Page 1

POWER BRUSH

ESCORT

115V

(OBS)

Page

1

of

8

Models

ESWEPB

1

INDUSTRIES,

INC.,

1351

W.

Stanford

Ave.,

Enalewood,

CO

80110

USA

@

303/762-1800

FAX

303/762-0817

Page 2

Page

2

of

8

POWER

BRUSH

ESCORT

115V

(OBS)

INSPECTION

Carefuii un ack and inspect your

ex

-

tractor

kr

slippin damage. Each unit

is operated and

tforoughiy inspected

before ship ing and any damage is the

responsibil&

01

the carrier who should

be notified immediately.

ELECTRICAL

This extractor o erates on a standard

15

amp,

115

VOIPAC circult: Voltages

below

105

volts

or

above

126

volts could

cause serious damage to motors.

‘230

volt

50

hz model available.

WARNING:

Make sure you are using

the correct voltage as

speclfied on

nameplate before connecting machine

power cord to outlet.

GROUNDING INSTRUCTIONS

To protect the operator from electric

shock, this machine must be grounded

while in use. The machine is equipped

with an approved

threeconductor power

cord and three

-

prong grounding type

plug to

fit the proper grounding

t

e

re

-

ceptacle. The vacuum power corJgas a

plug as shown in Fi

.

A.

if a receptacle

connected to the

efectricai ground as

shown in Fi

A

is not available use an

adapter as

88own In Fig.

C.

The

ada ter

must be connected to an

eiectrrcai

ground in the electrical outlet, using

metal screw shown in Fig.

B.

wARN/NG:

To avoid electric shock,

use indoors only.

EXTENSION CORDS

if

an extension cord is used, the wire

size must be at least one

size

iar er

than the ower cord on the machfne

and must

ge

limited to

50

feet in length.

The ESCORT

Is equipped with a

50

ft.

14/3

power cord.

EQUIPMENT SETUP

NOTE:

Attach strain reiieflcord retainer

to power cord.

1.

Make loop in

power cord a

proximately

14’;

rom twist lock

receptacle end.

2

Slide cord loop

through slot in

retainer and over

retainer arm.

Pull

slack cord back

through slot

to

secure.

3.

Plug power cable from machine into

properly grounded

wail outlet.

4.

Using a clean container,

fill

solution

tank with hot water. The maximum

capaclty

of

the ESCORT is 7 gallons.

Mix in a nonfoamlng cleaning con

-

centrate for use in hot water extrac

-

tion machines at the proportions

noted on the container for various

carpet soil conditions.

NOTE:

When using a powder cleaner,

premix with hot water in clean

con-

talner before adding to solution tank.

OPERATING THE ESCORT

NOTE:

Vacuum the car et and make

sure

it is cleared of su&e debris be

-

fore starting the cleaning process.

NOTE:

Pump

Prlmfng:

If the machine

has been in

storage or the pump runs

dry

-

air entrapment within the solution

line can occur. This is alleviated b de

pressing the tip of the auxiliary nrppie

momentarily while the pump is running.

Depress

plunger with pump running.

I

Hold until pressure begins.

1

1.

Dispense solution

using either

the

continuous flow sw%ch

for

lay open

areas

or

the

intermlttent 8w toh for

amaiier

mom

confined

emas

ObSninR

if mac ine is equipped with ower

brush Switch on

power

brusR,

de

press pedal to

Loww

brush head

8s-

sembly. Waikin backwards move the

machine

over

tie area to k cleaned.

Turn solution

off

about 8 inchw

be

fore the end

of

each

paw

to Insure

ail solution is removed from the car

-

pet. When through oieanlng depress

edai to

Re-

brush head arrembly.

!i

witch

off

vac and brueh ewitches.

WARNING:

Do

not leave power

brush running when machine is not

in cleaning mode. Damage to

carpet

could occur.

2.

As you work, check to

see

if there is

a foam buiidu in the recovery tank.

if there is a

&am buildup, turn the

machine

off

and

add

the recommended

amount of a defoaming solution to

the recovery tank.

NOTE:

Never put defoamer in the

solution tank.

WARNING:

An overflow of foam

into the vacuum intake can damage

the

vac motor. Always

be

aware of

the waste water level in the recovery

tank. When the tank is about

three-

quarters full, turn

off

the machine, re-

move drain hose from keeper and

empty dirty water into bucket

or

floor

drain.

3.

When machine runs out

of

cieanln

solution , turn off the machine an!

refill the solution tank. Turn machine

on and continue cleaning process.

OPERATING THE ESCORT

WITH

ACCESSORY

TOOLS

The ESCORT can easii

be

adapted for

use with

Windsor hanJ tools and floor

tools.

ACCESSORY

TOOL

CARPET

SPRAY

NOTE:

Turn machine off before con

-

necting any accessory tools.

1.

Turn solution control valve from “car-

g.1 spray” to accessory tool.

(See

2

Remove recovery hose from dome

and insert vacuum

hose

for accessory

tool in its place.

3.

Attach solution hose from acco

tool to solution outlet nipple on bax

panel of machine.

4.

Make sure that sufficient amount of

cleaning solution is in solution tank

and that the dome is in place and

ready for operation.

6.

Turn on vacuum and continuous

pump switches.

iagram

3.)

CAUTION:

Do

not switch on

power

brush when using

ESCORT

with

~80ry

tools.

NOTE:

Make sure the soiutlon control

valve

is returned to the “car et

mrav”

wsition

before

usino

dFtT

for &r+t cleaning.

-

WARNING:

Before making any ad

-

justments

or

repairs to the machine

disconnect the

power

cord

from

ekctrka/

source.

1.

Emp unused cieanllrg solution from

soiutlbn tank.

2

inspect and clean filter screen in

solution tank.

3.

Flush pumping system with 1 to

2

gallons

of

clean hot water.

4.

Empty and clean recovery tank with

clean water.

6.

Checkspray

pattern.

jets

daily

for full

6.

Check for and remove any debris or

lint buildup from vac shoe.

7.

On power brueh models

remove

lint

and dirt build

-

up from brush and

housing.

PERIODIC MAINTENANCE

1.

Twice a month flush a white vinegar

soiution one quart vinegar to one

paiion of hot water) or an anti-brown-

ng solution mixed as directed)

through the

E$CORT. This will help

revent buildup of alkaline residue

P

n system.

2

if spray jete become clogged, remove

the spray tips, wash them throughiy

in vinegar and blow dry.

NOTE

Do

not use pins, wires, etc. to

clean jets as this

will

destroy spray

pattern.

2

Page 3

POWER BRUSH ESCORT

11

5V

(OBS)

Page

3

of 8

3.

4.

1.

Remove

(2

tank mounting bolts from

rear

chassls pcinsl. (Refer to Photo

3)

.

Remove recovery tanklvac moto;

if spray jets continue to drip after

solution ump Is turned off, the

so

-

ienoid vate will need cleaning.

(see

MAINTENANCE on Solenoid Valve.) rear chassis panel. assembly.

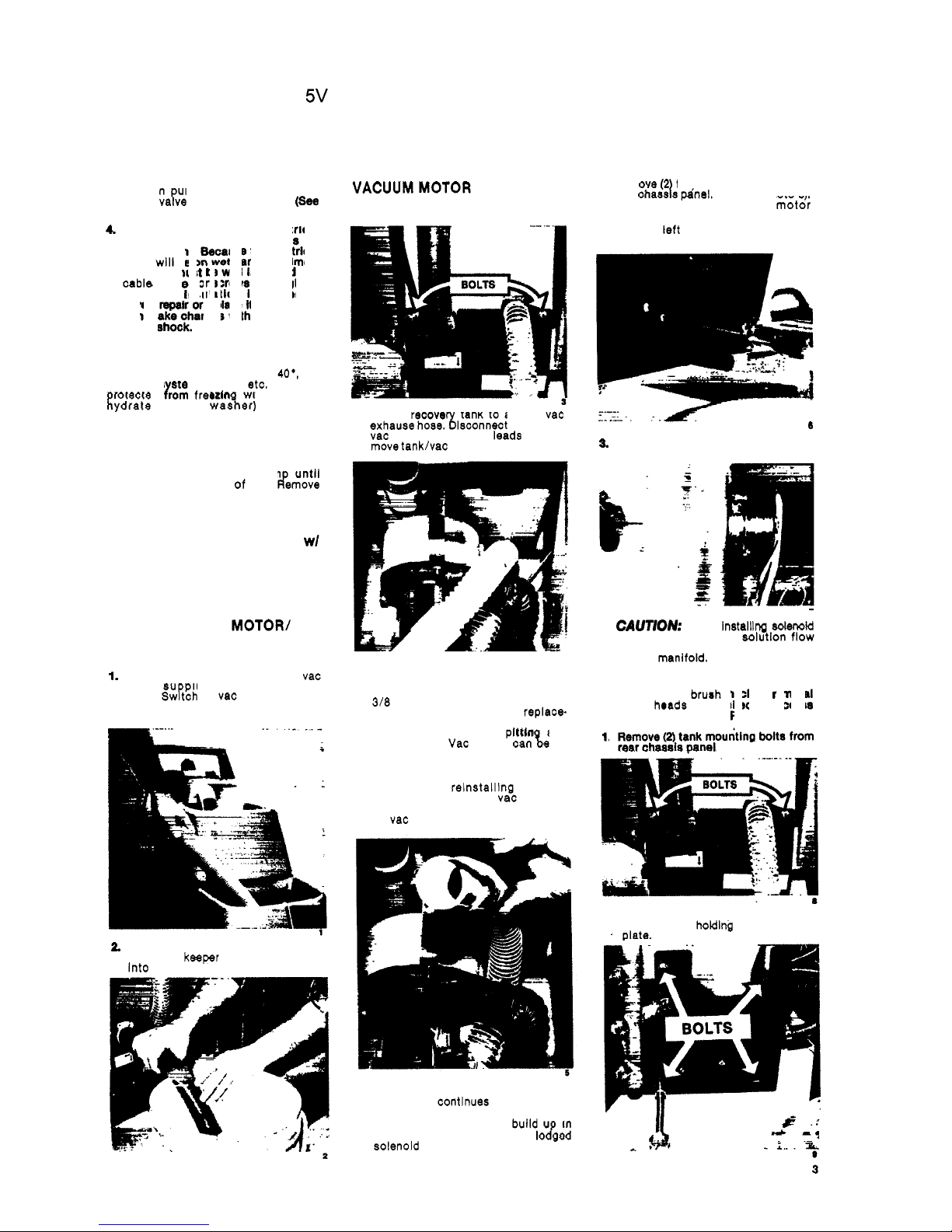

VACUUM

MOTOR

1.

Remove

(2)

tank mounting bolts from

Periodically inspect ail electrical

cables, filters and connections on

your machine. Because the electrical

cable

will lie on wet carpet at times,

the cable must be well insulated and

cabla connector screws kept tight. if

the cable insulation Is broken or

frayed, repair or replace

it

immediately.

Don't take chances with an electrical

fire or shock.

PROTECT

FROM

FREEZING

if it becomes necessary to store the

machine in temperatures below

40*,

the

pumping

s

stem, valves, etc. must be

rotected Lorn freezin with a methyl

Eydrate (window waster) antifreeze

solution.

NOTE:

Do

not

use

ethylene giycoie

or

cooling system antifreeze.

1.

Add window washer antifreeze to the

solution tank. Turn on pum

until

solution sprays out of jets. d'emove

unused portion of antifreeze from

tank.

MAINTENANCE INSTRUCTIONS

FOR

ESCORT AND

ESCORT

wl

POWER

BRUSH

WARNING:

Remove machine power

cord from electrical source before

making any repairs or adjustments to

the machine.

TO ACCESS VAC

MOTOR/

PUMP ASSEMBLY

Remove solution from both tanks.

I.

SOLUTION

TANK

Attach the 4 ft. vac

hose, su plied with machine, to

dome.

Swtch on vac motor and vac

-

uum unused solution into recovery

tank.

2.

RECOVERY TANK

Remove drain

hose from

keeper and empty solution

into bucket

or

floor drain.

2.

Lift up recove tank to access vac

exhause hose.%isconnect hose from

vac motor, motor wire leads and re

-

move tanklvac motor.

2

Remove left wheel to access valve

retaining screws.

6

3.

Remove iniine solenoid valve: Clean,

repair or replace a8 required.

7

4

3.

To inspect motor brushes, remove

brush holder assembly. Brushes

should be replaced when worn to

3/8

inch or after about

250

operating

hours. After second brush

repiace-

ment the armature commutator

should be checked for

pittin and

concentricity.

vac motors can%,

re

-

paired but such repairs should be

made

by

a quaiifled motor repair shop.

NOTE:

When reinstaiiina tanklvac

motor make sure the

vac recovery

hose is routed

ABOVE

exhaust horn

on

vac motor.

SOLENOID VALVE

if the machine contlnues to drlp solution

from manifold after pump is switched

off check for:

(A)

Alkaline build u in

solution lines

(B)

Lint or debris io&d

in solenoid valve.

CAUTION:

When instaiilng

edendd

valve make sure that solution flow

direction as indicated on valve Is

toward

manifold.

PUMP ASSEMBLY

NOTE:

On

power bruah machine removal

of brush

hrads is required to access

pump. (See Power Head Removal)

1.

Remove

(2)

tank mounting bolts from

rear chassis panel.

2

Lay machine on right side and re.

mow

(4)

bolts holding pump mounting

'

date.

Page 4

POWER BRUSH ESCORT

115V

(OBS)

3.

Disconnect pump motor wire leads.

Disconnect

solution

hoses

from

pump

head and remove pump. Refer to

pump drawlng

for

replacement parts.

10

CAUTION:

When reptactn hose

-

barbs on ump head

-

08

NOT

oVERn&N

-

as thls could crack

intake and discharge

~orts

in DumD

-.

..

head.

VAC SHOE

1.

Remove

(4)

bolts holding chassls and

pum plate to tanks. (Refer to Photos

2.

Remove

(3)

bolts hoidin vac shoe/

bracket to soiutlon

tan!. Repair or

reDlace as reaulred.

sas;

NOTE

When relnstalllng a new vac

shoe, proper alignment

of

shoe to

floor must be made.

1.

Install vac shoe and tlghten screws.

Attach chassis and pump plate as

-

sembly to tank and tlghten screws.

2.

Set machine upright on a flat-level

surface (a desk top works well) and

check

vac shoe for level contact

on

the fiat surface.

w

\

lllllll

4

VAC

SHOE

LEVEL

WITH

FLOOR

3.

Make adjustment at axle leveling

screws by tlghtenln

/loosening

both

of the lock nuts unti? shoe Is level.

TRANSPORT WHEELS

1.

Remove screw and hub cap and slide

wheel off axle. Before reinstalling

wheel, clean axle and apply

light

coating of silicone lubricant.

VAC

MOTOR

EXHAUST FILTER

1.

Remove

(4

bolts holding chassis to

tanks.

(Ref)er

to Photos

3

& 9)

2.

Lay machlne on side. Pull chassis

from tanks

to

expose exhaust muffler.

3.

Remove hex nut from

PVC

muffler.

Repair or replace as required.

1s

SWITCH CONTROL PANEL

1.

Remove

(2)

screws holdlng switch

housing to handle.

(EPB

housing

shown)

I

SCREWS

i

2.

Replace switches as required.

SERVICING POWER HEAD

BRUSH MOTORlRECTlFIER

1.

Tilt machine back to rest on handle.

2.

Remove

(6

screws holding motor and

plate to

houslng. Repair/repiace

motor rectifier as needed.

Page

4

of

8

BELT

ADJUSTMENT

1.

When servicing brush motor

or

brush

aseembly alwa

(I

check belt

for

proper

tension. The

LIt should

be

taut to

prevent it

from

sll

pin on cogged

pulleys. To tighten

Lit, pbosen motor

mounting nuts and rotate motor rear

-

ward lust enouah to tlahten belt.

BRUSHlBEARlNQ ASSEMBLY

1.

Remove belt guard.

2

Remove

screw

from

each

end

of brush

shaft and remove brush assembly

from housing. Replace brush

or

bear

-

rings as needed.

19

POWER HEAD

LIFT

CABLE

I.

Remove recovery tanklvac motor

assembly.

2.

Tilt machlne back to rest on handle.

Remove bolt holding cable to

lift

bracket and

(2)

power

head

pivot bolts.

4

Page 5

POWER BRUSH ESCORT

115V

(OBS)

Page 5 of

8

3.

Remove

guide pull bracket assembly

and remove

cableTom pulley.

21

4.

Remove pedal and bracket assernbl

(4

screws). Replace cable as requlred:

22

Reinstall pedal assembly and power

head assembly.

To

adjust cabic

Depress

cable

so

that power head almost touches

vac

shoe

houslng. Raise and lower

power head

with pedals to make sure

that head

will “lock”

In

UP posltion

when pedal

Is depressed.

POWER

HEAD

REMOVAL

1.

Tilt machine back to rest

on

handle.

Remove brush motor and plate

assembly.

(See

Photo 15)

2

Disconnect power cord from rectifier.

Loosen

strain

relief

and pull

cord

from

houslng.

(See

Photo 16)

3.

Remove cable from

lift

bracket and

(2)

pivot bolts.

(See

Photo

20)

4.

Disconnect solution hose from elbow

and

lay head

aside.

PUMP

ASSEMBLY

15

14

12.

WiRlNQ

DIAQRAM

EPB

CHASSIS ASSEMBLY

CONTROL PANEL END

MI#

CHASSISEND

A/-”

WlRlNQ

DIAQRAM ESC 115V

CHASSIS END

987

12

3

1

Q

15

I

CONTROL

PANEL END

PUMP

PARTS

LIST

w

CUTNO.

Duonicrwn

I

1

531 18 Molor 115V

(for

65067)

1A 531 19

Molor

230V

(for

65070)

2 67071

Rectifier/End

Bell

Asm.

3 47075

FanlShroud

Asm.

,

-

4-5-6 47076

Kit.

@se

Rat8

7g-911- 47087

Kll

Pum

Repair

(tor 65067

12

-

13

i

650!0)

10 27225

Bearing

Cover

14 41086

PumpHousing

15A 65071

Pump

Head

Asm.

115V

lfor

65067)

15B

65072

Pump

Head

Asm.

230V

(for

65070)

115/23OV

.

5

Page 6

POWER BRUSH ESCORT

115V

(OBS)

Page

6

of

8

POWER

BRUSH

ASSEMBLY

(EPB

Only)

m/";

I

fL\

66

1A

53146

MOW,

115V

Dc

msh

Drlw

I

19 62134

plate.

BSn

Wor

1

38

87013

WwhM.

114

ID x 5/8

00

I57

70218

ShoulduBoll.318ODx314L

I

39

87026

WMhU,

114St

158

14277

BRcM,R(ahtHulper

16

53147

MOIOT.

WOV

Dc

Brush

Oriw

I

20

31016

OW.

114

NPT

WWl

I

21

40014

Hasbarb.

114

MPT

x

3/8

I

40

70020

SCr.,

1/4-20

X

112

HHMS

I

!?

!?092

Nut.

5/18-18

LDCk

.

--

---

.-

..

.

.

.-

-

.

..

I

._

---.-

.. . _..

.

-I

,.__a__.

,_I

I,

_-_-_

2 - 35071

*!el,

I!!!!

x5

6

Page 7

POWER

BRUSH

ESCORl

r

I

15v

(OBS)

Page

7

of

8

TANK ASSEMBLY (ESWEPB)

37

35

39

Page 8

POWER BRUSH ESCORT

115V

(OBS)

CHASSIS

ASSEMBLY

(ESWEPB)

21'

I

Page 8

of

8

23

30

18 17na 16

I

ESWEPB

CHASSIS

I

WINDSOR

LIMITED

WARRANTY

WINDSOR warrants

to

the original

ur-

chaserluaar

that thm

prc&ct

M

frea

&in

defects in workmanship and materials

under normal

uae

and

senfloe

for

a

perlod

of

me

year

from

date

of

purchask WIND

SOR

will at its option repair

or

re lace

wthout

charge,

acepi

for

trnnsporl'etion

costs

parts that fail under normal

use

and hervice when operated and main

-

tained in accordance with the applicable

operation and instruction manuals This

warranty does not ap

ly

lo

normal wear.

or to items whose

iik

1s

dependent

on

their

use

and care, such as cords,

switches, hoses, rubber parts, electric

motor parts,

etc

Thls limlted warranty

is

in lieu

of

all other

warranties

ex

reased or im lied and

releases

WiNDgOR from all otler obliga

-

tions and liabilities

It

is appllcable only

in

the

U

8

A

and

Canada,

and

Is extended

only

to

the on inal userlpurchaser of

this

product WlhSOR is not

responsible

for

costs

for repairs performed by per

sons other than those specifically

authorized by WINDSOR This warranty

does not ap

ly

to

damage from frans-

portation aterattons by unauthorized

persons

inisuse

or

abuse

of

the equip

-

ment

u;e

of

noncompatible chemicals,

or

dimage

to

property or

loss

of income

due

to

malfunctionin~of the product.

If

a dilficulty develop8 with this machine,

you

should conlac1 the dealer from

whom it

wm purchased

dm

mn

INDUSTRIES,

INC.,

1351

W.

Stanford

Ave.,

Englewood, CO

80110

USA

303/782-1800

FAX

303/782-0817

Loading...

Loading...