Window Master WSC 204, WSC 204KP, WSC 204MH, WSC 204BZ Operating Manual/technical Information

DK

+45 4567 0300

info.dk@windowmaster.com

UK & IE

+44 (0) 1536 510990

info@windowmaster.co.uk

DE

+49 (0) 5221 6940 -500 Vertrieb / -650 Technik

info@windowmaster.de

CH

+41 (0) 62 289 22 22

info@windowmaster.ch

www.windowmaster.com

Other markets

+45 4567 0300

info@windowmaster.com

WSC 204 0102 / WSC 204MH 0102 / WSC 204BZ 0102 / WSC 204KP 0102 install 1606-UK ©WindowMaster 2011, 2016 ®WindowMaster is a registered trademark used under licence by WindowMaster Group

WSC 204

(WSC 204 0102 / WSC 204MH 0102 / WSC 204KP 0102 / WSC 204BZ 0102)

Smoke control panel

Operating manual / Technical information

WSC 204 0102 – WSC 204BZ 0102

plastic housing

WSC 204KP 0102

plastic housing with integrated break glass unit

WSC 204MH 0102 steel housing

Mitglied im

Fach krei s

elek trom otori sc h

betri eben e

Rauch - und Wärm e-

abz ugs anla gen

2

Table of contents

1. Safety information .......................................................................................................................................... 3

2. Technical description ..................................................................................................................................... 4

2.1. Accessories ........................................................................................................................................... 5

3. Operating elements and fuse review ............................................................................................................. 6

4. Function description....................................................................................................................................... 7

4.1. Smoke and heat extraction .................................................................................................................... 7

4.2. Ventilation functions............................................................................................................................... 8

4.3. General information ............................................................................................................................... 9

4.4. Connection possibilities ......................................................................................................................... 9

4.5. Optional plug-in modules ..................................................................................................................... 10

4.6. Back-up batteries charge ..................................................................................................................... 10

4.7. Operation/ Setting possibilities ............................................................................................................ 10

5. Installation .................................................................................................................................................... 11

5.1. Surface mounting ................................................................................................................................. 11

5.2. Countersunk mounting ........................................................................................................................ 12

5.3. Cable routing ....................................................................................................................................... 12

5.4. Installation ............................................................................................................................................ 12

5.5. Installation of the Break glass unit, ventilation keypad and detector ................................................... 13

6. Cable dimensioning ..................................................................................................................................... 13

6.1. Cable length table ................................................................................................................................ 13

7. Cable plan .................................................................................................................................................... 14

8. Wiring diagram ............................................................................................................................................. 15

8.1. Standard wiring diagram ...................................................................................................................... 15

8.2. Wiring diagram WSC 204KP ............................................................................................................... 16

8.3. Various wiring diagrams ...................................................................................................................... 17

9. Commisioning and troubleshooting ............................................................................................................. 18

10. Maintenance ............................................................................................................................................ 20

3

1. Safety information

Attention!

Adherence to the following information is mandatory:

Only allow correspondingly trained, qualified and skilled personnel to carry out installation work.

Reliable operation and the avoidance of damage and hazards is only guaranteed if installation and settings are

carried out carefully in accordance with these instructions.

Hazards to persons ensuing from flaps and wings operated by electric motors.

The forces occurring in the automatic mode can be such that parts of the body could get crushed.

When opened, actuators could protrude into the room. For this reason, measures have to be taken prior to

starting up the actuators, which exclude the danger of injury.

With wings tilting inwards or outwards, the wing must be protected from hinging down once the actuator is

unhooked (e.g. for window cleaning).

For safety reasons we recommend the use of catching shears.

In the event that wings and flaps are subjected to rain or high wind loads, we recommend to connect a rain

and/or wind detector to the smoke control panel, which will automatically close the flaps when comfort

ventilation.

The house can be mounted either as counter sunk or surface.

The manufacturer does not assume any liability for possible damage resulting from inappropriate use.

230V AC dangerous voltage

Can cause death, severe injury or considerable damage to assets.

The connection of the control system is reserved for qualified personnel.

Disconnect all poles of the unit from the supply voltage prior to opening, installation or assembling. Adhere to

national regulations.

Field of application

The central control system is exclusively designed for the automatic closing of smoke extraction systems,

windows, flaps or doors.

Always check that your system meets the valid regulations.

Pay particular attention to the opening cross section, the opening time and opening speed. The cable cross

sections depend on the cable length and current consumption (amperage).

Maintenance work

See last page in this instruction.

Cable routing and electrical connection

Fuse the 230V AC power supply cable separately on site.

Leave the insulation of the power supply cable in place up to the mains terminal.

Adhere to the DIN and VDE regulations (Germany) or equivalent in your country.

Establish the cable types, if necessary, with the local approval bodies or the fire protection authority.

Do not conceal flexible cables. Junction box must be accessible for maintenance purposes.

Disconnect all poles of the mains voltage and the accumulators prior to starting maintenance work or making

changes to the system.

Secure the system to prevent unintentional switching on again.

Design cable types, lengths and cross sections in accordance with the technical information.

Route all low voltage cables (24V DC) separate from the power current cables.

4

2. Technical description

Function

WSC 204 / WSC 204KP / WSC 204MH

Opens the window actuators when triggered by a SHE-signal caused by smoke

detector or break glass unit.

WSC 204BZ

Closes the window actuators when triggered by a SHE-signal caused by smoke

detector and opens the actuators when activating a break glass unit.

Supply voltage

230V AC / 50/60Hz ((±10%))

Safety transformer

according EN 61558

Power consumption

max. 150VA

Actuator secondary voltage

rated voltage 24V

open circuit voltage at 230 VAC typ. 28V DC

open circuit voltage at 253VAC max 31.3V DC

actuator voltage at 230 VAC / 4.8A load typ. 22V DC

ripple at full load (4.8A) max. 6% (= 3.8Vpp)

open circuit voltage at battery operation min 18.7V DC

Inrush current

Max 6A<5msec

Standby consumption

4W

Switch time between 230V- and

battery operation

max 2.5sec

Emergency power supply

batteries

2 x 12V / 3,4Ah. Expected lifetime 4 years. (2pcs. WSA 003). Only use genuine

WindowMaster back up batteries.

Charging unit:

Charging voltage: 27,7 – 27,8 at 20ºC

Charging current: 350mA, current limited

Operating duration (emergency

power supply )

72 hours if batteries are fully charged (1,9Ah)

Current load of the actuators

(battery and 230V operation)

max. 4,8A

Current load of the smoke unit

(batteries, surveillance, periphery)

max. 0,7A

Switch-on duration

40% ED

Reopening the actuators

during the first 30 min. after a SHE-trig the actuators cyclically every 2 min.

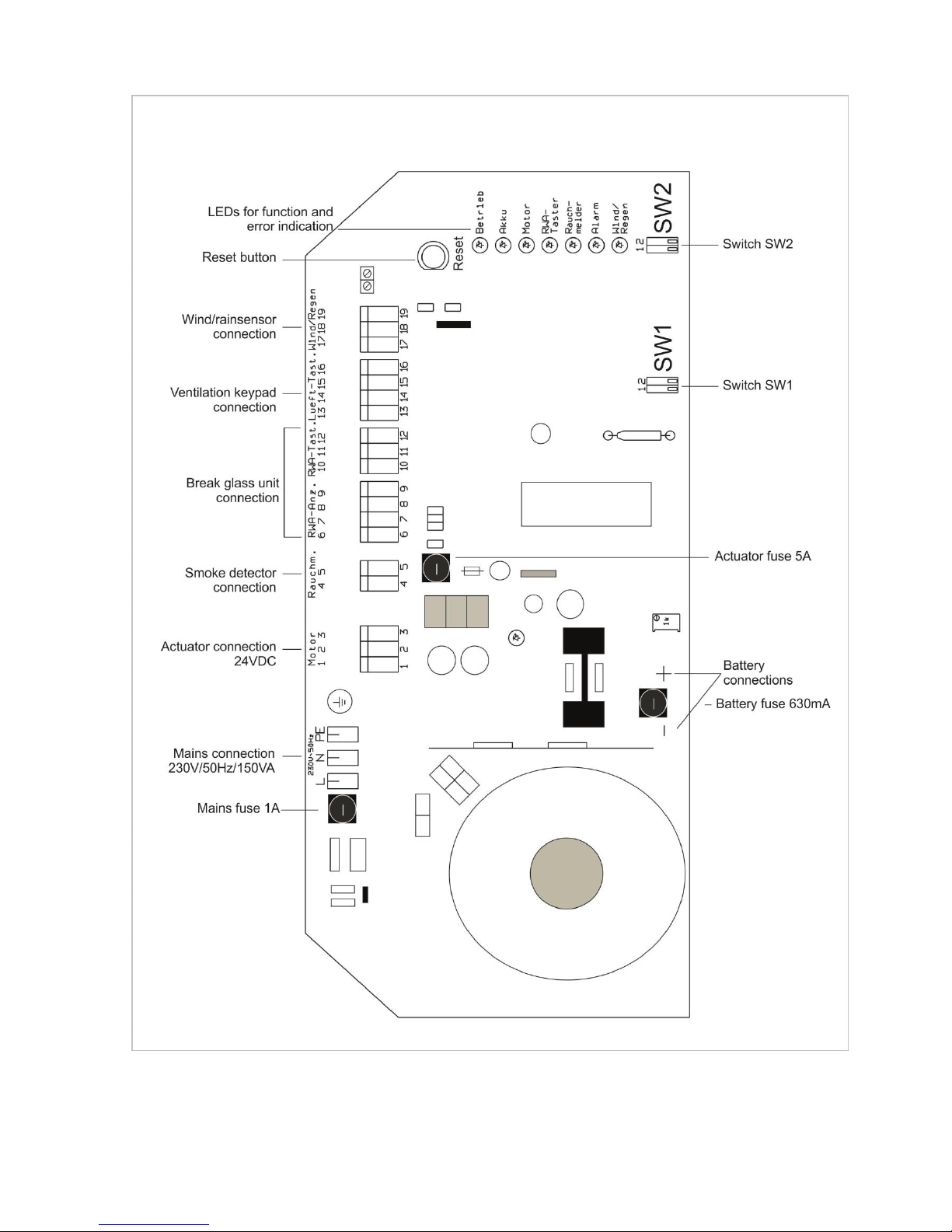

Review of fuses

mains 1A slow-blow

actuator fuse 5A slow-blow

battery 630mA medium slow-blow

Type of connection to external

mains screw terminal / plug-screw terminals / 0.5-2.5mm²

Cable monitoring

automatic detectors (detector circuit with active end module), break glass unit

(detector circuit with end resistor), actuators (with motor end module), batteries

(cyclic measurement)

Message OK, fault and alarm

optically alternating or steady signals by LED's:

steady green LED = operating

alternating yellow LED = malfunction of battery(at battery voltage less than 19V

or above 29V), actuator, break glass unit or smoke

steady red LED = alarm (short circuit)

Automatic smoke triggering

Smoke triggering when temperature inside the compact unit exceeds 72°C

Operating conditions

-5°C - 40°C, max. 90% relative humidity (not condensing)

Approval / Certification

WSC 204 / WSC 204KP / WSC 204BZ: approved according to EN12101-10

Protection type

WSC 204 / WSC 204KP / WSC 204BZ

IP 30 (plastic housing)

WSC 204MH

IP54 (steel housing)

5

Housing

WSC 204 / WSC 204KP / WSC 204BZ

Plastic house for flush.

Delivered with a plastic frame for surface mounting.

Protection class I

Dimensions (WxHxD) 368x353x97/95mm

Cut-out hole (WxHxD) 325±5 x 311±5 x min.80mm.

WSC 204MH

Steel housing for surface mounting.

300 x 300 x 120mm.

Delivery includes

Smoke control panel with 2 x 3,4Ah back-up batteries (2 x WSA 003).

Note

We reserve the rights to make changes

2.1. Accessories

Alarm and fault module (master slave)

WSA 301

Linking of wind/rain signal module

WSA 302

Timer ventilation module

WSA 303

Gap ventilation module

WSA 304B

ASV Module

WSA 306

Motor end module

WSA 432

Smoke detector end module

WSA 433

Replacement PCB without transformer for WSC 204 & WSC 204BZ

WSA 321 0102

Replacement PCB without transformer for WSC 204KP

WSA 327 0101

Transformer

WSA 328 0101

Locking cylinder with 2 keys for WSC 204, WSC 204BZ & WSC 204KP

WSA 440

Spare key for WSC 204, WSC 204BZ & WSC 204KP

WSA 441

Spare key for WSC 204MH

WSA 439

6

3. Operating elements and fuse review

Loading...

Loading...