Windhager VarioWIN Operating Manual

VarioWIN

Pellet central heating boiler

pneumatic + direct

Operating Manual

05/2010 092945/01

2

Table of contents: Page

Important information for system operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Checking the heating water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.5 Operating noises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.6 Filling the pellet store . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.7 Sources of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.1 Fire protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.2 Power failure (or if the blower is not running) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.3 Burner pot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.4 Heating door and ash door handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.5 Direct pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.7.6 Entering the pellet storage room, storage container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.1 VarioWIN Premium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.2 VarioWIN Exklusiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2 Functional elements and operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.1 VarioWIN with direct pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.2 VarioWIN with 41 kg reserve supply container, manual loading . . . . . . . . . . . . . . . . . . . . . .10

2.2.3 VarioWIN with pneumatic pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 Opening the cladding door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4 Check before switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5 Filling the reserve supply container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.1 VarioWIN Exklusiv-S – Manual filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.2 VarioWIN Exklusiv-P – Pneumatic pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.5.3 VarioWIN Premium/Exklusiv-D – Direct pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.6 InfoWIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.7 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.7.1 OFF mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.7.2 ON mode, lighting ON, self-test, lighting OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.7.3 Pellet feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.7.4 Solid fuel / buffer mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.7.5 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.7.6 Flue cleaning function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.7.7 Shutdown procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.8 Operating phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.1 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.2 Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.3 Ignition phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.4 Flame stabilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.5 Modulation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.6 Burnout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.8.7 Burner OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3

Table of contents: Page

2.9 Information texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.9.1 Next boiler cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.9.2 Operating hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.9.3 Total pellet consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.4 Flue gas temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.5 Boiler temperature setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.6 Current boiler output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.7 Display module software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.8 Main PCB software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.9.9 Boiler model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.10 Menu guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.10.1 Operator level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.10.2 Service level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2.10.2 VarioWIN with REG standard control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2.11 Heating system operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

2.11.1 VarioWIN with MES system control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Care, cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.1 Care of cladding and keyboard foil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2 Cleaning and operating implements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.3 Overview of intervals between maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.4 Heating surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.5 Ash pan, ash on heating surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.6 Combustion chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.6.1 Baffle plate, thermocontrol sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.6.2 Burner pot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.7 VarioWIN reserve supply container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.8 Top heating surfaces and linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

3.9 Blower wheel, blower box, exhaust pipe and rotary feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3.9.1 Blower wheel, blower box and exhaust pipe to flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3.9.1 Rotary feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.1 No display on InfoWIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2 Information messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.3 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.4 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Guarantee and warranty limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

I\n\h\a\l\t\s\v\e\r\z\e\i\c\h\n\i\s\)[2020]>

4

Important information for system operators

Dear Heating System Owners,

We would like to congratulate you on your new environmentally friendly boiler system. With the purchase of

this high-quality product by WINDHAGER ZENTRALHEIZUNG, you have selected a system that provides more

comfort and optimised fuel consumption while utilising an environmentally friendly means of saving resources. Your boiler was manufactured under strict ISO 9001 certified standards, was subjected to extensive tests

and all its components are recyclable.

On the following pages we have provided specific information and important tips regarding system operation,

unit functions and cleaning. Please pay close attention to these instructions. Familiarity with the material in this

document will allow you to enjoy long-term operation of the unit. We wish you all the best with your WINDHAGER boiler!

Cordially,

WINDHAGER ZENTRALHEIZUNG

Caution symbols

Please take careful note of the following symbols on the pellet boiler and in these instructions.

Ignoring the warnings identified can lead to personal injury.

Ignoring the warnings identified can lead to malfunction of or damage to the boiler or heating system.

1.1 Safety precautions

The boiler and related accessories reflect the state of the art and meet all applicable safety regulations.

Your boiler and all accessories operate using 230 V AC electric current. Improper installation or repair can pose

the danger of life-threatening electric shock. Installation may be performed only by appropriately qualified technicians.

Please note: Risk of crushing from rotating auger.

If you have to touch these parts, always deenergise the boiler.

Warning of hot surface: risk of burns!

Before touching these surfaces, you must switch off the boiler and let it cool.

5

Important information for system operators

1.3 Start-up and maintenance

Have Windhager Customer Service or one of our customer service PARTNERS put your new boiler into service. In this way, all functions of the new unit will be thoroughly checked; you will also benefit from the detailed

information provided by the system installer. Installation by a qualified technician as well as the maintenance

required by the guarantee limitations will guarantee the optimal use and service life of your boiler system. This

is the only way to assure the benefits of this technologically advanced boiler and guarantee safe, environmentally

friendly and energy-saving system operation.

The following preconditions must be met before you order the initial start-up:

1.) Boiler installed correctly.

2.) System fully wired up electrically.

3.) System rinsed, filled and vented – heat consumption must be possible.

4.) Boiler connected to domestic water and filled.

5.) Sufficient quantity of fuel available (pellets, split logs, oil or gas).

6.) The customer must be present during start-up.

The initial start-up cannot be carried out if any of these points are neglected. The customer will be charged for

any unnecessary costs arising as a result.

Start-up and maintenance are part of the guarantee requirements as listed in the enclosed „guarantee limitations“.

Note:

During the first few weeks after start-up, condensation can occur in the combustion chamber, on the hea-

ting surfaces and in the ash pan. This has no effect on the function and service life of the boiler.

1.4 Checking the heating water

The chemical composition of the heating water must meet the specifications of ÖNORM H 5195 Part 1 or VDI

2035 T1. According to ÖNORM M 5195 Part 1, the condition of the heating water must be checked every 2 years

by a heating technician in order to avoid corrosion and sediment accumulation in the heating system.

The check must be performed once every year in heating systems with more than 1500 litres of heating water.

In the event of repair work requiring a change of water in the heating system, the heating water is to be checked

within 4 to 6 weeks after such work.

Corrosion and sediment resulting from improper heating water are not covered by the guarantee and warranty.

The pellets must be stored in a dry place so that they can be transported without problems and in order to

achieve trouble-free operation with optimum combustion and at maximum efficiency.

1.2 Fuel

The boilers are designed to burn the following fuels:

Pellets according to ÖNORM M7135 and DIN

plus

.

Significant criteria based on the standards are as follows:

Diameter 6 mm Length 80% between 15 – 30 mm

Smooth surface

Density at least 1.1 kg/dm

3

Residual moisture content max. 10%

Energy content min. 18 MJ/kg = 5 kWh/kg

(in water-free condition)

Ash content max. 0.5% Abraded particles max. 2.3%

Chemical/synthetic binding agents are strictly prohibited No impurities from varnish or paint residues, etc.

6

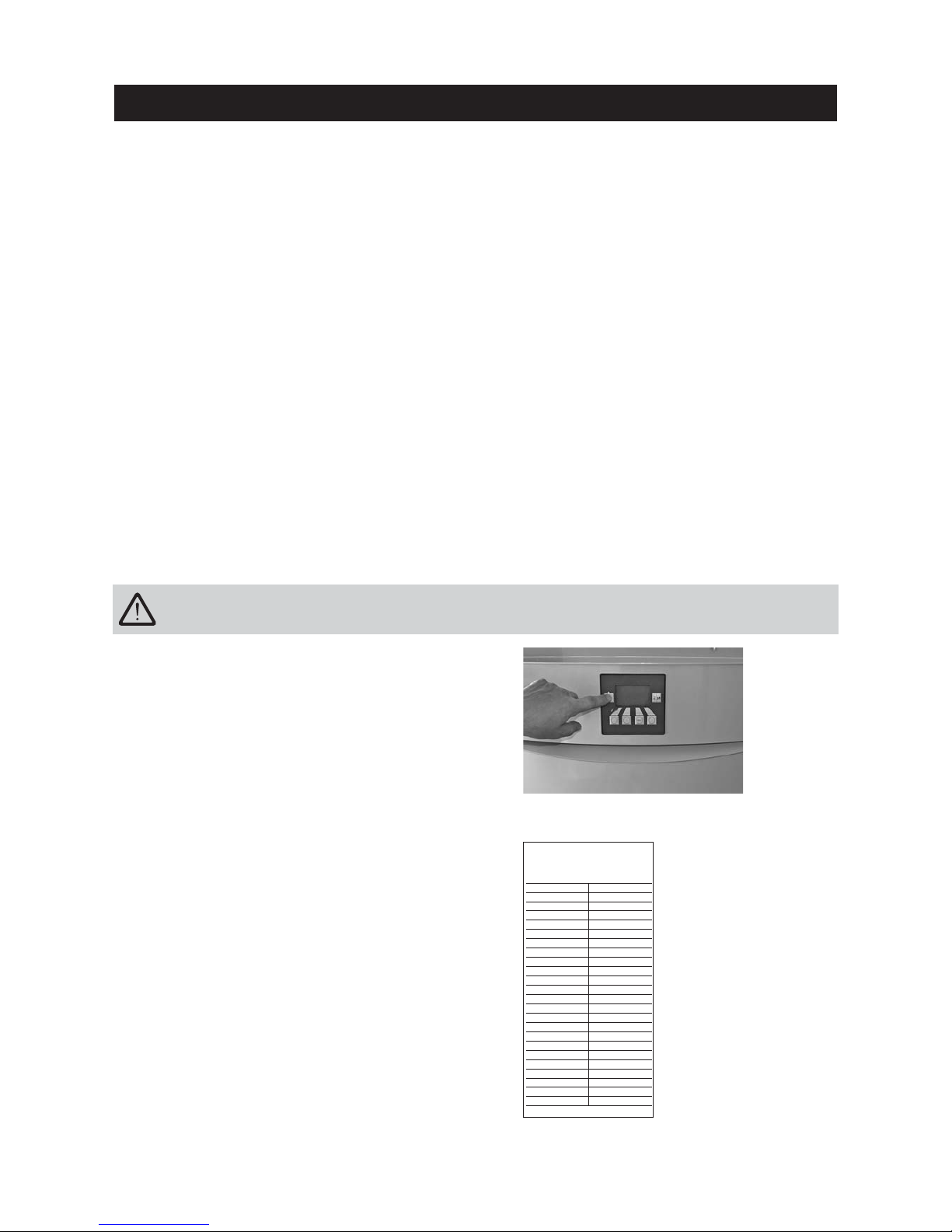

1.6 Filling the pellet store

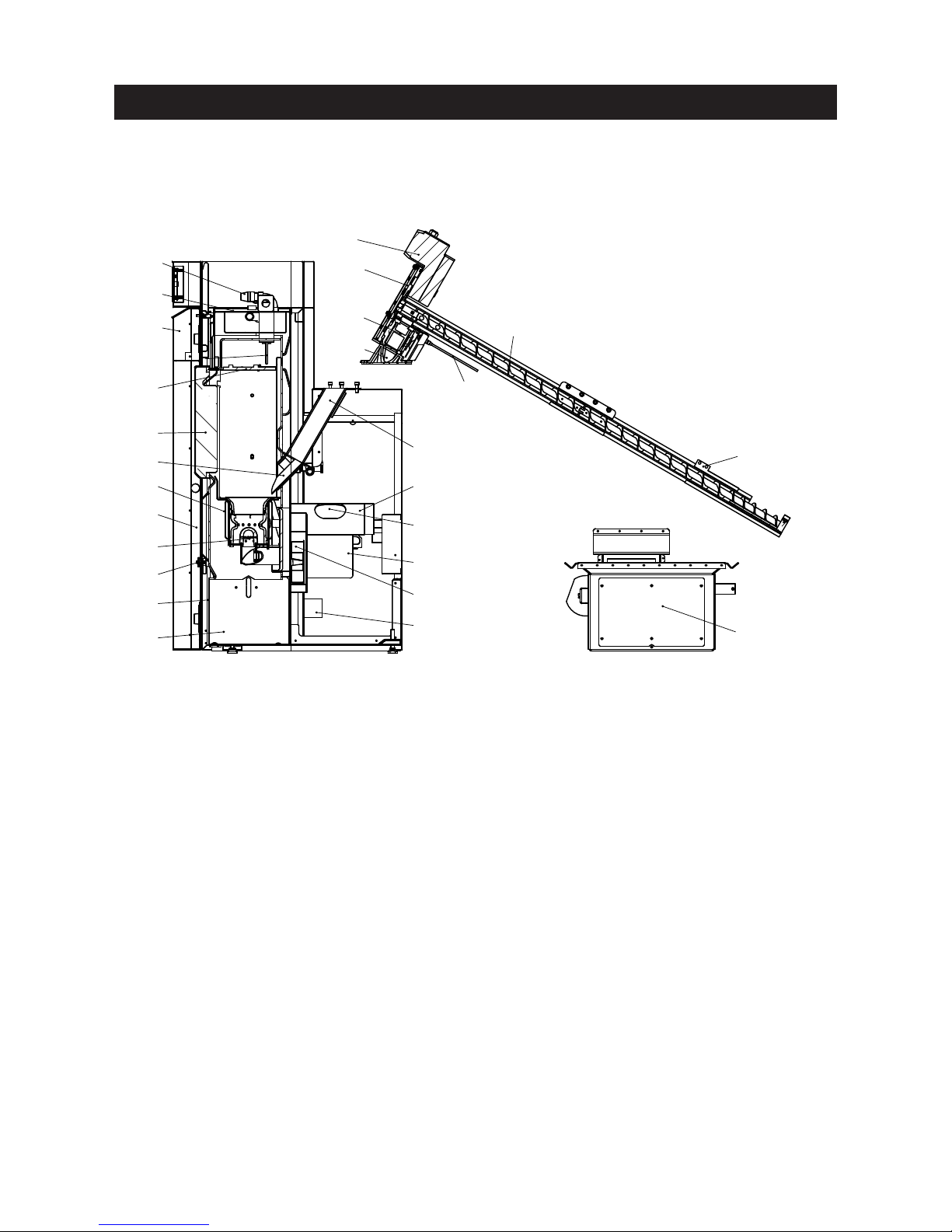

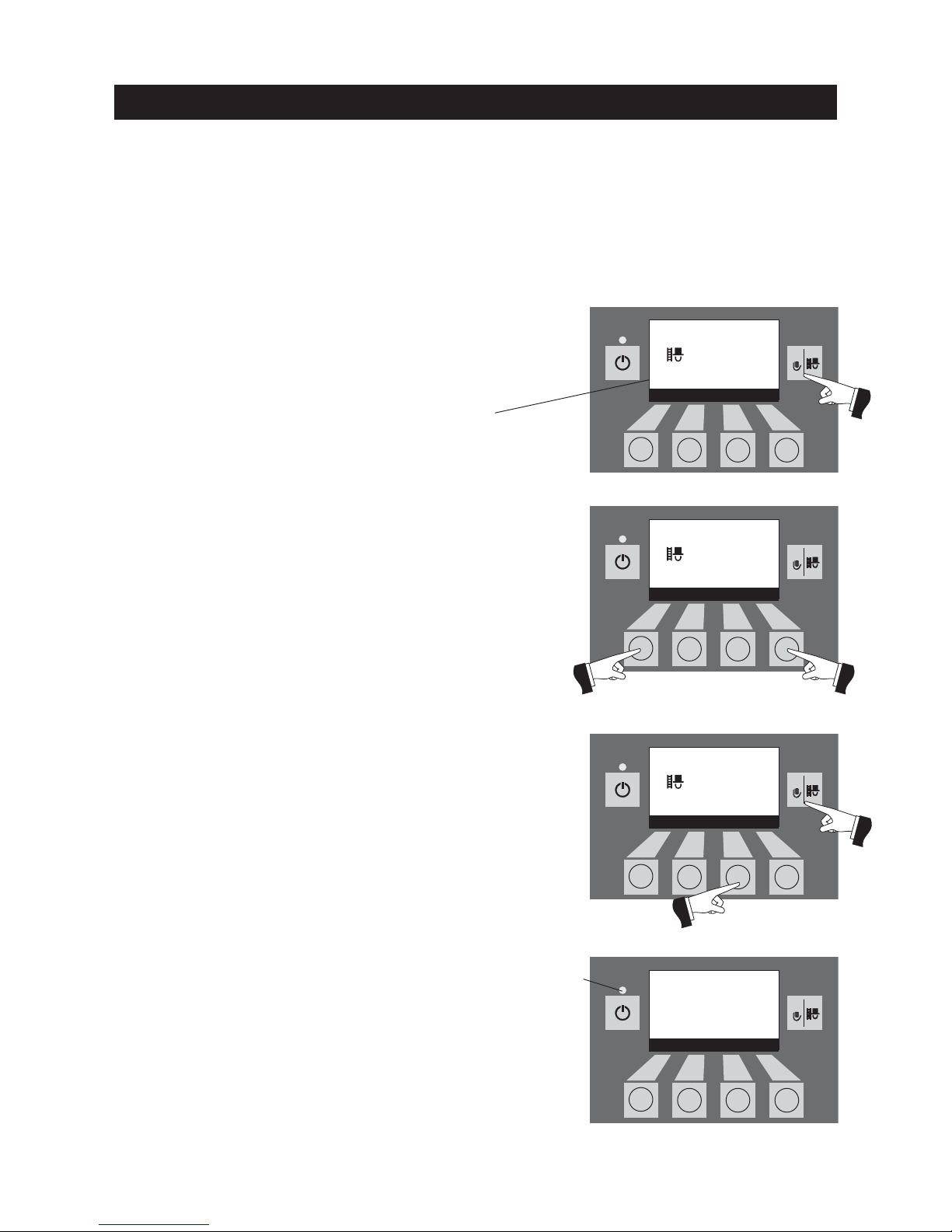

Fig. 2 Switching off the VarioWIN

Important information for system operators

1.5 Operating noises

The VarioWIN is a modern, fully automated pellet central heating boiler with a high level of convenience in terms

of operation and cleaning. This automation means that operating noises may occur during normal operation.

Normal operating noises are:

Flame noises

– Natural flame noise can be heard depending on the size of the flames.

Light scratching and scraping noises

– Depending on the level of contamination, cleaning noises may occur

during automated cleaning or shake-out. If these become louder over time ⇒ Clean the pellet central heating

boiler, especially the burner pot.

Trickling of pellets and vacuum cleaner noise

– Fully automated pellet supply involves pellets being sucked from

the storage room into the reserve supply container. During filling, the suction turbine generates a „vacuum cleaner noise“ in the storage room and the feed hose, and the trickling of the pellets can be heard in the reserve

supply container.

Clicking noises

– The relays switch on or off when the control unit is installed.

Liquid noise, gurgling

– This is caused by air in the heating water ⇒ Bleed the system.

Air induction noises

– Air induction noise occurs at the air supply induction point for combustion (air opening

in the device) ⇒ Use air supply pipes to relocate the induction point outside the house or into an adjacent room.

Note:

Due to these operating and flame noises, we do not recommend installing the device in bedrooms or

quiet rooms – see also the information in the VarioWIN „Assembly instructions“.

The pellet boiler must be switched off correctly at least 15 minutes before the store is filled – Fig. 2.

Press the ON/OFF button. Never switch off using the emergency OFF switch!

Pressing one of the six buttons firstly switches just the

lighting and display on. The boiler is only switched off

when the button is pressed for the 2nd time. Wait until

burnout mode has finished (not indicated on the display)

and open the combustion chamber doors.

During filling, negative pressure is created in the pellet

store and this can cause burn-back in the pellet boiler. Therefore, the boiler must be stopped from operating during

the filling procedure.

Fig 2a „Storage room fill“ sticker on the

storage room door

Every storage room fill should be documented by adding

the date and volume to the „Storage room fill“ sticker –

Fig. 2a.

002357/00

01/2010

Befüllung Lagerraum

Filling date and volume

Remplissage du silo de stockage

Datum/Date/Date

Menge/Volume/Quantité

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

kg

7

Never fill the burner pot with pellets by hand. Excessive combustion material in the burner pot means

that the pellets will not be ignited optimally. Too much low temperature carburisation gas will be generated and this can lead to deflagration.

1.7.3 Burner pot

Do not open the combustion chamber door, there is an increased risk of deflagration when opening the

combustion chamber door. A self-test is performed following a power failure during combustion and

then operation is continued automatically.

1.7 Sources of danger

1.7.1 Fire protection

The entire system must comply with technical fire protection requirements in accordance with the applicable

regulations, standards and guidelines.

1.7.2 Power failure (or if the blower is not running)

Important information for system operators

1.7.5 Direct pellet feed

Do not attempt to enter an unaired storage room (particularly buried tanks).

1.7.6 Entering the pellet storage room, storage container

In certain conditions, higher concentrations of harmful gases (e.g. carbon monoxide) may build up in pellet storage rooms. If these are allowed to build up over long periods, it may present a hazard. Even though there is

no risk under normal circumstances, this scenario cannot be completely ruled out.

– When working in filled pellet storage rooms, in the interests of safety a second person should always remain

outside the storage room. Always air pellet stores thoroughly before entering.

– For stores that are difficult to access or only accessible from above (e.g. buried tanks), the person entering

the store should use additional safety equipment.

– Keep children away from the pellet store!

1.7.4 Heating door and ash door handles

Warning of hot surface: risk of burns!

Before touching the combustion chamber and ash door handles, you must switch off the boiler and let

it cool.

Please note: Risk of crushing from rotating auger.

Before entering the pellet store or handling the unit with the auger open, always de-energise the boiler.

Never operate the boiler with the extraction port (auger) open!

8

Operation

2.1 Functional description

The VarioWIN pellet central heating boiler and the Modular Energy System MES or the REG standard control

combine to form a perfect unit. The VarioWIN automatically fires when the control system signals a heating requirement. Following „purging“ (safety function), ignition starts and the pellet metering auger switches on. The

burner pot is automatically filled with pellets. When flame formation has been detected (by the thermocontrol

sensor), the boiler enters flame stabilisation mode and then control mode (modulation mode) and keeps to the

specified boiler temperature setpoint (between 60 °C and 75 °C). The boiler enters burnout mode if the output

drops below the minimum nominal thermal output or no heating requirement is signalled by the control system.

The blower continues to run until the burner pot has cooled down. Therefore, do not switch off the electricity

supply to the device too soon.

2.1.1 VarioWIN Premium

Manual cleaning:

The heating surfaces are cleaned manually using the cleaning lever. The cleaning residues from the heating

surfaces and the combustion residues from the burner pot drop into the ash pan or ash pan space.

VarioWIN Premium-D with direct pellet feed and extraction port for mounting a year-round pellet container

Direct pellet feed transports the pellets from a sheet steel tank or self-build pellet store via a rotary feeder to

the burner pot.

2.1.2 VarioWIN Exklusiv

Automatic cleaning:

Fully automatic heating surface cleaning:

A motor moves the heating surface cleaning system vertically and the heating surfaces remain clean.

Fully automated ash compactor:

The fully automated ash compactor uses a motor and pressure plate to compress the ash in the ash container.

This makes the emptying intervals up to 3 times longer.

VarioWIN Exklusiv-S with 41 kg pellet reserve supply container

The reserve supply container is loaded by hand.

VarioWIN Exklusiv-P with pneumatic pellet feed

The pellet feed uses a maintenance-free suction turbine to fill the VarioWIN reserve supply container fully automatically with pellets from a pellet storage room or storage container. The pellet feed is switched on by the

lower fill level switch (proximity switch) in the reserve supply container or at the end of the enable time or the

beginning of the start time, and runs for as long as the reserve supply container is full. Filling is not started if

the boiler is in heating operation or the feed has been blocked by the control unit (outside the enable time, e.g.

at night). If the boiler is operating when filling is necessary, the boiler switches to burnout mode.

Switching between suction probes 1, 2 and 3 is fully automatic. The system changes to the next suction probe

after the reserve supply container has been filled a certain number of times. This means the storage room is

emptied as evenly as possible.

VarioWIN Exklusiv-D with direct pellet feed and extraction port for mounting a year-round pellet container

Direct pellet feed transports the pellets from a sheet steel tank or self-build pellet store via a rotary feeder to

the burner pot.

9

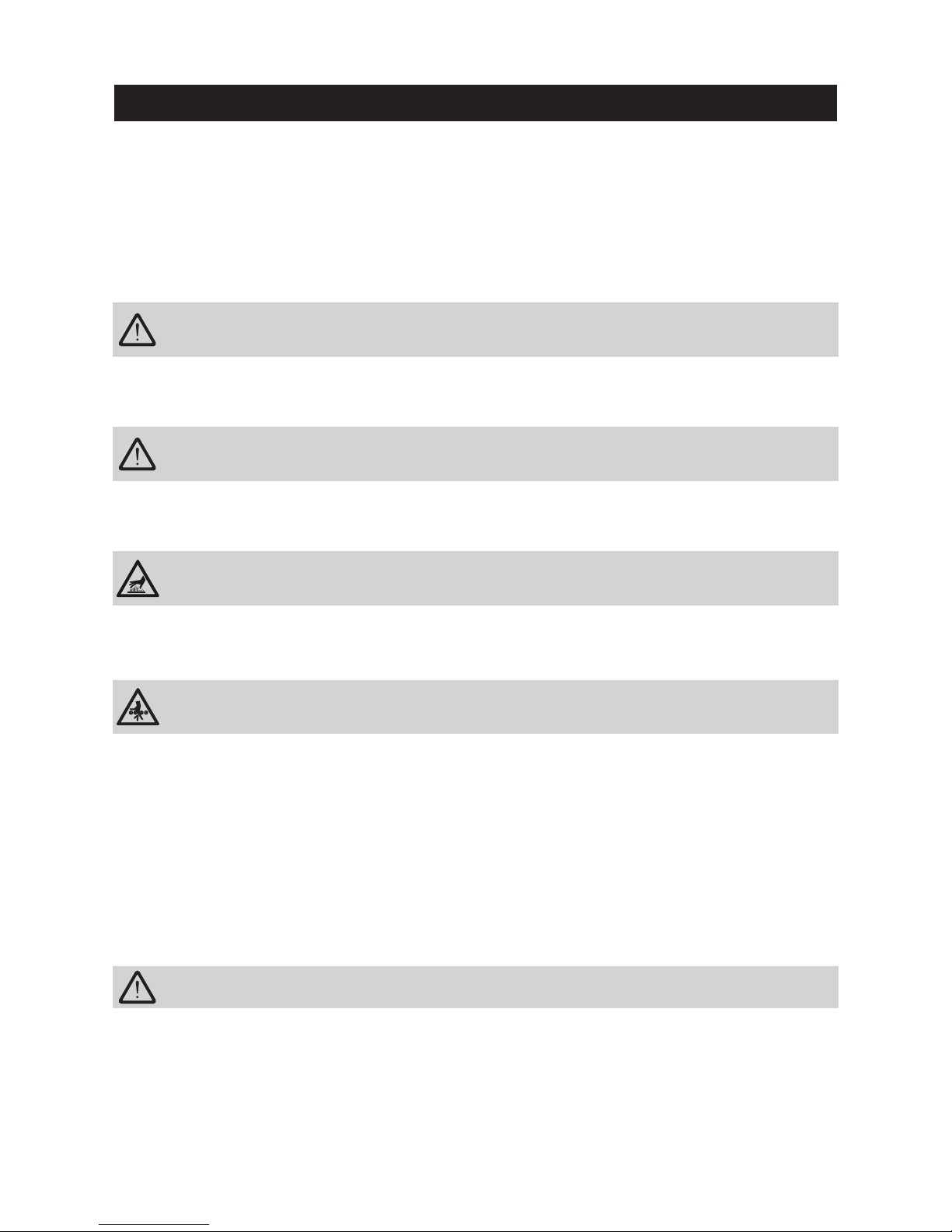

Fig. 3 VarioWIN with direct pellet feed – View from right

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 *

22

24

20

21

23

25

26

27

Operation

2.2 Functional elements and operating controls

2.2.1 VarioWIN with direct pellet feed

1 Ash pan

2 Ash door

3 Filling and evacuation cock

4 Primary air pin

5 Pressure gauge

6 Burner pot

7 Down chute

8 Combustion chamber door

9 Baffle plate

10 Thermocontrol sensor

11 Cladding door

12 Heating surface cover

13 Safety valve

14 Down channel

15 Exhaust pipe

16 Exhaust pipe cleaning opening

17 Blower motor

18 Blower box

19 Motor for ash compactor

20 Auger flange

21 Rotary feeder

Rotary feeder cleaning opening

22 Spur gear

23 Auger motor

24 Metering auger

25 Maintenance pipe

26 Rotary feeder proximity switch

27 Extraction port

10

Operation

2.2.2 VarioWIN with 41 kg reserve supply container, manual loading

Fig. 5 VarioWIN with pneumatic pellet feed – View from right

1

2

3

5

6

7

9

10

13

17

16

18

19

20

4

8

11

12

22

21

23

24 25

15

1 Ash pan

2 Ash door

3 Filling and evacuation cock

4 Primary air pin

5 Pressure gauge

6 Burner pot

7 Down chute

8 Combustion chamber door

9 Baffle plate

10 Thermocontrol sensor

11 Cladding door

12 Heating surface cover

13 Safety valve

14 Reserve supply container cover

15 Protective grille

16 Rotary feeder

17 Metering auger and motor

18 Rotary feeder cleaning opening

19 Exhaust pipe

20 Exhaust pipe cleaning opening

21 Blower motor

22 Blower box

23 Motor for ash compactor

2.2.3 VarioWIN with pneumatic pellet feed

1

2

3

5

6

7

9

10

13

14

15

17

16

18

19

20

4

8

11

12

22

21

23

Fig. 4 VarioWIN with 41 kg reserve supply container – View from right

1 Ash pan

2 Ash door

3 Filling and evacuation cock

4 Primary air pin

5 Pressure gauge

6 Burner pot

7 Down chute

8 Combustion chamber door

9 Baffle plate

10 Thermocontrol sensor

11 Cladding door

12 Heating surface cover

13 Safety valve

15 Reserve supply container cover

16 Rotary feeder

17 Metering auger and motor

18 Rotary feeder cleaning opening

19 Exhaust pipe

20 Exhaust pipe cleaning opening

21 Blower motor

22 Blower box

23 Motor for ash compactor

24 Inspection cover

25 Coarse filter

11

Operation

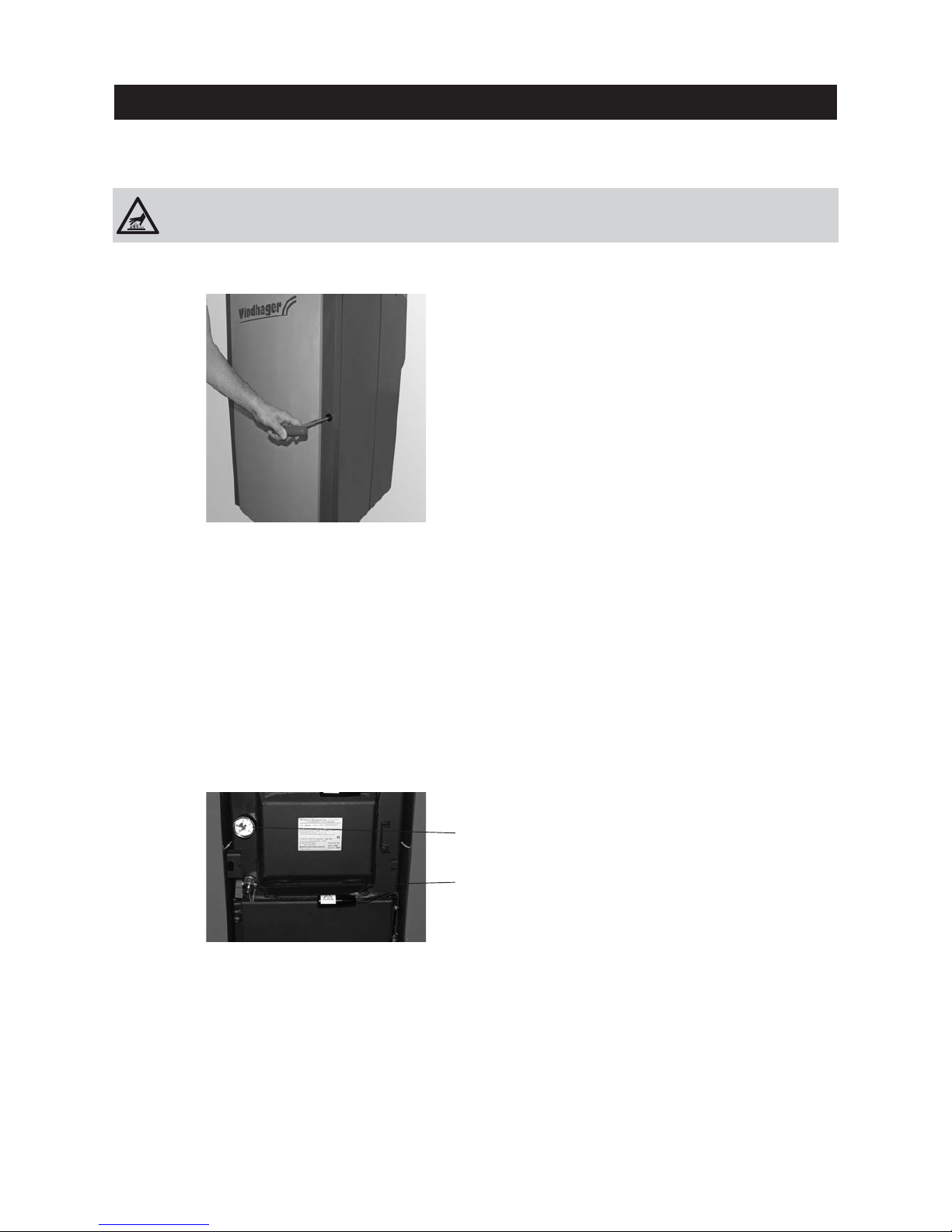

2.4 Check before initial start-up

a) System pressure (heating water pressure):

The system must be filled and vented. With the system cold, pressure should be at least 1.0 bar (maximum

1.8 bar) – Fig. 7. If you have any questions, your installer will gladly answer them.

Pressure gauge (system pressure)

Fig. 7 Filling the system

b) Ventilation:

If you are operating the device with room air, please make sure the room where it is installed is well ventilated. The air supply must be as free of dust as possible.

c) Flue:

Please have the chimney sweep check the flue, and, if necessary, clean it.

Filling and evacuation cock

2.3 Opening the cladding door

Fig. 6 Opening the cladding door with the key.

Warning of hot surface: risk of burns!

Before touching the combustion chamber and ash door handles, you must switch off the boiler and let

it cool.

Insert the key, turn a quarter turn to the left and open the cladding door – Fig. 6.

12

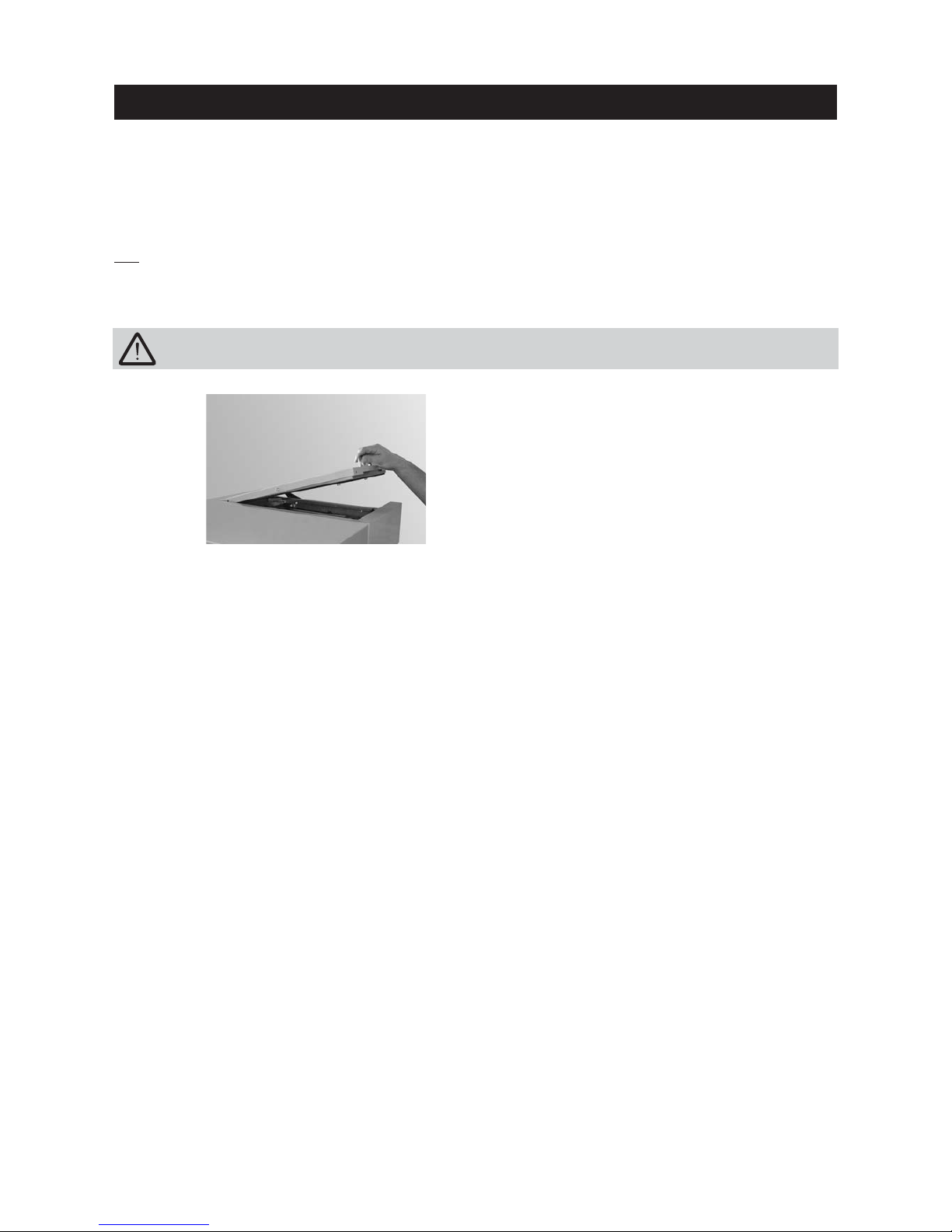

2.5 Filling the reserve supply container

2.5.1 VarioWIN Exklusiv-S – Manual filling

Fold open the cover of the reserve supply container (Fig. 8) and fill the reserve supply container up to max. 1

cm below the edge. Close the cover.

Tip:

The reserve supply container should always be completely filled with pellets. This allows the incoming pellets to drop into the container better, reduces the size of the conical part of the pile and means that the container empties better.

Fig. 8 Folding open the cover

When filling, make sure no extraneous materials (e.g. shreds of the pellet bags resulting from cutting

open the bags) get into the reserve supply container – they could block the rotary feeder!

2.5.2 VarioWIN Exklusiv-P – Pneumatic pellet feed

The reserve supply container is filled by the fully automatic pellet feed. WINDHAGER Customer Service or the

customer service PARTNER will perform the first fill (start-up), take the boiler and its pellet supply into service

and familiarise the customer with the operation and cleaning of the boiler, with reference to the Operating Manual.

Operation

2.5.3 VarioWIN Premium/Exklusiv-D – Direct pellet feed

The VarioWIN is supplied by the direct pellet feed from the year-round pellet reserve supply container. WINDHAGER Customer Service or the customer service PARTNER will perform the first fill (start-up), take the boiler

and its pellet supply into service and familiarise the customer with the operation and cleaning of the boiler,

with reference to the Operating Manual.

13

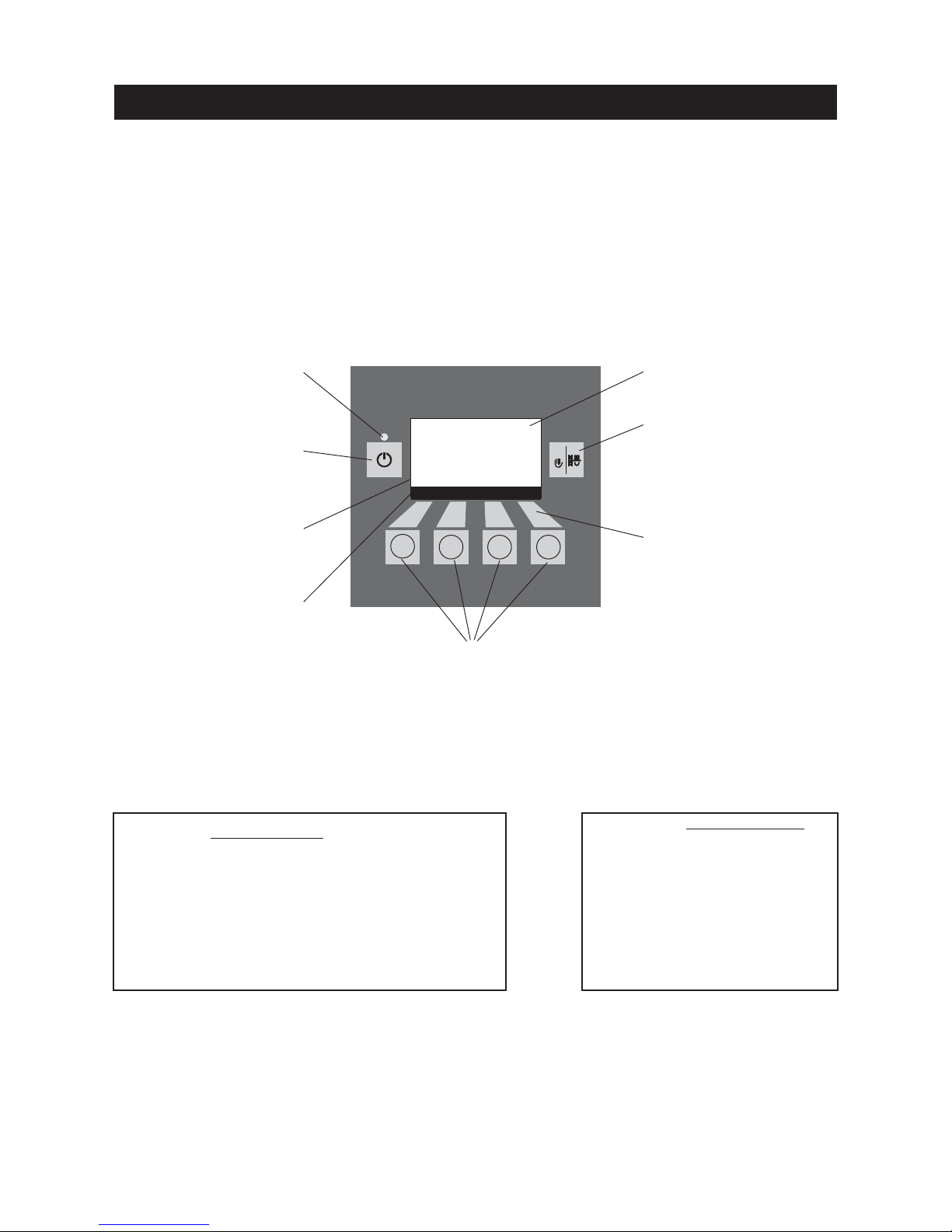

5s

RESET

Full-text display

(illuminated display)

Manual operation / flue cleaning

function

Signal lamp (LED)

„Operation“ – green;

„Malfunction“ – red

Menu buttons

ON/OFF button

Menu line

Operating phases are

displayed here, including

Standby, Burner OFF, etc.

Assignment of buttons to

their specific function

Operation

The various operating modes are displayed on InfoWIN together with the corresponding operating phases.

The following operating modes exist:

–OFF

– ON (with self-test, lighting ON, lighting OFF)

– Pellet feed

– Solid fuel / buffer mode

– Manual operation

– Flue cleaning function

– Shutdown procedure

Corresponding operating phases:

– Standby

– Purging

– Ignition phase

– Flame stabilisation

– Modulation mode

– Burnout

– Burner OFF

– Switch off heat generator

è

Boiler temperature

Standby

Info Menu

38

°C

Fig. 9 InfoWIN

2.6 InfoWIN

The InfoWIN is the boiler’s display and operating unit.

The InfoWIN unit consists of a large text display, an ON/OFF button with an LED signal lamp indicating Opera-

tion (green) or Malfunction (red); a switch for the flue cleaning function and four individual menu buttons. The

function of each menu button is displayed on the Menu line.

14

5s

RESET

5s

RESET

5s

RESET

Operation

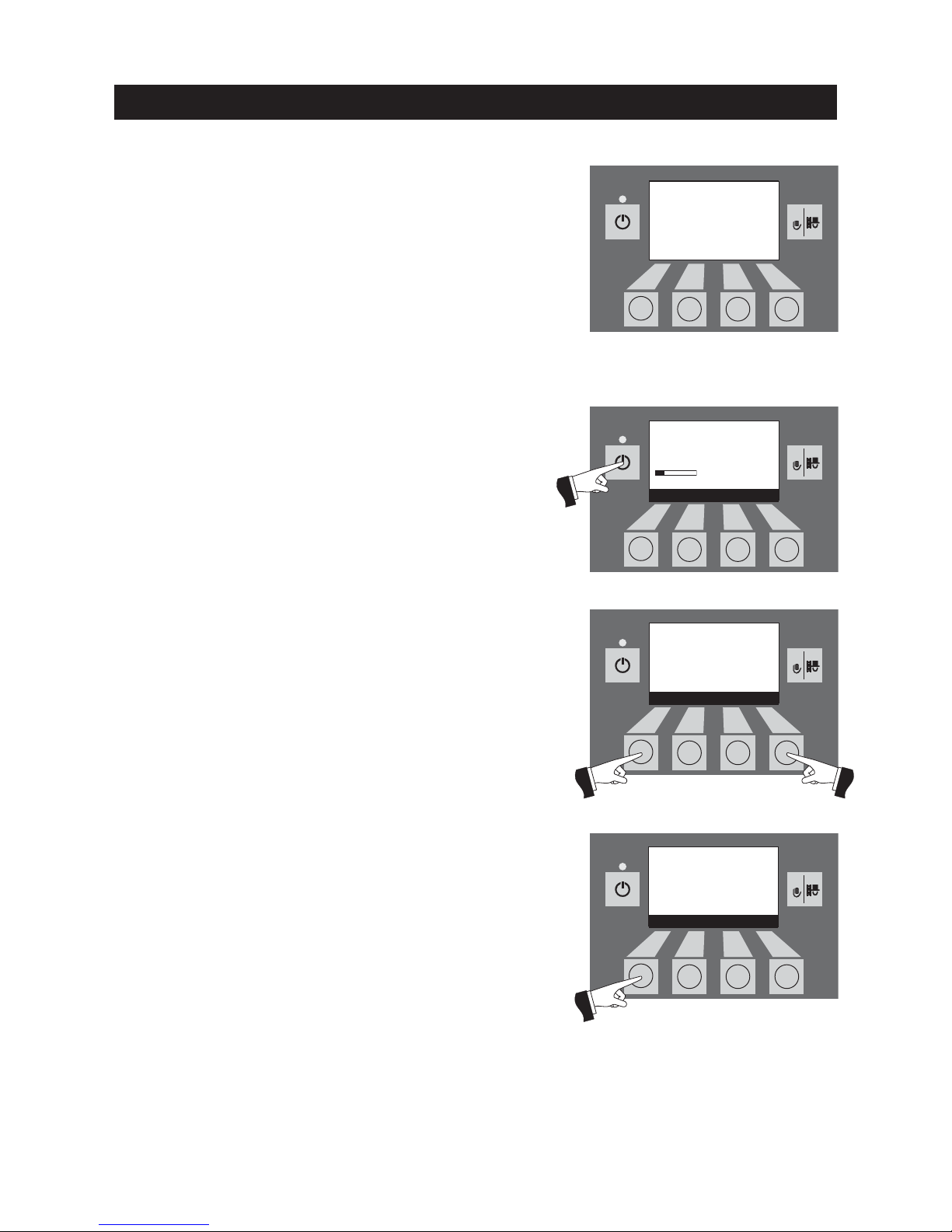

2.7 Operating modes

2.7.1 OFF mode

The boiler is switched off when in OFF mode. The display and all

buttons, with the exception of the

ON/OFF

button, do not function.

The LED on the InfoWIN is not illuminated – Fig. 10.

2.7.2 ON mode, lighting ON,

self-test, lighting OFF

Press the ON/OFF button, lighting and display are switched on and

the self-test starts automatically – Fig. 11.

Self-test:

Sensors, switches and motors are checked during the self-test.

After a successful self-test, the display shows an operating phase

and the boiler water temperature (standard display). The LED signal lamp lights green and the desired functions can be selected

using the buttons – Fig. 12.

If the self-test was unsuccessful, an information message (e.g. information, fault, alarm) is displayed (see sections 4.3 and 4.4).

Fig. 12 Standard display

Fig. 13 Display lighting OFF

Lighting ON/OFF

The display lighting switches off automatically after 10 min. (Fig.

13). Pressing one of the six buttons switches the lighting on again

for 10 min.

InfoWIN identifies and stores the various operating modes and states. Once the system is switched on, other operating modes may

also be displayed instead of the standard display, such as manual

operation or solid fuel/buffer mode; malfunctions are also displayed. These operating modes and states are described later in these

instructions.

Fig. 11 Self-test

5s

RESET

Fig. 10 OFF mode

Self-test active

.....

(Animated symbol)

Boiler temperature

(Operating phases)

Info Menu

42

°C

Boiler temperature

(Operating phases)

Info Menu

42

°C

15

Operation

2.7.4 Solid fuel/buffer mode

If the VarioWIN pellet central heating boiler is combined with a solid fuel boiler or an buffer tank, the WVF or BUL module automatically switches over between pellet and solid fuel/buffer mode.

Combustion of the VarioWIN is stopped when the WVF or BUL module sends

the request to switch over to solid fuel/buffer mode – Fig. 16.

Following this, the system switches over to solid fuel/buffer mode and the

VarioWIN burner is locked – Fig. 17

If the pellet central heating boiler is switched off using the ON/OFF button on

the InfoWIN, an automatic switchover to solid fuel/buffer mode is performed

in conjunction with a WVF module. Once the InfoWIN unit is switched on, the

pellet central heating boiler may be locked for a maximum of 15 minutes due

to the switch-over delay. This is displayed by InfoWIN – Fig. 17.

After an hour in solid fuel/buffer mode, the display is shut down fully and only

the green LED is lit up. The display is switched back on by pressing a button

or when there is a heating requirement.

Fig. 16

Fig. 17

Solid fuel/

buffer mode

Burnout

Info Menu

42

°C

Solid fuel/

buffer mode

Burner locked

Info Menu

42

°C

2.7.3 Pellet feed

Pellet feed – Burnout

Pellet feed from the storage room into the reserve supply container has been

requested. Combustion is stopped. Pellet transport into the burner pot is stopped, the vacuum fan continues to run until all the remaining pellets have been

burned and the burner pot has cooled down – Fig. 14.

Pellet feed in operation

The pellet feed is in operation. Pellets are supplied from the storage room into

the reserve supply container. The burner is locked – Fig. 15.

Fig. 14

Fig. 15

Pellet feed

Burnout

Info Menu

42

°C

Pellet feed

in operation

Burner locked

Info Menu

42

°C

16

5s

RESET5sRESET

5s

RESET5sRESET

Operation

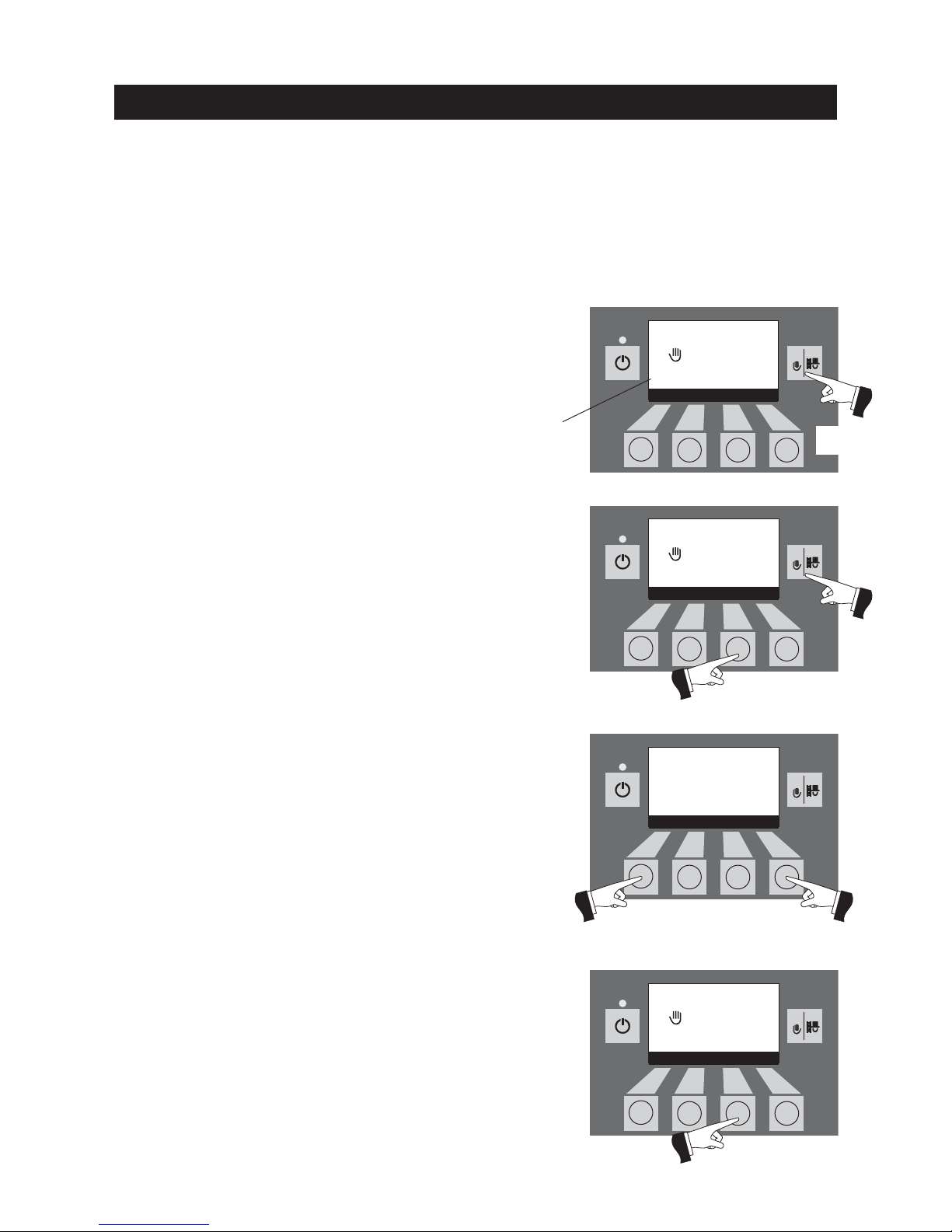

2.7.5 Manual operation

Fig. 18

Pressing the

Cancel

button or the

Manual operation / flue cleaning

function

button terminates the function – Fig. 19. The boiler returns

to automatic operation.

Setpoint adjustment for manual operation

By pressing the + or – button the display switches to the set temperature adjustment mode – Fig. 20. Use the

+

or –button to change the setpoint in 1 K steps. The temperature set in this mode is

not permanently saved. The original set temperature is used once

manual operation ends.

By pressing the

Back

button (Fig. 21) or after waiting 45 seconds,

the screen returns to its previous display.

Press for 5

seconds

The various operating phases are displayed here, including Burner in operation, Burner OFF, etc.

Fig. 19

Fig. 20

Fig. 21

Pressing one of the six buttons switches the lighting and display on.

Manual operation starts if the Manual operation / flue cleaning function button is pressed for more than five seconds – Fig. 18. This sets

the boiler temperature to the setpoint fixed for manual operation

(standard value 60 °C). The control system is not affected by this. The

lighting is switched off after the lighting timer has counted down

(10 min.); the function or display remains unchanged.

Note:

Manual operation cannot be started in „solid fuel/buffer mode“. Manual operation must not be started if

an installed solid fuel boiler is operating (heated up). Manual operation may be started if there is no solid fuel

boiler installed or if this is not operating and only the buffer tank is active. In this case, first set the operating

mode switch on the WVF module to relay test 2 or on the BUL module to relay test 1 (see WVF or BUL module operating manual).

16

Manual operation

Boiler temperature

(Operating phases)

– Cancel +

42

°C

(Symbol flashes)

Manual operation

Boiler temperature

(Operating phases)

– Cancel +

42

°C

(Symbol flashes)

Manual operation

Set temperature

– Back +

70

°C

Manual operation

Set temperature

– Back +

70

°C

(Symbol flashes)

17

5s

RESET5sRESET

5s

RESET5sRESET

Briefly pressing the

Manual operation / flue cleaning function

button

switches on the display illumination. Pressing the button again starts

the flue cleaning function – Fig. 22. The boiler temperature is set to

approx. 60 °C for 45 min.

Operation

2.7.6 Flue cleaning function

This function aids the performance of legally-required emissions testing.

The flue cleaning function ends

– when the

Cancel

button is pressed – Fig. 24.

– automatically after about 45 minutes.

The various operating phases are

displayed here, including Burner in

operation, Burner OFF, etc.

Fig. 24

Fig. 23

Fig. 22

2.7.7 Shutdown procedure

The boiler is switched off – Fig. 25.

Fig. 25

The green LED flashes

Note:

The flue cleaning function cannot be started in „solid fuel/buffer mode“. The flue cleaning function must

not be started if an installed solid fuel boiler is operating (heated up). The flue cleaning function may be started if there is no solid fuel boiler installed or if this is not operating and only the buffer tank is active. In this

case, first set the operating mode switch on the WVF module to relay test 2 or on the BUL module to relay test

1 (see WVF or BUL module operating manual).

Pressing the corresponding menu button enables the boiler to be operated with 30 % or 100 % output – Fig. 23. The lighting is switched off

after the lighting timer has counted down (10 min.); the function or

display remains unchanged. When the button is first pressed only the

lighting is switched on.

When the

Manual operation / flue cleaning function

button is pres-

sed again the operating time is reset to 45 min.

Flue cleaning function

Power 100% 45min

(Operating phases)

30% Cancel 100%

42

°C

(Symbol flashes)

Flue cleaning function

Power 30% 45min

(Operating phases)

30% Cancel 100%

42

°C

(Symbol flashes)

Flue cleaning function

Power 30% 45min

(Operating phases)

30% Cancel 100%

42

°C

(Symbol flashes)

Shutdown procedure

Burnout

Info Menu

42

°C

18

2.8.6 Burnout

Combustion is stopped. Pellet transport into the burner pot is stopped, the

vacuum fan continues to run until all the remaining pellets have been burned

and the burner pot has cooled down – Fig. 31.

2.8.7 Burner OFF

There is a heating requirement from the control system, but the boiler temperature (actual value) is higher than the boiler temperature setpoint. This

means combustion is stopped and the burner is switched off – Fig. 32.

Fig. 31

Fig. 32

Boiler temperature

Burnout

Info Menu

42

°C

Boiler temperature

Burner OFF

Info Menu

42

°C

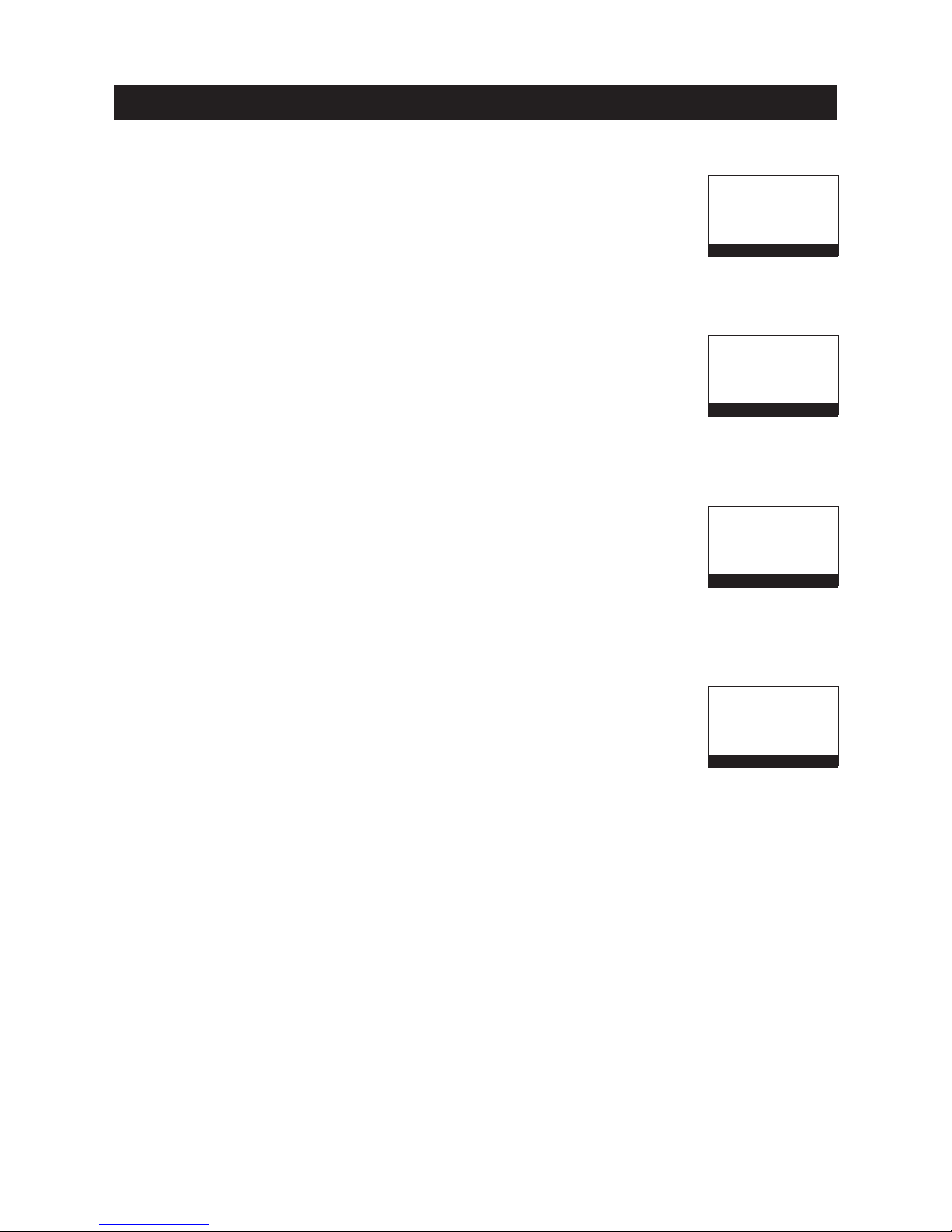

2.8 Operating phases

2.8.1 Standby

During this operating phase, the control system does not transmit requests

for heat. The burner is switched off and the boiler temperature setpoint is 0 °C

– Fig. 26.

After an hour in standby mode, the display is shut down fully and only the

green LED is lit up. The display is switched back on by pressing a button or

when there is a heating requirement.

2.8.2 Purging

The vacuum fan runs, the combustion chamber of the VarioWIN is flushed

through with fresh air. This phase can last several minutes before the burner

fires – Fig. 27.

2.8.5 Modulation mode

The burner is in modulation mode. The output can be infinitely varied between

30 % and 100 % – Fig. 30.

Operation

2.8.3 Ignition phase

The vacuum fan runs, pellets are transported into the burner pot and are ignited. When flame formation is detected, the system switches over to flame stabilisation – Fig. 28.

2.8.4 Flame stabilisation

Following the ignition procedure, even combustion is established and then the

system switches over to modulation mode – Fig. 29.

Fig. 26

Fig. 27

Fig. 28

Fig. 29

Fig. 30

Boiler temperature

Standby

Info Menu

42

°C

Boiler temperature

Purging

Info Menu

42

°C

Boiler temperature

Ignition phase

Info Menu

42

°C

Boiler temperature

Flame stabilisation

Info Menu

42

°C

Boiler temperature

Modulation mode

Info Menu

42

°C

Loading...

Loading...