Page 1

Armada BRC 40/22 120V

Carpet Extractor

Operating Instructions (ENG)

MODELS: BRC 40/22

1.008-060.0

86409500-E 02/01/17

Page 2

Warranty Registration

Thank you for purchasing a Kärcher North America product. Warranty registration is quick

and easy. Your registration will allow us to serve you better over the lifetime of the product.

To register your product go to :

http://warranty.karcherna.com/

For customer assistance:

1-800-444-7654

Machine Data Label

Overview

This carpet extractor is an electrical powered , portable carpet extractor inte nded for commercial use. The appliance

sprays a cleaning solution onto the carpet, agitates the wet carpet, and then extracts the soiled solution back into

the unit's recovery tank. The appliance is available with an optional hand tool for cleaning upholstery and stairs.

Karcher North America Headquarters

4555 Airport Way

Denver, CO 80239

2 86409500 Operator’s Manual - Armada BRC 40/22

Page 3

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How To Use This Manual . . . . . . . . . . . . . . . . . . . . .4

Safety

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . .6

CONSIGNES DE SÉCURITÉ IMPORTANTES . . . .7

HAZARD INTENSITY LEVEL. . . . . . . . . . . . . . . . . .8

NIVEAU D'INTENSITÉ DU DANGER. . . . . . . . . . . .9

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . .10

Operations

How This Machine Works. . . . . . . . . . . . . . . . . . . .11

Technical Specification. . . . . . . . . . . . . . . . . . . . . .12

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Rear Cover Storage . . . . . . . . . . . . . . . . . . . . . . . .15

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Pre Run Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Filling The Solution Tank . . . . . . . . . . . . . . . . . . . .18

Operating The Machine . . . . . . . . . . . . . . . . . . . . .19

Expected Run Time . . . . . . . . . . . . . . . . . . . . . . . .19

Brush Height Adjustment . . . . . . . . . . . . . . . . . . . .19

Operating The Machine . . . . . . . . . . . . . . . . . . . . .20

To Clean Under Desks Or Dead End Hallways . . .22

Emptying Recovery Tank . . . . . . . . . . . . . . . . . . . .22

Emptying Solution Tank . . . . . . . . . . . . . . . . . . . . .22

Accessory Tool Connection and Use . . . . . . . . . . .23

Table of Contents

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .25

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . .26

Daily / Regular Maintenance. . . . . . . . . . . . . . . . . .26

Vacuum Shoe Cleaning . . . . . . . . . . . . . . . . . . . . .27

Scrub Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Scrub Head Maintenance . . . . . . . . . . . . . . . . . . . .29

Scrub Brush Removal. . . . . . . . . . . . . . . . . . . . . . .29

Scrub Brush Replacement . . . . . . . . . . . . . . . . . . .29

Circuit Protection. . . . . . . . . . . . . . . . . . . . . . . . . . .30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Suggested Spare Parts. . . . . . . . . . . . . . . . . . . . . .33

86409500 Operator’s Manual - Armada BRC 40/22

3

Page 4

How To Use This Manual

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

This manual contains the following sections:

• How to Use This Manual

•Safety

• Operations

• Maintenance

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine model and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The SAFETY section contains important information

regarding hazardous or unsafe practices of the

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

The OPERAT IONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive

maintenance information to keep the machine and its

components in good working condition. They are listed

in this general order:

• Service Schedule

• Components

• Periodic Maintenance

• Daily/Regular Maintenance

• Scrub Deck & Brush Replacement

• Circuit Protection

• Troubleshooting

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

The model and serial number of your machine is

located under the recovery tank as shown

below:

NOTE: The manual part number is located on the

lower right corner of the front cover.

4

86409500 Operator’s Manual - Armada BRC 40/22

Page 5

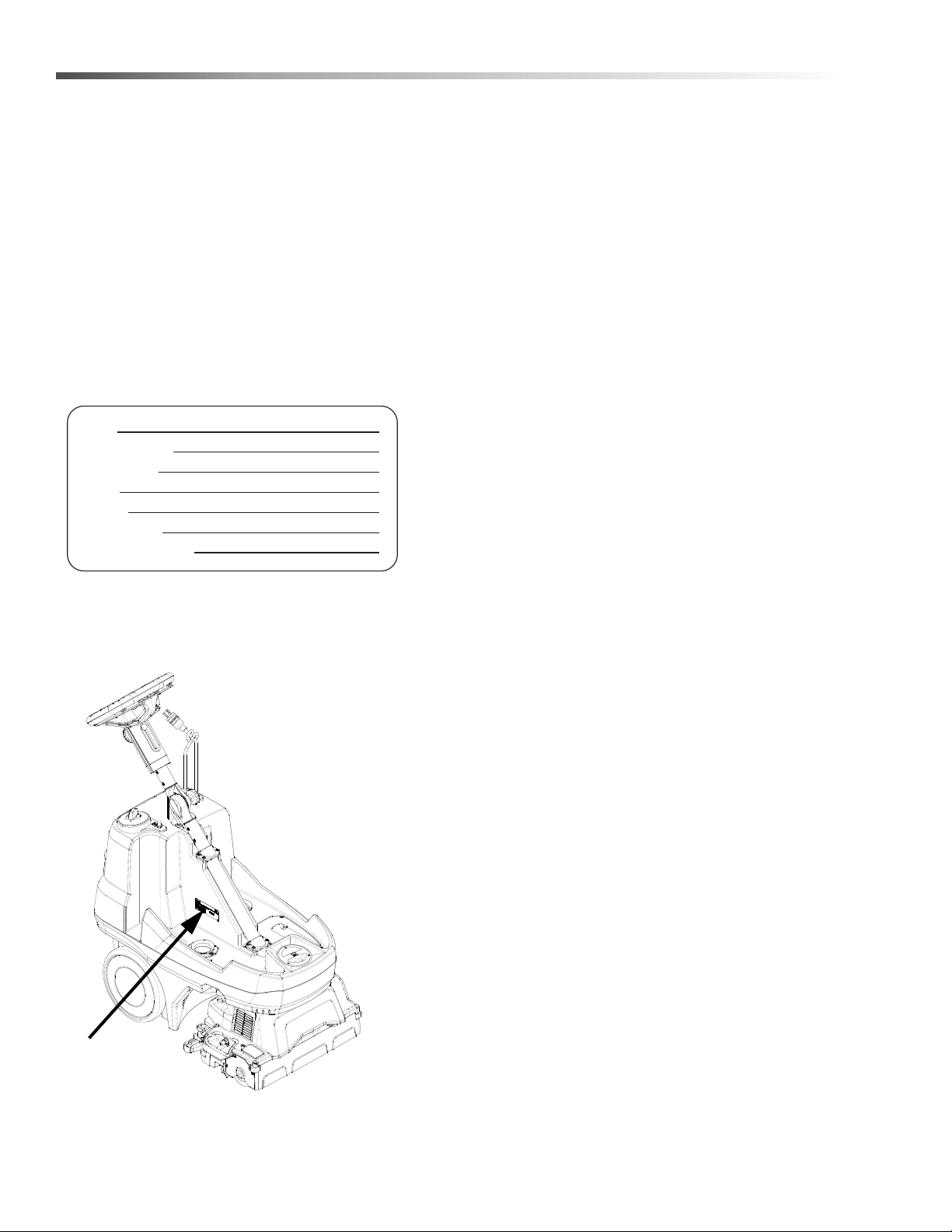

Safety

WARNING LABEL

86242230

WARNING LABEL

86402490

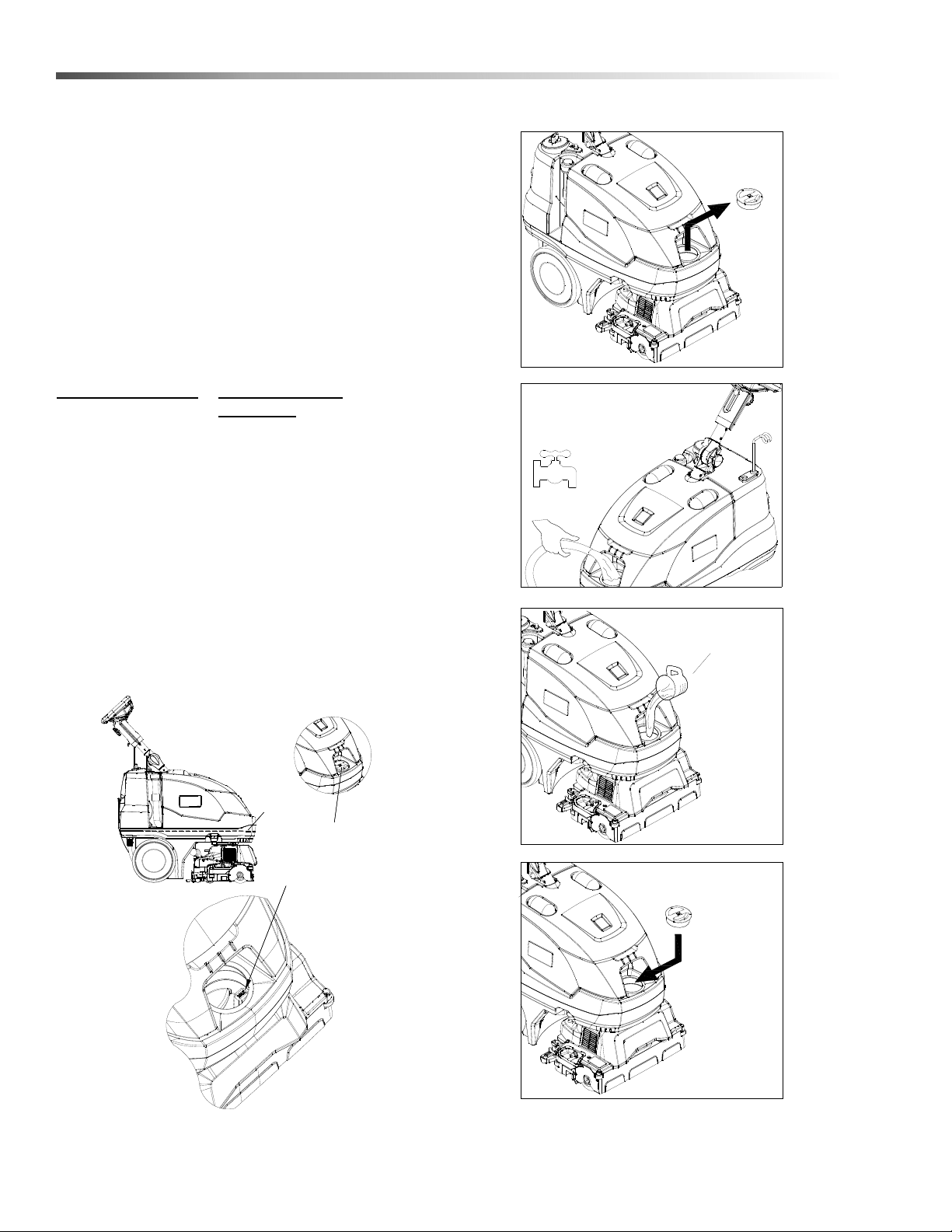

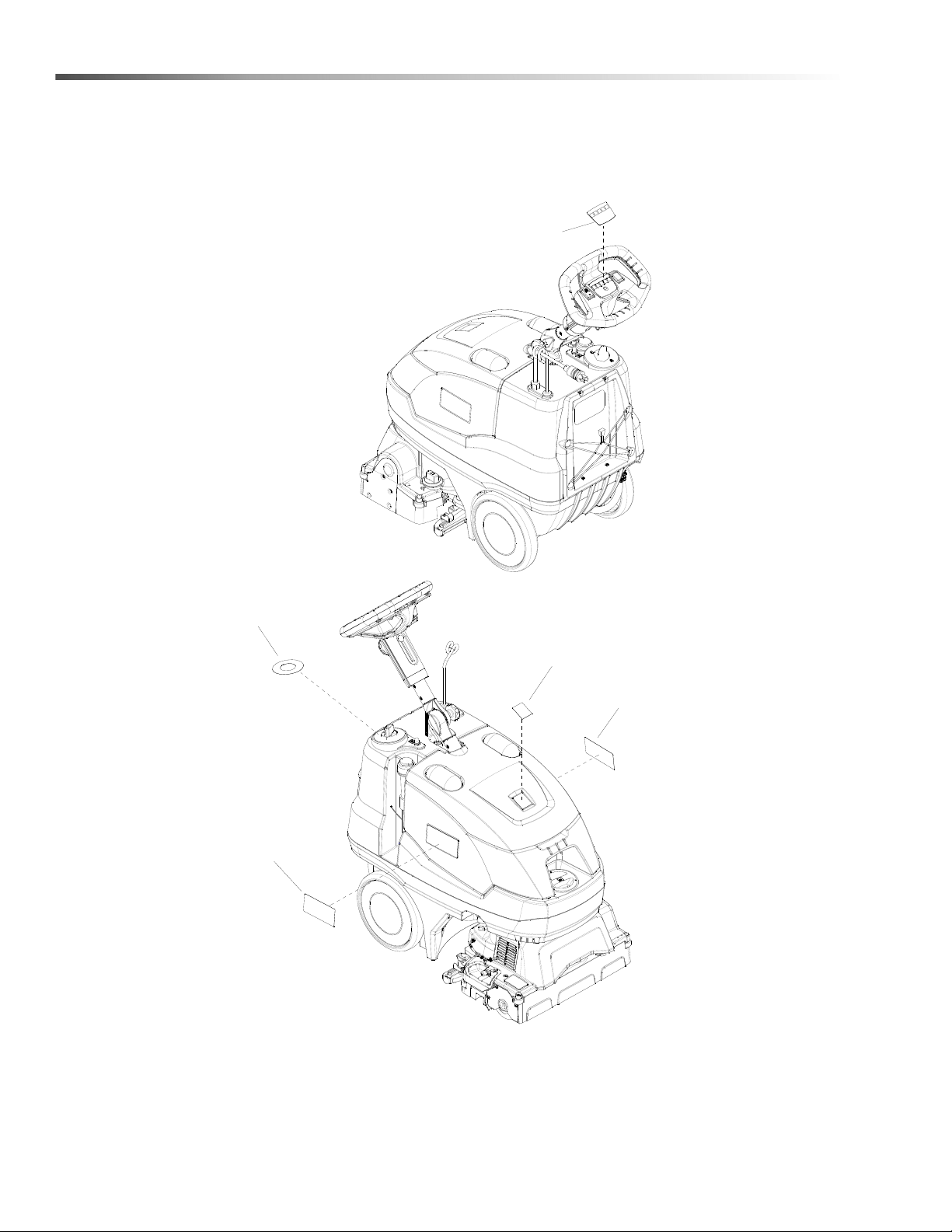

Safety Labels

NOTE: These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible, promptly replace them.

EMPLACEMENT DE L'ÉTIQUETTE DE SÉCURITÉ

REMARQUE : Ces dessins indiquent l'emplacement des étiquettes de sécurité sur la machine. Si, à tout moment,

les étiquettes deviennent illisibles, contactez votre représentant autorisé pour un remplacement rapid

86409500 Operator’s Manual - Armada BRC 40/22

5

Page 6

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Connect to a properly grounded outlet. See Gr ou nd in g Ins tr uct ion s.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before maintenance or

service.

Use only indoors. Do not use outdoors or expose to rain.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near children.

Use only as described in this manual. Use only manufacturer's recommended components and attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding the

machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water ,

return it to an authorized service center.

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord around sharp

edges or corners.

Do not allow the supply cord to come into contact with the rotating brushes. Keep cord away from heate d surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet ha nds.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.

This machine is intended for cleaning carpet only.

Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

This machine is not suitable for picking up health endangering dust.

Turn off all con trols before unplugging.

Do not operate this machine near flammable fluids, dust or vapors. Do not pick up flammable or combustible liquids

such as gasoline, and do not operate in locations where they may be of such liquids.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

READ AND SAVE THESE INSTRUCTIONS

6

86409500 Operator’s Manual - Armada BRC 40/22

Page 7

Safety

CONSIGNES DE SÉCURITÉ IMPORTANTES

Lors de l'utilisation de cette machine, des précautions de base

doivent toujours être prises, y compris les précautions suivantes :

LIRE TOUTES LES INSTRUCTIONS AVANT D'UTILISER CETTE MACHINE.

Pour réduire le risque d'incendie, d'électrocution

ou de blessure :

Cet appareil ne doit être connecter qu a des prises ayant une sortie de terre.

Ne pas laisser l'appareil sans surveillance lorsqu'il est branché. Débrancher lorsque l'appareil n'est pas utilisé et

avant l'entretien.

Pour reduire les risques de choc electrique, ne pas utiliser à l exterieur et ne pas aspirer de matières humides.

Ne pas permettre aux enfants de jouer avec l'appareil. Une attention particulière est nécessaire lorsque l'appareil

est utilisé par des enfants ou à proximité de ces derniers.

Utiliser cet appareil conformément aux instructions du présent manuel uniquement. N'utiliser que conformément à

cette notice avec les accessoires recommandés par le fabricant.

Ne pas utiliser si le cordon ou la fiche est endommagé. Retourner l'appareil à un atelier de réparation s'il ne

fonctionne pas bien, s'il est tombé ou s'il a été endommagé, oublié à l'extérieur ou immergé.

Ne pas tirer soulever ou traîner l'appareil par le cordon. Ne pas utiliser le cordon comme une poignée, le coincer

dans l'embrasure d'unée porte ou l'appuyer co ntre des a rêtes vives ou des coins. Ne pas faire rouler l'appar eil sur

le cordon.

Ne pas laisser le cordon d'alimentation entrer en contact avec les brosses rotatives. Garder le cordon à l'écart des

surfaces chaudes.

Ne pas débrancher en tirant sur le cordon. Tirer plutôt la fiche.

Ne pas toucher la fiche ou l'appareil lorsque vos mains sont humides.

N'insérer aucun objet dans les ouvertures. Ne pas utiliser l'appareil lorsqu'une ouverture est bloquée. S'assure

que de la poussière, de la peluche, des cheveux ou d'autres matières ne réduisent pas le débit d'air.

Cette machine est destinée pour nettoyer tapis seulement.

Ne pas aspirer de matiéres en combustion ou qui dégag ent de la fumée , comme des cigarettes, des allumettes ou

des cendres chaudes.

Cette machine n'est pas adaptée au ramassage de poussières dangereuses.

Mettre toutes les commandes à la position ARRÊT avant de débrancher l'appareil.

Ne pas l'utiliser près de liquides, de poussières ou de vapeurs inflammables. Ne pas aspirer des liquides inflamma-

bles ou combustibles, comme de l'essence, et ne pas faire fonctionner dans des endroits où peuvent se trouver de

tels liquides.

L'entretien et les réparations de la machine doivent être effectuées par un personnel qualifié.

Si de la mousse ou du liquide sort de la machine, la mettre hors tension immédiatement.

LIRE ET CONSERVER CES INSTRUCTIONS

86409500 Operator’s Manual - Armada BRC 40/22

7

Page 8

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal word s -WARNING and CAUTION and FOR SAFETY.

The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in min or personal in jury or pr oduct or pr operty damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on the

machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use

manufacturer approved replacement parts.

8

86409500 Operator’s Manual - Armada BRC 40/22

Page 9

Safety

Les symboles suivants sont utilisés dans tout ce manuel, tels que décrits ici :

NIVEAU D'INTENSITÉ DU DANGER

Il existe trois niveaux d'intensité du danger, identifiés par des termes d'avertissement - AVERTISSEMENT,

ATTENTION et POUR VOTRE SÉCURITÉ. Le niveau d'intensité du danger est déterminé par les définitions

suivantes :

AVERTISSEMENT - Les dangers ou des pratiques contraires à la sécurité qui POURRAIENT entraîner des

blessures personnelles ou la mort.

ATTENTION - Les dangers ou des pratiques contraires à la sécurité qui pourraient entraîner des blessures personnelles légères ou des dégâts sur le produit ou d'autres biens.

POUR DES RAISONS DE SÉCURITÉ : Pour identifier les actions qui doivent être exécutées pour un fonctionnement sûr de l'équipement.

Signaler immédiatement tout dommage subi par la machine ou fonctionnement défectueux. Ne pas utiliser la

machine si elle ne fonctionne pas correctement. Ci-dessous se trouvent les informations indiquant les conditions

potentiellement dangereuses pour l'opérateur ou l'équ ipement. Lire attentivement ces informations. Être conscient

que ces conditions peuvent survenir. Repérer tous les dispositifs de sécurité sur la machine. Suivre les étapes

nécessaires de formation du personnel qui utilise la machine.

POUR DES RAISONS DE SÉCURITÉ :

NE PAS FAIRE FONCTIONNER LA MACHINE :

Sauf si le personnel est formé et autorisé.

Sauf si le manuel d'utilisation est lu et compris.

Dans des zones inflammables ou explosives.

Dans des zones contenant des objets susceptibles de tomber

LORS DE L'ENTRETIEN DE LA MACHINE :

Éviter les pièces mobiles. Ne pas porter de vêtements, vestes, chemises ou manches vague s lors de l'entretien de

la machine. Utiliser les pièces de rechange approuvées par le fabricant.

86409500 Operator’s Manual - Armada BRC 40/22

9

Page 10

Safety

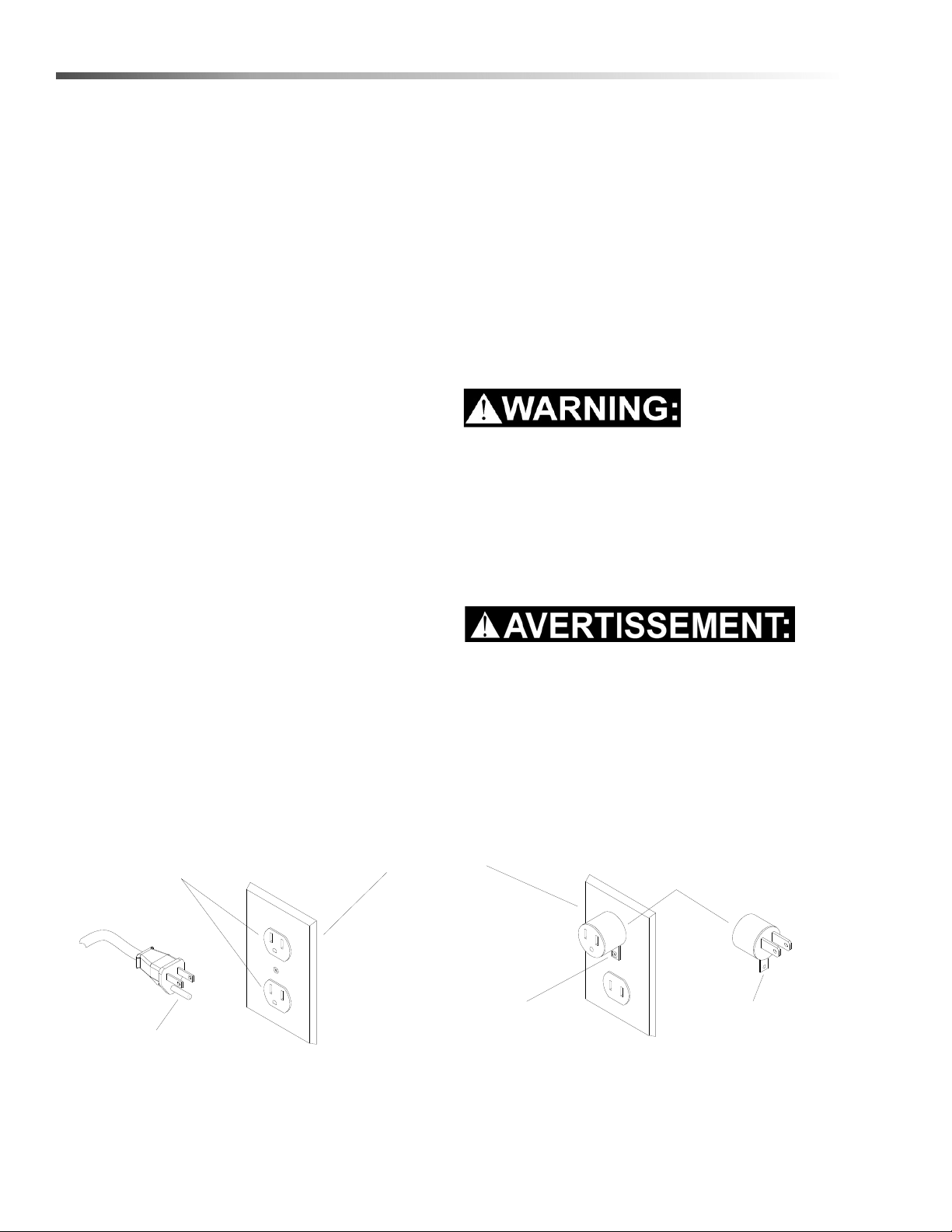

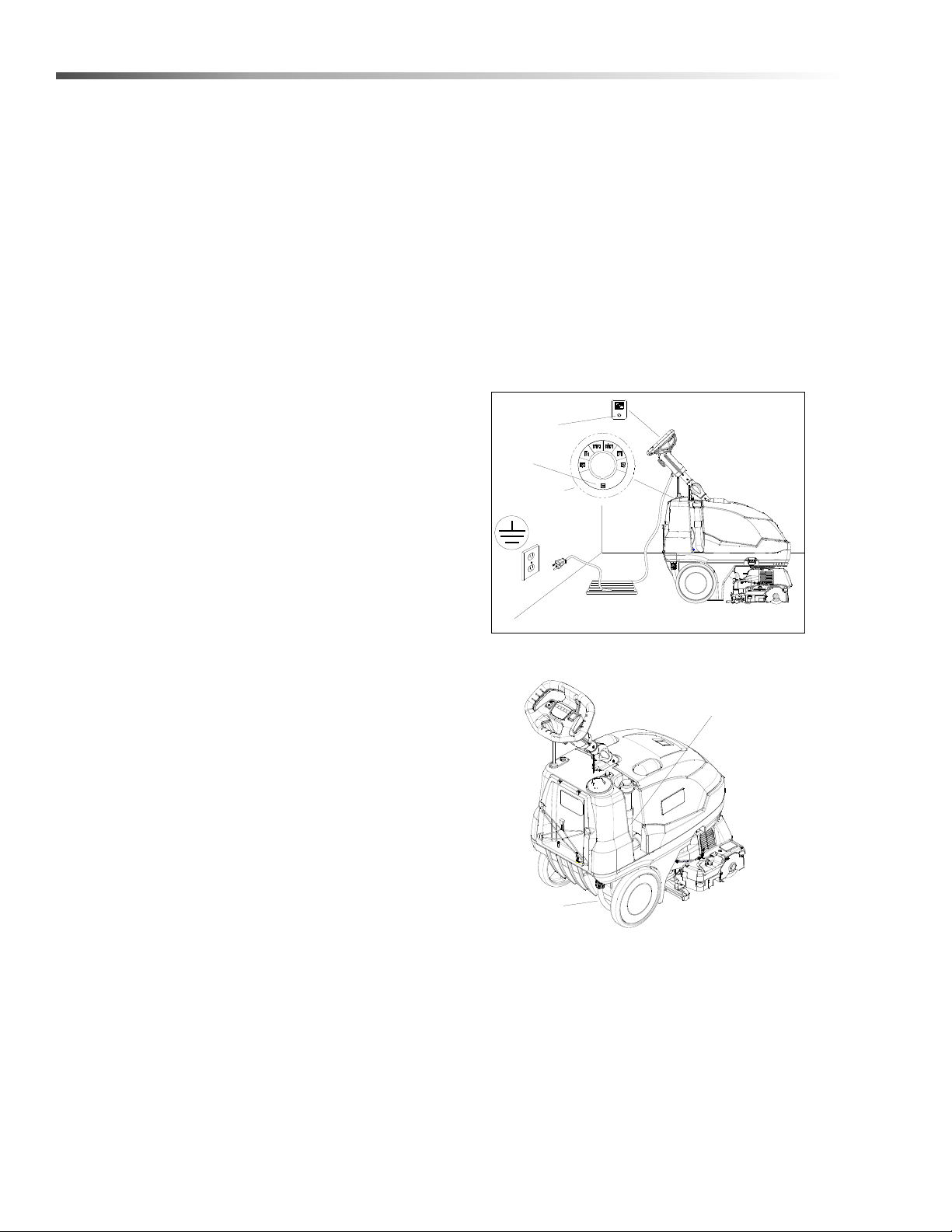

GROUNDING

PIN

GROUNDED

OUTLET

ADAPTER

METAL SCREW

TAB FOR

GROUNDING SCREW

GROUNDED

OUTLET BOX

(A) (B)

(C)

Grounding Instructions

THIS PRODUCT IS FOR COMMERCIAL

USE ONLY.

Electrical:

In the USA this machine operates on a standard 15

amp 120V, 60 hz, A.C. power circuit. The amp, hertz,

and voltage are listed on the data label found on each

machine. Using voltages above or below those

indicated on the data label will cause serious damage

to the motors.

Extension Cords:

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine, and must be limited to 50 feet (15.5m) in

length.

Grounding Instructions:

This appliance must be grounded. If it should malfunction or break down, grounding provides a path of least

resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord

having an equipment-grounding conductor and

grounding plug. The plug must be inserted into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

120 Volt Models:

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug in "Fig.

A". A temporary adapter that looks like the adapter in

"Fig. C" may be used to connect this plug to a 2-pole

receptacle as shown in "Fig. B", if a properly grounded

outlet is not available. The temporary adapter should

be used only until a properly grounded outlet (F ig. A)

can be installed by a qualified electrician. The green

colored rigid ear, lug, or wire extending from the

adapter must be connected to a permanent ground

such as a properly grounded outlet box cover.

Whenever the adapter is used, it must be held in place

by a metal screw.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service person

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the appliance - if it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

Le raccordement incorrect du conducteur de terre

d'équipement peut entraîner des risques d'électrocution. Vérifiez auprès d'un électricien qualifié ou

d'un responsable de l'entretien si vous avez

quelque doute que ce soit quant au r accordement à

la terre de votre prise murale. Ne modifiez pas la

fiche fournie avec l'appareil : si elle ne correspond

pas à la prise murale, faites installer une prise

adéquate par un électricien qualifié.

10

86409500 Operator’s Manual - Armada BRC 40/22

Page 11

Operations

How This Machine Works

This carpet extractor is an electrical powered, self

contained portable carpet extractor intended for

commercial use. The appliance sprays a cleaning

solution onto the carpet, agitates the wet carpet and

then extracts the soiled solution back into the unit's

recovery tank. The appliance is usable with a n optional

hand tool for cleaning upholstery and stairs.

The machine is also designed to restore your carpet

using carpet extraction chemicals.

The machine is designed to apply cleaning solution

onto carpeted floor, scrub the carpet with its brush, and

then vacuum the soiled water back into the recovery

tank.

The machine is designed to maintain your carpet using

the Encapsulating Interim Carpet Cleaning Process. By

using the Interim Carpet Maintainer in conjunction with

Windsor Red Carpet Encapsulating Interim Cleaning

(W450-4) or Encapsulating Interim Cleaning with

Carpet Protection (W455-4) chemical solution, you can

perform a regular light cleaning and grooming of your

carpet very quickly, and have the carpet dry and ready

for traffic within 30 minutes.

The machine's primary systems are the solution

system, scrub system, recovery system and operator

control system.

The function of the scrub system is to scrub the carpet,

mix the cleaning solution with the soil and lift and groom

the carpet pile as well as provide machine propel assistance. The scrub system consists of a cylindrical brush,

a motor and brush height adjustments. The brush

scrubs the carpet as the motor drives the brush. The

brush height adjustment allows for the proper amount

of agitation given various carpet types and brush wear.

The function of the recovery system is to vacuum the

soiled water back into the recovery tank. The recovery

system consists of the vacuum shoe, vacuum motor,

float ball filter and recovery tank. The vacuum shoe

extracts the dirty solution from the carpet as the

machine moves forward. The vacuum motor provides

suction to draw the dirty solution off the floor and into

the recovery tank. The float ball filter protects the

vacuum fan from debris and foam. The recovery tank

stores the dirty solution.

The function of the operator control system is to allow

the operator to select the desired function to perform.

NOTE: For best results, use this machine

immediately after vacuuming. Do not use this

machine as a vacuum cleaner. It is not intended to

vacuum dry dust, only soiled water.

The function of the solution system is to store mixed

solution and deliver solution to the appropriate spray

jet(s) or port. The solution system consists of the

solution tank, strainer, pum p, solenoid valves, spray

jets and accessory port. The solution tank stores the

water and chemical solution The strainer protects the

system from debris. The solution pump moves the

cleaning solution flow. The solenoids control the

direction of the solution flow. The jets deliver the

solution to the floor. The accessory port allows connection to a hand tool.

This appliance is not suitable for picking up hazardous

dust.

Cet appareil n'est pas conçu pour aspirer des poussières dangereuses.

86409500 Operator’s Manual - Armada BRC 40/22

11

Page 12

Operations

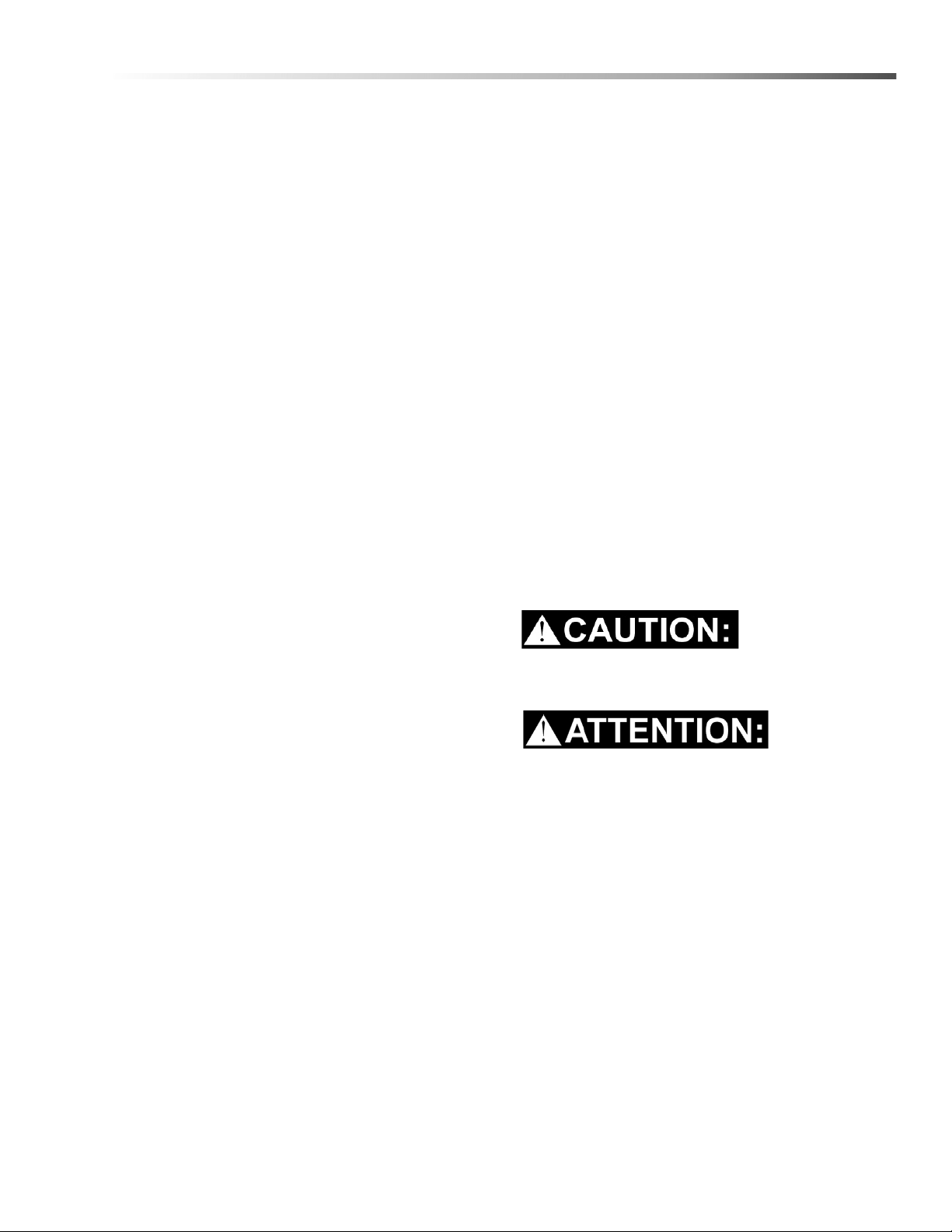

Technical Specification

ITEM MEASURE

Height 44 inches (1118 mm)

Length 35 inches (889 mm)

Width 18.5 inches (470 mm)

Width of scrub path 16 inches (406 mm)

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure

that they do not play with the appliance.

Cet appareil n'est pas prévu à l'usage des personnes (enfants y compris) avec des possibilités physiques, sensorielles ou mentales réduites, ou le manque d'expérience et de connaissance, à moins qu'ils aien t été donnés la

surveillance ou l'instruction au sujet de l'utilisation de l'appareil par une personne chargée de leur sûreté. Des

enfants devraient être dirigés pour s'assurer qu'ils ne jouent pas avec l'appareil.

12

86409500 Operator’s Manual - Armada BRC 40/22

Page 13

Technical Specifications

ITEM DIMENSION/CAPACITY

Construction Plastic Injection-molded chassis with rotationally molded polyethylene tank

Vacuum Motor

Solution Pump

Brush Motor .53 hp (400 watts) DC

Brush 16” (406 mm), ABS core

Cleaning Path 16" (40.6 cm)

Flow Rate

Solution Spray

Solution Tank 6 gallons ( 22 L)

Recovery Tank 5 gallons (19 L)

Vacuum Shoe 19" (483 mm) wide

Wheels 10" (254 mm) non-marking rubber

Power Cable 50' (15 m) detachable

Weight 100 lbs (45.5 kg) with cord

Sound Pressure Level

Operations

Three stage, bypass, 1.5 hp (1,119 watts), 100 cfm (2.8m³/min), 120" (3050

mm) waterlift

50 psi (3.5 bar) - Interim

100 psi (7 bar) - Restorative

Interim - 0.10 gpm ( 0.38 lpm)

Restorative - 0.65 gpm (2.5 lpm)

Interim - One quick-disconnect jet

Restorative - Two quick-disconnect jet

NOISE EMISSION

68.4 dB(A) Normal

(EN 60704-1)

Vibration Total Value (ISO 5349)

65.3 dB(A) ECO

MACHINE VIBRATION

0.70 m/s

2

86409500 Operator’s Manual - Armada BRC 40/22

13

Page 14

Operations

Solution Switch

Reverse

Yellow Trigger Switch

1

2

34

5

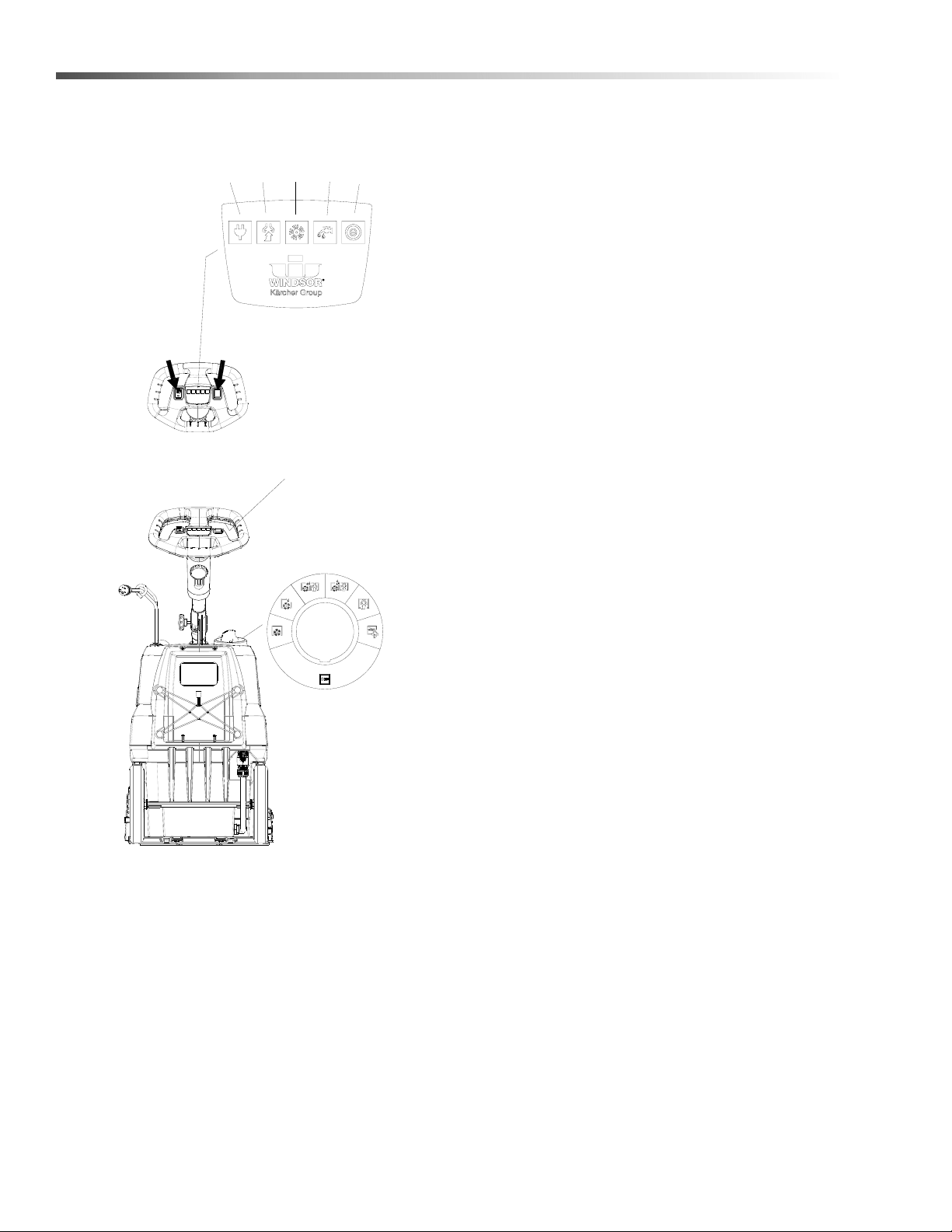

Controls

Display

The LED lights in the center are (from left to right):

1. Power

2. Vacuum

3. Brush

4. Solution

5. Eco! Mode.

The switch on the left controls the solution flow . The

switch on the right allows the operator to reverse the

brush motor, effectively moving the machine in an

opposite direction.

The yellow trigger switch on the steering wheel will turn

on the brush and solutions depending on which mode

the control switch is in.

Main Rotary Control Switch

Beginning with the off position and working clockwise,

the modes of operation are:

Brush Only

Encapsulation Mode

Eco! Mode Extraction

Deep Extraction

Vacuum Only

Accessory Tool

14

86409500 Operator’s Manual - Armada BRC 40/22

Page 15

Display

1. Power Light

• Green indicates that the machine has powe r.

• Off indicates the machine does not have power or rotary switch is set to the off position.

• See Trouble Shoo ting section if Green light is not on when it should be.

2. Vacuum Light

• Green indicates the vacuum motor is running pr op e rly.

• Flashing Red light: See Trouble Sho oting section

3. Brush Light

• Green indicates the brush is set and working prope rly.

• Amber (Orange) indicates the brush motor is overworking: See Troubleshooting section.

• Flashing Red light: See Trouble Shooting section.

4. Solution Light

• Green indicates that the solution pump is working properly

• Flashing Red light: See Trouble Shooting section.

5. Eco! Light

Operations

• Blue indicates the machine is in Eco! mode.

Main Rotary Control Switch Modes

Brush Only

• The brush will spin (when the yellow trigger switch is engaged). If the reverse switch is also

engaged, the brush will spin backwards.

Encapsulation

• The brush will spin and solution will be sprayed from the interim jet. If in reverse, no solution

will spray.

Eco! Extraction

• The brush will spin, the solution will be sprayed from the deep jets at a reduced flow and

vacuum motor will run at a reduced pressure and lower sound level.

Deep Extraction

• The brush will spin, the solution will be sprayed from the deep jets and the vacuum motor will

run.

Vacuum Only

• The vacuum motor will run and the brush will spin.

Accessory Tool

• The vacuum motor will run and solution will be supplied to the accessory port if the solution

switch is turned on.

Rear Cover Storage

Use the rear storage area to hold small cleaning bottles an d tools. Do not u se the elastic straps to ho ld large heavy

objects.

86409500 Operator’s Manual - Armada BRC 40/22

15

Page 16

Operations

6

1

2

3

4

5

7

8

9

10

12

11

14

13

11

11

1515

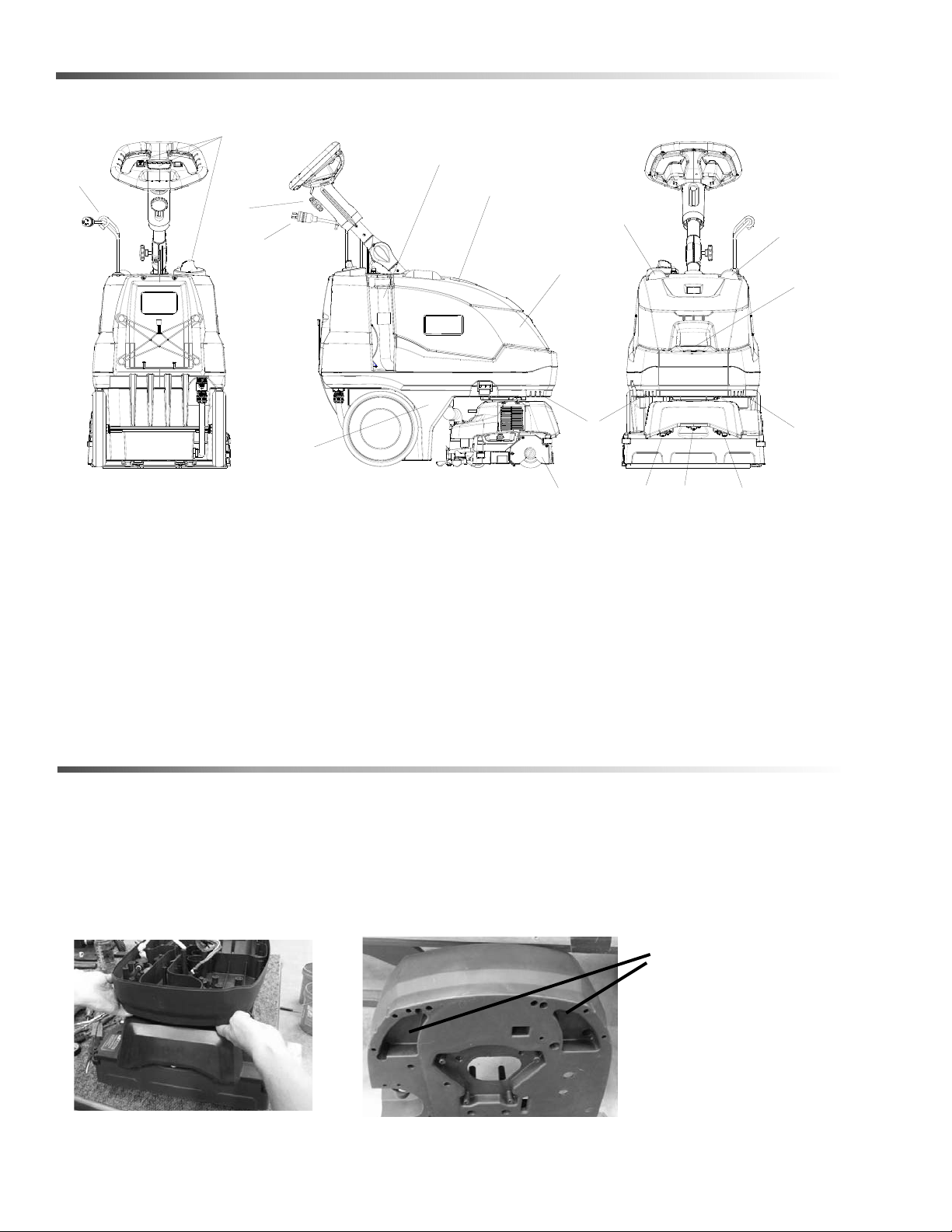

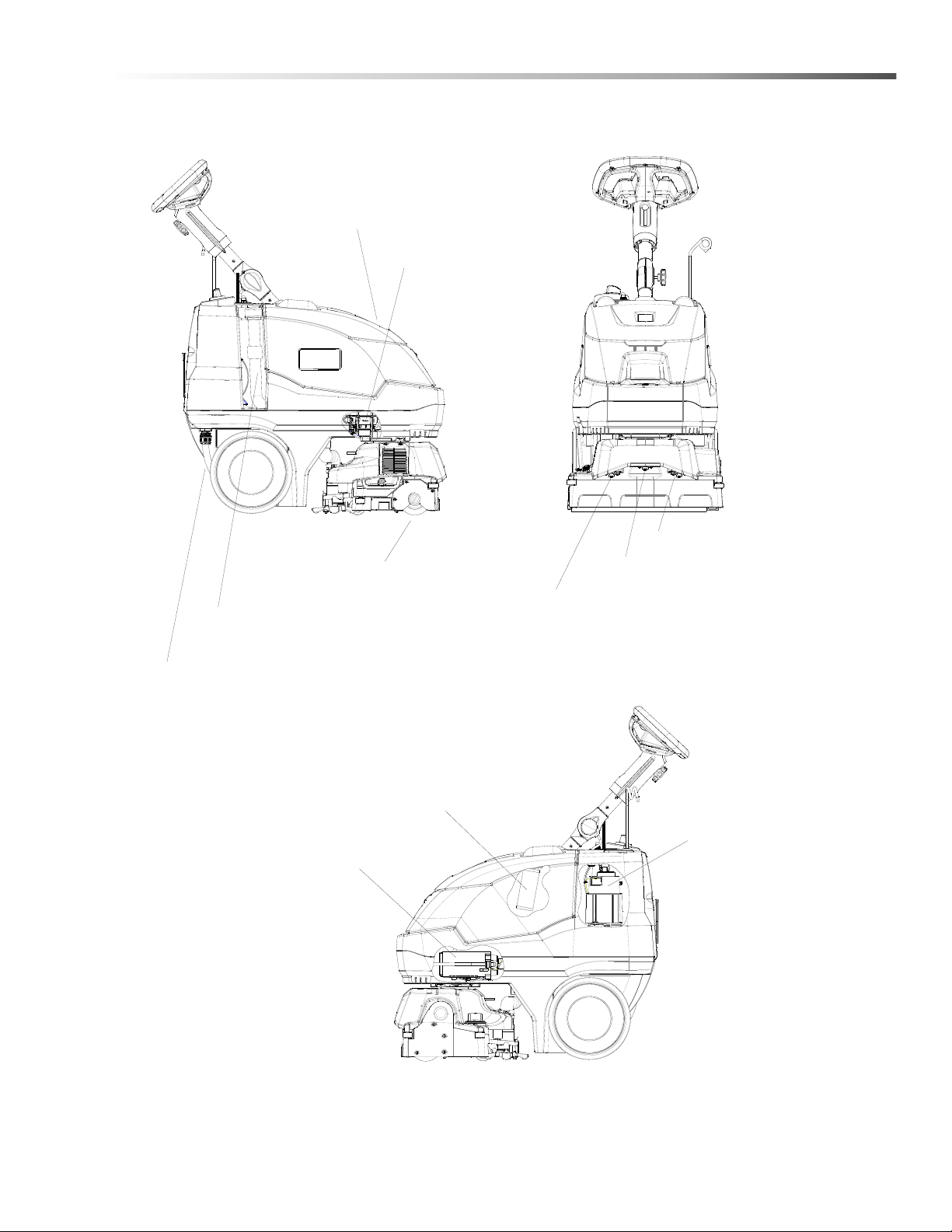

Components

1. Operator Controls and Display 8. Dirty Water Clear Observation Cover

2. Recovery Lid 9. Recovery Drain Hose

3. Recovery Tank 10. Control Height Adjustment - Operator Controls

4. Scrub Deck 11. Deep Extraction Jets

5. Solution Fill Cover 12. Interim Jet

6. Solution Tank 13. Power Cord Connection

7. Vacuum Air Clear Observation Cover 14. Cord Holder

15. Grips for lifting machine

Transporting The Machine Over Stairs

The machine should be carried up or down stairs by two people. One person to grab the front of the solution tank

using the two grip points / pockets on the front lower section. With the steering wheel fully extended, the second

person can grab the steering wheel

NOTE: Never grab the brush deck and the steering wheel as the machine will pivot around the steering column.

Grip pockets for

lifting machine.

16

86409500 Operator’s Manual - Armada BRC 40/22

Page 17

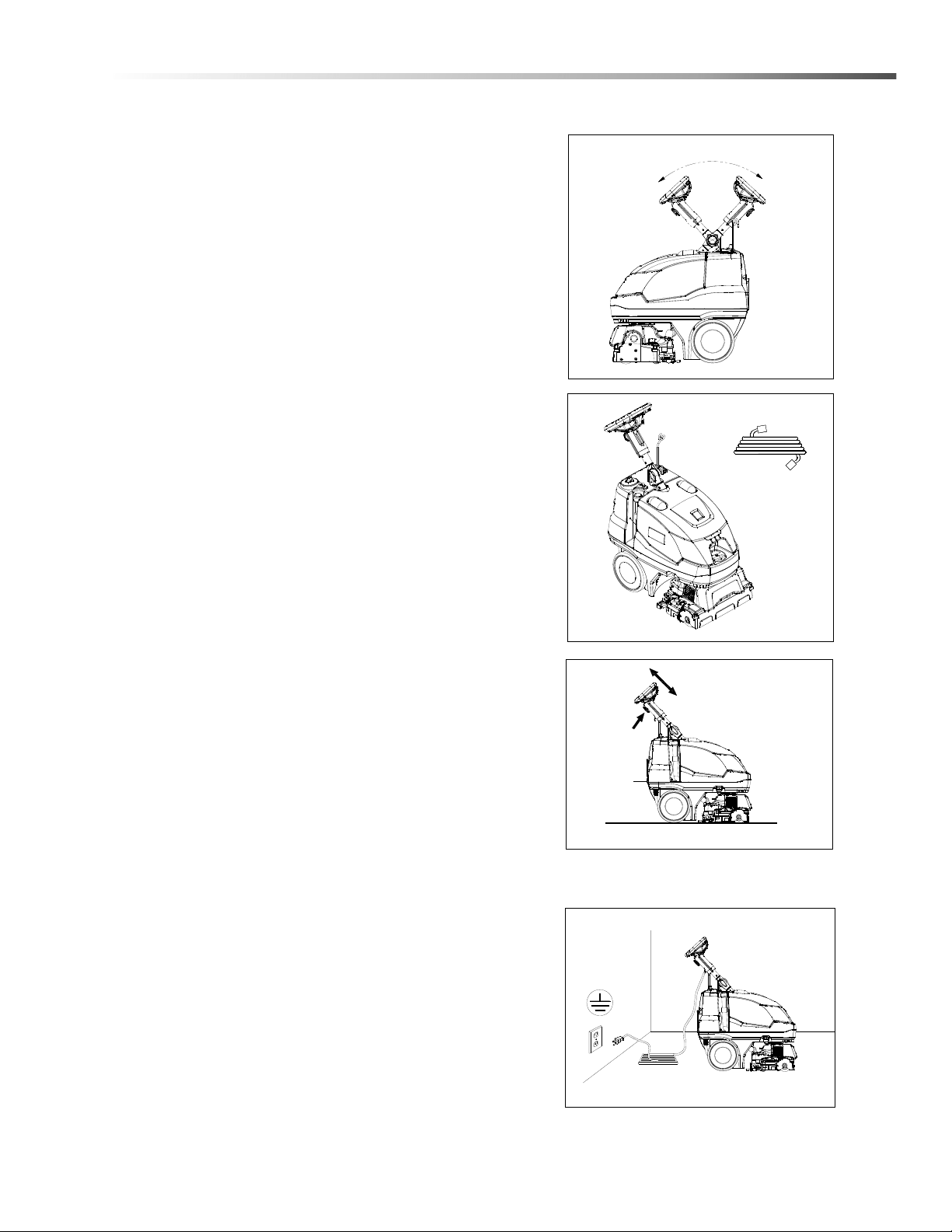

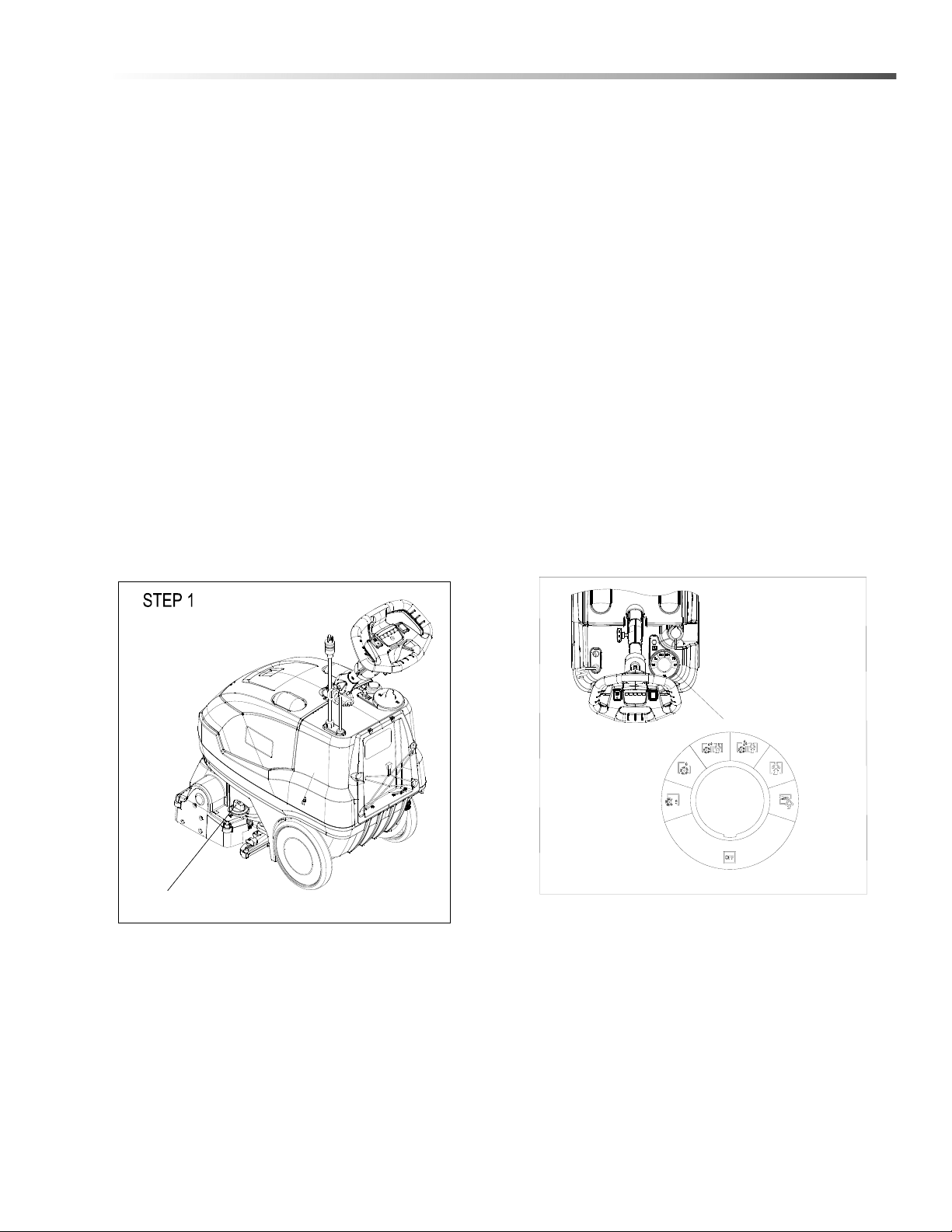

Pre Run Setup

STEP 2

OPERATION

STORAGE

STEP 1

FOR

STEP 3

STEP 4

1. To unfold handle, loosen knob, rotate upper

steering column and steering wheel back to stop.

Tighten knob.

2. Install the vacuum shoe and brush. Fill solution

tank with water and chemical. (see Filling the

Solution Tank instructions).

Operations

3. To adjust handle to comfortable operating position,

loosen knob, slide to comfortable height and

tighten.

4. Plug cord into grounded outlet. Place the powe r

cord in its holder on the machine by wrapping it

through the Cord Holder and plugging it into the

pigtail of the machine.

86409500 Operator’s Manual - Armada BRC 40/22

17

Page 18

Operations

FILL LINE

FILL CAP

INDICATOR

UNDER FILL CAP

FRONT TOP VIEW

MAXIMUM FILL

REMOVE SOLUTION

FILL COVER

STEP 1

STEP 2

OR

ADD WATER

6 Gal. MAX

(22 Lt)

STEP 3

ADD CLEANING

CHEMICAL PER

CHEMICAL LABELING

REPLACE SOLUTION

FILL COVER

STEP 4

Filling The Solution Tank

Do not put defoamer or solvent chemicals in the

solution tank.

Do not allow water to spill into vacuum motor inlet.

Dry spills from top of solution tank.

Do not tip machine on back when full as wat er may

spill from machine.

Use only the suitable chemicals listed below. Using

incompatible chemicals will damage the machine.

Damages of this type are not covered under warr an ty.

Carefully read ingredients on manufacturer's label

before using any product in this machine.

Chemicals

Suitable Chemicals

Alkalis

Detergents

Hydroxides

Soaps

Vinegar

Non-Compatible

Chemicals

Aldehydes

Aromatic Hydrocarbons

SP Butyls

Carbon Tetrachloride

Clorox*

Chlorinated Bleaches

Chlorinated Hydrocarbons

Lysol*

Methyl Ethel Ketone (MEK)

Perchorethylene (perc)

Phenolics

Trichlorethylene

D-Limonene

*Product Trademark Names

18

86409500 Operator’s Manual - Armada BRC 40/22

Page 19

Operations

Brush Height Adjustment Knob

STEP 2

Operating The Machine

Expected Run Time

The expected run time for this machine depends upon

which mode the machine is in. This duty cycle includes

an amount of time that the machine will be running

along with a period of time that the machine should be

off to empty the Recovery Tank, fill the Solution Tank,

check the Brush, and remove debris from the Debris

Tray.

Typical Run Time for each Mode:

Deep Extract 10 minutes ON

10 minutes OFF

Eco Mode 30 minutes ON

10 minutes OFF

Interim Mode 60 minutes ON

10 minutes OFF

Brush Height Adjustment

• Rotate the brush height adjustment knob to

position “1” which is the highest brush position.

Roll the machine forward to lower the machine

off the kickstand.

• Run the machine on the carpet to be cleaned.

The machine should now assist in the forward

direction due to the brush running on the carpet.

If not, raise the deck back onto the kickstand

and rotate the brush height adjustment knob to

the next lower brush position.

• Re-run the machine on the carpet and test for

forward assist; repeat previous step if nec es sary.

• If after a few seconds of running the brush ligh t

flashes red, rotate the brush height adjustment

knob to the next lower number position which

raises the brush and retest. If the brush light

continues to flash red, consult the Troubleshooting section.

2. Select a mode from the Main Rotary Control Switch

for the desired results.

See Controls section for detailed description of

each function.

Before adjusting brush height, transport the ma chine to

the work area by lifting the scrubbing head off of the

ground and rolling the machine on the rear wheels.

1. To set brush height for cleaning mode and carpet

type:

• Place the machine on the deck kick stand by

tipping the machine back about 30 degrees and

then setting the machine deck back to the

ground.

86409500 Operator’s Manual - Armada BRC 40/22

19

Page 20

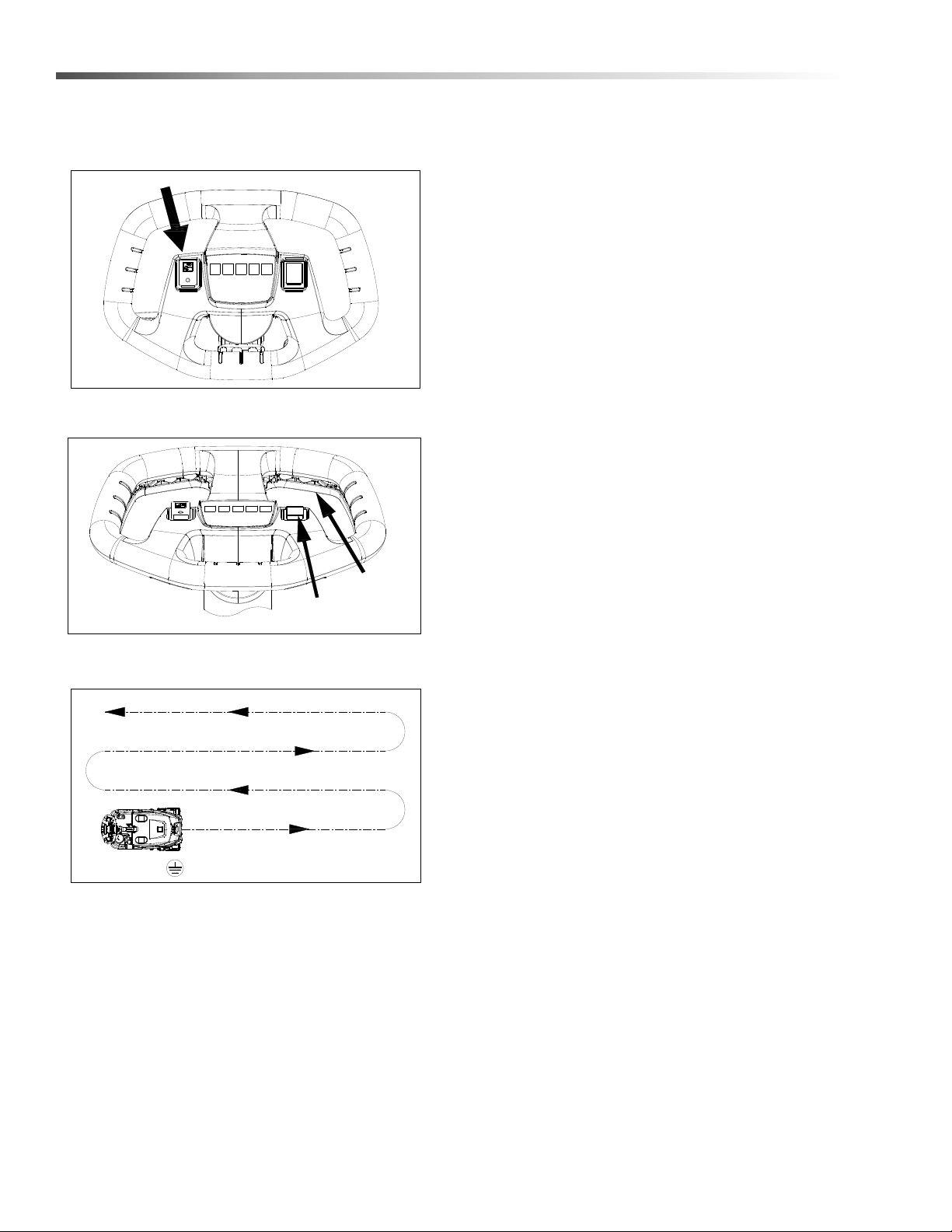

Operations

STEP 3

STEP 4

REVERSE

SWITCH

YELLOW

TRIGGER

SWITCH

CLEANING PATH

STEP 5

CLEANING PATH

WALL OUTLET

Operating The Machine

3. Turn on Solution Switch.

• Press the bottom of the switch to turn solution

on.

• Press the top of the switch to turn solution off.

4. Squeeze the large Yellow Trigger Switch to make

the machine move, run the brush and dispense

solution. Use the steering wheel to guide the

machine in the intended direction. Press the

bottom of the Reverse Switch to make the machine

travel backward while the yellow trigger switch is

depressed.

20

5. Start at wall closest to power outlet. For large

areas, operate machine in parallel passes, overlapping brush path. Clean perimeter last with right

side of machine toward outside of perimeter.

86409500 Operator’s Manual - Armada BRC 40/22

Page 21

Operations

STEP 6

SOLUTION INTAKE

VACUUM INTAKE

STEP 7

6. During operation, observe the following:

This machine is equipped with clear dome to facili-

tate operator viewing of dirty solution and vacuum

air flow.

During operation, observe the vacuum intake:

Any amount of water or foam ente ring the vacu um

system can damage the vacuum motor. If you

notice either condition, shut down the machine

immediately. Empty recovery tank and/or add

defoamer to recovery tank.

7. Use right side of machine for cleaning along walls.

86409500 Operator’s Manual - Armada BRC 40/22

8. To speed drying, use an airmover fan.

21

Page 22

Operations

SHUT

DOWN

OFF

POSITION

DOWN

STEP 1

PUMP SWITCH

SWITCH

CONTROL

MAIN

RECOVERY

DRAIN HOSE

SOLUTION

DRAIN HOSE

To Clean Under Desks Or Dead End

Hallways

By activating the momentary reverse switch, the brush

will spin in the opposite direction. Along with the

reverse switch, the trigger switch around the steering

wheel must also be engaged.

If the deck is pointing forward, jets in front, the machine

will propel backwards when the switch is pushed. This

is useful when cleaning under a desk or in a dead end

hallway where it is hard to turn around. This can be

used to scrub back and forth over a spot on the floor.

If the deck is spun 180 degrees, vacuum shoe in the

front, the machine will propel forward when the switch

is pushed. This is useful to drive the machine under a

desk or in a dead end hallway to be able to get the

vacuum shoe close to the wall.

Emptying Recovery Tank

If solution tank is empty , recovery tank is full or cleaning

is finished for the day, empty the recovery tank.

1. Turn of f all contro ls, an d ca refu lly unpl ug ma ch ine.

10. Place the tank back onto the base machine by

putting the front in first and then lowering the back

into place. Install the recovery drain cap and hang

back into place.

11. When finished for the day, prop recovery lid open

to allow tank to dry and to decrease odors. Drain

any extra clean solution and prop open the solution

fill lid.

12. Always store the machine with the deck lifted up on

the automatic kickstand.

13. If continuing to clean, replace recovery lid and fill

solution tank. (See Filling Solution Tank section)

2. Bring either the whole machine or just the recovery

tank to an approved drain.

3. Remove the recovery lid and rinse off any debris.

4. Empty recovery tank by releasing recovery drain

hose. Use a hose with cold water to clean out the

recovery tank.

5. Remove the recovery drain hose end above water

line and remove the cap. Squeeze the hose

section below the cap and lower the hose towards

the drain. Regulate the flow by the amount you

squeeze the hose.

6. Rotate the tank in a spiral direction to drain all dirty

water from the back left corner. If recovery tank is

still on the machine while draining, make sure the

deck is not on the kickstand to ensure the recovery

tank is emptied completely.

7. Use cold water to rinse all debris from the inside of

tank. Turn tank upside down and run water through

the two molded-in tubes going through the tank.

Turn tank right side up and rinse inside again.

8. Rotate the tank in a spiral motion to ensure all

water is drained from the back left corner.

9. Ensure that the two lip seals are in place on the

base machine to line up with the molded-in tubes in

the recovery tank and clean off any debris.

Emptying Solution Tank

To drain extra solution from tank, disconnect the

solution drain hose by sliding down the sleeve of the

yellow fitting to release the latch. Then pull the fitting

and hose down off of the tank mounting barb. When

reinstalling, fully engage the yellow fitting over the barb

on the tank until you hear it click.

22

86409500 Operator’s Manual - Armada BRC 40/22

Page 23

Operations

SOLUTION QUICK

DISCONNECT

VACUUM HOSE

CONNECTION

HAND TOOLHAND TOOL

VACUUM HOSE

HANDTOOL POSITION

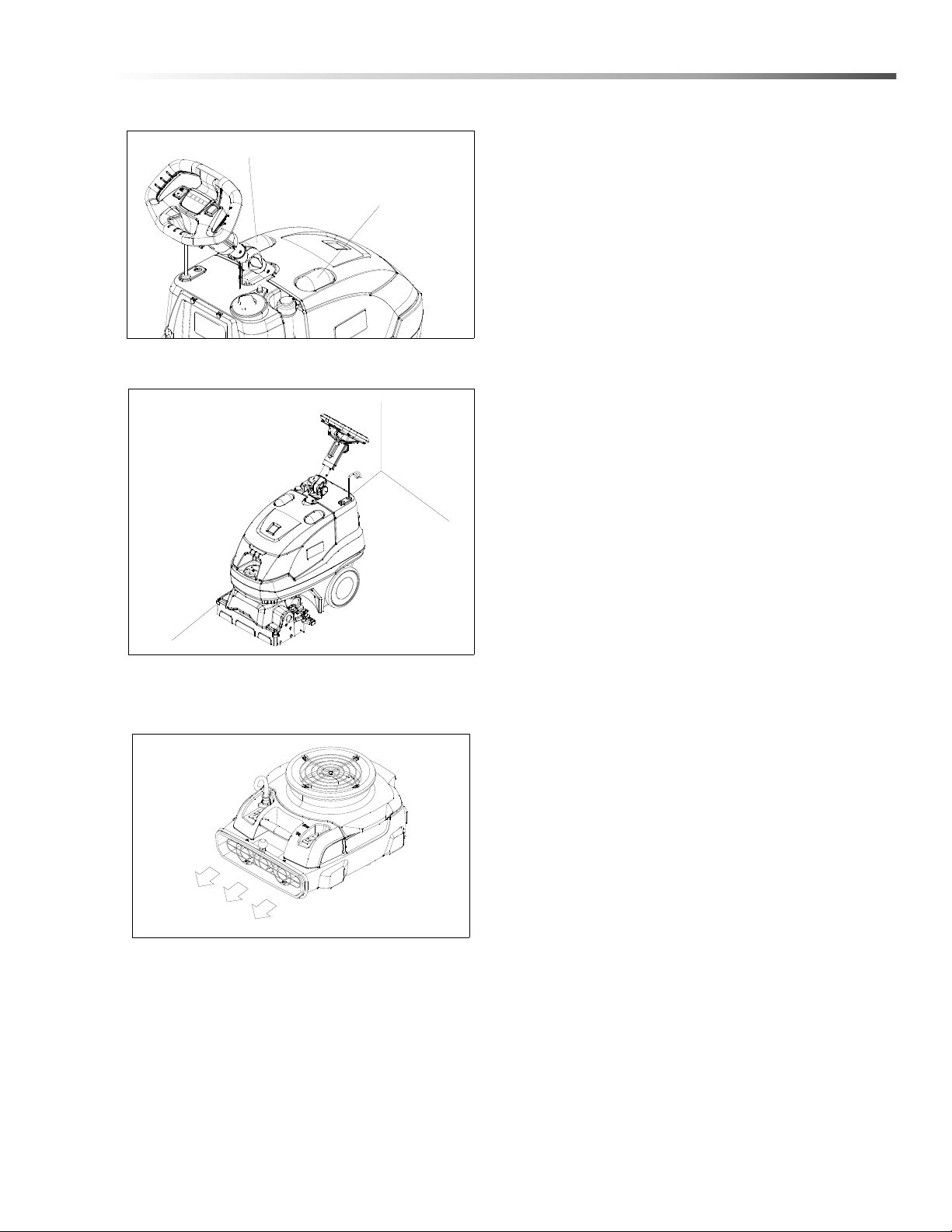

Accessory Tool Connection and Use

NOTE: Use only manufacturer supplied accessory

tools. See Optional Accessories section.

1. Spin the deck 180° so that the vacuum shoe is at

the front of the machine.

2. To connect solution hose pull back collar and insert

over machine mounted fitting, then release collar to

lock into place. Solution connection can remain

connected at all times.

3. Disconnect vacuum hose from the vacuum shoe

and connect the hand tool to the vacuum hose

connection as shown.

4. Select hand tool position on main rotary control

switch.

5. Press the top of the switch to turn solution on.

6. Press the bottom of the switch to turn solution of f if

only the Vacuum will be used for any extended

period of time.

7. Squeeze handle on accessory tool to begin

cleaning.

86409500 Operator’s Manual - Armada BRC 40/22

23

Page 24

Notes

24

86409500 Operator’s Manual - Armada BRC 40/22

Page 25

Maintenance

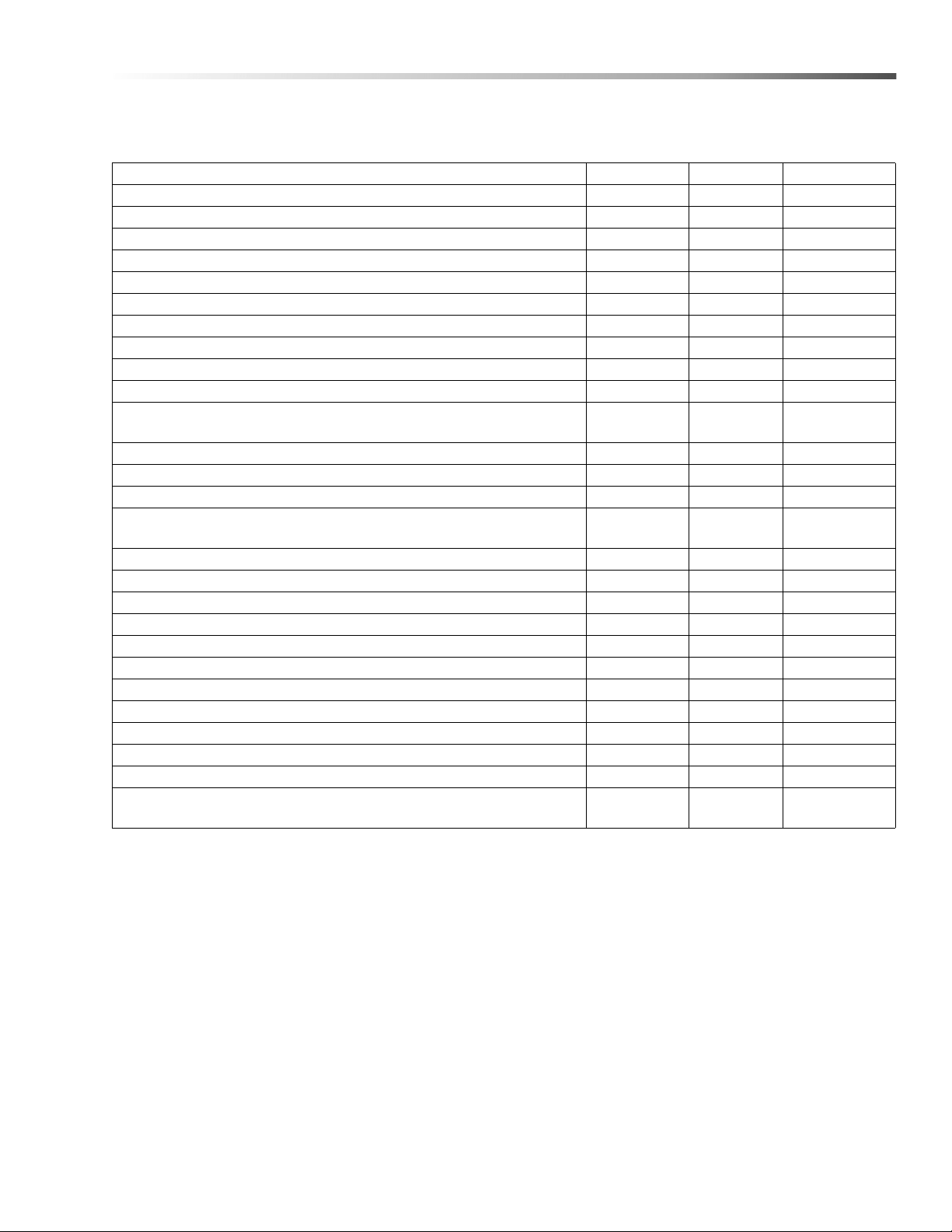

Service Schedule

MAINTENANCE DAILY WEEKLY QUARTERLY

Check machine for cord damage *

Check recovery dome and gasket for damage and cleanliness *

Check brushes - should be clean with no lint or strings attached *

Clean debris tray behind brush *

Clean the underside of the brush de ck ar ea *

Observe spray pattern *

Inspect vac shoe for blockage; Remove and rinse any debris *

Check hoses for wear, blockages, or damage *

Check handles, switches, and knobs for damage *

Run one gallon of water through solution system at end of day *

Clean out recovery tank, clean float screen and check float ball to

make sure it moves freely

Clean out solution tank *

Clean outside of all tanks and check for damage *

Run vac motor for at least one minute to allow motor to dry *

Store with recovery dome and solution lid removed to allow the tank

to dry

Remove bearing cap from end of brush. Clean bearing and cap. *

Check all bearings for noise *

Check all gaskets for wear and leakage *

Check and clean solution screen *

Check brush for wear; ensure bristles are not damaged *

Check condition of vac shoe and frame for damage *

Remove the bearing end cap off of the brush and clean *

Check overall performance of machine *

Clean debris from height adjust wheels *

Check belts for wear and replace as necessary *

Check cables for fraying *

Check pump pressure; observe spray pattern and check with gauge

if necessary

*

*

*

86409500 Operator’s Manual - Armada BRC 40/22

25

Page 26

Maintenance

Components

1. Brush 6. Solution Strainer

2. Deep Extraction Jets 7. Spray Jet - Interim

3. Debris Tray 8. Vacuum Shoe

4. Float Shut-off 9. Height Adjust Wheels

5. Solution Drain Hose

Periodic Maintenance

NOTE: Before making any adjustments or repairs to the

machine, disconnect the power cord from electrical

source

solution pressure loss. If the cable insulation is broken

or frayed, repair or replace it immediately. Do not take

chances with electrical fire or shock.

Daily / Regular Maintenance

Twice a month, flush a white vinegar solution (One

quart vinegar to two gallons of water) or anti-browning

solution (mixed as directed) through the extractor. This

will prevent build-up of alkaline residue in the system. If

spray jets become clogged, remove the spray tips,

wash them thoroughly, and blow-dry.

NOTE: Do not use pins, wire, etc. to clean nozzles as

this could destroy spray pattern.

1. Empty unused cleaning solution from the solution

tank.

2. Flush pumping system with 4 to 7 liters of clean,

hot water.

3. After each use, rinse tank with fresh water. Periodically inspect the recovery tank and decontaminate

if necessary, using a Hospital Grade Virucide or a

1-10 bleach to water solution. Waste water should

be disposed of properly.

Periodically inspect all hoses, electrical cables and

connections on your machine. Frayed or cracked hose s

should be repaired or replaced to eliminate vacuum or

26

86409500 Operator’s Manual - Armada BRC 40/22

4. Check for and remove any lint or debris around vac

shoe and deck wheels.

5. Check spray jets for full spray pattern.

Page 27

Maintenance

RETAINING CLIP

STEEL CLIP

6. Remove lint and dirt build-up from brush an d

housing.

7. Check float and shut-off screen and clean as

necessary.

8. Remove and clean debris tray.

V acuum Shoe and Hose

NOTE: Vacuum Shoe and hose flush should be done

daily after use. Place machine over drainage area

before beginning.

1. Remove recovery tank.

2. Insert water hose into vacuum hose.

3. With water pressure on high, rinse out hose and

vacuum shoe. Water should flow freely from

vacuum shoe.

Do not allow any water into the vacuum port.

V a cuum Shoe Cleaning

1. Unplug the power cord and move the machine to a

safe level area.

2. To remove the vacuum shoe assembly, spin the

deck around 180 degrees so vacuum shoe is at the

front of the machine,

3. Remove the recovery tank and set to the side.

4. Tip the machine back and let it rest at approximately a 45 degree angle.

5. Remove the hose from the top of the vacuum shoe.

6. Release (2) steel clips. (as shown below)

7. Rotate the (2) retaining clips (one on each end) to

remove clear vacuum shoe for easy cleaning.

Ne pas laisser d'eau dans l'orifice d'aspiration.

86409500 Operator’s Manual - Armada BRC 40/22

27

Page 28

Maintenance

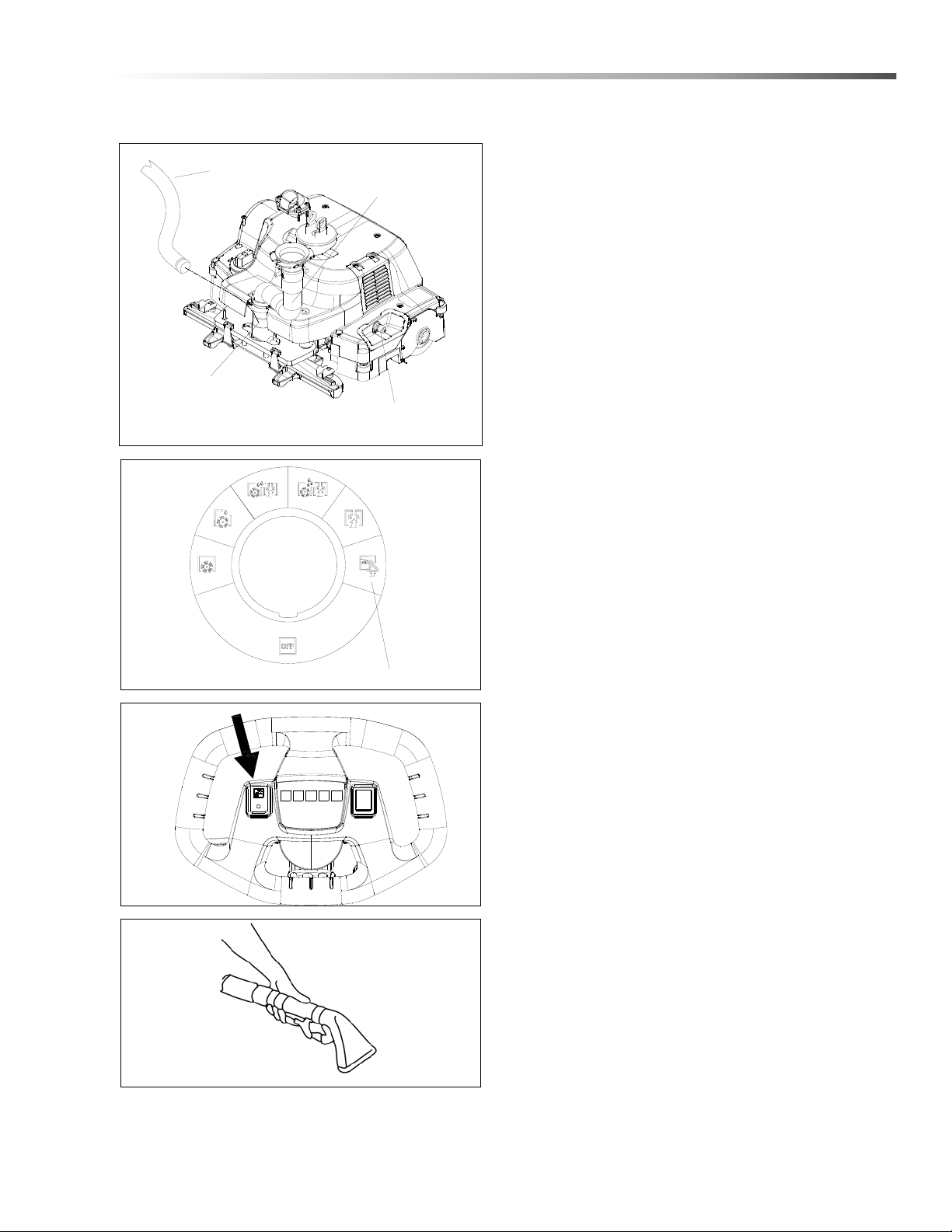

Scrub Deck

1. Scrub Brush Motor

2. Scrub Brush

3. Brush Height Adjustment

4. Vacuum Motor

5. Solution Pump

Only qualified maintenance personnel are to perform the following repairs.

Seul le personnel d'entretien qualifié peut effectuer des réparations.

28

86409500 Operator’s Manual - Armada BRC 40/22

Page 29

Maintenance

END CAP &

BEARING

Scrub Head Maintenance

The cylindrical scrub head is designed to scrub

chemicals into the carpet and propel the machin e.

The Scrub brush should be replaced when the brush is

no longer able to keep the front of the deck from

touching the ground.

Scrub Brush Removal

The scrub brush is removed from the right side of the

machine.

1. Disconnect all power.

2. Drain recovery tank.

3. Tip the machine back.

4. Push in on the brush end cap and then downward.

5. The brush assembly and end cap should drop

down. Then pull the brush down far enough to

clear the bottom of the housing.

Scrub Brush Replacement

Only use the brush provided with the appliance or

those specified in the instructions manual. The use

of other brushes may impair safety.

Utilisez uniquement la brosse fournie avec

l’appareil ou celles spécifiées dans le manuel

d'instructions. L’utilisation d’autres bross es

pourrait compromettre la sécurité.

1. Lift the drive side of the brush and push it onto

drive hub until a positive stop is felt. The brush

cannot be installed until the brush is fully seated on

the drive hub.

2. Slide brush up into the retaining clip until it clicks in

place.

3. Ensure the end cap is aligned with its mounting

plate.

6. Pull brush out with a rocking motion to free brush

from drive hub.

7. Check brush roller for wear, and replace when the

brush is no longer able to keep the front of the deck

from touching the ground.

8. Check to see if the end cap and bearing spin freely

and smoothly. Clean and replace if necessary.

86409500 Operator’s Manual - Armada BRC 40/22

29

Page 30

Maintenance

Circuit Breaker

Circuit Protection

Circuit breakers interrupt the flow of power in the event of an electrical overload. When a circuit breaker is tripped,

reset it by pressing the button. If a circuit breaker continues to trip, contact your service representative.

30

86409500 Operator’s Manual - Armada BRC 40/22

Page 31

Troubleshooting

PROBLEM CAUSE SOLUTION

Cord is not plugged in Plug in cord.

No power, nothing runs, no Circuit breaker tripped on machine. Reset breaker.

green light on power icon with Circuit breaker tripped in building. Reset breaker.

switch on. Faulty switch. Call for service.

Faulty power cord or pigtail. Call for service.

Recovery tank full Empty tank. Clean float screen.

V acuum motor will not run, red

light on vacuum icon.

V acuum motor runs but suction

is poor.

Poor or no water flow

(Carpet Is streaky)

Brush does not spin,

No brush light on brush icon. Brush belt broken. Call for service.

Brush light blinks orange.

Brush light turns solid red.

Machine stops working and

brush light blinks red 2 times.

Machine stops working and

brush light blinks red 3 times.

Faulty main vacuum switch. Call for service.

Loose wiring. Call for service.

Faulty vac motor. Call for service.

Debris lodged in vac shoe. Remove debris from vac shoe.

Dome or lid gasket defective or

missing.

V acuum hose cracked or hose cuff

loose.

Recovery tank full / float ball stuck

in the up position.

Jets clogged or missing.

Solution filter clogged. Clean solution filter.

Faulty solenoid. Call for service.

Main switch off or in hand tool

mode.

Faulty brush motor. Call for service.

Brush motor power is exceeding

the normal operating limit.

Brush motor does not have any

load.

Control board is overheating. Check function of control board cooling fan.

Brush motor has stalled. Remove brush and remove entanglement

Replace as necessary.

Replace or repair as necessary.

Turn off vac motor. Drain and rinse

recovery tank. Clean float screen.

Clean using a vinegar /water solution or

replace.

Turn main switch to machine mode.

Reduce brush motor load by adjusting deck

height to lower number setting with deck

height knob.

Check for worn brush.

Check for missing brush.

Check control board heat sink for debris.

Reduce brush motor load by adjusting deck

height to lower number setting with deck

height knob.

Remove all impediments from the path of

the machine.

Maintenance

86409500 Operator’s Manual - Armada BRC 40/22

31

Page 32

Maintenance

Troubleshooting

PROBLEM CAUSE SOLUTION

Machine stops working and

brush light blinks red 5 times

Machine stops working and

brush light blinks red 6 times

Machine stops working and

vacuum light blinks red 2 times

Machine stops working and

vacuum light blinks red 4 times

Allow brush motor to cool and reduce brush

Brush motor is overheating

Brush motor temperature sensor is

disconnected.

Brush motor is still cooling from

and overheat condition

Vacuum has stalled Check vacuum motor for debris.

Vacuum motor is working above

recommended range.

motor load by adjusting deck height to

lower number setting with deck height

knob.

Call for service.

Allow brush motor to cool and reduce brush

motor load by adjusting deck height to

lower number setting with deck height

knob.

Check vacuum motor for debris.

32

86409500 Operator’s Manual - Armada BRC 40/22

Page 33

86003630 FLOAT SHUT-OFF

86409460 STRAINER

86412780 JET MINI PROMAX (2)

86012550 JET PROMAX

86004570 JET BODY (3)

86411180 ROLLER BRUSH

86402850 GASKET, LID

86402570 RECOVERY DRAIN HOSE

86403040 SOLUTION HOSE

86414120 VACUUM MOTOR

86405260 PUMP

Suggested Spare Parts

86409500 Operator’s Manual - Armada BRC 40/22

33

Page 34

Page 35

Spare Parts List

(1.008-060.0)

Armada BRC 40-22

86409510-M 07/11/17

Page 36

How to Use this Spare Parts List

The PARTS LIST section contains assembled parts illustrations and corresponding parts list. The parts lists include

a number of columns of information:

• REF - column refers to the reference number on the parts illustration.

• PART NO. - column lists the part number for the part.

• QTY - column lists the quantity of the part used in that area of the machine.

• DESCRIPTION - column is a brief description of the part.

• SERIAL NO. FROM - If this column has an (*) and a Reference number, see the SERIAL NUMBERS page

in the back of your manual. If column has two asterisk (**), call manufacturer for serial number. The serial

number indicates the first machine the part number is applicable to. The main illustration shows the most

current design of the machine. When a boxed illustration is shown, it displays the older design.

• NOTES - column for information not noted by the other columns.

NOTE: If a service or option kit is installed on your machine, be sure to keep the KIT INSTRUCTIONS which

came with the kit. It contains replacement parts numbers needed for ordering future parts.

2 86409510 - Spare Parts List - Armada BRC 40-22

Page 37

How to Use this Spare Parts List . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Access Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Deck - Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Deck - Upper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Vacuum Shoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wiring 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table of Contents

86409510 - Spare Parts List - Armada BRC 40-22

3

Page 38

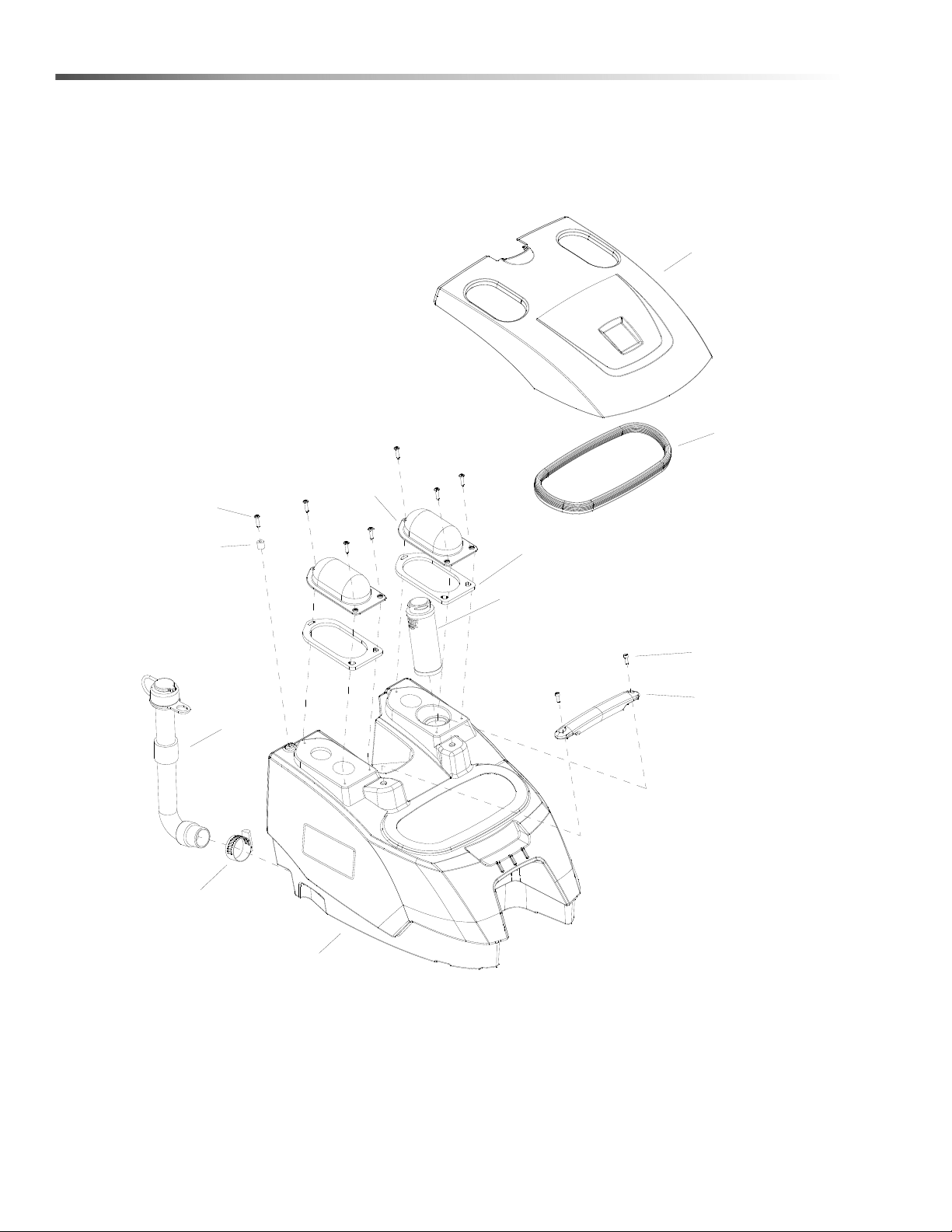

Access Cover

4

3

2

1

5

4

86409510 - Spare Parts List - Armada BRC 40-22

Page 39

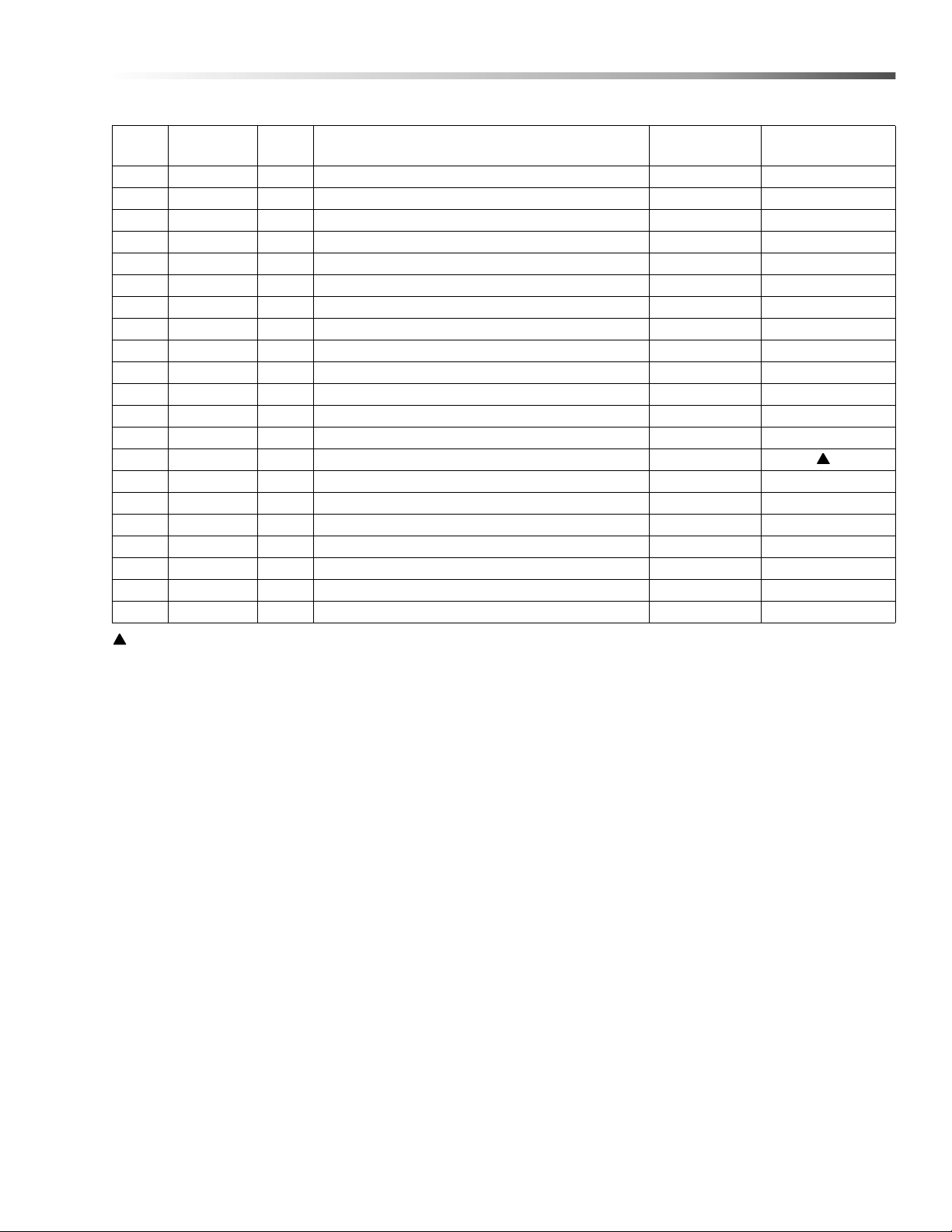

Access Cover

REF PART NO. QTY DESCRIPTION

1 86403350 4 SCREW, KA50X20 TSLTD SS BLK ZNPLT

2 86403000 1 CARGO NET

3 86397130 1 DOOR, COVER, TOWER

4 86379330 4 CLIP, X-MAS TREE, BLACK

5 86413120 1 GASKET, ACCESS PANEL

SERIAL NO.

FROM

NOTES

586409510 - Spare Parts List - Armada BRC 40-22

Page 40

Decals

4

3

2

3

1

6

86409510 - Spare Parts List - Armada BRC 40-22

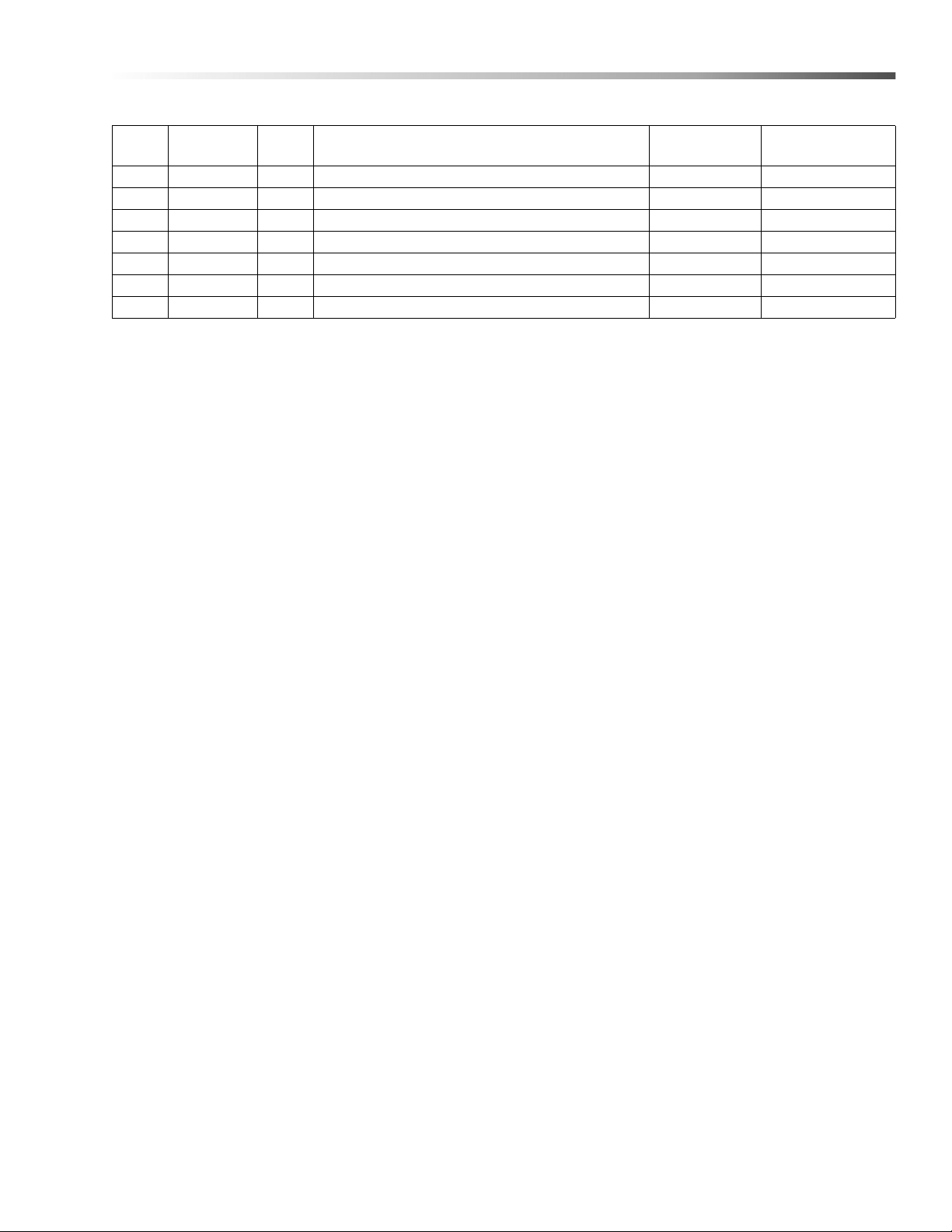

Page 41

Decals

REF PART NO. QTY DESCRIPTION

1 86402300 1 LABEL, ARMADA LIGHT PANEL

2 86403620 1 LABEL, LOGO

3 86402320 2 LABEL, ARMADA SIDE

4 86402310 1 LABEL ARMADA ROTARY SWITCH

SERIAL NO.

FROM

NOTES

786409510 - Spare Parts List - Armada BRC 40-22

Page 42

Deck

SEE DECK - LOWER

SEE DECK - UPPER

SEE VACUUM SHOE

11

1

2

3

4

5

6

7

8

9

10

TO LOWER STEERING PILLAR

8

86409510 - Spare Parts List - Armada BRC 40-22

Page 43

Deck

REF PART NO. QTY DESCRIPTION

1 86403350 2 SCREW, KA50X20 TSLTD SS BLK ZNPLT

2 86403340 2 SPRING, .085" X .072" X 4.0"

3 74019170 1 SPHERE 10,0 G100-1.4301 DIN 5401

4 73430190 1 LOCKING RING 45x1,75-FST-RF DIN 471

5 73122320 1

6 73110030 1 HEXAGON NUT M6 -8-A2E ISO 4032

7 50373030 1 SLIDE PART HEIGHT ADJUSTMENT

8 50372680 1 COVER REFRIGERATION MOTOR

9 50372630 1 SWEEP DRAWER

10 86411180 1 ROLLER BRUSH ARMADA COMPLETE

11 40370290 1 CARRIAGE COMPLETE

SERRATED LOCK WASHER A6,4-FSt-A3E

DIN 6

SERIAL NO.

FROM

NOTES

986409510 - Spare Parts List - Armada BRC 40-22

Page 44

Deck - Lower

1

3

4

5

20

9

10

11

12

13

14

15

16

17

18

8

7

2

2

2

2

2

2

6

19

10

86409510 - Spare Parts List - Armada BRC 40-22

Page 45

Deck - Lower

REF PART NO. QTY DESCRIPTION

1 86409470 2 ROLLER AXLE - M3X24 SS

2 86403350 14 SCREW, KA50X20 TSLTD SS BLK ZNPLT

3 86403210 1 PLATE, TOW PIVOT REINFORCEMENT

4 86402130 1 SPRAY SHIELD

5 86397180 1 LOWER DECK

6 86411250 1 MOTOR ASSY, 120VDC, 56HP

7 40370330 1 GEAR CASE REPLACEMENT

8 50370080 2 PLATE STOP

9 73122320 4

10 73060900 4 SCREW, M6x16 -8.8-R3R (In6Rd)

11 73030390 4 SCREW, M5x16 -St-A2R (In6Rd)

12 55152770 2 ROLLER

13 50373400 1 BAFFLE PLATE BRUSH HEAD

14 50373130 1 COUPLER

15 50372750 1 COVER GEAR CASE

16 50372620 4 DEFLECTOR ROLL

17 50372600 1

18 50372590 1 PLATE BRUSH HOLDER

19 63484800 1 TOOTHED BELT

20 86385340 1 FAN, BRUSH MOTOR

SERRATED LOCK WASHER, A6,4-FSt-A3E

DIN 6

SWIVEL JOINT SUCTION BEAM RETRACTION

SERIAL NO.

FROM

NOTES

INCLUDES

86385340

1186409510 - Spare Parts List - Armada BRC 40-22

Page 46

Deck - Upper

1

2

3

4

5

18

8

9

10

11

12

15

17

19

20

21

23

24

25

26

27

27

29

30

32

33

3

3

3

3

3

13

19

13

13

14

14

14

14

28

28

6

7

18

18

16

16

22

3

26

34

19

20

35

3

12

86409510 - Spare Parts List - Armada BRC 40-22

Page 47

Deck - Upper

REF PART NO. QTY DESCRIPTION

1 50372670 1 DECK PIVOT

2 86403640 1 STEM ADAPTER, JG 1/4" MPT X 1/4" STEM

3 86403350 27 SCREW, KA50X20 TSLTD SS BLK ZNPLT

4 86403200 2 HOSE, 1/4, 6 INCH

5 86403190 1 HOSE, 1/4, 13.5 INCH

6 86403180 1 HOSE, 1/4, 8 INCH

7 86403170 1 HOSE, 1/4, 9.5 INCH

8 86403160 1 HOSE, 1/4, 30 INCH

9 86403150 1 HOSE, 1/4, 23.5 INCH

10 86403140 1 NIPPLE BRACE

11 86403130 1 NIPPLE CLAMP HOLDER

12 86403120 1 SOLENOID PLATE

13 86403110 3 STEM ADAPTER, JG 1/8" MPT X 1/4" STEM

14 86400850 6 NOZZLE HOLDER

15 86397200 1 UPPER DECK

16 86379880 2 ELBOW, JG, 1/4

17 86373610 1 CONNECTOR, JG, 1/4 TUBE X 1/8 MNPT

18 86367170 3 TEE, UNION, JG, 1/4 TUBE

19 86424130 2 ASSEMBLY, SOLENOID, 120V FROM *(1)

- 86412480 2 ASSEMBLY, SOLENOID, 120V PRIOR TO *(1)

20 86270990 3 NUT, 10-32 HEX NYLOCK SS

21 86412780 2 JET, MINI PROMAX 8003

22 86198440 4 CLAMP, 1/4 PLASTIC CABLE

23 86173300 1 WASHER, M8 FLT SS ISO7098

24 86012550 1 JET, PROMAX, 11001

25 86353090 4 SCREW, 8-32 X 0.313 PHPNHMS SS

26 86005580 1 NIPPLE, 1/4 FPT QD

27 86004570 3 JET BODY, MINI PROMAX BODY

28 86002480 3 CONNECTOR, 1/8FPT X 1/4 TUBEQC

29 73433000 1 LOCK WASHER, 7-A2 DIN 6799

30 53322070 1 HELICAL SPRING

31 50373320 1 SPLASH GUARD BRUSH-HEAD

32 50373020 1 THREADED PART

33 50373010 1 BUTTON HEIGHT ADJUSTMENT

34 86385960 1 SPACER, ACCY NIPPLE

35 86417120 1 SOLUTION BRACKET ASSEMBLY

SERIAL NO.

FROM

NOTES

*See Serial Number Page

1386409510 - Spare Parts List - Armada BRC 40-22

Page 48

Electrical

14

86409510 - Spare Parts List - Armada BRC 40-22

Page 49

Electrical

REF PART NO. QTY DESCRIPTION

1 86409790 1 ROD, CORD HOLDER, PAINTED

2 86403350 4 SCREW, KA50X20 TSLTD SS BLK ZNPLT

3 53217380 1 HANDHOLD OPERATIONAL CONCEPT

4 86403090 1 POWER SUPPLY

5 86387520 1 ASSEMBLY, PCB, 120V, SERVICE

6 86234110 1 CORD SET,14/3 SJTW-A X 50' YLW

7 86354810 1 GASKET, ROTARY SWITCH

8 86354560 1 BEZEL, ROTARY SWITCH

9 86349400 2 SCREW, M4-.7 X 20 FLHMS SS

10 86274570 8 SCREW, 4-40 X .25 PHPNHMS STL ZNPLT

11 86005700 2 NUT, 10-32 HEXSTRW LK STL ZNPLT

12 66832700 1 SWITCH, EASY OPERATION

13 86423570 1 PLATE SWITCH SPACER

14 86234320 1 CORD ASM, 14/3 X 22" YLW

15 86198440 3 CLAMP, 1/4 PLASTIC CABLE

16 86173330 1 WASHER, M5 SS ISO7093

17 86005670 1 NUT, 1/2-14 CONDUIT LK STL ZNPLT

18 86002010 1 BOOT, 3/8 CIRCUIT BREAKER

19 86001730 1 BREAKER, 18A 250VAC, 50VDC

20 63130140 1 SPRING ELEMENT

21 66832710 1 SWITCH, EASY OPERATION

SERIAL NO.

FROM

NOTES

THIS PART SHOULD ONLY BE REPLACED BY A CERTIFIED TECHNICIAN.

1586409510 - Spare Parts List - Armada BRC 40-22

Page 50

Frame

1

2

3

4

5

6

7

16

86409510 - Spare Parts List - Armada BRC 40-22

Page 51

Frame

REF PART NO. QTY DESCRIPTION

1 86403350 4 SCREW, KA50X20 TSLTD SS BLK ZNPLT

2 86400680 1 AXLE, 5/8" OD

3 86226050 2 WHEEL, 9.75" X 1.5"

4 86219480 2 HUBCAP, 9.75" WHEEL

5 86010730 4 WASHER, 5/8 X .64 X 1.188 SS

6 86001660 2 HUBCAP, 5/8" SHAFT

7 50373090 2 FIXING AXLE

SERIAL NO.

FROM

NOTES

1786409510 - Spare Parts List - Armada BRC 40-22

Page 52

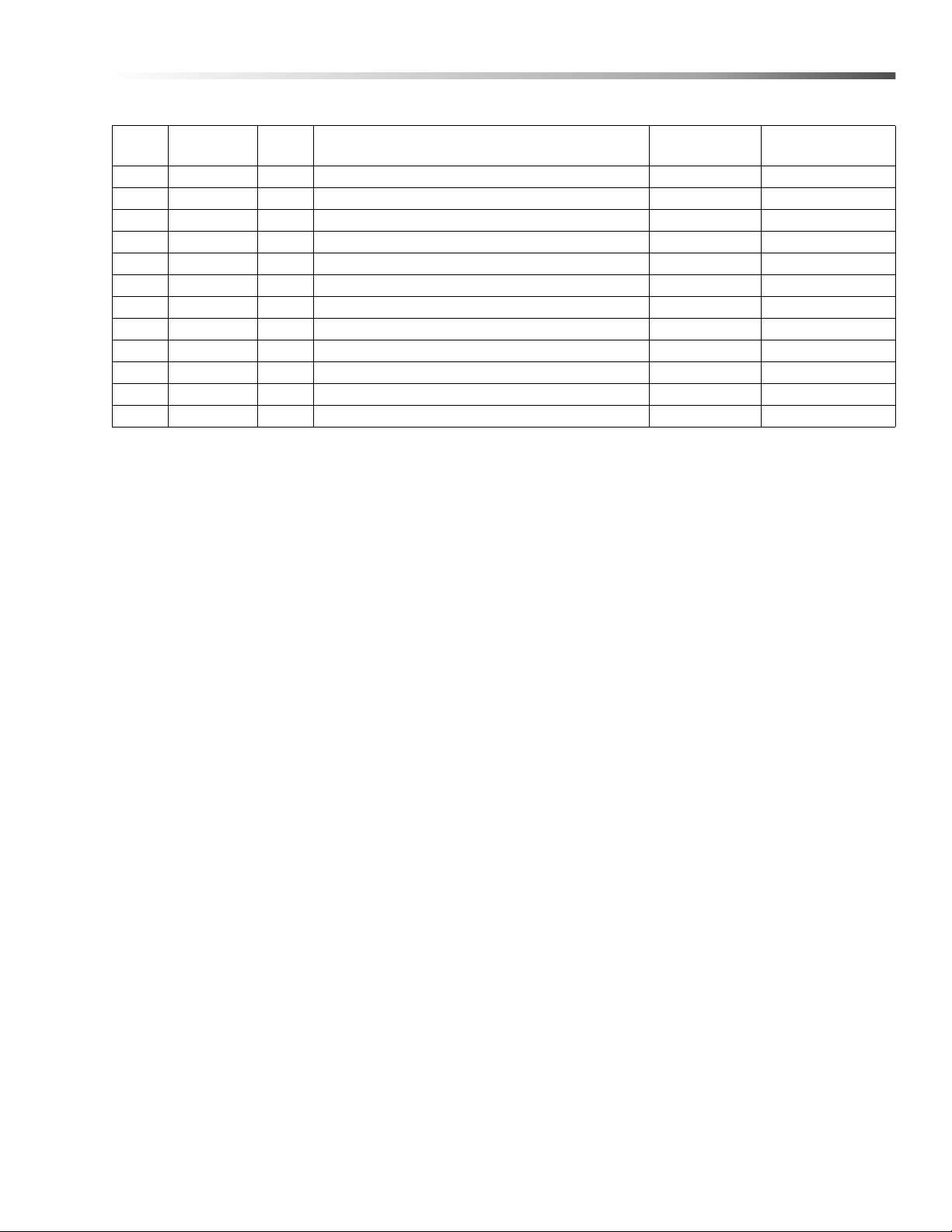

Recovery

1

2

3

4

5

6

7

8

9

10

11

12

18

86409510 - Spare Parts List - Armada BRC 40-22

Page 53

Recovery

REF PART NO. QTY DESCRIPTION

1 86403410 2 GASKET, DOME, .25" THICK

2 86403350 7 SCREW, KA50X20 TSLTD SS BLK ZNPLT

3 86402850 1 GASKET, LID, 28.75"

4 86402740 1 ARMADA RECOVERY TANK, TRIMMED

5 86402570 1 RECOVERY DRAIN HOSE, 12" LG

6 86397190 2 DOME, CLEAR, RECOVERY

7 86397140 1 LID, DOME, RECOVERY

8 86278390 1 SPACER, 1/2"ODX.219IDX1/2"NYLO

9 86273540 2 SCREW, 10-32 X .5 SCHCS SS

10 86218530 1 HANDLE, RECOVERY TANK

11 86177050 1 CLAMP, HOSE #20

12 86003630 1 FLOAT SHUT-OFF

SERIAL NO.

FROM

NOTES

1986409510 - Spare Parts List - Armada BRC 40-22

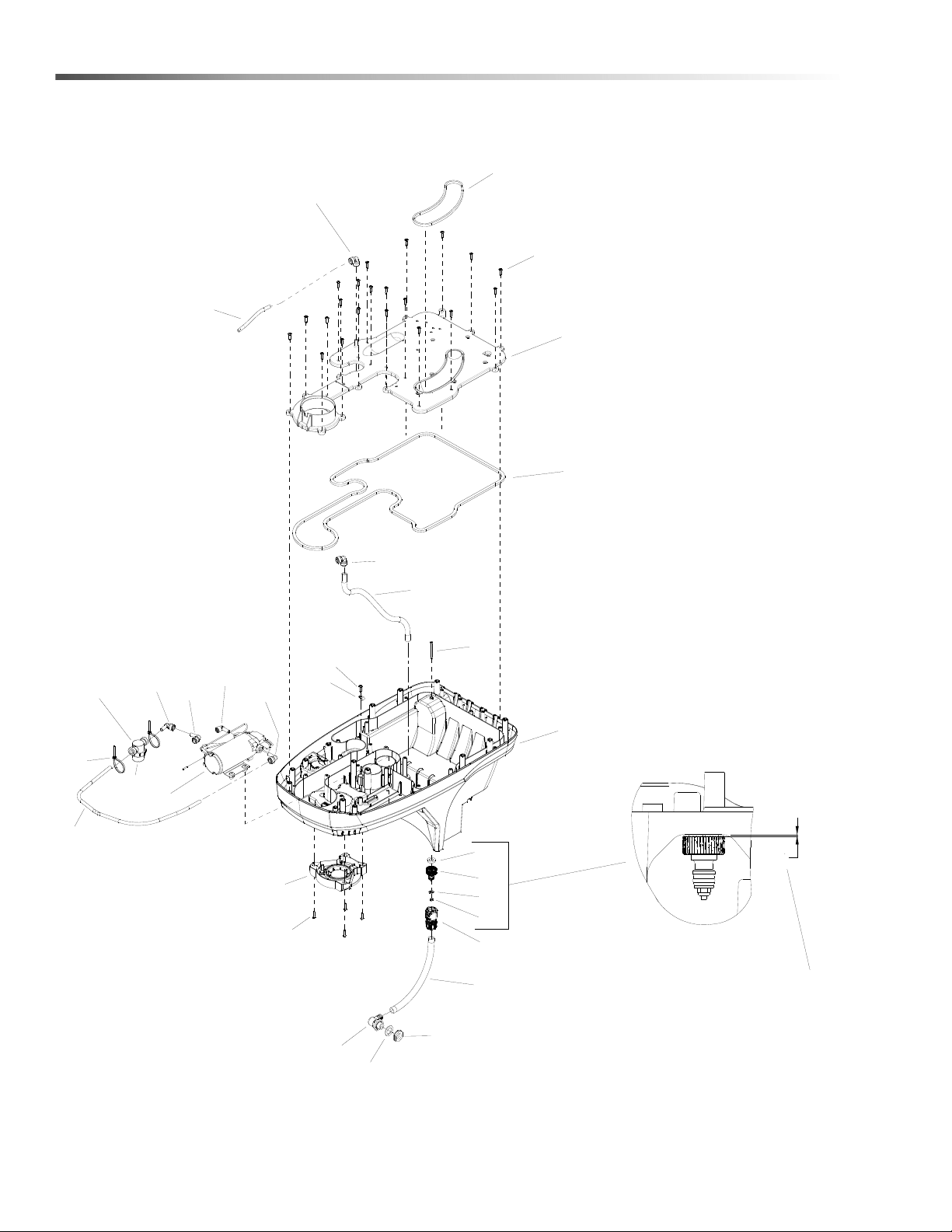

Page 54

Solution

22

2

28

8

6

7

1

9

10

13

14

15

16

17

18

20

21

14

19

24

12

11

5

3

16

16

9

23

4

.05

LEAVE .05 GAP WHEN TIGHTENING

9

25

26

27

9

29

20

86409510 - Spare Parts List - Armada BRC 40-22

Page 55

Solution

REF PART NO. QTY DESCRIPTION

1 86412830 1 SCREW, 8-32 X 2.25 PHPNHMS SS

2 86424140 1 PUMP ASSEMBLY FROM *(1)

- 86405260 1 PUMP ASSEMBLY PRIOR TO *(1)

3 26451910 1 HOSE COUPLING ENTRY UNIVERSAL

4 86270850 1 NUT, 8-32 HEX NYLOCK SS

5 50372850 1 BEARING - BRUSH HEAD

6 86403390 1 HOSE, 3/8" OD, 17" LENGTH

7 86403380 1 HOSE, 3/8" OD, 27" LENGTH

8 86412820 1 WASHER, .18 X .60 FLT SS

9 86403350 27 SCREW, KA50X20 TSLTD SS BLK ZNPLT

10 86403040 1 HOSE, 9/16"ID X 3/4"OD, 10.375" L

11 55152530 1 SEAL D34

12 63100040 1 HEXAGON NUT G 1/2”

13 86397100 1 TANK, SOLUTION BASE

14 86367640 2 ELBOW, UNION, JG, 3/8 TUBE

15 86367130 1 ELBOW, JG, 3/8 STEM X 1/4 TUBE

16 86367120 3 ELBOW, JG, 3/8 STEM X 3/8 TUBE

17 86417260 1 FIELD KIT, SOLUTION TANK LID ASSY

18 86415310 1 ASSEMBLY, SUCTION TUBE

19 86394080 1 WASHER, .500 X 1 X .188 NPRN

20 86264940 2 CABLE TIE, 11.38" UL/CSA

21 86198440 1 CLAMP, 1/4 PLASTIC CABLE

22 86409460 1 STRAINER, ASSEMBLY

23 64650310 1 CONNECTION 3/4

24 63951630 1 ANGLE BUSHING G1-2

25 86313160 - CAP, STRAINER SHORT

26 86005870 - O-RING SEAL FILTER SEAL RON-VIK

27 86313580 - SCREEN, 60 MESH STRAINER SHORT

28 86405250 1 GASKET, .25 X .36 X 101

29 86360270 1 GASKET, .188 X .31 X 22.8

SERIAL NO.

FROM

NOTES

•

PART OF

86409460

PART OF

86409460

PART OF

86409460

PART OF

86417260

PART OF

86417260

WHEN INSTALLING 64650310 CONNECTION 3/4, DISCARD WASHER GASKET AND REPLACE WITH

86394080 WASHER GASKET.

• WHEN REMOVING SOLUTION TANK LID, DO NOT REUSE 86405250 GASKET.

* SEE SERIAL NUMBER PAGE

2186409510 - Spare Parts List - Armada BRC 40-22

Page 56

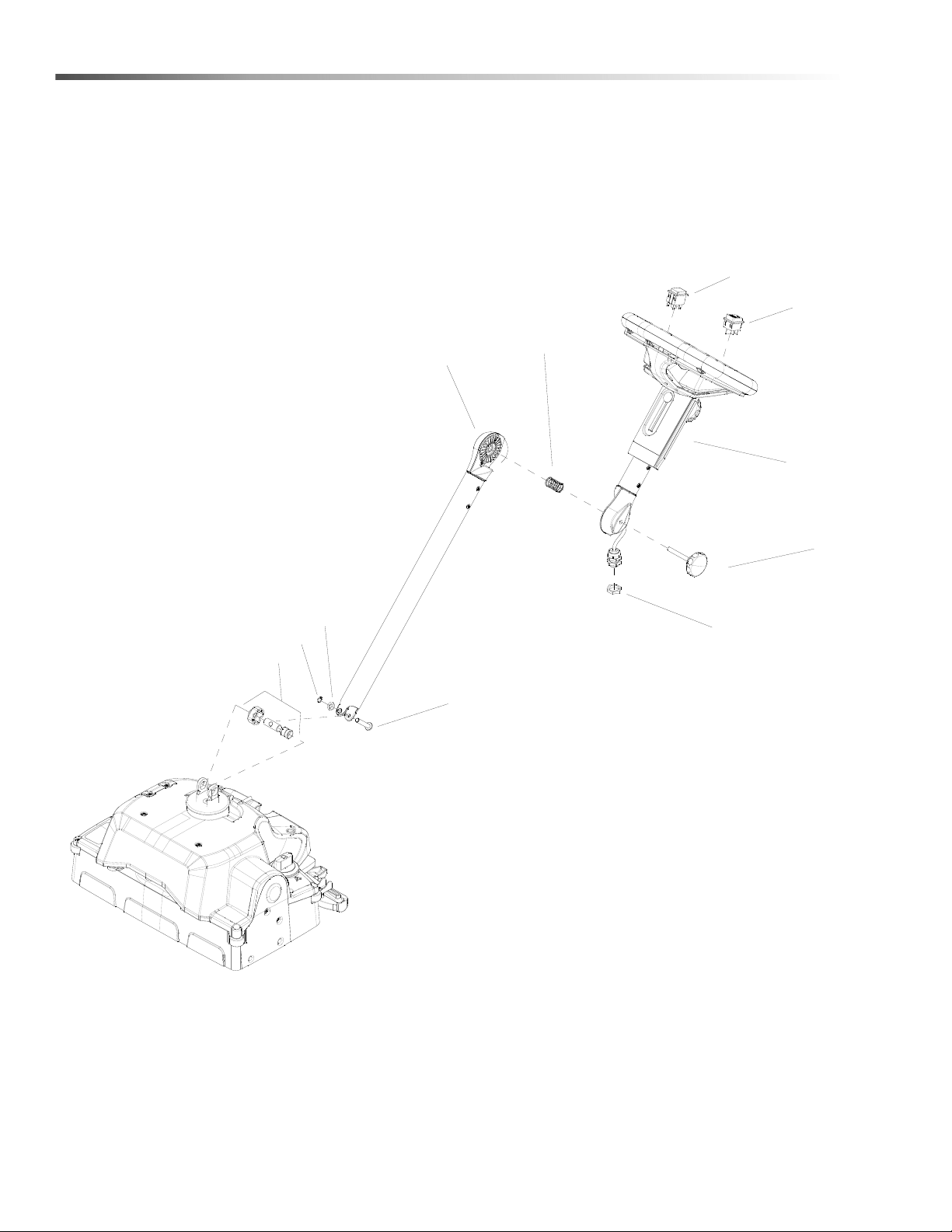

Steering

1

3

2

4

5

6

7

8

9

10

11

22

86409510 - Spare Parts List - Armada BRC 40-22

Page 57

Steering

REF PART NO. QTY DESCRIPTION

1 86404710 1 LOWER STEERING PILLAR

2 86403430 1 UPPER STEERING PILLAR

3 86403520 1 SWITCH, ROCKER, MARQUARDT 1661.0101

4 86173300 1 WASHER, M8 FLT SS ISO7098

5 73430140 1 LOCKING RING, 8 x0,8-FST-PHR DIN 471

6 63211790 1 STAR GRIP

7 53329810 1 PRESSURE SPRING

8 50373180 1 BOLT STEERING PILLAR

9 40370040 1 BEARING SET

10 66484160 1 LOCKNUT BLACK M20

11 66325420 1 SWITCH, PUMP

SERIAL NO.

FROM

NOTES

2386409510 - Spare Parts List - Armada BRC 40-22

Page 58

Tower

17

1

3

2

4

5

6

7

8

9

10

11

13

12

14

15

16

TO VACUUM SHOE

24

86409510 - Spare Parts List - Armada BRC 40-22

Page 59

Tower

REF PART NO. QTY DESCRIPTION

1 86404440 1 GROMMET, 5/16” ID X 1/8” GROOVE

2 86403350 18 SCREW, KA50X20 TSLTD SS BLK ZNPLT

3 86403060 1 HOSE ASM, 1.5" X 16" LENGTH

4 86399970 2 GASKET, PUMP, W/ ADHESIVE

5 86398260 1 COVER, PUMP, SOLUTION

6 86397770 1 SEAL, RECOVERY LIP

7 86397760 1 TUBE, RECOVERY

8 86397120 1 TOWER, SOLUTION

9 86349400 2 SCREW, M4-.7 X 20 FLHMS SS

10 86279080 2 WASHER, M4 FLT STL DIN125A ZNPLT

11 86177050 1 CLAMP, HOSE #20

12 86172630 2 NUT, M4X.7 LK ISO7040 SS

13 73030860 8 SCREW, 5 X 30 -10.9-R2R (K-In6Rd)

14 50503590 1 COVER METERING, FRESH WATER

15 50373490 2 HOSE HANGER

16 50372890 4 HALF SHELL BEARING OPERATING UNIT

17 86413200 1 SEAL, VAC TUBE

SERIAL NO.

FROM

NOTES

2586409510 - Spare Parts List - Armada BRC 40-22

Page 60

Vacuum

2

6

3

1

5

4

10

8

12

11

7

9

26

86409510 - Spare Parts List - Armada BRC 40-22

Page 61

Vacuum

REF PART NO. QTY DESCRIPTION

1 86414120 1 ASSEMBLY, VACUUM 120V

2 86403510 1 HOSE, 2" ID X 14" LENGTH

3 86403500 1 HOSE, 2" ID X 11" LENGTH

4 86403480 1 SCREW, M6X1.00X90 HHCS DIN 931 ZNPLT

5 86403470 4

6 86403350 6 SCREW, KA50X20 TSLTD SS BLK ZNPLT

7 86397770 1 SEAL, RECOVERY LIP

8 86397730 1 VAC HOUSING, LOWER

9 86002380 2 CLAMP, 2.25" WORM GEAR

10 86360270 1 GASKET, .188 X .31 X 22.8

11 86173310 5 WASHER, M6 SPL SS DIN127B

12 86013850 5 WASHER, M6 FNDR SS ISO7093

SCREW, M6 X 1.00 X 25 HHCS DIN 933

ZNPLT

SERIAL NO.

FROM

NOTES

2786409510 - Spare Parts List - Armada BRC 40-22

Page 62

Vacuum Shoe

1

9

3

5

7

2

4

6

6

8

10

28

86409510 - Spare Parts List - Armada BRC 40-22

Page 63

Vacuum Shoe

REF PART NO. QTY DESCRIPTION

1 86397230 1 LINKAGE, VACUUM SHOE

2 86275080 2 SCREW, 10-32 X .75 SCHCS SS

3 86397210 1 COVER, VACUUM SHOE

4 86270990 2 NUT, 10-32 HEX NYLOCK SS

5 86371770 1 O-RING, 3/16 DIA X 9.5 DIA FOAM

6 86173330 8 WASHER, M5 SS ISO7093

7 86340850 2 CLIP, DEBRIS TRAY SPRING

8 86385390 1 VAC SHOE ALIGNMENT BRACKET

9 86412470 1 ASSEMBLY, VACUUM SHOE, BRC 40/22

10 86387810 2 CABLE W/STOPS, 5.5IN

SERIAL NO.

FROM

NOTES

2986409510 - Spare Parts List - Armada BRC 40-22

Page 64

Flow Diagram

(86002480) (3)

(86004570) (3)

(86412780) (2)

(86012550)

(86403110) (3)

(86403360)

(86005580)

(86403640)

(86379880) (2)

(86367170) (3)

(86373610)

(86367130)

(86367640)

SOLUTION PLATE

STRAINER

(86367120) (3)

(86403390 YELLOW)

FLOW DIRECTION

(86403180 YELLOW)

(86403170 GREEN)

(86403160 BLACK)

(86403190 BLUE)

(86403200 GREY)

(86403200 GREY)

SOLENOID (2)

(86403380 BLACK)

(86403380 BLACK)

PUMP

(86403150 RED)

(86367640)

30

86409510 - Spare Parts List - Armada BRC 40-22

Page 65

Notes

3186409510 - Spare Parts List - Armada BRC 40-22

Page 66

Wiring 1

ROTARY PWR

4

3

1

2

32

86409510 - Spare Parts List - Armada BRC 40-22

Page 67

Wiring 1

REF PART NO. QTY DESCRIPTION

1 86424120 1 HARNESS, MAIN *(1) ▲

2 86267400 1 WIRE, 22" GRN/18 76011 X 76011

3 86405680 1 HARNESS, MOTOR *(1)

4 86267090 1 WIRE, 11" GRN/18 76008 X 76014 *(1)

▲ IF REPLACING IN SERIAL NUMBER PRIOR TO SERIAL NUMBER *(1) ALSO ORDER: 8.641-703.0,

2X 8.642-413.0, & 8.642-414.0

SERIAL NO.

FROM

NOTES

3386409510 - Spare Parts List - Armada BRC 40-22

Page 68

Wiring 2

1

2

34

86409510 - Spare Parts List - Armada BRC 40-22

Page 69

Wiring 2

REF PART NO. QTY DESCRIPTION

1 86417030 1 HARNESS, DECK *(1) ▲

2 86405190 1 HARNESS, THERMISTER, 12"

▲ IF REPLACING IN SERIAL NUMBER PRIOR TO SERIAL NUMBER *(1) ALSO ORDER: 8.642-412.0,

2X 8.642-413.0, & 8.642-414.0

SERIAL NO.

FROM

NOTES

3586409510 - Spare Parts List - Armada BRC 40-22

Page 70

Wiring 3

36

86409510 - Spare Parts List - Armada BRC 40-22

Page 71

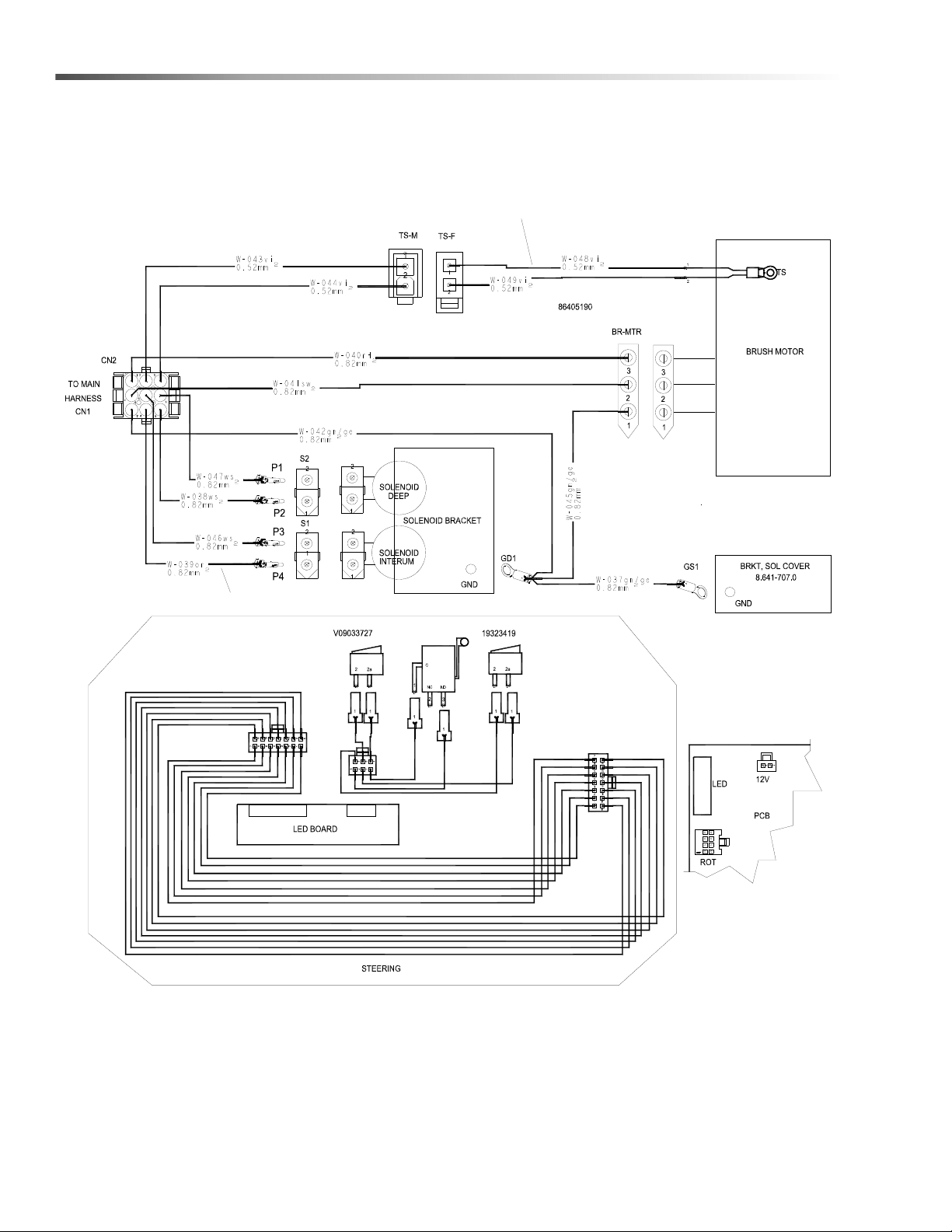

REF DESCRIPTION

A0 CPU MODULE

A1 TCU

A10 POWER SUPPLY

M2 BRUSH MOTOR

M4 VACUUM MOTOR

M6 PUMP MOTOR

Y4 SOLENOID

Y5 SOLENOID

S2 ROTARY SWITCH

S3 FWR/REV SWITCH

S4 WATER SWITCH

S5 TRIGGER

T1 TEMP MONITOR

H1 LED GN POWER

H2 LED GN/RT VAC

H3 LED GN/RT BRUSH

H4 LED GN/RT WATER

H5 LED BL ECO

U1 MAINS CONNECTION, 120V / 60HZ/15A

F1 IN-LINE FUSE

Wiring 3

3786409510 - Spare Parts List - Armada BRC 40-22

Page 72

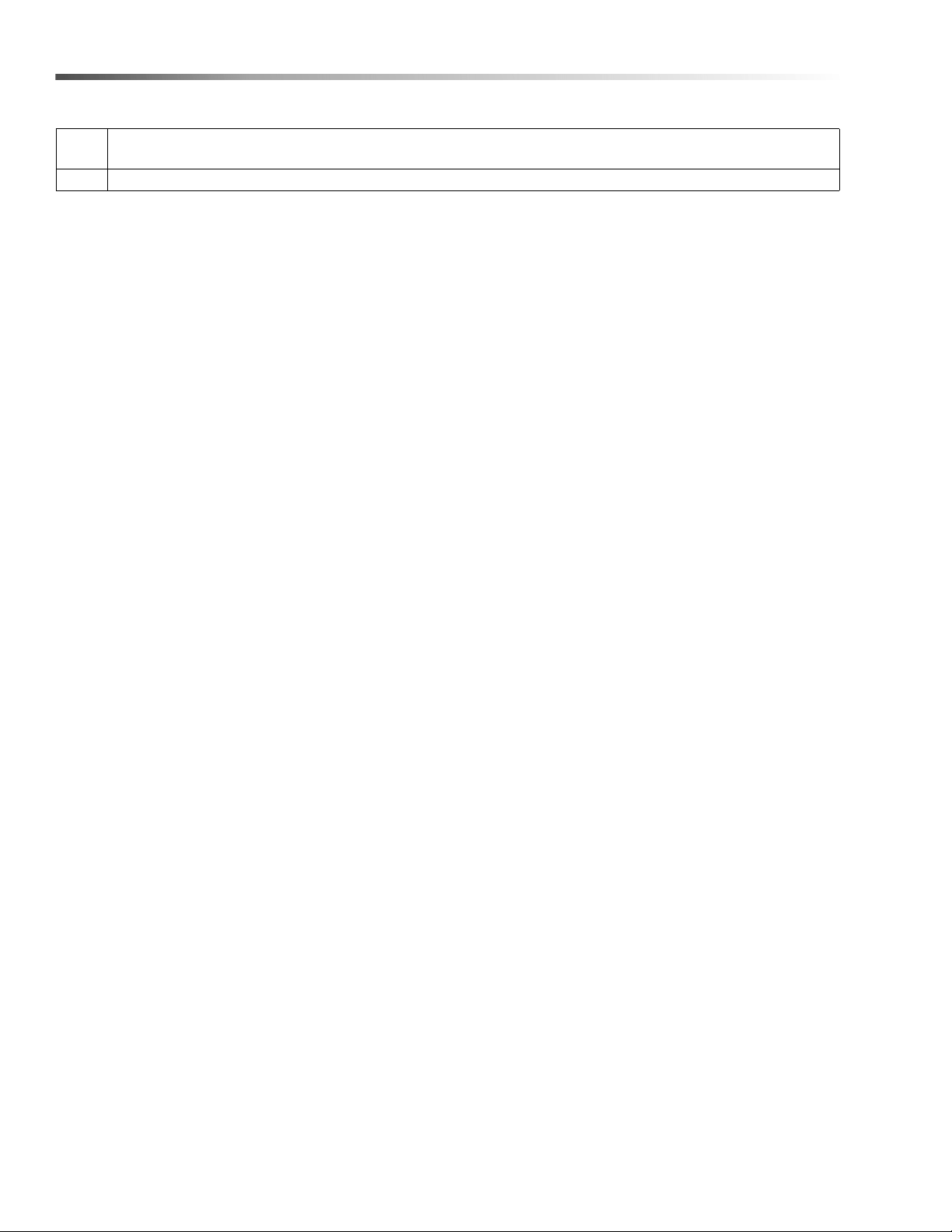

Serial Number

REF.

NO.

1 10080060001130

MODEL: SERIAL #

38

86409510 - Spare Parts List - Armada BRC 40-22

Page 73

39

Loading...

Loading...