Page 1

CARPET EXTRACTOR

Operating Instructions (ENG)

MODEL: D250 (115V)

D250IE (230V)

Prior to Serial No. 1000054536

F

98637 04/25/02

Read these instructions before operating the machine

Page 2

SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

WARNING:

Connect to a properly grounded outlet. See Grounding Instructions.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before

maintenance or service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near

children.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding

the machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or

dropped into water, return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord

around sharp edges or corners.

Do not run machine over cord. Keep cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

To reduce the risk of fire, electric shock, or injury:

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of ma chine, switch off imme diately.

SAVE THESE INSTRUCTIONS

D-250 98637 01/19/99

2

Page 3

GROUNDING INSTRUCTIONS

t

p

e

A

A

A

THIS PRODUCT IS FOR COMMERCIAL USE ONLY.

ELECTRICAL:

The amp, hertz, and voltage are listed on the

data label found on each machine. Using

voltages above or below those indicated on the

data label will cause serious damage to the

motors.

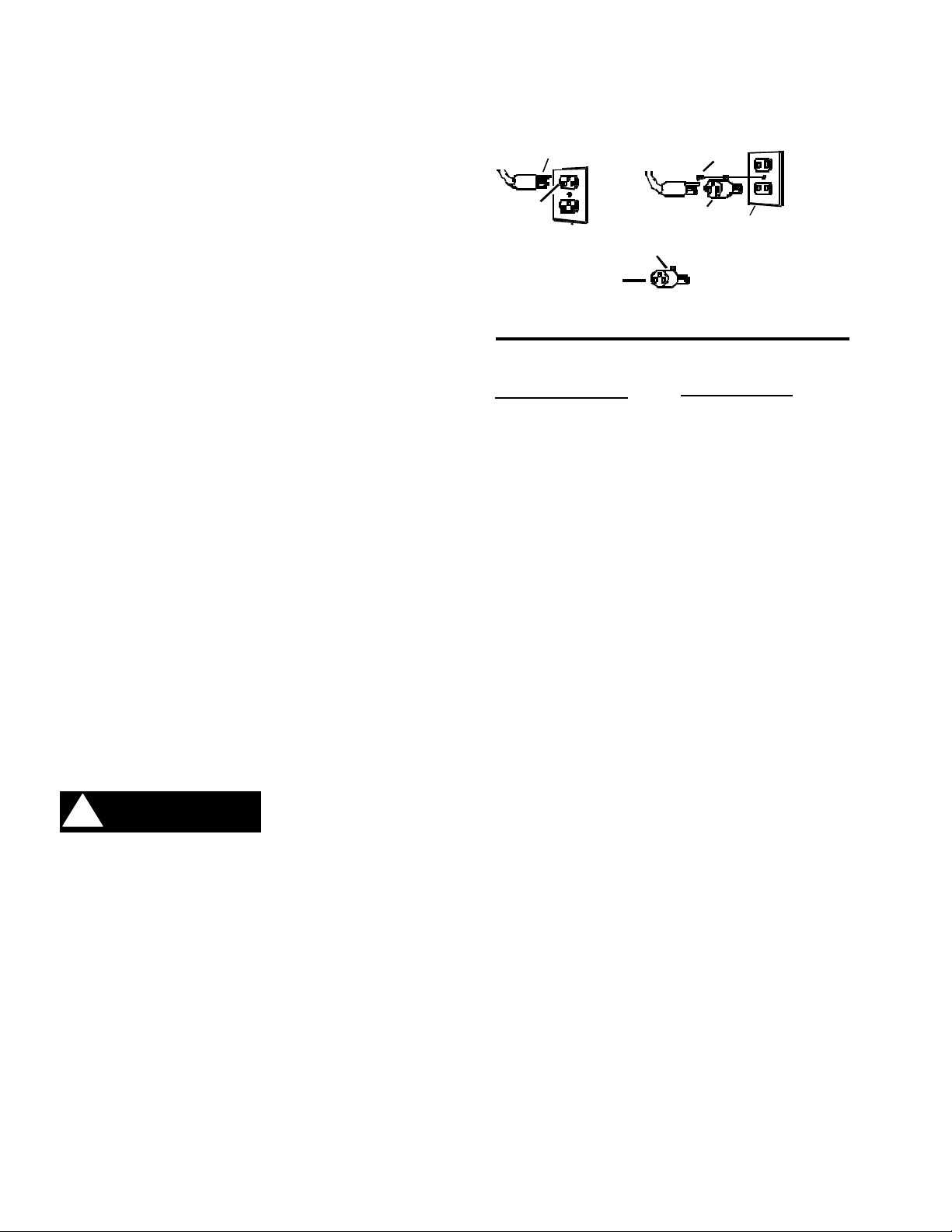

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to

reduce the risk of electric shock. This appliance

is equipped with a cord having an equipmentgrounding conductor and grounding plug. The

plug must be inserted into an appropriate outlet

that is properly installed and grounded in

accordance with all local codes and ordinances.

The D250 is for use on a nominal 115-volt circuit,

and has a grounded plug that looks like the plug

in “Fig. A”. A temporary adaptor that looks like

the adaptor in “Fig . C” may be used to connect

this plug to a 2-pole receptacle as shown in “Fig.

B”, if a properly grounded outlet is not available.

The temporary adaptor should be used only until

a properly grounded outlet (Fig. A) can be

installed by a qualified electrician. The green

colored rigid ear, lug, or the like extending from

the adaptor must be connected to a permanent

ground such as a properly grounded outlet box

cover. Whenever the adaptor is used, it must be

held in place by a metal screw.

The D250IE is for use on a nominal 230-volt

circuit.

WARNING:

Improper

connection of the

equipment-grounding conductor can result in a

risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as

to whether the outlet is properly grounded. Do

not modify the plug provided with the appliance if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

PROPER GROUNDING (115V)

Grounding Pin

Grounded

Outlet

Fig. A

Tab For Grounding Screw

Adaptor

NOTE: In Canada, the use of a temporary a daptor is no

ermitted by the Canadian Electrical Cod

CHEMICALS

Suitable Chemicals

lkalis

Detergents

Hydroxides

Soaps

Vinegar

Metal Screw

Adaptor

Grounded Outlet Box

Fig. B

Fig. C

Non-Compatible

ldehydes

romatics Hydrocarbons

SP Butyls

Carbon Tetrachloride

Clorox*

Chlorinated Bleaches

Chlorinated Hydrocarbons

Lysol*

Methyl Ethel Ketone (MEK)

Perchorethylene (perc)

Phenolics

Trichlorethylene

D-Limonene

Warning:

Using the incompatible chemicals listed above

will damage the machine. Damages of this

type are not covered under the 6-3-1 warranty.

Carefully read ingredients on manufacturer's

label before using any product in this machine.

3

D-250 98637 04/25/02

Page 4

OPERATIONS

CARPET INSPECTION:

Determine precisely what areas you are

going to clean. Note problem areas in the

carpet or tack strip. Look for loose carpet,

heavily damaged areas, discolored stains,

or grease spots that will require prespotting.

Note the carpet type. Check the availability

of hot water, drains, and suitable electrical

outlets. If the carpet is loose or worn, have

it repaired before attempting to clean it.

Plan the cleaning route, work from the most

remote area towards the exit. Try not to

travel over the cleaned areas when getting

fresh water or dumping old. Furniture

should be moved out away from the walls

before cleaning. If furniture is moved back

in place before carpet is completely dry,

place plastic or foil protectors under the

legs to prevent possible carpet staining.

When poss i ble use a Windblower (WB3)

and open all windows and doors to speed

carpet drying.

ACCESSORIES:

The D-250 can be used with the following

Windsor equipment: Deluxe Hand Tool

(DHT), Pile Jogger(PJ2A), Standard Floor

Wands(SFW, SW, SW-PRO, PROW), &

Wind Blower carpet dryer(WB3). Contact

an authorized Windsor dealer for

assistance in choosing the right equipment .

GENERAL INFORMATION:

On heavily soiled carpets, or on areas of

high foot traffic, it may be necessary to

use a prespray or traffic lane cleaner

applied with a Pro-Spray. Do not add

presprays to the machine's solution tank. If

a spotter is used, follow the manufacturer's

instructions exactly as printed on the label.

Remove the spotter with the floor tool when

done, spotter left in the carpet may bleach

or brown it permanently.

As the carpet is being cleaned, check to

see if there is foam building up in the

recovery bucket. Add a little defoaming

compound to the recovery tank but never to

the solution tank.

For infrequent use or long periods of

storage, flush the system with a

neutralizing solution of 1 quart white

vinegar mixed with 2 gallons hot water.

Flush the system with clean hot water after

neutralizing.

For hose fitting lubrication, use a light

silicone lubricant which will not damage orings.

PROTECT THIS MACHINE FROM

FREEZING.

D-250 98637 0 1/15/99

4

Page 5

OPERATIONS

EQUIPMENT SET-UP:

1.) Plug power cable from machine into

properly grounded wall outlet.

2.) Turn vacuum motor switch on and off

to make sure there is electrical power at

machine.

3.) Connect vac hose to machine. Slide

the swivel cuff over the outlet on the tank.

4.) Connect the hose set to the machine

and wand. Pull back the knurled collar on

the quick disconnect coupler and push onto

the connection on the chassis. To avoid

leaks, check to be sure a positive

connection was made.

5.) Using a clean container, fill the

solution tank with clean, hot water. Mix in a

non-foaming cleaning concentrate for use in

hot water extraction machines following the

manufacturer's instructions, as printed on

the container. When using a powder

cleaner, premix with hot water in a clean

container before adding to the solution

tank.

6.) Turn pump and vacuum switch to the on

position.

NOTES:____________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

___________________________________

Serial

Number:____________________________

_____________

7.) Start cleaning.

5

Date

Purchased__________________________

______________

D-250 98637 01/19/99

Page 6

MAINTENANCE

DAILY MAINTENANCE:

(At the end of each working day) :

1.) Flush the entire system, including floor tool, hand tool, etc., with 1 to 3 gallons of clean,

hot water.

2.) Vacuum out the solution tank .

3.) Rinse tank with fresh water. Periodically inspect the recovery tank and decontaminate if

necessary, using a Hospital Grade Virucide or a 1-10 bleach to water solution. Waste

water should be disposed of properly.

4.) Remove lint build-up from the float shut-off screen in the recovery tank . (Occasionally

check filter screen at the bottom of the solution tank and rinse clean with hot water if

necessary).

5.) Inspect hoses for wear. Frayed or cracked hoses should be replaced to avoid vacuum

or solution pressure loss.

6.) Inspect power cord for wear or damage. This cable will lay on wet carpet. To prevent

electrical shock replace cords that are frayed or have cracked insulation immediately.

7.) Ensure automatic shut-off ball is working properly.

8.) Clean all dirt and obstructions from drain valve and gaskets to prevent possible leakage

and premature wear.

9.) Run clean water through solution pump when work is complete.

10.) Empty both tanks and rinse, run vacuum (s) for at least one minute to dry motor(s).

11.) Store with access covers removed to allow tanks to dry.

PERIODIC MAINTENANCE

1.) Twice a month, flush a white vinegar solution (One quart vinegar to two gallons of

water) or anti-browning solution (mixed as directed) through the extractor, turning pump

switch on/off several times, flush with clean water. This will prevent build-up of alkaline

residue in the system.

2.) Check hoses for wear, blockages, or damage. Frayed or cracked hoses should be

repaired or replaced to eliminate vacuum or solution pressure loss.

3.) Check all handles, switches, knobs, electrical cables and connections on your machine for

damage. If the cable insulation is broken or frayed, repair or replace it immediately. Don’t

take chances with electrical fire or shock.

4.) Clean out solution tank and remove and clean solution screen.

5.) Clean outside of all tanks and check for damage.

Monthly Maintenance

1.) Check all bearings for noise and wear.

2.) Check all gaskets for wear and leakage.

3.) Check pump pressure; observe spray pattern and check with gauge if necessary.

4.) Check overall performance of machine.

5.) Grease piston inside pressure regulator.

SEMI-ANNUALLY

1.) Check vacuum motor brushes.

D-250 98637 0 1/19/99

6

Page 7

MAINTENANCE

WARNING:

THE FOLLOWING REPAIRS.

VACUUM MOTOR REPLACEMENT

1. Turn off all switches and unplug machine.

2. Remove recovery tank.

3. Locate the vacuum motor wires and

disconnect at the connector.

4. Remove the vacuum motor.

5. Reverse process to install vacuum motor.

ONLY QUALIFIED MAINTENANCE PERSONNEL ARE TO PERFORM

Vac Motor Carbon Brushes Replacement

End Cap

Carbon Brushes

Note: When replacing carbon vac motor brushes

loosen wire terminal BEFORE removing screws on

bracket.

If armature commutator is not concentric, extremely

pitted, or grooved the motor will need to be replaced

or sent to a qualified service center to restore vac

performance.

Wire Terminal

WARNING: The green

ground wire must be

attached for safe

operation.

See wiring diagram.

Wire

Terminal

SOLUTION PUMP REPLACEMENT

1. Turn off all switches and unplug the

machine.

2. Remove recovery tank.

3. Remove solution hoses from fittings in

pump.

4. Remove the (2) screws that fasten the

pump to the frame.

5. Reverse process to install pump.

Important:

These brushes wear quicker

as the length shortens due to

increased heat.

Spring inside brush

housing will damage motor

if brushes are

allowed to wear away

completely.

Note:

Place

stop in

groove.

3/8

Periodically check the length of the carbon brushes.

Replace both carbon brushes when eit her is les s

than 3/8" long.

7

D-250 98637 06/19/00

Page 8

MAINTENANCE & TROUBLESHOOTING

8

D-250 PUMP MAINTENANCE

Per manufacturer’s recommendations the following maintenance should be performed

utilizing noted kits:

1.) 500 hours-Kit 55250751 replaces the V-packing, wave washer, packing spreader and

plunger guide.

2.) 500 hours-Kit 55250753 replaces the CAM bearing and insert.

3.) 1000 hours-kit 55250752 valve assembly and o-rings.

NOTE: Maintenance and repairs must be done by qualified personnel. Using nonWindsor parts to repair this machine will void the warranty. Contact an authorized

Windsor dealer for complete details.

TROUBLE SHOOTING CHART :

PROBLEM POSSIBLE CAUSE SOLUTION

No power to Dead electrical circuit Check building circuit breaker or fuse

machine box.

Faulty power cord Replace.

Electrical shock Equipment not grounding Follow grounding instructions exactly.

Receptacle not grounded Contact an electrician to check

building's wiring.

Internal wiring problem Have a trained service technician check

machine's wiring.

Vac motor speed Worn motor brushes Replace.

varies or doesn't run

Motor worn out Replace.

Faulty switch Replace.

Loss of Loose vacuum dome Center and seal dome over tank.

Vacuum

Crack in dome or Replace or repair using acrylic plastic

poor joint cement only.

Lint or dirt clogging With power off clean screen.

vacuum screen

Loose cuffs on vacuum Tighten cuffs turning counterclockwise.

hose

Vac motor seals leaking Replace.

Floor tool vac chamber Wash out with hose. Pick lint out with a

clogged wire.

Vac motor, hose, or Replace.

dome gasket

D-250 98637 1/15/99

Page 9

TROUBLESHOOTING CONT.

Solution hose Corrosion on fittings Clean with steel wool.

fitting hard to Soak in acetic acid (white vinegar).

connect Lubricate lightly with silicone base

lubricant.

Carpet not Severe soil conditions Make several passes at right angles to

getting clean. other. Use a prespray.

Carpet too wet Over saturation Adjust solution pressure to lower setting.

Make several passes without spray.

Carpet browning Leaving carpet too wet Check for loss of vac pressure.

Too much chemical in Check label for correct solution

concentration. .

Solution not Solution hose connection Check for positive connection

flowing properly

Faulty pump Repair or replace.

Faulty floor tool valve Repair or replace.

Faulty pump switch Repair.

TECHNICAL SPECIFICATIONS

POWER TYPE

ELECTRICAL: 115 V, 60 Hz, 15 Amps per power cable ((D250)

230 V, 50 Hz, 15 Amps (D250IE)

ELECTRIC VACUUM MOTOR: (1) –2/1.25 HP, 2 stage, Waterlift –150” (381cm)

SOLUTION PUMP: 250 psi, adj.

SOLUTION CAPACITY: 17 gallons (64.3ltr)

RECOVERY CAPACITY: 15 gallons (56.75ltr)

GENERAL DIMENSIONS/WEIGHT

WEIGHT: 97 lbs. ( 44 kg)

LENGTH: 20” (50.80 cm)

HEIGHT: 36” (91.44 cm)

WIDTH: 16” (40.64 cm)

POWER CABLE: 2-25’ (6.35 m) (D250)

1-25' (6.35 m) (D250IE)

9

D-250 98637 06/19/00

Page 10

115V WIRING DIAGRAM

D-250 98637 11/07/00

10

Page 11

230V WIRING DIAGRAM

11

D250 98637 06/19/00

Page 12

THIS PAGE LEFT BLANK INTENTIONALLY

D250 98637 06/19/00

12

Page 13

RECOVERY TANK ASSEMBLY

6

7

5

2

3

1

8

4

9

10

11

12

13

14

15

16

17

32

31

16

30

29

16

28

33

34

13

35

18

16

19AB

16

20

36

D-250 98637 11/07/00

21

22

23

24

27

25

26

Page 14

RECOVERY TANK ASSEMBLY

REF PART NO. QTY DESCRIPTION

1 05151 1 TUBE ASM, RECOVERY TANK

2 500009 1 LABEL, WARNING

3 260-64A 1 ACCESS COVER CLEAR 6” W/RIM

4 70546 6 SCR, 8 X 3/4 PFHT/S BLK ZINC

5 090-12A 1 FLOAT CAGE ASSY COMPLETE SLIP

6 240-46 1 FLOAT SCREEN ADAPTER 30 DEGREE

7 300-08 1 FL HD WD SCREW PH 6 X 1/2 SS

8 78460 1 TUBE, 1.5 PVC X 16.5

9 04032 1 ADPTR, 1.5 MPT X 1.5 FS PVC

10 320-05 2 VELCRO STRAPS

11 370-06A 1 DUMP VALVE 1-1/2 M THREAD

12 31032 1 ELBOW, 1.5 FS X FS 45D PVC

13 390-26 3 SPACER NYLON 1/4 ID X 1/2 OD

14 110-26B 1 GASKET VAC BRACKET

15 360-24 1 PLATE, VAC

16 87013 13 WASHER, 1/4 ID X 5/8 OD SS

17 35011 1 GASKET, 3/8T 5.7 VAC FAN SEAL

18 065-92 3 VAC SPACER 2 1/4 II STAGE

19A 360-04A 1 VACUUM 110V TWO STAGE 116392-0

19B 360- 0 6 1 VACUUM 116213 220V SM 2 ST G

20 70250 1 SCR, 1/4-20 X 3.5 HHCS PLTD

21 87016 3 WASHER, #10 LOCK EXT STAR SS

22 70335 1 SCR, 10-32 X 1/2 PHTR GRN/GRND

23 20063 1 CLAMP, 1.75” WORM GEAR X .312

24 39337 1 HOSE, 1.5 BLK VAC X 24”

25 27508 1 CUFF, VAC HOSE BLU

26 20046 1 CLAMP, 2.25” WORM GEAR

27 880292 1 WIRE, 4” GRN/14 76010 X 76014

28 75334 1 TANK, RECOVERY DB DK GRY

29 70015 2 SCR, 1/4-20 3/4 HHCS SS DL

30 065-25 1 TANK BRACE ASM, D/B

31 70020 2 SCR, 1/4-20 X 1/2 HHCS SS NP

32 40001R 1 HOSEBARB, 1.5 MPT X 1.5

33 39574 1 HOSE ASM, 1/4 HP SLTN 16.5FT

34 150-44A 1 VAC HOSE 16-1/2’ W/CUFFS 1 1/2

35 47356 1 KIT, HOSE ASM W/BAG DOM50

36 150-65 1 HOSE BAG 24” X 36”

SERIAL NO.

FROM

NOTES:

D-250 98637 11/07/00

14

Page 15

SOLUTION TANK ASSEMBLY

12A

230V

14

15

20

13

14

15

16

18

19

20

12B

13

16

17

21

31

26B

25

24

23

17

21

30

29

28

27

31

25

24

23

22

40

41

42

44

30

27

26A

6

5

7

8

8

9

10

11

29

28

33

34

37

38

8

39

43

35

36

38

8

45

46

4

3

2

1AB

67

68

41

69

70

32

60

8

54

53

52

46

51

50

49

48

47

38

63

66

65

64

63

62

38

58

57

8

61

59

38

56

55

15

D-250 98637 11/07/00

Page 16

SOLUTION TANK ASSEMBLY

REF PART NO. QTY DESCRIPTION

1A 360-04A 1 VACUUM 110V TWO STAGE 116392-0

1B 360-06 1 VACUUM 116213 220V SM 2 STG

2 05152 1 TUBE ASM, VAC EXHAUST

3 50009 1 PAN HD SH MTL SCREW 10 X 1/2 SS

4 88208 1 WIRE, 21” GRN/14 76001 X 76010

5 87016 1 WASHER, #10 LOCK EXT STAR SS

6 70335 1 SCR, 10-32 X 1/2 PHTR GRN/GRND

7 70663 3 SCR, 1/4-20 X 3 1/4 HHCS PLT

8 87013 18 WASHER, 1/4 ID X 5/8 OD SS

9 065-92 3 VAC SPACER 2 1/4 II STAGE

10 35011 1 GASKET, 3/8T 5.7 VAC FAN SEAL

11 360-24A 1 PLATE ASM, VAC 90 DEG

12 070-08 1 FAN 105 CFM AXIAL

13 61367 1 PANEL ASM, CONT. 3 SW W/HEAT

14 070-08A 1 FAN FINGER GUARD

15 70626 4 SCR, #10 X 3/4 PPHST HI-LO BLK

16 70018 1 SCR, 1/4-20 X 1 HHCS SS

17 330-02 3 ROCKER SWITCH 2 PRONG

18 060-04A 1 CORD 25’ BLK 14/3 SJTW/A PLUG

19 060-04 1 CORD 25’ BLK 12/3 SJTW/A PLUG

20 170-41 2 LABEL CIRCUIT INTERUPTER

21 170-31 1 HEATER MATE WARNING T AG

22 73195 2 STRAIN RELIEF, 1/2 NPT (.48M)

23 330-06 1 TOGGLE SWITCH BOOT

24 330-05 1 TOGGLE SWITCH

25 3350-04 1 TOGGLE SWITCH PLATE ON/OFF

26 51116 1 LIGHT ASM, 115V BRUSH WEAR

27 22046 1 CLIP, NEON LAMP

28 500345 1 LABEL, DOM3 SWITCH W/HEAT

29 57040 2 NUT, 1/2 NPT CONDUIT

30 140-11 2 KNOB RT/TANK

31 57105 3 NUT, 1/4-20 HEX W/STAR WASHER

32 87217 1 WASHER, 9/16 ID MCHD

33 030-16 1 ELBOW, 1/4 NPT STREET LONG 90D

34 010-02 1 AXLE ASM, RIGHT

35 151-50C 1 DB 200PSI PUMP TO QD

36 70088 1 SCR, 10-32 X 1/2 PPHMS SS NP

37 20008 1 CLAMP, 5/8 NYLON UL/USA

38 70020 20 SCR, 1/4-20 X 1/2 HHCS SS NP

39 065-26 1 HEATER MOUNT ASM, D/B

40 31017 1 ELBOW, 1/4 FPT X FPT UNION

41 56014 2 NIPPLE, 1/4 CLOSE

42 41396 1 HEATER ASM, DB COMPLETE

43 31021 1 ELBOW, 1/4 NPT 45D STREET

44 151-51C 1 DB 200PSI PUMP TO HEATER

45 31016 1 ELBOW, 1/4 NPT STREET

46 20042 2 CLAMP, 3/8 HOSE (D-SLOT)

47 40047 1 HOSEBARB, 1/4NPT X 1/2H 90D DL

48 250-79 1 PUMPTEC 200PSI PUMP & MOTOR

49 66017 2 PLUG, 1/4 BRASS PIPE

50 39174 1 HOSE, 1/2 WIRE BOUND X 23”

SERIAL NO.

FROM

NOTES:

D-250 98637 11/07/00

16

Page 17

SOLUTION TANK ASSEMBLY CONT'.

REF PART NO. QTY DESCRIPTION

51 065-28A 1 PLATE, PUMP MOUNT

52 40013 1 HOSEBARB, 3/8 MPT X 1/2 DL

53 31026 3 ELBOW, 3/8NPT STREET

54 70232 2 SCR, 10-32 X 3/8 PPHMS SS

55 57196 2 NUT, 1/2 PUSH-ON DOME CAP

56 040-06 1 WHEEL 8” BLK CENTERED HUB

57 010-01 1 AXLE ASM, LEFT

58 065-28 2 DIAMONDBACK 200 PUMP SUPPORT

59 040-03 1 CASTER SWIVEL 4” SWIVEL

60 290-08 1 SOL SCREEN (ACORN) W/RUB BASE

61 75349 1 TANK, SOLUTION DOM 250 DK BLU

62 500378 2 LABEL, DOMINATOR

63 280-02 2 RIVIT AL. 3/16 X 1/2 CLOSED

64 390-24 2 WASHER 1/4 X 5/8 BONDED NEOPRN

65 140-12 1 KNOB 1/4-20 X 3/4 S/S CUPPOINT

66 27912 1 CHAIN ASM, #10 BEAD S/S W/EVES

67 260-71 2 SOLUTION COVER D/B

68 56012 1 NIPPLE 1/4 FPT QD

69 250-35 1 D/B BPR 200PSI

70 151-50B 1 HOSE, 42” GRY 3/8 1/4 MPTXCUT

SERIAL NO.

FROM

NOTES:

17

D-250 98637 06/19/00

Page 18

SUGGESTED SPARE PARTS

SUGGESTED SPARE PARTS

DESCRIPTION PART NUMBER PAGE/REF

FUSE 55100041 15/203

BPR KIT 55250331 15/191

THERMOSTAT 55130149

THERMOSTAT 55130143

KIT, PACKING PUMP 55250751

KIT, BEARING PUMP 55250752

KIT, VALVE PUMP 55250753

CARBON BRUSHES, VAC MOTOR 115V 140370

VAC MOTOR ASM, 115V UPPER 5536032 13/111A

VAC MOTOR ASM, 115V LOWER 5536033 15/131A

VAC MOTOR ASM, 230V UPPER 55360321 13/111B

VAC MOTOR ASM, 230V LOWER 55360331 15/131B

PUMP, 200 PSI 115V 5525079 15/168A

PUMP, 200 PSI 230V 55250791 15/168B

SWITCH 5533002 15/142

8” GRAY RUBBER WHEEL 5504006 15/171

WHEEL CAP 1/2 5504007 15/172

4” CASTER 5504003 15/177

SOLUTION TANK KNOB 5514012 15/180

SWITCH PLATE KNOB 5514011 15/141

ACCESS COVER 55260641 13/114

STRAINER 5529008 15/199

SEAL, DUMP VALVE 5537008

PANEL LAMP 110V 5505030 15/146A

PANEL LAMP, 230V 5505031 15/146B

TOGGLE SWITCH, 115V 5533005 15/147A

TOGGLE SWITCH, 230V 55330051 15/147B

HOSE, PRIMING 5515076 15/204

NOTES:

D-250 98637 06/19/00

18

Page 19

LIMITED WARRANTY

Windsor Industries, Inc. warrants new machines against defects in material and workmanship

under normal use and service to the original purchaser. The warranty period is subject to the

conditions stated below.

3 YEARS FOR PARTS AND 1 YEAR FOR SERVICE LABOR

Exceptions: Rotationally molded polyethylene tanks carry a 6 year parts and 1 year service

labor warranty.

motors, and belts, and a 1 year service labor warranty. SENSOR

warranty on vacuum motors and belts, and a 1 year service labor warranty. Extractor brush

motors, pump motors, pc boards and electronics, vac motors (other than

VERSAMATIC

SENSOR®), pumps, and FLEXSOL™ diaphragms, all RADIUS™, all AXCESS™ and

TITAN™1 carry a 1 year parts and service labor warranty. Propane equipment has a 1 year

parts and service warranty. The Onan® engines have a 3 year manufacturers’ warranty. The

Honda® engines have a 2 year manufacturers’ warranty. The engine warranty is administered

through the engine manufacturer and must be repaired at an authorized service center.

Normal wear items including, but not limited to, belts, brushes, capacitors, carbon brushes,

casters, clutches, cords, filters, finishes, gaskets, hoses, light bulbs, rectifiers, switches, squeegees, bearings, pulleys, relays, actuating cables, tires and wheels will be warranted for

manufacturing defects for 90 days from the purchase date.

The warranty commences on the purchase date by the original end user from an authorized

Windsor Agent, subject to proof of purchase. The Machine Registration Card must be

completed and returned immediately at the time of purchase. If proof of purchase cannot be

identified, the warranty start date is 90 days after date of sale to an authorized Windsor

distributor. Parts replaced or repaired under warranty are guaranteed for the remainder of the

original warranty period.

®

models carry a 3 year warranty on brush motors, vacuum

®

models carry a 2 year

VERSAMATIC® and

90 DAY WARRANTY EXTENSION AVAILABLE

Upon receipt of the Machine Registration Card, Windsor will extend the warranty period an

additional 90 days from the purchase date. Does not include items warranted 90 days for

manufacturing defects.

STATED WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED.

Any statutory implied warranties, including any warranty of merchantability or fitness for a

particular purpose, are expressly limited to the duration of this written warranty. Windsor will not

be liable for any other damages, including but not limited to indirect or special consequential

damages arising out of or in connection with the furnishing; performance, use or inability to use

the machine. This remedy shall be the exclusive remedy of the buyer.

This warranty shall not apply to: 1.damage in transit; 2.misuse or abuse(including the use of

incompatible or corrosive chemicals or overloading of capacity); 3. failure due to lack of proper

maintenance and care (including cleaning); 4.any design alterations performed by an

organization not authorized or specified by Windsor; 5.batteries and chargers. 6. high pressure

washing. 7.electrical components exposed to moisture.

If difficulty develops during the warranty period, contact the authorized Windsor Agent from

whom the product was purchased. Windsor, Inc. may elect to require the return of components

to validate a claim. Any defective part to be returned must be shipped freight pre-paid to an

authorized Windsor Distributor/Service Center or to the Windsor factory.

USE OF PARTS NOT APPROVED BY WINDSOR, INC.

WILL VOID ALL WARRANTIES.

This warranty is valid only for all products sold after July 1, 1995. A product sold before that

date shall be covered by the limited Warranty in effect at the date of sale to the original

purchaser.

ã 1999 Windsor Industries, Inc. All rights reserved. REVISED 03/24/9 9

Loading...

Loading...