Window Master WCC 310, WCC 320, WCC 310 UL, WCC 320 UL Installation Instructions Manual

UK

+44 (0) 1536 0614 070

info.uk@windowmaster.com

Other markets

+45 4567 0300

info@windowmaster.com

www.windowmaster.com

WCC 3xx STANDARD install 1711-Firmware v122 - UK ©WindowMaster 2016, 2017 ®WindowMaster is a registred trademark used under the license by WindowMaster International A/S

WindowMaster International A/S, Skelstedet 13, DK-2950 Vedbæk

WCC 310 & WCC 320

Standard versions

Installation instruction

MotorController

(Version 1711 – for firmware from version 1.22 (motorline card))

Save this installation instruction to the end user

2

1 Safety information ........................................................................................................................................................ 3

1.1 Safety ................................................................................................................................................................ 3

1.2 230V AC ............................................................................................................................................................ 3

1.3 Application ......................................................................................................................................................... 3

1.4 Cable routing and electrical connection ............................................................................................................. 3

2 Structure of the MotorController ................................................................................................................................ 4

3 Variants of MotorControllers ....................................................................................................................................... 4

3.1 MotorController versions ................................................................................................................................... 5

3.2 Max numbers of actuators per motor line and MotorContoller

................................................................................ 5

4 Accessories and spare parts ...................................................................................................................................... 6

5 Technical data .............................................................................................................................................................. 7

6 Mounting ....................................................................................................................................................................... 7

7 Installation .................................................................................................................................................................... 8

7.1 Cable routing ..................................................................................................................................................... 8

7.2 Cables into housing ........................................................................................................................................... 8

7.3 Connection of safety earth wire and 230V AC ................................................................................................... 8

7.4 Installation of the ventilation keypad .................................................................................................................. 8

7.5 Assembly instructions ........................................................................................................................................ 8

8 Cable dimensioning ..................................................................................................................................................... 9

8.1 Max. cable Length ............................................................................................................................................. 9

8.1.1 Formula for the calculation of the maximum actuator cable length ............................................................... 9

8.1.2 Max cable length – ±24V standard actuators ................................................................................................ 9

8.1.3 Max cable length – actuators with MotorLink® ............................................................................................... 9

9 Cable plan for connection to WCC 310 / 320 Standard version ............................................................................. 11

10 Description of cards and mains connection ............................................................................................................ 12

10.1 WCC connection to mains and power supply units – WCA 3P3, WCA 3P5 and WCA 3P6 .............................12

10.2 Motor line card WCA 3M4 and WCA 3M8 ........................................................................................................13

10.3 Input card – WCA 3KI .......................................................................................................................................15

10.4 Power supply card – WCA 3P6 ........................................................................................................................17

11 Configuration of the MotorController ....................................................................................................................... 17

12 Fault detection via LED.............................................................................................................................................. 17

12.1 Fault detection on the MotorController .............................................................................................................17

13 Hardware error ........................................................................................................................................................... 18

14 Commissioning and test run ..................................................................................................................................... 18

14.1 The MotorController is completely installed, without the operating voltage applied .........................................18

14.2 With mains voltage ...........................................................................................................................................18

14.3 Ventilation keypad ............................................................................................................................................18

14.4 Wind/rain detector ............................................................................................................................................18

15 Maintenance ............................................................................................................................................................... 19

15.1 Maintenance agreements .................................................................................................................................19

15.2 Replacement 3M4, 3M8 and 3KI card ..............................................................................................................19

16 Declaration of Conformity ......................................................................................................................................... 19

3

1 Safety information

1.1 Safety

Only allow correspondingly trained, qualified and skilled personnel to carry out installation work.

Reliable operation and the avoidance of damage and hazards are only guaranteed if installation and settings are carried out

carefully in accordance with these instructions.

There may be personal danger by electrically operated windows:

- the forces occurring in the automatic mode can be such that parts of the body could get crushed

- when opened, actuators (spindles) could protrude into the room

For this reason, measures have to be taken prior to starting up the actuators, which exclude the danger of injury.

For safety reasons we recommend to install opening restrictors on bottom-hung windows.

In the event that windows are subjected to rain and/or high wind loads, we recommend connecting a wind/rain sensor to the

MotorController for the automatically closing of the windows.

The MotorController is to be located in a safe place, protected from the effects of fire and smoke.

The MotorController is to be surface mounted.

The MotorController is to be supplied with 230V AC.

The manufacturer does not assume any liability for possible damage resulting from inappropriate use.

1.2 230V AC

230V AC can cause death, severe injury or considerable damage to assets.

The connection of the MotorController is reserved for qualified personnel.

Disconnect all poles of the MotorController from the supply voltage prior to opening, installation or assembling.

Installation and use according to the national regulations.

1.3 Application

The MotorController is exclusively designed for the automatic opening and closing of windows, flaps or doors.

Always check that your system meets the valid national regulations.

Pay particular attention to the opening cross section, the opening time and opening speed.

The cable cross sections depend on the cable length and current consumption (amperage).

1.4 Cable routing and electrical connection

Fuse the 230V AC power supply cable separately on site.

Cable routing and connection - adhere to national regulations.

Establish the cable types, if necessary, with the local approval bodies.

Do not conceal flexible cables.

Junction box must be accessible for maintenance purposes.

Disconnect all poles of the mains voltage prior to starting maintenance work or making changes to the system.

Secure the system to prevent unintentional switching on again.

Route all low voltage cables (24V DC) separate from the power current cables.

Design cable types, lengths and cross sections in accordance with the technical information.

Cable specifications is a guide only, the overall responsibility resides with the electrical contractor on site.

Installation must be in accordance with the national electrical regulations.

4

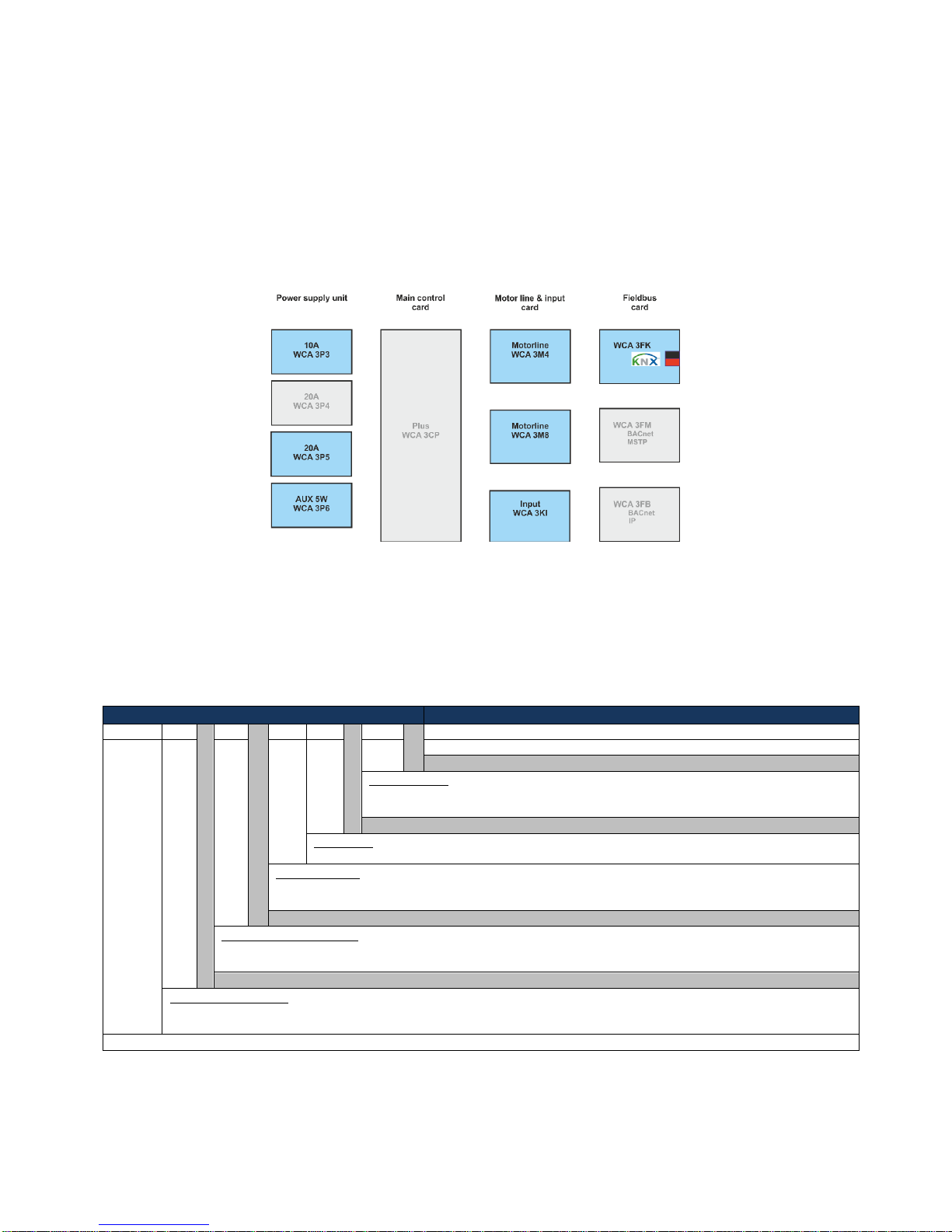

2 Structure of the MotorController

Sizes & Versions

The WCC 310 and WCC 320 MotorControllers are available in two different versions namely a Standard and a Plus version.

This installation instruction only deals with the Standard versions. Please see separate installation instruction for the Plus

versions of WCC 310 and WCC 320.

Cards

Each MotorController contains a power supply unit (SMPS), either a WCA 3P3 or a WCA 3P5 for the 10A or 20A version

respectively, as well as a 5W auxiliary power supply for wind / rain sensor. Aside from the power supply units the Standard

version also includes a motorline card type WCA 3M4 or WCA 3M8 with 4 and 8 motor lines respectively and an input card

WCA 3KI with 10 inputs. Additionally, the Standard version is also available in a version with fieldbus interface for KNX.

If additional motor lines, inputs or fieldbus connection is required a Plus version of the MotorController is necessary.

Motor groups and motor lines

A motor group consists of one or more motor lines and all the motor lines are operated simultaneously.

All motor lines on the motor cards (WCA 3M4 & WCA 3M8) can be configured for either a ±24V standard actuators or

MotorLink® actuators. A motor group can contain motor lines with both ±24V standard actuators and MotorLink® actuators,

whereas a motor line only can have ±24V standard or MotorLink® actuators connected.

3 Variants of MotorControllers

Item composing

WCC 3

xx x xx

xx xxx 01

01 = Product version number

Fieldbus card

” ” = No fieldbus card

KNX = Fieldbus card with interface to KNX

Input card

10 = Input card with 10 inputs

Motorline card

04 = Motor line card with 4 motor lines

08 = Motor line card with 8 motor lines

MotorController version

S = Standard

P = Plus

MotorController size

10 = 10A

20 = 20A

MotorController series 3

5

3.1 MotorController versions

Number of motor lines and other functions

Cards

Item number

WCC 310 versions

Standard version

4 motor lines

10 keypads / inputs

1 x WCA 3M4

1 x WCA 3KI

WCC 310 S 0410 01

Standard version

4 motor lines

10 keypads / inputs

KNX interface

1 x WCA 3M4

1 x WCA 3KI

1 x WCA 3FK

WCC 310 S 0410 KNX 01

WCC 320 versions

Standard version

8 motor lines

10 keypads / inputs

1 x WCA 3M8

1 x WCA 3KI

WCC 320 S 0810 01

Standard version

8 motor lines

10 keypads / inputs

KNX interface

1 x WCA 3M8

1 x WCA 3KI

1 x WCA 3FK

WCC 320 S 0810 KNX 01

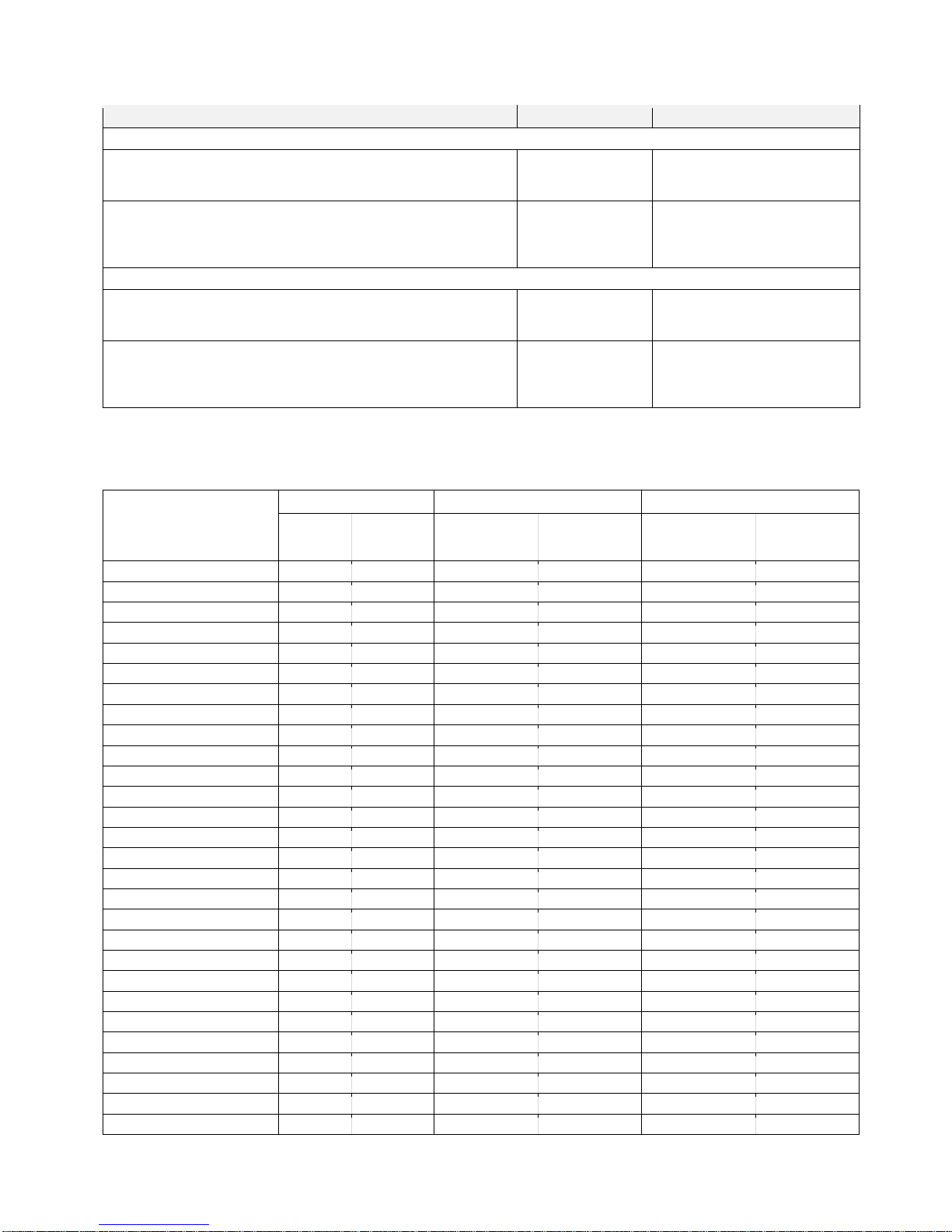

3.2 Max numbers of actuators per motor line and MotorContoller

The table shows the maximum number of actuators, which can be connected per motor line and MotorController depending on the

type of the actuators, MotorController and connected cards. The total power consumption of all the connected actuators must not

exceed 10A or 20A depending on MotorController size.

Per motorline

Per 10A MotorController

Per 20A MotorController

± 24V

Actuators

MotorLink®

Actuators

± 24V

Actuators

MotorLink®

Actuators

(4 Motorlines)

± 24V

Actuators

MotorLink®

Actuators

(8 Motorlines)

WMS 306-1

10 4 10

10

20

20

WMS 306-2

10 2 10 8 20

16

WMS 306-3

9 3 9 9 18

18

WMS 306-4

8 4 8 8 20

20

WMS 309-1

10 4 10

10

20

20

WMS 309-2

10 2 10 8 20

16

WMS 309-3

9 3 9 9 18

18

WMS 309-4

8 4 8 8 20

20

WMS 409 xxxx 01

5 0 5 0 10

0

WMS 409-1

5 4 5 5 10

10

WMS 409-2

4 2 4 4 10

10

WMS 409-3

3 3 3 3 9

9

WMS 409-4

4 4 4 4 8

8

WMS 515 2 0 2 0 4 0

WMU 836-1

10 4 10

10

20

20

WMU 836-2

10 2 10 8 20

16

WMU 836-3

9 3 9 9 18

18

WMU 836-4

8 4 8 8 20

20

WMU 861-1

6 4 6 6 12

12

WMU 861-2

6 2 6 6 12

12

WMU 861-3

6 3 6 6 12

12

WMU 861-4

4 4 4 4 12

12

WMU 842 / 862 / 882-1

4 4 4 4 8

8

WMU 842 / 862 / 882-2

4 2 4 4 8

8

WMU 842 / 862 / 882-3

3 3 3 3 6

6

WMU 842 / 862 / 882-4

4 4 4 4 8

8

WMU 863 / 883-1

3 3 3 3 6

6

WMU 863 / 883-2

2 2 2 2 6

6

6

Per motor line

Per 10A MotorController

Per 20A MotorController

± 24V

Actuators

MotorLink®

Actuators

± 24V

Actuators

MotorLink®

Actuators

(4 Motor lines)

± 24V

Actuators

MotorLink®

Actuators

(8 Motor lines)

WMU 863 / 883-3

3 3 3 3 6

6

WMU 863 / 883-4

0 0 0 0 0

0

WMU 864 / 884-1

2 2 2 2 4

4

WMU 864 / 884-2

2 2 2 2 4

4

WMU 864 / 884-3

0 0 0 0 0

0

WMU 864 / 884-4

0 0 0 0 0

0

WMU 885 / 895-1

2 2 2 2 4

4

WMU 885 / 895-2

2 2 2 2 4

4

WMU 885 / 895-3

0 0 0 0 0

0

WMU 885 / 895-4

0 0 0 0 0

0

WMX 503 / 504 / 523 / 526-1

20 4 20

16

40

32

WMX 503 / 504 / 523 / 526-2

20 2 20 8 40

16

WMX 503 / 504 / 523 / 526-3

18 3 18

12

39

24

WMX 503 / 504 / 523 / 526-4

20 4 20

16

40

32

WMX 803 / 804 / 823 / 826-1

10 4 10

10

20

20

WMX 803 / 804 / 823 / 826-2

10 2 10 8 20

16

WMX 803 / 804 / 823 / 826-3

9 3 9 9 18

18

WMX 803 / 804 / 823 / 826-4

8 4 8 8 20

20

WML 820/825

10 0 10 0 20

0

WML 860-1

10 4 10

10

20

20

WML 860-2

10 2 10 8 20

16

WML 860-3

9 3 9 9 18

18

WML 860-4

8 4 8 8 20

20

WMB 801/802*

max. 4A connected to WMB

WMB 811/812 */**

10 2 10 8 20

16

* Do not exceed the total power consumption of the motor line

** When having two locking actuators per motor line, it must be one of each type: 1 x WMB 811 and 1 x WMB 812

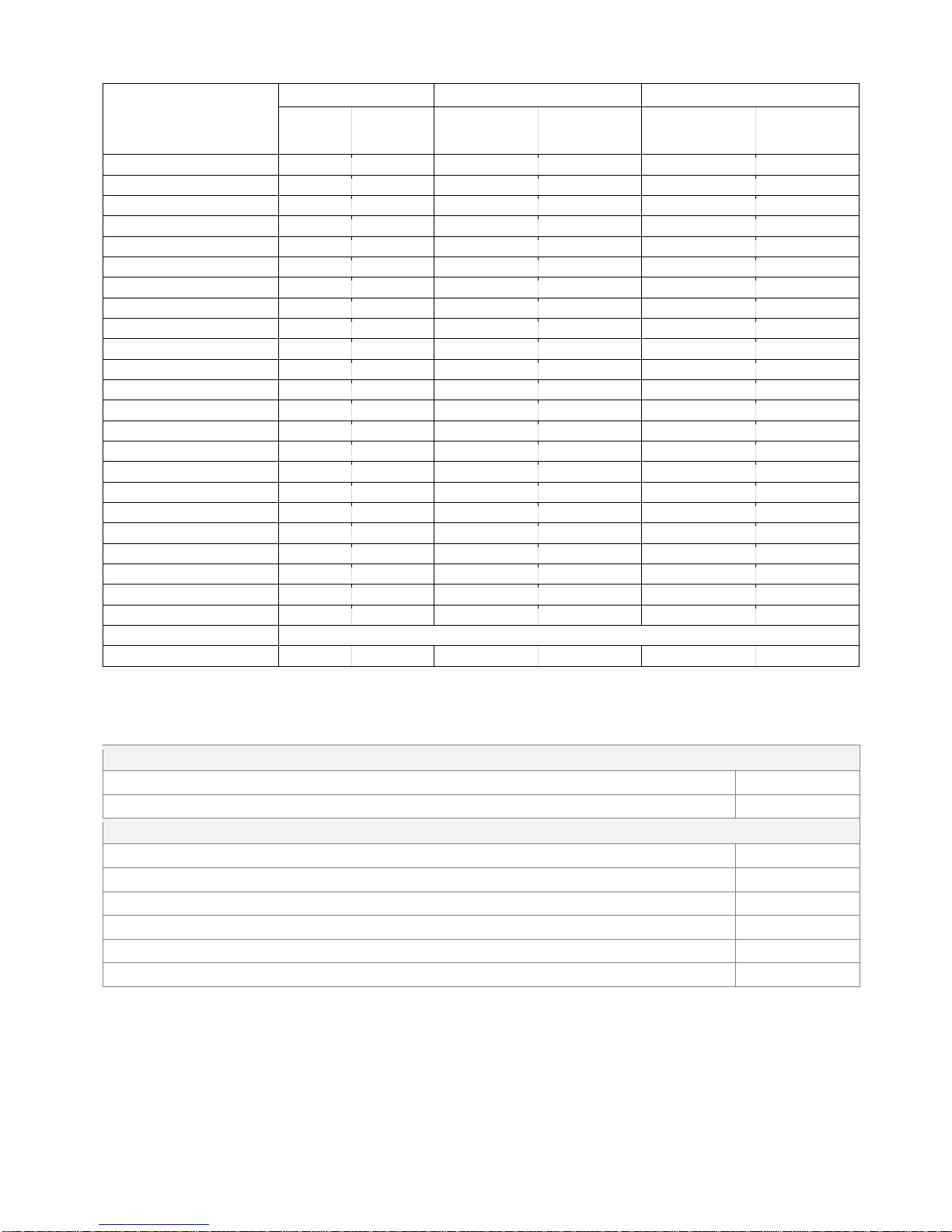

4 Accessories and spare parts

Accessories

Rain sensor

WLA 331

Rain/wind speed sensor

WLA 330

Spare parts

10A power supply unit for WCC 310

WCA 3P3

20A power supply unit for WCC 320

WCA 3P5

5W 230 AC / 24V DC – 24V AUX supply for sensors

WCA 3P6

Motor line card with 4 motor lines incl cover

WCA 3M4

Motor line card with 8 motor lines incl cover

WCA 3M8

Input card with 10 inputs for e.g. comfort keypad incl. cover

WCA 3KI

Loading...

Loading...