Page 1

ELECTRA-MATIC

1

15V

Page 1 of

26

Page 2

ELECTRA-MATIC

11

5V

Page

2

of

26

b

ELECTRA-MATIC

\

XI

\

\

\

\

I

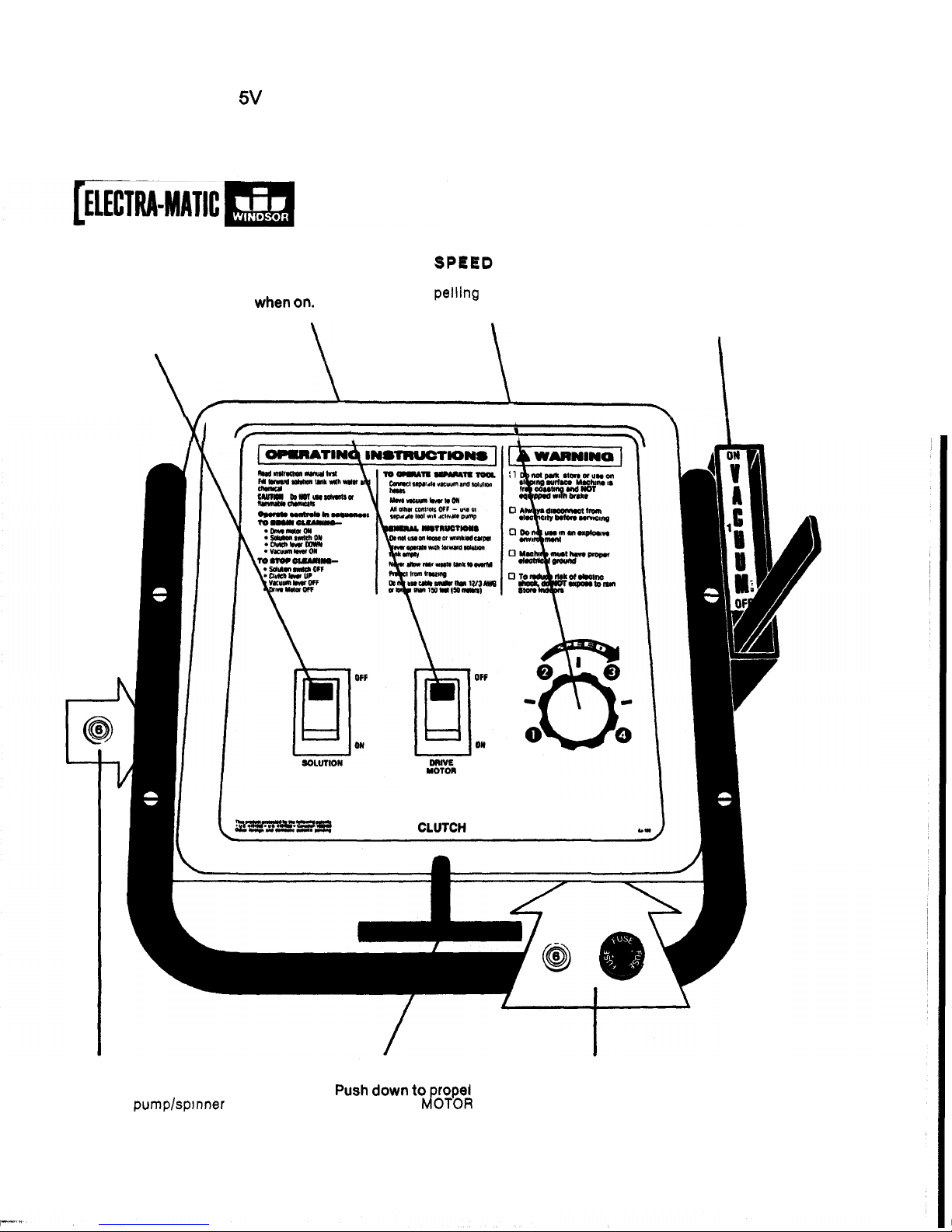

SOLUTION/ DRIVE

MOTOR

SPEJED VACUUM LEVER

THRUSTERJET

Turns on solution motor. Glows red pelling speed from

1

position to lower pickup

pump and THRUSTER

-

when

On.

(stop) to 4 (max.). assembly to carpet as

JET

drive motor.

Glows

red when

on.

motor.

Turns on propelling Control forward pro

-

Release to forward

well

as

start vacuum

\

\

THRUSTERJET CLUTCH DRIVE

MOTOR

LINE

FUSE

Protects pumplspinner drive

when

DRIVE

JOTOR

motor from burn-out. Push to

is

on.

reset after correcting problem.

CIRCUIT BREAKER

Push

down to rope1

AND CIRCUIT BREAKER

Protects drive motor and circuit board.

Replace fuse or push to reset breaker

after correcting problem.

Page 3

ELECTRA-MATIC

115V

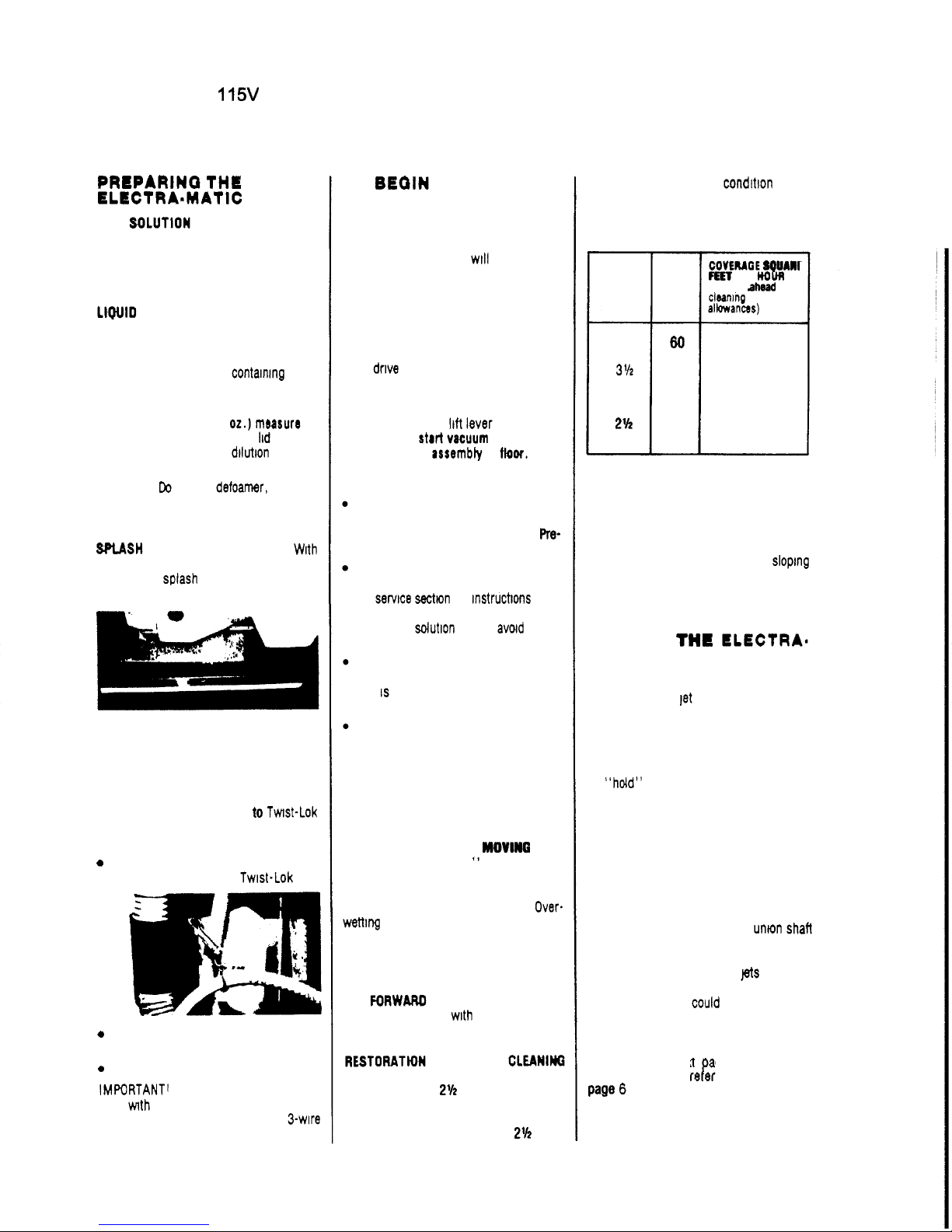

PREPARING

THE

FILL SOLUTlON TANK

to

the desired

level according

to

the marked gauge

inside the tank CAUTION‘ If a bucket

is used

to

fill the tank. be sure that it is

clean

however if a powdered detergent is used,

be sure it is fully dissolved

BEFORE

put

-

ting it in the solution tank

Do

this by

dissolving it in a bucket

contaning about

1

gallon of hot water before emptying it

into the solution tank

You will find a

1

cup

(8

02.)

mersure

on

the

bottom

of the solution tank iid

to

assist

you in making the proper

dilutlon

of

clean

-

ing chemical and water

CAUTION

Do

not

put defoamer. solvents,

spotter or prespray chemicals in the

solution tank

ELECTRA=MATlC

LIQUID

DETERGENTS ARE PREFERRED,

SPLASH

APRON ADJUSTMENT - Wah

machine setting on carpet

to

be cleaned,

adjust each

splash apron to touch top

of

carpet pile

PLACE RECOVERY DOME

atop recovery

tank, being sure that gasket material is

undamaged and making a good seal

with the recovery tank

ATTACH ELECTRIC CABLE

to

TWISt-LOk

connection

at

rear

of

control

panel beneath

operating handle

0

Note that all switches are in

“off”

position when attaching Twist-Lok

0

Attach cable strain reliever as shown

to

prevent electrical problems

0

Plug into grounded wall outlet

IMPORTANTI An extension cable may be

used

Hnth the ELECTRA-MATIC. however,

use nothing less than a

12

gauge, 3-Wire

of not more than

75

feet in length

TO

BEGIN CLEANING:

FOLLOW THE SEQUENCE BELOW.

.

.

1.

Set forward speed with control knob

2.

Press “drive“ motor switch

to

“on”

posdion

-

red light will glow

CAUTION Never turn on drive motor

with clutch lever down, damage to

motor and clutch could result

3.

Begin moving by pressing down on

clutch lever CAUTION Never secure

clutch lever in down position, damage

to

dnve motor and clutch could result

4.

Press thruster jet switch to “on”

position

-

red light will glow

5.

Release vacuum

lift

lever to forward

position

to

start

vacuum

motor,

and

lower

pkkup 8SSembly

to

fkw.

CLEANING TIPS

. . .

GO

SLOW

on very dirty carpet

to

avoid

streaking

Be

prepared

to

make two

cleanings

if

carpet is badly soiled

Pre-

spraying may also be necessary

Narrow bands

of

streaking can result

from a plugged THRUSTERJET nozzle

See

servlce sectlon for instructms Pay

more attention

to

using a clean bucket

when filling

solution tank to amd future

problems

Paths, or wide stripes. over the carpet

can occur with certain types of carpets

This

is due to the “lay”

of

the carpet

fibers

It

will go away when vacuumed

uncleaned stripe

Be

sure

to

overlap enough

to

prevent

WORK AWAY

from the power source

if

possible Begin cleaning next

to

wall

This will allow you

to

always make turns

away from the cable

KEEP ELECTRA-MATIC

MOVINO

when

thruster jets are “on

“

If

it becomes

necessary

to

stop

to

maneuver in a turn

or corner, push the thruster jet switch

to

the

“off”

position CAUTION Over-

wettlng

of

the carpet is likely. or damage

to

the carpet is possible,

if

the ELECTRA

-

MATIC is permitted to stand in one posi

-

tion with the thruster jets on

THE FORWAR0

SPEED

of

the

ELECTRA

-

MATIC

is

controlled mth the knob on the

control panel, numbered from

1

to

4

RESTORATW OR SALVAGE CLEANllsQ

will be best accomplished with the con

-

trol set from

1

to

2%

MAINTENANCE CLEANING

can

be

best

accomplished somewhere from

2%

up

to

Page

3

of

26

4,

depending upon the condition of the

carpel being cleaned.

Forward speeds and approximate cover

-

ages are

COVEMOE

SQUAnl

Far

PER

(Ioun

(Straight

ahmi

SPEED

clming

-

no

FPM

albwances)

4

60

5400

3%

43

3800

3

32

2800

2% 25 2250

TO PULL THE ELECTRA-MATIC

IN

REVERSE,

or

go

forward without power,

raise the pickup assembly by pulling

back on the vacuum motor lever

CAUTION: ELECTRA

-

MATIC is free

-

wheeling

It

should not be used

on

slopmg

surfaces or ramps Care should be

exercised when approaching walls,

obstructions or open stairways

TO

STOP

THE

LLECTRA-

MATIC:

FOLLOW THE SEQUENCE BELOW.

.

.

1.

Push thruster let switch

to

‘off”

2

to

3 feet before stopping

2.

Release clutch lever

to

bring ELECTRA

-

MATIC

to

complete stop

3.

Pull

vacuum

lever

backward

to

notched

“hold” position

4.

Do

not

push drive switch

“off”

unless

you are done working with machine for

the day or an extended period

It

is

preferred that the drive motor remain

on during brief periods

of

nonuse.

SPINNER

REMOVAL

To

avoid the possibility of the spinner

assembly seizing on the rotary

unm

shaft

due

to

alkaline buildup, remove spinner

at the end

of

each day The lets can be

removed

for cleaning Wash

pts

and blow

dry

Do

not use pins

or

wire to remove

obstruction as this

could

damage

jets

and

change spray pattern

To

remove

spinner,

tilt machine forward and remove spinner

assembly by turning counter clockwise.

(See

photo on next age). If spinner is

seized on shaft,

rekr

to

Photo

13

on

Page

6

3

Page 4

ELECTRA-MATIC

11

5V

Page 4 of

26

TO

USE

FLOOR

AND

HAND

TOOLS

wrth

the

ELECTRA-MATIC, attach solution hose

to male attachment at lower right rear of

machine, and the vacuum hose

to

the

clear plastic recovery

dome

Release the vacuum lever

to

the

forward

posfion

to

create

mum.

Solution

punp

turns on when valve at attachment

is

activated CAUTION. Switches on

ELECTRA

-

MATIC control panel must

remain

"

off

"

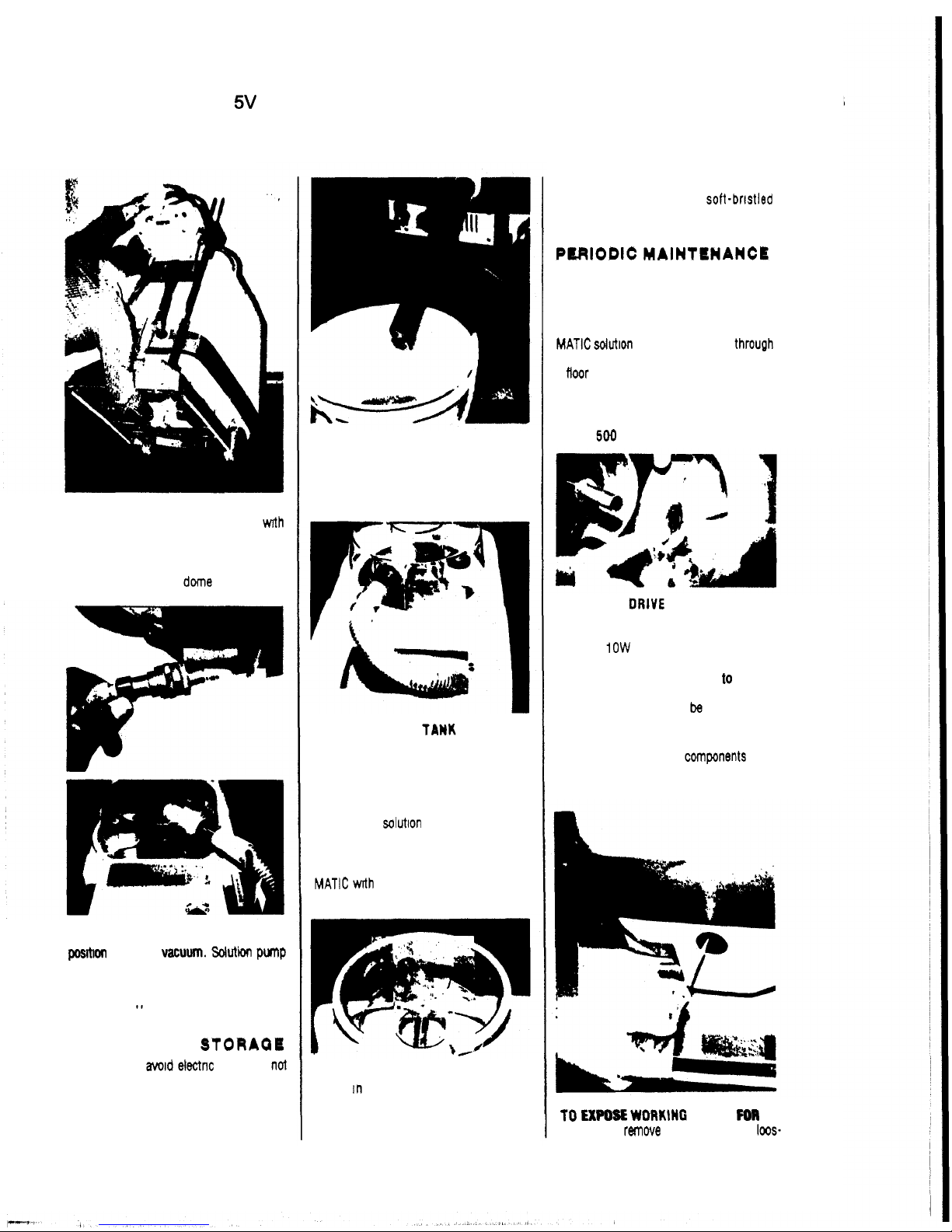

CLEANUP AND STORAQII

WARNING:

To

mid

electnc

shock

do

not

expose to rain. Store indoors

EMPTY RECOVERY TANK

directly into

floor drain

or

into bucket for disposal

Flush inside

of

recovery tank with clean

water Clean the inside of the recovery

dome

EMPTY

SOLUTION

TAnK

by detaching

recovery hose at floor

tool

and placing

into solution tank with vacuum motor

running

CAUTION Never allow recovered solutlon

to

remain in tank when not in use, nor

allow

unused solmon to remain in solutlon

tank when

in

storage

WIPE

the enbre outside of the ELECTRA

-

MATIC wrth a cleaning cloth. using warm

water and mild soap

STORE

ELECTRA-MATIC with recovery

shoe

in the "up" position Place

recovery dome upside down in recovery

tank

as shown

to

permit drying of

gasket

and the inside of the tank

INSPECT

screens in solutlon and

re

-

covery tanks Clean with soft-bristled

brush if necessary

PUIlODlC

MAlNTIINANCll

EVERY

TWO

WEEKS:

CLEAN

SOLUTION

SYSTEM

by diluting

2

gallons of clean water with a quart of

white vinegar (acetic acid) in ELECTRA

-

MATIC solution

tank

Run solutlon through

the system with the machine parked over

a

Hoor

drain

This procedure will

free

the

system

of

harmful buildups which could

eventually cause it to plug

EVERY

500

OPERATING

HOURS:

OIL FRONT ORlVE WHEEL BEARINGS

by removing hub cap and

snap

ring

on

axle Slide wheel off axle and apply

6

drops

of

1OW

oil

to

bearings

REMOVE VACUUM MOTOR

to

inspect

carbon brushes for wear

If

worn

to

3/8

inch, the brushes should

be

replaced

See

service section for instructions

WIPE

clean all working components when

exposed for vacuum motor inspection

TO

EX-

WORKING

PARTS

FOR

IN

-

SPECTION

remove inspection plugs,

100s-

4

Page 5

ELECTRA-MATIC

115V

Page

5

of

26

en screws holding tank support bracket

to

frame and

tip

tank assembly forward.

CAUTION:

Be

sure

ELECTRA-MATIC

IS

UNPLUGGED FROM WALL OUTLET AND

THAT TANKS ARE EMPTY.

TO REMOVE TANK ASSEMBLY

FROM

MACHIHE

disconnect internal

hoses,

pull

pins from front

hinges and tip

off.

This digital recorder keeps track of

operating hours.

It

is wired into the

vacuum motor circuit

so

that all opera

-

tions using the vacuum are recorded.

IF

YOU

WILL

USE AND CARE

FOR

YOUR

ELECTRA

-

MATIC

AS

WE

HAVE

DESCRIBED

IN

THIS SECTION, IT

WLl

GIVE YOU

YEARS

OF

TROUBLE-FREE SERVICE.

SERVICING

THE

I

ELECTRA=MATIC

DRAIN AND CLEAN TANKS

SOLUTION TANK

-

(To remove unused

solution).

1.

Plug extension cable from machine into

2.

Remove hose from vac shoe and pull

properly grounded outlet.

through guide on handle

1.

3.

Position dome

on

waste water tank to

allow

vac hose

to

be lowered into

solution lank.

4.

Lower vacuum lever

to

turn on vac

motor. Vacuum solution into waste

water tank. Use water hose to rinse

inside

of

tank. Reattach vac hose to

shoe when finished.

WASTE WATER TANK:

2.

1.

Remove drain hose

from

keeper on

bottom

of control housing and put hose

over drain

or

bucket.

2.

Use

water hose and detergent

to

clean

inside

of

tank.

TANK REMOVAL

1.

Empty solution and waste water tanks.

3.

2.

Remove inspection plugs. Loosen

screws holding tank support bracket

to

frame

and

tip

tank

assembly

forward.

4.

5.

3.

Tilt

tank forward and disconnect hoses

from tank and

vac motor.

6.

4.

Remove front hinge pins and set tank

aside.

5

Page 6

ELECTRA-MATIC

1

15V

Page 6 of

26

lank

Repair:

The tanks are made

of

Polyethylene.

Small holes, cracks, etc., can be re

-

paired by using heat. Apply low

heat

from torch

to

damaged area

until

ma.

terial Is softened. Use screw driver

blade or other flat metal

tool

to

seal

damaged area.

TO

REINSTALL TANKS

1.

Set

tank in front

of

machine and in

-

2.

Connect solution and vac hoses.

3.

Lower tank

to

base

...

check position

of

hoses to make sure that they are not

pinched.

4.

Tighten screws to hold tank support

bracket

to

frame.

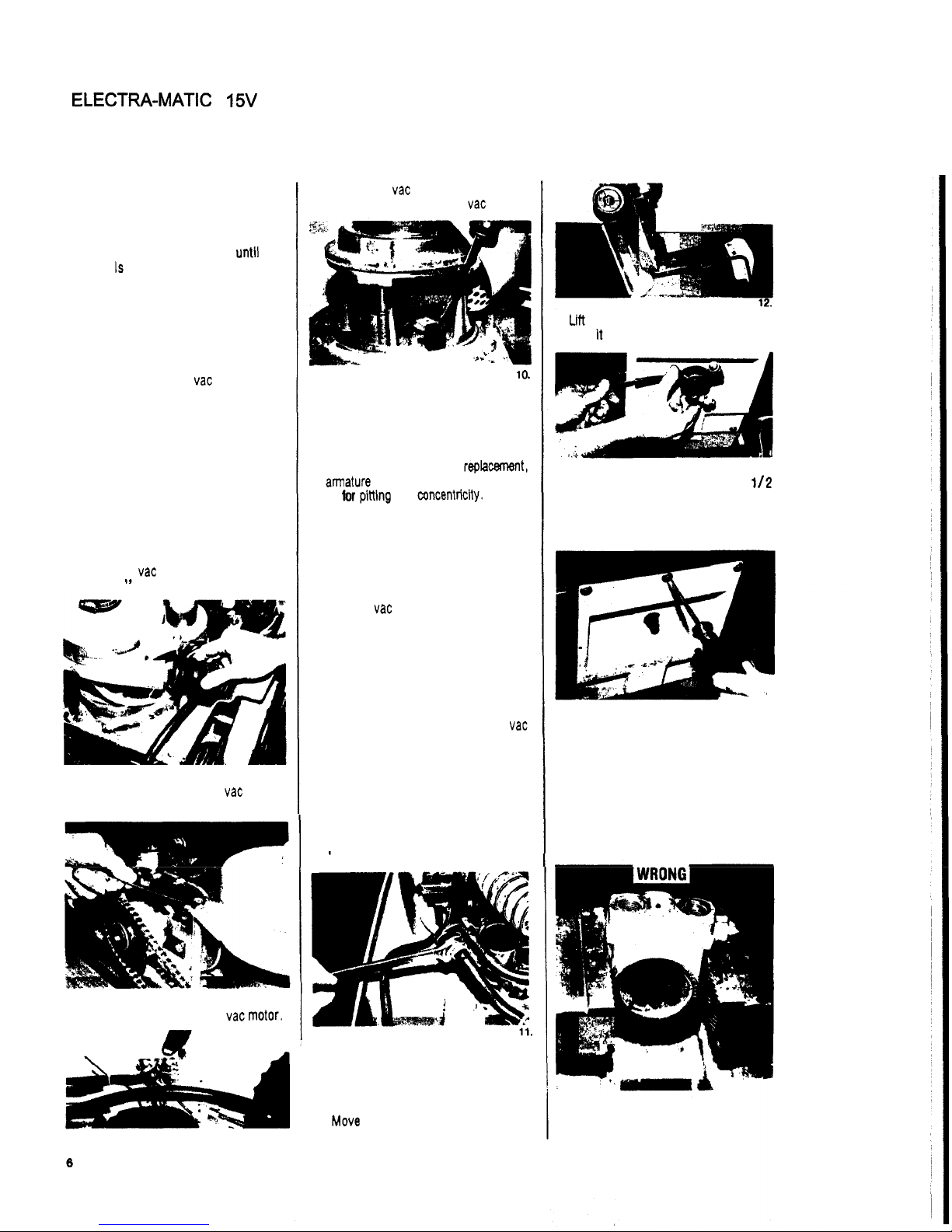

VACUUM

MOTOR

REMOVAL

1.

Disconnect machine power cord from

2.

To access vac motor, refer

to

"

Tank

stall hinge pins.

electrical source.

Removal

' '

instructions.

7.

3.

Disconnect hose from vac motor

exhaust.

8.

4.

Remove 3 screws holding vac motor.

R

9.

5.

Disconnect vac motor leads from

terminal block and remove

vac motor.

lo.

6.

To inspect motor brushes, remove

metal band around motor and remove

brush holder assembly. Brushes

should be replaced when worn

to

3/8

inch or after about

750

operating

hours.

After second brush

replacement,

armature commutator should

be

check

-

ed

for

pitting

and concentriciiy. Vacuum

motors can be repaired but such re

pairs should be made by a qualified

motor repair shop.

VACUUM

MOTOR

INSTALLATION

1.

Position vac motor on supports and

secure with screws and washers.

2.

Attach hoses

to

motor.

3.

Connect motor leads

to

terminal block

(refer

to

machine wiring diagram as

required.)

4.

Plug power cord from machine

to

properly grounded outlet and test vac

motor

by

lowering vacuum control

lever.

SOLUTION PUMP

REMOVAL

1.

Disconnect machine power cord from

2.

To access solution pump, refer

to

electrical source.

'

'Tank Removal" instructions.

3.

Remove hosebarbs from pump fittings.

(NOTE:

Special hosebarbs allow hose

to

swivel on barb during removal with

-

out damage

to

hose.)

4.

Move machine rearward slightly

to

position casters in rearward position.

5.

W

front of machine and

tilt

backwards

until

It

rests on the control handle.

13.

6.

Remove spinner assembly using

112

inch open end wrench

to

hold shaft

and turn spinner counterclockwise

(facing spinner).

14.

7.

Remove belt access cover.

8.

Loosen 3 nuts and screws that hold

pump

to

base and slide pump rearward

to

allow

belt

to

be

removed from pulley.

Remove nuts and screws and pump

from base.

SOLUTION PUMP

INSTALLATION

Page 7

ELECTRA-MATIC

1

15V

Page

7

of

26

1.

Remove elbows from old pump and

install on new pump using pipe

joint

sealant

CAUTION - if a vise is used to hold

pump, see photo for correct way to

clamp pump

Do

not overtighten vise

as this could

cause

Internal damage

to

pump.

Ekira

caution should

be

taken

to

keep

foreign

material lrom enterlng

pump

during assembly.

19

4.

Disconnect solenoid leads

from

terminal

5.

Use wrench

to

remove solenoid valve

6.

Clean, inspect or replace as required

ROTARY UNION AND SOLENOID VALVE

ASSEMBLY:

1.

heed as outlined in Steps 1 through

4 under “Solenoid Valve

“

2.

Lift front

of

machine and tilt backwards

until machine rests on control handle

(Photo 12)

3.

Remove belt access cover (Photo 14)

block and top of capacitor

from rotary union

2.

Install pulley

on

pump shaft at dimen

-

sion shown in Photo W17 (1 1/32 inch

between pump face and pulley flange)

3.

Set pump in position

on

main frame

and

Dut belt on Dujlev Install screws

and

nuts that hold pimp Slide pump

forward

to

tighten belt and tighten

pump mounting screws

4.

Install

belt

access cover, lower

ma

-

chine

to

Mor

and install tank

assembly.

Reinstall spinner assembly Put solu-

,I

-

-

tion in tank and test pumd

I

-

-

/I

I

ROTARY UNION AND/OR

SOLENOID VALVE

REMOVAL

SOLENOID

VALVE ONLY:

1.

Disconnect machine power cord from

2

To

access solenoid valve, refer

to

electrical source

“Tank Removal” instructions

3.

Remove hosebarb from solenoid (the

special push

lock hosebarb allows hose

to

swivel during removal without

damage to hose)

/

20

4.

Remove

belt

from rotary union pulley

(roll

off

being careful not

to

damage

belt)

22

5.

Loosen set screws

(2)

in pulley and

remove pulley from rotary union shalt

(use gear puller)

6.

Remove 3 screws holding rotary

unm

to

main frame

and

lift out solenoid

valve and rotary union assembly

7.

Inspect, repatr,

or

replace as

required

(Refer

to

rotary union breakdown for

replacement parts

)

ROTARY

UWlON

INSTALLATION

I.

Position rotary union on main nousing

and install mounting screws

23

2.

Slide pulley on shaft

to

dimension

noted and tighten set screws

(1

1/

16

inch between pulley and frame.)

3.

Install belt on pulley (roll belt onto

pulley

as

shown In

Photo

20).

If

belt

is

loose.

tighten by adjusting drive motor

or refer

to

“Belt

Adjustment“

in

-

structions

4.

Install belt access cover and spinner

assembly

5.

Lower machine

to

floor and install

tanks

6.

Put

solution

in

tank and test machine

BELT

REPLACEMENT!

ADJUSTMENT

I.

Disconnect machine power cord from

electrical source

2.

To access drive belts, refer

to

“Tank

Removal

’

’

instructions

3.

Lift front of machine and tilt backwards

until machine rests on control handle

(Photo 12)

4.

Remove belt access cover (Photo 14)

5.

Loosen motor mounting screws

(4)

and slide motor forward then remove

belt@)

7

Page 8

ELECTRA-MATIC 1 15V

Page

8

of

26

When installing new belts

use

tho

following sequence:

24

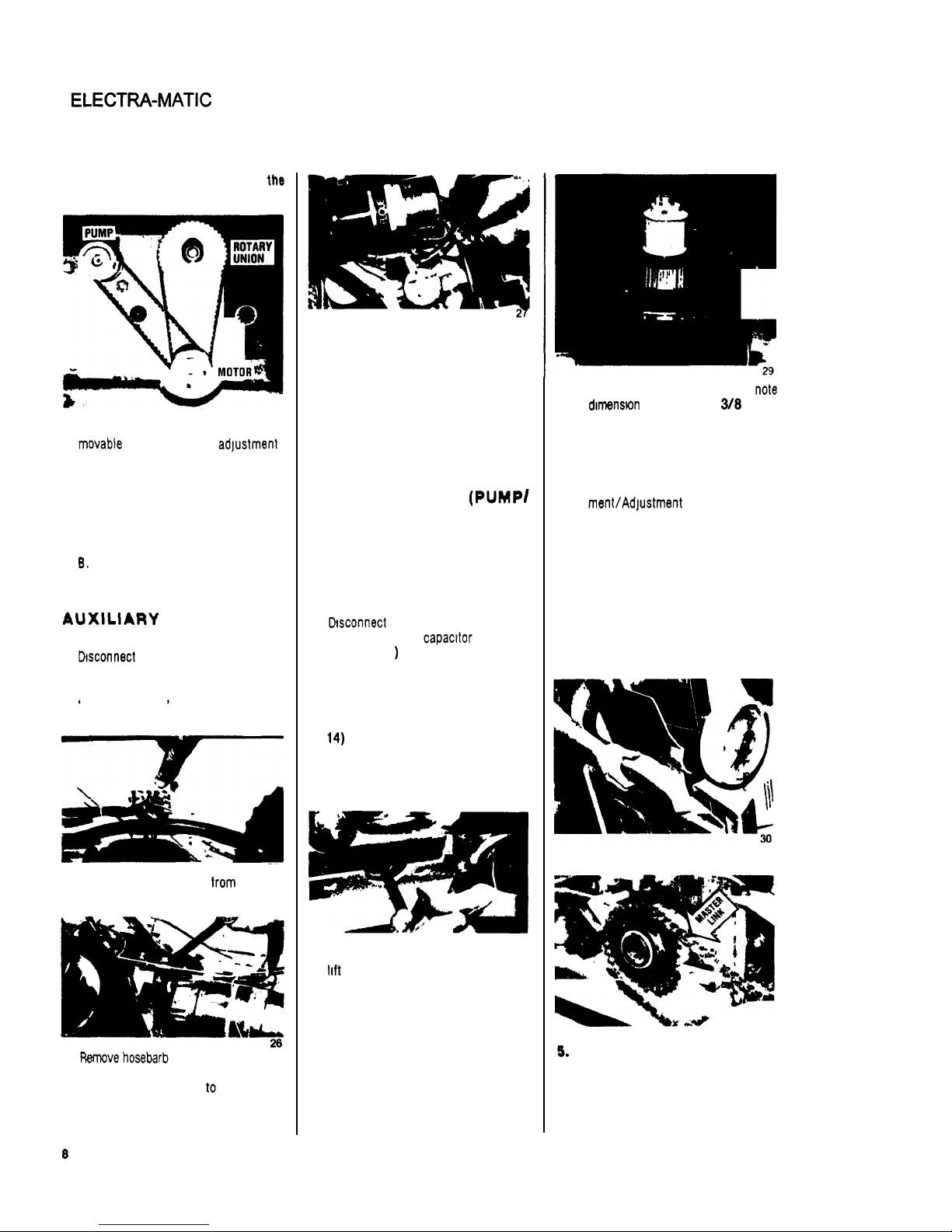

NOTE Drive motor and pump are

movable

to

allow for belt adjustment

Loosen screws holding pump and

motor

A.

Install pump drive belt then rotary

union drive belt Slide motor rear

ward until rotary union drive belt

is

tight Tighten motor screws

B.

Slide pump forward until drive belt

is tight Tighten pump screws

AUXlLlARY

PUMP

REMOVAL

1.

Dsconnect machine power cord from

2.

To access auxiliary pump, refer

to

electrical source

’

‘Tank Removal’ ’ instructions

25

3.

Disconnect pump leads from terminal

block

4.

Ranove hosebarb

at

branch

tee

(special

push lock hosebarbs allow hose

to

swivel without damage

to

hose during

removal and assembly)

5.

Remove 4 screws holding pump

to

frame and lift

out

pump

6.

Remove outlet hose with hosebarb from

pump head

7.

Lay pump on bench and refer

to

auxiliary pump breakdown for replace

-

ment parts

8.

Reinstall pump in reverse of Step

1

through 6 above

MOTOR

REMOVAL

(PUMP/

ROTARY

UNION

DRIVE

MOTOR)

1.

Disconnect machine power cord

from electrical source

2.

To

access dnve motor, refer

to

“Tank Removal” instructions

3.

Dtsconnect motor leads from ter

-

minal block and capacttor (Refer

to

Photo 25

)

4.

Lift front

of

machine and tilt back

-

wards until machine

rests

on

control

handle

(Photo

12)

5.

Remove belt access cover

(Photo

14)

6.

Loosen 4 screws holding motor

to

frame, slide motor forward and

re

-

move belts from motor pulleys

28

7.

Remove screws holding motor and

6.

Inspect motor, repair or replace as

lift motor

out

required

9.

When installing motor pulley, note

dimenstan

for

spacing

(1

38

inches

from face

of

motor

to

inside edge

of outer flange on pulley).

10.

Install motor in reverse of above

steps

11.

If

required, refer

to

“Belt

Replace

-

menVAdjustment

”

FRONT

AXLE

AND

WHEEL

ASSEMBLY

REMOVAL

1.

Disconnect machine power cord

from electrical source

2.

Remove tanks, refer

to

“Tank

Re

-

moval” instructions

3.

Remove belt access cover (Photo

12).

4.

Remove bottom splash guard

31

5.

Remove dnve cham

from

sprocket

NOTE:

Chain has master link for

easy removal

8

Page 9

ELECTRA-MATIC

1

15V

Page

9

of

26

32.

6.

Remove nuts and bolts holding

flange bearing

to

frame.

33.

7.

Remove axle assembly from machine

and put on workbench

to

service.

8.

Remove snap ring on each end

of

axle.

WHEEL

AND

AXLE

SERVICE/INSTALLATION

1,

Install flange bearings on axle. Po

-

sition set screws (in locking collars)

over innermost flats on axle and

tighten screws. (Slight adjustment

of bearings may be necessary when

reinstalling assembly

to

frame.)

2.

When replacing sprocket on axle

note dimension

-

approx.

3

5/16

from end

of

axle

to

face of sprocket.

(Photo

34)

34.

3.

Replacing bearing/clutch bearings

in wheels. These are directional

bearings and

must

be installed as

follows

:

35.

LEFT WHEEL:

Bearing must be

pressed in from

in

-

board side of wheel

with knurled end of

bearin sleeve on

inboar! side of

wheel.

36.

RIGHT WHEEL:

Bearing must be

pressed in from

outboard side of

wheel with knurled

end of bearing

sleeve on outboard

side of wheel.

NOTE: Both right and left bearinq assem

-

blies must be pressed in flush with the

inside

of

wheel hubs.

37.

1.

To check assembly: hold axle

-

each wheel should rotate forward

freely and lock on shaft when rota

-

tion is reversed.

TRAVERSE

DRIVE

MOTOR

AND

CLUTCH

REMOVAL

(Bodlne

Motor)

1.

Disconnect machine power cable

from electricat source.

2.

To access traverse drive motor, re

-

fer

to

"

Tank Removal" instructions.

38

39.

3.

Disconnect Molex connector from

motor and clutch lead connector.

4.

Remove chain. NOTE: Chain has

master link for easy removal

(Photo

31).

5.

Remove belt access cover

(Photo

12)

and

bottom

splash guard

(Photo

30).

40.

6.

fkmove 4 screws and nuts holding

motor and clutch

to

frame and re-

move motor. Put on workbench

7.

To

check motor brushes:

(utch

Wo

bottom

OI

kush

box

AS

UlOWN

Wng

R.Wnlng

Bnclut

Use

Long

NOW

Plkn for

R.mwsl

of

COns1sn1+we,

Roll-Type

Spring

Top

of

hsh.

Note

low

end

of

bewl

should

be

toward

spring

osvlty.

Brush

aspa

u.

hdd

In

@ace

wlth

maptypo

riwts.

Snap

bnah

orps

out using

irrgest

poeslbls

sow

drlver

tlp

undw

cap

owrheng.

Brush

Box

Tab

Alumlnum

Brush

Box

Page 10

ELECTRA-MATIC

1

15V

Page

10

of

26

BRUSH REMOVAL

(Bodlne

Motor)

41.

Brush

caps

are held

in

place with snap-

type rivets. Snap brush caps out using

large screwdriver

tip

under

cap

overhang.

Brushes are retained by constant

-

force,

d-type

springs. To remove springs, press

inward on the end of the spring retaining

bracket using the tip of a pair

of

long nose

pliers or other appropriate

tool.

Springs

should “pop”

out.

If

they don’t, they

can be removed by pulling outward on

the spring retaining bracket with a pair

of

long nose pliers. Brushes can now be

removed

by

pulling them out of the brush

boxes

by their “pigtails.”

It

is not neces

-

sary

to

rme the brush pigtail

dip

from

its connection to the brush box tab for

brush inspection.

BRUSH INSPECTION AND

CLEANINQ

(Ilodlne

Motor)

Brushes should be replaced

before

they

are

less

than

114

inch

(7

mm.) in length.

Carbon dust accumulation should be re

moved periodically. If the end shield has

been removed from the drive. a clean.

dry,

nonlinting cloth can be used

for

cleaning.

Do

not use solvents as they

may damage the nonmetallic end shield.

IMPORTANT

-

Make certain that the rdl-

type springs are positioned directly on

the brushes.

8.

The drive motor is equipped with

sealed ball bearings and does not

require lubrication.

9.

The gear

box

on traction drive motor

is grease

-

lubricated

to

last

tor

the

design life of the gear motor.

CLUTCH ADJUSTMENT

AND

SHRVICINd

(Electro Magnetic Clutch)

1.

Depending on the duty cycle and

load, periodic inspections of the

wear rate should be made. The air

gap

I

S

preset at the factory

to

.005/

010.

When this gap increases

to

,025

it

must

be

readjusted

to

factory

specs

(.005/.010).

42.

L3L.

To adjust, use a feeler gauge (of

spec. value) and turn the

(3)

set

screws

in

equally

to

close air gap.

When air gap can no longer

be ad

-

justed clutch must be replaced.

Care should

be

taken

to

insure that

dust,

dirt. oil. grease, soap, water.

etc. does not come in contact with

the working surfaces (rotor and

armature faces) of the

unit.

If fric

-

tion faces become dirty, the clutch

will slip, causing overheating and

a

loss

of

torque.

If

clutch fails to engage, check the

following:

A.

Check air gap: regap as required.

B.

Check for contamination of the

C.

Check electrical connections.

D.

Check for

grounded

or

open

coil.

Grounded

Coil: Disconnect ma

chine from power source. With

ohmmeter connected between

clutch lead and housing, there

should be no reading on meter

(check

both

clutch leads).

If

ohm

meter shows a reading, the coil

is grounded and clutch must be

replaced.

Open

Coil: Use ohmmeter

to

measure resistance

between

clutch leads. Reading on ohm

-

meter

should

be

775 i 40

ohm.

An

open coil indicates near

zero reading and clutch must

be replaced.

working faces.

TRAVERSE DRIVE

MOTOR

ANDCLUTCHREMOVAL

(Von

Welre

Motor

and

Marquette

Cluteh)

1.

Disconnect machine power cable

from electrical source.

2.

To access traverse drive

motor,

re

-

fer to “Tank Removal” instructions.

3.

Disconnect

motor

lead connector.

43.

4.

Disconnect leads from clutch arm

solenoid.

5.

Remove chain.

NOTE:

Chain has

master link for easy removal.

(Photo

31)

6.

Remwe

belt

access cwer

(Photo

12)

and

bottom

splash guard

(Photo

30).

7.

Remove

(4)

screws

and nuts hddlng

motor and clutch

to

main frame.

Remove motor and clutch and put

on work bench

to

service.

44.

8.

Remove brush cap and Inspect

motor brushes periodically. Brushes

should be replaced when

they

reach

318”

length or after approximately

750

operating hours. The gear

box

is

sealed

and

permanently

lubrkated

for

the life

of

motor.

CLUTCH ADJUSTMENT

AND

SERVICINQ

(Marquette

Mochankal

Clutch)

1.

Depending

on

the duty cycle

of

the

clutch, periodic inspections should

be

made.

10

Page 11

ELECTRA-MATIC

11

5V

Page

11

of

26

2.

Check

(2)

set screws located in

outer cogged clutch

rlng. If screws

loosen and back out, clutch slip

-

page will occur.

To

reset cogged

ring;

remove set screws from ring.

Rotate

rlng

to

align

set

screw hdes

in ring with corresponding hole in

metal clutch body. Using

allen

wrench install the

set

screws finger

tlght. CAUTION:

DO

NOT

owrlightsn

as

this will distort cogged ring and

cause

it

to

rotate

“out

of

round.”

46.

3.

Clutch actuator arm/solenoid ad

-

justment:

A

space of

1/16

to

3/32 must be

maintained between the tip

of

the

actuator arm and the cogged ring.

To

adjust, loosen the nut holding

eccentric spacer and rotate spacer

until proper adjustment is made.

Retighten nut

to

secure spacer.

VACUUM

SHOE

REMOVAL

47.

1.

Remove

lift

rod from casting (snap

spring connector).

48.

2.

Remove lower ball joint connectors

from

vac casting (snap spring con

-

nector).

3.

Use pliers

to

remove springs from

anchor screws.

4.

Loosen set screws that secure

shoulder

bolts

to

frame.

5.

Remove shoulder bolts that hold

upper link arms

to

frame and remove

vac casting.

6.

Repair as required and replace in

reverse of above steps.

VAC SHOE ADJUSTMENT

0-

.1w.

11#(1

rt

ri

n

no.

i

FIB.

I

m.

a

With machine on smooth level surface

the front and rear shoe of

vac casting

should be parallel with surface.

1.

If

front shoe is off floor (Fig. 3),

lengthen lower adjusting rods.

2.

if

rear shoe is off floor (Fig.

2),

shorten lower adjusting rods.

3.

Retighten lock nuts on adjusting

rods after completing

vac shoe

adjustment.

4.

Vsc

Shoe Height Adjustment-Place

machine on smooth level surface,

lower

vac shoe. Le-

.

ver should have

approximately

1”

of

additional forward

travel when properly

adjusted. Lengthen

or shorten lift rods

A

& B as required

(Fib.4).

CONTROL

BOX

REMOVAL

AND SERVICE

1.

Disconnect machine

power

cord from

electrical so~rce.

2.

Remove (4) screws and nuts hold

-

ing control

box

to

handle.

3.

Remove

(2)

screws

and nuts holding

upper and lower section of control

box together.

.

The following instructions pertain

to

identification and troubleshooting the

repairable components in the control box.

CAUTION: Repairs should only be at

tempted by qualified personnel since

damage can be done by persons not

experienced

in

working with printed cir

cuit boards and components. TeJting can

be

done with an ACIOC volt-ohmmeter.

TO

TEST SWITCHES AND

CIRCUIT BREAKERS

Remove them from machine and use an

ohmmeter or continuity tester. The correct

reading is zero for an

open

swltch/breaker

nuity) for a closed

switch/breaker.

QUULTCI)

and Infinity (conti

-

-~

THRUSTERJET/SPINNER

DRIVE

MOTOR

CIRCUIT

BREAKER:

If

circuit breaker trips after being reset,

check the following:

A.

Incorrect size

extensbn

cable

-

use nothing less than a 12

gauge, 3

-

wire of not more

than

75

feet In length.

B.

F#llty

pump/spinner drive

w.

C.

Plugged thruster jet)s).

0.

Faulty rotary unlon or pump.

E.

Faulty capacitor.

F.

Faulty circuit board.

11

Page 12

ELECTRA-MATIC 1 15V

TO

CHECK SPINNER

SPRAYPATTERN

Use

a commercial

low

pile

carpet

(a dark

color is preferable) to test spray pattern.

With solution in tank, activate solution

switch momentarily

to

roduce a "

suds

"

pattern on carpet. Tfie inside pattern

dbnrster

[Jet

#1) must

be

15%" to 16%"

The middle pattern

diameter

(Jet #2)

must

be

17%" to 1896". The outslde

pattern diameter (Jet

#3)

must be 18%"

to 19".

1.

SOLID STATE CLUTCH

CONTROL (DC CIRCUIT):

(Bodlne

PC

Board)

This control supplies

DC

current to clutch.

To check solid state control raise front

of

machine and use wood block

to

hold front

drive wheels

off

floor. Plug machine power

cord into properly grounded outlet. Turn

on drive

-

motor switch and depress clutch

switch lever.

If

clutch does not engage,

check voltages on octal socket. Voltage

at terminals

2

and 5 should

be

115

VAC

f

10% (on 115 volt models) and 230

VAC f 10%

(MI

230

vdt

models).

Vdt-

age

a!

terminals 4 and 7 should

be

90

to

110

VDC

f

10%.

If zero reading at

terminals

4

and

7,

replace solid state

control.

SOLID

STATE

CLUTCH

CONTROL (DC CIRCUIT):

(D8rt

PC Control)

This control supplies

DC

current to the

clutch.

To

check solid state control. raise

front of machine and use wood block to

hold front drive wheels

off

floor. Plug

machine

power cord into properly grounded

outlet. Turn

on

drive-rnotor switch and

depress clutch switch lever. If clutch does

not engage, check voltages at control

board. Voltage at terminals marked

AC

should be 115

VAC

-t

10% (on 115

volt models) and

230

VAC f 10% (on

230

volt models). Voltage at terminals

F-

and

F+

should be

85

to

105

VDC

f

10%. If zero reading at terminals

F

-

and

F+

replace solid state control.

SPEED CONTROL/

TRACTION DRIVE

MOTOR

(DC CIRCUIT):

(Bodlne Motor and PC Bo8rd)

12

The magnetic circuit breaker and in-line

(ceramic) armature fuse protects circuit

board and traction drive gear motor.

If

drlve

motor

does not

run,

check the

following:

1.

2.

3.

4.

5.

6.

7.

With machine ptugged in use

AC

volt meter to check input voltage at

terminals Ll

-

L2 (with drive-motor

switch on); reading should

be

115

VAC

2

10%

(on

115 volt models)

and 230

VAC

f

10% (on 230 volt

models). The output voltage at ter

-

minal A1 and A2 should

be

0-130

volts D.C.

Check for loose electrical connec

-

tions (at terminal block, switch,

motor P.C. board and receptacle).

Open

S-2

lead - use ohmmeter

to

check continuity from

speed

poten

-

tiometer to P.C. control board.

Check circuit breaker

for

continuity

(use ohmmeter). If breaker trips

after being reset, check for cause

-

faulty power cord

or

short In

cir

-

cuit. If this does not correct the

problem. the P.C. control board may

k

faulty.

Check in

-

line armature fuse

(2

amp

ceramic

fuse).

If blown, replace

with

(Iwc1

same

type.

If fuse blows

after being replaced, the gear

motor

may be grounded or short circuited.

To

test motor for ground or short

circuit, first disconnect machine

power cord from electrical source

then disconnect motor lead Molex

connector from motor. Using ohm

meter, check resistance between

each motor lead and the motor

frame. If readings are

inlnlty (con

-

tinuity), the armature is grounded;

replace gear motor.

To check for shorted armature, use

ohmmeter to measure the resistance

between the motor leads.

If

resist

-

ance

is

5

ohms

or

&,

the armature

is short

-

circuited: replace gear

motor.

If

motor

runs at maximum

speed

(no

speed

control), check leads S-1 and

S-3

for open circuit between speed

potentiometer and the

P.C.

control

board.

If

no open circuit is found,

the control board may be faulty.

Erratic starting and stopping

of

trav

erse motor could

be

due to a faulty

P.C.

board. With power connected

to machine and motor switch on,

Page

12

of

26

check

D.C.

output voltage at termi

-

nals

A1

and A2. If voltage does not

remain constant this is an indication

that

the P.C. board

is

shorted

or

open internally.

Replace

as

required.

SPEED CONTROL/

TRACTION

DRIVE

MOTOR

(DC CIRCUIT):

(D8rt

PC

Control)

The magnetic circuit breaker and in-line

(ceramic) armature fuse protects

arcuit

board and traction drive gear motor.

If

driw

motor

does

not

run,

check the

following:

1.

2.

3.

4.

5.

With machine plugged in use

AC

voltmeter

to

check input voltage

at

terminals

AC.

AC

(with drive

motor

switch on), readin should

be

115

VAC

f

10% (on 815 volt models)

and 230

VAC

f

10% (on 230

voll

models). The output volta e at ter

-

minals

A+

and

A

-

should&

0-105

volts DC.

Check for loose electrical connec

tions (at terminal block, switch,

and

P.C.

board).

Check circuit breaker for continuity'

(use ohmmeter).

If

breaker trips

after

being

reset,

check for cause-

faulty power cord

or

short in circuit.

If

this does not correct the roblem,

the P.C. board may be fau&y.

Check in-line armature

(2

amp

csramlc

fuss).

If

blown, replace

wilfi

exact

same

type.

If fuse blows

after being replaced, the

gear

motor

may

be

grounded or short circuited.

To

test for around or short circuit

tirst disconnect machine power

cord

from electrical source then discon

-

nect motor lead Molex connector

from

motor. Using ohmmeter, check

resistance

between each motor

lead

and the motor frame.

If

readings

are not infinity (continuity), the

armature is grounded, replace

gear motor.

To

check for shorted armature use

ohmmeter to measure the

resisdance

between the motor leads.

if

resis

-

tance is 5 ohms or less, the arma

ture is short circuited; replace gear

motor.

Erratic starting and stopping

of

trav

-

erse

motor could be due to a faulty

P.C. board. With power connected

to machine and motor switch on,

check

DC

output voltage at termi

-

nals

A+

and

A-.

If voltage does

not remain constant this is an in

-

dication that the

P.C.

board

is

shorted

or

open internally. Replace

as required.

Page 13

1-

I

LOWER

-

-

I

UPPER

CONTROL

BOX

CIRCUIT

(Bodin.

PC

Control

Boord

tW.21C)

w

115V WlRlNO SCHEMATIC

mw

LOWER

CONTROL

BOX

CIRCUIT

,

(lodin.

w

control

.owl

EII.21C)

uu

220V

WlRlNa

SCHLWATIC

UPPER

CONTROL

BOX

CIRCUIT

7

-

.IIp

220V WlRlNO SCHEMATIC

I-L

Page 14

ELECTRA-MATIC

1

15V

I

UI

VACUUM CIRCUIT

Page

14

of

26

ELECTRICAL

cin

(Bodlno

Motor

and

CLUTCH CIRCUIT

14

1-

Page 15

ELECTRA-MATIC

1

15V

Page

15

of

26

THRUSTER CIRCUIT

DRIVE

SYSTEM

CIRCUIT

15

Page 16

ELECTRA-MATIC

1

15V

Page

16

of

26

ELECTRICAL CIRCUIT IDENTIFICATION

(Bodlno Motor and PC Control

Board

EM-nlC)

TERMINAL

\

BOX

r

POWER

IN

GROUND

GROUNDING CIRCUITS EM-21 C

16

Page 17

ELECTRA-MATIC

115V

115V

WlRlNa SCHWATIC UPPER CONTROL

BOX

CIRCUIT

(Dart

PC

Control Board)

TO

115V

WIRING

SCHEMATIC

BASE

ASSEMBLY

(Dart PC Control Board)

101

Page

17

of

26

17

Page 18

ELECTRA-MATIC

11

5V

Page

18

of

26

ELECTRICAL

PARTS

IDLNTlFlCATlON

(Dort

PC

Contrd

mrd)

CIRCUIT MEAKER

1401s

CIRCUIT BREAKER

14027

P

SWITCH

72015

0

115VAC-

INLET

POWER

14017

[

4,"C VAC

smcn

mls

VACUUM CIRCUIT

(DWI

PC

DIIIT~lwAnO

1712s

11R

ma

t5ov

Control bard)

I

OROUNDINQ CIRCUITS

(Dart PC Control Wrd)

n

w

115VAC

INLET

WWER

1

pq

0-0

I

-

1,,

Page 19

ELECTRA-MATIC

11

5V

Page

19

of

26

CLUTCH CIRCUIT

(Dart PC Control Board)

d

I

1

--I

u

THRUSTER

CIRCUIT

[Dart

PC Control

bard)

1

DRIVE

SY8TLM

CIRCUIT

(Dart

PC Control

Board)

~

115VAC

INLET

4

I

lrn

Page 20

ELECTRA-MATIC

1

15V

1-

Page 21

A

A

Page 22

ELECTRA-MATIC

11 5V

53

73030

Skirt,

Front

I

54

31025

Elbow.

318"

45'St.

Page

22

of

26

EM-21

A

SOLUTION

/RECOVERY

TANK

22

Page 23

ELECTRA-MATIC

1

15V

EM-21C CONTROL PANEL BREAKDOWN

(Bodino

PC

Control

Board)

Page

23

of

26

23

Page 24

ELECTRA-MATIC

1

15V

CONTROL

PANEL

BREAKDOWN

(D8t't

Pc

Control)

Page

24

of

26

0--19

8-21

24

Page 25

ELECTRA-MATIC

1

15V

Page

25

of

26

EM-21

A

LOWER

SHROUDS

25

Page 26

ELECTRA-MATIC

11

5V

Page

26

of

26

~~

PUMP

PARTS

LIST

-

KEY

PlRT

NO.

DESCRIPTION

I

65018

65010

Pump and Motor Asm..

llOV

Pump and Motor Asm..

230V

1

53016

Motor,

115V

1A

53017

Motor.

230V

2

67066

Rectifier/End

MI

Asm.

3

62023

Plate, Motor Mounting

4

36006

Grommet

(set

of

4)

5-7-8-9

47015

Kit. Pump Repair

6

27057

Bearing

Cover

10

41010

Pump Housing

I1

72017

Pressure

Switch

12

65016

Pump Complete

47023

KIT, ROTARY

UNION

BEARING

?

47026

KIT, ROTARY

UNION

SEAL

26

PROBLEM

No

electrical power.

Loss

of

vacuum/

solution recovery.

No

forward movement

of machine.

No

solution flow.

Solution will not

shut

off.

Uneven cleaning.

TROUBLE=SHOOTINO

OUlDE

CAUSE

Dead electrical circuit.

Faulty main power switch on machine.

Faulty power cord.

Fuse-blown or circuit breaker tripped (on

machine).

iracuum lever in

"off"

position.

Faulty

vac motor switch.

Worn

vac motor brushes or faultv vac motor.

Crack in recovery dome

Obstruction or

damage in vac shoe linkage

or

vac hose.

Incorrectly installed or adjusted

vac

shoe.

Loose

wires at switch or connections.

Faulty drive motor switch.

Worn carbon brushes

in

gear drive motor

or faulty motor.

Fuse blown or circuit breaker tripped (on

machine).

Faulty speed control potentiometer.

Faulty pump drive motor.

Faulty pump.

Broken pump drive belt

Faulty switch.

"

Clogged" or faulty solenoid.

Obstruction in thrusterjets.

Faulty thruster control switch.

Dirt in solenoid valve or faulty valve.

One or

more thrusterjets plugged.

Broken rotary union

drive belt.

SOLUTION

Check building circuit breaker or fuse box.

Replace switch.

Repair or replace power cord.

Replace fuse or reset breaker after correcting

problem,

Put lever in

"on"

position.

Replace swltch.

Replace motor brushes or motor.

Repair or replace.

Remove obstruction, repair or replace

vac

casting.

Adjustvac shoe.

Repair as required.

Replace switch.

Repair or replace motor

Rplace hose or reset breaker after correcting

problem.

Replace control.

Repair or replace motor

Replace pump.

Replace belt.

Replace switch.

Remove obstruction or replace.

Remove spinner assembly and clean

jets.

Replace switch.

Remove obstruction or replace valve.

Remove spinner assembly and clean

lets.

Replace belt.

Loading...

Loading...