09113 1 BEARING, RIGHT

15 70740 3 SCR, 10-32 X 1/2 PTHMS BLK

16 64085 1 PULLEY, MOTOR

17 53608 1 MOTOR ASM, BRUSH DRIVE

18 140036 1 BRACKET ASM, BRUSH MOTOR

19 09114 1 BEARING, LEFT

20 140040 1 BRUSH

21 64086 1 PULLEY, BRUSH

22 11039 1 BELT, BRUSH DRIVE

23 03084 1 AXLE, BRUSH

24 35176 1 GASKET, BOTTOM COVER

25 39468 REF HOSE, ¼ ID NYLOBRD X 11.5”

26 27639 1 COVER, BOTTOM

27 35171 1 GASKET, ACCESS PORT COVER

28 140087 1 BULKHEAD, 1/4 MPT X 1/4 BARB

29 56012 1 NIPPLE, 1/4 FPT QD

30 70303 2 SHOULDER BOLT, 1/4 OD X 5/8 L

31 - - OPEN

32 09117 2 BEARING, BRUSH BRACKET

33 57018 2 NUT, 10-24 HEX LOCK

34 70578 2 SCREW, 8-32 X 1” FHMS SS

35 70031 2 SCR, 10-32 X 1/4 PPHMS

36 87003 1 WASHER, 3/8 ID X 7/8 OD SS

37 62556 1 PLATE, GUARD ON LEFT SIDE ONLY

38 - - OPEN

39 70595 1 SCR, 10-32 X 1.0 PHMS GRN

40 20086 1 CLAMP, CORD

41 73781 4 HOSE, 5/16 X 3/16 ID CLR VINYL

42 70351 4 SCR, 10-32 X 3/8 HHTR W/STAR

43 70604 1 SCR, 10-32 X 5/8 PHMS BLK

44 87189 1 WASHER, .2 ID X .5 OD BLK SS

SERIAL NO.

FROM

NOTES:

NOTE: The left and right sides of the machine are assigned as if

standing behind the machine in the operator’s position.

EXP 98363 08/25/04

5-4

Page 22

PUMP ASSEMBLY

5-5

EXP 98363 08/25/04

Page 23

PUMP ASSEMBLY PARTS LIST

REF PART NO. QTY DESCRIPTION

1 20016 2 CLAMP, 1/4 ID HOSE

2 39510 1 HOSE, 3/8 WIREBOUND X 3”

3 39468 1 HOSE, 1/4 NYLOBRAID X 11.5”

4 39508 1 HOSE, 1/4 NYLOBRAID X 15”

5 70484 2 SCR, 10-32 X 5/8 PPHMS SS

6 87016 2 WASHER, #10 LOCK EXT. STAR

7 140034 1 BRACKET, PUMP

8 40009 1 HOSEBARB, 1/4 MPT X 1/4

9 40065 1

10 65164 1 PUMP ASM, EXPERT

11 70581 2 SCR, 10-32 X 3/8 HHTFW/WASH

12 78024 1 TEE, 1/4 BRANCH

13 40033 1

14 20042 1 CLAMP, 3/8 (D-SLOT)

HOSEBARB, 1/4 MPT X 1/4 X 90°

HOSEBARB, 1/4 MPT X 3/8 90°

SERIAL NO.

FROM

NOTES:

EXP 98363 08/25/04

5-6

Page 24

SOLUTION LEVER/MAIN HANDLE

5-7

EXP 98363 08/25/04

Page 25

SOLUTION LEVER/MAIN HANDLE PARTS LIST

REF PART NO. QTY DESCRIPTION

1 57238 3 NUT, 10-24 JOINT CONNECTOR BLK

2 51251 1 LEVER, SOLUTION

3 41302 2 HOUSING, SOLUTION LEVER

4 70537 3 SCR, 10-24 TRUSS HEAD BLK

5 36046 1 GRIP, HANDLE X 13”

6 38247 1 HANDLE

7 27785 1 CABLE, VALVE SOLUTION 27-1/2 LG

8 87029 1 WASHER, 5/16 FLAT SAE 441847 WAS 57138 (QTY 1)

9 57234 1 NUT, 3/8-16 SQUARE

10 57022 1 NUT, 3/8-16 HEX NYLOCK

11 87080 1 WASHER, .52 1.25 FLAT PLTD

12 87016 3 WASHER, #10 LOCK

13 87139 2 WASHER, 3/16 FLAT USS 441847 (QTY WAS 3)

14 67397 1 ROD, HANDLE ADJUSTMENT EXP II

15 80604 1 RING, RUE COTTER 1/4”

16 51142 1 LEVER, HANDLE LOCK

17 66133 1 PIN, CLEVIS

18 51184 2 LOCK, HANDLE ADJUSTMENT

19 62716 1 PLATE, STOP EXPT

20 73735 1 SPACER, 1.0 OD X .26 ID X 1 BLK NYL

21 70556 1 SCREW, 1/4-20 X 1.5 SS

22 84153 1 VALVE, KINGSTEN

23 40065 2

24 - - OPEN

25 - - OPEN

26 57018 1 NUT, 10-24 LOCK

27 89144 1 WELDMENT, LEVER VALVE EXP

28 41144 1 HOOK, CORD

29 70361 2 SCR, #10-32 X 1/2 PHTR

30 50729 1 CARD, INSTRUCTION

31 27417 1 CORD, 1/8 X 12”

32 73169 1 STRAIN RELIEF, CORD HOOK

33 99620 7” HEAT SHRINK, 3/8 ID UL/CSA

34 70031 4 SCR, 10-32 X 1/4 PPHMS PLTD

35 40043 1

36 39508 1 HOSE, 1/4 NYLOBRAID 15”

37 39507 1 HOSE, 1/4 NYLOBRAID 17”

38 88551 1 WIRE ASM, 19” GRN/18 78008 X 78008

39 20016 2 CLAMP, 1/4 ID HOSE

40 73866 1 SPACER, 1/2 OD X .219 ID X 1/2 NYLON

41 140308 1 BRACKET, VALVE EXPERT

42 70745 3 SCR, #10-5/8 PPHST HI LO BLK

43 66086 1 PIN, ROLL 3/16 X 5/8

HOSEBARB, 1/4 MPT X 1/4 90°

HOSEBARB, 3/8 MPT X 3/8 90° NYLON BLK

SERIAL

NO.

NOTES:

EXP 98363 02/23/05

5-8

Page 26

RECOVERY TANK

8

5

4(3)

9

TO REAR

COVER

1

7

10

3

2

6

11

5-9

EXP 98363 08/25/04

Page 27

RECOVERY TANK PARTS LIST

REF PART NO. QTY DESCRIPTION

1 28050 1 DOME

2 35178 1 GASKET, DOME

3 62465 1 PLATE, COVER

4 70114 3 SCR, 10-32 X 3/4 POLYFAST

5 35167 1 GASKET, COVER

6 75212 1 TANK, RECOVERY

7 34140 1 FILTER, VAC INTAKE

8 78162 1 TUBE, 1.5 PVC X 4.88”

9 27417 1 CORD, 1/8 X 1/2”

10 500009 1 LABEL, WARNING

11 500016 1 LABEL, EXPERT

SERIAL NO.

FROM

NOTES:

EXP 98363 08/25/04

5-10

Page 28

SOLUTION PLUMBING/SPRAY JET

5-11

EXP 98363 08/25/04

Page 29

SOLUTION PLUMBING/SPRAY JET PARTS LIST

REF PART NO. QTY DESCRIPTION

1 40069 1 HOSEBARB, 3/8 NPT X 3/8 TEE

2 20016 2 CLAMP, 1/4 ID HOSE

3 20042 1 CLAMP, 3/8 HOSE

4 31028 1

5 39509 1 HOSE, 3/8” CLEAR X 15.5”

6 62800 1 PLATE, GUARD EXPERT

7 40064 1 HOSE BARB, 1/8” FPT X 1/4”

8 - - OPEN

9 44066 1 JET, BRASS MINI-QUICK

10 44052 1 JET BODY, MINI-QUICK W/SEAL

11 - - OPEN

12 87185 1 WASHER, 3/8 SEALING X 3/4 OD

ELBOW, 1/8 45° STREET

SERIAL NO.

FROM

NOTES:

EXP 98363 08/25/04

5-12

Page 30

SPARE PARTS AND ACCESSORIES

PART NO. DESCRIPTION

11039 BELT, BRUSH DRIVE

35178 GASKET, DOME

35171 GASKET, ACCESSORY PORT

140040 BRUSH, EXP

44066 JET, 11004 BRASS MINI-QUICK

44051 JET SEAL, MINI-QUICK

44052 JET BODY, MINI-QUICK W/SEAL

35175 GASKET, TANK TO VAC COVER

50729 INSTRUCTION CARD

09114 BEARING, LEFT

09113 BEARING, RIGHT

64085 BRUSH MOTOR PULLEY

64086 BRUSH PULLEY

35176 GASKET, BOTTOM COVER

73169 STRAIN RELIEF, CORD HOOK

34140 FILTER, VAC INTAKE

41258 BRUSH SET, 120V 5.7 VAC, AMETEK

140687 BRUSH SET, 120V VAC, WINDSOR

SERIAL #

FROM

ACCESSORIES

89227 STANDARD WAND

SPW SPOTTING WAND

HT HANDTOOL W/1/4 MQD

DHTK DHT ACCESSORY KIT

DDH DOUBLE DRY HAND TOOL

*

5-13

EXP 98363 08/25/04

Loading...

Loading...