Page 1

Chariot 2 iGloss 20

Burnisher

Operating Instructions (ENG)

MODELS: CBPS20

1.002-031.0

CBPSC20

1.002-032.0

CBPL20

1.002-033.0

WARNING:

This product and accessories may contain a chemical known to the

State of California to cause cancer and birth defects or other

reproductive harm.

CBPLC20

1.002-034.0

CBAL20

1.002-035.0

CBALC20

1.002-036.0

From Serial Number (Ref No. 1*)

* See Serial Number page in

Spare Parts List or

call manufacturer.

For more information about this regulation: www.P65Warnings.ca.gov

86398800-C 03/02/18

Page 2

The Chariot iGloss 20 is a battery powered, ride-on, hard floor burnisher intended for comme rcial use. This

Warranty Registration

Thank you for purchasing a Kärcher North America product. Warranty registration is quick

and easy. Your registration will allow us to serve you better over the lifetime of the product.

To register your product go to :

http:// warranty.karcherna.com/

For customer assistance:

1-800-444-7654

machine applies a high luster to hard floor surface s.

4

Page 3

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How To Use This Manual . . . . . . . . . . . . . . . . . . . . .4

Safety

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . .5

HAZARD INTENSITY LEVEL . . . . . . . . . . . . . . . . . .7

SAFETY LABEL LOCATIONS . . . . . . . . . . . . . . . . .9

Operation

Technical Specifications . . . . . . . . . . . . . . . . . . . . . 10

How This Machine Works . . . . . . . . . . . . . . . . . . . . 12

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Drive Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Function Mode Switch. . . . . . . . . . . . . . . . . . . . . . . 18

Pre-Run Machine Inspection. . . . . . . . . . . . . . . . . .20

Starting Machine . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Emergency Stop Procedure . . . . . . . . . . . . . . . . . .20

Operating the Machine . . . . . . . . . . . . . . . . . . . . . . 21

Normal Burnishing . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table of Contents

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking Battery Specific Gravity. . . . . . . . . . . . . . 26

Changing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . 28

Battery Charger Programming . . . . . . . . . . . . . . . .29

Burnishing Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Burnisher Motor Carbon Brush Ring Replacement.32

Deck Actuator Removal / Replacement . . . . . . . . . 32

Body Assembly Removal . . . . . . . . . . . . . . . . . . . .34

Drive Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . .34

Vacuum - Optional . . . . . . . . . . . . . . . . . . . . . . . . .36

Drive Motor-From Serial Number (3*) . . . . . . . . . . . 38

Drive Motor Carbon Brush Replacement . . . . . . . . 38

Drive Chain Tension . . . . . . . . . . . . . . . . . . . . . . .38

Drive Motor-Prior to Serial Number (3*) . . . . . . . . . 40

Drive Motor Carbon Brush Replacement . . . . . . . . 40

Drive Chain Tension . . . . . . . . . . . . . . . . . . . . . . . .40

Machine Tie-Downs . . . . . . . . . . . . . . . . . . . . . . . .42

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Suggested Spare Parts. . . . . . . . . . . . . . . . . . . . . 46

86398800 Operator Manual - Chariot 2 iGloss 20

3

Page 4

How To Use This Manual

This manual contains the following sections:

• HOW TO USE THIS MANUAL

• SAFETY

•OPERATIONS

• MAINTENANCE

• PARTS LIST

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized Kärcher North

America dealers. When placing an order for parts, the

machine model and machine serial number are

important. Refer to the MACHINE DATA box which is

filled out during the installation of your machine. The

MACHINE DATA box is located on the inside of the

front cover of this manual.

The SAFETY section contains important information

regarding hazard or unsafe practices of the machine.

Levels of hazards are identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in

good working condition. They are listed in this general

order:

• Batteries

•Brush Deck

• Circuit Protection

• Drive Motor and Brake

• Service Schedule

• Vacuum Motor

• Machine Troubleshooting

The number on the lower right corner of the front cover

is the part number for this manual.

The model and serial number of your machine are

located below the battery compartment of the machine.

4

86398800 Operator Manual - Chariot 2 iGloss 20

Page 5

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer's recommended components and attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water, return it to

an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is not suitable for picking up hazardous dust.

Do not operate this machine near flammable fluids, dust or vapors.

Maintenance and repairs must be done by qualified personnel.

Disconnect battery before cleaning or servicing.

Before the machine is discarded, the batteries must be removed and properly disposed of.

Make sure all warning and caution labels are legible and properly attached to the machine.

During operation, attention shall be paid to other persons, especially children.

Before use all covers and doors shall be put in the positions specified in the instructions.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

This appliance has been designed for use with the pads specified by the manufacturer. The fitting of other pads

may affect its safety.

Do not use on surfaces having a gradient of over 10% (6 degrees).

SAVE THESE INSTRUCTIONS

86398800 Operator Manual - Chariot 2 iGloss 20

5

Page 6

Safety

MESURES DE SÉCURITÉ IMPORTANTES

Lors de l'utilisation d'un appareil à batteries, il est nécessaire de respecter systématiquement des mesures de

sécurité de base, comme suit :

PRENEZ NOTE DE TOUTES CES MESURES AVANT D'UTILISER CETTE MACHINE.

Pour réduire les risques d'incendie, de chocs électriques, ou de blessures :

N'utiliser cette machine qu'en intérieur. Ne jamais l'utiliser à l'extérieur ou dans la pluie.

Utiliser cet appareil conformément aux instructions du présent manuel uniquement. N'utiliser que les composants

et les accessoires conseillés par le fabricant.

Lorsque la machine ne fonctionnant pas correctement, a fait l'objet d'une chute ou d'une détérioration, a été laissée

à l'extérieur, est tombée dans l'eau, la retourner au centre de service agréé.

Ne pas opérer la machine lorsque les conduits de ventilation sont bloquées. Débarrasser les débris des conduits,

car ils peuvent réduire l'écoulement d'air.

Cette machine n'est pas adaptée au ramassage de poussières dangereuses

Ne pas l'utiliser près de liquides, de poussières ou de vapeurs inflammables.

L'entretien et les réparations de la machine doivent être effectuées par un personnel qualifié.

Si de la mousse ou du liquide sort de la machine, la mettre hors tension immédiatement.

Déconnecter les batteries avant de nettoyer la machine ou de la soumettre à un entretien.

Avant de se débarrasser de la machine, il est nécessaire de retirer les batteries et de les jeter correctement.

S'assurer que toutes les plaques d'avertissement ou de précaution sont lisibles et fixées correctement sur la

machine.

Durant la manoeuvre de la machine, prendre garde aux personnes environnantes et notamment aux enfants.

Avant l'utilisation de la machine, veiller à positionner tous les couvercles et portes comme indiqué dans les instructions.

Lorsque la machine est laissée sans surveillance, s'assurer qu'elle ne se déplace pas de manière accidentelle.

Cette machine ne doit être manoeuvrée que par un personnel expérimenté et qualifié.

Lorsque la machine est laissée sans surveillance, la mettre hors tension ou verrouiller l'interrupteur principal afin

d'empêcher un emploi non autorisé.

Seuls les produits chimiques recommandés par le fabricant doivent être utilisés.

Cette machine a été conçue pour être utilisée avec des garnitures spécifiées par le fabricant.

L'utilisation d'autres garnitures peut affecter sa sûreté.

N'employez pas sur des surfaces ayant un gradient de plus de 10% (6 degrés).

CONSERVER CES INSTRUCTIONS

6

86398800 Operator Manual - Chariot 2 iGloss 20

Page 7

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR SAFETY.

The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on the

machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use

Kärcher North America approved replacement parts.

Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep battery

compartment open during charging. Keep sparks and flames away from the batteries. Do not smoke

around batteries.

Disconnect batteries before working on machine. Only qualified personnel should work inside machine.

Always wear eye protection and protective clothing when working on or ne ar batte ries. Avoid sk in co ntact

with the acid contained in the batteries.

Never allow metal to lie across battery tops.

86398800 Operator Manual - Chariot 2 iGloss 20

7

Page 8

Safety

Les symboles ci-dessous sont utilisés à travers ce manuel comme illustré dans leurs descriptions :

DEGRÉS DE RISQUES EN CAS DE DANGER

Il existe trois degrés de risques identifiés par les termes signalétiques -AVERTISSEMENT et ATTENTION et POUR

VOTRE SÉCURITÉ. Le degré de risque est défini de la manière suivante:

AVERTISSEMENT - Dangers ou méthodes dangereuses qui POURRAIENT provoquer de graves blessures ou

entraîner la mort.

ATTENTION - Dangers ou méthodes dangereuses qui pourraient provoquer des blessures légères ou une détérioration du produit ou des biens immobiliers.

POUR VOTRE SÉCURITÉ: ce signe permet d'identifier les mesures de précaution à prendre pour assurer un bon

fonctionnement du matériel.

Rendre compte immédiatement d'une défaillance ou d'une détérioration de la machine. Ne pas utiliser la machine

si celle-ci ne fonctionne pas correctement. Lire soigneusement les informations ci-dessous signalant certains

dangers potentiels pour l'opérateur de la machine. L'opérateur doit être absolument au courant de ces dangers

potentiels. Localiser tous les dispositifs de sécurité sur la machine. Il est conseillé de prendre les mesures nécessaires pour former le personnel opérateur.

POUR VOTRE SÉCURITÉ:

NE PAS MANOEUVRER LA MACHINE:

Lorsqu'on n'est pas expérimenté ou qualifié.

Lorsque le guide d'utilisation n'est pas été lu ou compris.

Dans des zones inflammables ou explosives.

Dans des zones où des objets peuvent tomber.

LORS DE L'ENTRETIEN DE LA MACHINE:

Éviter les parties amovibles. Ne pas porter de vêtements amples, tels que des vestes, des chemises ou des

vêtements avec manches lors de l'utilisation de la machine. Utiliser les pièces détachées Kärcher North America

homologuées.

Les batteries émettent le gaz d'hydrogène. L'explosion ou le feu peut résulter. Étincelle s de subsistance et

flamme nue loin. Compartiment de batterie de subsistance ouvert en char geant. Étincelles et flammes de

subsistance loin des batteries. Ne fumez pas autour des batteries.

Déconnecter les batteries avant de travailler sur la machine. La machine ne doit être confiée qu'à un

personnel qualifié. Porter systématiquement des lunettes et des vêtements de protection lors d'une intervention sur les batteries ou aux alentours. Éviter tout contact de la peau avec l'acide contenu dans les

batteries.

Ne jamais placer d'objets métalliques sur le dessus des batteries.

8

86398800 Operator Manual - Chariot 2 iGloss 20

Page 9

Safety

CAUTION

BATTERY

86252520

CAUTION

CAUTION LABEL

86244310

86385070

WARNING LABEL

SAFETY LABEL LOCATIONS

These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible,

promptly replace them.

EMPLACEMENT DE L'ÉTIQUETTE DE SÉCURITÉ

REMARQUE : Ces dessins indiquent l'emplacement des étiquettes de sécurité sur la machine. Si, à tout moment,

les étiquettes deviennent illisibles, contactez votre représentant autorisé pour un remplacement

rapide.

86398800 Operator Manual - Chariot 2 iGloss 20

9

Page 10

Operation

Technical Specifications

ITEM DIMENSION/CAPACITY

Nominal Power Passive Dust Control 2232W, Active Dust Control 2628W

Rated Voltage 36 Volts DC

Rated Amperage Passive Dust Control 62A, Active Dust Control 73A

Batteries 3 X12 Volt 114 AH, 130 AH, 225AH, or 234AH @ 20 hr. rate

Battery Compartment Dimensions 21.5 in. x 15.25 in. x 16 in. tall (546mm x 387mm x 406mm tall)

Burnisher Motor 3.0 HP, 36V, 2000RPM (2237W)

Vacuum Motor .63 HP (470 W)

Maximum flow rate of vacuum motor 72 cfm (33.98 liters per second)

Maximum suction of vacuum motor 47.3 inches of water (11.7 kPa)

Propelling Motor .38 HP (280W)

Mass (GVW) 838 lbs (380 kg)

Weight empty without batteries 231 lbs (105 kg)

Burnisher pad diameter 20 inch (508 mm)

Tires 8 in. (203mm) drive, 6 in. (156mm) rear, polyurethane

Maximum Speed 2.3 mph (3.7Km/hour)

Theoretical Coverage 19,800ft²/hr @ 2.5 mph with 2 in. overlap

Brake Electrical parking brake,sets automatically whenever operator stops.

Minimum aisle u-turn width 51in. (1295 mm)

Maximum rated climb and descent angle 10% (6 degrees)

Vibration, hands 1.58 m/s²

Vibration, feet 1.39 m/s²

Uncertainty 0.5 m/s²

Sound pressure level Passive Dust Control 59.7 dBA, Active Dust Control 62.2 dBA

Sound power level Passive Dust Control 76.3 dBA, Active Dust Control 80.1 dBA

Uncertainty 3.0 dBA

10

86398800 Operator Manual - Chariot 2 iGloss 20

Page 11

ITEM MEASURE

WIDTH

LENGTH

Height 51.8 in (1316mm)

Length 44.0 in (1118mm)

Width 23.4 in. (594mm)

Width of burnish path 20 in (508mm)

Operation

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure

that they do not play with the appliance.

Cet appareil n'est pas prévu à l'usage des personnes (enfants y compris) avec des possibilités physiques, sensorielles ou mentales réduites, ou le manque d'expérience et de connaissance, à moins qu'ils aient été donnés la

surveillance ou l'instruction au sujet de l'utilisation de l'appareil par une personne chargée de leur sûreté. Des

enfants devraient être dirigés pour s'assurer qu'ils ne jouent pas avec l'appareil.

86398800 Operator Manual - Chariot 2 iGloss 20

11

Page 12

Operation

How This Machine Works

The Chariot® iGloss 20 is a battery powered, selfpropelled, hard floor burnisher intended for commercial

use. The appliance spins a high-speed burnishing pad

in contact with the floor surface to produce a high luster

shine.

The machine's primary systems are the burnishing

system, the dust control system, and the operator

control system.

The function of the burnishing system is to spin a highspeed burnishing pad in contact with a floor surface

that has had a burnishable floor finish applied. The

burnishing pad can be lowered to the floor and raised

by the operator. The burnishing pad will spin only when

the machine is directed to move by the operator.

The function of the dust control system is to collect the

dust that is created during the burnishing process. It is

normal for a portion of the floor finish to be removed in

the form of dust during the process. While burnishing,

air movement is created within the burnishing head by

the spinning pad. The dust that is also created is

entrained in the air stream and transported to a filter

bag where it is collected and separated from the air

stream. The filter bag can be easily changed without

releasing the collected dust. The optional active dust

control system uses a vacuum motor to improve dust

collection before, during, and after burnishing.

The function of the operator control system is to control

the direction and speed of the machine. The directional

control system consists of the direction control drive

reset switch, throttle pedal, emergency stop/brake

switch, steering wheel, propel controller, and drive

wheel. The directional control drive reset switch signals

forward or reverse direction and makes sure the

operator is on the platform before machine will propel.

The controller interprets signals from the throttle pedal

to command the drive wheel to propel or slow the

machine. The steering wheel points the drive wheel in

the direction desired by the operator. The parking brake

automatically engages when the operator stops the

machine. The emergency stop/brake can be used to

hold the machine on slopes.

12

86398800 Operator Manual - Chariot 2 iGloss 20

Page 13

Operation

1

2

3

4

5

6

7

8

9

Components

1. Drive Control

2. Burnisher Controls

3. Control Console

4. Pedal Platform

5. Lower Body

6. Bag Enclosure

7. Bag Enclosure Cover

8. Burnisher Deck

9. Rear Cover

86398800 Operator Manual - Chariot 2 iGloss 20

13

Page 14

Operation

6

4

10

3

2

5

18 9

7

11

12

Drive Controls

1. Key Switch

2. Emergency Stop/Brake Switch

3. Directional Control / Drive Reset Switch

4. Throttle Pedal

5. Horn Button

6. Steering Wheel

7. Speed Control/Function Select

8. Battery Discharge Indicator

9. Hour Meter

10. Operator Presence Switch

11. Bag Present indicator

12. Check Pad Indicator

14

86398800 Operator Manual - Chariot 2 iGloss 20

Page 15

Operation

1. KEY SWITCH

Controls the power for machine functions.

To turn the machine power on, rotate key clockwise.

To turn the machine off, rotate key counterclockwise.

When the key is turned on the battery symbol will flash once and stay on continuously.

2. EMERGENCY STOP/BRAKE SWITCH

This safety feature is designed to cut all power to the machine at any time and apply parking brake.

To shut the machine power off, push the Emergency Stop Switch, this will also engage the parking brake and

cause the machine to stop immediately.

To reset the machine, rotate the switch clockwise.

3. DIRECTIONAL CONTROL / DRIVE RESET SWITCH

This safety feature is designed to ensure safe engagement of propel drive. Each time the machine power is

turned on, or each time an operator steps on to the platform, the Drive Reset Switch must be pushed before

machine will propel.

The switch controls the direction of travel of the vehicle. The lighted arrow on the switch indicates direction of

travel.

To travel forward, press the top of the switch.

To travel in reverse, press the bottom of the switch.

86398800 Operator Manual - Chariot 2 iGloss 20

15

Page 16

Operation

4. THROTTLE PEDAL

Controls the speed of the vehicle within the speed control setting selected. Pressing the pedal causes the

machine to travel in the direction selected by the Directional Control Switch.

To increase speed, increase pressure on the pedal.

To decrease speed, decrease pressure on the pedal.

5. HORN BUTTON

The horn is activated by pressing the horn button.

6. STEERING WHEEL

The steering wheel turns the front wheel causing the machine to change direction.

7. SPEED CONTROL

Controls the maximum speed of the machine. There are two settings, slow and fast.

To change speed, rotate the dial to either slow or fast position. The slow position is to the left (counterclockwise), fast to the right (top position).

The throttle pedal will always regulate the speed between 0 and maximum

16

86398800 Operator Manual - Chariot 2 iGloss 20

Page 17

Operation

8. BATTERY DISCHARGE INDICATOR

Indicates the charge level of the batteries.

The indicator will be illuminated if the batteries have a sufficient charge. A slow, continuous flash indicates the

batteries require charging.

The Battery Lockout function will activate when the batteries are low.

Once active, the LED status indicator will begin to flash slowly and the controller will inhibit the burnisher motor.

The vacuum and drive remain functional. Return the unit to the charging station and charge the batteries.

NOTES: Continuing usage may damage the batteries.

When the machine is left overnight with less than a full charge, the display may initially indicate a full charge. It

will also indicate a full charge if the batteries are disconnected, then reconnected. After a few minutes of

operation the indicator will give the correct charge level.

9. HOUR METER

Records the number of hours the machine has been in burnishing operation. This information is useful in determining when to service the machine.

10. OPERATOR PRESENCE SWITCH

Must be pressed down prior to any machine functions enabled.

11. BAG PRESENT INDICATOR

Notifies operator if dust collection bag is missing. LED is red when bag is missing or not properly installed.

12. CHECK PAD INDICATOR

Notifies operator of potential problem with pad or missing pad. When LED is red, operator should remove pad

driver and verify pad condition and proper installation.

86398800 Operator Manual - Chariot 2 iGloss 20

17

Page 18

Operation

1

Function Mode Switch

1. Function Mode Switch

The first two positions are for transport only. See drive controls section.

Light burnishing

This mode is used for light burnishing. In this mode the machine will propel at fast

speed. The ‘floating’ burnisher deck is in the down position. When equipped with

optional active dust collection, vacuum motor will be on.

Deep burnishing

This mode is used for deep burnishing. In this mode the machine will propel at slow

speed. The ‘floating’ burnisher deck is in the down position. When equipped with

optional active dust collection, vacuum motor will be on.

18

86398800 Operator Manual - Chariot 2 iGloss 20

Page 19

Notes:

86398800 Operator Manual - Chariot 2 iGloss 20

19

Page 20

Operation

Machine Operation

Pre-Run Machine Inspection

Do a pre-run inspection to find possible problems that

could cause poor performance or lost time from breakdown. Follow the same procedure each time to avoid

missing steps.

NOTE: See maintenance section for pre-run machine

inspection checklist items.

Starting Machine

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before starting machine, make sure

that all safety devices are in place and operating

properly.

1. Disconnect or unplug battery charger.

2. Close the cover(s).

3. Verify condition of burnishing pad, replace if neces-

sary.

4. Verify removable pad driver is installed correctly

and pad rotation lock is released.

5. The operator should be on the pedal platform. The

throttle pedal must be in the neutral position.

6. Turn the machine power on by turning key switch

clockwise to the “ON” position.

7. Verify dust collection bag is installed.

8. Press the Drive Reset Directional Control Switch to

reset and set the intended direction for travel.

9. Press lightly on the throttle pedal with right foot

Emergency Stop Procedure

Push in emergency stop button. This will also engage

the parking brake and cause the machine to stop immediately.

20

86398800 Operator Manual - Chariot 2 iGloss 20

Page 21

Operation

INEFFICIENT BURNISHING PATH

Operating the Machine

When operating the machine around people, pay close

attention for unexpected movement. Use extra caution

around children.

1. Stand on the operator platform. Throttle pedal must

be in neutral position.

2. Turn machine power on.

3. Select transport speed from Function Mode Switch.

4. Press the Drive Reset/Directional Control Switch,

selecting the desired travel direction.

5. Select Light burnishing or Deep burnishing from

the Function Mode Switch. Deck will Lower.

6. The pad motor will only run when the burnishing

head is lowered to within 2 inches of the floor.

7. Occasionally verify “check pad” indicator light is

“green”. If not, stop machine, remove pad driver

and check pad. Replace or flip as needed.

NOTE: To prevent possible damage to the floor

surface, always keep the machine moving while the

pad is spinning.

Normal Burnishing

Plan the burnishing pattern in advance. The longest

track is around the perimeter of the area to be

burnished. For efficient operation, the runs should be

the longest possible without turning, stopping, or

raising or lowering the burnisher head.

In order to achieve the best possible results, the area

which is to be burnished should be swept and auto

scrubbed before burnishing.

RE CO MMENDED BURNISHING PATH

8. When the head is down and the machine is

propelled, the pad motor runs.

9. When the battery light flashes it indicates

discharged batteries, stop operation and charge

batteries.

86398800 Operator Manual - Chariot 2 iGloss 20

21

Page 22

Maintenance

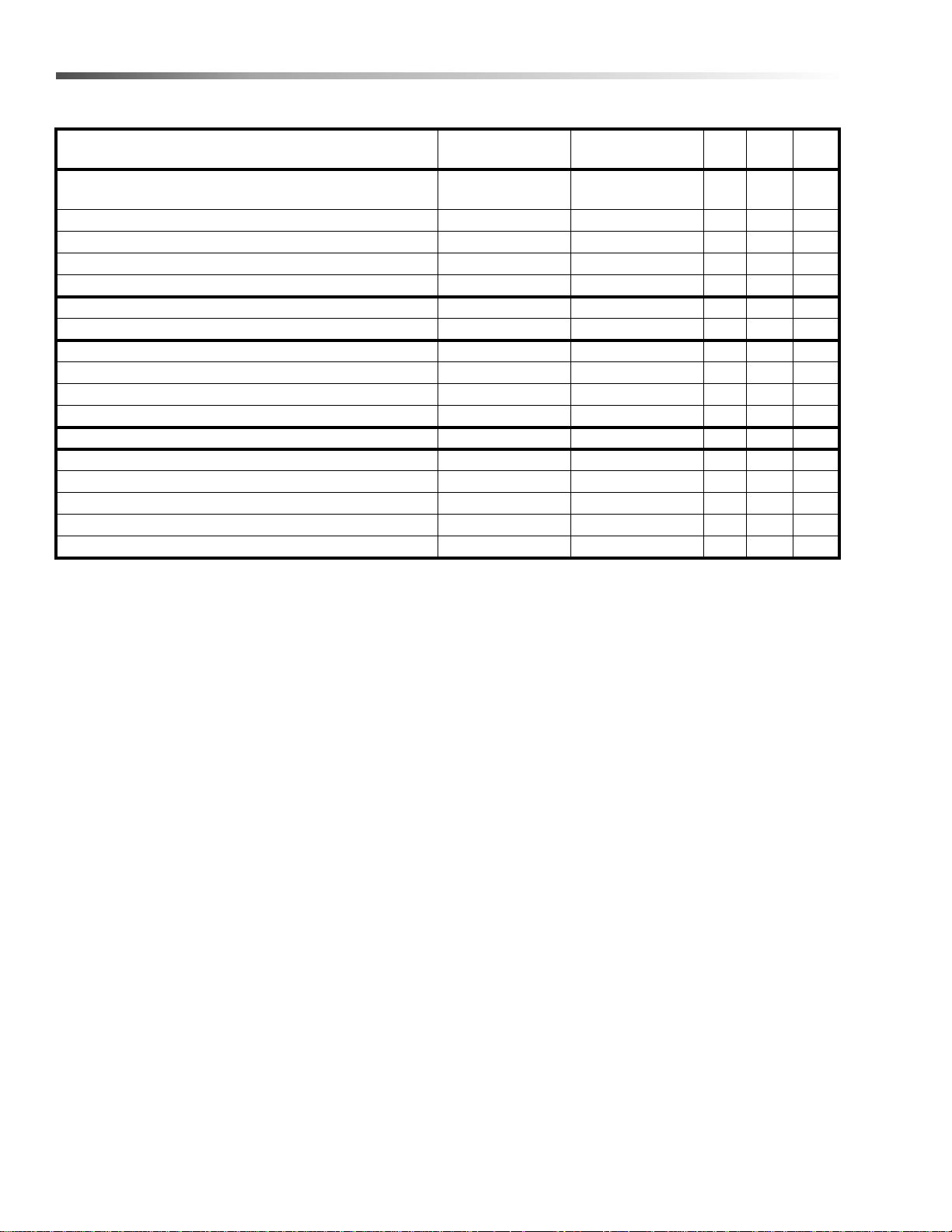

Service Schedule

MAINTENANCE

Check water level of batteries after charging; add

distilled water if necessary. (Wet cell only)

Visually check for damaged or worn tires. *

Check brush or pad for proper installation. *

Check vacuum hose connections. *

Check pedal, brake and steering for proper operation. *

Check dust bag. *

Charge batteries if needed. *

Clean off top of batteries. *

Check battery cells with hydrometer. (Wet cell only) *

Inspect deck skirt. *

Check battery connections are tight. *

Clean battery cases and battery compartment. *

Check parking brake. *

Clean pivot points on burnishing head. *

Check all motors for carbon brush wear. *

Check steering chain tension. *

Check drive chain tension. *

BEFORE EACH

WORK PERIOD

*

AFTER EACH

WORK PERIOD

50

HRS

100

HRS

200

HRS

22

86398800 Operator Manual - Chariot 2 iGloss 20

Page 23

Maintenance

4

5

3

1

2

1. Cover Retainer Latch

2. Rear Cover

3. Battery Connector-Machine

4. Batteries

5. Battery Tray

86398800 Operator Manual - Chariot 2 iGloss 20

23

Page 24

Maintenance

Batteries (Wet Cell)

The batteries provide the power to operate the

machine. The batteries require regular maintenance to

keep them operating at peak efficiency.

The machine batteries will hold their charge for long

periods of time, but they can only be charged a certain

number of times. To get the greatest life from the

batteries, charge them when their charge level reaches

25% of a full charge. Use a hydrometer to check the

charge level.

Do not allow the batteries to remain in a discharged

condition for any length of time. Never expose a

discharged battery to temperatures below freezing.

Discharged batteries will freeze causing cracked

cases. Do not operate the machine if the batteries are

in poor condition or if they have a charge level below

25% (specific gravity below 1.155).

Keep all metallic objects off the top of the batteries, as

they may cause a short circuit. Replace worn or

damaged cables and terminals.

Check the electrolyte level in each battery cell before

and after charging the batteries. Never add acid to the

batteries, use distilled water. Do not allow water level to

fall below the battery plates. Portions of plates exposed

to air will be destroyed. Do not overfill. Keep plugs

firmly in place at all times.

Not all batteries require maintenance. AGM

batteries are maintenance free. Do not attempt to

remove sealed caps from AGM batteries. Warranty

is void if caps are removed from AGM battery.

L’entretien n’est pas nécessaire pour toutes les

batteries. Les batteries AGM ne nécessitent pas

d’entretien. N'essayez pas d'enlever les bouchons

scellés des batteries AGM. La garantie est a nnulée

si les bouchons sont retirés des batteries AGM.

24

86398800 Operator Manual - Chariot 2 iGloss 20

Page 25

When servicing machine, avoid contact with

battery acid.

Lors de l'entretien de la machine, évitez tout

contact avec l'acide de batterie.

Maintenance

Battery Maintenance

1. When cleaning the batteries, use a solution of

baking soda and water. Do not allow the cleaning

fluid to enter the battery cells, electrolyte will be

neutralized.

2. Maintain the proper electrolyte level in each battery

cell. If a cell should accidentally overflow, clean

immediately.

3. Wipe off the top of the batteries at least once a

week.

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

Les batteries émettent du gaz hydrogène. Une

explosion ou un incendie peut en résu lt er.

Maintenez les étincelles et les flammes nues à

l’écart. Gardez les carters ouverts lors du chargement.

Wear eye protection and protective clothing when

working with batteries.

Portez des lunettes de protection et des v êtements

de protection lorsque vous travaillez avec des

batteries.

4. Test battery condition with a hydrometer at least

once a week.

5. Ensure that all connections are tight and all

corrosion removed.

6. Every 4 to 6 months, remove the batteries from the

machine and clean the battery cases and battery

compartment.

Charge batteries in a well ventilated area.

Chargez les batteries dans un endroit bien ventilé

86398800 Operator Manual - Chariot 2 iGloss 20

25

Page 26

Maintenance

Checking Battery Specific Gravity

Use a hydrometer to check the battery specific gravity.

CHECKING GRAVITY

a. Hydrometer Battery

b. Battery

NOTE: Do not take readings immediately after adding

distilled water, if the water and acid are not

thoroughly mixed, the reading may not be accurate.

Check the hydrometer readings against this chart.

SPECIFIC GRAVITY

@ 80

F (27C) BATTERY CONDITION

1.265 100% CHARGED

1.225 75% CHARGED

1.190 50% CHARGED

1.155 25% CHARGED

1.120 DISCHARGED

NOTE: If the readings are taken when the battery

electrolyte is any temperature other than 80°F (27°C) ,

the reading must be temperature corr ected.

To find the corrected specific gravity reading when the

temperature of the battery electrolyte is other than 80°F

(27°C): Add (+) to the specific gravity reading 0.004 (4

points), for each 10°F (6°C) above 80° (27°C). Subtract

(-) from the specific reading 0.004 (4 points), for each

10°F (6°C) below 80°F (27°C).

26

86398800 Operator Manual - Chariot 2 iGloss 20

Page 27

Maintenance

Charging Batteries

When servicing machine, avoid contact with

battery acid.

Lors de l'entretien de la machine, évitez tout

contact avec l'acide de batterie.

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

Les batteries émettent du gaz hydrogène. Une

explosion ou un incendie peut en résu lt er.

Maintenez les étincelles et les flammes nues à

l’écart. Gardez les carters ouverts lors du chargement.

Use a 36 volt, 20 amp maximum output DC charger

which will automatically shut off when the batteries are

fully charged.

1. Stop the machine in a clean, well ventilated area

next to the charger.

2. Turn “OFF” machine.

FOR SAFETY: Before leaving or servicing machine;

stop on level surface, turn off machine and remove

key.

3. Remove rear cover, unplug batteries from

machine.

Batteries emit hydrogen gas. Explosion or fire can

result. Keep sparks and open flame away. Keep

covers open when charging.

Les batteries émettent du gaz hydrogène. Une

explosion ou un incendie peut en résulter.

Maintenez les étincelles et les flammes nues à

l’écart. Gardez les carters ouverts lors du chargement.

Wear eye protection and protective clothing when

working with batteries.

Portez des lunettes de protection et des v êtements

de protection lorsque vous travaillez avec des

batteries.

Charge batteries in a well ventilated area.

Chargez les batteries dans un endroit bien ventilé

4. Check the electrolyte level in each battery cell.

Before charging, add just enough distilled water to

cover the plates. After charging is complete, add

just enough distilled water to bring up the level to

the indicator ring. If the water level is too high

before charging, normal expansion rate of the electrolyte may cause an overflow resulting in a loss of

battery acid balance and damage the machine.

86398800 Operator Manual - Chariot 2 iGloss 20

27

Page 28

Maintenance

RED

BLACK

RED

BLACK

RED

BLACK

REAR OF MACHINE

5. Replace the battery caps, and leave them in place

while charging.

6. Unplug the battery connector from the machine.

FOR SAFETY: When charging, connect the charger

to the batteries before connecting the charger to

the AC wall outlet. Never connect the charge r to the

AC wall outlet first. Hazardous sparks may result.

7. Plug the charger connector into the battery

connector. Connect the charger AC plug to a wall

outlet. The charger gauge should indicate that the

batteries are charging.

8. When the batteries are fully charged, disconnect

the charger from the AC wall outlet, then disconnect the charger from the batteries.

9. Connect the batteries to the machine connector.

10. Check the electrolyte level. It should be up to the

indicator ring. If necessary, add distilled water.

11. Install the rear cover.

Changing Batteries

4. Disconnect main positive lead and secure cable

terminals away from batteries.

5. Loosen both terminals on each jumper cable and

remove one at a time.

6. Prepare a suitable site to place the batteries.

Attach suitable battery lifting device and lift

batteries from the machine. Batteries are a

potential environmental hazard. Consult your

battery suppler for safe disposal methods.

Fixez le dispositif de levage d e batterie approprié et

levez les batteries de la machine. Les batteries

constituent un danger potentiel pour l'environnement. Consultez le fournisseur de votre batterie

pour connaître les méthodes d'élimination sûres.

Stop the machine in a clean area next to the charger.

Turn off machine.

FOR SAFETY: Before leaving or servicing the

machine; stop on level surface, turn off machine and

remove key.

1. Open the console cover.

2. Remove rear cover.

3. Disconnect battery pack from machine.

Use the proper size open end wrench to disconnect

main ground wire first and secure cable terminal away

from batteries.

NOTE: Red (+) and Black (-) installed opposite for

225 AH (J185) battery configuration.

28

86398800 Operator Manual - Chariot 2 iGloss 20

Page 29

Maintenance

Battery Charger Programming

NOTE: For machines equipped with optional onboard charger. When replacing batteries, charger

programming changes may be required. If replacing

batteries with same type, (e.g. maintenance free

batteries with maintenance free) no programming is

required. When batteries with different type

(e.g.maintenance free with wet cell), programming

changes are required. Failure to make programming

changes may lead to reduced battery life.

Programming Instructions

The charger is pre-loaded with the charge algorithms

shown below:

AlgID Description

1 Trojan J185H

5 Trojan 30XHS

42 Discover AGM EV31A-A

43 Discover AGM EV185A-A

Check Default Charge Algorithm

Check Default Charge Algorithm

1. Enter Algorithm Display Mode (as above).

2. While Algorithm Number is displayed (for 11

seconds), touch positive lead to the battery pack

positive terminal for 3.0 seconds (± 0.5s).

3. Remove lead from battery pack. Algorithm Number

will increment.

4. To increment the Algorithm Number again, repeat

Steps 2 and 3 within 30 seconds.

5. Touch positive lead to positive terminal and hold

until relay clicks (>10 seconds). The new default

algorithm is now stored.

6. Remove AC power and check default algorithm.

Contact your original equipment manufacturer if your

battery pack is not supported by the charge algorithms

loaded in your charger.

Enter Algorithm Display Mode:

1. Disconnect AC Power.

2. Remove positive lead from battery pack.

3. Apply AC power and the charger will display the

algorithm number after the Power On Self Test:

a. All algorithms will display as a series of flashes

of the 80% LED.

b. Algorithms #1 - 6 will also be indicated by the

Ammeter LEDs (see Users Guide).

Examples:

☼☼☼ = Algorithm #3

☼☼ , Short Pause, ☼ = Algorithm #21

4. Algorithm number display repeats for 11 seconds,

then Algorithm Display Mode ends.

5. Remove AC Power and reconnect positive lead.

86398800 Operator Manual - Chariot 2 iGloss 20

29

Page 30

Maintenance

1

4

2

3

5

Burnishing Deck

1. Burnisher Motor

2. Skirt

3. Pad Driver/Pad

4. Pad Rotation Lock Lever

30

Dust Collection

5. Dust Bag

86398800 Operator Manual - Chariot 2 iGloss 20

Page 31

Maintenance

Burnishing Pad

Many types of pads are available for floor burnishing.

Select a pad type based on floor type and floor finish for

best results.

Dust Bag Replacement

1. Release latch and raise cover to access dust bag.

2. Turn thumb screw to horizontal position to release

dust bag.

3. Remove dust bag at the plastic frame from the bag

mounting bracket.

4. Reverse procedure to install new bag.

• Rotate firmly counterclockwise. Pad driver will

disconnect from motor hub.

• Release Pad Rotation Lock lever.

3. To remove pad from pad driver:

• Set pad driver on flat surface with pad facing

up.

• Release pad retainer from center of pad using

retainer's wire clip.

• Peel pad off pad driver.

Dust Control Skirt Replacement

1. Raise burnisher deck with Function Mode Switch

set to transport mode.

2. Find ends of brush skirt. Pull down on one end to

release from shroud snap features. Once released

from two snaps, gently pull skirt parallel to the floor

to fully remove from shroud.

3. Install new skirt by pushing up into snaps one at a

time working around shroud diameter.

4. Where the ends meet, trim any excess skirt with

scissors or wire cutter.

Pad Replacement

1. Set the burnisher deck to the raised position.

2. To remove the pad driver:

• Push in and hold the Pad Rotation Lock lever.

• Grip the outside diameter of the pad and pad

driver.

4. To install pad on pad driver:

• Center the pad on pad driver with pad facing up.

• Check the pad inner diameter where the pad fits

over the raised ring of the pad retainer.

• Install pad retainer making sure wire clips snap

in place. Pad will need to compress to engage

pad retainer clips

5. To install the pad driver:

• Push in and hold the Pad Rotation Lock lever.

• Hold the pad driver parallel to the floor under

the shroud.

• Lift pad driver up to contact hub keeping level

and centered with motor shaft.

• Rotate pad driver clockwise applying light

pressure up on the hub. Pad driver will align

with hub and move up.

• Continue rotating clockwise approximately 15

degrees to fully engage hub.

• Release Pad Rotation Lock lever.

NOTE: Final tensioning of the pad driver occurs as

the motor rotates during burnishing.

86398800 Operator Manual - Chariot 2 iGloss 20

31

Page 32

Maintenance

Burnisher Motor Replacement

1. Remove the pad driver assembly.

2. Lower the burnisher deck using the Function Mode

Switch.

3. Turn the key to the off position.

4. Unplug the battery pack from the machine.

5. Disconnect the positive and negative wires from

the posts at the front of the motor. Note the

positions for reassembly. Isolate the ends of the

wires as batteries will be connected in step 6.

6. Unhook deck lift springs, one per side. Prevent

bracket from retracting inside body of machine by

using holes and temporary cross pin.

7. Remove the hardware (4X) connecting the linkage

to the motor mount. Note the stack arrangement of

the hardware for reassembly.

8. Plug in the battery pack. Turn on the key. Turn the

Function Mode Switch to transport to raise upper

linkage.

9. Slide the deck assembly from under the machine.

6. Prepare new brush assembly for use by inserting

individual brush springs into brush guides. Check

each brush to ensure proper movement after

installing springs.

7. Depress brushes as required to insert brush

housing over commutator.

8. Check area under cable lugs to make sure brush

ring is seated against casting fully.

9. Replace hex head screws (4X) holding the brush

ring assembly.

10. Rotate motor to check for smooth rotation.

11. Replace motor cover and flat head screws (4X).

12. Reverse steps in step 1 to reinstall to machine.

Deck Actuator Removal / Replacement

FOR SAFETY: Before leaving or servicing machine,

stop on a level surface. Turn off machine.

1. Support deck under pad driver so that actuator pins

can be removed.

2. Remove bumper screws (2).

10. Flip the deck assembly over.

11. Slide Pad Rotation Lock lever in and hold while

removing bolt and washer from pad driver hub.

12. Release Pad Rotation Lock lever slide hub and key

off motor shaft.

13. Remove bolts and washers (4X) holding inner

shroud and plate. Remove motor from shrouds

and motor mount.

14. Reverse process to reinstall.

Burnisher Motor Carbon Brush Ring

Replacement

1. Follow steps 1-9 of “Burnisher Motor Replacement”

to access the top of the motor.

2. Remove flat head screws (4X) in the motor cover.

Remove the cover.

3. Remove hex head screws (4X) holding the brush

ring assembly to the motor casting.

4. Slide the brush ring assembly off the motor

commutator.

3. Remove front battery.

4. Pull steering shaft.

5. Disconnect actuator from wiring harness.

6. From the underside of the machine, remove lower

lifting pin from actuator.

7. Remove clevis pin from actuator upper bracket.

8. Lift actuator upward and free from machine.

9. Reverse steps to install.

5. Clean excessive carbon deposits off motor components with compressed air.

32

86398800 Operator Manual - Chariot 2 iGloss 20

Page 33

Maintenance

CIRCUIT BREAKERS

100A CIRCUIT BREAKER

Circuit Breakers

Circuit breakers interrupt the flow of power in the event of an electrical overload. When a circuit breaker is tripped,

reset it by pressing the exposed button. If a circuit breaker continues to trip, the cause of the electrical overload

should be found and corrected.

1.5 Amp protects the deck lift actuator, horn & controller.

18 Amp protects the vacuum motor.

100 Amp protects the burnisher motor.

86398800 Operator Manual - Chariot 2 iGloss 20

33

Page 34

Maintenance

Body Assembly Removal

In order to access the frame or drive components, the

entire tank/console cover assembly can be removed as

a single unit.

Body Removal:

1. Open the console cover.

2. Remove back panel.

3. Grasp the lower end of the flexible steering shaft

and pull it straight up until it is disengaged with the

hex steering shaft.

4. Disconnect the five electrical plugs located just

forward of the battery tray. Access plugs through

front left hole in main body.

5. Remove the battery cable connection from the rear

cross member.

6. Close the console cover.

7. Remove the bumper. One mounting bolt per side is

located just above the tip pads on the inside.

8. Remove 6 bolts holding the body in place.

Drive Unit Removal

1. Remove tank assembly.

2. Pull the brake and drive electrical connectors off of

their support plate.

3. Remove the P-clamp holding the cable.

4. Lift the chain cover plate off of the motor.

5. Support the chassis on the tip pads so that the

front wheel is 10 inches off the floor.

6. Locate and remove two mounting nuts and remove

the drive unit from below.

7. To reinstall, reverse the process.

NOTE: The small tab at the front of the drive unit

frame should line-up with the notch in the mating

plate.

9. The body assembly can now be lifted off the

chassis and set aside.

10. Reverse the process for reassembly.

34

86398800 Operator Manual - Chariot 2 iGloss 20

Page 35

Notes:

86398800 Operator Manual - Chariot 2 iGloss 20

35

Page 36

Maintenance

1

2

Vacuum - Optional

1. Vacuum Motor

2. Vacuum Filter

36

86398800 Operator Manual - Chariot 2 iGloss 20

Page 37

Maintenance

3

8

[9.5mm]

Vacuum Motor Carbon Brushes

Carbon

Brushes

End Cap

If armature commutator is grooved, extremely pitted or not

concentric, the motor will need to be replaced or sent to a

qualified service center.

Inportant:

These brushes wear quicker as the length shortens due to

increased heat. Spring inside brush housing will damage

motor if brushes are allowed to wear away completely.

Periodically check the length of the carbon brushes. Replace

both carbon brushes when either is less tan 3/8" (9.5mm)

long.

MOUNT .80" FROM SEALING SURFACE OF

CONSOLE TO THE TOP OF THE MOUNTING

TABS (3).

VACUUM

CONSOLE SEALING

.80"

MOUNTING TAB

SURFACE

To Replace Vacuum Filter

1. Open dust bag cover.

2. Remove dust bag.

3. Unlock bottom of filter frame by bending it slightly

and slide from under the bolt head.

4. Lift filter out of housing.

5. Reverse steps to install.

Vacuum Motor Carbon Brush Replacement

To Repair or Replace Vacuum Motor

1. Remove four (4) screws from top of control panel.

2. Tip control panel back from console to expose

vacuum motor wires.

3. Disconnect electrical connector from the vacuum

motor.

4. Replace control panel, attach with one (1) screw to

secure in place.

5. Open console.

6. Remove three (3) screws and mounting bracket

that secure vacuum motor.

7. Reverse steps to install.

FOR SAFETY: before leaving or servicin g machine,

stop on a level surface, turn off machine and

disconnect power.

NOTE: If vacuum motor is not mounted as shown,

vacuum may not seal properly, resulting in poor

performance.

86398800 Operator Manual - Chariot 2 iGloss 20

37

Page 38

Maintenance

Drive Motor-From Serial Number (3*)

Drive Motor Carbon Brush Replacement

Do not use a pressure washer to clean around the

brush motors. Use tap pressure only.

N’utilisez pas de nettoyeur haute pression pour

nettoyer autour des moteurs des brosses. Utilisez

seulement la pression du robinet.

FOR SAFETY: Before leaving or servicing machine,

stop on a level surface, turn off machine and remove

motor carbon brushes.

1. Open the console cover.

2. Tilt the rear panel back until it stops on the lanyard.

3. Grasp the lower end of the flexible steering shaft

and pull it straight up until it is disengaged with the

hex steering shaft.

4. Remove the cover and gasket at the steering shaft

area.

Drive Chain Tension

The drive chain should deflect about 1/4 inch on either

side of the loop when the opposite side is tight.

To adjust chain tension:

1. Remove bumper.

2. Loosen the 1/4” nut behind the idler sprocket.

3. Tighten the front screw to increase chain tension.

4. Re-tighten the 1/4” nut behind the idler.

5. Reinstall the bumper.

Transporting Machine

This machine is equipped with a drive gear engagement/disengagement lever.

The brake automatically engages and keeps the

machine from moving whenever the operator stops the

machine.

The drive gear can be disengaged so the machine can

be pushed or towed (slowly).

When the drive gear is disengaged the machine cannot

be driven.

5. Grasp the drive wheel by reaching under the front

bumper and turn it to near the left steering stop.

6. The drive motor carbon brushes are located under

the metal band. Remove the band to access the 4

brushes.

7. Remove the phillips screw that holds each lead.

Remove the brushes.

8. Install the new brushes and reinstall the band.

9. Replace the gasket and cover, set the drive wheel

straight ahead, set the steering wheel straight

ahead, and gently align the steering shaft coupling

and slide onto the lower shaft.

10. Slowly close the cover and make sure the shaft

slides without binding.

38

86398800 Operator Manual - Chariot 2 iGloss 20

Page 39

Maintenance

Access Port

Brake Override

1. Disconnect battery to prevent injury.

2. Turn wheel slightly to the right.

3. Access to the Brake lever is through the access

port on the front left side of the Lower Body.

4. Push the lever as indicated to disengage the

brake.

5. Push the machine slowly. Take care as voltage is

generated while pushing the machine and may

cause the controller to temporarily stop the

machine.

6. To re-engage the brake, push the lever as indicated.

Inclines

When navigating an incline the machine may come to a

stop. Turn the machine off. Wait 5 minutes and start the

machine and proceed up the incline.

Overheating may occur if you do not wait the full 5

minutes.

Une surchauffe peut se produire si vous n'attendez

pas les 5 minutes complètes.

86398800 Operator Manual - Chariot 2 iGloss 20

39

Page 40

Maintenance

Drive Motor-Prior to Serial Number (3*)

Drive Motor Carbon Brush Replacement

Do not use a pressure washer to clean around the

brush motors. Use tap pressure only.

N’utilisez pas de nettoyeur haute pression pour

nettoyer autour des moteurs des brosses. Utilisez

seulement la pression du robinet.

FOR SAFETY: Before leaving or servicing machine,

stop on a level surface, turn off machine and remove

motor carbon brushes.

1. Open the console cover.

2. Tilt the rear panel back until it stops on the lanyard.

3. Grasp the lower end of the flexible steering shaft

and pull it straight up until it is disengaged with the

hex steering shaft.

4. Remove the cover and gasket at the steering shaft

area.

5. Grasp the drive wheel by reaching under the front

bumper and turn it to near the left steering stop.

6. The drive motor carbon brushes are located under

screw caps. The caps are accessible by gently

moving the harness aside.

Drive Chain Tension

The drive chain should deflect about 1/4 inch on either

side of the loop when the opposite side is tight.

To adjust chain tension:

1. Remove bumper.

2. Loosen five (5) screws that hold the drive gear

motor and slide the gear motor up until the chain

tension is correct. Tighten the five (5) mounting

screws.

3. Models equipped with jack screw on front side of

drive should not use jack screw to apply tension.

Use only as a stop once chain is properly

tensioned.

4. Reinstall the bumper.

Transporting Machine

This machine is equipped with a drive gear engagement/disengagement lever.

The brake automatically engages and keeps the

machine from moving whenever the operator stops the

machine.

The drive gear can be disengaged so the machine can

be pushed or towed (slowly).

When the drive gear is disengaged the machine cannot

be driven.

NOTE: Front bumper removed for clarity and to show

access to lever.

7. Rotate the drive wheel to near the right hand stop

to access the right side carbon brush.

8. Replace the gasket and cover, set the drive wheel

straight ahead, set the steering wheel straight

ahead, and gently align the steering shaft coupling

and slide onto the lower shaft.

9. Slowly close the cover and make sure the shaft

slides without binding.

40

86398800 Operator Manual - Chariot 2 iGloss 20

Page 41

Maintenance

Lever access

Turn wheel to left and reach up under bumper and steel

brake.

Drive gear engaged

Machine can be driven.

Rotate lever firmly in direction of arrow

Drive gear disengaged

Machine can be pushed or towed (slowly).

When disengaged the machine rolls easily. Disengage

on a level surface.

Rotate lever firmly in direction of arrow.

Inclines

When navigating an incline the machine may come to a

stop. Turn the machine off. Wait 5 minutes and start the

machine and proceed up the incline.

Overheating may occur if you do not wait the full 5

minutes.

Une surchauffe peut se produire si vous n'attendez

pas les 5 minutes complètes.

86398800 Operator Manual - Chariot 2 iGloss 20

41

Page 42

Maintenance

CONNECT

AT

FRAME

VIEW FROM

BOTTOM

Recommended Tie-Down Points

Preparation for Loading/Unloading Trailer

Burnisher Deck must be in the up position before loading.

When transporting the machine on a trailer or in a truck, in addition to using tie-downs, be sure to block the tires to

prevent the machine from rolling.

Machine Tie-Downs

There are two tie points located in front of the rear wheels on the frame, and a Tie-down wrap point on the back

panel. Tie-down devices must be of the proper type and strength. The combined strength of all tie-downs must be

strong enough to lift two times the weight of the machine. Tie-downs must be positioned to prevent the machine

from moving forward, backward, or either side to side. Use all four corners of the machine with the tie-downs

running out opposite directions. Tie-downs must be attached to the transporting vehicle securely.

42

86398800 Operator Manual - Chariot 2 iGloss 20

Page 43

Maintenance

Troubleshooting

PROBLEM CAUSE SOLUTION

No machine function Console lid is open Close console lid

No power to machine Battery disconnected Check all battery cable connections

Emergency shut-off activated Reset

Battery cables corroded Clean connections

Faulty key switch Replace switch

Batteries not plugged in Plug batteries in

On Board charger plugged in Un-plug and stow cord

Little or no propel Low battery charge Charge batteries

Tripped circuit breaker Reset controller circuit breaker

Controller limits motor amperage. Allow

unit to cool down for several minutes.

Remove obstacle or push machine away

from obstacle

Check wires and connections from

controller to motor

Check wires and connections from and

potentiometer resistance

Machine does not

change speeds

Forward speed only

Reverse speed only

Battery indicator light

flashing

Controller protecting motor from overload

Machine is stalled against an obstacle

(threshold, curb, etc.)

Controller overheated Allow cool down period

Loose motor connection

Faulty throttle circuit or potentiometer

Drive Lever disengaged Engage drive

Faulty speed control circuit or switch Check wires & connections

Faulty forward/reverse circuit Check wires & connections

Battery needs charged Charge Battery

Controller is indicating a fault code See fault code table

86398800 Operator Manual - Chariot 2 iGloss 20

43

Page 44

Maintenance

PROBLEM CAUSE SOLUTION

Vacuum motor does not run, or

runs slowly

Poor burnishing performance Debris caught in pad Remove debris or change pad

Burnisher motor does not run, or

runs slowly

Deck does not go down Actuator circuit breaker tripped Reset actuator circuit breaker

Faulty vacuum circuit or switch Check wires & connections

Worn vacuum motor brushes Replace brushes, check commutator

Vacuum circuit breaker tripped Reset circuit breaker

Worn pad Replace pad or flip pad

Improper pad used

Low battery charge Charge batteries

Circuit breaker tripped Reset circuit beaker

Low battery charge Charge battery

Faulty brush circuit or motor Check wires, connections and motor

Worn brush motor brushes Replace brushes, check commutator

Contact equipment or application

specialists

44

86398800 Operator Manual - Chariot 2 iGloss 20

Page 45

Maintenance

Battery Discharge Indicator Troubleshooting

The battery indicator flashes when a problem occurs. The table below list solutions for the indicated problems.

Number of

flashes

The battery needs charging, there is a bad connection to

the battery or dependent on the programming, may

1

2

3

4

5 Not used. -

6

7

8

9

10

- Blinks once every 5 seconds Sleep mode, cycle key switch

indicate that the battery lockout function is active and the

controller is in a restricted mode of operation. Check the

connections to the battery.

There is a bad connection to the drive motor. Check all connections between the

The drive motor has a short circuit to a battery connection. Contact your service agent.

The battery charge level has fallen below the battery

Lockout Level and the controller is inhibiting burnisher

motor function.

The controller is being inhibited from driving, this may be

because the battery charger is connected (on board

charger only).

A throttle fault is indicated. Make sure that the throttle is in the

A controller fault is indicated. Make sure that all connections are

The parking brake has a bad connection. Check the parking brake and motor

An excessive voltage has been applied to the controller.

This is usually caused by a poor battery connection.

Problem Solution

If the connections are good, try

charging the battery.

motor and the controller.

Charge the battery.

Disconnect battery charger.

rest position before switching on the

machine.

secure.

connections. Make sure the

controller connections are secure.

Check the battery connections.

86398800 Operator Manual - Chariot 2 iGloss 20

45

Page 46

Suggested Spare Parts

86348010 BRUSH SET

86326980 BRUSH SET

86369160 WHEEL

86333980

86384090 BRUSH SET

DRIVE MOTOR

BURNISHER MOTOR

VACUUM MOTOR

86353780

FLEXIBLE STRIP BRUSH

FILTER BAG (10 PACK)

86143330

MOTOR FILTER

86326220 SPACER

86223470 RING

46

86398800 Operator Manual - Chariot 2 iGloss 20

Page 47

Notes

86398800 Operator Manual - Chariot 2 iGloss 20

47

Page 48

Table of contents

CHARIOT iGLOSS 20", SB, PASS, SHLF CHRGR (1.002-031.0) 2

40 BODY BRACE 3

50 BODY LOWER 5

60 BODY LOWER MOUNTING 7

70 BUMPER 9

80 BURNISHING DECK 11

90 BURNISHING DECK MOUNTING 13

100 BURNISHING DECK LIFT 15

110 BURNISHING DECK - PAD DRIVER 17

120 CONSOLE - BAG ENCLOSURE 19

130 CONSOLE - HINGE 21

140 CONTROL PANEL 1 23

150 CONTROL PANEL 2 25

160 CHARGER - OPTIONAL 27

170 DECALS 29

180 SLEW/STEERING-FROM SERIAL NUMBER (3*) 31

190 DRIVE-CHAIN PRIOR TO SERIAL NUMBER (3*) 33

200 DRIVE LOWER - FROM SERIAL NUMBER (3*) 35

1 Traction motor C2 (8.641-117.0) 38

210 DRIVE-LOWER PRIOR TO SERIAL NUMBER (3*) 40

5 Wheel drive motor (8.636-401.0) 43

220 FRAME & REAR WHEELS 45

230 DRIVE MOUNTING - FROM SERIAL NUMBER (3*) 47

240 DRIVE MOUNTING - PRIOR TO SN (3*) 49

250 PEDAL PLATFORM 51

260 PEDAL PLATFORM MOUNTING 53

270 STEERING 55

280 VACUUM - OPTIONAL 57

290 WIRING - BATTERY 58

Valid on 27.09.2018 Page 1 / 59

Page 49

CHARIOT iGLOSS 20", SB, PASS, SHLF CHRGR (1.002-031.0)

POS Description Quantity Unit

40 BODY BRACE 1.000 ST

50 BODY LOWER 1.000 ST

60 BODY LOWER MOUNTING 1.000 ST

70 BUMPER 1.000 ST

80 BURNISHING DECK 1.000 ST

90 BURNISHING DECK MOUNTING 1.000 ST

100 BURNISHING DECK LIFT 1.000 ST

110 BURNISHING DECK - PAD DRIVER 1.000 ST

120 CONSOLE - BAG ENCLOSURE 1.000 ST

130 CONSOLE - HINGE 1.000 ST

140 CONTROL PANEL 1 1.000 ST

150 CONTROL PANEL 2 1.000 ST

160 CHARGER - OPTIONAL 1.000 ST

170 DECALS 1.000 ST

180 SLEW/STEERING-FROM SERIAL NUMBER (3*) 1.000 ST

190 DRIVE-CHAIN PRIOR TO SERIAL NUMBER (3*) 1.000 ST

200 DRIVE LOWER - FROM SERIAL NUMBER (3*) 1.000 ST

210 DRIVE-LOWER PRIOR TO SERIAL NUMBER (3*) 1.000 ST

220 FRAME & REAR WHEELS 1.000 ST

230 DRIVE MOUNTING - FROM SERIAL NUMBER (3*) 1.000 ST

240 DRIVE MOUNTING - PRIOR TO SN (3*) 1.000 ST

250 PEDAL PLATFORM 1.000 ST

260 PEDAL PLATFORM MOUNTING 1.000 ST

270 STEERING 1.000 ST

280 VACUUM - OPTIONAL 1.000 ST

290 WIRING - BATTERY 1.000 ST

Valid on 27.09.2018 Page 2 / 59

Page 50

40 BODY BRACE

Valid on 27.09.2018 Page 3 / 59

Page 51

40 BODY BRACE

POS Article no. Description Quantity Unit

1 8.627-382.0 SCREW, 1/4-20 X 1.25 HHMS SS 2.000 ST

2 8.601-063.0 WASHER, 1/4 SS 6.000 ST

3 8.634-002.0 COVER, PANEL MNT BREAKER 1.000 ST

4 8.627-512.0 SCREW, 1/4-20 X .75 PHPNHMS STL ZNPLT 4.000 ST

5 8.634-003.0 BREAKER, 100A CIRCUIT 1.000 ST

6 8.627-750.0 SCREW, 1/4-20 X .625 CARR SS 2.000 ST

7 8.622-977.0 BLOCK, SHUNT MOUNT 1.000 ST

8 8.600-570.0 NUT, 10-32 HEXSTRW LK STL ZNPLT 2.000 ST

9 8.627-179.0 NUT, 6-32 HEX BRS 2.000 ST

10 8.627-960.0 WASHER, 6 FLT BRS 4.000 ST

11 8.625-360.0 SHUNT, 50MV 70AMP 1.000 ST

12 8.627-625.0 SCREW, 6-32 X .375 SLTDPNHMS BRS 2.000 ST

13 8.627-077.0 NUT, 1/4-20 HEX SS 2.000 ST

14 8.627-137.0 NUT, 1/4-20 SERFLG STL ZNPLT 8.000 ST

15 8.635-327.0 BRACKET, CONTACTOR COVER 1.000 ST

16 8.637-145.0 RELAY 36VDC 100A HD 1.000 ST

17 8.627-112.0 NUT, 5/16-18 HEX BRS 2.000 ST

18 8.601-067.0 WASHER, 5/16 FLT SS 2.000 ST

19 8.635-326.0 BRACKET, SOL TANK BRACE 1.000 ST

20 8.601-068.0 WASHER, 3/8 NYL 2.000 ST

21 8.627-913.0 WASHER, 5/16 SPLT STL ZNPLT 2.000 ST

Valid on 27.09.2018 Page 4 / 59

Page 52

50 BODY LOWER

Valid on 27.09.2018 Page 5 / 59

Page 53

50 BODY LOWER

POS Article no. Description Quantity Unit

1 8.627-398.0 SCREW, 10-32 X .75 PHPNHMS SS 2.000 ST

2 8.601-065.0 WASHER, .203 X .562 X .040 FLT 2.000 ST

3 8.635-499.0 CLAMP, .75 DIA, FLEX LOOP, NYLON 2.000 ST

4 8.601-067.0 WASHER, 5/16 FLT SS 2.000 ST

5 8.627-913.0 WASHER, 5/16 SPLT STL ZNPLT 4.000 ST

6 8.627-678.0 SCREW, 5/16-18 X .75 HHCS SS 2.000 ST

7 8.635-457.0 BRACKET, SPRING, UPPER 2.000 ST

8 8.635-322.0 SPRING, EXTENSION 2.000 ST

9 8.635-372.0 BRACKET, SPRING, LOWER 2.000 ST

10 MAIN BODY, NO OBC, GRAY, TRIM 1.000 ST

Item text1: SHELF CHARGER MODELS ONLY,

Item text2: 1.002-033.0 AND 1.002-035.0

10 8.636-841.0 Main body 1.000 ST

11 8.635-328.0 Hose 1.000 ST

12 8.626-494.0 Cable tie 11.38" UL/CSA 3.000 ST

Valid on 27.09.2018 Page 6 / 59

Page 54

60 BODY LOWER MOUNTING

Valid on 27.09.2018 Page 7 / 59

Page 55

60 BODY LOWER MOUNTING

POS Article no. Description Quantity Unit Serial number from

1 8.627-963.0 WASHER, 5/16 X 1.13 X .09 FLT 5.000 ST *(3)

Item text1: QTY WAS 6

2 8.600-676.0 SCREW, 5/16-18 X .75 HHCS 3.000 ST *(3)

Item text1: QTY WAS 4

3 8.627-518.0 SCREW, 5/16-18 X .5 STL GR5 ZNPLT 2.000 ST

Valid on 27.09.2018 Page 8 / 59

Page 56

70 BUMPER

Valid on 27.09.2018 Page 9 / 59

Page 57

70 BUMPER

POS Article no. Description Quantity Unit

1 8.636-682.0 BUMPER, TRIM, BLACK 1.000 ST

2 8.627-698.0 SCREW, 5/16-18 X 2 HHCS SS 2.000 ST

3 8.601-067.0 WASHER, 5/16 FLT SS 7.000 ST

4 8.627-607.0 SCREW, 5/16-18 X .75 CARR SS 4.000 ST

5 8.627-083.0 NUT, 5/16-18 HEX NYLOCK SS 4.000 ST

6 8.632-395.0 PAD TIP 2.000 ST

7 7.303-104.0 Screw 5x16 -A2-70 (IN6RD) 2.000 ST

8 8.627-184.0 NUT, 5/16-18 HEXTHIN NYLOCK SS 1.000 ST

9 8.632-791.0 SCREW, KA50 X 25 PTOVHS STL WN1412 ZNPLT 2.000 ST

10 8.625-613.0 STRAP, STATIC, .2T X 1W X 3L 1.000 ST

11 8.627-963.0 WASHER, 5/16 X 1.13 X .09 FLT 1.000 ST

12 8.600-676.0 SCREW, 5/16-18 X .75 HHCS 1.000 ST

13 8.635-951.0 BRKT, STATIC STRAP 1.000 ST

Valid on 27.09.2018 Page 10 / 59

Page 58

80 BURNISHING DECK

Valid on 27.09.2018 Page 11 / 59

Page 59

80 BURNISHING DECK

POS Article no. Description Quantity Unit

- 8.634-801.0 Brush set 1.000 ST

1 8.635-498.0 MOTOR, 36VDC 3 HP 2000RPM 1.000 ST

2 8.628-685.0 KEY, 3/16 X 3/16 X 1.5 LCST GR1018 1.000 ST

3 8.635-347.0 BRACKET, MOTOR LIFT 1.000 ST

4 8.635-291.0 SHROUD, OUTER 1.000 ST

5 8.635-378.0 Brush 1.000 ST

6 8.635-290.0 SHROUD, INNER 1.000 ST

7 8.635-375.0 PLATE, SUPPORT, INNER SHROUD 1.000 ST

8 8.627-692.0 SCREW, 3/8-16 X 1 HHCS SS NP 4.000 ST

9 8.637-214.0 HUB, PAD DRIVER 1.000 ST

10 8.601-071.0 WASHER, 7/16 FLT STL YW ZNPLT 1.000 ST

11 8.627-754.0 SCREW, 7/16-20 X 1 HHCS STL GR5 ZNPLT 1.000 ST

12 8.600-693.0 SCREW, 5/16-18 X 1 SCHBTNHCS SS 1.000 ST

13 8.633-099.0 WASHER, 5/16 INTLK SS 1.000 ST

14 8.622-884.0 BUSHING, .314 X .502 X .5 FLG 1.000 ST

15 8.627-903.0 WASHER, .515 X 1.47 X .05 FLT NYL 1.000 ST

16 8.600-791.0 Spring EXT .31D X 2.0L X .03W 2.000 ST

17 8.635-376.0 BRACKET, MOTOR LOCK 1.000 ST

18 8.627-911.0 WASHER, 3/8 INTLK 4.000 ST

19 8.627-191.0 Nut 5/16-18 FLEX LK STL GRA ZNPLT 2.000 ST

20 8.601-067.0 WASHER, 5/16 FLT SS 2.000 ST

Valid on 27.09.2018 Page 12 / 59

Page 60

90 BURNISHING DECK MOUNTING

Valid on 27.09.2018 Page 13 / 59

Page 61

90 BURNISHING DECK MOUNTING

POS Article no. Description Quantity Unit Serial number from

1 8.638-852.0 DECK LINKAGE ARM 2.000 ST (5*)

2 8.627-747.0 SCREW, 5/16-18 X 1.5 CARR SS 4.000 ST

3 8.622-884.0 BUSHING, .314 X .502 X .5 FLG 8.000 ST

4 8.625-941.0 WASHER, .51 X 10 X .063 THR 8.000 ST

5 8.627-935.0 WASHER, 1/2 X .771 X .013 WV 16.000 ST

6 8.625-942.0 WASHER, .510 X 1 THR 8.000 ST

7 8.601-067.0 WASHER, 5/16 FLT SS 14.000 ST

8 8.627-083.0 NUT, 5/16-18 HEX NYLOCK SS 12.000 ST

9 8.627-607.0 SCREW, 5/16-18 X .75 CARR SS 2.000 ST

10 8.627-184.0 NUT, 5/16-18 HEXTHIN NYLOCK SS 2.000 ST

11 8.638-850.0 TOP LINK ASSY 1.000 ST (5*)

12 8.601-077.0 WASHER, 7/16 X1 X .08 FLT SS 4.000 ST

13 8.635-381.0 SHOULDER BOLT, 3/8 X .25L SS 2.000 ST

14 8.601-068.0 WASHER, 3/8 NYL 2.000 ST

15 8.635-380.0 Holder 2.000 ST

16 8.627-703.0 SCREW, 5/16-18 X 1.25 CARR SS 4.000 ST

17 8.635-379.0 BRACKET, LINKAGE ARM 2.000 ST

18 8.635-374.0 BRACKET, LIFT ASSY, TOP 1.000 ST

Valid on 27.09.2018 Page 14 / 59

Page 62

100 BURNISHING DECK LIFT

Valid on 27.09.2018 Page 15 / 59

Page 63

100 BURNISHING DECK LIFT

POS Article no. Description Quantity Unit

1 8.632-804.0 PIN, CLEVIS 1/4 X 2 STL ZNPLT 2.000 ST

2 8.635-475.0 WASHER, .264 X 1 X .07 NYL BLK 2.000 ST

3 8.632-088.0 ACT, 36VDC, 3.0" STK, 8.74 LNG 1.000 ST

4 8.600-865.0 PIN, COTTER RING 1/4 X .041 X .844 2.000 ST

5 8.634-224.0 SPACER, .81 X 1.06 X .125 1.000 ST

Valid on 27.09.2018 Page 16 / 59

Page 64

110 BURNISHING DECK - PAD DRIVER

Valid on 27.09.2018 Page 17 / 59

Page 65

110 BURNISHING DECK - PAD DRIVER

POS Article no. Description Quantity Unit

1 8.635-246.0 HUB, PAD DRIVER 1.000 ST

2 8.635-565.0 GROMMET, .155ID X .438OD X .188T 1.000 ST

3 8.617-314.0 SCREW, KA40 X 10 OVHCS STL WIN1412 ZNPLT 3.000 ST

4 8.635-562.0 RETAINER, PAD CENTER LOCK 1.000 ST

5 8.617-333.0 WASHER, M5 SS ISO7093 8.000 ST

6 8.632-791.0 SCREW, KA50 X 25 PTOVHS STL WN1412 ZNPLT 8.000 ST

7 8.635-561.0 Pad drive 1.000 ST

8 ASM, PAD DRIVER iGLOSS 20 1.000 ST

Item text1: NOT SHOWN

8 8.635-166.0 SCREW, 6-19 X .5 PHPNHSMS HL STL ZNPLT 3.000 ST

Valid on 27.09.2018 Page 18 / 59

Page 66

120 CONSOLE - BAG ENCLOSURE

Valid on 27.09.2018 Page 19 / 59

Page 67

120 CONSOLE - BAG ENCLOSURE

POS Article no. Description Quantity Unit

1 8.617-314.0 SCREW, KA40 X 10 OVHCS STL WIN1412 ZNPLT 2.000 ST

2 8.616-180.0 LATCH & CONCEALED KEEPER 1.000 ST

3 8.636-843.0 COVER, BAG ENCL, BLK 1.000 ST

4 8.635-365.0 SHAFT, .25 X 7.3, SS 1.000 ST

5 8.627-581.0 SCREW, 10-32 X 1 PHPNHMS STL BLKOX 4.000 ST

6 8.601-065.0 WASHER, .203 X .562 X .040 FLT 4.000 ST

7 8.635-926.0 WASHER, 1.5 X 1.7 X .19 NPRN 1.000 ST

8 8.635-317.0 BRKT, HINGE 1.000 ST

9 8.622-879.0 BUSHING, .753 X .875 X .75 FLG 2.000 ST

10 8.632-783.0 GASKET,.188X.31X41.0 1.000 ST

11 8.627-633.0 SCREW, 1/4-20 X 1.25 CARR 2.000 ST

12 8.627-952.0 WASHER, 1/4 FLT STL BLK ZNPLT 4.000 ST

13 8.635-613.0 BUMPER, 7/8OD X 13/32H, RUBBER 2.000 ST

14 8.600-660.0 SCREW, 10-16 X .75 PHPNH HL SS 2.000 ST

15 8.635-464.0 WASHER, 1.5ID SINK, RUBBER 1.000 ST

16 8.633-398.0 FILTER BAG (10/PK) 1.000 ZST

17 8.600-704.0 SCREW, 5/16-18 X 1 THUMB SS 1.000 ST

18 8.635-682.0 WASHER, .315 X .89 X .215 NYL 1.000 ST

19 8.632-768.0 SWITCH, INTERLOCK 1.000 ST

20 8.635-459.0 BRACKET, BAG MOUNT 1.000 ST

21 8.635-463.0 GASKET, BAG MOUNT 1.000 ST

22 8.627-184.0 NUT, 5/16-18 HEXTHIN NYLOCK SS 1.000 ST

23 8.635-366.0 GASKET, BAG COVER, 43.6" 1.000 ST

24 8.636-680.0 CONSOLE, iGLOSS 20 TRIMMED GRAY 1.000 ST

Item text1: ACTIVE DUST CONTROL

24 8.639-950.0 CONSOLE, PASSIVE, TRIMMED 1.000 ST

Item text1: PASSIVE DUST CONTROL

25 8.600-832.0 WASHER, .315 X .6 X .36 NYL 1.000 ST

Valid on 27.09.2018 Page 20 / 59

Page 68

130 CONSOLE - HINGE

Valid on 27.09.2018 Page 21 / 59

Page 69

130 CONSOLE - HINGE

POS Article no. Description Quantity Unit

1 8.627-678.0 SCREW, 5/16-18 X .75 HHCS SS 6.000 ST

2 8.601-067.0 WASHER, 5/16 FLT SS 6.000 ST

3 8.632-886.0 NUT, 5/16 PUSH LK STL ZNPLT 1.000 ST

4 8.627-086.0 NUT, 10-24 TYPEU BLK 1.000 ST

5 8.627-711.0 SCREW, 10-24 X .75 PHPNHMS SS 1.000 ST

6 8.632-768.0 SWITCH, INTERLOCK 1.000 ST

7 8.632-632.0 BRACKET, HINGE UPPER 1.000 ST

8 8.622-899.0 BUSHING, .314 X .502 X .375 FLG BRZ 2.000 ST

9 8.632-634.0 PIN, CLEVIS 5/16 X 4 STL ZNPLT 1.000 ST

10 8.635-501.0 BRKT, HINGE LOWER 1.000 ST

11 8.616-180.0 LATCH & CONCEALED KEEPER 1.000 ST

12 8.617-314.0 SCREW, KA40 X 10 OVHCS STL WIN1412 ZNPLT 2.000 ST

13 8.636-836.0 PANEL, BACK TRIMMED, BLK 1.000 ST

14 8.600-892.0 BOOT, RUBBER TERM. ISOLATOR 1.000 ST

Valid on 27.09.2018 Page 22 / 59

Page 70

140 CONTROL PANEL 1

Valid on 27.09.2018 Page 23 / 59

Page 71

140 CONTROL PANEL 1

POS Article no. Description Quantity Unit Serial number from Serial number to

1 8.627-526.0 SCREW, 4-40 X .5 PHPNHMS STL ZNPLT 4.000 ST

2 8.632-639.0 CONN, 8MM PITCH, 10 POS 2.000 ST

3 8.635-249.0 PANEL, CONTROL iGLOSS 20 1.000 ST