Page 1

COMMODORE

1

15V-98048

Model

CMD

I

WINDSOR

INDUSTRIES, INC., 1351

W.

Stanford

Ave..

Englewood.

CO

80110

USA

303/762-1800

FAX

303/7626817

Page 2

COMMODORE 115V

IMPORTANT

SAFETY

INSTRUCTIONS

When using an electrical appliance, basic precautions

should always be followed, including the following:

Read all instructions before using this machine.

This machine

is

for commercial use.

SHOCK,

OR

INJURY:

WARNINO:

TO

REDUCE

THE

RlSK

OF

FIRE, ELECTRICAL

A

1.

Do not use outdoors or expose to rain.

2.

Machines can cause a fire when operated near flam

-

mable vapors or materials.

Do

not operate this machine

near flammable fluids, dust, vapors or gas.

Do

not pick

up burning materials such as cigarettes or matches.

3.

Do

not leave the machine unattended. Unplug machine

from power outlet when not in use.

4.

Switch off switches before disconnecting power cord

from electrical outlet.

5.

Maintenance and repairs must be done by qualified

personnel.

6

Do

not disconnect cord from outlet by pulling on cord.

Grasp plug to remove from outlet.

7.

Do

not use power cord as a handle, close door on cord,

or pull cord around sharp edges or corners.

8

Do

not

operate machine with any openings blocked.

Keep openings free of debris that may reduce air flow.

9.

Do

not use machine as a step or operate machine

unless

it

is completely assembled.

SAVE

THESE

INSTRUCTIONS

Page 3

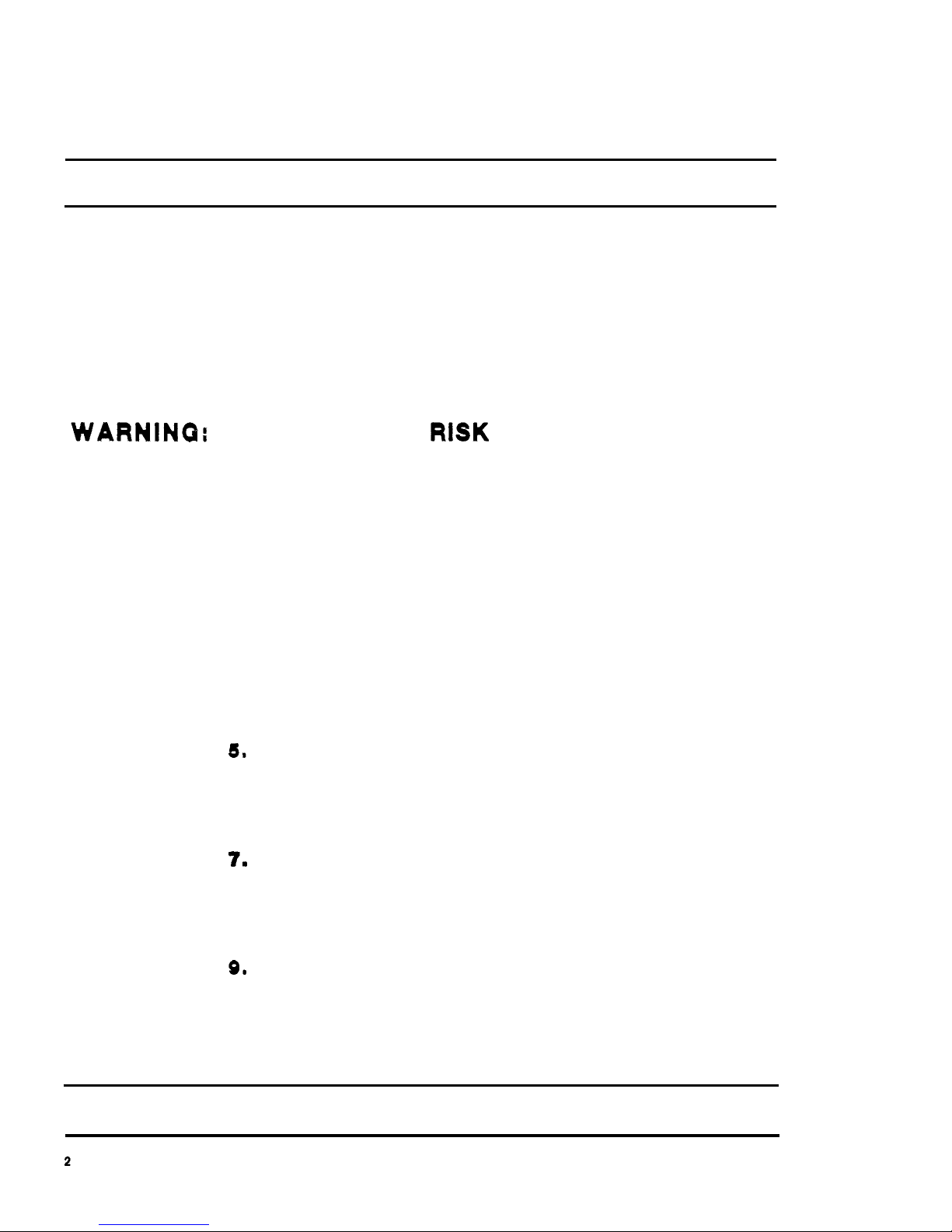

COMMODORE

1

15V

[COMMODORE

SOLUTION

SWITCH

DRIVE

MOTOR

SPIEDCONTROL VACUUM

LEVER

Turns on solution pump.

Turns

on

PrOPelling

Controls forward pro

-

Release to forward

Glows red when on.

motor. Glows red

pelllng speed from position to lower vac

when on. stop to 4 (max.). shoe assembly to

carpet as well as start

\

\

\

vacuum motor.

CIRCUIT

BREAKER

Protects brush drive

motor from burn

-

out.

Push to reset after

correcting problem.

CLUTCH LEVER

Push down to propel

when

DRIVE

MOTOR

is on.

DRIVE

MOTOR

LINE FUSE

Protects drive motor and circuit board.

Replace fuse after correcting problem.

3

Page 4

COMMODORE

11

5V

PREPARING

THE

COMMODORE

FILL SOLUTION TANK

to

the desired

tevel according

to

the marked gauge

inside the tank.

CAUTION:

If a bucket

Is

used

to

fill the tank, be sure that

it

Is clean.

CAUTION:

To avoid oossible distortion

of polyethylene

solution/recovery tanks,

DO NOT

USE

WATER TEMPERATURE

THAT EXCEEDS

150°F

(65°C).

UPUID

DETERGENTS ARE

PREFERRED,

however if a powdered detergent is

used, be sure

it

is fully dissolved

BEFORE

putting

it

in the solution tank.

Do

this by dissolving it in a bucket

containing about

1

gallon of hot water

before emptying it into the solution tank.

You will find a

1

cup

(8

02.)

measure

on the bottom of the solution tank lid

to

assist you in making the proper

dilution of cleaning chemical and water.

WARNING:

Do not put defoamer.

solvents, spotter or prespray chemicals

in the solution tank.

CHEMICALS

The internal parts

of

the pump used in

the extractor is suitable for use with

most carpet cleaning chemicals. But it

is susceptible

to

chemical attack from

some cleaning substances, such as

hydrocarbon solvents and chlorinated

Meaches. These noncompatible materials

are not of the type normally used for

carpet cleaning,

SUITABLE

MOMCOMPATIBLE

CHEMICALS CHEMICALS

Alkalls

Aldehydes

Clomx

II

Bleach’

Aromatlc

Hydrocarbons

Moamlng

Agents

But

Is

Detergents

Carion

Tetrachloride

Hydroxides

Clomx’

Oxygen

Bleaches

Chlorinated

Bleaches

soaps

Chlorinated

Hydrocarbons

Sta-Puf

Fabric

Softener’

1

sol.

Vinegar

dthyls

(MEK)

White

Monday

Bleach’

Phenols

*wm

rrmlr

Trlchlorethylene

PLACE RECOVERY DOME

atop recovery

tank, being sure that gasket material

is undamaged and making a good seal

with the recovery tank. Connect hose

from

vac shoe

to

dome.

1.

4

ATTACH ELECTRIC CABLE

to

Twist-Lok

connection at rear of control panel

beneath operating handle.

.

Note that all switches are in

“off”

position when attaching Twist-Lok.

.

Attach cable strain reliever as shown

to

prevent damage

to

power cord

connections.

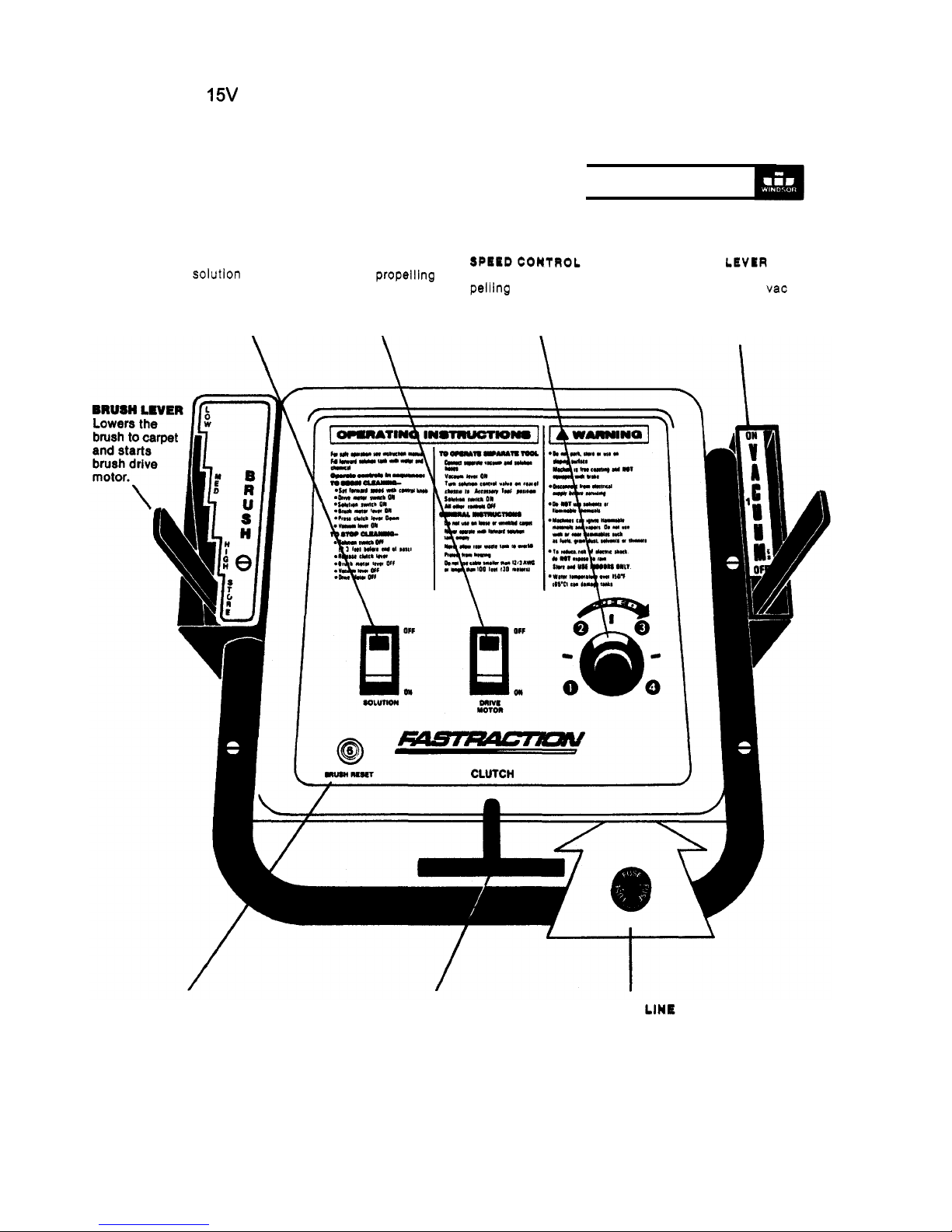

GROUNDINQ INSTRUCTIONS

This appliance must be grounded. If

it

should malfunction or breakdown,

grounding provides a path of least re

-

sistance for electric current

to

reduce

the risk

of

electric shock. This appliance

is equipped with a cord having an

equipment

-

grounding conductor and

grounding plug. The plug must be

plugged

Into an appropriate outlet that

is

properly Installed and grounded In

accordance with all local codes and

ordinances.

WARNING;

Improper con

-

nection

of

the equipment-grounding con

-

ductor can result in a risk

of

electrical

shock. Check with a

qualified

electrician

or

service person if you are in doubt

as

to

whether the outlet is properly

grounded.

Do

not modify the plug pro

-

vided with the appliance - If

it

will not

fit the outlet, have a proper outlet in

-

stalled by a qualified electrician.

This machine is for use on a nominal

120

-

volt circuit, and has a grounded

plug that looks llke the plug illustrated

In

Fig.

A.

A

temporary adapter that

looks like the adapter illustrated in

Figs.

B

and C may be used

to

connect

this plug

to

a 2-pole receptacle as

shown in Fig. B if a properly grounded

outlet is not available. The temporary

adapter would be used only

until

a

properly grounded outlet (Fig.

A)

can

be installed by a qualified electrician.

The green colored

rigid ear, lug, or the

llke extending from the adapter must

be connected

to

a permanent ground

such as a properly grounded outlet

box

cover. Whenever the adapter Is used,

it

must

be

hew

in

place

byametal

m.

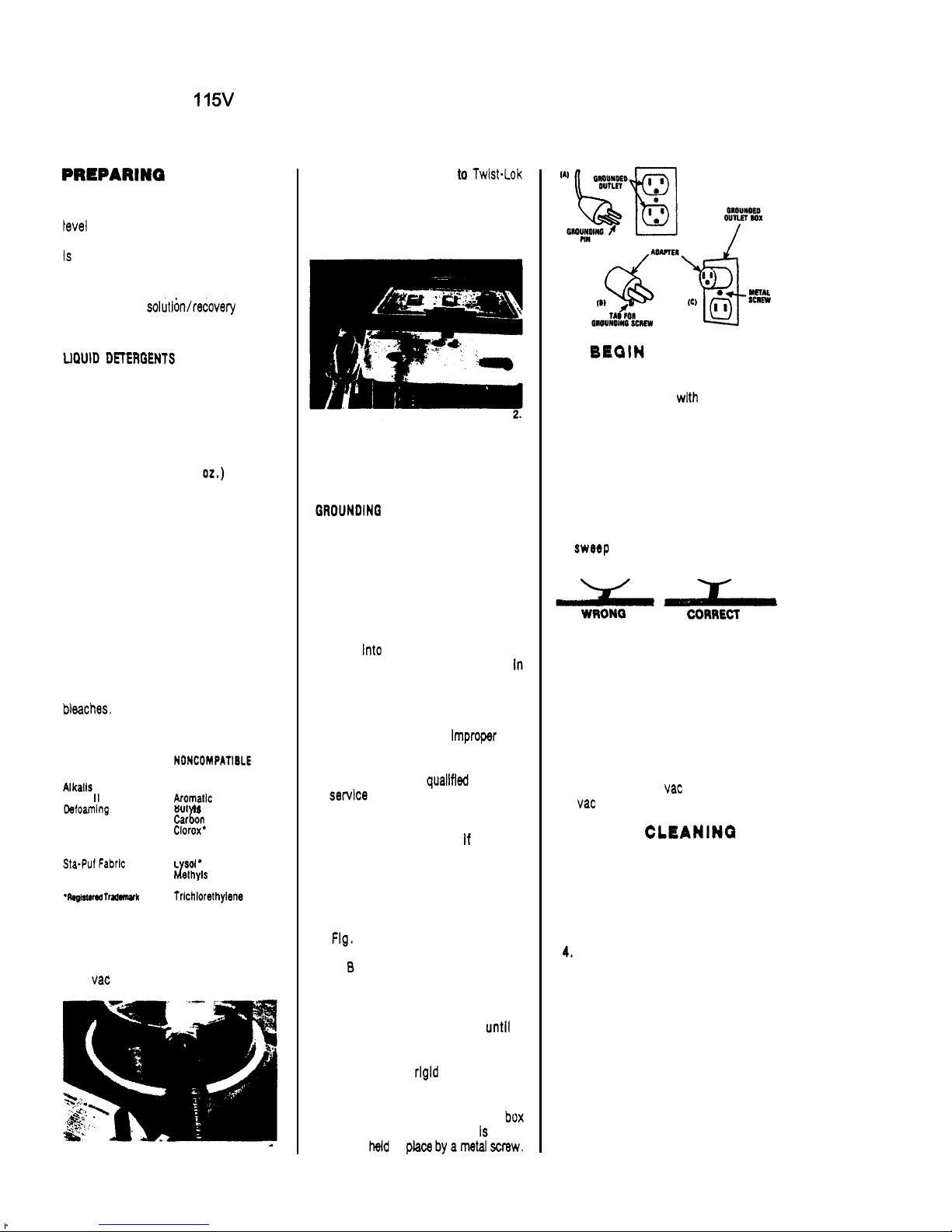

TO

BEQlW

CLEAWINQ:

FOLLOW THE SEQUENCE BELOW.

.

.

1.

Set

forward speed with control knob.

2.

Press

“drive” motor switch

to

“on”

position. Red light will glow.

3.

Press “solution” switch

to

“on”

position. Red light will glow.

4.

Release “Brush Motor Lever”

to

“on” position and adjust brush

to

correct cleaning height. The brush

setting Is correct when the bristles

swwp

the surface of the carpet.

wmona

commm

NOTE:

Starting the machine with

dry bush resting on the carpet may

trip circuit breaker.

5.

Press down on clutch lever

to

start

forward movement.

WARNING:

Do

not secure clutch lever

in “down” position. Damage

to

machine could occur.

6.

Release vacuum lever

to

“on”

position

to

start vac

motor

and

lower

vac shoe

to

carpet.

TO

STOP

CLEANINQ

FOLLOW THE SEQUENCE BELOW

.

.

.

1.

Push solution switch

to

“off”

(2

or

3

2.

Release clutch lever.

3.

Lift brush lever

to

“off” position.

4,

Lift vacuum lever

to

“off”

position.

5.

Push drive motor switch

to

”off”

position.

WARNING:

The drive train of the

COMMODORE is

FREE WHEELING

and the machine should not

be

left

unattended or used on sloping sur

-

faces or ramps.

feet before end

of

pass.)

TO PULL THE COMMOOORE IN RE

-

VERSE,

or go forward without power

...

first raise vacuum and brush levers

to

“off”

position.

I’

’

Page 5

COMMODORE

1

15V

CLEANING TIPS

.

.

.

GO

SLOW

on very dirty carpet

to

avoid streaking.

Be

prepared

to

make

two cleanings if carpet

is

badly

soiled. Prespraying may also be

necessary.

Narrow bands of streaking

can

result

from a plugged nozzle. See service

section for Instructions. Pay more

attention

to

using a clean bucket

when filling solution tank

to

avoid

future problems.

Paths, or wide stripes, over the

carpet can occur with certain types

of

carpets. This is due

to

the “lay”

of the carpet fibers.

It

will go away

when vacuumed.

Be

sure

to

overlap enough

to

prevent

uncleaned stripe.

WORK AWAY

from the power source

if

possible. Begin cleaning next

to

wall.

This will allow you

to

always make

turns away from the cable.

KEEP

THE MACHINE MOVING

when

jets

are “on.” If

it

becomes necessary

to

stop

to

maneuver in a turn or corner,

push the solution switch

to

the

“off”

position.

CAUTION:

Overwetting of the

carpet

is

likely,

or

damage

to

the carpet

is possible, if the COMMODORE is

permitted

to

stand in one position with

the jets or brush on.

THE FORWARD SPEED

of the COM

-

MODORE

is

controlled with the knob on

the control panel, numbered from

1

to

4.

RESTORATION

OR

SALVAGE CLEANING

will be best accomplished with the

control set from

1%

to

2%.

MAINTENANCE CLEANING

can be best

accomplished somewhere from

2%

up

to

4,

depending upon the condition of

the carpet being cleaned.

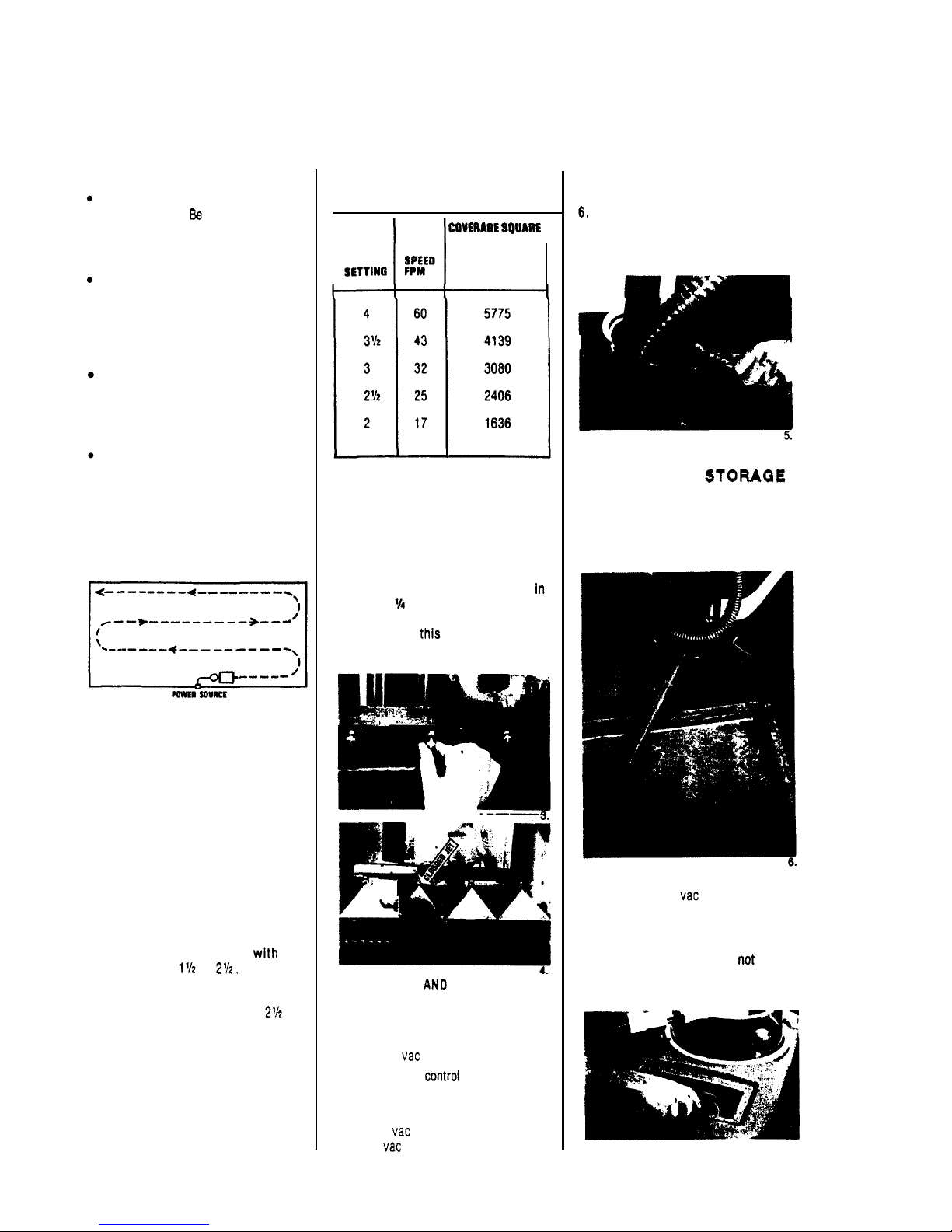

Forward speeds and approximate

coverages are:

I

COVERIOE

SQtJARE

I

II

FEET

PER HOUR

(Straight ahead

SPEED

cleaning - no

SETTINO

FPM

allowances)

I

II

SPRAY

JETS

To prevent clogged jets due

to

alkaline

build

-

up, the spray system should be

flushed with

2

or

3

gallons of clean hot

water at the end of each day. The

COMMODORE

is

equipped with “quick

change”

jets

that can be easily removed

for cleaning. To remove

-

push jet

In

and rotate

l/4

turn. Wash jets and blow

dry.

Do

not use pins or wire

to

remove

obstruction as

this will change spray

pattern.

TO USE FLOOR AN0 HAND TOOLS

with

the COMMODORE:

1.

Attach auxiliary solution hose

to

outlet nipple.

2.

Connect vac hose

to

recovery dome.

3.

Turn solution control valve

to

“acces

-

4.

Press pump switch “on.“

5.

Lower vac lever

to

“on”

position

to

sory

tool”

position.

start

vac motor.

WARNING:

All

other switches on

control panel must remain

“OFF.”

6.

Make sure solution control valve is

returned

to

“carpet spray” position

before using the COMMODORE for

self

-

contained carpet cleaning.

CLEANUP AND

STORAQE

EMPTY RECOVERY TANK

directly into

floor drain. Flush inside

of

recovery

tank with clean water. Clean the inside

of the recovery dome.

EMPTY SOLUTION TANK

by detaching

recovery hose at

vac shoe and placing

into solution tank with vacuum motor

running.

CAUTION:

Never allow recovered solu

-

tion

to

remain in tank when not in use;

nor allow unused solution

to

remain in

solution tank when in storage.

7.

5

Page 6

COMMODORE

115V

STORE

COMMODORE

with recovery

shoe in the “up” position. Place

recovery dome upside down in recovery

tank as shown

to

permit drying of

gasket and the inside

of

the tank.

INSPECT

screens in solution and re

covery tank. Remove and rinse with

hot water.

PERIODIC MAINTENANCE

EVERY

TWO

WEEKS:

CLEAN SOLUTION SYSTEM

by diluting

2

gallons of clean water with a quart of

white vinegar (acetic acid) in solution

tank. Run solution through the system

with the machine parked over a floor

draln. This procedure will free the

system of harmful buildups which

could eventually cause it

to

plug.

EVERY

500

OPERATING HOURS:

OIL FRONT DRIVE WHEEL BEARINGS

by

removing hub cap and snap ring on

axle. Slide wheel

oft

axle

and

apply

6

drops of

1OW

oil

to

bearings.

SPECTION

loosen screws holding tank

support bracket

to

frame and

tilt

tank

assem bly forward.

WARNING:

Remove machine power

cord from electrical source before

maklng any adjustments or repairs

to

the machine.

TO

EXPOSE WORKING PARTS

FOR IN-

1

0.

6

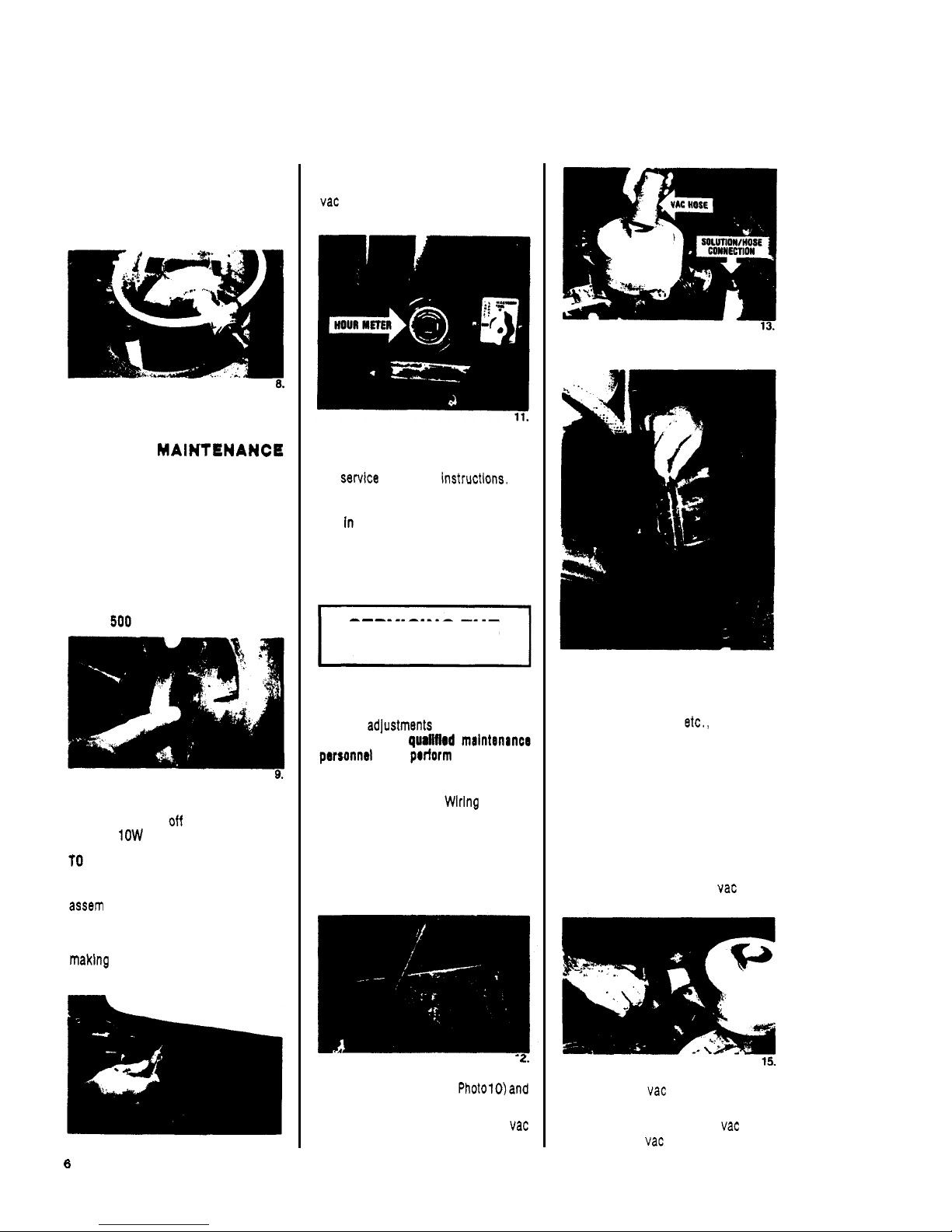

THE HOUR METER

keeps track of

operating hours.

It

is wired into the

vac motor circuit

so

that all operations

using the vacuum are recorded.

REMOVE VACUUM MOTOR

to

inspect

carbon brushes for wear.

If

worn to

3/8

inch, the brushes should be replaced.

See

service section for instructions.

USE COMPRESSED AIR

to

blow out

dust

In brush drive motor.

SERVICING THE

COMMODORE

WARNING:

Remove machine power

cord from electrical source before mak

-

ing any adjustments or repairs

to

the

machine.

Only

qualified

malntenano

personnel

an

to

parform repairs.

CAUTION:

When replacing electrical

parts refer

to

machine Wiring Diagram

for proper connections.

TANK REMOVAL

1.

Empty solution and waste water

tanks

.

I

L.

2.

Loosen screws holding tank support

bracket

to

frame (see Photo10)and

tip tank assembly forward.

3.

Disconnect hoses from tank and vac

motor.

4.

Remove front hinge pins and

set

tank

aside.

14.

TANK REPAIR:

The tanks are made of Polythylene.

Small holes, cracks,

etc., can be re

-

paired by using heat. Apply low heat

from torch

to

damaged area

until

material is softened. Use screw driver

blade or other flat metal tool

to

seal

damaged area.

VACUUMMOTOR

REMOVAL

1.

Disconnect hose from vac motor

exhaust.

2.

Disconnect vac motor leads from

3.

Remove 3 screws holding vac motor

terminal block.

and remove

vac motor.

Page 7

COMMODORE

1

15V

4.

To

inspect

motor

brushes, remove

metal band around motor and remove

brush holder assembly. Brushes

should be replaced when worn

to

318

Inch

or

after about

750

operating

hours. After second brush replace

ment, armature commutator should

be checked

for

pitting and concen

-

tricity. Vacuum motors can be re

-

paired but such repairs should be

made

by

a qualified

motor

repair

shop.

SOLUTION

PUMP

REMOVAL

1.

Disconnect solution lines at pump.

2.

Remove

(4)

screws holding pump

to

base.

3.

uft

pump up

to

access solution inlet

line and disconnect from pump head.

Refer

to

Pump Drawing for Replace

-

ment

Pump Parts.

CAUTION:

When replacing fittings

on

pump head

M)

NOT

OVERTIGHTEN

as this could crack inlet and outlet

ports in pump head.

SOLENOID VALVE

REMOVAL

1.

Disconnect solenold valve leads

from terminal block.

2.

Disconnect solution hoses from

solenoid valve.

3.

Lay machine on side and remove

(2)

screws holding valve

to

chassis.

4.

Clean.

repair, or replace

as

required.

BELT/BRUSH ASSEMBLY

REMOVAL

1.

Remove belt guard.

20.

2.

Lay machine on side and remove

brush pulley guard.

Z1.

3.

Roll belt

off

motor pulley.

4.

Retwve

(2)

screws holding

seal

plate.

5.

Remove screw from each end

of

6.

Swing brush assembly out of housing

BRUSH %HAP TIBRUSH

BEARINQ REMOVAL

1.

Remove the large snap ring from

brush pulley.

2.

Drive the shaft and bearing out from

OPPOSITE

pulley end.

NOTE:

Insert a

‘14-20

x

2”

screw into

threaded shaft or use

a

brass drift

to

prevent damage

to

internal threads

in shaft.

brush shaft.

to

remove belt.

INSTALLINO

NEW

BRUSH BEARINQS

1,

Install bearing

OPPOSITE

pulley end

first.

2.

Install shaft making sure

inner

snap

ring is on shaft.

3.

Install bearing in pulley. Use arbor

press or tap in with a hammer and

socket.

24.

4.

Install the

wter

snap ring on shaft,

and bearing retaining snap ring inside

pulley.

7

Page 8

COMMODORE

1

15V

BRUSHHEADASSEMBLY

1.

Remove belt guard.

2.

Roll

belt

off

motor pulley.

3.

Loosen set screws in locking collars

on pivot shaft. Slide out shaft

to

lower brush head assembly.

BRUSH DRIVE

MOTOR

1.

To

access motor mounting bolts,

lower brush head assembly.

2.

Disconnect motor leads from terminal

block.

3.

Rm

(4)

motor mounting screws.

4.

Lift out motor and repair or replace

as required.

NOTE:

When reinstalling motor,

make sure pulleys are properly

aligned and belt tension is adjusted

to

prevent slipping.

VACUUM

SHOE

RullOVIL

1.

Remove upper link arms.

2.

Remove ball joint linkage.

3.

Disconnect

lift

cable from vac shoe.

4.

Remove tension springs.

5.

Repair or replace as required.

VAC

SHOE

ADJUSTMENT

NOTE:

When replacing vac shoe or bail

joint(s), adjust vac shoe as follows:

With machine on smooth level

surface

the front and rear shoe of vac casting

should be parallel with surface.

1.

If front of shoe is off floor (Fig.

3),

lengthen lower adjusting rods.

2.

If

rear

of shoe is off floor (Fig.

2),

shorten lower adjusting rods.

3.

Retighten lock nuts on adjusting

rods after completing

vac shoe

adjustment.

Vac

Shoe Hdght Adjustment

-

Place machine on smooth

shoe, Lever should have

level surface, lower

vac

approximately

1

"

of

additional forward travel

when properly adjusted.

Lengthen or shorten lift

rods

A

&

B

as required

(Fig.

4).

TO

ADJUST VAC SHOE

TRACKINO

1.

With machine moving forward check

vac shoe for "tracking.

"

2.

If shoe pulls

to

the

LEFT

tighten right

hand spring adjusting knob.

3.

It

shoe pulls

to

the

RIGHT

tighten

left hand spring adjusting knob.

27.

TRAv@RsEDRlvItMoToR

AND CLUTCH RLMOVAL

1.

Disconnect motor leads.

2.

Disconnect leads from clutch coil.

3.

Remove chain.

NOTE:

Chain has

master link for easy removal.

4.

Remove

(4)

bolts

holding motor

to

chassis and lift out motor.

5.

Remove

brush

cap

and inspect motor

brushes periodically. Brushes should

be replaced when they reach

318"

length or after approximately

750

operating hours. The gear box is

sealed and permanently lubricated

for the

life of motor.

CLUTCH REMOVAL

AND

SERVICINO

Depending on the duty cycle of the

clutch, periodic inspections and clean

-

ing of the clutch

parts

should

be

made.

1.

Remove

bolt from center of gear unit

shaft.

30.

2.

Remove bolt holding clutch stabaliz-

ing arm.

3.

Remove sprocket from shaft. Use

bearing puller as needed.

Page 9

COMMODORE 1 15V

32.

To check clutch coil

resistance-

1.

Disconnect machine power cord from

2.

Disconnect clutch lead connection.

3.

Set

volt/ohm meter

to

check ohms.

4.

Connect meter leads

to

clutch leads.

If the meter reads below

160

ohms

or above

195

ohms replace coil.

Accumulation

of

alrbom dust

and

dls

may bause the clutch

to

slip and

lose traction. Remove clutch and

clean

mating parts with a cleaning

solvent.

outlet.

fRONTAXLeANDWHEEL

ASSEMBLY REMOVAL

1.

Remove drive chain (see Photo

28).

2.

Lay machine on side.

3.

Remove nuts and bolts holding

flange bearing to frame.

4.

Remove axle assembly from machine

and put on workbench

to

service.

5.

Remove snap ring on each end of

axle

to

remove wheels.

WHEEL AND AXLE

SERVICE/INSTALLATION

1.

Install flange bearing on axle.

Po

-

sition set screws (in locking collars)

over innermost flats on axle and

tighten screws.

(Slight adjustment

of bearings may be necessary when

reinstalling assembly

to

frame.)

2.

When replacing sprocket on axle

note dimension

-

approximately

3

5/16

from end of axle to face of

sprocket. (Photo

33)

35.

3.

Replacing bearing/clutch bearings

in wheels. Thsss are directional

bsarlngs and must be Installed as

fdlows:

36.

LEFT WHEEL:

Bearing must be

pressed in from

inboard

side of

wheel with knurbd

end of bearing

sleeve on Inboard

side of wheel.

37.

RIGHT

WHEEL:

Bearing must be

pressed in from

outboard side of

wheel with knurled

end of bearing

sleeve on

outboard

side of wheel.

NOTE:

Both right and left bearing

assem

-

blies must be pressed

in

flush with the

hride of wheel hubs.

38.

4.

To check assembly: hold axle

-

each wheel should rotate forward

freely and lock on shaft when rota

-

tion is reversed.

TESTINO

COMMODORE

fiLtCTRlCAL CIRCUITS:

CAUTION: Repalrs should only be at

tempted by qualified personnel since

damage can be done by persons not

experienced

in

working with printed clr-

cuit

boards

and components. TSrting

an

k

done

wlth

an AC/DC

volt.ohmmeter.

SWITCHES AND

CIRCUIT

BREAKERS

Fiemove them from machine and use an

ohmmeter or continuity tester. The

correct

reading is zero for an

open

switchlbreaker

and infinity (conti

-

nuity) for a closed

switch/ brea ker

.

-m

BRUSH DRIVE

MOTOR

This motor operates on a

115V

60

hz

circuit

(or

230V

50

ht depending on

machine model).

A

6

amp breaker Is

Installed

in

the drive motor circuit

to

prevent damage

to

the motor in case

an

overload condition occurs.

If the breaker

trips after being

reset,

check for probable cause:

1.

Incorrect power cord. Use nothing

less than

12-3

cable wire size and

no longer than

100

ft

.

2.

Brush height lever set too low. Ad

-

just

to

correct height.

3.

Faulty drive motor. Repair or re

-

place as required.

4.

Brush assembly “locked-up.” Check

for obstruction

-

faulty brush bear

-

ings, etc.

9

Page 10

COMMODORE

1

15V

Ul

MMN.RIEIM#I

1 53118

Motor

ll5V

(for

65067)

1A 53119

Motor

23OV

((or

65070)

2

67071

tbctimr/Ene

B~H

~m.

3

47075

FanlShroud

Awn.

4-56 47076

Kit,

Base

Plate

7-8-9-11- 47087

Kit

Pum

Repair

(for

65067)

11- 12-13

and

6!&70)

115/23OV

W

)III1N.IUOIYCI#*

10

27225

BeaflngCowc

14 41088

PumpHousing

15A 65071

PumpHead

Asm.

ll5V

(for

65067)

156

65072

Pump

WAsm.

23OV

(for

650701

SOLID

STATE

CONTROL

BOARD

(DC CIRCUIT)

The

PC

Control Board converts aiter-

nating current (AC)

to

direct current

(DC) for the traverse drive motor and

clutch solenoid.

A

2

amp sio-blow ceramic fuse is

in

-

stalled

in

the motor circuit

to

protect

the circuit

board

and motor

in

the event

an overload condition occurs.

NOTE:

Always use the same type and

size fuse for replacement.

IC

DRIVE

MOTOR

DOES

POLL0

W

INQ:

1.

Check continuity (use ohmmeter) of

power cord, drive motor switch, and

slow

-

blow fuse.

2.

If fuse blows after replacing, check

for short circuit in system or faulty

motor. If this does not correct prob

-

lem the

PC

Control Board may be

faulty.

NOT

RUN,

CHECK THE

To

test

voltage

at

PC

Control

Board:

Aug power cord into properly grounded

outlet and press on drive motor switch,

Use AC volt meter

to

check

Input

volt

-

age at terminals AC and

AC

on PC

Board. Voltage should be

115V

(on

11

5

volt

models) and 230V (on

230

volt

models). Use DC

volt meter

to

check

DC

output

voltage at terminals A+

and

A-.

With the speed control knob

set at MAX

(4)

DC volts should be

95

VDC

f

10%.

if there is "0" voltage

or the voltage does not remain constant,

this is an indication that the circuit

board is faulty. Replace as required.

TO

TEST

TRAVIRSI

DRlVB

MOTOR:

To test for around or short circuit, first

disconnect machine power cord from

electrical source then disconnect motor

lead.

Using ohmmeter, check resistance

between each motor lead and the motor

frame. If readings are not infinity (con-

tinuity), the armature is grounded,

replace gear motor.

To

check for shorted armature, use

ohmmeter

to

measure the resistance

between the motor

leads. if resistance

is

5

ohms or less, the armature is

short circuited; replace gear motor.

IC

CLUTCH

DOBS

NOT

ENOAOE CHECK THE

POLL0

WINO:

NOTE:

A 1 amp fast blow fuse is in

-

stalled

in

the clutch actuator circuit

to

protect the PC Control Board in the

event an overload condition occurs.

The fuse is located in

-

line near the

clutch actuator

coil.

1.

Check clutch switch (use ohmmeter)

for continuity.

2.

Check in-line 1 amp fuse. If fuse

blows after replacing, the coil is

faulty. Replace as required.

3.

Use a DC volt meter

to

check DC

voltage

to

clutch coil at terminals

F+

and

F

-

on Control Board. The DC

voltage

should be

95

VDC

f

10%.

If there is

"0"

or iow voltage or if

the voltage does not remain constant,

the circuit board is faulty. Replace

as required.

PUMP

ASSEMBLY

15

14 12

987

12

15

10

Page 11

COMMODORE

11

5V

CONTROL PANEL ASSEMBLY

I

COMMOOOAE CONTROL PANEL

Page 12

2

CHASSIS

WIDRIVE

ASSEMBLY

Page 13

1 76013 Ser.10-32x5/8FHMS

2 41132

Hubbp,CMDblPck

3

70119

Sd

Ser.

1/4-20

x

318

KCP

4 67010

~.5/8Mt.%op

5

67012

Race.Thrusl

6

89019

Whwl,CMDmachlnd

1

09011

0Wla

Am..

whad

8

87038

Hhshsr,5/8wIM

9 27122

Cc(kr,ShaN

10

70126

W

Scr.,

1/4-28

x

114

KCP

11

o!mos

06XhQ.

W8

Ancr

12 03012

Ark,whd

13

73045

Sprat

kU,

135

W8-P

25

beth

14 4llOll8 Kap,3/16x1.75

15

4o(ls

w.

18

Wdrufl

17 57032

Nut,3/8FlanprLock

18 70043

Scr.,

10-32x

3/4

FHUS

16 22012

CWU,

3/8

OD

St-Thru

48

-

0

0

E

I

0

0

0

A

m

Page 14

COMMODORE

1

15V

14

Page 15

REV

mi

Y

O

.

omcairim

1 70085

Scr..

1/4-20 x 112

PHMS

8-

36068

Guard,BruJhPulley

9

41129

Housinp,Brush

10 73245 Spring, 2'

Compression

12 09025

Bearing,

1/210Nyllner

13

03041

Me,

0rush Housing

PIVol

14

70088

Scr.,

1032x 1/2fWMS

15

27281

Cap.

Brush

Houslnq

End

17

36070

Guard,Splash

18

67106

Relalner,

Splash

Guard

19

70066

W.,

10-32

x

314

PHMS

20

36051

Guard.Thread

21 09019

Bsarhrp

I

Brush

22 67098

Wnp

,

Tokmo

23 12006

Bush

24 70177

Scr..

1632

x

112

FHMS

25 62171

pl;dS.Pulby

seal

11

57047

Nut.

1/4-20 lock

16

57090

Nu!.

10-321o~k

26 73241

!hi.

Pulley

27 35085

Gasket,

Seal

PMe

I

76 11019

Bell.

CMO

Brush

Drive

I

8

E:

R

K

K

0

cn

<

Page 16

COMMODORE

1

15V

SQtUTION/RECOVERY

TANKS

16

Page 17

COMMODORE 1 15V

CONTROL

PANEL

WIRING

DIAGRAM

115

VOLT

m

n

avoc

.,

1-

rl

wllc

I

II

‘I

..

w-T

1

CHASSIS

WIRING

DIAQRAM

1 1

S

VOLT

n

I

17

Page 18

COMMODORE

11

5V

CONTROL

PANE1

WIRING

DIAGRAM

230

VOLT

CHASSIS

WIRING

DIAORAM

230

VOLT

+A.

I

8%%

i

18

Page 19

COMMODORE

115V

~

COMMODORE

TROUBLE-SHOOTINQ

GUIDE

PROBLEM

No

electrical power.

Loss

ol

vacuum/

solution recovery.

No

forward

movement

of

machine.

No

solution flow.

Solution will

not

shut

off.

Uneven

cleaning.

CAUSE

Dead

electrical circuit.

Faulty

main

power switch

on

machine.

Faulty power cord.

Fuse blown

or

circuit breaker tripped

(on

machine).

Vacuum lever

in

"

off" position.

Faulty

vac

motor

switch.

Worn

vac

motor brushes

or

faulty

vac

motor.

Crack

in

recovery dome.

Obstruction

or

damage in vac shoe linkage

or

vac hose.

Incorrectly installed

or

adjusted vac shoe.

Loose wires at switch

or

connections.

Faulty drive

motor

switch.

Worn

carbon brushes in gear drive motor

or

faulty motor.

Fuse blown

or

circuit breaker tripped

(on

machine).

Faulty speed control potentiometer.

Faulty pump.

Faulty switch.

"

Clogged

"

or

faulty solenoid.

Obstruction in jets.

Faulty switch.

Dirt

in

solenoid valve

or

faulty valve.

One

or

more jets plugged.

SO

LUTlO

N

Check building circuit breaker

or

fuse box.

Replace switch.

Repair

or

replace power

cord,

Replace fuse

or

reset

breaker

after

correcting

problem.

Put

lever

in

"on"

position.

Replace switch.

Replace motor brushes

or

motor.

Repair

or

replace.

Remove obstruction, repair or replace

MC

casting.

Adjust

vac shoe.

Repair as required.

Replace switch.

Replace fuse

or

reset breaker after

correcting problem.

Replace control.

Replace pump.

Replace switch.

Remove obstruction

or

replace.

Remove and clean jets.

Replace switch.

Remove obstruction

or

replace valve.

Clean jets.

19

Loading...

Loading...