Windhager LogWIN Assembly Instructions

Assembly instructions

08/2008 xxxxxx/00

LogWIN

Wood gasification boiler

2

Table of contents: Page

Important initial information for the Technician . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Please note! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

For the Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Delivery, packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Taking into the building and installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Dimensional sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5 Installing the cladding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.6 Installing the exhaust pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.7 Installing the thermal process safeguard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.8 Storing the instruction booklets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.9 Initial start-up and operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

For the Electrician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

For the Service Technician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.1 Service and repair work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.2 Checking and servicing the thermal process safeguard . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.3 Technical data for calculating the flue gas system acc. to EN 13384-1 . . . . . . . . . . . . . . .26

4.4 Technical data – General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.5 Service level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.6 LogWIN basic circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Guarantee and warranty limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3

Important initial information for the Technician

The following instructions are available for operation and installation:

Heating expert: Assembly/installation instructions, list of spare parts

System owner: Operating Manual, quick guide, heating instructions

1.1 Safety

The boiler and related accessories are state of the art and meet all applicable safety regulations.

1.2 Please note!

Your boiler and all accessories can be operated using 230 V AC electrical voltage. Improper installation or repair

can pose the danger of life-threatening electrical shock. Installation and repair may be performed only by appropriately qualified technicians.

Caution symbols

Please take careful note of the following symbols in these assembly instructions.

Ignoring the warnings identified can lead to personal injury.

Ignoring the warnings identified can lead to malfunction of, or damage to the boiler or heating sys-

tem.

The specified safety requirements are to be followed in accordance with nationally applicable regulations, standards and guidelines.

1.3 Flue

A properly dimensioned flue is required for optimal functioning of the combustion system. Measurement of the

dimensions must follow EN 13384-1. See the Technical data section (section 4.3) for values required for this calculation.

Please note that in the permissible performance range, flue gases may be below 160°C. A draught limiter is

needed if the maximum draught is exceeded during operation.

Note: We would recommend fitting the draught limiter outside the flue around ½ m below where the exhaust

pipe intersects with the flue.

Frequently, overhaul of existing systems involves over-sized flue cross-sections or unsuitable flues. We sug-

gest an evaluation by the local building inspector before installing the boiler system. In this way appropriate modifications can be made to the flue before system installation (see section 4.3 for flue calculation

values).

4

For the Installer

2.1 Delivery, packaging

2.1.1 LogWIN

Boiler covered with a plastic sack.

The cladding, control panel and small parts can be found in the 4 cardboard boxes and in the filler chamber.

2.1.2 Optional accessories

Fitted in control panel, if ordered:

– MES system control (installed and pre-wired)

Supplied with the boiler if ordered:

– Thermal process safeguard – FK-060

– Energy-saving intake regulator

– Return hold-up group – SK RH or SK RH 54

– Motorised mixing valve, mixer groups, heating distributor

FAX 090 cleaning package comprising: vacuum cleaner, magnetic flashlight, gloves and apron

Fig. 2 LogWIN boiler 180 – 500

Fig. 3 Cladding and control panel in 4 cardboard boxes.

In the filling chamber:

– Instruction booklets

– Screws and small part

– Top insulation

– Air control

– Connecting bracket cladding

(for LWP 360 – 500 only)

– Hanger

– Cleaning tools

– Ash pan

In cardboard box no. 1 (LWP03):

– Control panel complete

– InfoWIN (display/operating module)

In cardboard box no. 2 (LWP06):

– Side panel left

– Side panel right

In cardboard box no. 3 (LWP09/LWP10):

– Insulation flue outlet

– Rear wall top

– Rear wall bottom

– Hook-in plate ash pan

– Lever for cleaning heating surfaces

– Cladding door

– Cover for cladding door switch

In cardboard box no. 4 (LWP07/LWP08):

– Cladding door cover

– Front boiler cover

– Rear boiler cover

5

For the Installer

2.2 Taking into the building and installing

The appliance must be taken into the building and installed without subjecting it to significant knocks and jolts,

in order to avoid damaging the combustion chamber and/or the parts slipping. The warranty will be invalidated if the appliance is damaged due to having been taken into the building and installed incorrectly or if the appliance malfunctions as a consequence of this.

2.2.1 Taking into the boiler room/installation room

The LogWIN may only be transported upright and without cladding and it is easiest to transport using a lift truck

or by rolling on pipes. There is a crane lug on the top of the boiler for transport using hoisting winches. When

transporting via stairs and the such like, the boiler must be suitably secured. Also refer to the technical data in

section 4.4 for transport dimensions.

Tip:: The weight can be reduced by approx. 130 kg by removing parts which are easy to disassemble (e.g. doors,

hook-in plates, burnthrough plates, heating surface cleaning etc.).

2.2.2 Installing in the boiler room/installation room

The boiler can be installed directly on a non-flammable surface and does not require special foundations.

2.2.3 Note before connection

Move the boiler to its definitive installation position and use the set screws to align it inclined slightly upwards

towards the rear.

Tip: Before connecting the heating system, install the insulation, flue outlets and rear wall – see section 2.5.

Please note:

– The minimum clearances for connections, cleaning and maintenance should be observed – see section 2.2.4.

– Set up the boiler only in a dry area.

– Follow local regulations and guidelines regarding the boiler room/installation room.

– Sufficient ventilation of the set-up area must be assured.

Air consumption: LWP 18 kW: approx. 40 m

3

/h

LWP 25 kW: approx. 55 m

3

/h

LWP 30 kW: approx. 70 m

3

/h

LWP 36 kW: approx. 80 m

3

/h

LWP 50 kW: approx. 110 m

3

/h

The combustion air must be free from halogens and hydrocarbons (detergents, e.g. washing

machine) otherwise malfunctions may occur.

6

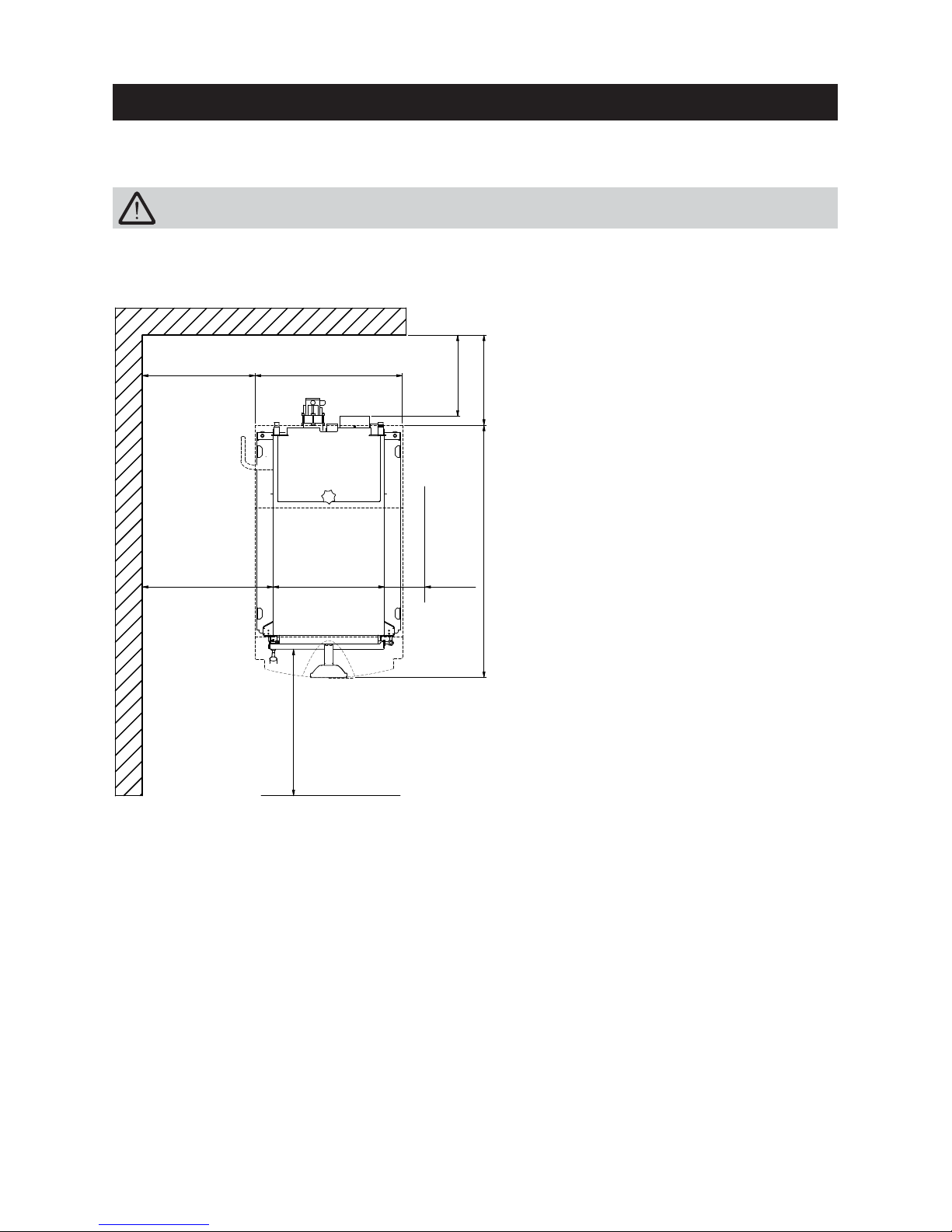

For the Installer

2.2.4 Minimum clearances

Fig. 4 View from above

Follow the installation guidelines for boiler room/installation room!

494

(604)

min.

580

(680)

min.

180

min.

650

(760)

min.

360

400

min.

500

(600)

654

(764)

1120

1)

Recommended minimum room heights: 1950 mm

All measurements in mm.

Details provided in brackets apply

to

LPW 360,500.

1) min 280 mm with door catch

on this side

7

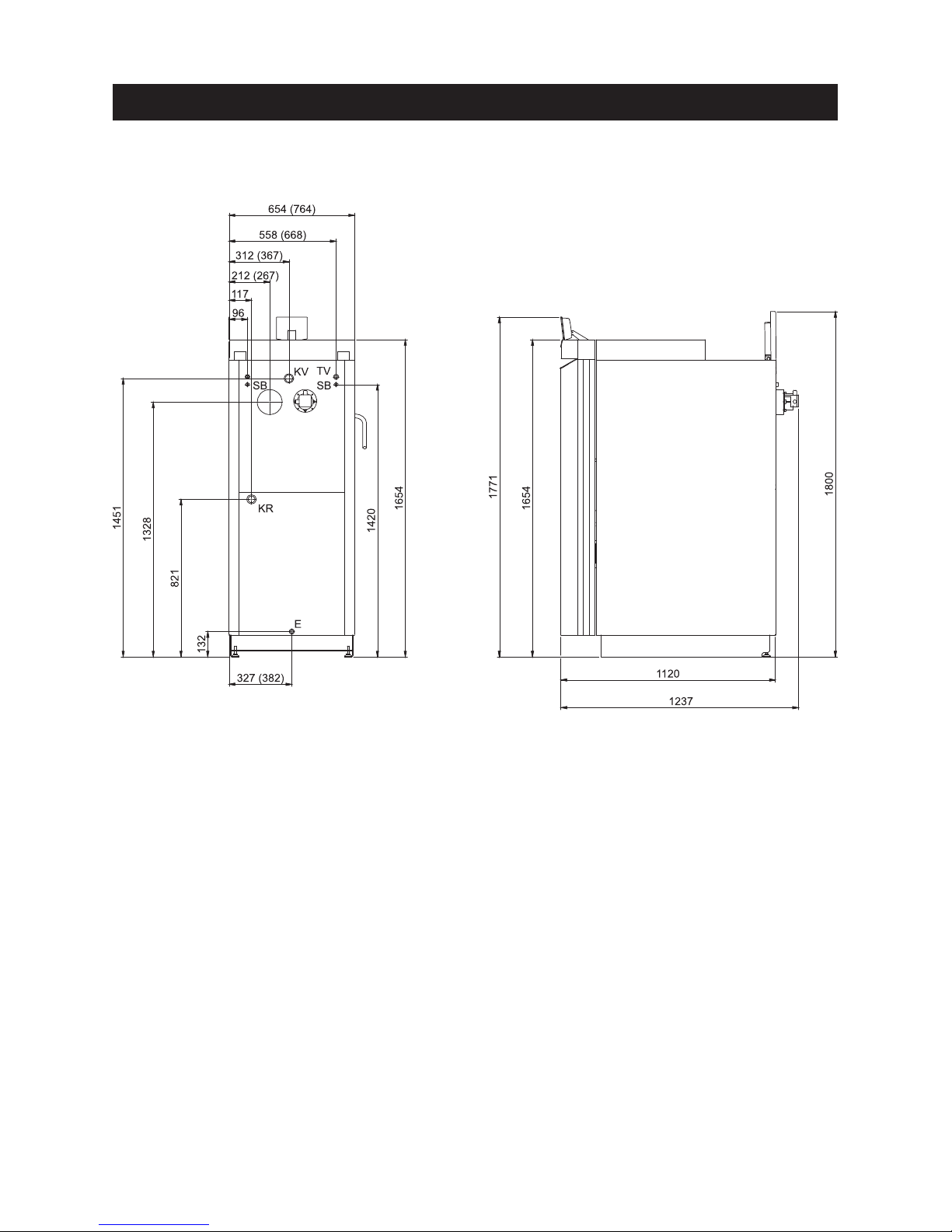

2.3 Dimensional sketches

Fig. 5 Rear view Fig. 6 Left view

KV . . . . .Boiler feed (5/4” pipe)

KR . . . . .Boiler return (5/4” pipe)

TV . . . . .Thermal valve sensor (1/2” sleeve)

SB . . . . .Thermal safety device (1/2” tube)

E . . . . .Discharge

For the Installer

2)

All dimensions in mm:

Details provided in brackets apply to

LPW 360 and 500.

2) with cleaning cover open

8

For the Installer

2.4 System

2.4.1 Area of use

For heating buildings acc. to EN 12831.

The boilers are designed and approved as heat generators for hot water heating systems with permissible flow

temperatures of up to 90 °C.

2.4.2 Standards

The following European standard should be followed: EN 12828, this specifies that the following should be fitted:

a) A closed expansion tank.

b) A reliably functioning safety valve installed at the highest point of the boiler or at a non-closable line.

c) A thermometer, a pressure gauge.

d) An automatic device for dissipating heat which will prevent the maximum permitted operating temperature

from being exceeded. The built-in thermal safety device (heat exchanger) should always be used in conjunction with the thermal process safeguard. In addition, a gravity feed hot water tank with thermal process safeguard can also be used.

e) A low-water cut-off: A low-water cut-off is not required for systems providing up to 300 kW nominal thermal

output, if it can be assured that excess heating will not result from a lack of water in the system.

If the boiler is above the radiators, then a low-water cut-off must be installed.

2.4.3 Accumulator tank

Having a correctly sized accumulator tank is essential for correct operation of a wood-fired heating system. The

fuel must always be selected and the heat load of the building calculated. Heating characteristics (e.g. bringing

the hot water tank up to temperature in summer) and the system configuration (ground and/or radiator heating

circuits) should also be taken into consideration.

Tip: Correct amount of fuel – i.e. boiler only ¼ – ½ full at the turn of the seasons.

With domestic water supply plants, a heat dissipation of the smallest possible boiler output must

be assured even if there is a power failure! Failure to comply with this requirement can result in a

thermal overload of the boiler components and invalidation of the warranty.

Rooms that are not heated at times (guest rooms, living areas only used at weekends, etc.) must be

subtracted from the calculated heat load (Q

H

) for the accumulator tank configuration!

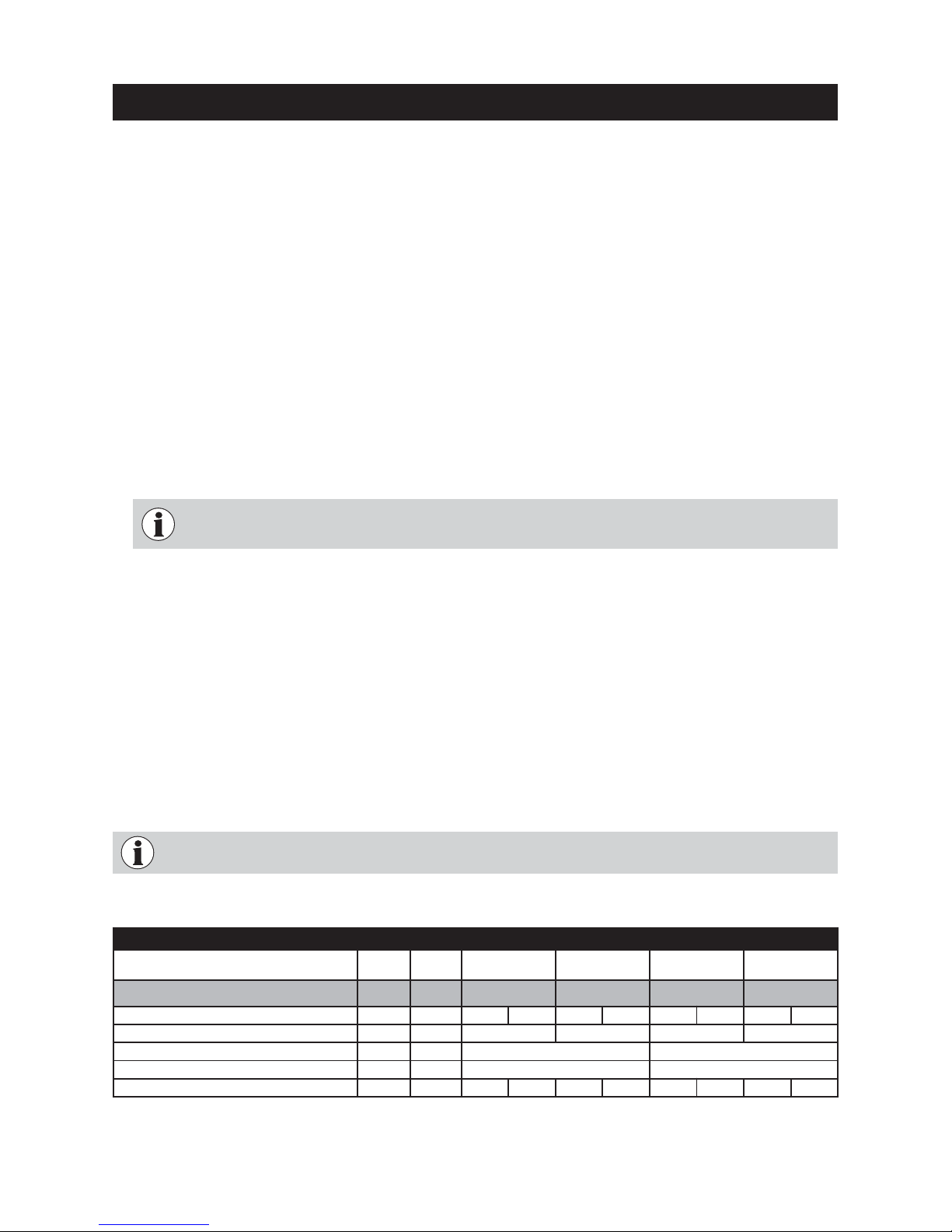

LogWIN LWP 180 LWP 250

Formula

symbol

Unit Beech fully filled

Spruce fully

filled

Beech fully filled

Spruce fully

filled

Recommended accumulator tank content: l 2000 2000 2000 2000

Heat load of the building acc. to EN 12831

Q

H

kW 13.0 17.4 13.0 17.4 13.0 25.0 13.0 25.0

Burning duration of the LogWIN at nominal thermal output

T

B

h 10.3 6.6 7. 2 4.6

Nominal thermal output of the LogWIN

Q

N

kW 17.4 25.0

Minimum thermal output of the LogWIN

Q

min

kW 13.0 13.0

Correction factor

1)

f 1.0 19 1.029 1.029 1.046 1.047 1. 15 6 1.074 1. 24 6

Recommended accumulator tank content:

9

For the Installer

Vsp= f · 15 · TB· QN· (1 – 0.3

Q

H

)

Q

min

Vsp= 15 · TB· QN· (1 – 0.3

Q

H

)

Q

min

Vsp= 55 litres · Q

N

1)

Correction factor f (Holzenergie Schweiz quality mark): A firewood boiler must be operated at nominal output for about 1 hour after starting. Additionally,

about 0.5 hour is required for heating up. As a rule, it is not possible to operate with the lowest possible output right from the start. The correction factor f

depends on the relationship between the nominal and lowest possible output levels and is individually set for each boiler (assumption: system reaches

nominal output 1.5 hours after starting).

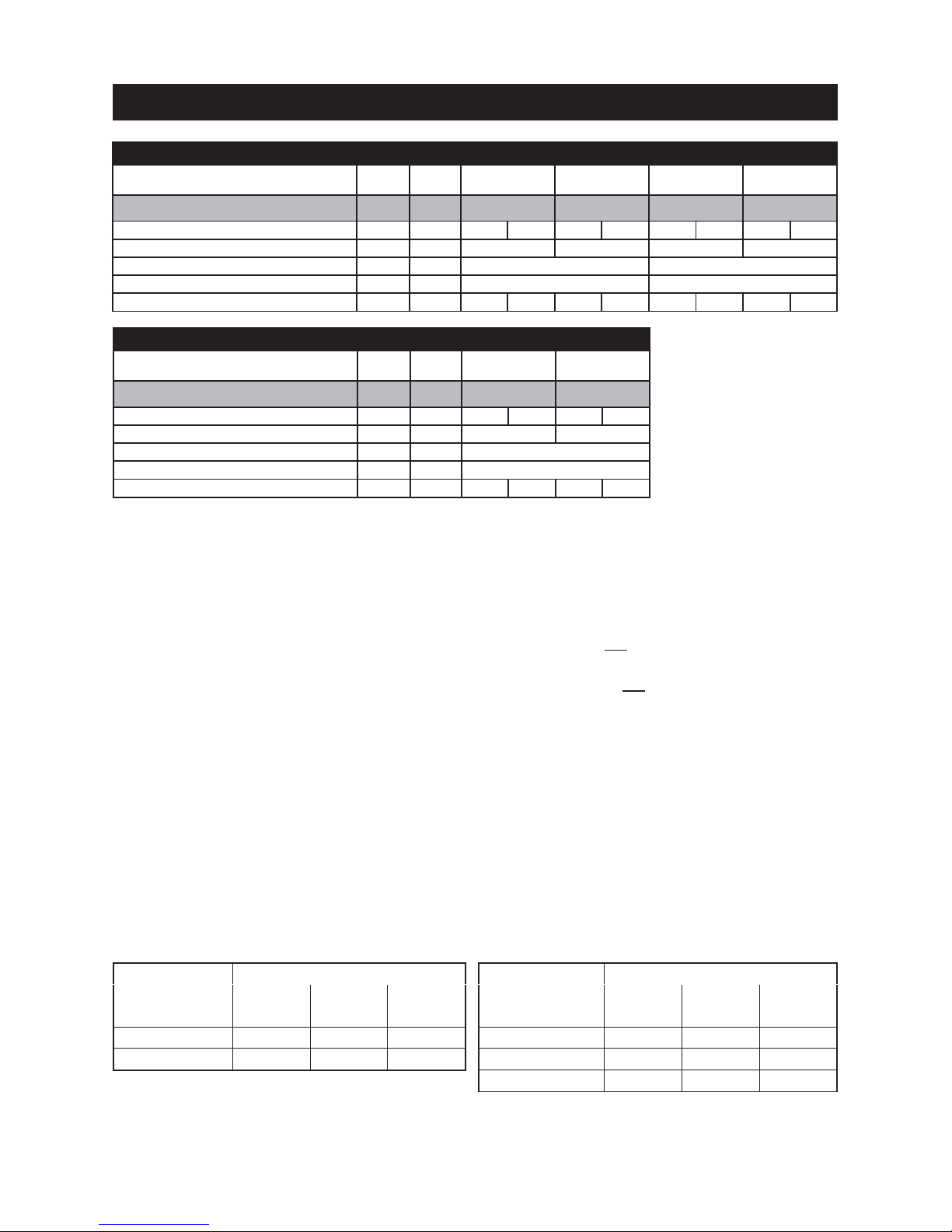

LogWIN LWP 500

Formula

symbol

Unit Beech fully filled

Spruce fully

filled

Recommended accumulator tank l 3000 3000

Heat load of the building acc. to EN 12831

Q

H

kW 24.0 49.9 24.0 49.9

Burning duration of the LogWIN at nominal thermal output

T

B

h 4.6 2.9

Nominal thermal output of the LogWIN

Q

N

kW 49.9

Minimum thermal output of the LogWIN

Q

min

kW 24.0

Correction factor

1)

f 1.0 72 1.280 1.11 4 1.439

Selection and combinations of accumulator tank CWK/CWK or CWK/CWP:

The accumulator tanks can be combined with one another in parallel in a flexible way. The connection set CW021 (accessory) can be used for the following tank combinations.

Klassik

Premium

CWK 700

(720 l)

CWK 1000

(1000 l)

CWK 1500

(1500 l)

CWP 800 (800 l) 1520 l – –

CWP 1000 (960 l) – 1960 l 2460 l

Klassik

Klassik

CWK 700

(720 l)

CWK 1000

(1000 l)

CWK 1500

(1500 l)

CWK 700 (720 l) 1440 l – –

CWK 1000 (1000 l) – 2000 l 2500 l

CWK 1500 (1500 l) – 2500 l 3000 l

CaloWIN Premium with CaloWIN Klassik Two CaloWIN Klassik appliances

Other combinations are also possible in series operation. In this case, the accumulator tanks must be connected by the client (no connection set is available).

LogWIN LWP 300 LWP 360

Formula

symbol

Unit Beech fully filled

Spruce fully

filled

Beech fully filled

Spruce fully

filled

Recommended accumulator tank content: l 2000 2000 2500 2500

Heat load of the building acc. to EN 12831

Q

H

kW 13,0 29,9 13.0 29.9 17.8 35.6 17.8 35.6

Burning duration of the LogWIN at nominal thermal output

T

B

h 6.0 3.8 6.3 4.1

Nominal thermal output of the LogWIN

Q

N

kW 29.9 35.6

Minimum thermal output of the LogWIN

Q

min

kW 13.0 17.8

Correction factor

1)

f 1.066 1. 36 8 1.10 3 1.579 1. 05 1 1.1 79 1.0 78 1. 27 3

10

2.4.4 Heating circuits

Several heating circuits:

The total consumed output is not allowed to exceed the nominal thermal output of the boiler. In-line regulating

valves must be installed to permit better regulation of the system. In a building without insulation (new building, not yet plastered) the calculated and actually required heating requirements often differ to a considerable

extent.

Minimum heat consumption:

It must be possible for the smallest possible boiler output must be continuously dissipated from the boiler during operation (see technical data in section 4.4.). Alongside an accumulator tank of a sufficient size, suitable measures for minimum heat consumption (e.g. never completely closing the manual mixing valve, “consumer circuit” or radiators that cannot be blocked off, not all radiators fitted with thermostatic valves) must be guaranteed

in each phase of operation.

Having a correctly sized accumulator tank is essential for correct operation.

Mixer valve:

A 3-way mixer valve is always necessary; in conjunction with outside temperature control, there must be a 3way motorised mixing valve and an accumulator tank.

Underfloor heating:

Possible with an accumulator tank (with outside temperature control, motorised mixing valve).

Return flow temperature increase:

This is necessary in all systems with an accumulator tank and in old systems with a large volume of water (>

200 l). It is essential for the temperature of the return flow to be kept to at least 45 °C during heating, otherwise

the temperature of the return flow must be increased using a mixing pump or valve.

In order to achieve good temperature stratification in the accumulator tank, we recommend setting the boiler

circuit to a 15-20 K differential by means of the return hold-up group SK RH or SK RH 54. See the enclosed instructions for the return hold-up group for guidance values for the setting.

Boiler start-up relief:

A boiler start-up relief must be installed and connected in all cases so that the circulation pump(s) are switched

off when the boiler temperature is below 60 °C. This prevents condensation forming in the boiler and extends

its service life.

A boiler start-up relief of this kind is contained in the MES control system.

2.4.5 Heating water

a) The chemical composition of the heating water must meet the specifications of ÖNORM H 5195 Part 1 or VDE

2035 P1. According to ÖNORM M 5195 Part 1, the condition of the heating water must be checked every 2

years by a heating technician in order to avoid corrosion and sediment accumulation in the heating system.

The check must be performed once every year in heating systems with more than 1500 litres of heating water.

For the Installer

“Komfort” Pufferspeicher: Won’t open in tag editor “Comfort” accumulator tank

In this case, the size of the accumulator tank is based on the long-term heat output, i.e. how long the customer

wants to heat from the accumulator tank. The boiler output does not depend on the heating requirements of the

building, but on the filling chamber size of the boiler and how often the customer wants to replenish fuel to

bring the accumulator tank up to temperature.

A sensible precaution for a buffer solution of this kind is a low temperature heating circuit design (< 35 °C).

Loading...

Loading...