Window Master WSC 320, WSC 310 Installation Instructions Manual

UK

+44 (0) 1536 614 070

Info.uk@windowmaster.com

Other markets

+45 4567 0300

Info.dk@windowmaster.com

www.windowmaster.com

WSC 3xx STANDARD install 1809-Firmware v132 - UK ©WindowMaster 2015, 2018 ®WindowMaster is a registred trademark used under the license by WindowMaster Group

WindowMaster International A/S, Skelstedet 13, DK-2950 Vedbæk

WSC 310 & WSC 320

Standard versions

Installation instruction

CompactSmoke™

(Version 1809 – from firmware version 1.32 (main card))

Save this installation instruction to the end user

2

1 Safety information ........................................................................................................................................................ 3

1.1 Safety ................................................................................................................................................................ 3

1.2 230V AC ............................................................................................................................................................ 3

1.3 Back-up batteries .............................................................................................................................................. 3

1.4 Application ......................................................................................................................................................... 3

1.5 Cable routing and electrical connection ............................................................................................................. 3

2 Structure of the smoke panel ...................................................................................................................................... 4

3 Variants of panels ........................................................................................................................................................ 5

3.1 Max numbers of actuators per motor line and panel

............................................................................................. 5

4 Accessories and spare parts ...................................................................................................................................... 7

5 Technical data .............................................................................................................................................................. 7

6 Mounting ....................................................................................................................................................................... 9

7 Installation .................................................................................................................................................................... 9

7.1 Cable routing ..................................................................................................................................................... 9

7.2 Cables into housing ........................................................................................................................................... 9

7.3 Connection of safety earth wire and 230V AC ................................................................................................... 9

7.4 Installation of the break glass unit, ventilation keypad and smoke detector ...................................................... 9

7.5 Assembly instructions .......................................................................................................................................10

8 Cable dimensioning ................................................................................................................................................... 10

8.1 Maintaining the cable functions ........................................................................................................................10

8.2 Max. cable Length ............................................................................................................................................10

8.2.1 Formula for the calculation of the maximum actuator cable length ............................................................. 10

8.2.2 Max cable length – ±24V standard actuators .............................................................................................. 11

8.2.3 Max cable length – actuators with MotorLink® ............................................................................................. 11

9 Cable plan for connection to WSC 310 / 320 Standard version ............................................................................. 12

10 Description of cards and mains connection ............................................................................................................ 13

10.1 WSC 310 mains connection and power supply (WCA 3P1) .............................................................................13

10.2 WSC 320 mains connection and power supply (WCA 3P2) .............................................................................13

10.3 Main control card WCA 3SS – Standard Version .............................................................................................14

11 DIP switch configuration ........................................................................................................................................... 20

12 Back-up batteries ....................................................................................................................................................... 21

13 Configuration of panel ............................................................................................................................................... 21

13.1 Motor lines – motor groups – smoke zones ......................................................................................................21

13.1.1 Assigned components per smoke zone ....................................................................................................... 22

13.1.2 Examples with motor lines / motor groups / smoke zones ........................................................................... 22

13.1.3 Motor line .................................................................................................................................................... 22

13.1.4 Smoke zone ................................................................................................................................................ 22

13.1.5 Local input ................................................................................................................................................... 23

13.1.6 Local output ................................................................................................................................................. 23

14 Fault detection via LED.............................................................................................................................................. 23

14.1 Fault detection on the smoke panel..................................................................................................................23

14.2 Fault indication on break glass unit ..................................................................................................................25

15 Hardware error ........................................................................................................................................................... 25

15.1 Error on the Power supply ................................................................................................................................25

15.1.1 Blown fuse – 20A fast .................................................................................................................................. 25

16 Commissioning and test run ..................................................................................................................................... 25

16.1 The control ventilation panel is completely installed, without the operating voltage applied .............................26

16.2 With mains voltage, without accumulator .........................................................................................................26

16.3 With mains voltage, with accumulator ..............................................................................................................26

16.4 Ventilation keypad ............................................................................................................................................26

16.5 Break glass unit WSK 50x ................................................................................................................................26

16.6 Smoke detectors ..............................................................................................................................................26

16.7 Emergency power supply test ..........................................................................................................................26

16.8 Wind/rain detector ............................................................................................................................................26

17 Maintenance ............................................................................................................................................................... 27

17.1 Maintenance agreements .................................................................................................................................27

17.2 Replacement 3SS card ....................................................................................................................................27

18 Declaration of Conformity and Declaration of Perfomance.................................................................................... 27

3

1 Safety information

1.1 Safety

Only allow correspondingly trained, qualified and skilled personnel to carry out installation work.

Reliable operation and the avoidance of damage and hazards are only guaranteed if installation and settings are carried out

carefully in accordance with these instructions.

There may be personal danger by electrically operated windows:

- the forces occurring in the automatic mode can be such that parts of the body could get crushed

- when opened, actuators (spindles) could protrude into the room

For this reason, measures have to be taken prior to starting up the actuators, which exclude the danger of injury.

For safety reasons we recommend to install opening restrictors on bottom-hung windows.

In the event that windows are subjected to rain and/or high wind loads, we recommend connecting a wind/rain sensor to the

smoke ventilation panel for the automatically closing of the windows.

The smoke ventilation panel is to be located in a safe place, protected from the effects of fire and smoke.

The smoke ventilation panel is to be surface mounted.

The smoke ventilation panel has two energy suppliers: 230V AC and back-up batteries.

The manufacturer does not assume any liability for possible damage resulting from inappropriate use.

1.2 230V AC

230V AC can cause death, severe injury or considerable damage to assets.

The connection of the smoke ventilation panel is reserved for qualified personnel.

Disconnect all poles of the panel from the supply voltage prior to opening, installation or assembling.

Installation and use according to the national regulations.

1.3 Back-up batteries

Back-up batteries 2 batteries per panel can cause severe injury or considerable damage to assets.

The connection of the smoke ventilation panel is reserved for qualified personnel.

Disconnect all poles of the panel from the back-up batteries prior to installation or assembling.

Ensure that the mains cable can be switched via an external or customer-supplied two-pole switch element or a switch element

controlling all poles – see section 7.1 “Cable routing”

Installation and use according to the National regulations.

Dispose of used batteries according to the National regulation.

CAUTION

RISK OF EXPLOSION IF BATTERIES ARE REPLACED BY AN INCORRECT TYPE.

1.4 Application

The smoke ventilation panel is exclusively designed for the automatic opening and closing of smoke extraction systems,

windows, flaps or doors.

Always check that your system meets the valid national regulations.

Pay particular attention to the opening cross section, the opening time and opening speed.

The cable cross sections depend on the cable length and current consumption (amperage).

1.5 Cable routing and electrical connection

Fuse the 230V AC power supply cable separately on site.

Cable routing and connection - adhere to national regulations.

Establish the cable types, if necessary, with the local approval bodies or the fire protection authority.

Do not conceal flexible cables.

Junction box must be accessible for maintenance purposes.

Disconnect all poles of the mains voltage and the back-up batteries prior to starting maintenance work or making changes to the

system.

Secure the system to prevent unintentional switching on again.

Route all low voltage cables (24V DC) separate from the power current cables.

Design cable types, lengths and cross sections in accordance with the technical information.

Cable specifications is a guide only, the overall responsibility resides with the electrical contractor on site.

Installation must be in accordance with the national electrical regulations.

4

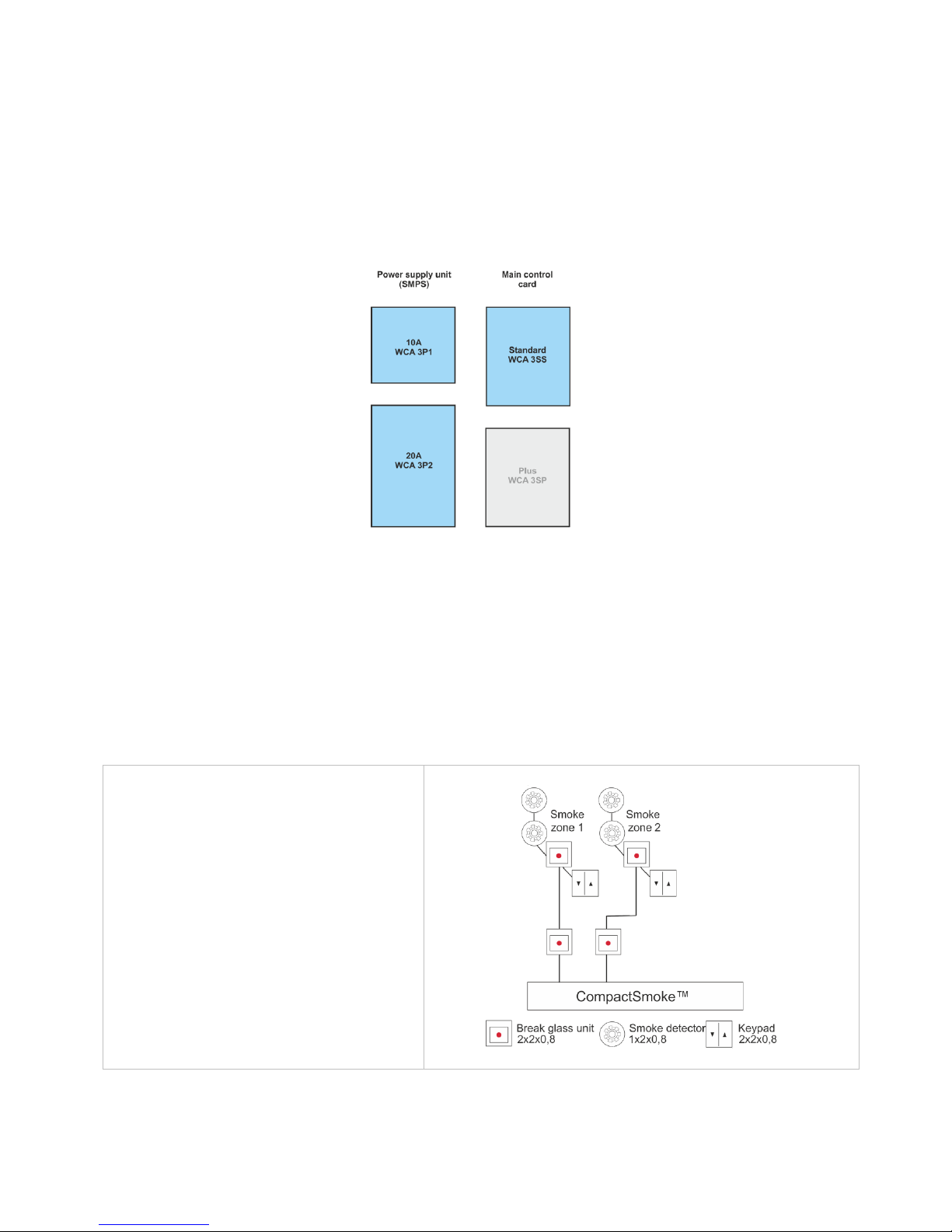

2 Structure of the smoke panel

Sizes & Versions

The WSC 310 and WSC 320 smoke ventilation panels are available in two different versions namely a Standard and a Plus

version. This installation instruction only deals with the Standard versions. Please see separate installation instruction for the

Plus versions of WSC 310 and WSC 320.

Cards

Each panel contains a power supply unit (SMPS), either a WCA 3P1 or a WCA 3P2 for the 10A or 20A version respectively.

Aside from the power supply unit the Standard version also includes a main control card type WCA 3SS.

If additional motor lines, inputs or fieldbus connection is required a Plus version of the panel is necessary.

The Main control card type WCA 3SS allows connections of 2 motor lines and 2 keypads.

Motor groups and motor lines

A motor group consists of one or more motor lines and all the motor lines are operated simultaneously.

Both motor lines on the main control card (WCA 3SS) can be configured for either a ±24V standard actuators or MotorLink®

actuators. A motor group can contain motor lines with both ±24V standard actuators and MotorLink® actuators, whereas a motor

line only can have ±24V standard or MotorLink® actuators connected.

Break glass unit

Break glass unit type WSK 50x are to be used together with WSC 310/320. The number of smoke zones is determined by the

number of inputs to which break glass units are connected. On the Standard version max 2 smoke zones are possible.

Inputs

Cabling

The WSC 3xx CompactSmoke™ uses bus

technology and the overall cabling for break

glass units, smoke detectors and keypads is

significantly reduced compared to other types of

smoke panels.

The main control card has 1 input for a smoke

detector, 2 inputs for break glass units (where

up to 10 break glass units can be connected)

and 2 inputs for ventilation keypads (no max

number of keypads).

Smoke detectors are either connected to the

smoke detector input or to a break glass unit

(type WSK 501 / 502).

The panel can have up to 2 smoke zones and 2

motor groups.

5

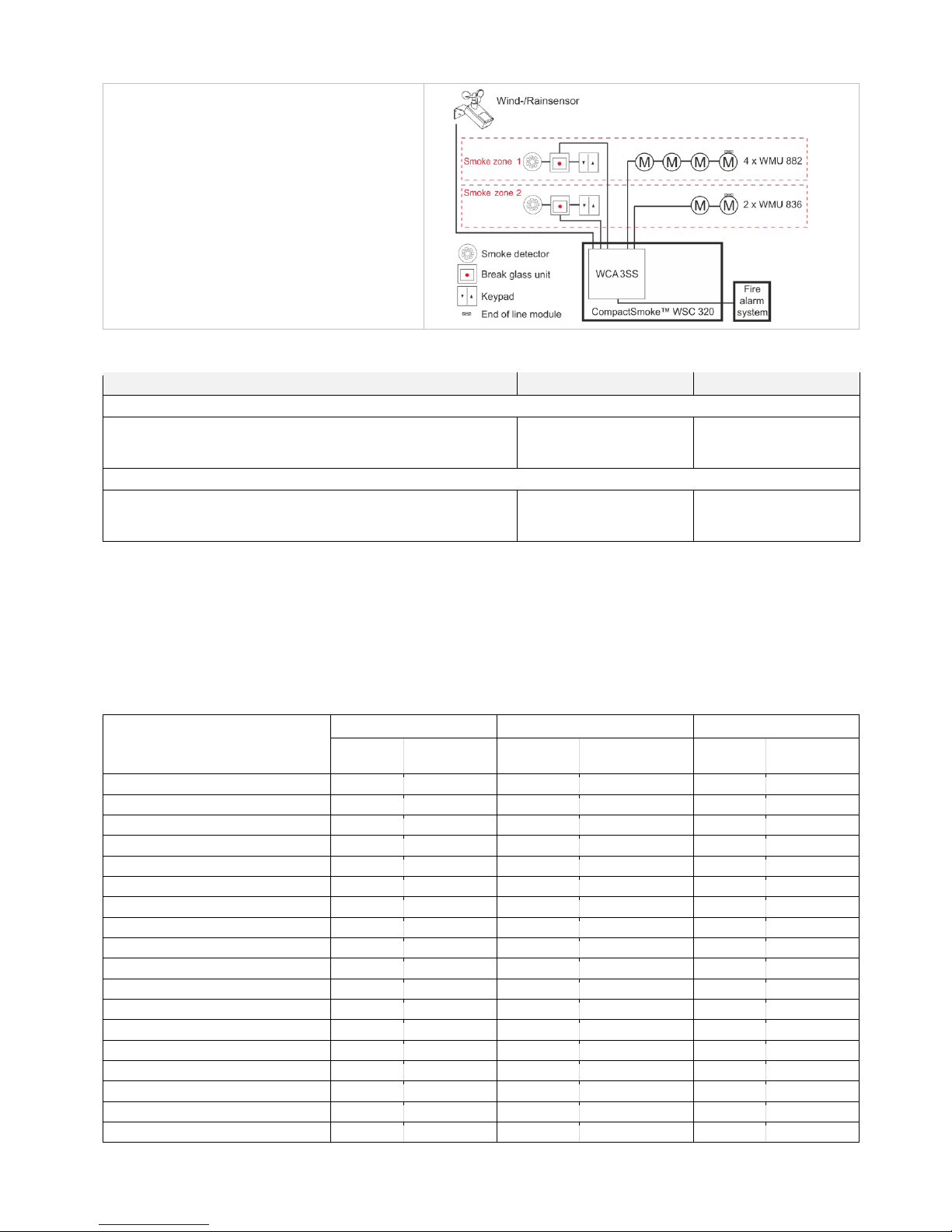

System example with

WSC 320

Smoke ventilation panel (20A) with 2 smoke

zones.

The keypads and smoke detectors are cabled

directly to the break glass units in the smoke

zones, which means that the need for cabling in

the building is significantly reduced.

A wind/rain sensor is connected to close the

windows during comfort ventilation in case of

high wind and/or rain.

The smoke ventilation panel is connected to the

Fire Alarm System via the WCA 3SS card.

3 Variants of panels

Number of motor lines and other functions

Cards

Item number

WSC 310

Standard version

2 motor lines

2 keypads / inputs

No cards

WSC 310 S 0202 E1

WSC 320

Standard version

2 motor lines

2 keypads / inputs

No cards

WSC 320 S 0202 E1

The standard version of the panels have 16 DIP switches for easy configuration of the panel, see section 11 for further

information.

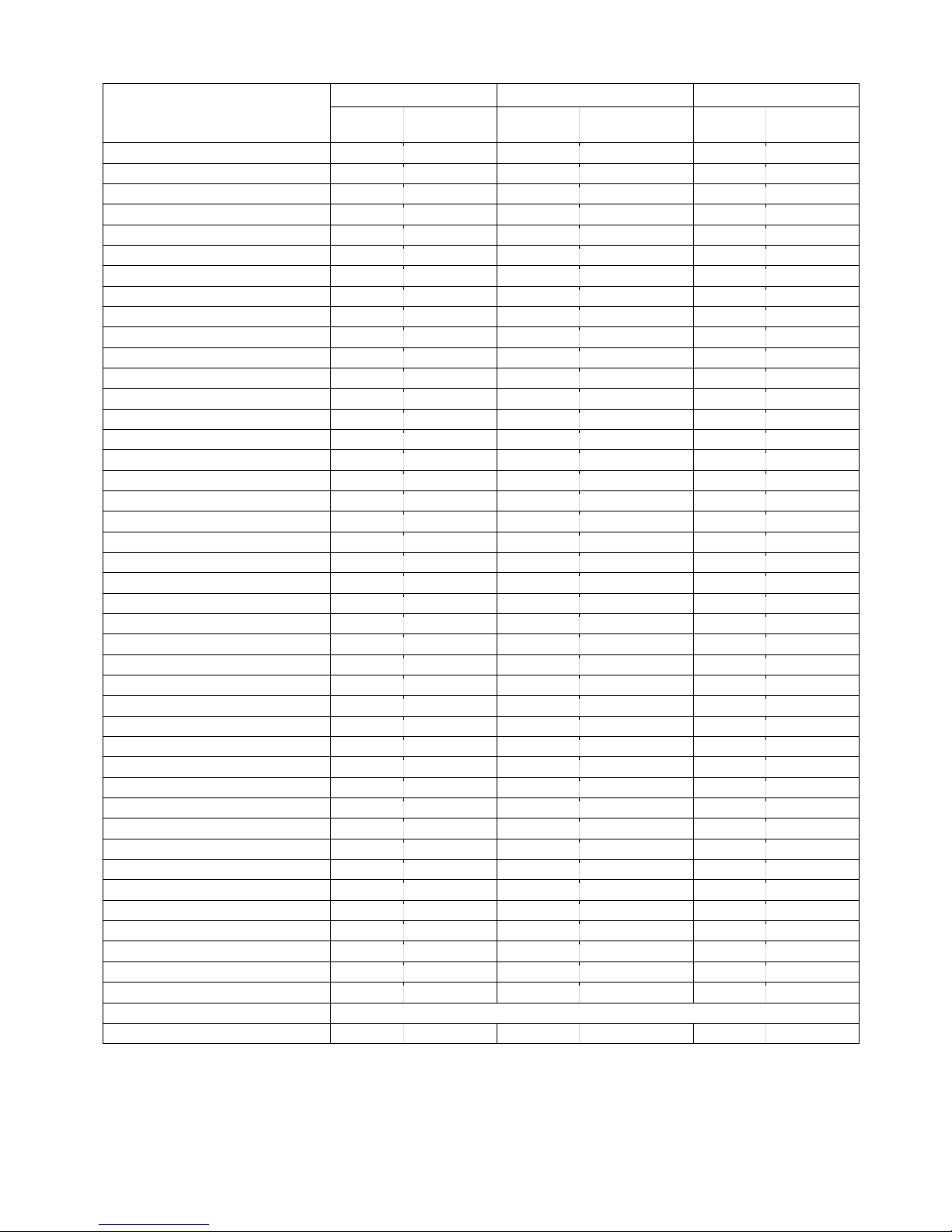

3.1 Max numbers of actuators per motor line and panel

The table shows the maximum number of actuators, which can be connected per motor line and panel depending on the type of the

actuators, panel and connected cards. The total power consumption of all the connected actuators must not exceed 10A or 20A

depending on panel size.

WSC 320 with 20A includes up to two motor lines each with 10A. If there is a need of more than 10A on one motor line, DIP switch

2.6 is set to 20A. Hereafter one motor line can be loaded with 20A or two motor lines can loaded up to a total of 20A e.g. 17A and

3A.

Per Motor line

Per 10A Panel

Per 20A Panel

± 24V

Actuator

MotorLink®

Actuator

± 24V

Actuator

MotorLink®

Actuator

± 24V

Actuator

MotorLink®

Actuator

WMS 306-1

10 4 10 8 20

8

WMS 306-2

10 2 10 4 20

4

WMS 306-3 9 3 9 6

18

6

WMS 306-4 8 4 8 8

20

8

WMS 309-1

10 4 10 8 20

8

WMS 309-2

10 2 10 4 20

4

WMS 309-3 9 3 9 6

18

6

WMS 309-4 8 4 8 8

20

8

WMS 409 xxxx 01

5 0 5 0 10

0

WMS 409-1 5 4 5 4

10

8

WMS 409-2 4 2 4 4 8 4

WMS 409-3 3 3 3 3 9 6

WMS 409-4 4 4 4 4 8 8

WMS 515 2 0 2 0 4 0

WMU 836-1

10 4 10 8 20

8

WMU 836-2

10 2 10 4 20

4

WMU 836-3 9 3 9 6

18

6

WMU 836-4 8 4 8 8

20

8

6

Per Motor line

Per 10A Panel

Per 20A Panel

± 24V

Actuator

MotorLink®

Actuator

± 24V

Actuator

MotorLink®

Actuator

± 24V

Actuator

MotorLink®

Actuator

WMS 409-1 5 4 5 4

10

8

WMS 409-2 4 2 4 4 8 4

WMS 409-3 3 3 3 3 9 6

WMS 409-4 4 4 4 4 8 8

WMS 515 2 0 2 0 4 0

WMU 836-1

10 4 10 8 20

8

WMU 836-2

10 2 10 4 20

4

WMU 836-3 9 3 9 6

18

6

WMU 836-4 8 4 8 8

20

8

WMU 861-1 6 4 6 6

12

8

WMU 861-2 6 2 6 4

12

4

WMU 861-3 6 3 6 6

12

6

WMU 861-4 4 4 4 4

12

8

WMU 842 / 862 / 882-1

4 4 4 4 8

8

WMU 842 / 862 / 882-2

4 2 4 4 8

4

WMU 842 / 862 / 882-3

3 3 3 3 6

6

WMU 842 / 862 / 882-4

4 4 4 4 8

8

WMU 863 / 883-1

3 3 3 3 6

6

WMU 863 / 883-2

2 2 2 2 6

4

WMU 863 / 883-3

3 3 3 3 6

6

WMU 863 / 883-4

0 0 0 0 4

4

WMU 864 / 884-1

2 2 2 2 4

4

WMU 864 / 884-2

2 2 2 2 4

4

WMU 864 / 884-3

0 0 0 0 3

3

WMU 864 / 884-4

0 0 0 0 4

4

WMU 885 / 895-1

2 2 2 2 4

4

WMU 885 / 895-2

2 2 2 2 4

4

WMU 885 / 895-3

0 0 0 0 3

3

WMU 885 / 895-4

0 0 0 0 4

4

WMX 503 / 504 / 523 / 526-1

20 4 20 8 40

8

WMX 503 / 504 / 523 / 526-2

20 2 20 4 40

4

WMX 503 / 504 / 523 / 526-3

18 3 18 6 39

6

WMX 503 / 504 / 523 / 526-4

20 4 20 8 40

8

WMX 803 / 804 / 823 / 826-1

10 4 10 8 20

8

WMX 803 / 804 / 823 / 826-2

10 2 10 4 20

4

WMX 803 / 804 / 823 / 826-3

9 3 9 6 18

6

WMX 803 / 804 / 823 / 826-4

8 4 8 8 20

8

WML 820/825

10 0 10 0 20

0

WML 860-1

10 4 10 8 20

8

WML 860-2

10 2 10 4 20

4

WML 860-3 9 3 9 6

18

6

WML 860-4 8 4 8 8

20

8

WMB 801/802*

max. 4A connected to the WMB

WMB 811/812 */**

10 2 10 4 20

4

* Do not exceed the total power consumption of the motor line

** When having two locking actuators per motor line, it must be one of each type: 1 x WMB 811 and 1 x WMB 812

7

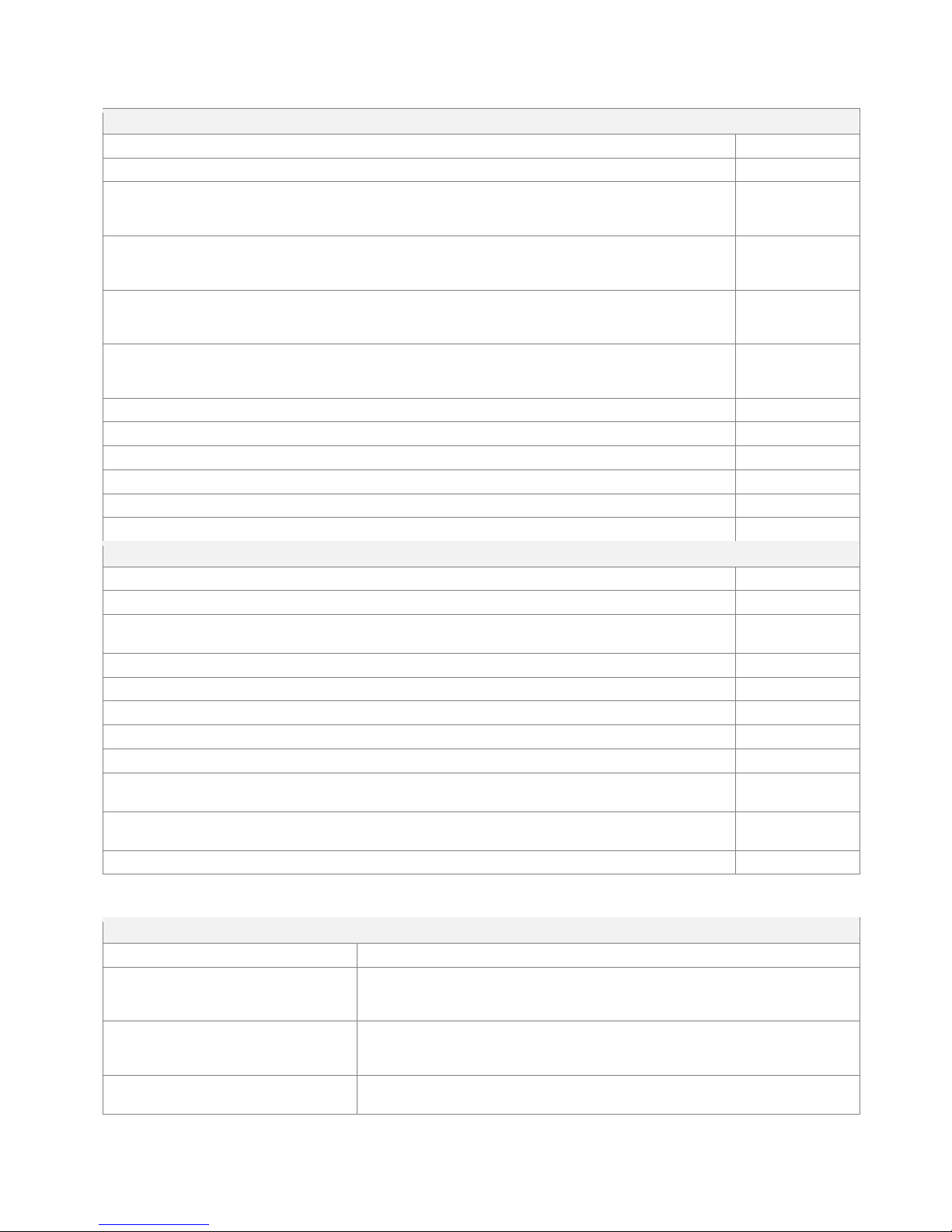

4 Accessories and spare parts

Accessories

Back-up battery for WSC 310 - 7Ah (2 x WSA 007 per panel )

WSA 007

Back-up battery for WSC 320 - 12Ah (2 x WSA 012 per panel)

WSA 012

Break glass unit, primary, with data communication, PVC housing. With input for smoke detector and

comfort keypads. Only one unit per line.

x = colour of the housing: 1=red, 2=yellow, 3=grey, 4=blue, 5=orange

WSK 501 000x

Break glass unit, primary, with data communication, metal housing. With input for smoke detector and

comfort keypads. Only one unit per line.

x = colour of the housing: 2=yellow, 3=grey, 5=orange

WSK 502 000x

Break glass unit, primary, with data communication, PVC housing. No input for smoke detector or

keypad. Max five units per line.

x = colour of the housing: 1=red, 2=yellow, 3=grey, 4=blue, 5=orange

WSK 503 000x

Break glass unit, primary, with data communication, metal housing. No input for smoke detector or

keypad. Max five units per line.

x = colour of the housing: 2=yellow, 3=grey, 5=orange

WSK 504 000x

Smoke detector

WSA 300

Rain sensor

WLA 331

Rain/wind speed sensor

WLA 330

End of line motor module

WSA 510

End of line smoke detector module (10kΩ resistor), 10 pcs.

WSA 501

Cables for smoke ventilation – see separate data sheet for further information

WLL 8xx

Spare parts

10A power supply unit for WSC 310

WCA 3P1

20A power supply unit for WSC 320

WCA 3P2

Main control card for Standard version WSC 310 / WSC 320 incl. cover + 2 end of line modules

(WSA 510)

WCA 3SS

Plastic cover for the main control card in the WSC 310 / WSC 320 Standard version

WCA 302

Lock cylinder incl. 2 keys for WSC 310/320 panel

WCA 307

Replacement glass for break glass units type WSK 501 / 502 / 503 / 504, 5 pcs.

WSK 397

Keys for break glass units type WSK 501 / 503, 5 pcs.

WSK 398

Keys for break glass units type WSK 502 / 504, 1 pcs.

WSK 453

Lockable replacement PVC housing for break glass unit

x=colour of the housing: 1 = red, 2 = yellow, 3 = grey, 4 = blue, 5 = orange

WSK 399 000x

Back-up battery cable kit for WSC 310 / 320 (cable between WCA 3SP / 3SS and the batteries and

between the batteries)

WSA 330 0101

20A battery fuse. The battery fuse on the WCA 3SP/3SS, 10 pcs

WSA 331 0101

5 Technical data

Technical data

Output current (nominal)

WSC 310: 10A / WSC 320: 20A

Secondary voltage

Voltage 24V DC (±15%)

Open circuit voltage (no load) 27.6V DC @ 20°C

Ripple at max load max. 6% (3.5Vpp)

Motor lines

Motor groups

Smoke zones

2 motor lines – a line can be either ±24V standard motor line or MotorLink® motor

lines - in max 2 motor groups and max 2 smoke zones

Primary voltage

WSC 310: 230V AC, 50Hz (85-264V AC, 47-63Hz)

WSC 320: 230V AC, 50Hz (85-264V AC, 47-63Hz)

8

Power consumption

WSC 310: min 3.2W

1+2

, typ. 4.8W

1+3

. At max load 300W

WSC 320: min 5.0W

1+2

, typ. 5.6W

1+3

. At max load 600W

1) no load: system operational but no actuators are running

2) min: 1 x break glass unit WSK 501 and 1 x smoke detector WSA 300

3) max load: 1 x break glass unit WSK 501, 4 x break glass unit WSK 503 and

10 x smoke detector WSA 300

Inrush current on primary site

70A<5ms

Max. 3 x WSC 310/320 per 10A supply group.

Circuit breaker “C” characteristic.

±24V change over time

min 500ms

Back-up batteries

WSC 310: 2 x WSA 007 (12V / 7Ah)

WSC 320: 2 x WSA 012 (12V / 12Ah)

Expected lifetime max 4 years, only use genuine WindowMaster batteries

Emergency power

>72 hours in accordance with EN 12101-10

Automatic smoke triggering

Smoke triggering when the temperature inside the compact unit exceeds 72ºC

Charging unit (integrated in WCA 3SS

card)

Charging voltage: 27.7 – 27.8V at 20ºC

Charging current: 1.7A, current limited

Priority

Smoke signal has always highest priority

Cable monitoring

±24V standard actuators with end of line module and smoke detectors are

monitored by closed-circuit

Actuators with MotorLink® and break glass units are monitored by data

communication

Back-up batteries are monitored by cyclic measuring

LED message OK, fault and alarm

Green

Yellow

Red

all OK

fault

fire

Reopening the actuators

Every 2.min. in 30min. after a SHE open (selectable) Pre-set: no reopening

Connection cable

Actuators

Other

components

flexible max 6 mm² / solide max 10 mm²

min 0,2mm² / max 1,5mm²

Operating conditions

-5°C - +40°C, max. 95% relative humidity (not condensing)

EN 12101-10: Operation class A, Environmental class 1, with IP value increased

to IP 54 (according to EN 12101-10 is min. IP 30 required)

Max actuator activation duration (duty

cycle)

ED 40% (4min. per 10min.)

Max allowed current drawn from the

battery when the primary power

source is disconnected

WSC 310: 10A

WSC 321: 20A

Max interruption time during switching

between power sources

<2.0sec

Break glass unit

Up to 10 break glass units type WSK 50x can be connected to the WCA 3SS, but

only 1 WSK 501 / 502 per line, meaning max 2 WSK 501 / 502 per panel.

Smoke detectors and ventilation keypads can only be connected to the break

glass units type WSK 501 / 502.

Up to 10 smoke detectors can be connected to each WSK 501 / 502, and 10

smoke detectors can be connected to the smoke detector input on the main

control card, which give a total maximum of 30 smoke detectors.

There is no limit on the number of ventilation keypads connected to the WSK 501

/ 502.

Smoke detectors and ventilation keypads cannot be connected to WSK 503 /

504.

Number of motor lines

2 x 10A motor line for ±24V standard or MotorLink® actuators

Material

Metal housing for surface mounting

Colour

Grey (RAL 7035)

9

Size

WSC 310: 300 x 400 x 120mm (HxWxD)

WSC 320: 300 x 400 x 210mm (HxWxD)

Weight

WSC 310: 6kg no batteries, 10.8kg with batteries (2 x WSA 007)

WSC 320: 8.6kg no batteries, 16.6kg with batteries (2 x WSA 012)

Protection class

IP 54

Approval / certification

Approved and certified according to EN 12101-10

Delivery

CompactSmoke™ smoke ventilation panel with WSA 501 (10kΩ resistors, 10

pcs.) and 2 pcs. end of line module WSA 510. Back-up batteries included.

Note

We reserve the right to make technical changes

6 Mounting

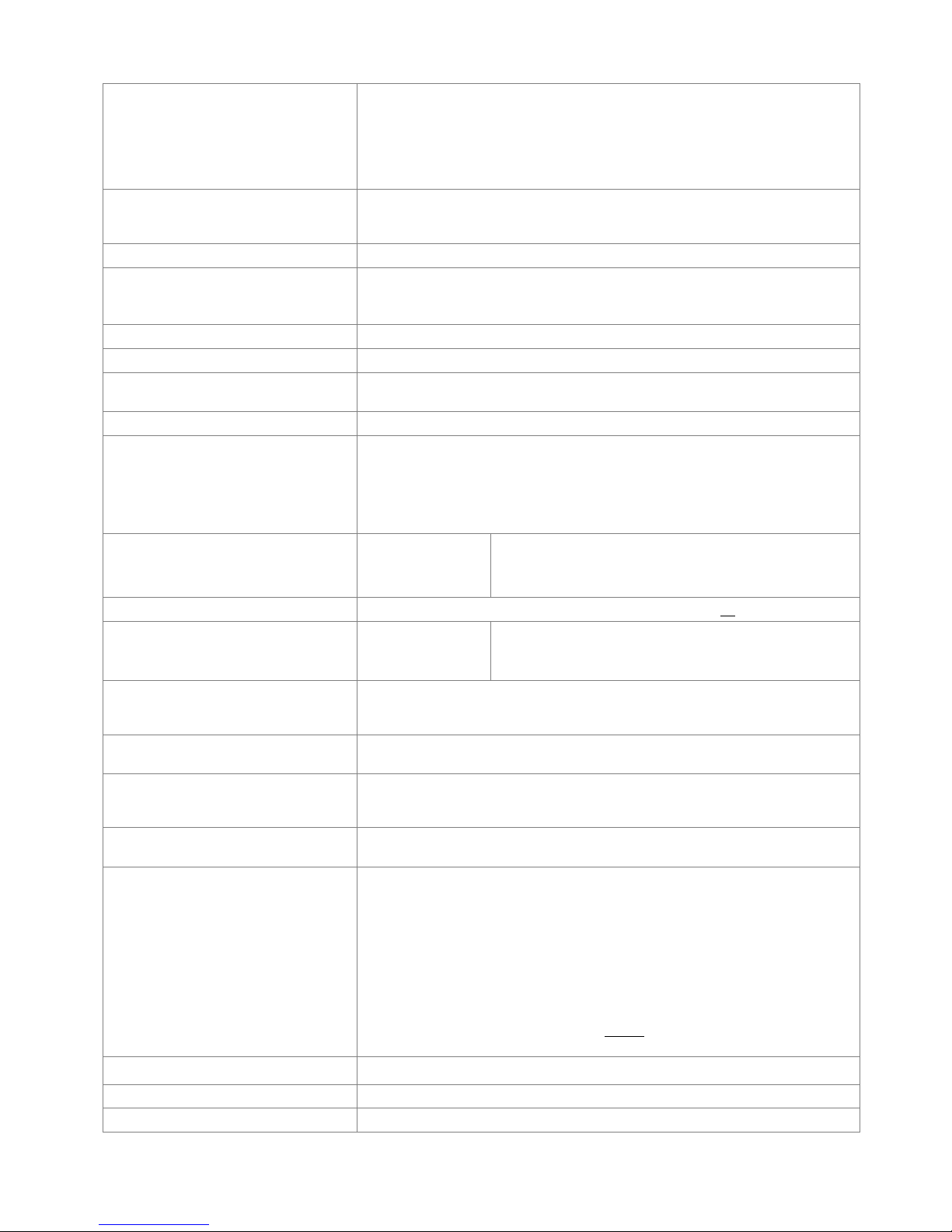

The smoke ventilation panel is fixed to the wall through the Ø8.5mm holes in the back plane of the

housing.

If the panel is fixed in different way, the holes are to be blinded with the 4 blind grommets, this way

the IP class is maintained.

The door is turnable.

When turning the door also move the blind grommets to the new holes.

The smoke ventilation panel is to be located in a safe place, protected from the effects of fire and

smoke.

7 Installation

7.1 Cable routing

For cable routing we recommend the use of fire protected cables retaining their function E90 or E30.

See also chapter 8 “Cable dimensioning” in this instruction.

However, this has to be agreed with the Engineer or, if necessary, with the local fire protection department.

Do not reduce the cable cross sections specified in the cable lengths table.

All cables of the control (except the mains supply cable) carry 24V DC and have to be routed separate from the mains supply

cable.

Adhere to the pertinent national and local regulations when routing the cables.

Lead the connection cables into the housing of the control panel from above

and the cable glans shall comply with fire class V-1 (IEC/EN 60695-11-20 / UL

94) or higher and be in accordance with national and local regulations.

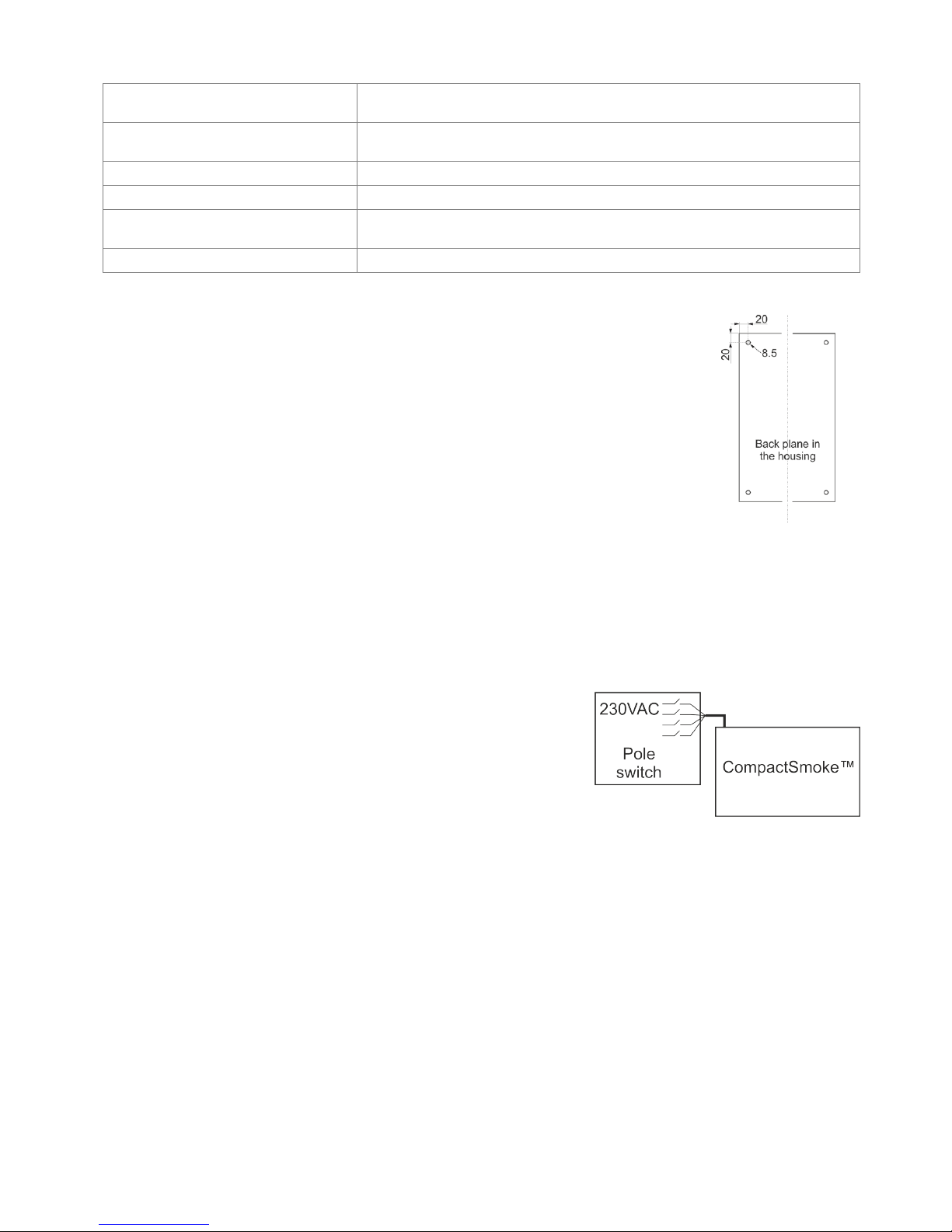

Ensure that the mains cable can be switched via an external or customer-supplied

two-pole switch element or a switch element controlling all poles – see drawing.

7.2 Cables into housing

All connection terminals (except the mains terminals) are of the plug-in type.

Connect the connection cables in accordance with the terminal plan. Ensure that the connections are made correctly.

Incorrect cable clamping, mixing up numbers or colours could lead to malfunctions of the control panel or of the external

components.

Ensure that the electrical cables are always routed according to the valid national and local regulations.

7.3 Connection of safety earth wire and 230V AC

See chapter 10 ‘Description of cards’, section 10.1 for further description.

7.4 Installation of the break glass unit, ventilation keypad and smoke detector

Ensure that the break glass unit and the ventilation buttons are visible and well accessible. Do not install behind protruding

walls, door panels or hidden by the building structure.

Note: Installation height of the break glass unit 1.5 – 1.7m above floor.

Install the smoke detectors in accordance with their enclosed instructions

Loading...

Loading...