Windsor Chariot iVacuum CVXCD28, 10125260, 10125510, Chariot iVacuum CVE28, 10125160 Operator Instructions Manual

...Page 1

Operating instructions (ENG)

iVacuum™

MODELS: CV28

10125260

CVX28

10125190

CVXCD28

10125510

CVE28

10125160

CVXE28

10125180

86037810-CT

08/20/12

Read these instructions before using the machine.

Page 2

Machine Data/Overview

OVERVIEW

The Chariot® iVacuum™ is a battery powered, stand-on, wide area vacuum intended for commercial use. The

Chariot® iVacuum™ brushes and vacuums debris from carpeted surfaces and stores in vacuum bags

Warranty Registration

Thank you for purchasing a Windsor product. Warranty registration is quick and easy.

Your registration will allow us to serve you better over the lifetime of the product.

www.windsorind.com/WarrantyRegistration.aspx

2

To register you product go to :

For customer assistance:

1-800-444-7654

86037810 Chariot iVacuum

Page 3

Table of Contents

Machine Data/Overview . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . .4

Safety

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . .5

Hazard Intensity Level . . . . . . . . . . . . . . . . . . . . . . .6

Safety Label Location . . . . . . . . . . . . . . . . . . . . . . . .7

Operations

Techincal Specifications . . . . . . . . . . . . . . . . . . . . . .8

How This machine Works. . . . . . . . . . . . . . . . . . . .10

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Drive Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operations

Deck Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pre-run Machine Inspection . . . . . . . . . . . . . . . . . .17

Emergency Stop Procedures . . . . . . . . . . . . . . . . .17

Normal Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . .18

To Begin Vacuuming. . . . . . . . . . . . . . . . . . . . . . . .18

To Stop Vacuuming . . . . . . . . . . . . . . . . . . . . . . . .19

Changing Vacuum Bag. . . . . . . . . . . . . . . . . . . . . .19

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .20

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Battery Maintenance. . . . . . . . . . . . . . . . . . . . . . . .22

Checking Battery Specific Gravity. . . . . . . . . . . . . .23

Charging Batteries . . . . . . . . . . . . . . . . . . . . . . . . .23

Changing Batteries . . . . . . . . . . . . . . . . . . . . . . . . .24

Brush Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Brush Installation . . . . . . . . . . . . . . . . . . . . . . . . . .26

Brush Deck Adjustment . . . . . . . . . . . . . . . . . . . . .27

Adjustment Deck Levelness Testing. . . . . . . . . . . .27

Leveling the Brush Head. . . . . . . . . . . . . . . . . . . . .27

To Replace Brush Motor. . . . . . . . . . . . . . . . . . . . .28

Brush Motor Carbon Brush Replacement. . . . . . . .28

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Vacuum Motor Carbon Brush Replacement. . . . . .30

To Remove Vacuum Motor. . . . . . . . . . . . . . . . . . .30

Drive Motor & Brake . . . . . . . . . . . . . . . . . . . . . . . .31

Electric Parking Brake Engagement . . . . . . . . . . . .32

Drive Motor Carbon Brush Replacement . . . . . . . .33

Brake Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Pushing Machine . . . . . . . . . . . . . . . . . . . . . . . . . .34

Machine Tie-downs. . . . . . . . . . . . . . . . . . . . . . . . .34

Preparation for Loading/Unloading Trailer . . . . . . .34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Propel Circuit Board Troubleshooting. . . . . . . . . . .36

Parts

Brush Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Brush Deck Linkage . . . . . . . . . . . . . . . . . . . . . . . 42

Brush Deck Motor & Nozzle . . . . . . . . . . . . . . . . . 44

Brush Deck Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Control Panel Housing . . . . . . . . . . . . . . . . . . . . . 52

Decal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Frame-lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Frame-Upper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Pedal Platform-From Serial Number (17*) . . . . . . 62

Pedal Platform-To Serial Number (17*) . . . . . . . . 64

Pedal Platform Mounting. . . . . . . . . . . . . . . . . . . . 66

Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Side Broom-Deluxe. . . . . . . . . . . . . . . . . . . . . . . . 70

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Vaccum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Wheel-Front Drive-Chain . . . . . . . . . . . . . . . . . . . 76

Wheel-Front Drive-Gear . . . . . . . . . . . . . . . . . . . . 78

Wheel-Front Drive Brake . . . . . . . . . . . . . . . . . . . 80

Wheel-Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Wiring-Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wiring-Components . . . . . . . . . . . . . . . . . . . . . . . 86

Wiring-Control Panel. . . . . . . . . . . . . . . . . . . . . . . 88

Wiring-Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . 90

Wiring-Main Harness . . . . . . . . . . . . . . . . . . . . . . 92

Wiring-Pedal Platform-From Serial number *(17). 94

Wiring-Pedal Platform-To Serial number *(17) . . . 96

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Suggested Spare Parts. . . . . . . . . . . . . . . . . . . . . 99

Back-Up Alarm-Option . . . . . . . . . . . . . . . . . . . . 100

Battery Cart-Option. . . . . . . . . . . . . . . . . . . . . . . 102

Seat-Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Warning Light-Option . . . . . . . . . . . . . . . . . . . . . 108

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 110

86037810 Chariot iVacuum

3

Page 4

How to Use This Manual

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

This manual contains the following sections:

• HOW TO USE THIS MANUAL

• SAFETY

•OPERATIONS

• MAINTENANCE

• PARTS LIST

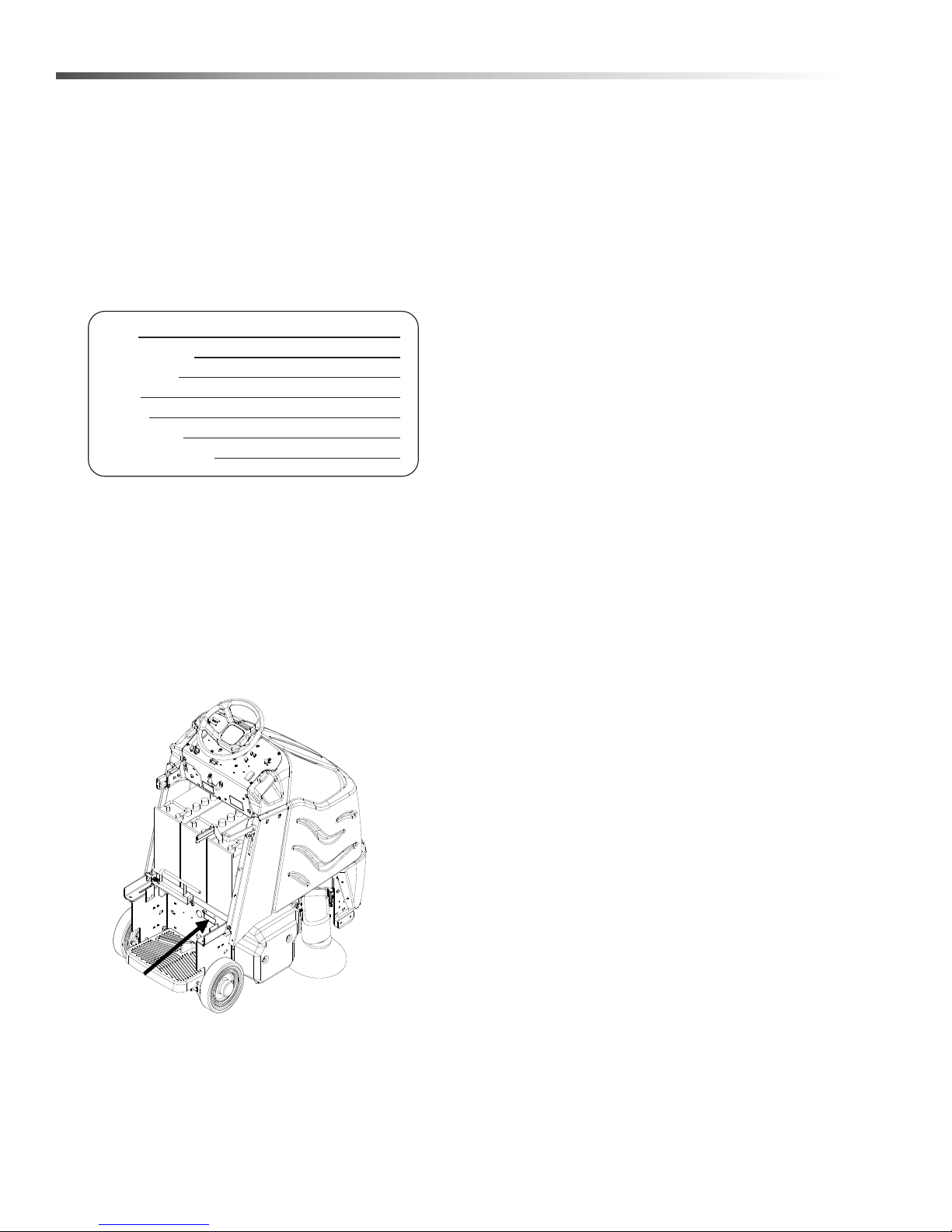

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized Windsor

dealers. When placing an order for parts, the machine

model and machine serial number are important. Refer

to the MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The model and serial number of your machine are

located below the battery compartment of the machine.

The SAFETY section contains important information

regarding hazard or unsafe practices of the machine.

Levels of hazards are identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in

good working condition. They are listed in this general

order:

• Service Schedule

• Batteries

•Brush Deck

• Circuit Protection

• Vacuum Motor

• Drive Motor & Brake

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

REF - column refers to the reference number on the

parts illustration.

PART NO. - column lists the part number for the part.

PRV NO. - reference number.

QTY - column lists the quantity of the part used in that

area of the machine.

4

DESCRIPTION - column is a brief description of the

part.

SERIAL NO. FROM - If this column has an (*) and a

Reference number, see the SERIAL NUMBERS page

in the back of your manual. If column has two asterisk

(**), call manufacturer for serial number. The serial

number indicates the first machine the part number is

applicable to. The main illustration shows the most

current design of the machine. When a boxed illustration is shown, it displays the older design.

NOTES - column for information not noted by the other

columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts

86037810 Chariot iVacuum

Page 5

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer's recommended components and attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water, return it to

an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is not suitable for picking up hazardous dust.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine near

flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offices

for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

Disconnect battery before cleaning or servicing.

Before the machine is discarded, the batteries must be removed and properly disposed of.

Make sure all warning and caution labels are legible and properly attached to the machine.

During operation, attention shall be paid to other persons, especially children.

Before use all covers and doors shall be put in the positions specified in the instructions.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

This appliance has been designed for use with the brushes specified by the manufacturer. The fitting of other

brushes may affect its safety.

Do not use on surfaces having a gradient of over 10% (6 degrees).

SAVE THESE INSTRUCTIONS

86037810 Chariot iVacuum

5

Page 6

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR SAFETY.

The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on the

machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use

Windsor approved replacement parts.

Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep battery

compartment open during charging. Keep sparks and flames away from the batteries. Do not smoke

around batteries.

Disconnect batteries before working on machine. Only qualified personnel should work inside machine.

Always wear eye protection and protective clothing when working on or near batteries. Avoid skin contact

with the acid contained in the batteries.

Never allow metal to lie across battery tops.

6

86037810 Chariot iVacuum

Page 7

Safety

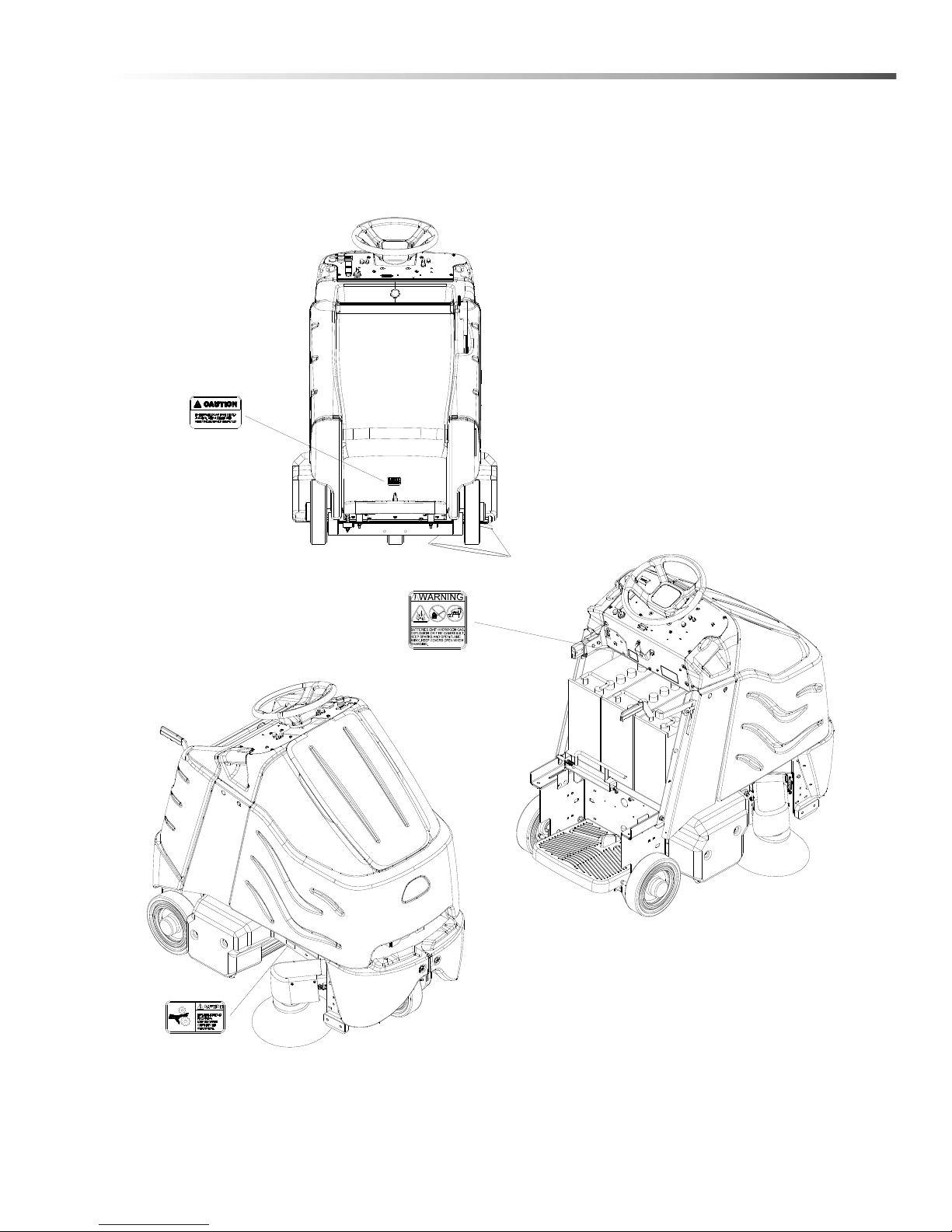

CAUTION LABEL

86244310

BATTERY

CAUTION

86252520

86243830 (2)

PRV NO. 500956

PRV NO. 80885

PRV NO. 500663

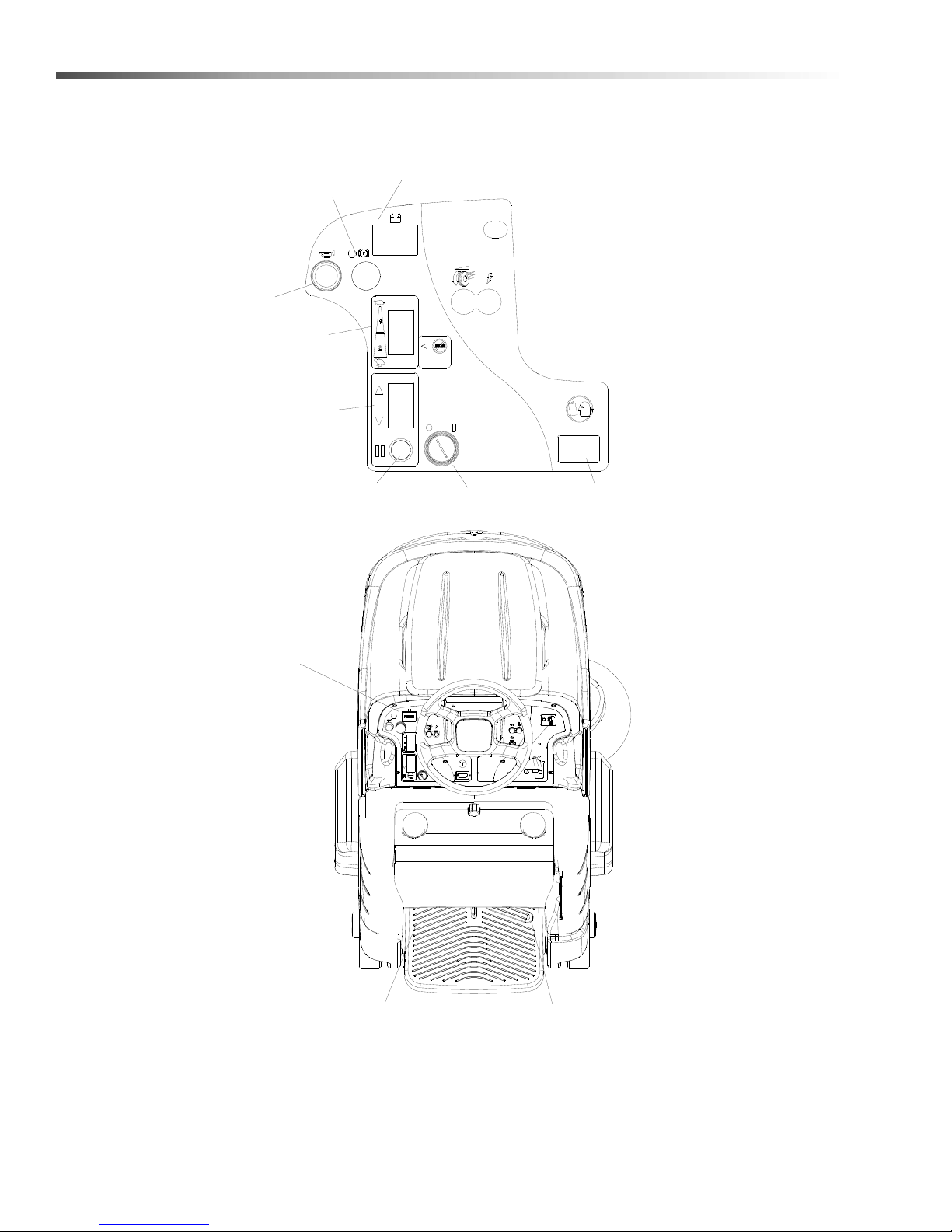

Safety Label Location

These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible,

promptly replace them.

86037810 Chariot iVacuum

7

Page 8

Operations

Techincal Specifications

ITEM DIMENSION/CAPACITY

Nominal Power (Basic) 1548 W

Nominal Power (Deluxe) 1692 W

Rated Voltage 36 Volts DC

Rated Amperage (Basic) 43 amps

Rated Amperage (Deluxe) 47 amps

Batteries 3 X12 Volt 195-215 AH @ 20 hr. rate

Battery Compartment Dimensions 21 in. x 16 in. x 17 in. tall (533mm x 406mm x 432mm)

Propelling Motor .75 HP (560 W)

Brush Motor .75 HP (560 W)

Bag Capacity 2150 in³ (35 L)

Brushes Two 28 in. (71 cm) by 4 in. (10 cm) diameter

Brush Speed 1725 RPM

Vacuum Motor(s) .75 HP (560 W)

Maximum flow rate of vacuum motor 200 cfm (95liters per second)

Maximum suction of vacuum motor1 3.8 inches of water ( 3.43 kPa)

Mass (GVW) (Basic) 1055 lbs (478 kg)

Mass (GWB) (Deluxe) 1065 lbs (483 kg)

Weight Empty Without Batteries (Basic) 495 lbs (225 kg)

Weight Empty Without Batteries (Deluxe) 505 lbs (229 kg)

Tires 10 in. (254mm) Solid Gray non-marking

Foundation Pressure (Basic) 77 psi (530 kPa)

Foundation Pressure (Deluxe) 79 psi (544 kPa)

Maximum Speed 3.5 miles/hour (5.6 Km/hour)

Frame Construction Powder coated steel

Brake

Minimum Aisle U-Turn Width 56 in. (1425 mm)

Maximum Rated Climb And Descent Angle 9.5 degrees

Electrical parking brake, sets automatically whenever

operator steps off platform or engages emergency stop.

8

86037810 Chariot iVacuum

Page 9

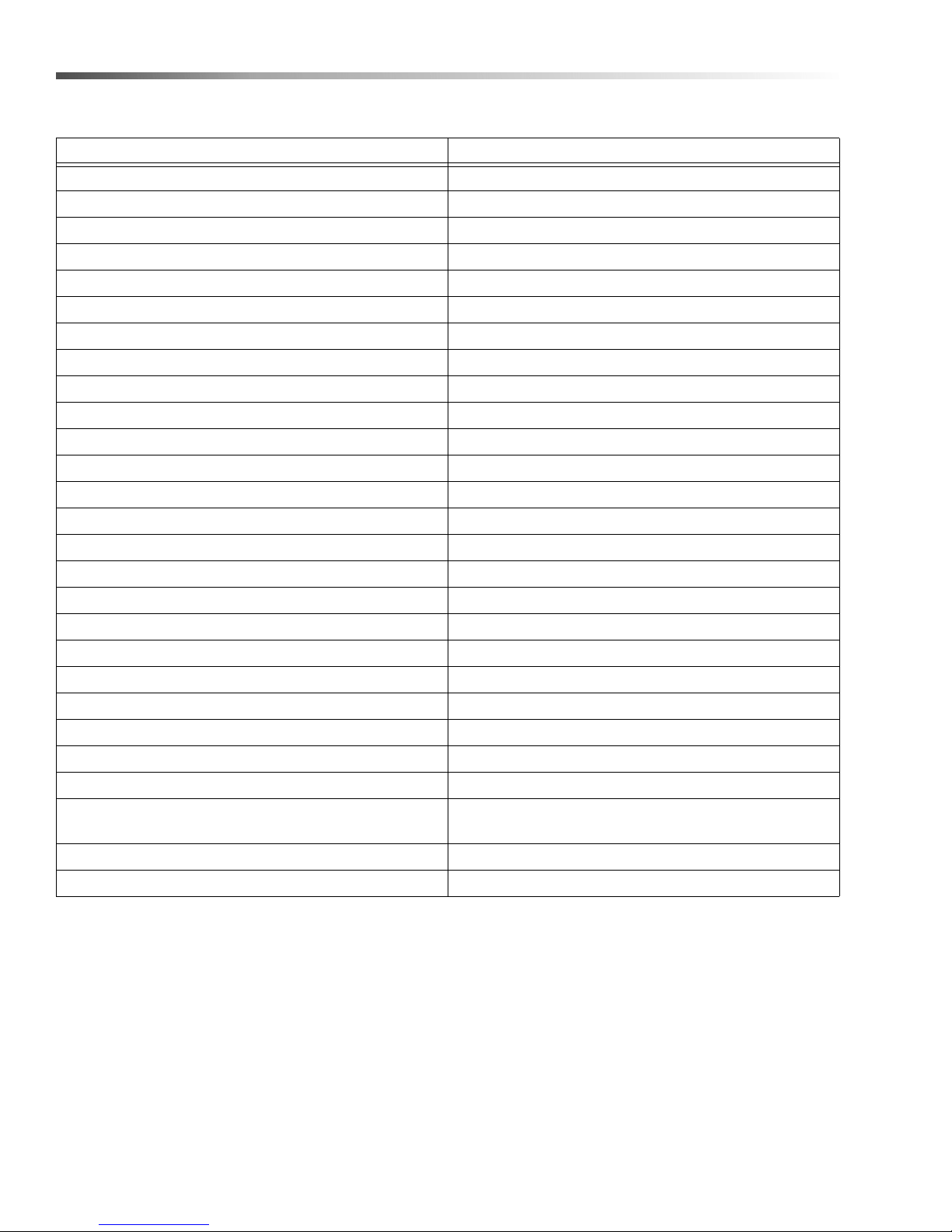

ITEM MEASURE

LENGTH

WIDTH

HEIGHT

Height 50.6 inches (1285 mm)

Length 52.5 inches (1330 mm)

Width without deck 26.5 inches (670 mm)

Width of deck 32.5 inches (826 mm)

Width with side broom (Deluxe only) 36.5 inches (927 mm)

Operations

SPECIAL NOTES:

The sound pressure level at the operator's ear was

measured to be 73 dBA (Basic) and 69 dBA (Deluxe).

This was a nearfield, broad-band measurement taken

on a carpeted floor. This appliance contains no

possible source of impact noise. The instantaneous

sound pressure level is below 63 Pa.

The weighted root mean square acceleration at the

operator's arms was measured to be below 2.5m/s2 .

This was a tri-axial, third-octave-band measurement

made during normal operation on a composite tile floor.

The measurement and related calculations were made

in accordance with ANSI S3.34-1986.

86037810 Chariot iVacuum

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.

9

Page 10

Operations

How This machine Works

The Chariot® iVacuum™ is a battery powered, selfpropelled, carpet vacuum intended for commercial use.

The appliance vacuums debris and dirt from the carpet

and collects it in a disposable bag.

The machine's primary systems are the brush system,

vacuum system, and operator control system.

The function of the brush system is to brush the carpet.

The brush system consists of two cylindrical type

brushes, motor, brush deck, and controls.

The front brush turns clockwise when viewed from the

right side of the machine. The rear brush turns counterclockwise. Both brushes work to agitate the carpet

and to route the debris up in to the central vacuum

nozzle.

The function of the vacuum system is to vacuum dirt

and debris into the vacuum bag. The recovery system

consists of the vacuum nozzle, vacuum motor, cloth

vacuum bag and paper vacuum bag. The vacuum

nozzle captures the dirt off the floor as the machine

moves forward. The vacuum motor provides suction to

draw the dirt into the vacuum bag. The vacuum bag

stores the dirt.

The function of the operator control system is to control

the direction and speed of the machine. The directional

control system consists of the direction control switch,

throttle pedal, speed control switch, drive reset switch,

emergency stop/brake switch, steering wheel, propel

controller, drive wheel and operator presence pedal

prior to Serial Number(17*). The directional control

switch signals forward or reverse direction. The

controller interprets signals from the throttle pedal to

command the drive wheel to propel or slow the

machine. The drive reset switch is to make sure the

operator is on platform before machine will propel. The

steering wheel points the drive wheel in the direction

desired by the operator. The parking brake automatically engages when the operator steps off the platform.

The emergency stop/brake can be used to hold the

machine on slopes.

*See Serial Number page.

10

86037810 Chariot iVacuum

Page 11

Operations

4

6

13

12

1

5

10

11

2

7

3

9

8

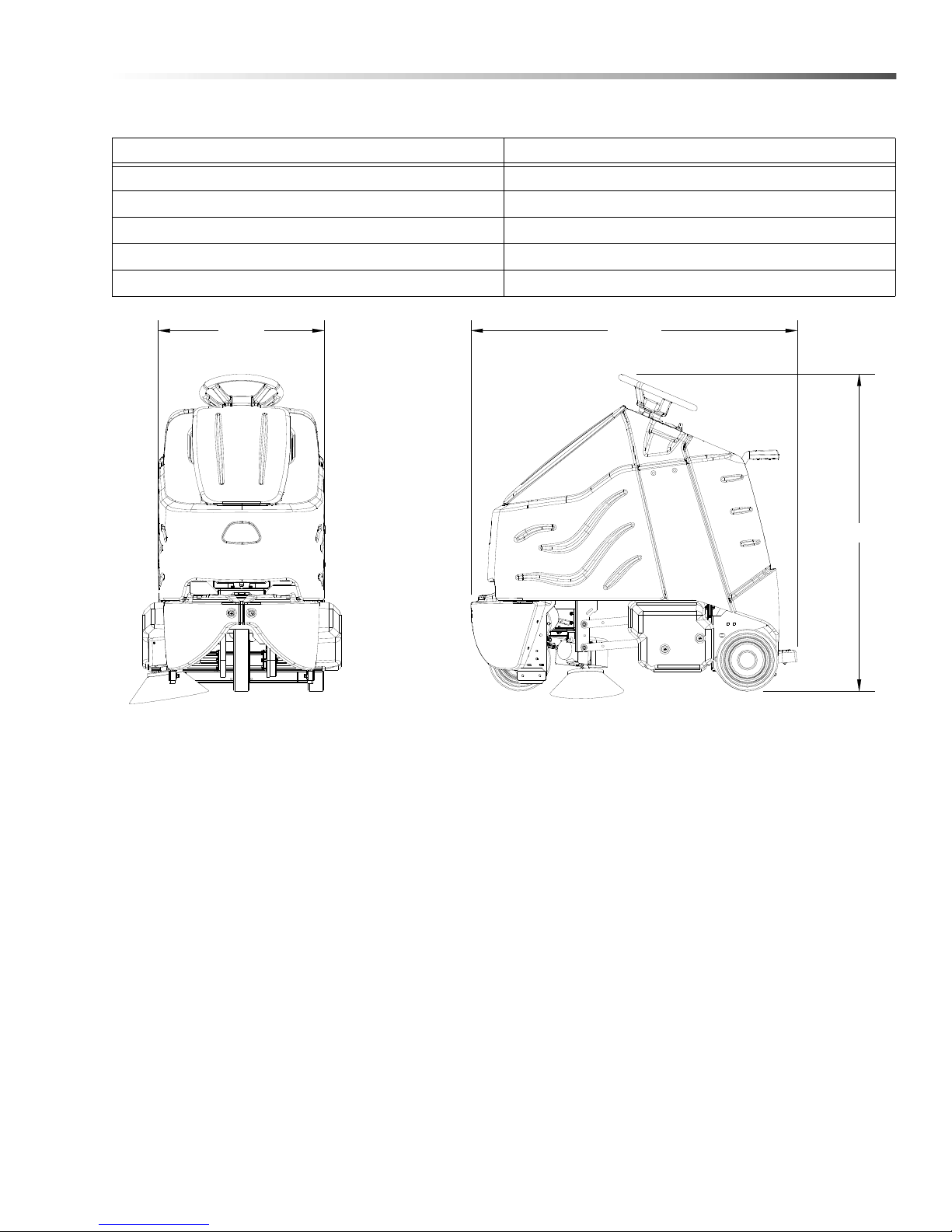

Components

1. Bag Access Lid

2. Brush Deck

3. Cloth Bag

4. Control Panel-Drive

5. Control Panel-Vacuum

8. Deck Lift

9. Paper Bag

10. Pedal Platform

11. Rear Cover

12. Cover

13. Side Broom (Deluxe Only)

6. Control Housing

7. Cover Lid

86037810 Chariot iVacuum

11

Page 12

Operations

4

5

9

2

10

1

3

6

7

8

11

Drive Controls

12

86037810 Chariot iVacuum

Page 13

Operations

1. Key Switch

2. Emergency Stop/Brake Switch

3. Directional Control Switch

4. Throttle Pedal

5. Operator Presence Pedal-Prior to Serial Number

(17*)

6. Speed Control Switch

1. KEY SWITCH

Controls the power for machine functions.

To turn the machine power on, rotate key clockwise.

To turn the machine off, rotate key counterclockwise.

2. EMERGENCY STOP/BRAKE SWITCH

This safety feature is designed to cut all power to the machine at any time and apply parking brake.

To shut the machine power off, push the Emergency Stop Switch, this will also engage the parking brake and

cause the machine to stop immediately.

To reset the machine, rotate the switch clockwise.

7. Drive Reset Button

8. Horn Button

9. Steering Wheel

10. Battery Discharge Indicator

11. Hour Meter

3. DIRECTIONAL CONTROL SWITCH

Controls the direction of travel of the vehicle. The position of the switch indicates direction of travel.

To travel forward, press the top of the switch.

To travel in reverse, press the bottom of the switch.

4. THROTTLE PEDAL

Controls the speed of the vehicle within the speed control setting selected. Pressing the pedal causes the

machine to travel in the direction selected by the Directional Control Switch.

To increase speed, increase pressure on the pedal.

To decrease speed, decrease pressure on the pedal.

86037810 Chariot iVacuum

13

Page 14

Operations

5. OPERATOR PRESENCE PEDAL - Prior to Serial Number (17*)

This safety feature is designed to ensure that the operator has their left foot on pedal platform whenever

machine is moving. The operator must have left foot on Operator Presence Pedal for machine to move.

6. SPEED CONTROL SWITCH

Controls the maximum speed of the machine. Speed 1 is intended for vacuuming. Speed 2 is recommended

for transport only, not vacuuming.

To increase speed, press the top of the switch.

To decrease speed, press bottom of the switch. Speeds can be adjusted at any time, whether machine is

moving or not.

7. DRIVE RESET SWITCH

This safety feature is designed to ensure safe engagement of propel drive. Each time the machine power is

turned on, and each time an operator steps on to the platform, the Drive Reset Switch must be pushed before

machine will propel.

8. HORN BUTTON

The horn is activated by pressing the horn button.

9. STEERING WHEEL

The steering wheel turns the front wheel causing the machine to change direction.

*See Serial Number page.

14

86037810 Chariot iVacuum

Page 15

Operations

10. BATTERY DISCHARGE INDICATOR

Indicates the charge level of the batteries.

The meter display is divided into 10 vertical bars. Bars illuminated on the far right indicate full charge. Bars

flashing near the left side indicate the batteries should be recharged. Further operation of the machine could

damage the machine or the batteries. Bars flashing near left side also indicate that machine has been left unattended with key on for more that 15 minutes. Turn key off then on to reset.

When the machine is left overnight with less than a full charge, the display may initially indicate a full charge. It

will also indicate a full charge if the batteries are disconnected, then reconnected. After a few minutes of

operation the meter will give the correct charge level.

11. HOUR METER

Records the number of hours the machine has been in operation. This information is useful in determining

when to service the machine.

86037810 Chariot iVacuum

15

Page 16

Operations

Brush Lift Lever

Deck Controls

Brush Lift Lever

Raises and lowers the brush deck and turns the vacuum motor on and off.

To lower brush deck and start vacuum motor and brushes, lift the lever from its raised position.

To raise brush deck and stop vacuum motor and brushes, lift the lever from its lowered position.

Side brush on deluxe model only.

Deluxe Model

The brush lift lever also raises and lowers the side broom.

16

86037810 Chariot iVacuum

Page 17

Operations

Pre-run Machine Inspection

Do a pre-run inspection to find possible problems that

could cause poor performance or lost time from breakdown. Follow the same procedure each time to avoid

missing steps.

NOTE: See maintenance section for pre-run machine

inspection checklist items.

STARTING MACHINE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before starting machine, make sure

that all safety devices are in place and operating

properly.

1. Stand on the operator platform. Throttle pedal must

be in neutral position.

Note: Prior to Serial Number (17*). Place left foot on

operator presence pedal. Throttle pedal must be in

neutral position.

2. Turn the machine power on by turning key switch

clockwise to the "ON" position.

Emergency Stop Procedures

1. Release the throttle pedal by lifting right foot.

2. Turn machine power off with key switch by turning

key switch counterclockwise.

3. If an electrical problem is suspected, push in

emergency stop button. This will also engage the

parking brake and cause the machine to stop

immediately.

3. Check the position of the Directional Control

Switch to make sure the machine will travel in the

direction intended.

4. Press the Drive Reset Switch.

5. Press lightly on the throttle pedal with right foot.

*See Serial Number page

86037810 Chariot iVacuum

17

Page 18

Operations

Normal Vacuuming

Plan the vacuuming pattern in advance. The longest

track is around the perimeter of the area to be cleaned.

For efficient operation, the runs should be the longest

possible without turning or stopping.

In order to achieve the best possible results, the area

which is to be cleaned should be picked up before

vacuuming. Large debris, strings and wire must be

removed to prevent being caught in brushes.

If machine is allowed to stand in neutral with the

vacuum deck down for more than 2 seconds, the brush

motor stops. If either forward or reverse travel is

selected, the brush motor will continue once movement

of machine begins. Overlap the brush path and avoid

transporting over previously cleaned areas.

Recommended Path

To Begin Vacuuming

When operating the machine around people, pa y

close attention for unexpected movement. Use

extra caution around children.

1. Stand on the operator platform. Throttle pedal must

be in neutral position.

NOTE: Prior to Serial Number (17*). Place left foot on

operator presence pedal. Throttle pedal must be in

neutral position.

2. Turn machine power on.

3. Check position of Directional Control Switch to

ensure that machine is set to travel in direction

intended.

4. Press the Drive Reset Switch.

5. Lower the Brush Deck.

6. Drive machine forward to begin vacuuming.

7. Adjust the speed of the machine as necessary.

*See Serial Number page.

18

86037810 Chariot iVacuum

Page 19

Operations

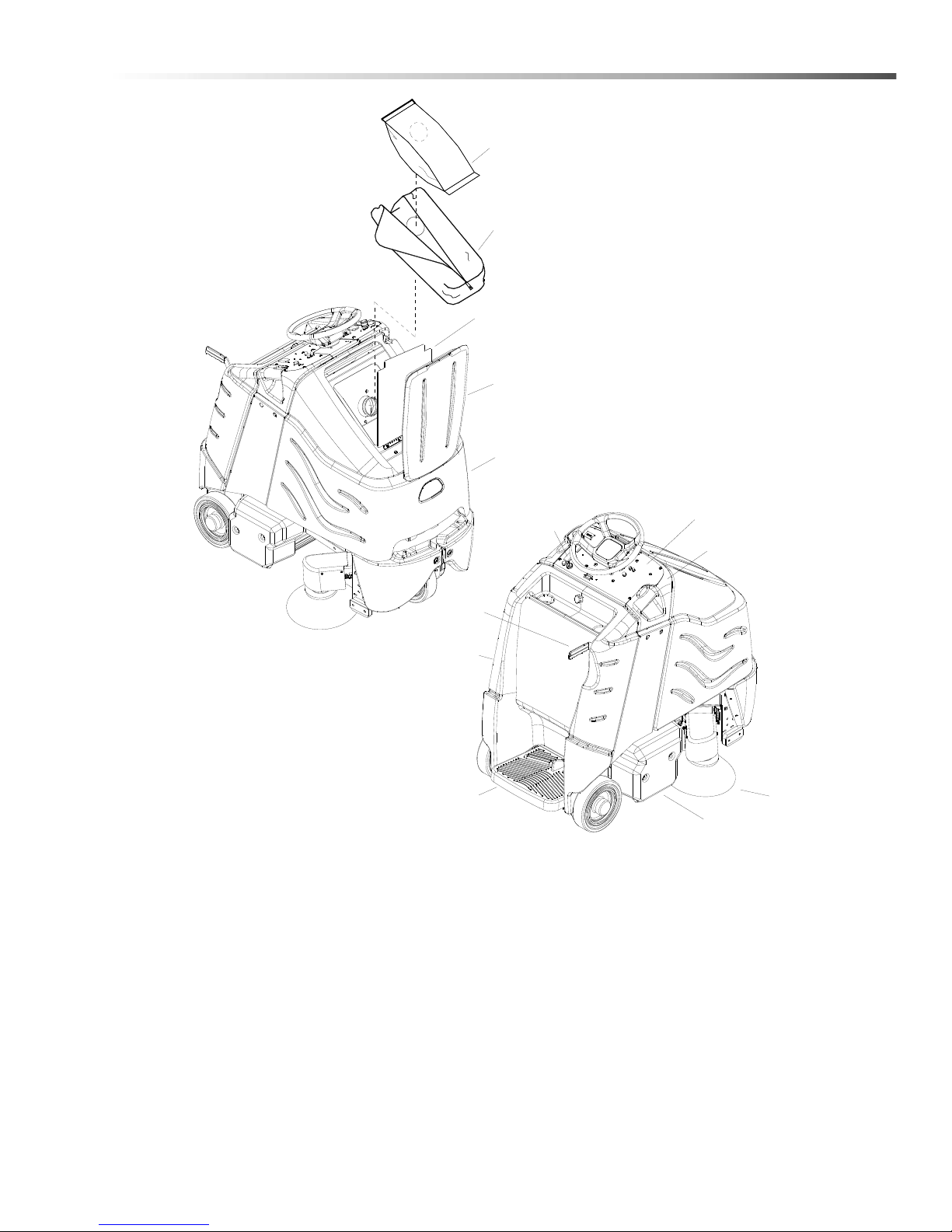

PAPER BAG

CLOTH BAG

STORAGE

EXTRA BAG

To Stop Vacuuming

1. Raise the brush deck, which turns off brushes and

vacuum.

2. Allow the throttle pedal to return to neutral.

3. Turn machine power off.

FOR SAFETY: Before leaving or servicing machine:

stop on level surface, turn off machine and remove key.

FOR SAFETY: When using machine, go slow on

inclines.

Changing V acuum Bag

A convenient bag storage is built into the lid.

1. Park machine on level area.

2. Turn the machine power off.

3. Open cover lid and vacuum box lid.

4. Unzip cloth bag.

5. Remove paper bag lip from nozzle.

6. Remove cloth bag lip from nozzle.

7. Remove cloth band and paper bag together from

vacuum box.

8. Remove paper bag from cloth bag and dispose of

properly.

9. Clean vacuum box and remove any debris from

inside screen.

10. Shake cloth bag to remove any extra debris.

11. Place cloth bag back into vacuum box and push

the rubber collar over the nozzle.

12. Retrieve a new clean paper bag from the storage

compartment in the coverlid.

13. Place a new paper bag into the cloth bag and push

the rubber collar over the nozzle.

14. Close all lids and covers.

86037810 Chariot iVacuum

19

Page 20

Maintenance

Service Schedule

BEFORE

MAINTENANCE

Check water level of batteries after

charging; add distilled water if necessary

Check that the vacuum box lid seal tightly *

Visually check for damaged or worn tires. *

Check vacuum hose connections. *

Check hoses for debris buildup. *

Check pedal(s), brake and steering for

proper operation

Check vacuum bag fullness and change if

necessary.

Clean brushes and check wear. *

Charge batteries. *

Clean off top of batteries. *

Check battery cells with hydrometer. (Wet

cell only)

Check battery connections are tight. *

Clean battery cases and compartment. *

Clean and check drive tension chain for

wear and tension.

Check parking brake. *

Clean chains, cables and pulleys for

brush deck lift.

Check all motors for carbon brush wear. *

Check motor commutators. *

Check steering chain tensioner. *

EACH WORK

PERIOD

*

*

*

AFTER EACH

WORK

PERIOD

50 HRS 100 HRS 200 HRS

*

*

*

NOTE: A Vacuum hose cleaning brush is included with your vacuum. If debris is caught in the vacuum hose, use

brush to clear the vacuum hose. Remove vacuum bag and clear hose of debris with the brush. It may be

necessary to clear the hose at vacuum shoe connection. Disconnect vacuum hose and clear hose. Check

vacuum shoe for debris also.

20

86037810 Chariot iVacuum

Page 21

Maintenance

3

4

5

6

2

1

Batteries

1. Rear Cover Retainer Knob

2. Rear Cover

4. Batteries

5. Battery Tray

6. Battery Tray Latch

3. Battery Connector-Machine

86037810 Chariot iVacuum

21

Page 22

Maintenance

Batteries (Wet Cell Only)

The batteries provide the power to operate the

machine. The batteries require regular maintenance to

keep them operating at peak efficiency.

The machine batteries will hold their charge for long

periods of time, but they can only be charged a certain

number of times. To get the greatest life from the

batteries, charge them when their charge level reaches

25% of a full charge. Use a hydrometer to check the

charge level.

Do not allow the batteries to remain in a discharged

condition for any length of time. Never expose a

discharged battery to temperatures below freezing.

Discharged batteries will freeze causing cracked

cases. Do not operate the machine if the batteries are

in poor condition or if they have a charge level below

25% (specific gravity below 1.155).

Keep all metallic objects off the top of the batteries, as

they may cause a short circuit. Replace worn or

damaged cables and terminals.

Check the electrolyte level in each battery cell before

and after charging the batteries. Never add acid to the

batteries, use distilled water. Do not allow water level

to fall below the battery plates. Portions of plates

exposed to air will be destroyed. Do not overfill. Keep

plugs firmly in place at all times.

When servicing machine, avoid contact with

battery acid.

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

Wear eye protection and protective clothing when

working with batteries.

Charge batteries in a well ventilated area.

Battery Maintenance

1. When cleaning the batteries, use a solution of

baking soda and water. Do not allow the cleanin g

fluid to enter the battery cells, electrolyte will be

neutralized.

2. Maintain the proper electrolyte level in each battery

cell. If a cell should accidentally overflow, clean

immediately.

3. Wipe off the top of the batteries at least once a

week.

4. Test battery condition with a hydrometer at least

once a week.

5. Ensure that all connections are tight and all

corrosion removed.

6. Every 4 to 6 months, remove that batteries from

the machine and clean the battery cases and

battery compartment.

22

86037810 Chariot iVacuum

Page 23

Maintenance

Checking Battery Specific Gravity

Use a hydrometer to check the battery specific gravity.

NOTE: Do not take readings immediately after adding

distilled water, if the water and acid are not

thoroughly mixed, the reading may not be accurate.

Check the hydrometer readings against this chart.

SPECIFIC GRA V ITY @

80° F (27°C)

1.265 100% CHARGED

1.225 75% CHARGED

1.190 50% CHARGED

1.155 25% CHARGED

1.120 DISCHARGED

NOTE: If the readings are taken when the battery

electrolyte is any temperature other than 80°F (27°C),

the reading must be temperature corr ected.

BATTERY CONDITION

Charging Batteries

When servicing machine, avoid contact with

battery acid.

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

Wear eye protection and protective clothing when

working with batteries.

Charge batteries in a well ventilated area.

Use a 36 volt, 20 amp maximum output DC charger

which will automatically shut off when the batteries are

fully charged.

1. Empty recovery tank.

2. Stop the ma chine in a clean, well ventilated area

next to the charger.

3. Turn "OFF" machine.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, turn off machine

and remove key.

4. Unplug the machine from the battery pack.

Remove front cover. Disconnect recovery hose

from "Y" tube. Raise recovery tank and verify prop

rod latch is safely engaged.

To find the corrected specific gravity reading when the

temperature of the battery electrolyte is other than 80 °F

(27°): Add (+) to the specific gravity reading 0.004 (4

points), for each 10°F (6°C) above 80° (27°C).

Subtract (-) from the specific reading 0.004 (4 points),

for each 10°F (6°C) below 80°F (27°C).

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

5. Check the electrolyte level in each battery cell.

Before charging, add just enough distilled water to

cover the plates. After charging is complete, add

just enough distilled water to bring up the level to

the indicator ring. If the water level is too high

before charging, normal expansion rate o f the electrolyte may cause an overflow resulting in a loss o f

battery acid balance and damage the machine.

86037810 Chariot iVacuum

23

Page 24

Maintenance

REAR OF MACHINE

+

--

++

-

RED

BLK

RED

BLK

RED

BLK

5. Replace the battery caps, and leave them in place

while charging.

6. Unplug the battery connector from the machine.

SAFTEY: When charging, connect the charger to the

batteries before connecting the charger to the AC

wall outlet. Never connect the charger to the AC wall

outlet first. Hazardous sparks may result.

7. Plug the charger connector into the battery

connector. Connect the charger AC plug to a wall

outlet. The charger gauge should indicate that the

batteries are charging.

8. When the batteries are fully charged, disconnect

the charger from the AC wall outlet, then disconnect the charger from the batteries.

9. Connect the batteries to the machine connector.

10. Check the electrolyte level. It should be up to the

indicator ring. If necessary, add distilled water.

11. Install the rear cover.

Changing Batteries

Stop the machine in a clean area next to the charger.

Turn off machine.

SAFETY: Before leaving or servicing the machine;

stop on level surface, turn off machine and remove

key.

1. Remove the rear cover.

2. Disconnect battery pack from machine.

3. Unlatch battery tray from machine and pull out to

expose batteries.

4. Use the proper size open end wrench to disconnect main ground wire first and secure cable

terminal away from batteries.

5. Disconnect main positive lead and secure cable

terminals away from batteries.

6. Loosen both terminals on each jumper cable and

remove one at a time.

7. Prepare a suitable site to place the batteries.

8. Attach suitable battery lifting device and lift

batteries from the machine.

Batteries are a potential environmental hazard.

Consult your battery supplier for safe disposal

methods.

24

86037810 Chariot iVacuum

Page 25

Maintenance

2

3

1

4

5

Brush Deck

1. Brush Deck Lift Cable

2. Brush Door

3. Brush Motor

4. Side Broom (Deluxe)

5. Side Broom Lift Cable (Deluxe)

86037810 Chariot iVacuum

25

Page 26

Maintenance

Brush Deck

The dual cylindrical head is designed to agitate the

carpet while vacuuming. The first scrubbing brush

turns in a clockwise rotation when viewed from the right

of operator's side of machine. The first brush scrubs

dirt and debris between the brushes. The second

brush, turns in a counter clockwise rotation, picks up

debris and throws it into the nozzle.

Maintenance

The brushes should wear evenly side to side. Brushes

should be replaced as a set when bristle length wears

to height of yellow PerformAlertTM bristles.BRUSH

REMOVAL

The brushes are removed from the right side of the

machine.

1. Remove right deck side cover by removing the two

mounting screws.

2. Remove the brush door by removing the three

mounting screws.

3. Slide the brushed out the side opening.

Brush Installation

The front and rear brush are opposite in brush pattern

and must be installed in the correct orientation.

1. Slide brush through door opening and onto drive

shaft. Make sure it is fully seated and is driven by

the deck system.

2. Install the brush door and deck side cover.

26

86037810 Chariot iVacuum

Page 27

Maintenance

Pattern

Uneven

Pattern

Parallel

Even and

INCORRECT BRUSH PATTERN

CORRECT BRUSH PATTERN

1"-1 1/2"

Brush Deck Adjustment

Brush deck adjustment consists of one adjustment to

make the pattern of equal width between front and rear

brushes. Unequal patterns are caused by the deck not

being parallel to the floor. Proper adjustment is

obtained when the contact patterns of the brushes on

the floor show two rectangles the width of the brushes.

The rectangles should be parallel to each other.

Adjustment Deck Levelness Testing

1. Move the machine to an area of hard floor to avoid

damaging carpet.

2. Lower brush head to floor. Allow brushes to run for

approximately 30 seconds. It may be necessary to

repeat this step in the same location until a good

mark can be seen on the floor. This can be accomplished by touching lightly the throttle pedal to

restart the scrub deck without moving the machine.

3. Raise the brush deck and note the brush patterns

on the floor. There should be two rectangles with

parallel sides. The width of the front and rear

rectangle should be equal.

Leveling the Brush Head

Leveling the brush head is accomplished by adjusting

the lower links at the point the deck arms attach to the

frame. To increase pattern width on rear brush, loosen

the mounting hardware and slide that joint forward and

retighten.

To increase pattern width on the front brush, loosen the

mounting hardware and slide that joint rearward and

retighten.

Retest for levelness.

86037810 Chariot iVacuum

27

Page 28

Maintenance

Do not use a pressure washer to clean around the

brush motors. Use tap pressure only.

To Replace Brush Motor

1. With the scrub deck in the lowered position,

disconnect brush motor wiring connector from

harness.

2. Remove deck covers.

3. Remove motor mounting bolts from motor base

plate.

4. Remove motor from deck assembly.

5. Remove coupler from end of shaft.

6. Reverse to reassemble.

Brush Motor Carbon Brush Replacement

1. Scribe alignment mark on motor barrel to motor

cap. Remove two bolts.

2. Remove end cap from motor.

NOTE: Motors contain two wave washers in cap. Do

not lose these.

3. Release brush from spring tension. Remove screw

connecting brush wire lead to brush holder. Clean

brush holder to insure free movement.

4. Retract spring and install new brush. Install

connector screw and lead.

5. When all new brushes are installed. Place all in

retracted position, held into brush holder by spring

tension.

6. Carefully place end cap onto bearing on motor

shaft.

NOTE: Use care to assure wave washer alignment.

7. With end cap in partially installed position, release

all brushes to contact position with motor commutator.

NOTE: Failure to insure all brushes are released will

result in motor failure.

8. Reset end cap and realign with scribe marks on

motor barrel. Reinstall the two attach bolts from

cap into base.

9. Maintain alignment between motor barrel base and

cap.

28

86037810 Chariot iVacuum

Page 29

Maintenance

CIRCUIT BREAKERS

Circuit Breakers

Circuit breakers interrupt the flow of power in the event

of an electrical overload. When a circuit breaker is

tripped, reset it by pressing the exposed button. If a

circuit breaker continues to trip, the cause of the electrical overload should be found and corrected.

30 Amp. Protects the brush motor.

30 Amp. Protects the propel motor.

3 Amp. Protects the machine controls.

3 Amp. Protects the side broom.

30 Amp. Protects the vacuum motor.

86037810 Chariot iVacuum

29

Page 30

Maintenance

To Remove Vacuum Motor

Disconnect batteries before working on machine. Only

qualified personnel should work inside machine.

Always wear eye protection and protective clothing

when working on or near batteries. Avoid skin contact

with the acid contained in the batteries.

V acuum Motor Carbon Brush Replacement

1. Remove rear cover from machine.

2. Remove batteries from machine.

3. Remove 4 bolts holding access cover in place and

remove cover.

4. Pull top clips from vacuum motor top brush

retainers.

5. Remove and inspect brushes.

6. Replace both if either is less than 3/8" (9.5

mm)long.

7. Reverse steps to assemble.

1. Remove rear cover.

2. Remove two screws from top of control panel and

four screws from side of control panel housing.

3. Slide control housing back from tank to expose

main cover bolts.

4. Remove four bolts in front of console from cover,

and 2 bolts from the bottom front of main cover,

and two inside, next to batteries.

5. Remove main cover.

6. Remove four bolts from vacuum motor and disconnect plug.

7. Reverse steps to assemble

30

86037810 Chariot iVacuum

Page 31

Maintenance

1

2

3

Drive Motor & Brake

1. Drive motor

2. Parking brake

3. Drive chain

86037810 Chariot iVacuum

31

Page 32

Maintenance

Electric Parking Brake Engagement

SAFETY: Before leaving or servicing machine, stop

on a level surface, turn off machine and remove key.

Electric Brake Engagement

This machine is equipped with an electric parking

brake.

The brake automatically engages and keeps the

machine from moving whenever the operator steps off

the platform or when emergency stop is engaged.

The brake has a mechanical over-ride that can be

engaged so machine can be pushed or towed (slowly).

When the mechanical over-ride is engaged the

machine cannot be driven.

To engage brake:

To disengage brake:

1. Mechanical over-ride disengaged

2. Machine can be driven.

3. Push lever firmly in direction of arrow.

1. Mechanical over-ride engaged.

2. Machine can be pushed or towed (slowly).

Push lever firmly in direction of arrow

NOTE: There is an intermediate stop. Make sure

lever is fully in the down position.

32

86037810 Chariot iVacuum

Page 33

Maintenance

ROLL PIN

SMALL PIN OR SCREW

HEX HUB

Drive Motor Carbon Brush Replacement

Do not use a pressure washer to clean around the

motors. Use tap pressure only.

SAFETY: Before leaving or servicing machine, stop

on a level surface, turn off machine and remove key.

1. Disconnect batteries from machine.

2. Disconnect the electrical connection to the traction

motor.

Brake Removal

(Must be done to access carbon brushes)

3. Remove 4 mounting screws and remove brake.

4. Drive roll pin out of the hex hub enough to allow

hex hub to slide off shaft. It is recommended that

the roll pin be left partially in the hex hub.

7. Install new brush and reinstall connecting screw

and lead.

8. When all new brushes are installed. Place all in

retracted position, held into brush holder by spring

tension.

9. Carefully replace brush cap.

Reinstalling:

10. When replacing the hex hub, use a small pin or

screw to help align the holes.

11. Drive the pin into the hub and make sure it is flush

to the hex surface. The brake will not fit on the hub

if the roll pin is protruding from the hub.

12. Replace the hub and use Lock-Tite on the screws.

5. Remove brush cap.

6. Release brush from spring tension. Remove screw

connecting brush wire lead to brush holder. Clean

brush holder to insure free movement.

86037810 Chariot iVacuum

33

Page 34

Maintenance

TIE DOWN POINTS

Pushing Machine

The machine may be pushed for short distances at

speeds not to exceed 5 mph. Be careful to avoid

damaging machine. The machine may be pushed by

hand from the rear.

NOTE: To avoid damage caused by regenerative

voltage, disconnect traction motor before towing or

pushing machine.

Machine Tie-downs

There are two tie points located at front and each side

of foot box frame and two at the front side of frame.

Tie-down devices must be of the proper type and

strength. The combined strength of all tie-downs must

be strong enough to lift two times the weight of the

machine. Tie-downs must be positioned to prevent the

machine from moving forward, backward, or either side

to side. Use all four corners of the machine with the tiedowns running out opposite directions. Tie-downs must

be attached to the transporting vehicle securely.

Preparation for Loading/Unloading Trailer

Before loading or unloading machine from trailer, brush

head must be in the up position before loading.

NOTE: When transporting the machine on a trailer or

in a truck, in addition to using tie-downs, be sure to

set the parking brake, and block the tires to prevent

the machine from rolling

34

86037810 Chariot iVacuum

Page 35

Maintenance

Troubleshooting

PROBLEM CAUSE SOLUTION

No power to machine Battery disconnected Check all battery cable connections

Emergency shut-off activated Reset

Faulty key switch Replace switch

Little or no propel Low battery charge Charge batteries

Machine does not

change speeds

Forward speed only

Reverse speed only

Vacuum and brush do

not turn on

Poor vacuums

performance

Brush motors do no run,

or run slowly

Machine turned on with pedal not in

neutral position

Tripped circuit breaker Reset circuit breaker and check brush

Controller overheated Allow cool down period

Loose motor connection

Faulty throttle circuit or potentiometer

Faulty drive reset circuit or switch Check wires, connection and switch

Faulty operator presence pedal circuit or

switch-Prior to Serial Number (17*)

Faulty platform circuit or switch Check wires, connections and switch

Brake over-ride engaged Disengage brake over-ride

Faulty brake circuit or over-ride switch Check wires, connections and switch

Faulty speed control circuit or switch Check wires, connections and switch

Faulty forward/reverse switch Replace Switch

Circuit breaker tripped Reset

Full bag or clog in system (bag full light

on)

Debris caught in system Remove debris

Low battery charge Charge batteries

Bag full light on Replace bag or remove clog

Circuit breaker(s) tripped Reset circuit breaker(s)

Low battery charge Charge battery

Fault brush circuit or motor Check wires, connections and motor

Allow pedal to return to neutral. Restart

Check wires and connections from

controller to motor

Check wires and connections from throttle

to controller and potentiometer resistance

Check switch engagement, wires, connections and switch

Replace bag, check for and remove debris

*Call manufacturer for Serial Number.

**See Serial Number page.

86037810 Chariot iVacuum

35

Page 36

Maintenance

Propel Circuit Board T roubleshooting

Curtis 1228 LED DIAGNOSTICS- Basic and Cylindrical

During normal operation, with no faults present, the status LED is steadily on.

If the controller detects a fault, the status LED provides two types of information.

First, it displays a slow flash (2 Hz) or a fast flash (4 Hz) to indicate the severity of the fault. Slow-flash faults are

self-clearing; as soon as the fault is corrected, the vehicle will operate normally. Fast-flash faults ("." in Table 2) are

considered to be more serious in nature and require that the key switch be cycled to resume operation after the fault

is corrected.

After the severity indication has been active for 10 seconds, the status LED flashes a 2-digit fault identification code

continuously until the fault is corrected. For example, code "1,4"-low battery voltage-appears as: one LED flash,

followed by a pause, then 4 LED flashes, and then repeats.

LED

CODE

1,1 THERMAL CUTBACK

1,2 THROTTLE FAULT 1 throttle fault

1,3 SPD LIMIT POT FAULT speed limit pot fault

1,4 LOW BATTERY VOLTAGE battery voltage too low

1,5 OVERVOLTAGE battery voltage too high

PROGRAMMER LCD DISPLAY EXPLANATION POSSIBLE CAUSE

over-/under-temperature

cutback

1. Temperature >92°C or < -25°C.

2. Excessive load on vehicle.

3. Operation in extreme environments.

4. Electromagnetic brake not

releasing.

1. Throttle input wire open or

shorted.

2. Throttle pot defective.

3. Wrong throttle type selected

1. Speed limit pot wire(s) broken

or shorted.

2. Broken speed limit pot.

1. Battery voltage <17 volts.

2. Bad connection at battery or

controller.

1. Battery voltage >36 volts.

2. Vehicle operating with charger

attached.

2,1 MAIN OFF FAULT main contactor driver Off fault

2,3 MAIN CONT FLTS main contactor fault

2,4 MAIN ON FAULT main contactor driver On fault

36

3. Intermittent battery connection.

1. Main contactor driver failed

open.

1. Main contactor welded or stuck

open.

2. Main contactor driver fault.

3. Brake coil resistance too high.

1. Main contactor driver failed

closed.

86037810 Chariot iVacuum

Page 37

Maintenance

LED

CODE

3,1 PROC/WIRING FAULT HPD fault present for >10 sec.

3,2 BRAKE ON FAULT brake On fault

3,3 PRECHARGE FAULT precharge fault

3,4 BRAKE OFF FAULT brake Off fault

3,5 HPD HPD (High Pedal Disable) fault

PROGRAMMER LCD DISPLAY EXPLANATION POSSIBLE CAUSE

1. Misadjusted throttle.

2. Broken throttle pot or throttle

mechanism.

1. Electromagnetic brake driver

shorted.

2. Electromagnetic brake coil

open.

1. Low battery voltage.

2. KSI and throttle turned on at

same time.

1. Electromagnetic brake driver

open.

2. Electromagnetic brake coil

shorted.

1. Improper sequence of throttle

and KSI,

push, or inhibit inputs.

2. Misadjusted throttle pot.

1. Short in motor or in motor

4,1 CURRENT SENSE FAULT current sense fault

4,2 HW FAILSAFE motor voltage fault (hardware)

4,3 EEPROM FAULT EEPROM fault 1. EEPROM failure or fault.

4,4 POWER SECTION FAULT power section fault

wiring.

2. Controller failure.

1. Motor voltage does not correspond to throttle request.

2. Short in motor or in motor

wiring.

3. Controller failure.

1. EEPROM failure or fault.

2. Short in motor or in motor

wiring.

3. Controller failure.

86037810 Chariot iVacuum

37

Page 38

Notes:

38 86037810 Chariot iVacuum

Loading...

Loading...