Page 1

CARPET EXTRACTOR

Operating Instructions (USA)

Bedienungsanleitung (GER)

MODEL: COUNTRY

CDT7IA/10080050 AUSTRALIA

CDT7IB/10080060 BRITIAN

CDT7IE/10080070 EUROPE

CDT7IS/10080080 SWITZERLAND

Read instructions before operating the machine

Bitte lesen Sie diese Anleitungen, bevor Sie die Maschine in Gebrauch nehmen

AJ

86038340 04/26/11

PRV NO. 98707

IPX4

Page 2

MACHINE DATA LOG/OVERVIEW

Warranty Registration

Thank you for purchasing a Windsor product. Warranty registration is quick and easy.

Your registration will allow us to serve you better over the lifetime of the product.

www.windsorind.com/WarrantyRegistration.aspx

2ENG

To register your product go to:

For customer assistance:

1-800-444-7654

CADET 86038340 04/26/11

Page 3

Machine Data Log/Overview (English). ........1

Machine Data Log/Overview (German)........2

Table of Contents (English)..........................3

Table of Contents (German).........................4

HOW TO USE THIS MANUAL

How to use this Manual. ........................1-1ENG

SAFETY

Important Safety Instructions.................2-1ENG

Hazard Intensity Level...........................2-2ENG

Safety Label Location............................2-3ENG

OPERATIONS

Technical Specifications........................3-1ENG

Controls/Components............................3-2ENG

Filling the Solution Tank ........................3-5ENG

Machine Operation. ...............................3-6ENG

Cleaning Procedure...............................3-9ENG

Accessory Tool Usage........................3-10ENG

MAINTENANCE

Periodic Maintenance............................4-1ENG

Daily/Regular Maintenance....................4-1ENG

Vacuum Motor Replacement.................4-2ENG

Belt Replacement ..................................4-3ENG

Solution Pump Replacement.................4-3ENG

Machine Troubleshooting ......................4-4ENG

Wiring Diagram......................................4-5

GROUP PARTS LIST

Frame Assembly..........................................5-1

Brush Assembly...........................................5-3

Pump Assembly...........................................5-5

Vacuum Shoe Assembly .............................5-9

Control Panel Assembly..............................5-11

Solution Tank Assembly..............................5-13

Recovery Tank Assembly............................5-15

Suggested Spare Parts ...............................5-17

EC Declaration of Conformity......................5-18

CADET 86038340 04/19/07

TABLE OF CONTENTS

3ENG

Page 4

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized Windsor

dealers.

machine model and machine serial number are

important. Refer to the MACHINE DATA box which

is filled out during the installation of your machine.

The MACHINE DATA box is located on the inside of

the front cover of this manual.

The model and serial number of your machine is on

the bottom back-end of the machine.

When placing an order for parts, the

1-1ENG

CADET 86038340 04/26/11

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

- Vacuum Motor Replacement

- Belt Replacement

- Solution Pump Replacement

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- PRV NO. – reference number.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs. If

column has an asterisk (*), call

manufacturer for serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The number on the lower left corner of the

front cover is the part number for this manual.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

!

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for commercial use.

To reduce the risk of fire, electric shock, or injury:

WARNING:

Connect to a properly grounded outlet. See Grounding Instructions.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before

maintenance or service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near

children.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding

the machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or

dropped into water, return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord

around sharp edges or corners.

Do not run machine over cord. Keep cord away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all controls before unplugging.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

SAVE THESE INSTRUCTIONS

CADET 86038340 04/19/07

2-1ENG

Page 6

HAZARD INTENSITY LEVEL

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

! WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

! CAUTION

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

2-2ENG

CADET 86038340 04/19/07

Page 7

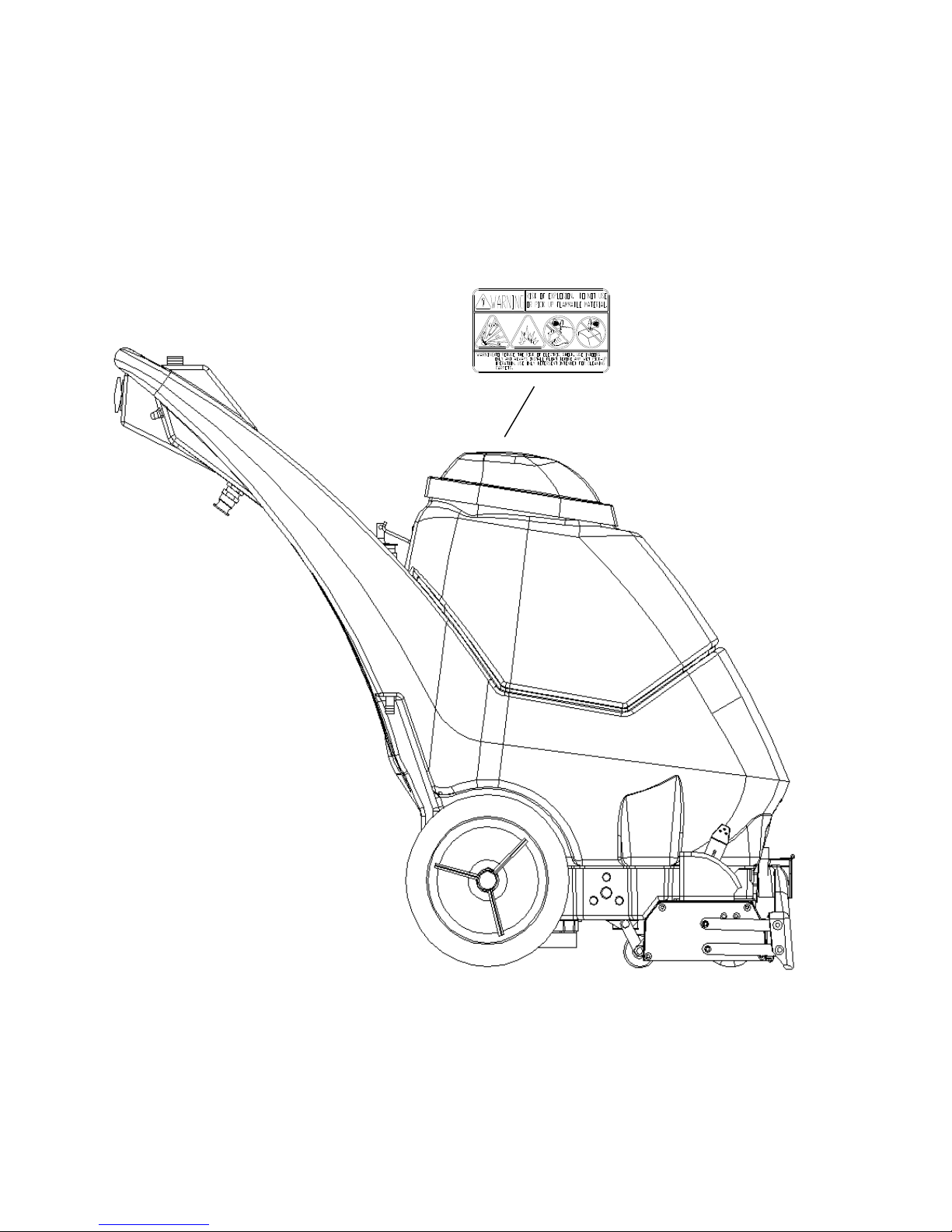

SAFETY LABEL LOCATION

NOTE: These drawings indicate the location of safety labels on the CDT7//10080230. If, at any time, the labels

become illegible contact your Windsor representative for prompt replacement.

WARNING DECAL

86242230

PRV NO. 500009

CADET 86038340 04/19/07

2-3ENG

Page 8

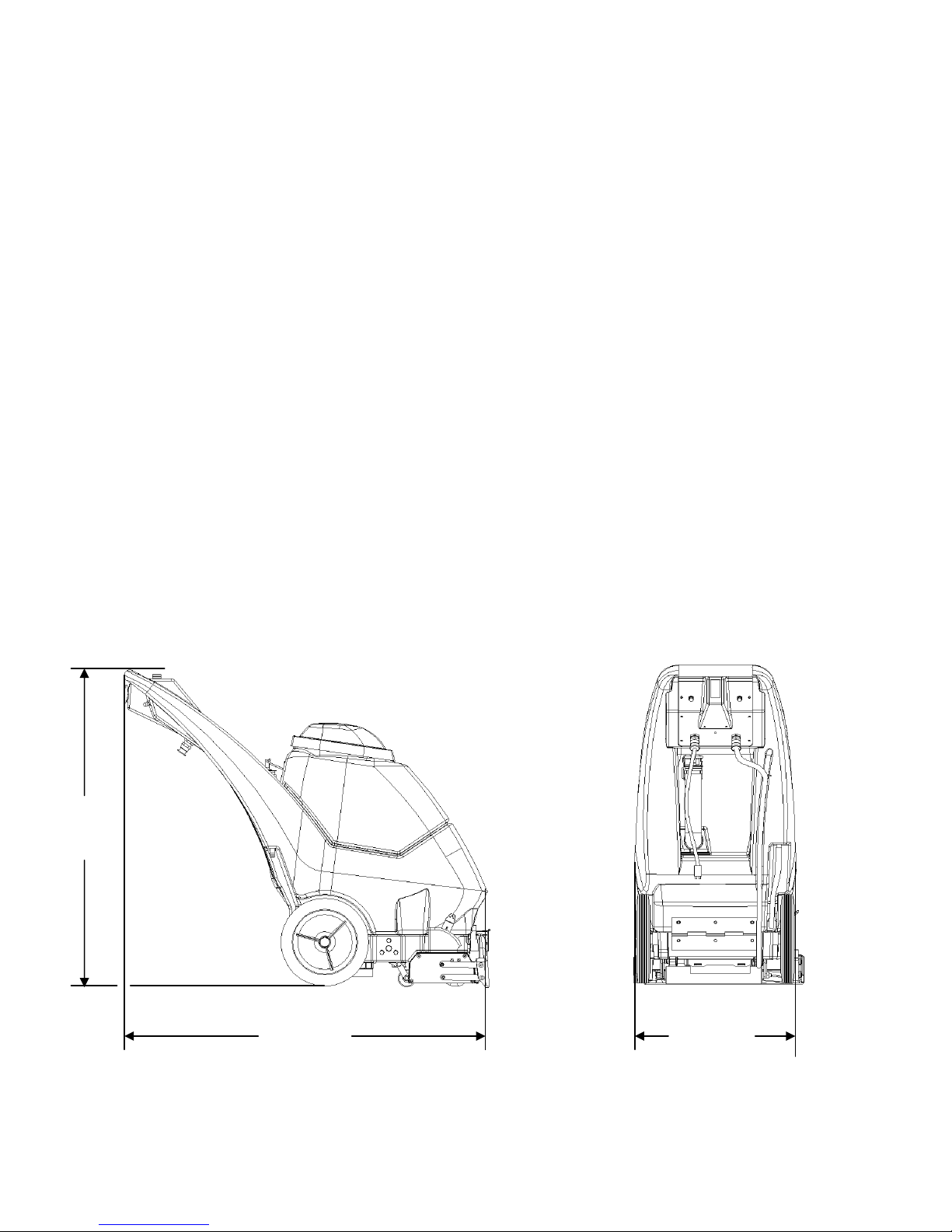

TECHNICAL SPECIFICATIONS

POWER TYPE

ELECTRICAL: 230-240 V, 7 A, 50 HZ

ELECTRIC VACUUM MOTOR: (1) –3 stage, 1.5 hp,

100 cfm (2.80 cubic meters/min.) Waterlift –121” (304

cm)

BRUSH: (1) 15” (38.1 cm.)

SOLUTION PUMP: 90 PSI, diaphragm style, internal

bypass

SOLUTION CAPACITY: 7 gallons (26.5ltr)

RECOVERY CAPACITY: 7 gallons (26.5ltr)

BRUSH SPEED: 1000 rpm

GENERAL DIMENSIONS/WEIGHT

Vacuum shoe: 17” (43.18 cm) cast

aluminum with spring loaded down

pressure

WHEELS: (2) 10” dia. (25 cm) wheels

by 2”

WEIGHT: 92lbs. (42kg)

LENGTH: 41” (104 cm)

HEIGHT: 34” (86.36 cm)

WIDTH: 17.5” (44.45 cm)

SOLUTION SPRAY: 2 quick change

jets.

POWER CABLE: 50’ (12.7 m) (1mm)

34”

(86.36cm)

41”

(104cm)

3-1ENG

17.5”

(44.45cm)

CADET 86038340 11/02/10

Page 9

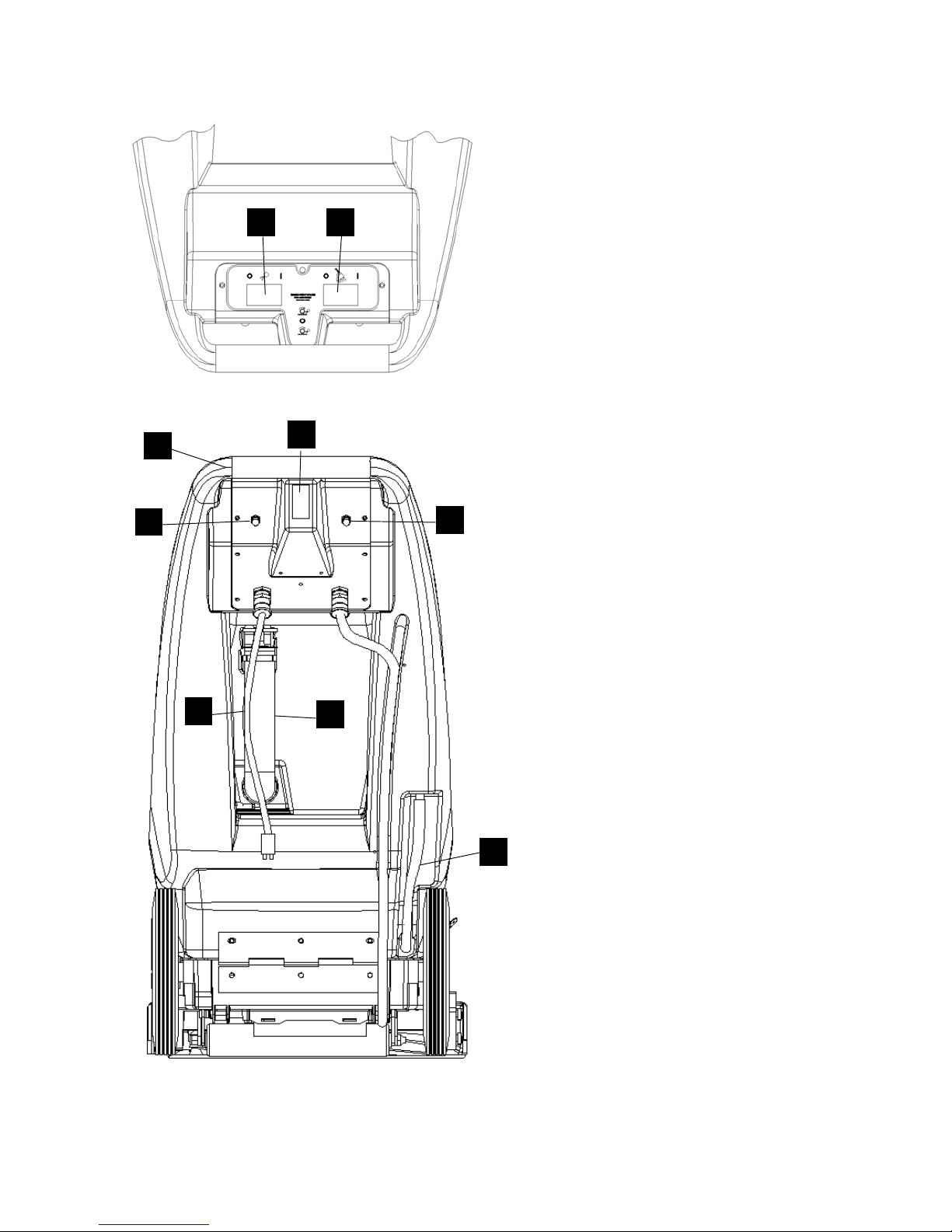

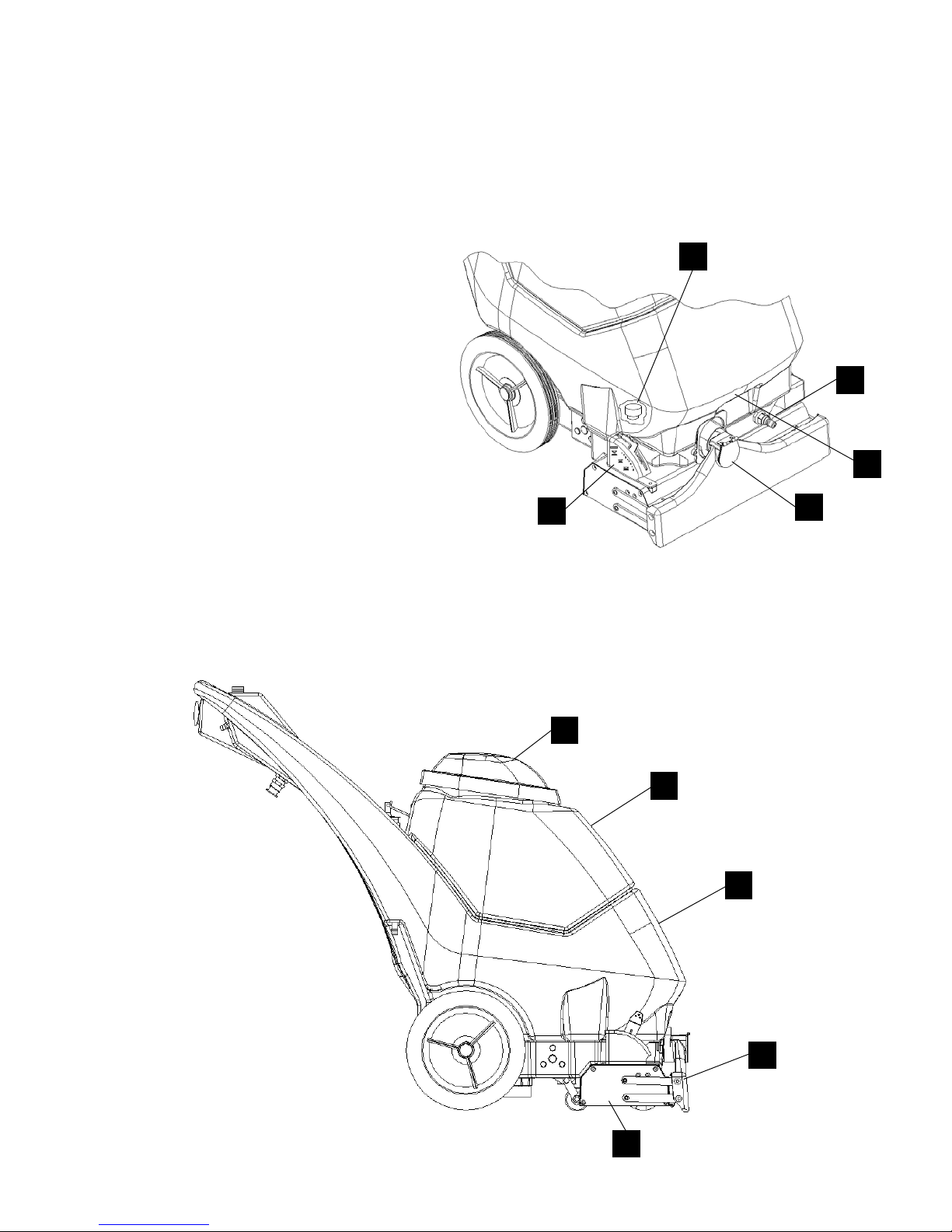

CONTROLS/COMPONENT LOCATIONS

1. Main Handle. Used to pull and maneuver

machine.

2. Electrical Cord.

3. Pump Switch. Turns on pump and enables

spray.

4. Brush/Spray switch. Turns on brush motor

and activates electro-valve to dispense

solution to floor through jets. Intermittent, off,

and continuous settings.

5. Vacuum Motor Switch. Turns on vacuum

motor

6. Brush Motor Circuit Breaker. 4 amp.

Breaker protecting brush motor.

7. Vacuum Motor Circuit Breaker. 7 amp.

Breaker protecting vacuum motor.

8. Recovery Dump Hose. Facilitates draining

dirty cleaning solution.

9. Solution Dump Hose. Facilitates draining

excess cleaning solution from solution tank.

6

1

2

3 5

4

7

8

9

CADET 86038340 04/19/07

3-2ENG

Page 10

CONTROLS/COMPONENT LOCATIONS

1. Solution Accessory Tool Hookup. Used for

various auxiliary cleaning tools.

2. Vacuum Hose Door. Used to connect

various auxiliary 1-1/2 inch cleaning tool

vacuum hoses.

3. Brush Height Adjustment. Used to regulate

brush height from storage position to various

carpet heights.

4. Recovery Tank. Used to collect dirty

cleaning solution.

5. Solution Tank. Used to hold cleaning

solution.

6. Recovery Tank Dome.

7. Vacuum Shoe.

8. Brush Housing.

9. Front Lifting Handle.

10. Cleaning Solution Filter.

10

1

9

3

2

3-3ENG

6

4

5

7

8

CADET 86038340 04/19/07

Page 11

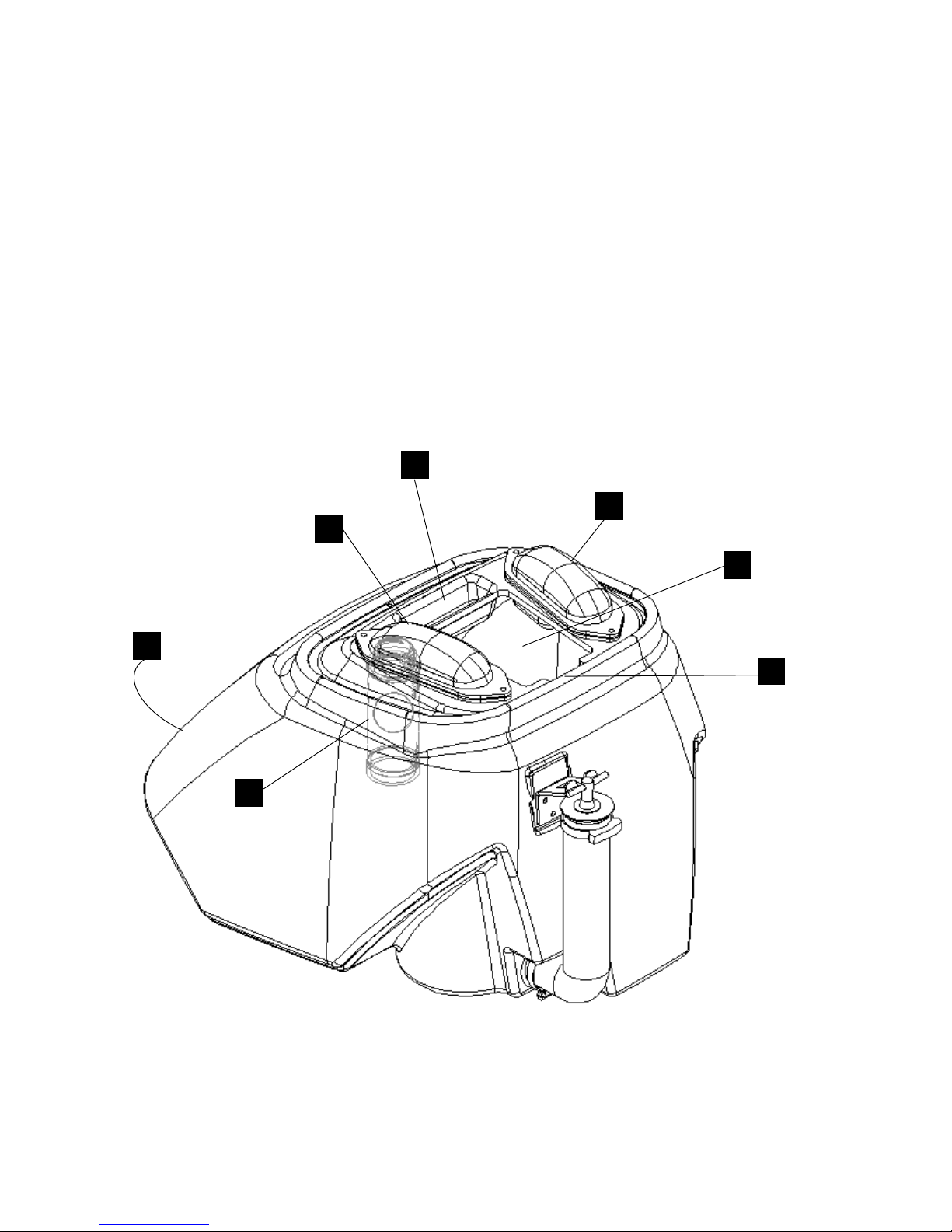

CONTROLS/COMPONENT LOCATIONS

1. Solution Intake Cover.

2. Vacuum Intake Cover.

3. Float Shut-Off.

4. Clean-Out Opening.

5. Pour Spout.

6. Lift Handle.

6

1

2

6

4

5

3

CADET 86038340 04/19/07

3-4ENG

Page 12

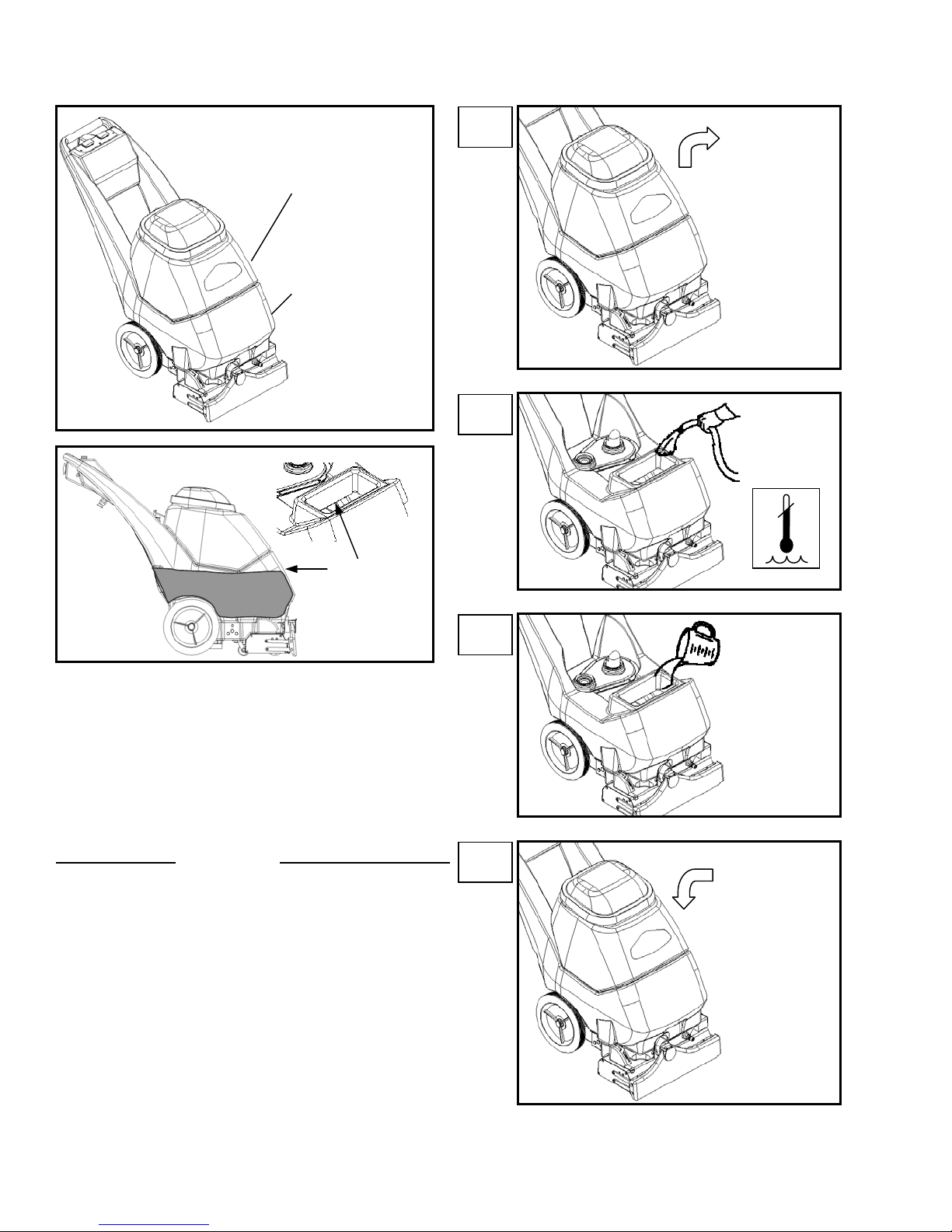

FILLING OPERATIONS

A

A

)

RECOVERY TANK

SOLUTION

TANK

FILL LINE

FILLING THE CADET

NOTE: Use clean bucket of water to fill solution tank

Do not put defoamer, solvents, spotter or

prespray chemicals in the solution tank.

Do not allow water to spill into vacuum motor inlet. Dry

spillage from top of solution tank before replacing

recovery tank.

CHEMICALS

Suitable Chemicals Non-Compatible Chemicals

Alkalis Aldehydes

Detergents Aromatic Hydrocarbons

Hydroxides SP Butyls

Soaps Carbon Tetrachloride

Vinegar Clorox*

Chlorinated Bleaches

Chlorinated Hydrocarbons

Lysol*

Methyl Ethel Ketone (MEK)

Perchorethylene (perc)

Phenolics

Trichlorethylene

D-Limonene

* Product Trademark Names

STEP

1

STEP

2

STEP

3

STEP

4

Remove recovery

tank

dd water

7 gal.

(26.5 ltr.)

140°F (60°C

7 – 14oz.

(207ml – 414ml)

dd cleaning

chemical

Replace recovery

tank

3-5ENG

CADET 86038340 04/19/07

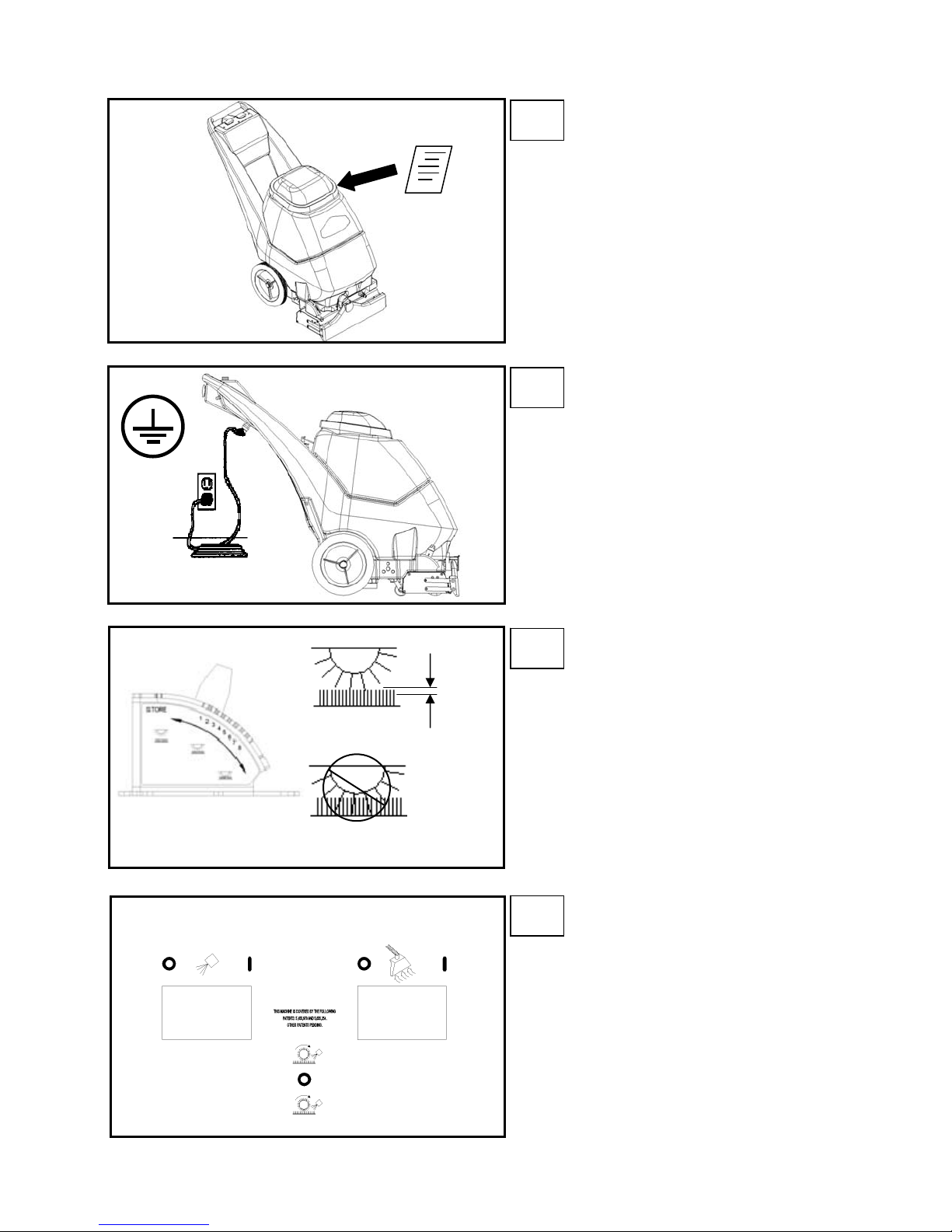

Page 13

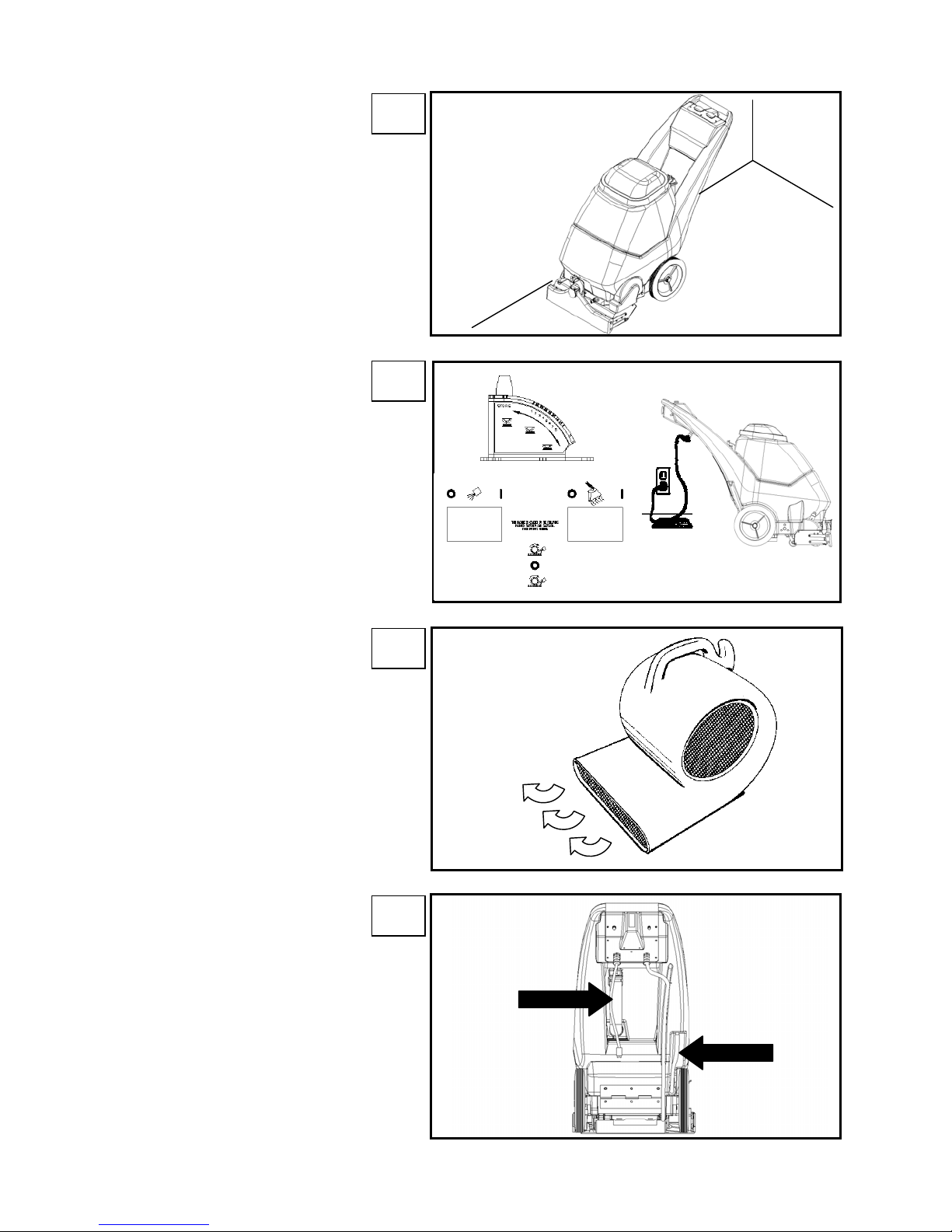

OPERATIONS

STEP

Remove literature from recovery

1

tank. Fill solution tank (see filling

operations, page 3-5).

CORRECT

1/8in

(3mm)

STEP

Plug cord into grounded outlet. Note:

2

Be sure dome is seated on recovery

tank, and float shut-off is installed

correctly.

STEP

Adjust brush to proper setting. Note:

3

For good operation the brush must

skim the carpet. If circuit breaker

trips raise brush to prevent damage

to motor or carpet.

INCORRECT

PUMP VACUUM

ON ON

STEP

CADET 86038340 11/02/10

Turn on both Vacuum and Pump

4

motor switches (“ON”=“I”).

3-6ENG

Page 14

OPERATIONS

Tip machine back by main handle

to move to starting point.

STEP

5

Lower machine to floor.

Select intermittent or continuous

switch setting to turn on brush and

start solution spray.

The intermittent setting requires the

operator to hold the switch in the

“on” position with the thumb, and is

typically used in small areas where

short cleaning passes are made.

The continuous setting allows the

operator to set the switch in the “on”

position with one touch, and is

typically used in large areas where

long cleaning passes are made.

STEP

6

STEP

7

INTERMITTENT

CONTINUOUS

3-7ENG

CADET 86038340 04/19/07

Page 15

CLEANING PROCEDURE

STEP

1

Start at wall closest to power outlet.

Pull straight back without pushing

down on handle.

1in.

(25mm)

1ft.

(30cm)

OFF

STEP

2

STEP

3

Release intermittent setting or turn

off continuous setting on

brush/spray switch approximately 1

foot before ending cleaning pass.

Push down on handle to raise

vacuum shoe and brush before

moving to the next cleaning pass.

Overlap brush contact area a

minimum of 1 inch on the right

(close cleaning) side of machine.

Overlap a minimum of 2 inches on

the left (drive belt) side of machine.

VACUUM

INTAKE COVER

SOLUTION

INTAKE COVER

CADET 86038340 04/19/07

STEP

During operation, observe the following:

The Cadet is equipped with clear

4

internal covers to facilitate operator

viewing of dirty solution and vacuum air

flow.

During operation, observe the vacuum

intake cover. Large amounts of water or

foam entering the vacuum system can

damage the vacuum motor. If you

notice either condition, shut down the

machine immediately. Empty recovery

tank and/or add defoamer to recovery

tank.

3-8ENG

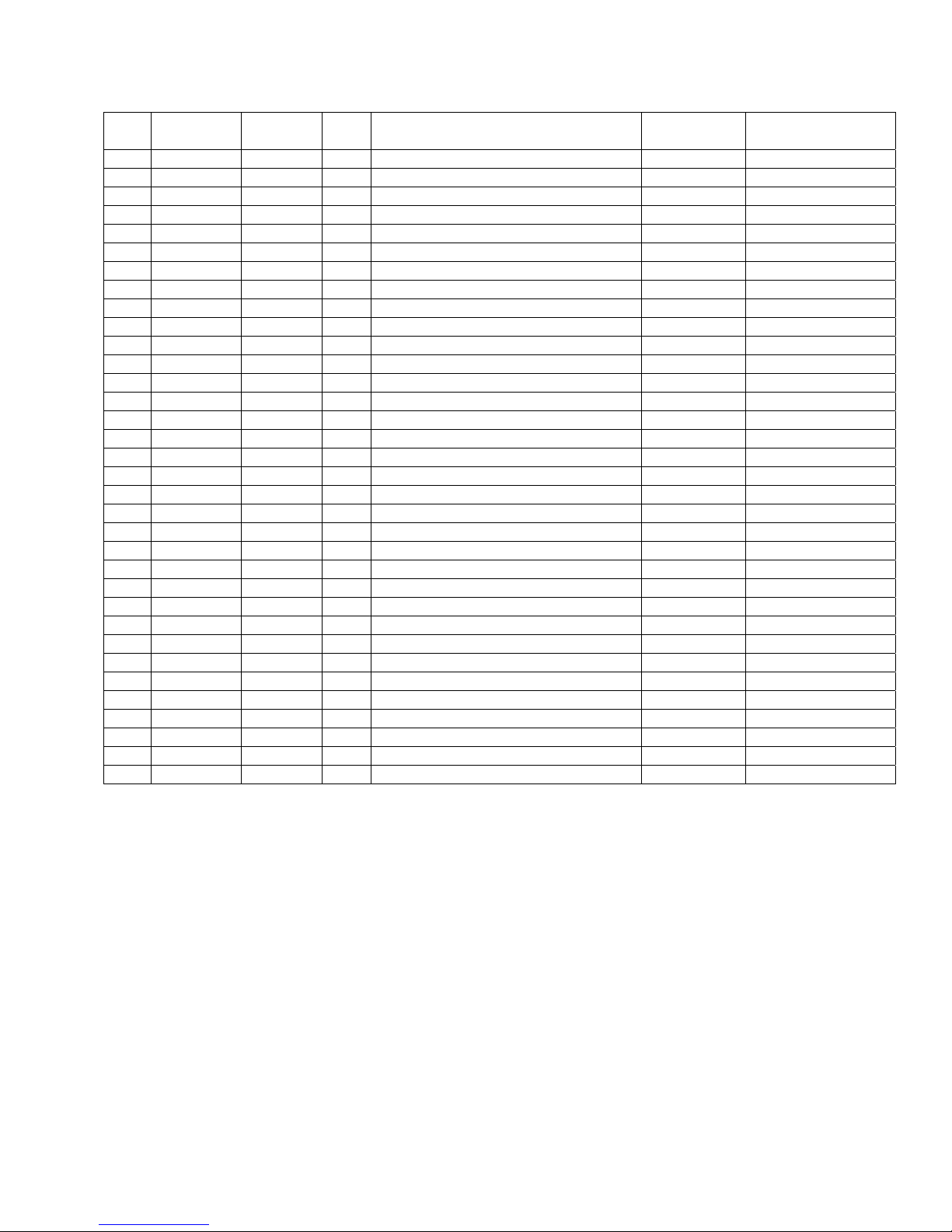

Page 16

CLEANING PROCEDURE

Use right side of machine for

cleaning against walls.

STEP

5

After cleaning, turn off all controls,

return brush to storage position and

carefully unplug machine.

To speed drying, use a

Windblower™ fan.

STEP

6

OFF OFF

OFF

STEP

7

Empty recovery tank by releasing

dump hose. Use a hose with cold

water to clean out the recovery tank.

Also drain solution tank after each

use.

3-9ENG

STEP

8

RECOVERY

DRAIN

SOLUTION

DRAIN

CADET 86038340 04/19/07

Page 17

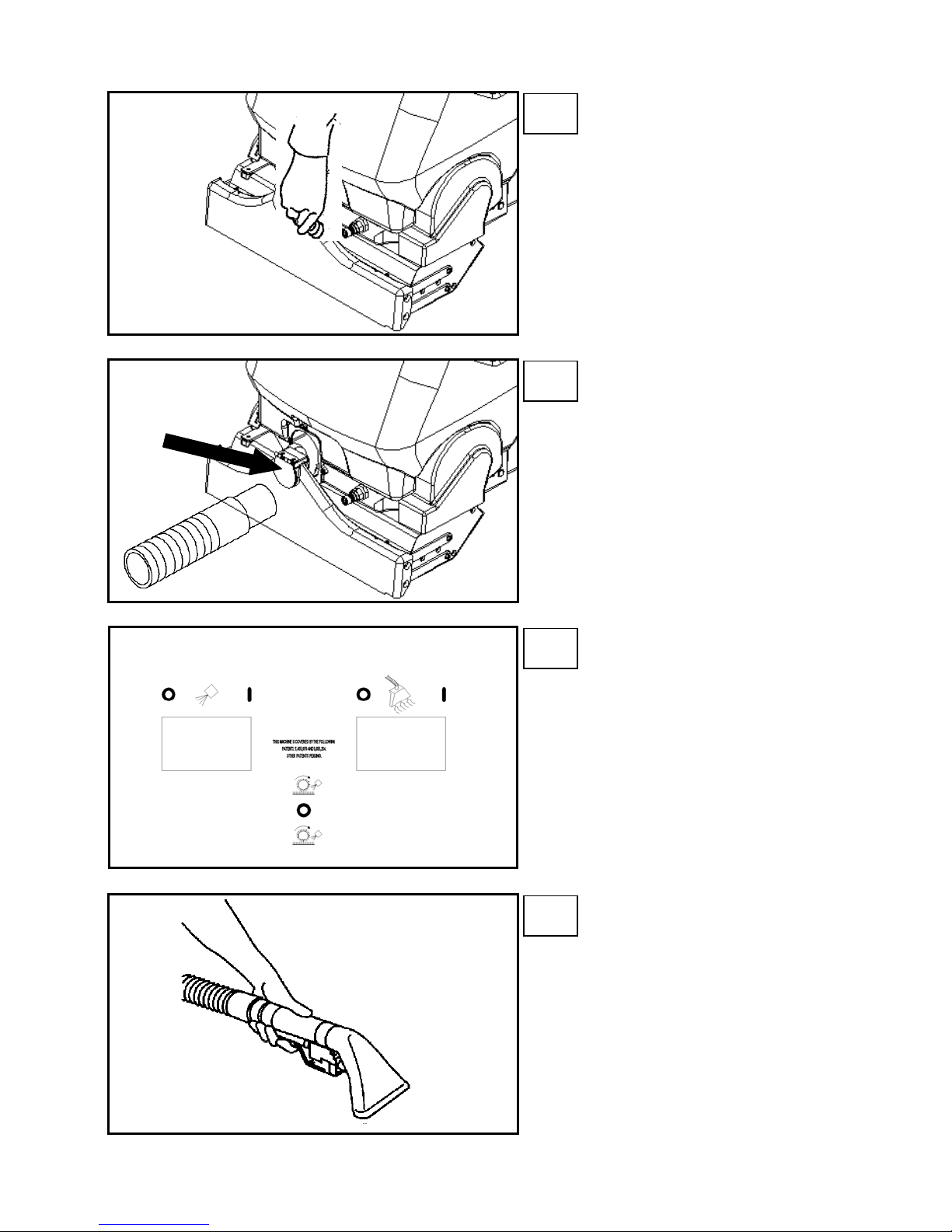

ACCESSORY TOOL USAGE

STEP

1

Use only one of the following

acceptable accessory tools.

86000000 – PRV NO. DDH

86031540 – PRV NO. 39504

86041180 – PRV NO. ESW

86000050 – PRV NO. SPW

86000020 – PRV NO. HT

Pull back collar and insert over

machine mounted fitting, then

release collar to lock into place.

STEP

2

PUMP VACUUM

ON ON

OFF

STEP

3

Lift door on front of vacuum shoe

and insert 1 ½ inch hose cuff into

hole.

Turn on Pump and Vacuum Switch.

Note: Be sure

intermittent/continuous switch is in

center (off) position and brush is in

storage position.

STEP

4

CADET 86038340 04/19/07

Squeeze handle on accessory tool

to begin cleaning.

3-10ENG

Page 18

MAINTENANCE

PERIODIC MAINTENANCE

Twice a month, flush a white vinegar solution

(One quart vinegar to two gallons of water) or

anti-browning solution (mixed as directed)

through the extractor. This will prevent build-up

of alkaline residue in the system. If spray jets

become clogged, remove the spray tips, wash

them thoroughly, and blow-dry.

NOTE: Do not use pins, wire, etc. to clean

nozzles as this could destroy spray pattern.

Periodically inspect all hoses, electrical cables

and connections on your machine. Frayed or

cracked hoses should be repaired or replaced

to eliminate vacuum or solution pressure loss. If

the cable insulation is broken or frayed, repair

or replace it immediately. Don’t take chances

with electrical fire or shock.

DAILY / REGULAR MAINTENANCE

Before making any adjustments or repairs to

the machine, disconnect the power cord from

electrical source.

1. Empty unused cleaning solution from the

solution tank.

2. Inspect and clean filter screen in solution

tank.

3. Flush pumping system with 4 or 7 liters of

clean, hot water.

4. After each use, rinse tank with fresh water.

Periodically inspect the recovery tank and

decontaminate if necessary, using a

Hospital Grade Virucide or a 1-10 bleach to

water solution. Waste water should be

disposed of properly.

5. Check for and remove any lint or debris

around vac shoe.

6. Check spray jets for full spray pattern.

7. Remove lint and dirt build-up from brush

and housing.

NOTE: Brush removal.

A. To remove brush, grab and pull brush

out from end opposite drive belt

(operator’s right). Remove other end

from brush driver.

B. To install brush, line up slots in brush

core with pin in driver on drive belt side

(operator’s left) and push brush onto

driver. Then snap bearing end (opposite

end) of brush into retaining clip.

8. Check cooling air screen (located on frame

behind left wheel) for lint or debris.

9. Check float and shut-off screen and clean

as necessary.

NOTE: Always store machine with brush in

“Store” position.

4-1ENG

CADET 86038340 04/19/07

Page 19

MAINTENANCE

!

ONLY QUALIFIED

WARNING:

MAINTENANCE

PERSONNEL ARE

TO PERFORM THE FOLLOWING REPAIRS.

VACUUM MOTOR REPLACEMENT

1. Turn off all switches and unplug machine.

2. Remove recovery tank.

3. Remove the (2) screws that fasten the

solution tank to the frame, and tilt tank back

to expose the inside of the frame.

4. Locate the vacuum motor wires and

disconnect at the connector. Close the

solution tank.

5. Remove the (6) screws holding the vacuum

motor cover (p/n 86003080-PRV NO.

27809) to the solution tank.

6. Remove the vacuum motor.

7. Reverse process to install vacuum motor.

Vac Motor Carbon Brushes Replacement (Ametek)

End Cap

Carbon Brushes

Note: When replacing carbon vac motor brushes

loosen wire terminal BEFORE removing screws on

bracket.

If armature commutator is not concentric, extremely

pitted, or grooved the motor will need to be replaced

or sent to a qualified service center to restore vac

performance.

Wire Terminal

WARNING: The green

ground wire must be

attached for safe

operation.

See wiring diagram.

Wire

Terminal

Vacuum Motor Carbon Brushes Replacement (Windsor)

End Cap

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a

qualified service center.

Important:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will dama ge

motor if brushes are allowed to wear away completely.

WARNING: The green

ground wire must be

attached for safe operation.

See wiring diagram.

Important:

These brushes wear quicker

as the length shortens due to

increased heat.

Spring inside brush

housing will damage motor

if brushes are

allowed to wear away

completely.

Note:

Place

stop in

groove.

3/8

Periodically check the length of the carbon brushes.

Replace both carbon brushes when either is less

than 3/8" long.

3

8

Periodically check the length of the carbon brushes. Replace

both carbon brushes when either is less than 3/8" (9.5mm)

long.

[9.5mm]

CADET 86038340 04/19/07

4-2ENG

Page 20

MAINTENANCE

!

BELT REPLACEMENT

1. Turn off all switches and unplug machine.

2. Remove recovery tank and brush.

3. Remove the (2) screws that fasten the

solution tank to the frame, and tilt tank back

to expose the inside of the frame.

4. Loosen the (4) screws that hold the brush

motor in place and slide motor forward to

release tension in belt.

5. Remove the (2) screws that fasten the

vacuum shoe links (p/n 86227350 – PRV

NO. 05016) to the brush housing.

ONLY QUALIFIED MAINTENANCE PERSONNEL ARE TO PERFORM

WARNING:

THE FOLLOWING REPAIRS.

SOLUTION PUMP REPLACEMENT

1. Turn off all switches and unplug the

machine.

2. Remove recovery tank.

3. Remove the (2) screws that fasten the

solution tank to the frame, and tilt tank back

to expose the inside of the frame.

6. Remove the (3) screws that fasten the side

plate (p/n 86249420 – PRV NO. 62759) to

the brush housing to remove belt. NOTE: All

components associated with driving the

brush will come out with the side plate.

7. Reverse process to install belt.

86249420

PRV NO. 62759

62759

86227350

05016

PRV NO. 05016

4. Remove solution hoses from fittings in

pump.

5. Remove the (2) screws that fasten the

pump to the frame.

6. Reverse process to install pump.

Pump Head

86251040

PRV NO. 65187

4-3ENG

PRV NO. 42-809332

Pump Hsng

86288790

PRV NO. 41387

Pressure Switch

86161980

Pump Replacement Parts for Shurflo 100 psi (86026400-PRV NO. 65254)

Valve Asm

86258830

Pump Replacement Parts for Flojet 73 psi (86006110-PRV NO. 65189)

PRV NO. 84161

Diaphram

86235100

PRV NO. 29206

Pump Repair Kit

86004600 – PRV NO. 47176

Hsng/Pump Repair Kit

86136040 – PRV NO. 47350

CADET 86038340 04/19/07

Page 21

TROUBLESHOOTING CHART

PROBLEM CAUSE SOLUTION

No Power, Nothing Runs

Vacuum Motor Will Not

Run

Vacuum Motor Runs But

Suction Is Poor

Poor Or No Water Flow

(Carpet Is Streaky)

Brush Does Not Spin

1. Is the cord plugged in.

2. Circuit breaker tripped in building.

3. Faulty switch.

4. Faulty power cord or pigtail.

1. Vacuum circuit breaker tripped.

2. Faulty main vacuum switch.

3. Loose wiring.

4. Faulty vac motor.

1. Debris lodged in vac shoe.

2. Dome gasket defective or missing.

3. Vacuum hose cracked or hose cuff loose.

4. Recovery tank full / float ball stuck in the up

position.

1. Main pump switch off.

2. Jets clogged or missing.

3. Solution filter clogged.

4. Faulty solenoid.

1. Brush switch off.

2. Brush circuit breaker tripped

3. Brush belt broken.

4. Faulty brush motor.

1. Plug in cord.

2. Reset breaker

3. Call for service.

4. Call for service.

1. Reset breaker

2. Call for service.

3. Call for service.

4. Call for service.

1. Remove debris from vac shoe.

2. Replace as necessary.

3. Replace or repair as necessary.

4. Turn off vac motor. Drain and rinse

recovery tank.

1. Turn on.

2. Clean using a vinegar /water solution or

replace.

3. Drain solution tank and clean solution

filter.

4. Call for service.

1. Turn on brush switch.

2. Reset circuit breaker.

3. Replace as necessary.

4. Call for service.

CADET 86038340 04/19/07

4-4ENG

Page 22

WIRING DIAGRAM

86268750

PRV NO. 88567

86268750

PRV NO. 88567

86003650

PRV NO. 34362

86268900

PRV NO. 88655

86268900

PRV NO. 88655

86004480

PRV NO. 41353

86268750

PRV NO. 88567

86268350

PRV NO. 88270

86001240

PRV NO. 14020

86268750

PRV NO. 88567

4-5ENG

CADET 86038340 04/19/07

Page 23

NOTES

CADET 86038340 04/19/07

4-6ENG

Page 24

FRAME ASSEMBLY

1

30

7

15

11

10

5

22

2

28

19

18

(SEE PG. 5-11)

21

3

12

34

A

B

33

3

6

26

9

32

25

27

6

20

29

5-1

8

CADET 86038340 04/19/07

13

14

4

24

Page 25

FRAME ASSEMBLY

2

REF PART NO. PRV NO. QTY DESCRIPTION

1 - OPEN - -

2 86003620 34341 1 FRAME, CLP FAMILY

3 86004340 39528 1 HOSE ASM, 1.5 BLK VAC X 15.5

4 86001660 41236 2 HUBCAP, 5/8" SHAFT

5 86004480 41353 1 HARNESS, MAIN, CDT

6 86239610 41354 1 HINGE, TANK TO FRAME

7 86005370 53641 1 MOTOR ASM, BRUSH CLP FAMILY

8 86005640 57030 2 NUT, 10-32 HEX NYLOCK

9 86005810 57245 3 NUT, 1/4-20 HEX NYLOCK SS

10 86198530 99809 2 FOAM TAPE, 1/8 THK X 3/4 1SDA

11 86249430 62761 1 PLATE, BRUSH MTR CLAMP

12 86006020 64099 1 PULLEY, 1.4 OD, 6GR, MICRO-V

13 86250130 66282 6 PLUG, HOLE, .375" BLK

14 86250140 66288 2 PLUG, 9/16 OD BLK NYLON

15 86006580 70085 2 SCR, 1/4-20 X 1/2 PPHMS SS

16 86273980 70066 2 SCR, 10-32 X 3/4 PPHMS

17 - OPEN - -

18 86010630 87013 2 WASHER, 1/4 ID X 5/8 OD SS

19 86010660 87025 2 WASHER, 1/4 LOCK EXT STAR SS

20 86010650 87018 2 WASHER, #10 X 9/16 OD

21 86006550 70074 2 SET SCR, 10-32 X 1/4 KCP

22 86256190 73197 1 STRAIN RELIEF, 90 DEGREE

23 - OPEN - -

24 86259960 89506 2 WHEEL, 1-15/16 X 10” HOOSIER

25 86066230 03107 1 AXLE, 5/8 X 17.06L

26 86134490 99667 10” HEAT SHRINK, 3/4 ID UL/CSA

27 86253090 73943 1 SEAL, FRAME/TANK

28 86002370 20035 1 CLAMP, 7/16 DIA NYLON UL

29 86233140 20041 1 CLAMP, 2.0" WORM GEAR

30 86274760 70271 2 SCR, ¼-20 X ½ HHCS PLTD

31 86006530 70057 2 SCR, ¼-20 X 1 PPHMS SS

32 86272160 66052 1 PIN, ROLL I/8” X 1.0”L

33 86276610 70697 1 SCR, ¼-20 X 1.25 PPHMS SS

34 86005710 57105 3 NUT, ¼-20 HEX W/ STD WASHER

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-

Page 26

BRUSH ASSEMBLY

15

25

31

30

17

34

24

18

11

44

25

29

47

30

45

26

16

36

33

43

32

7

13

16

8

12

38

39

10

22

4

40

37

41

26

35

28

3

21

42

1

6

19

27

5-3

23

20

25

14

17

30

29

CADET 86038340 04/19/07

46

25

3

9

2

5

Page 27

BRUSH ASSEMBLY

4

REF PART NO. PRV NO. QTY DESCRIPTION

1 86003730 03110 1 AXLE, ROLLER

2 86227100 04084 1 ADAPTER, BRUSH BRG.

3 86000900 09019 2 BEARING, 1.125ODX.500IDX.375

4 86001100 11045 1 BELT, 180J6 MICRO-V

5 86001140 12514 1 BRUSH, 15L X 3.38OD

6 86001300 140343 1 BRKT, BRUSH PULLEY

7 86001310 140351 1 BRKT, BRUSH HEIGHT

8 86003620 34341 REF FRAME, CLP FAMILY

9 86004060 36192 2 GUARD, THREAD

10 86004470 41345 1 HOUSING, BRUSH 15"

11 86004980 50998 1 LABEL, BRUSH HEIGHT

12 86093080 51311 1 LINKAGE, ASM, BRUSH HEIGHT

13 86005110 51312 1 LINKAGE ASM, ROLLER SUPPORT

14 86005120 51314 2 LINK, ROLLER, FRONT

15 86005130 51317 1 LEVER, HEIGHT ADJUSTMENT

16 86005640 57030 4 NUT, 10-32 HEX NYLOCK

17 86005850 57271 2 NUT, 3/8 DIA CAP, TYPE PUSH PLT

18 86249410 62758 1 PLATE, BRUSH HOUSING RH

19 86249420 62759 1 PLATE, BRUSH HOUSING LH

20 86005930 62762 2 PLATE, AXLE RETAINER

21 86250680 64098 1 PULLEY, 2.2 OD, 6GR, MICRO-V

22 86006220 66192 1 PIN, ROLL 1/4 X 1.25L

23 86006430 67411 1 ROLLER, 1.9 DIA X 10.5 LG

24 86006510 70043 2 SCR, 10-32 X 5/8 PFHMS

25 86006590 70088 6 SCR, 10-32 X 1/2 PPHMS SS DL

26 86006650 70177 7 SCR, 10-32 X 1/2 FHMS SS

27 86006700 70232 2 SCR, 10-32 X 3/8 FHMS SS

28 86275530 70497 2 SCR, #10-24 X 1/2 SHCS

29 86010640 87016 4 WASHER, #10 LOCK EXT STAR SS

30 86010650 87018 6 WASHER, #10 X 9/16 OD

31 86136750 70675 4 SCR, 1/4-20 X.5/8 THMS PLTD NP

32 86230620 12524 1 BRUSH, 15 L X 3.35 OD G2 1000090563

33 86251710 67467 1 RING, TOLERANCE 7/8 ID X 1/2 W 1000090563

34 86003070 27805 1 CLIP, BEARING

35 86003370 29157 1 DRIVER, BRUSH

36 86278130 70737 1 SHLDR BOLT, 3/8 OD X 3/8 L SS NP 1000090563

37 86272770 67094 1 RING, 1/2 EXT. SNAP

38 86272510 66310 2 PIN, CLEVIS 1/4 X 1/2 PLTD

39 86008650 80604 2 COTTER, 1/4" RING

40 86342240 - 1 SPACER, .81 X 1.06 X .125

41 86006030 64102 1 PULLEY ASM, BRUSH

42 86003390 29208 1 DRIVER ASM, BRUSH

43 86001140 12514 1 BRUSH ASM, 15 IN

44 86227150 05158 1 ADAPTER, BRUSH BRG. DIE CAST 1000090563

45 86228890 09137 2 BEARING, R6 3/8 ID 1000090563

46 86028010 47383 1 BRUSH BEARING ASM.

47 86004750 47416 REF KIT, BRNG/ADPTR EXTRCTR

SERIAL NO.

FROM

NOTES:

CADET 86038340 02/22/11

5-

Page 28

PUMP ASSEMBLY

14

19

15

11

3

8

4

23

118

20

17

10

16

20

13

9

2

16

21

12

7

5-5

28

26

26

25

(SEE SOLUTION

TANK)

24

CADET 86038340 04/19/07

27

C

6

5

Page 29

PUMP ASSEMBLY

6

REF PART NO. PRV NO. QTY DESCRIPTION

1 86002470 22072 1 COUPLING, 1/4 ANCHOR W/1" HEX

2 86002480 22090 2 CONNECTOR, 1/8FPT X 1/4 TUBE QC

3 86003470 31072 1 ELBOW, SWIVEL, 1/4MPTX1/4TUBE

4 86003490 31074 1 ELBOW, SWIVEL,3/84MPTX3/8TUBE QC

5 86004570 44067 2 JET BODY, MINI PROMAX BODY

6 86241680 44073 2 JET, MINI PROMAX 9503

7 86241680 57030 2 NUT, 10-32 HEX NYLOCK

8 86026400 65254 1 PUMP ASM, 230V 100 PSI W/CONN

9 86250140 66288 2 PLUG, 9/16 OD BLK NYLON

10 86250140 70195 2 SCR, 10-32 X 1.25 PPHMS SS

11 86273750 70011 2 SCR, 1/4-20 X 5/8 HHCS SS

12 86003640 34355 1 FITTING,1/4 TUBE,"Y", QC

13 86008360 78419 1 TEE, 3/8 MPT X 3/8 TUBE, QC

14 86010570 84165 1 VALVE ASM,SOLENOID CLP FAMILY

15 86010810 87191 2 WASHER, 1/4"IDX1.0OD. FLAT SS

16 86010650 87018 4 WASHER, #10 X 9/16 OD

17 86010820 87192 2 WASHER, 7/16 X 3/4 X .19RUBBER

18 86005590 56014 1 NIPPLE, 1/4 CLOSE

19 86005580 56012 1 NIPPLE, 1/4 FPT QD

20 86003500 31076 2 ELBOW, 1/4 MPT X 3/8 TUBE, QC

21 86006590 70088 2 SCR, 10-32 X 1/2 PPHMS SS

22 - OPEN - -

23 86267400 880278 1 WIRE, 22" GRN/18 76011 X 76011

24 86282340 39720 1 HOSE, 3/8 OD X 1/4 ID URTHN X 22”

25 86279930 29277 2 DUCT, 1/2 ID SPLT FLX X 16”

26 86281900 39531 3 HOSE, 1/4 ID NYLON X 5"

27 86253020 73963 1 SCREEN, INTAKE

28 86282350 39721 2 HOSE, 3/8 ID NYL11 YLW X 17”

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-

Page 30

PUMP ASSEMBLY

PRIOR TO S/N 1000153482

14

19

18 1

15

23

3

8

4

10

16

20

13

9

2

16

21

12

28

26

26

11

24

25

20

17

C

(SEE SOLUTION

TANK)

27

7

6

5

5-7

CADET 86038340 04/19/07

Page 31

PRIOR TO S/N 1000153482

PUMP ASSEMBLY

REF PART NO. PRV NO. QTY DESCRIPTION

1 86002470 22072 1 COUPLING, 1/4 ANCHOR W/1" HEX

2 86002480 22090 2 CONNECTOR, 1/8FPT X 1/4 TUBEQC

3 86003470 31072 1 ELBOW, SWIVEL, 1/4MPTX1/4TUBE

4 86003480 31073 1 ELBOW, SWIVEL,1/4MPTX3/8TUBEQC

5 86004570 44067 2 JET BODY, MINI PROMAX BODY

6 86004580 44068 2 JET, MINI PROMAX 9504

7 86004580 57030 2 NUT, 10-32 HEX NYLOCK

8 86251080 65197 1 PUMP ASM, 230V 73 PSI

9 86250140 66288 2 PLUG, 9/16 OD BLK NYLON

10 86006830 70386 2 SCR, 10-32 X 1.0 PPHMS

11 86273750 70011 2 SCR, 1/4-20 X 5/8 HHCS SS

12 86003640 34355 1 FITTING,1/4 TUBE,"Y", QC

13 86008370 78420 1 TEE, 1/4 MPT X 3/8 TUBE, QC

14 86010570 84165 1 VALVE ASM,SOLENOID CLP FAMILY

15 86010810 87191 2 WASHER, 1/4"IDX1.0OD. FLAT SS

16 86010650 87018 4 WASHER, #10 X 9/16 OD

17 86010820 87192 2 WASHER, 7/16 X 3/4 X .19RUBBER

18 86005590 56014 1 NIPPLE, 1/4 CLOSE

19 86005580 56012 1 NIPPLE, 1/4 FPT QD

20 86003500 31076 2 ELBOW, 1/4 MPT X 3/8 TUBE, QC

21 86006590 70088 2 SCR, 10-32 X 1/2 PPHMS SS

22 - OPEN - -

23 86267400 880278 1 WIRE, 22" GRN/18 76011 X 76011

24 86281890 39529 1 HOSE, 3/8 URETHANE X 29"

25 86004350 39530 1 HOSE, 3/8 NYLON X 6"

26 86281900 39531 3 HOSE, 1/4 ID NYLON X 5"

27 86253020 73963 1 SCREEN, INTAKE

28 86004400 39591 1 HOSE, 3/8 ID NYLON YLW X 29”

29 86003490 31074 REF ELBOW, SWIVEL 1/4 MPT X 1/4 TUBE

30 86008360 78419 REF TEE, 3/8 MPT X 3/8 TUBE QC

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-8

Page 32

VACUUM SHOE ASSEMBLY

1

4

13

2

12

8

6

3

11

11

7

10

5

7

5-9

CADET 86038340 04/19/07

Page 33

VACUUM SHOE ASSEMBLY

REF PART NO. PRV NO. QTY DESCRIPTION

1 86227350 05016 4 ARM, VAC SHOE PARALLEL

2 86234760 27674 1 COVER, ACCESSORY PORT

3 86005810 57245 4 NUT, 1/4-20 HEX NYLOCK SS

4 86006790 70351 2 SCR, 10-32 X 3/8 HHTR W/STAR

5 86006790 70360 4 SCR, 1/4-20 X.75 PPHMS PHIL

6 86006840 70390 4 SCR, 1/4-20 X 1 FHCS PLTD

7 86008130 73958 8 SPACER, 3/8ODX.058WX.2814,CRS

8 86010620 85039 1 VAC SHOE, 15"

9 - OPEN - -

10 86010630 87013 4 WASHER, 1/4 ID X 5/8 OD SS

11 86010700 87074 8 WASHER, WAVE 3/8ID X3/4D X.125

12 86003780 35171 1 GASKET, ACCESSORY PORT

13 86008120 73955 2 SPRING, EXT .38D X2.75L X.055W

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-10

Page 34

CONTROL PANEL ASSEMBLY

16

12

6

18

21

1

8

11

2

7

4

17

3

14

9

10

19

13

15

D

(SEE PG. 5-11)

SEE SOLUTION

TANK

5-11

CADET 86038340 04/19/07

5

20A, 20B

20C, 20D

Page 35

CONTROL PANEL ASSEMBLY

2

REF PART NO. PRV NO. QTY DESCRIPTION

1 86001240 14020 1 TERMINAL BLOCK, 115V (3-4-3)

2 86230110 14312 1 BREAKER, 7 AMP

3 86002020 14949 1 BREAKER, 4 AMP

4 86002010 14942 2 BOOT, 3/8 CIRCUIT BREAKER

5 86261000 23671 1 CORD ASM

6 86005670 57040 2 NUT, 1/2 NPT CONDUIT

7 86005760 57116 2 NUT, 6-32 W/STAR WASHER PLTD

8 86064400 61348 1 PANEL, CADET CONTROL

9 86006950 70532 9 SCR, 10-32 X 1/2 PPHMS BLK NP 1000032157

10 86006710 70235 2 SCR, 6-32 X 1.0 PH BLK NYLON

11 86007120 72126 1 SWITCH, DPDT 3-POSITION ROCKER

12 86007140 72130 2 SWITCH, SPST 2-POSITION ROCKER

13 86256240 73505 1 STRAIN RELIEF, 1/2 NPT TRUMPET

14 86010800 87189 9 WASHER, .2IDX.500 BLK SS

15 86004480 41353 REF HARNESS, MAIN, CDTI

16 86242270 500019 1 LABEL, CONTROL PANEL, CDT

17 86010750 87100 2 WASHER, 3/8 ID INT.LOCK THIN

18 86005700 57104 3 NUT, 10-32 W/STAR WASHER PLTD

19 86006830 70386 1 SCR, 10-32 X 1.0 PPHMS

20A 86002610 23683 1 CORD ASM, 230V BRITIAN

20B 86002600 23682 1 CORD ASM, 230V EURO

20C 86031550 23681 1 CORD ASM, 230V SWISS

20D 86260960 23521 1 CORD ASM, 230V, AUST

21 86245040 50279 1 LABEL, GROUND SYMBOL

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-1

Page 36

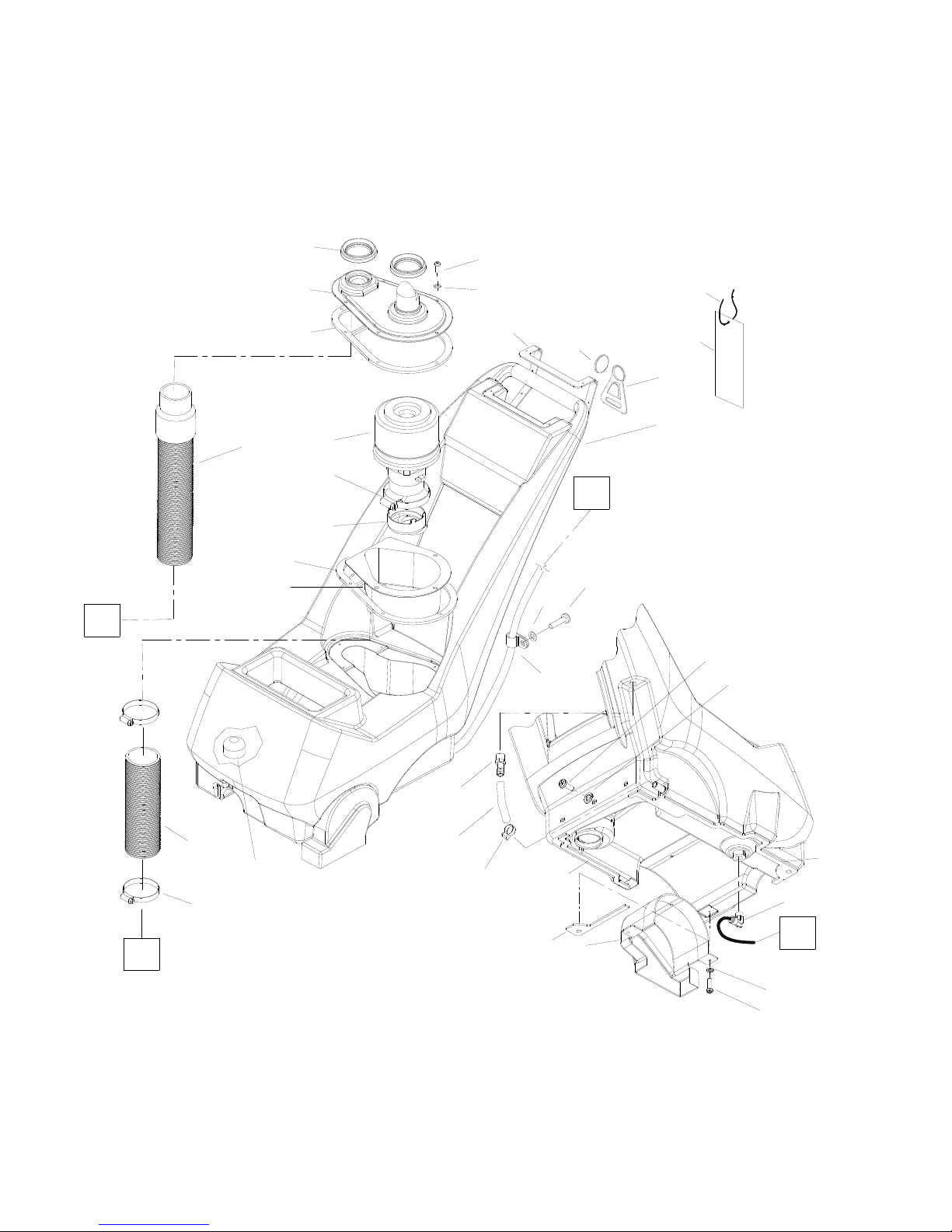

SOLUTION TANK ASSEMBLY

SEE FRAME)

A

10

12

7*

6

3

7

13

13A

13B

23

17

29

18

30*

18

22

24

32

33

25

16*

(SEE CONTROL PANEL)

D

15

21

20

9

19*

1

B

(SEE FRAME)

5-13

11

8

2

CADET 86038340 04/19/07

27*

26*

28*

5*

C

4

(SEE PUMP)

18

14

Page 37

SOLUTION TANK ASSEMBLY

4

REF PART NO. PRV NO. QTY DESCRIPTION

1 86233140 20041 3 CLAMP, 2.0" WORM GEAR

2 86233150 20042 1 CLAMP, 3/8 HOSE (D-SLOT)

3 86003080 27809 1 COVER, VAC MOTOR

4 86003090 27810 1 COVER, BELT

5 86235500 31081 1 ELBOW, 3/8 MPT X 3/8 TUBE, PLASTIC

6 86003790 35175 2 GASKET, TANK TO VAC COVER

7 86003920 35231 2 GASKET, VAC COVER (CLP FAMILY)

8 86281880 39526 1 HOSE,1/2 CLEAR X 12

9 86240090 39527 1 HOSE, 1.5 BLK VAC X 3.0

10 86004340 39528 REF HOSE ASM, 1.5 BLK VAC X 15.5

11 86001590 40049 1 HOSEBARB, 3/8MPT X 1/2 NYLON

12 86240980 41348 1 HOUSING, VAC MOTOR

13 86005420 53791 1 VAC MOTOR ASM, CLP FAMILY

13A 86230760 140216 - BRUSH SET, 230V VAC AMETEK

13B 86135330 140688 - BRUSH SET, 230V VAC MTR WINDSOR

14 86006600 70114 2 SCR, #10 X 3/4 PPHST TYPE B

15 86006590 70088 2 SCR, 10-32 X 1/2 PPHMS SS

16 86032240 75257 1 TANK, CDT SOLUTION

17 86259060 85037 1 VENT, COOLING AIR SMALL

18 86010650 87018 10 WASHER, #10 X 9/16 OD

19 86007970 73864 1 STRAINER, 3/8 IN. NPT 60 MESH

20 86010630 87013 3 WASHER, 1/4 ID X 5/8 OD SS

21 86006580 70085 3 SCR, 1/4-20 X 1/2 PPHMS SS DL

22 86002370 20035 2 CLAMP, 7/16 DIA NYLON UL

23 86233260 20092 1 CLAMP, 3.5" WORM GEAR

24 86272840 67147 1 RING, 2" DIA SPLIT

25 86256170 73169 1 STRAIN RELIEF, CORD HOOK

26 86003950 35236 1 GASKET, TANK, L-F

27 86003960 35237 1 GASKET, TANK, L-R

28 86003970 35238 1 GASKET, TANK, RH

29 86275690 70525 6 SCR, #10 X 1.0 PPHST TYPE B

30 86003940 35235 1 GASKET, CDT PANEL

31 86026660 75276 1 TANK ASM, SOLUTION CDT7

32 86002870 27417 1 CORD, 99807 1/8 X 12"

33 86232280 500012 1 CARD, INSTRUCTION CDT7

SERIAL NO.

FROM

SERVICE

* SERVICE

NOTES:

ONLY

ONLY

*

CADET 86038340 04/19/07

5-1

Page 38

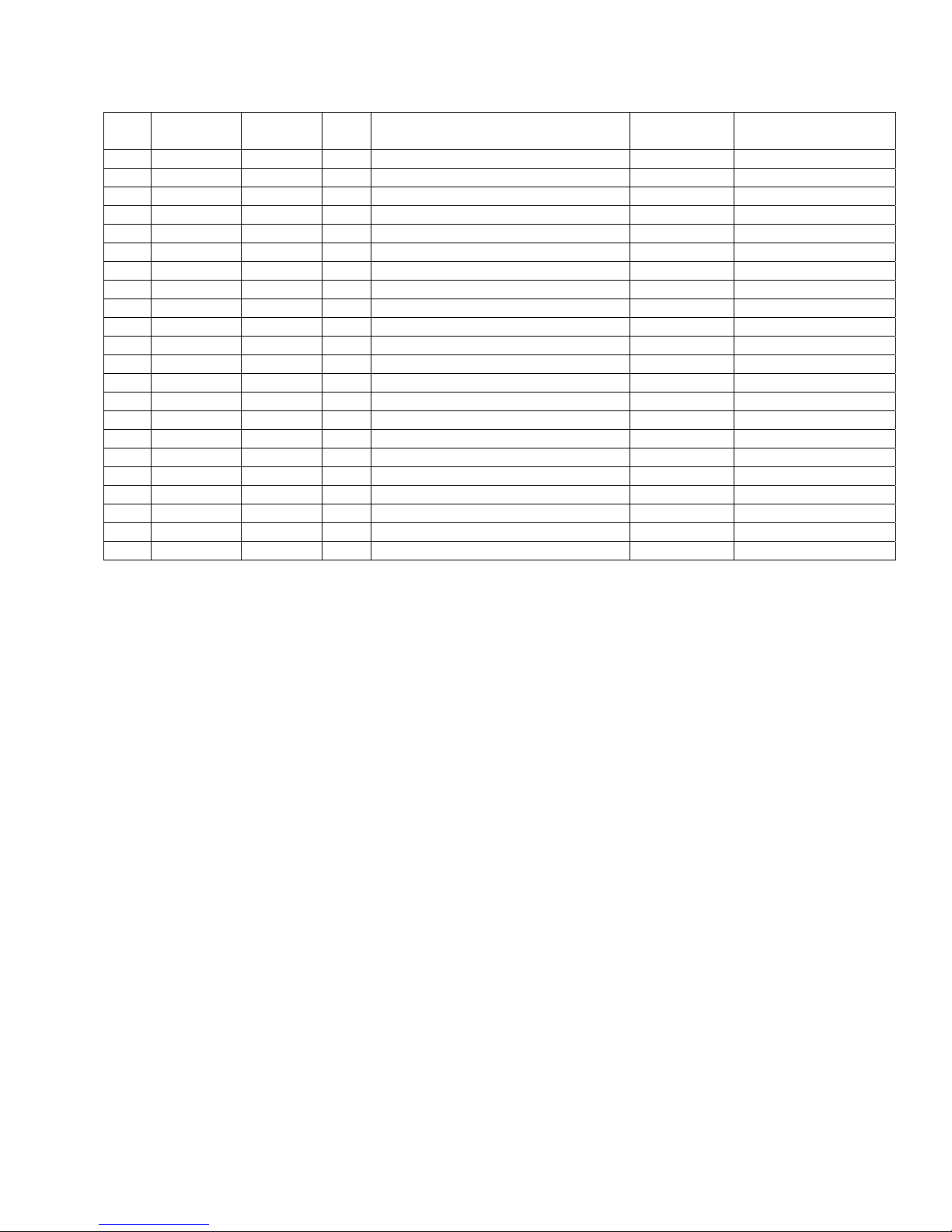

RECOVERY TANK ASSEMBLY

18

5

7

8

4

E

16

15

E

11

12

10

1

14

17

13

12

6

2

9

3

14B

11B

10B

1B

12

5-15

CADET 86038340 04/19/07

Page 39

RECOVERY TANK ASSEMBLY

6

REF PART NO. PRV NO. QTY DESCRIPTION

1A 86002400 20064 1 CLAMP, 2.0" WORM GEAR X .312 1000083948

1B 86002350 20002 1 CLAMP, 2.0” NYLON RATCHET

2 86233140 20041 1 CLAMP, 2.0" WORM GEAR

3 86002930 27670 1 CORD, DRAIN HOSE

4 86008400 78499 2 COVER, REC. TANK

5 86235280 28060 1 DOME, CLP FAMILY

6 86003630 34351 1 FLOAT SHUT-OFF

7 86003910 35230 1 GASKET, DOME

8 86003930 35232 2 GASKET, PORT COVER

9 86004200 39353 1 HOSE, 1.5 X 12.0 DRAIN

10A 86004510 41391 1 HOSE, INSERT 1000083948

10B 86004450 40019 1 HOSEBARB, 1.5 DOUBLE MCHD

11A 86004500 41390 1 HOSE, CAP 1000083948

11B 86006240 66227 1 PLUG, DRAIN HOSE

12 86006600 70114 6 SCR, #10 X 3/4 PPHST TYPE B

13 86032250 75258 1 TANK, CDT RECOVERY

14A 86001370 140408 1 BRKT, HOSE HOOK 1000083948

14B 86001190 140133 1 BRKT, RECOVERY HOSE MTG

15 86002870 27417 1 CORD, 99807 1/8 X 12"

16 86242230 500009 1 LABEL, WARNING

17 86245940 50995 1 LABEL, CADET MAIN

18 86003330 28061 1 DOME ASM, CLP FAM

SERIAL NO.

FROM

NOTES:

CADET 86038340 04/19/07

5-1

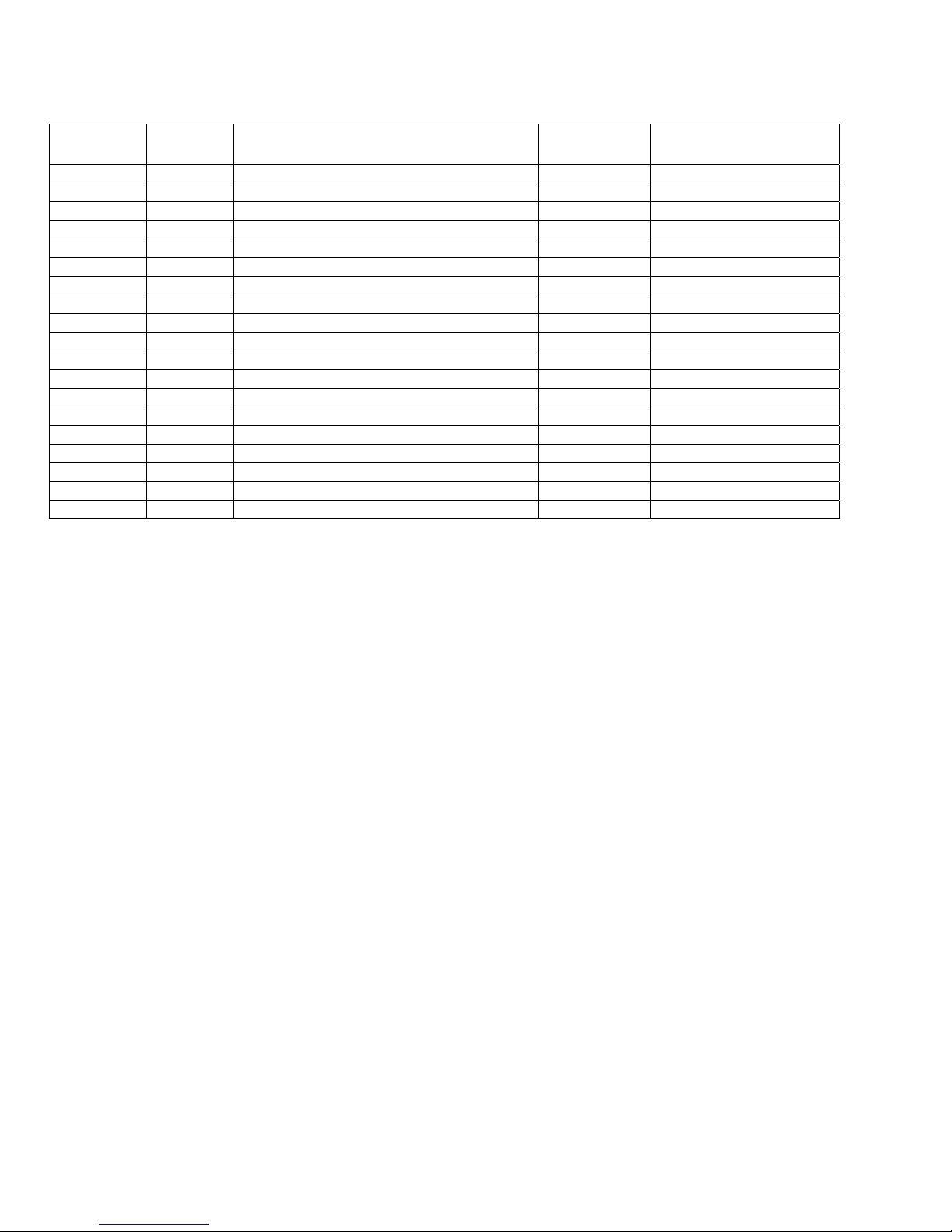

Page 40

SUGGESTED SPARE PARTS

PART NO. PRV NO. DESCRIPTION

86001140 12514 BRUSH, 15L X 3.38OD

86001100 11045 BELT, 180J6 MICRO-V

86000900 09019 BEARING, 1.125ODX.500IDX.375

86004570 44067 JET BODY, MINI PROMAX BODY

86241680 44073 JET, MINI PROMAX 9503

86026400 65254 PUMP ASM, 230V 100PSI W/CONN

86010570 84165 VALVE ASM, SOLENOID CLP FAMILY

86003780 35171 GASKET, ACCESSORY PORT

86230110 14312 BREAKER, 250VAC 50 VDC

86002020 14949 BREAKER, VDE CIRCUIT

86007140 72130 SWITCH, SPST 2-POSITION ROCKER

86007120 72126 SWITCH, DPDT 3-POSITION ROCKER

86005420 53791 VAC MOTOR ASM, CLP FAMILY

86007970 73864 STRAINER, 3/8 IN. NPT 60 MESH

86230760 140216 BRUSH SET, 230V VAC AMETEK

86135330 140688 BRUSH SET, 230V VAC MTR WINDSOR *

86003630 34351 FLOAT, SHUT-OFF

86003330 28061 DOME ASM, CLP FAM

86006240 66227 PLUG, DRAIN HOSE

SERIAL NO.

FROM

NOTES:

5-17

CADET 86038340 04/19/07

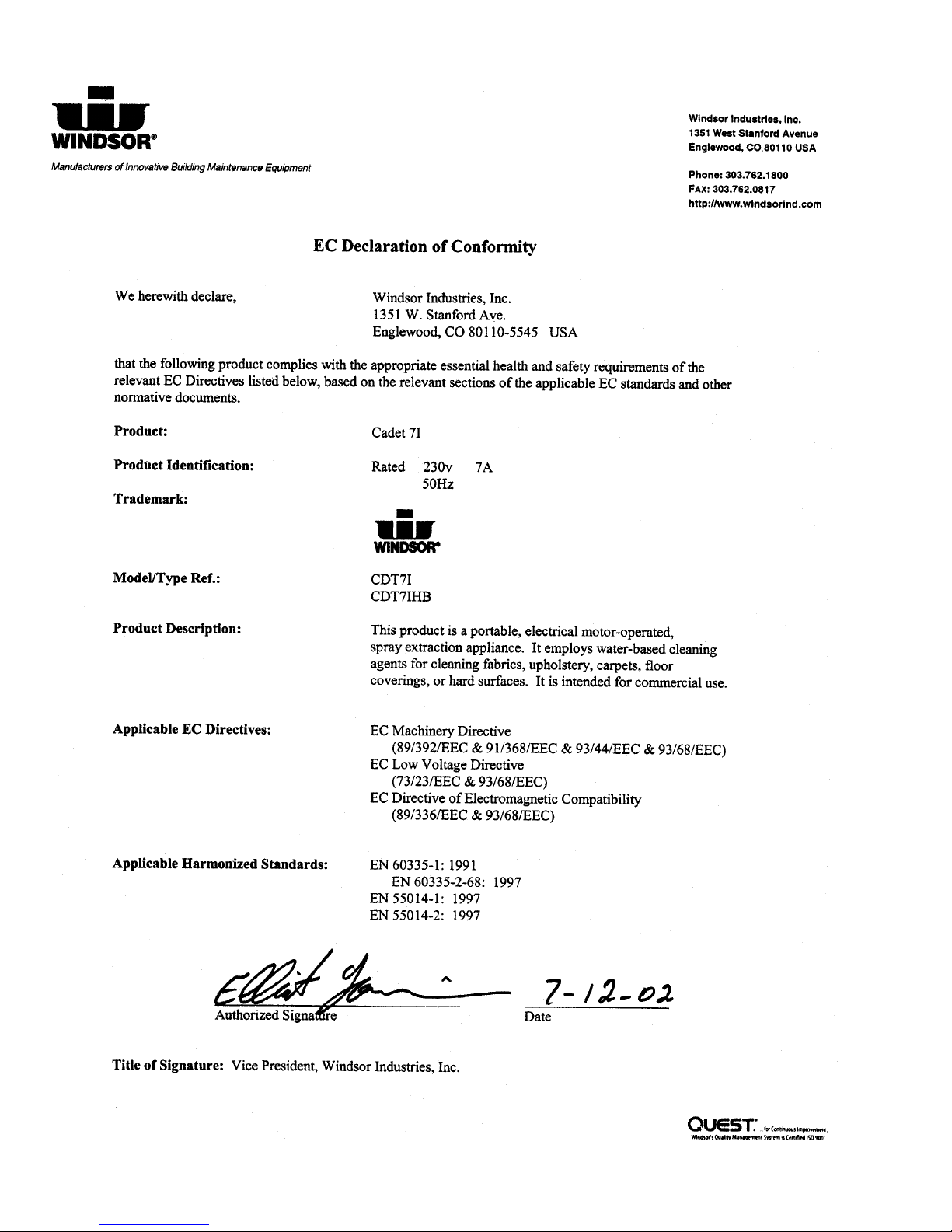

Page 41

5-18

CADET 86038340 04/19/07

Loading...

Loading...